Page 1

AN2509

Application note

Wide range 400W (+200 V@1.6 A / +75 V@1 A)

L6599-based HB LLC resonant converter

Introduction

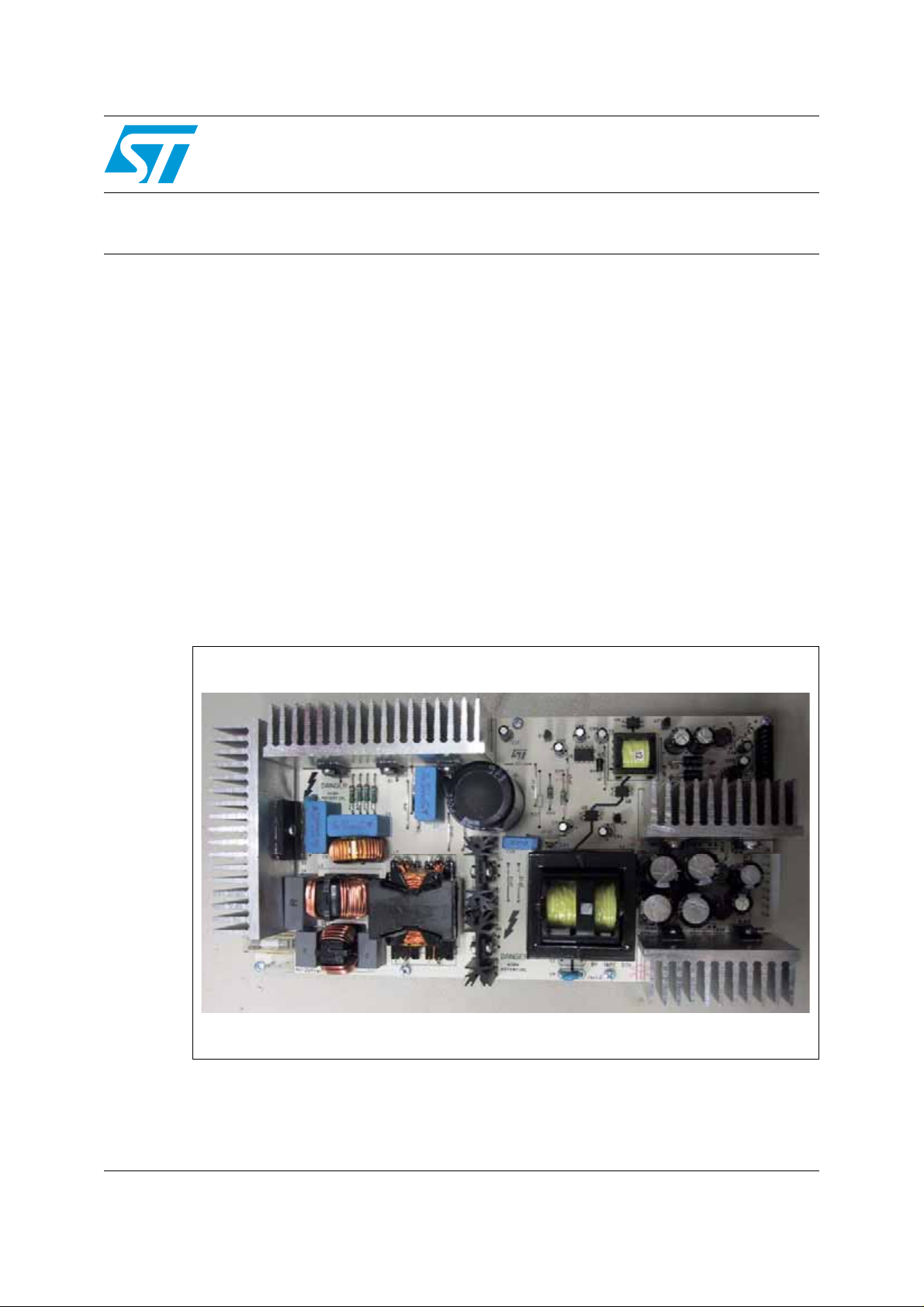

This note describes the performances of a 400W reference board, with wide-range mains

operation and power-factor-correction (PFC) and presents the results of its bench

evaluation. The electrical specification refers to a power supply for general purpose

application, with two main output voltages (200 V and 75 V).

The main features of this design are the very low no-load input consumption (<0.5 W) and

the very high global efficiency, better than 90% at full load and n ominal mains v o ltage (115 230 V

The circuit consists of three main bloc ks. The first is a front-end PFC pre-re gulator based on

the L6563 PFC controller. The second stage is a multi-resonant half-bridge converter with

two output volta ges of +200 V/300 W a nd 75 V/75 W, whose control is implemented through

the L6599 resonant controller. A further auxiliary flyback converter based on the VIPer12A

off-line primary switcher completes the architecture. This third block, deliv ering a total power

of 7 W on two output voltages (+3.3 V and +5 V), is mainly intended for microprocessor

supply and display power management operations

AC

).

L6599 & L6563 400W demonstration board

April 2007 Rev 3 1/37

www.st.com

Page 2

Contents AN2509

Contents

1 Main characteristics and circuit description . . . . . . . . . . . . . . . . . . . . . 4

2 Electrical test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Harmonic content measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Efficiency measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Resonant stage operating waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Standby and no-load power consumption . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5 Short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Thermal tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Conducted emission pre-compliance test . . . . . . . . . . . . . . . . . . . . . . 21

5 Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 PFC coil specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Mechanical aspect and pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7 Resonant power transformer specification . . . . . . . . . . . . . . . . . . . . . 30

7.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Auxiliary flyback power transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9 Board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2/37

Page 3

AN2509 List of figures

List of figures

Figure 1. PFC pre-regulator electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Resonant converter electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Auxiliary converter electrical diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

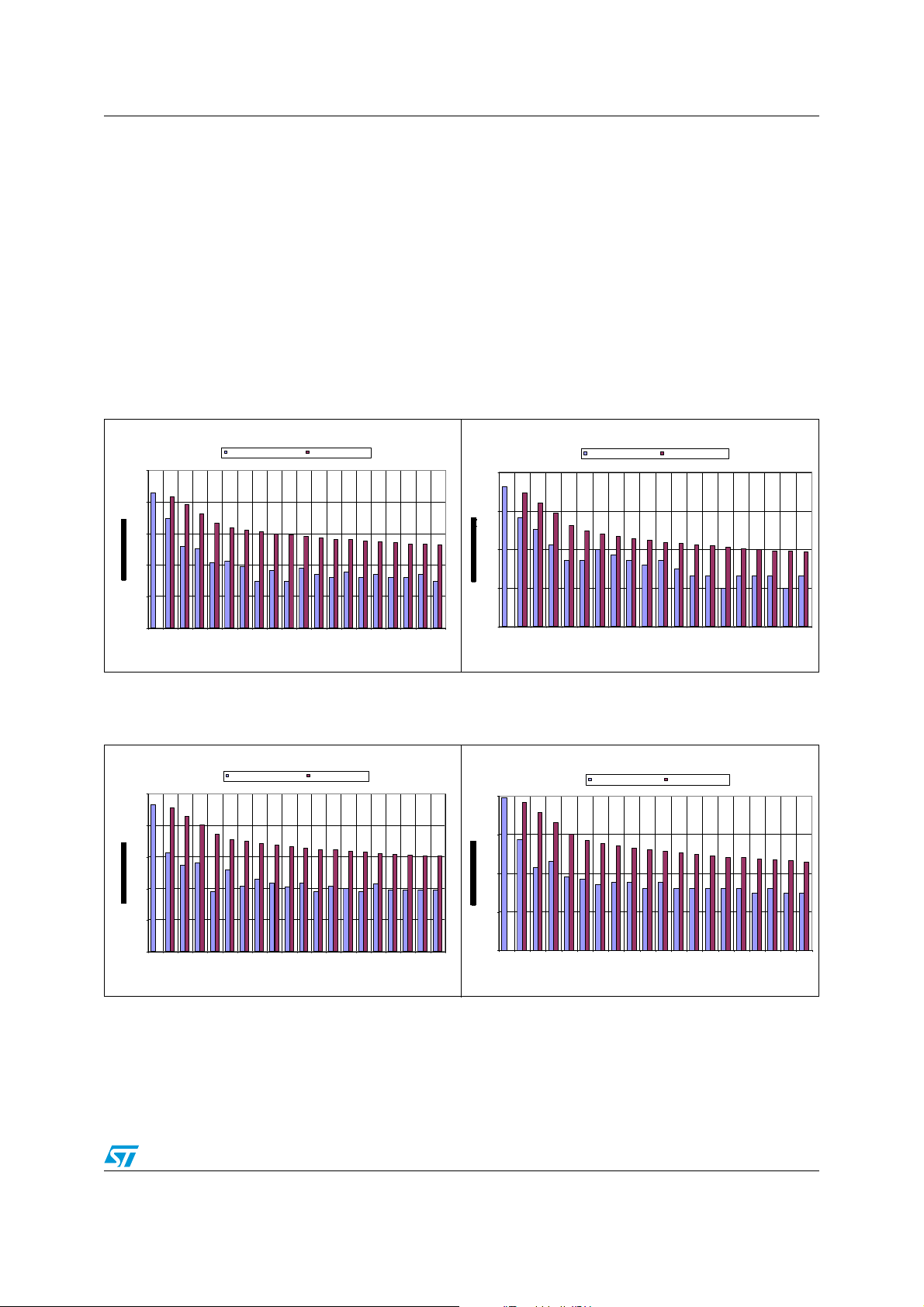

Figure 4. Compliance to EN61000-3-2 standard for harmonic reduction: full load . . . . . . . . . . . . . . . 9

Figure 5. Compliance to EN61000-3-2 standard for harmonic reduction: 70 W load. . . . . . . . . . . . . . 9

Figure 6. Compliance to JEIDA-MITI standard for harmonic reduction: full load . . . . . . . . . . . . . . . . . 9

Figure 7. Compliance to JEIDA-MITI standard for harmonic reduction: 70 W load . . . . . . . . . . . . . . . 9

Figure 8. Power factor vs. Vin & load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 9. Total harmonic distortion vs. Vin & load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 10. Overall efficiency versus output power at nominal mains voltages. . . . . . . . . . . . . . . . . . . 12

Figure 11. Overall efficiency versus input mains voltage at various output power levels . . . . . . . . . . 12

Figure 12. Resonant circuit primary side waveforms at full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 13. Resonant circuit primary side waveforms at light load (about 45 W output power) . . . . . . 14

Figure 14. Resonant circuit primary side waveforms at no load condition. . . . . . . . . . . . . . . . . . . . . . 14

Figure 15. Resonant circuit secondary side waveforms: +200 V output . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 16. Resonant circuit secondary side waveforms: +75 V output . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 17. Low frequency (100 Hz) ripple voltage on +200 V and + 75 V outputs . . . . . . . . . . . . . . . 16

Figure 18. Load transition (0.16 A - 1.6 A) on +200 V output voltage . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 19. +200 V output short-circuit waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 20. Thermal map @115 V

Figure 21. Thermal map at 230 V

Figure 22. Peak measurement on LINE at 115 V

Figure 23. Peak measurement on Neutral at 115 V

Figure 24. Peak measurement on LINE at 230 V

Figure 25. Peak measurement on Neutral at 230 V

Figure 26. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 27. Pin side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 28. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 29. Mechanical aspect and pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 30. Winding position on coil former. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 31. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 32. Auxiliary transformer winding position on coil former . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 33. Copper tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 34. Thru-hole component placing and top silk screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 35. SMT component placing and bottom silk screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

- full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

AC

- full load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

AC

and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AC

and full load. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AC

and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC

and full load. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC

3/37

Page 4

Main characteristics and circuit description AN2509

1 Main characteristics and circuit description

● The main characteristics of the SMPS are listed below:

● Universal input mains range: 90 to 264 V

● Output voltages: 200 V @ 1.5 A - 75 V @ 1 A - 3.3 V @ 0.7 A - 5 V @ 1 A

● Mains harmonics: compliance with EN61000-3-2 specifications

● Standby mains consumption: less than 0.5 W @230 V

●

Overall efficiency: better than 87% at full load, 90-264 V

●

EMI: Compliance with EN55022-class B specifications

● Safety: Compliance with EN60950 specifications

● PCB single layer: 132x265 mm, mixed PTH/SMT technologies

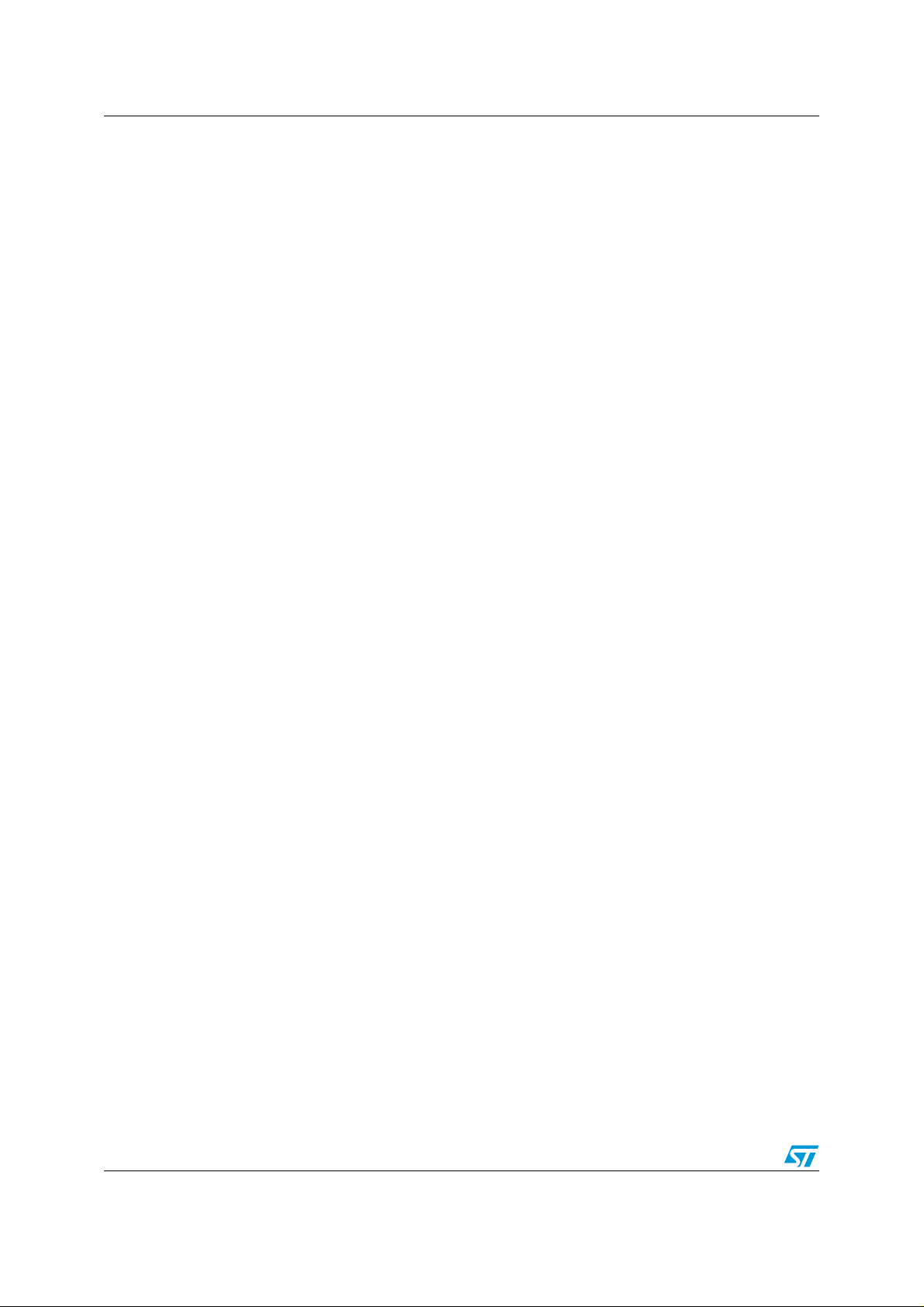

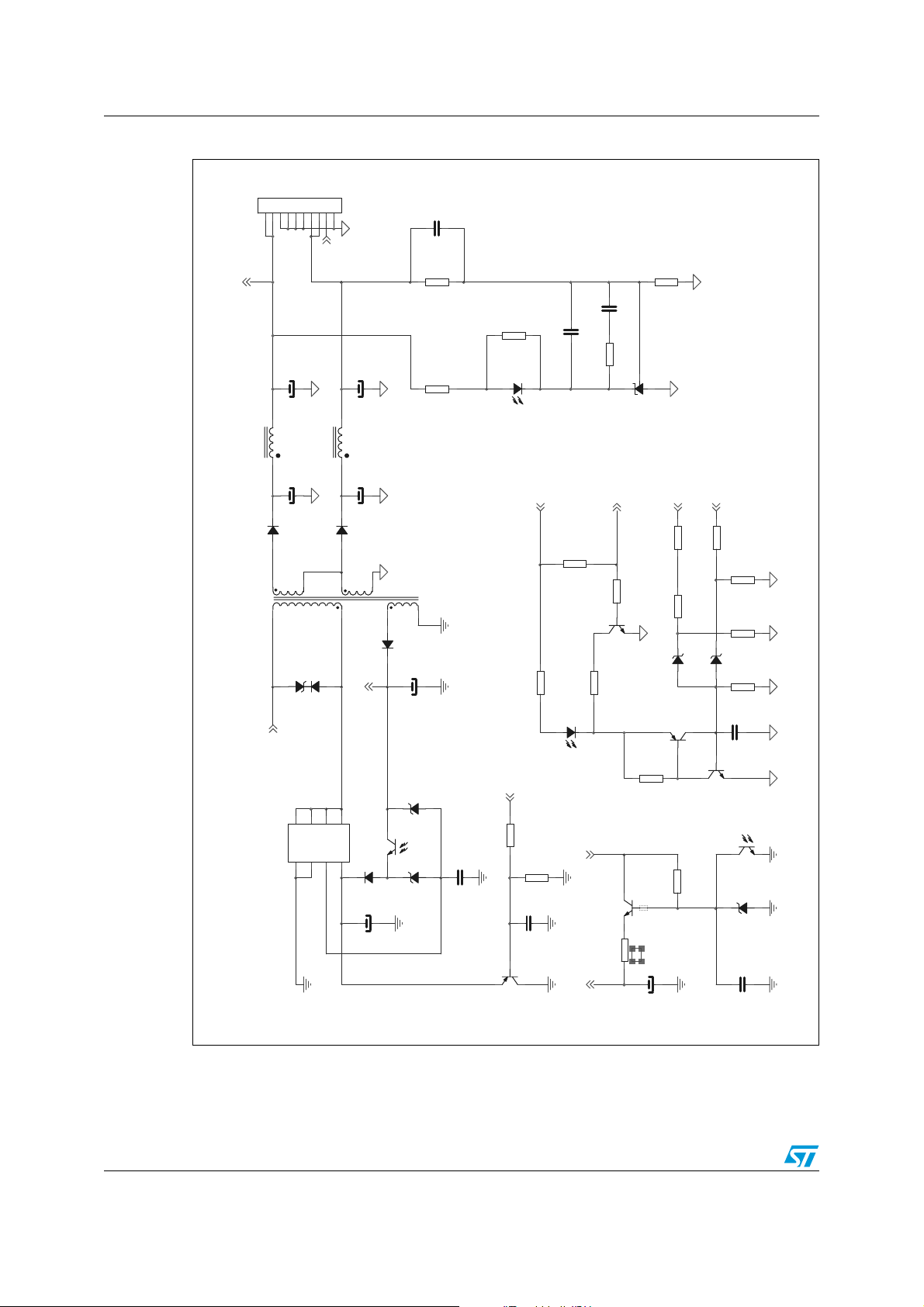

The circuit consists of three stages. A front-end PFC pre-regulator implemented by the

controller L6563 (Figure 1), a half-bridge resonant DC/DC conve rter based on the reson ant

controller L6599 (Figure 2), and a 7 W flyback converter intended for standby management

(Figure 3) utilizing the VIPer12A off-line primary switcher.

The PFC stage delivers a stable 400 VDC supply to the do wnstream con v erters (resonant +

flyback) and provides for the reduction of the current harmonics drawn from the mains, in

order to meet the requirements of the Euro pe a n no rm EN61000-3-2 and the JEIDA-MITI

norm for Japan.

- 45 to 65 Hz:

AC

AC

AC

The PFC controller is the L6563 (U1), integrating all functions needed to operate the PFC

and interface the downstream resonant converter. Although this controller chip is designed

for Transition-Mode (TM) operation, where the boost inductor wo rks next to the boundary

between Continuous (CCM) and Discontin uous Conduction Mode (DCM), by adding a

simple external circuit, it can be operated in LM-FOT (line-modulated fixed off-time). This

mode allows for CCM o perat ion, normally achie v ab le with more e x pensiv e contro l chips and

more complex architectures . The LM-F O T mode allows the use of a lo w-cost de vice lik e the

L6563 at a high power level, usually covered by CCM topologies. For a detailed and

complete description of the LM-FOT operating mode see the application note AN1792. The

external components to configure the circuit in LM-FOT mode are: C15, C17, D5, Q3, R14,

R17 and R29.

The power stage of the PFC is a conventional boost converter, connected to the output of

the rectifier bridge through a differential mode filtering cell (C5, C6 and L3) for EMI

reduction. It includes a coil (L4), a diode (D3) and two capacitors (C7 and C8). The boost

switch consists of two power MOSFETs (Q1 and Q2), connected in parallel, which are

directly driven by the L6563 output drive thanks to the high current capability of the IC.

The divider (R30, R31 and R32), connected to MULT pin 3, provides the information of the

instantaneous voltage that is used to modulate the boost current and to derive further

information like the average value of the AC line used by the V

(voltage feed-forward)

FF

function. This function is used to keep the output voltage almost independent of the mains.

The divider (R3, R6, R8, R10 and R11) is dedicated to detecting the output voltage while a

further divider (R5, R7, R9, R16 and R25) is used to protect the circuit in case of voltage

loop failure.

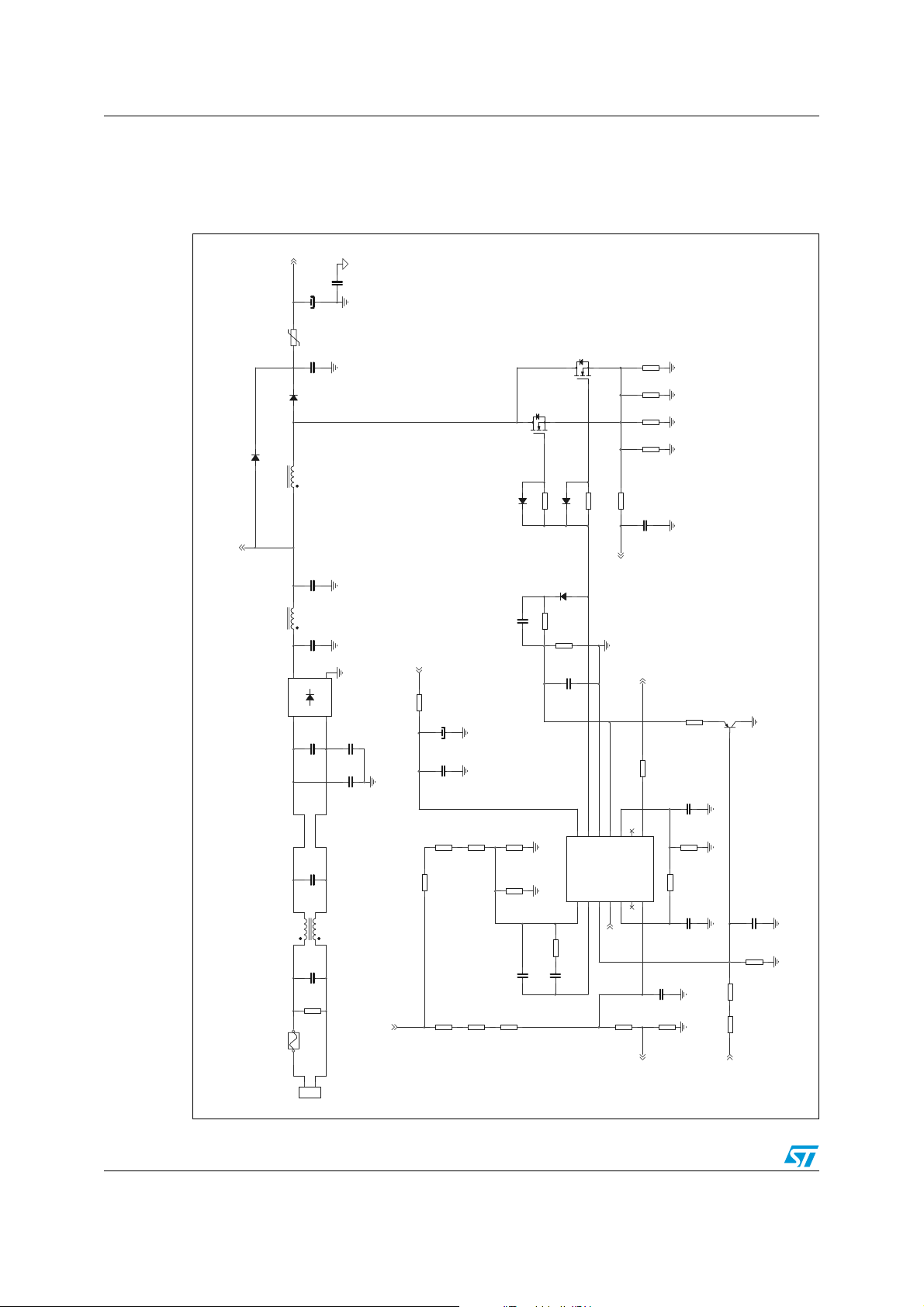

The second stage is an LLC resonant converter, with half-bridge topology implementation,

working in ZVS (zero voltage switching) mode.

4/37

Page 5

AN2509 Main characteristics and circuit description

The controller is the L6599 integrated circuit that incorporates the necessary functions to

properly drive the two half-bridge MOSFETs b y a 50 % fix ed duty cycle with fixed dead-time,

changing the frequency according to the feedback signal in order to regulate the output

voltages against load and input voltage variations. The main features of the L6599 are a

non-linear soft-start, a current protection mode used to program the hiccup mode timing, a

dedicated pin for sequencing or brown-out (LINE) and a standby pin (STBY) for burst mode

operation at light loads (not used in this design).

The transformer (T1) uses the magne tic integration approach, incorporating the resonant

series and shunt inductances of the LLC resonant tank. Thus, no additional external coils

are needed for the r esonance. F or a detaile d analysis of the LLC r esonant con v erter , please

refer to the application note AN2450.

The secondary side power circuit is configured with center- tap windings and two diodes

rectification for each outpu t (diod es D8A, D8B, D10A, D10B). The two center tap windings

are connected in series on the DC side (r efer to Figure 2). The +75 V rail is connected to

the center tap of the higher voltage winding (the one connected to the anodes of D8A and

D8B diodes). Therefore the higher v oltage windin g only has to provide a v oltage equal to the

difference of the two output voltages: 200 V - 75 V = 125 V. This winding arrangement has

the advantage of a better cross regulation with respect to the case of two completely

separated outputs. F urthermore, due to the fact that the +200 V diodes only have to

withstand a voltage of about 25 0 V (2 x 125 V), inst ead of about 400 V in case of complet ely

separated windings, the designer can select a diode with a lower junction capacitance

minimizing the effect of this capacitance refle ct ed at transformer primary side. This may

affect the behavior of the resonant tank, changing the circuit from LLC to LLCC type, with

the risk that the conv erter, in light-load/n o-load condition ( when the f e edbac k loop increa ses

the operating frequency), can no longer control the output voltage.

The feedbac k loop is implemented b y means of a classical con figuration using a TL431 (U4)

to adjust the current in the optocoupler diode (U3). The optocoupler transistor modu lates the

current from controller Pin 4, so the frequency will change accordingly, thus achieving the

output voltage regulation. Resistors R46 and R54 set the maximum operat ing frequency.

In case of a short circuit, the current entering the primary winding is detected by the lossless

circuit (C34, C39, D11, D12, R43, and R45) and the resulting signal is fed into L6599 Pin 6.

In case of overload, the voltage on Pin 6 exceeds an internal threshold that triggers a

protection sequence via Pin 2, keeping the current flowing in the circuit at a safe level.

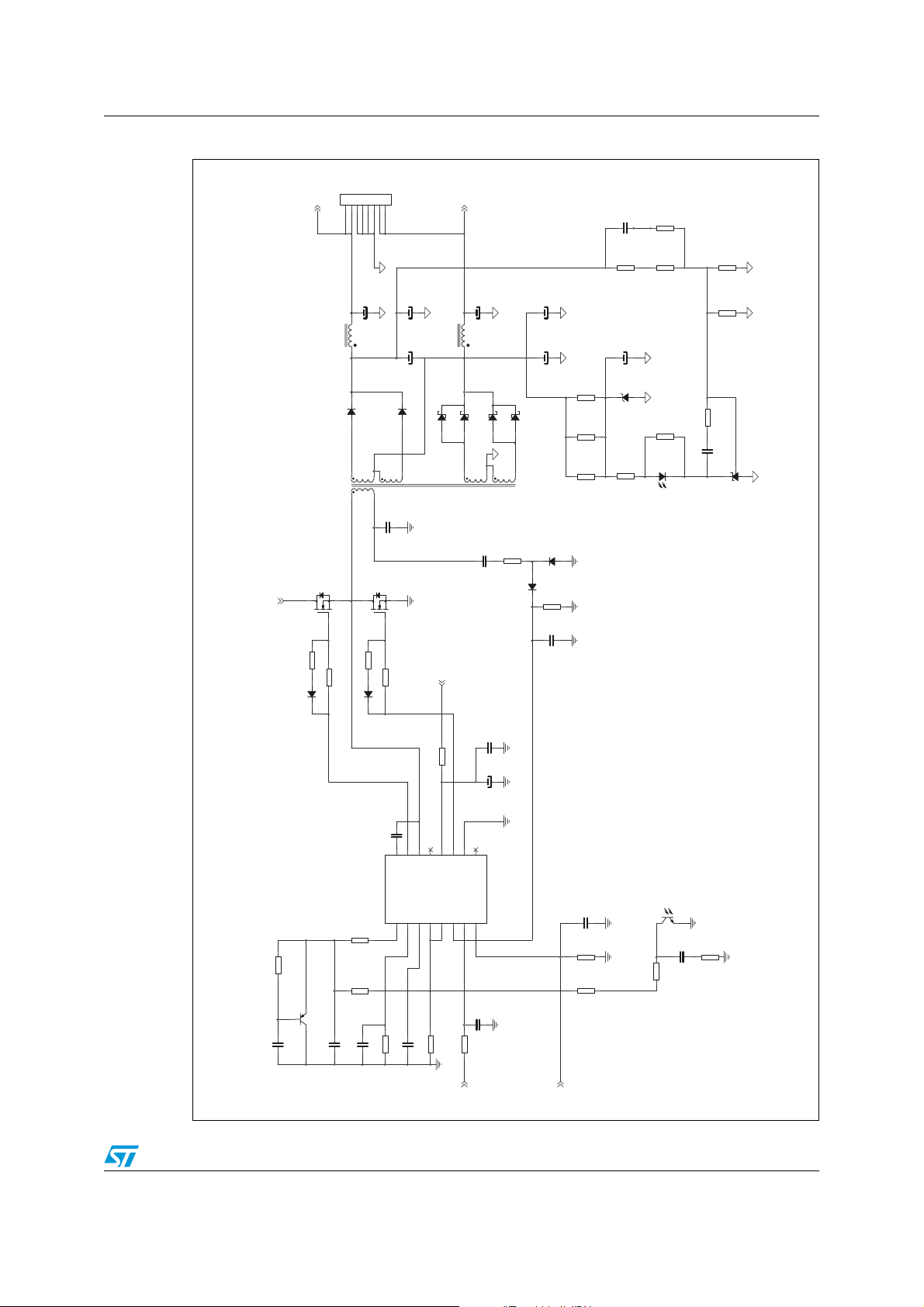

The third stage is a small flyback converter based on the VIPer12A, a current mode

controller with integrated power MOSFET, capable of delivering about 7 W total output

power on the output voltages (5 V and 3.3 V). The regulated output voltage is the 3.3V

output and, also in this case, the feedback loop uses the TL431 (U7) and optocoupler (U6)

to control the output volta ge.

This converter is able to operate in the whole mains voltage range, even when the PFC

stage is not working. From the auxiliary winding on the primary side of the flyback

transformer (T2), a voltage Vs is available, intended to supply the other controllers (L6563

and L6599) in addition to the VIPer12A itself.

The PFC stage and the resonant converter can be switched on and off through the circuit

based mainly on components Q7, Q8, D22 and U8, which, depending on the level of the

signal ST-BY, supplies or removes the auxiliary voltage (VAUX) necessary to start-up the

controllers of the PFC and resonant stages. When the AC input voltage is applied to the

power supply, the small flyback converter switches on first. Then, when the ST-BY signal is

asserted low, the PFC p re-regulator becomes oper ative , and last the resonant conv erter can

deliver the output power to the load. Note that if Pin 9 of Connector J3 is left floati ng (no

5/37

Page 6

Main characteristics and circuit description AN2509

signal ST-BY present), the PFC and resonant converter will not operate, and only +5 V and

+3.3 V supplies are availa ble on the output. In order to enable the +200 V and +75 V

outputs, Pin 9 of Connector J3 must be pulled down to ground.

Figure 1. PFC pre-regulator electrical diagram

Vdc

+400V

C9

2nF2-Y 1

330uF/450V

C8

R2

NTC 2R5-S237

C7

470nF/630V

D3

STTH8R06

1-2

D1

1N5406

L4

PQ40-500uH

5-6

D4

LL4148

Q2

STP12NM50FP

Q1

STP12NM50FP

D6

LL4148

R18

R15

6R8

6R8

R24

0R39

R23

0R39

R22

0R39

R21

0R39

R19

1k0

C18

330pF

Vrect

C6

470nF/630V

L3

DM-51uH-6A

C5

470nF/630V

Vaux

+

-

D2

D15XB60

~

~

C11

2

680nF-X2

Jumper

330nF-X2

470nF-X2

1M5

2nF2-Y2

C10

2nF2-Y2

CON2-IN

C4

Jumper

C3

L1

CM-1.5mH-5A

C2

R1

F1

8A/250V

1

J1

R4

47

C13

10uF/50V

C12

100nF

R6

680kR8680k

R3

680k

R5

Vdc

2M2

R11

R10

R7

2M2

R9

D5

C15

100pF

R14

3k3

R17

C17

15k

U1

L6563

100k

R13

56k

C14

100nF

C16

1uF

2M2

CSCS

LL4148

15k

220pF

GD

VCC

INV

COMP

ZCD

GND

MULTCSVFF

PWM-Latch

R29

1k5

Q3

BC857C

R20

1k0

C21

2nF2

R28

RUN

PWM-STOP

TBO

PFC-OK PWM-LATCH

R16

5k1

LINE

240k

R26

150k

C20

470nF

C19

10nF

R25

30k

C22

10nF

R32

10k

R31

620k

R30

620k

Vrect

6/37

Page 7

AN2509 Main characteristics and circuit description

Figure 2. Resonant converter electrical diagram

1234567

J2

+200V

L5

T1

8

CON8

C25

22uF/250V

C29

10uH

C30

D8A

T-RE S-ER 49- 400 W

D8B

BYT08P-400

BYT08P-400

C28

47nF/630V

+75V

C38

C35

100uF/250V

JP

100uF/250V

47uF/100V

L6

22uH

D10B

D10A

STTH1002C

STTH1002C

220uF/100V

C37

220uF/100V

R50

56k

R49

56k

R48

56k

R86

C59

R53

C41

D13

R52

470R

47nF

R61

75k

R58

75k

10uF/50V

C-12V

R56

1k0

3k3

U3A

SFH617A-2

2k7

R60

6k2

R59

1k0

C44

47nF

U4

TL431

R43

150

C34

220pF/630V

Vdc

Q5

R33

D7

R88

560k

Q12

BC557

C61

470nF

Q6

STP14NK50Z

0R

R35

47

LL4148

C23

100nF

STP14NK50Z

R39

0R

R40

47

D9

LL4148

C27 100nF

U2

L6599

R36

0R

R34

2k7

C24

470nF

R37

2M2

VBOOT

CSS

C26

OUT

HVG

DELAYCFRFMIN

270pF

R41

Vaux

C32

100nF

R38

47

C31

10uF/50V

NC

LVG

VCC

STBY

ISEN

LINE GND

DIS PFC-STOP

C33

4nF7

R42

10

16k

D11

LL4148

D12

LL4148

R45

100R

C39

1uF0

U3B

C40

10nF

R47

10k

R46

1k5

SFH617A-2

R87

220R

C60

470nF

R54

1k5

LINE

PWM-Latch

7/37

Page 8

Main characteristics and circuit description AN2509

Q10

BC847C

C54

100nF

U7

TL431

C53

2nF2

U6A

SFH617A-2

U6B

SFH617A-2

Vs

+200V

R67

1k0

SSFB

Vdd D

D

D

D

U5

VIPER-12A

R82

100k

R79

2k2

D15

1N5822

D16

1N5821

D20

BAV103

C56

100nF

C45

1000uF/10V

C47

1000uF/10V

C50

10uF/50V

C46

100uF/10V

C49

100uF/10V

Q9

BC857C

C48

10uF/50V

R76

150k

U8A

SFH617A-2

R75

150k

U8B

SFH617A-2

R74

10k

R77

4k7

D19

C-30V

St-By

D18

B-10V

123456789

10

J3

CON10

R69

0R

Vdc

C52

47nF

R68

22k

C51

100nF

R71

10k

Q8

BC847C

R72

10k

C55

10uF/50V

R66

1k0

T2

T-FLY -AUX-E20

+400V

R70

22R

Vdc

+400V

R83

1M0

R84

150k

C58

10nF

Q11

BC557C

+5Vst -by

R81

30k

R80

30k

+3V3

+5Vst-by

Q7

BC547C

D22

C-15V

L7

33uH

L8

33uH

D17

LL4148

+75V

D21

B-15V

D23

B-15V

R62

47

R64

1k6

C57

1nF0

Vs

Vaux

+5Vst -by

D14

PKC-136

St-By

R73

8k2

Figure 3. Auxiliary converter electrical diagram

8/37

Page 9

AN2509 Electrical test results

2 Electrical test results

2.1 Harmonic content measurement

The current harmonics drawn from the mains have been measured according to the

European rule EN61000-3-2 Class-D and Japanese rule JEIDA-MITI Class-D, at full load

and 70 W output power, at both nominal input voltages (230 V

in Figure 4 to Figure 7 show that the measured current harmonics are well below the limits

imposed by the regulations , both at full-load and at 70 W load.

and 100 VAC). The graphs

AC

Figure 4. Compliance to EN61000 -3 -2

standard for harmonic reductio n :

10

1

0.1

0.01

0.001

0.0001

full load

Measurements @ 230Vac Full load EN61000-3-2 class D limit s

1234567891011121314151617181920

Harmoni c Order (n)

Figure 6. Compliance to JEIDA-MITI standard

10

for harmonic reduction: full load

Measurements @ 100Vac Full load J EIDA- M ITI c la ss D l im it s

Figure 5. Compliance to EN61000-3-2

standard for harmonic reduction:

70 W load

Measurement s @ 230Vac 70W EN61 000-3-2 cl ass D limits

1

0.1

0.01

0.001

0.0001

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Harmoni c Order (n)

Figure 7. Compliance to JEIDA-MITI standard

for harmonic reduction: 70 W load

Measurement s @ 100V ac 70W JEI DA -MIT I cla s s D limits

1

1

0.1

0.01

0.001

0.0001

1234567891011121314151617181920

Harmoni c Order (n)

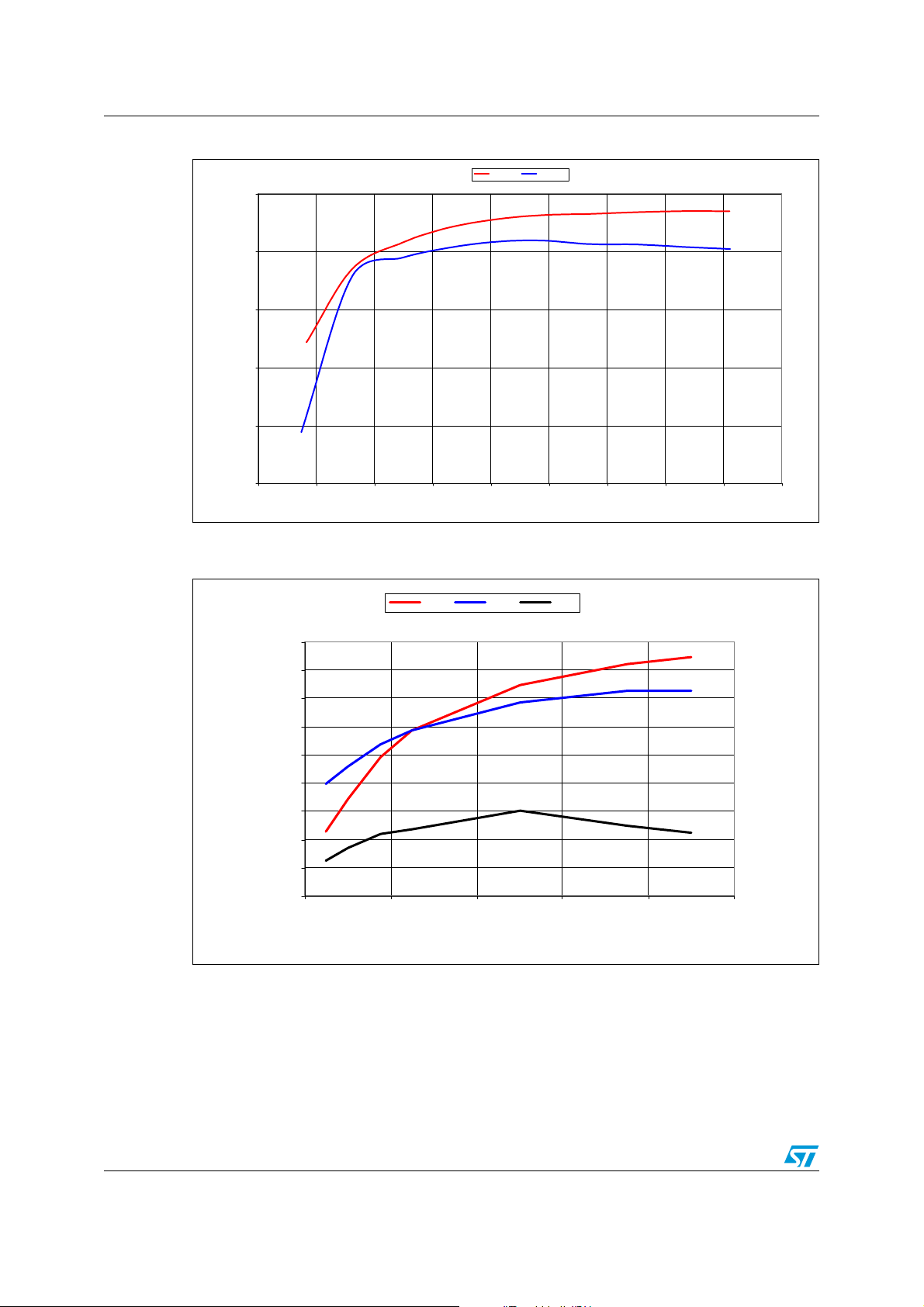

The Power Factor (PF) and the Total Harmonic Distortion (THD) are reported in Figure 8

and Figure 9. It is evident from the graph that th e PF stays close to unity in the whole mains

voltage range at full load and at half load, while it decreases at high mains at low load

(70 W). The THD has similar behavior, remaining within 25% overall the mains voltage

range and increasing at low load (70 W) at high mains voltage.

0.1

0.01

0.001

0.0001

1234567891011121314151617181920

Harmoni c Orde r (n )

9/37

Page 10

Electrical test results AN2509

Figure 8. Power factor vs. Vin & load Figure 9. Total harmonic distortion vs. Vin &

PF

1.00

0.98

0.95

0.93

0.90

0.88

0.85

80 120 160 200 240 280

400W

200W

70W

Vin [Vrms]

THD [%]

25.00

20.00

15.00

10.00

5.00

0.00

80 120 160 200 240 280

load

400W

200W

70W

Vin [Vrms]

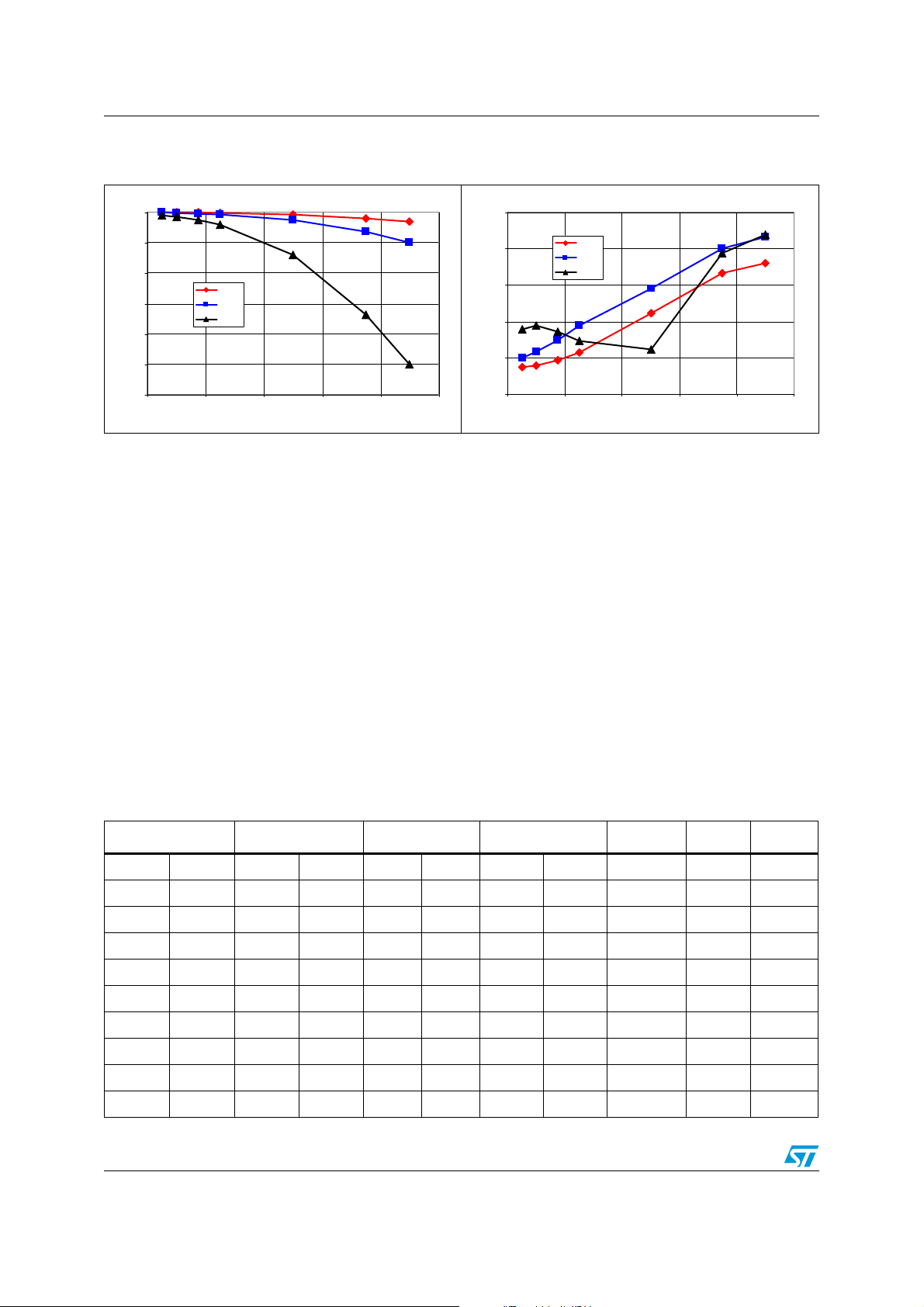

2.2 Efficiency measurements

Table 1 and Table 2 show the output voltage measurements at the nominal mains voltages

of 115 V

load and at light load operations, the input power is measured using a Yokogawa WT-210

digital power meter. Particular attention has to be paid when measuring input power at full

load in order to avoid measurement errors due to the voltage drop on cables and

connections.

and 230 VAC, with different load condi tions. For all measurements, both at full

AC

Figure 10 shows the overall circuit efficiency, measured at each load condition, at both

nominal input mains voltages of 115 V

and 230 VAC. The values were measured af ter 30

AC

minutes of warm-up at maximum load. The high efficiency of the PFC pre-regulator working

in FOT mode and the very high efficiency of the resonant stage working in ZVS (i.e. with

negligible switching losses), provides for an overall efficiency better than 87% at full load in

the complete mains voltag e r a ng e. This is a significant high value for a two-stage converter ,

especially at low input mains voltage where the PFC conduction losses increase. Even at

lower loads, the efficiency still remains high.

Table 1. Efficiency measurements @VIN = 115 V

+200 V @load(A) +75 V@load(A) +5 V @load(A) +3.3 V@load(A) POUT(W) PIN(W) Eff. %

200.29 1.591 77.77 1.020 4.88 0.975 3.33 0.695 405.06 433.30 93.48%

200.29 1.441 77.78 0.894 4.88 0.975 3.33 0.695 365.23 390.68 93.48%

200.31 1.281 77.78 0.801 4.88 0.975 3.33 0.695 325.97 348.98 93.41%

200.31 1.120 77.79 0.694 4.88 0.975 3.33 0.695 285.41 306.05 93.25%

200.32 0.962 77.79 0.600 4.88 0.502 3.33 0.352 243.00 260.90 93.14%

200.34 0.802 77.80 0.506 4.88 0.502 3.33 0.352 203.66 219.52 92.78%

200.34 0.642 77.80 0.399 4.88 0.502 3.33 0.352 163.28 177.37 92.06%

200.34 0.481 77.81 0.306 4.88 0.502 3.33 0.352 123.80 136.39 90.77%

200.40 0.321 77.83 0.199 4.86 0.144 3.33 0.097 80.84 91.34 88.50%

AC

200.43 0.161 77.83 0.105 4.86 0.146 3.33 0.099 41.48 50.48 82.17%

10/37

Page 11

AN2509 Electrical test results

Table 2. Efficiency measurements @V

+200 V @load(A) +75 V @load(A) +5 V @load(A) +3.3 V @load(A) POUT(W) PIN(W) Eff. %

200.32 1.593 77.78 1.022 4.88 0.977 3.33 0.695 405.68 449.65 90.22%

200.32 1.442 77.79 0.896 4.88 0.977 3.33 0.695 365.64 404.46 90.40%

200.32 1.282 77.80 0.802 4.88 0.977 3.33 0.695 326.29 360.10 90.61%

200.32 1.120 77.80 0.694 4.88 0.977 3.33 0.695 285.43 314.90 90.64%

200.35 0.962 77.80 0.600 4.88 0.502 3.33 0.351 243.04 267.18 90.96%

200.32 0.802 77.79 0.508 4.88 0.502 3.33 0.351 203.79 224.33 90.84%

200.31 0.641 77.79 0.399 4.88 0.503 3.33 0.351 163.06 180.53 90.32%

200.34 0.480 77.80 0.305 4.88 0.503 3.33 0.351 123.52 138.06 89.47%

200.40 0.321 77.83 0.197 4.86 0.144 3.33 0.097 80.68 91.83 87.86%

200.43 0.160 77.84 0.050 4.86 0.146 3.33 0.099 405.68 49.72 74.42%

= 230 V

IN

AC

The global efficiency at full load has been measured even at the limits of the input voltage

range, with good results:

At VIN = 90 V

At VIN = 264 V

- full load, the efficiency is 87.27%

AC

- full load, the efficiency is 93.49%

AC

Also at light load, at an output power of about 10% of the maximum level, the overall

efficiency is very good, reaching a v alue of about 75% a t nominal main s v oltag es. Figure 11

shows the efficiency measured at various output power levels versus input mains voltage.

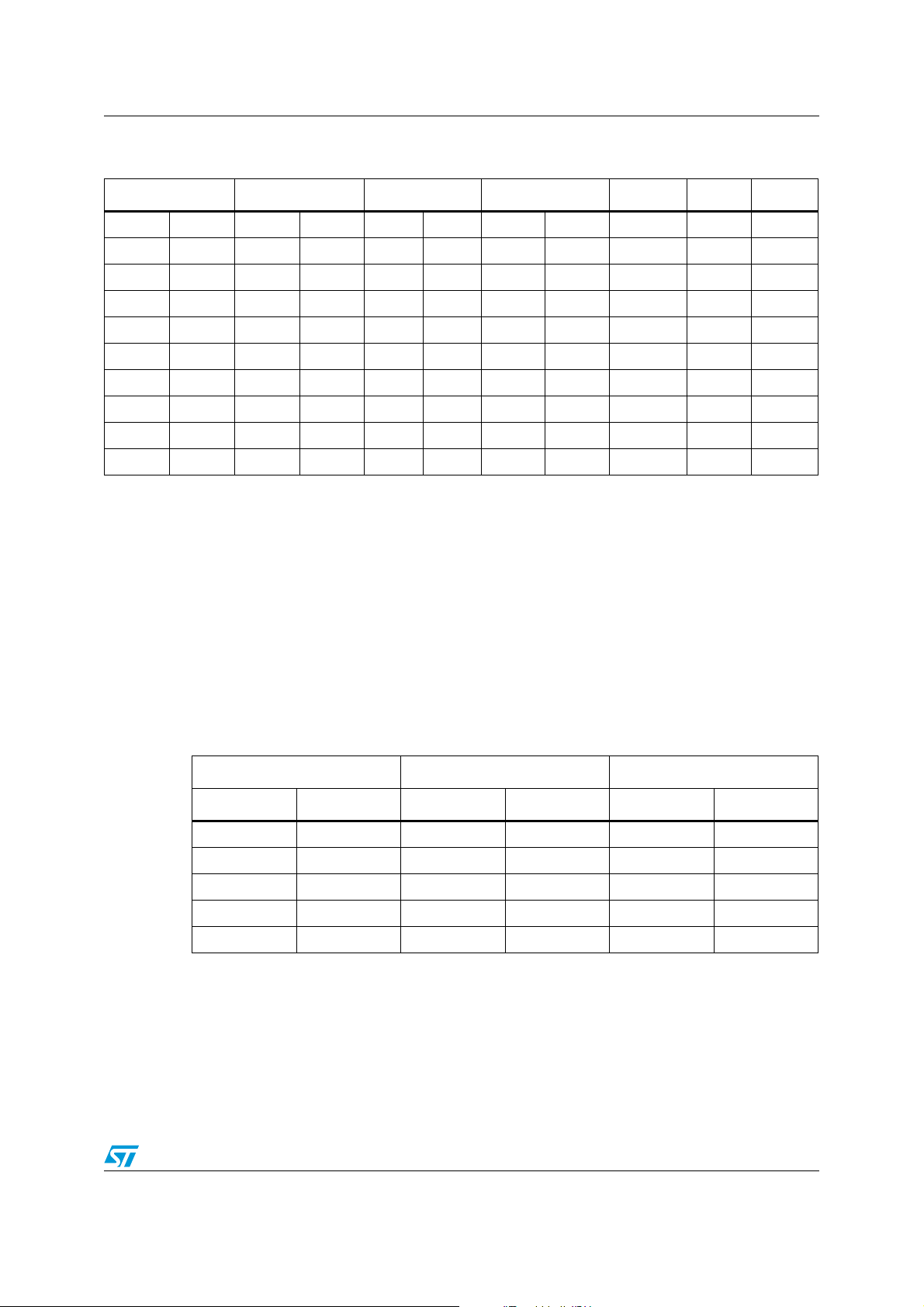

The cross regulation of the resonant converter stage is very good as shown in Table 3,

where the +200 V and +75 V output v o ltages are measur ed in different load conditions, with

minimum output current equa l to 10% of maximum current for both the output volta ges.

Table 3. Cross regulation

230 V

AC

200 V load 75 V load 200 V 75 V 200 V 75 V

max max 200.26 77.77 200.32 77.78

max min 200.35 77.92 200.35 77.94

min max 200.35 77.58 200.35 77.58

min min 200.42 77.82 200.45 77.84

no-load no-load 200.76 77.66 200.76 77.65

115 V

AC

11/37

Page 12

Electrical test results AN2509

Figure 10. Overall efficiency versus output power at nominal mains voltages

230Vac 115Vac

95%

90%

85%

Eff. (%)

80%

75%

70%

0 50 100 150 200 250 300 350 400 450

Output Power (W)

Figure 11. Overall efficiency versus input mains voltage at various output power

levels

400W 200W 70W

Eff[%]

94%

93%

92%

91%

90%

89%

88%

87%

86%

85%

80 120 160 200 240 280

Vin [Vrms]

2.3 Resonant stage operating waveforms

Figure 12 shows some waveforms during steady state operation of the resonant circuit at full

load. The Ch1 waveform is the half-bridge square voltage on Pin 14 of L6599, driving the

resonant circuit. In the picture it is not e vident, but the switching frequency is normally

slightly modulated following the PFC pre-regulator 100-Hz ripple that is rejected by the

12/37

Page 13

AN2509 Electrical test results

resonant control circuitry. The Ch2 waveform represents the transformer primary current

flowing into the resonant tank. As shown, it has almost a sinusoidal shape. The resonant

tank has been designed (follo wing the pr ocedure present ed in the applica tion note AN2450)

to operate at a resonance frequency of about 120 kHz when the dc input voltage of the halfbridge circuit is at 390 V (that is the nominal output voltage of the PFC stage).

The resonant frequency has been selected at appr oximately 120 kHz in order to have a

good trade-off between transformer losses and dimens ion s.

The resonant tank circuit has been designed in orde r to have a good margin for ZVS

operation, providing good efficiency, while the almost sinusoidal current wavef orm allows for

an extremely low EMI generation.

Figure 12. Resonant circuit primary side waveforms at full load

Ch1: half-bridge square

voltage on pin 14 of L6599

Ch2: resonant tank current

Ch3: low side MOSFET

drive signal

Figure 13 and Figure 14 show the same waveforms as in Figure 12, when the resonant

converter is light-loaded (about 45 W) or not loaded at all. These two graphs demonstrate

the ability of the converter to operate down to zero load, with the output voltages still within

the regulation range.

The resonant tank current has ob viou sly a triangul ar shape and r epresen ts the m agnet izing

current flowing into the transformer primary side. The oscillation superimposed on the tank

current depends on the occurrence of a further resonance due to the parallel of the

inductances at primary side (the series and shunt inductances in the APR (all primary

referred) transformer model presented in AN2450) and the undesired se condary side

capacitance reflected at transformer primary side.

13/37

Page 14

Electrical test results AN2509

Figure 13. Resonant circuit primary side waveforms at light load (about 45 W outpu t

power)

Ch1: half-bridge square

voltage on pin 14 of L6599

Ch2: resonant tank current

Ch3: low side MOSFET

drive signal

Figure 14. Resonant circuit primary side waveforms at no load condition

Ch1: half-bridge square

voltage on pin 14 of L6599

Ch2: resonant tank current

Ch3: low side MOSFET

drive signal

In Figure 15 and Figure 16, waveforms relevant to the seco ndary side are represented. For

Figure 15, the waveform Ch1 is the voltage at the anode of D8B diode , referenced to

secondary ground, while the waveforms CH2 and CH3 show the current flowing out of the

cathode of D8B and D8A diodes. For Figure 16, the waveform Ch1 is the voltage at the

anode of D10B diode, referenced to secondary ground, while the waveforms CH2 and CH3

show the current flowing out of the cathode of D10B and D10A diodes.

Also these current waveforms, at secondary side, have almost a sine shape, and the total

average value is the output average current.

14/37

Page 15

AN2509 Electrical test results

Figure 15. Resonant circuit secondary side waveforms: +200 V outpu t

Ch1: anode voltage of diode D8B

Ch2: current flowing out of diode

D8B cathode

Ch3: current flowing out of diode

D8A cathode

Figure 16. Resonant circuit secondary side waveforms: +75 V output

Ch1: anode voltage of diode D10B

Ch2: current flowing out of diode

D10B cathode

Ch3: current flowing out of diode

D10A cathode

Thanks to the adv antages o f t he reso nant converter, t he h igh fr eque ncy no ise on t he o utpu t

voltages is less than 50 mV, while the residual ripple at twice the mains frequency (100 Hz)

is less than 200 mV on +200 V output and less than 100 mV on +75 V output, at maximum

load and worse line condition (90 V

), as shown in Figure 17.

AC

15/37

Page 16

Electrical test results AN2509

Figure 17. Low frequency (100 Hz) ripple voltage on +200 V and + 75 V outputs

Ch3: +75 V output voltage

ripple at 100 Hz

Ch4: +200 V output voltage

ripple at 100 Hz

Figure 18 shows the dynamic behavior of the converter during a load variation from 10% to

100% on the +200 V output. This figure also high lights the induced eff ect of th is load change

on the PFC pre-regulator output voltage (+400 V on Ch1 track). Both the transitions (from

10% to 100% and from 100% to 10%) are clean and do not show an y prob lem for the output

voltage regulation.

This shows that the proposed architecture is also highly suitable for power supplies

operating with strong load variation without any problems related t o the load regulation.

Figure 18. Load transition (0.16 A - 1.6 A) on +200 V output v oltage

Ch1: PFC output voltage

Ch2: resonant tank current

envelope

Ch4: +200 V output voltage

ripple

16/37

Page 17

AN2509 Electrical test results

2.4 Standby and no-load power consumption

The board is specifically designed for light load and zero load operations, typical conditions

occurring during Standby or Power-off operations, when no power is requested from the

+200 V and +75 V outputs. Though the resonant converter can operate down to zero load,

some actions are required to k ee p the inpu t power drawn from the mains very low when the

complete system is in this load condition. Thus, when entering this power manageme nt

mode, the ST-BY signal needs to be set high (by the microcontroller of the system). This

forces the PFC pre-regulator and the resonant stage to switch off because the supply

voltage of the two control ICs is no longer present (Figure 3) and only the auxiliary flyback

converter continues working just to supply the microprocessor circuitry.

Table 4 and Table 5 show the measurements of the input power in several light load

conditions at 115 and 230 V

than 0.5 W.

. These tables show that at no-load the input power is less

AC

Table 4. S tandby consumption at VIN = 115 V

+5 V @load(A) +3.3 V @load(A) POUT(W) PIN(W)

5.06 - 0.016 3.33 - 0.110 0.447 0.850

5.00 - 0.016 3.33 - 0.077 0.336 0.693

4.95 - 0.016 3.33 - 0.054 0.259 0.595

4.87 - 0.016 3.33 - 0.021 0.148 0.445

4.50 - 0.000 3.33 - 0.000 0.000 0.220

Table 5. S tandby consumption at VIN = 230 V

+5 V @load(A) +3.3 V @load(A) POUT(W) PIN(W)

5.06 - 0.016 3.33 - 0.110 0.081 1.220

5.00 - 0.016 3.33 - 0.077 0.080 1.045

4.95 - 0.016 3.33 - 0.054 0.079 0.925

4.87 - 0.016 3.33 - 0.021 0.078 0.740

4.50 - 0.000 3.33 - 0.000 0.000 0.480

2.5 Short-circuit protection

AC

AC

The L6599 is equipped with a current sensing input (pin 6, ISEN) and a dedicated

overcurrent management system. The current flowing in the circuit is detected (through the

not dissipative sensing circuit already me ntioned in Section 1, mainly based on a capacitive

divider formed by the resonant capacitor C28 and the capacitor C34, followed by an

integration cell D12, R45, C39) and the signal is fed into the ISEN pin. This is internally

connected to the input of a first comparator, referenced to 0.8 V, and to that of a second

comparator referenced to 1.5 V. If the voltage ex ternally applied to the ISEN pin exceeds

0.8V, the first comparator is tripped causing an internal switch to be turned on discharging

the soft-start capa cito r CSS.

For output short-circuits, this operation results in a nearly constant peak primary current.

17/37

Page 18

Electrical test results AN2509

The designer can externally program the maximum time (tSH) that the converter is allowed

to run overloaded or under short-circuit conditions. Overloads or shortcircuits lasting less

than t

duration phenomena. If , instead, t

will not cause any other action, hence providing the system with immunity to short

SH

is exceeded, an o verload protection ( OLP) procedure is

SH

activated that shuts do wn the device and, in case of continuous overload/short circuit,

results in continuous intermittent operation with a user-defined duty cycle. This function is

controlled by the DELAY pin 2 of the resonant controller, by means of the capacitor C24 and

the parallel resistor R37 connected to ground. As the voltage o n the ISEN pin e xceeds 0.8 V,

the first OCP comparator, in addition to discharging CSS, turns on an internal current

generator that, via the DELAY pin, charges C24. As the voltage on C24 reaches 3.5 V, the

L6599 stops switching and the internal generator is turned off, so that C24 is slowly

discharged by R37. The IC restarts when the voltage on C24 becomes less than 0.3 V.

Additionally, if the voltage on the ISEN pin reaches 1.5 V for any reason (e.g. transformer

saturation), the second comparator is triggered, the device shuts down an d the operation

resumes after an on-off cycle. Figure 19 illustrates the short-circuit protection sequence

described above. The on-off operation is controlled by the voltage on pin 2 (DELAY),

providing for the hiccup mode of the circuit. Thanks to this control pin, the designer can

select the hiccup mode timing and thus keep the average output current at a safe level.

In order to allow a long soft-start time, that lets the tank current at start-up increase

gradually, a high value capacitor should be connected on the CSS pin. Anyway, values

above 1-2 µF shou ld not be used, oth erwise, during short circuit, the CSS pin internal s witch

will not be able to properly discharge this capacitor and, therefore, the operating frequency

will not increase quickly to the maximum value and the throughput po wer will not be reduced

as desired. To resolve this problem, the circuit based on Q12, C61 and R88 can be used

(see Figure 2) in addition to C23 and R34. The voltage increase across C23, and therefore

the soft-start duration, mostly depends on the C61 capacitor value and on the high gain of

transistor Q12, while, during short circuit, the small value capacitor C23 can be quickly

discharged to push frequency to the maximum programmed v alue.

Figure 19. +200 V output short-circuit waveforms

Ch1: L6599 pin 2 (DELAY)

Ch2: resonant tank current

Ch3: L6599 pin 6 (ISEN)

Ch4: +200 V output voltage

18/37

Page 19

AN2509 Thermal tests

2.6 Overvoltage protection

Both the PFC pre-regulator and the resonant converter are equipped with their own

overvoltage protection circuit. The PFC controller is internally equipped with a dynamic and

a static overvoltage protection circuit sensing the current flowing through the error amplif ier

compensation network and entering in the COMP pin (#2). When this current reaches about

18 µA, the output voltage of the multiplier is forced to decrease, thus reducing the energy

drawn from the mains . If the current exceeds 20 µA, the OVP is triggered (Dynamic OVP),

and the external power tr ansistor is s witch ed off until th e current falls approximately below 5

µA. However, if the overvoltage persists (e.g. in case the load is completely disconnected),

the error amplifier will eventually saturate lo w , triggering an internal comparator (Static OVP)

that keeps the external power s witch t urned off until th e ou tput voltage comes back close to

the regulated value.

Moreover, in the L6563 there is an additional protection against loop failures using an

additional divider (R5, R7, R9, R16 and R25) connected to a dedica ted pin (PFC_OK, Pin 7)

protecting the circuit in case of loop failures, disconnection or deviation from the nominal

value of the feedback loop divider. The PFC output voltage is always under control and if a

fault condition is detected, the PFC_OK circuitry latches the PFC operation and using the

PWM_LATCH pin 8, it also latches the L6599 via the DIS pin of the resonant controller.

The OVP circuit (see Figure 3) for the output voltages of the resonant converter uses

resistive dividers (R75, R76, R80, R81, R82) and the zener diodes D21 and D23 to se nse

the +200 V and +75 V outputs. If the sensed voltage exceeds the threshold imposed by

either zener diodes plus the VBE of Q10, the transistor Q9 starts conducting and the

optocoupler U8 opens Q7, so that the VAUX supply voltage of the controller ICs L6563 and

L6599 is no longer available. This state is latched until a mains voltage recycle occurs.

3 Thermal tests

In order to check the design reliability, a thermal mapping by an IR Camera wa s performed.

Figure 20 and Figure 21 show the thermal measurements of the board, component side, at

nominal input voltage. The correlation between measurement points and comp onents is

indicated for both diagrams in Table 6.

All other board components work well within the temperature limits, assuring a reliable long

term operation of the power supply.

Note that the temperatures of L4 and T1 have been measured both on the ferrite core (Fe)

and on the copper winding (Cu).

Table 6. Key components temperature at nominal voltages and full load

Point Item 230 V

A D2 40,3°C 47,6°C

B L4-(FE) 44,2°C 50,5°C

C L4-(CU) 46,0°C 55,5°C

D Q1 44,5°C 53,4°C

E R2 63,5°C 73,0°C

AC

115 V

AC

19/37

Page 20

Thermal tests AN2509

Table 6. Key components temperature at nominal voltages and full load

Point Item 230 V

F D3 46,1°C 51,0°C

G C8 39,3°C 40,1°C

H Q6 51,4°C 52,8°C

I T1-(CU) 63,7°C 62,6°C

J T1-(FE) 51,3°C 49,6°C

K U5 53,2°C 53,4°C

L D14 51,8°C 52,3°C

M C38 39,4°C 38,5°C

N C45 36,1°C 35,7°C

O D8A 44,5°C 44,9°C

P R22 41,4°C 55,6°C

Q D15 43,3°C 43,5°C

R D16 42,6°C 42,1°C

S T2 43,3°C 43,6°C

Figure 20. Thermal map @115 VAC - full load

AC

115 V

AC

Figure 21. Thermal map at 230 V

20/37

AC

- full load

Page 21

AN2509 Conducted emission pre-compliance test

4 Conducted emission pre-compliance test

The measurements have been taken in peak detection mode, both on LINE and on Neutral

at nominal input mains and at full load. The limits indicated on the following diagrams refer

to the EN55022 Class- B specifications (the higher limit curve is the quasi-peak limit while

the lower curve is the average limit) and the measurements show that the PSU emission is

well below the maximum allowed limit.

Figure 22. Peak measurement on LINE at 115 V

Figure 23. Peak measurement on Neutral at 115 V

AC

and full load

and full load

AC

21/37

Page 22

Conducted emission pre-compliance test AN2509

Figure 24. Peak measurement on LINE at 230 VAC and full load

Figure 25. Peak measurement on Neutral at 230 V

and full load

AC

22/37

Page 23

AN2509 Bill of materials

5 Bill of materials

Table 7. Bill of materials

Item Part Description Supplier

C2 470 nF-X2 275

C3 330 nF-X2 275

C4 680 nF-X2 275

C5 470 nF/630 V POLYPROPYLENE CAPACITOR HIGH RIPPLE MKP R71 ARCOTRONICS - EPCOS

C6 470 nF/630 V POLYPROPYLENE CAPACITOR HIGH RIPPLE MKP R71 ARCOTRONICS - EPCOS

C7 470 nF/630 V POLYPROPYLENE CAPACITOR HIGH RIPPLE MKP R71 ARCOTRONICS - EPCOS

C8 330 µF/450 V ALUMINIUM ELCAP USC SERIES 85 DEG SNAP-IN RUBYCON

C9 2nF2-Y1 400

C10 2nF2-Y1 250

C11 2nF2-Y1 250

C12 100 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C13 10 µF/50 V ALUMINIUM ELCAP GENERAL PURPOSE 85 DEG RUBYCON

C14 100 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C15 100 pF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C16 1 µF 25 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C17 220 pF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C18 330 pF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C19 10 nF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C20 470 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

V

X2 SAFETY CAPACITOR MKP R46 ARCOTRONICS

AC

V

X2 SAFETY CAPACITOR MKP R46 ARCOTRONICS

AC

V

X2 SAFETY CAPACITOR MKP R46 ARCOTRONICS

AC

V

Y1 SAFETY CERAMIC DISK CAPACITOR MURATA

AC

V

Y1 SAFETY CERAMIC DISK CAPACITOR MURATA

AC

V

Y1 SAFETY CERAMIC DISK CAPACITOR MURATA

AC

C21 2nF2 100 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C22 10 nF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C23 100 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C24 470 nF 25 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C25 22 µF/250 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C26 270 pF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C27 100 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C28 47 nF/630 V POLYPROPYLENE CAPACITOR HIGH RIPPLE PHE450 RIFA-EVOX

C29 100 µF/250 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C30 100 µF/250 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C31 10 µF/50 V ALUMINIUM ELCAP GENERAL PURPOSE 85 DEG RUBYCON

C32 100 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C33 4nF7 100 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

23/37

Page 24

Bill of materials AN2509

Table 7. Bill of materials (continued)

Item Part Description Supplier

C34 220 pF/630 V POLYPROPYLENE CAPACITOR HIGH RIPPLE PFR RIFA-EVOX

C35 47 µF/100 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C37 220 µF/100 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C38 220 µF/100 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C39 1 µF0 25 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C40 10 nF 100 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C41 10 µF/50 V ALUMINIUM ELCAP GENERAL PURPOSE 85 DEG RUBYCON

C44 47 nF 100V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C45 1000 µF/10 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C46 100 µF/10 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C47 1000 µF/10 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C48 10 µF/50 V ALUMINIUM ELCAP GENERAL PURPOSE 85 DEG RUBYCON

C49 100 µF/10 V ALUMINIUM ELCAP YXF SERIES 105 DEG RUBYCON

C50 10 µF/50 V ALUMINIUM ELCAP GENERAL PURPOSE 85 DEG RUBYCON

C51 100 nF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C52 47 nF 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C53 2nF2 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C54 100 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C55 10 µF/50 V ALUMINIUM ELCAP GENERAL PURPOSE 85 DEG RUBYCON

C56 100 nF 50 V 1206 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C57 1nF0 100 V 0805 SMD CERCAP GENERAL PURPOSE BC COMPONENTS

C58 10 nF 50 V X7R STANDARD CERAMIC CAPA CITOR BC COMPONENTS

C59 47 nF/250 V POLCAP PHE426 SERIES RIFA-EVOX

C60 470 nF 25 V 1206 SMD CERCAP GENERAL PURPOSE VISHAY

C61 470 nF 50 V CERCAP X7R BC COMPONENTS

D1 1N5406 GENERAL PURPOSE RECTIFIER VISHAY

D2 D15XB60 SINGLE PHASE BRIDGE RECTIFIER SHINDENGEN

D3 STTH8R06 TO220FP ULTRAFAST HIGH VOLTAGE RECTIFIER STMicroelectronics

D4 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D5 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D6 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D7 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D8A BYT08P-400 TO220FP ULTRAFAST HIGH VOLTAGE RECTIFIER STMicroelectronics

D8B BYT08P-400 TO220FP ULTRAFAST HIGH VOLTAGE RECTIFIER STMicroelectronics

D9 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

24/37

Page 25

AN2509 Bill of materials

Table 7. Bill of materials (continued)

Item Part Description Supplier

D10A STTH1002C TO220FP ULTRAFAST MEDIUM VOLTAGE RECTIFIER STMicroelectronics

D10B STTH1002C TO220FP ULTRAFAST MEDIUM VOLTAGE RECTIFIER STMicroelectronics

D11 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D12 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D13 C-12V BZV55-C SERIES ZENER DIODE VISHAY

D14 PKC-136 PEAK CLAMP TRANSIL STMicroelectronics

D15 1N5822 POWER SCHOTTKY RECTIFIER STMicroelectronics

D16 1N5821 POWER SCHOTTKY RECTIFIER STMicroelectronics

D17 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D18 B-10 V BZV55-B SERIES ZENER DIODE VISHAY

D19 C-30 V BZV55-C SERIES ZENER DIODE VISHAY

D20 BAV103 GENERAL PURPOSE DIODE VISHAY

D21 B-15 V BZV55-B SERIES ZENER DIODE VISHAY

D22 C-15 V BZV55-C SERIES ZENER DIODE VISHAY

D23 B-15 V BZV55-B SERIES ZENER DIODE VISHAY

F1 8A/250 V T TYPE FUSE 5X20 HIGH CAPABILITY & FUSEHOLDER WICKMANN

J1 CON2-IN 3 PINS CONN. (CENTRAL REMOVE) P 3.96 KK SERIES MOLEX

J2 CON8 8 PINS CONNECTOR P 3.96 KK SERIES MOLEX

J3 CON10 10 PINS CONNECTOR P 2.54 MTA SERIES AMP

L1 CM-1.5 mH-5 A LFR2205B SERIES COMMON MODE INDUCTOR DELTA

L2 CM-10 mH-5 A

L3 DM-51 µH-6 A LSR2306-1 DIFF. MODE TOROIDAL INDUCTOR DELTA

L4 PQ40-500 µH 86H-5410B BOOST INDUCTOR DELTA

L5 10 µH ELC08 DRUM CORE INDUCTOR PANASONIC

L6 22 µH ELC08 DRUM CORE INDUCTOR PANASONIC

L7 33 µH ELC08 DRUM CORE INDUCTOR PANASONIC

L8 33 µH ELC08 DRUM CORE INDUCTOR PANASONIC

Q1 STP12NM50FP TO220FP N-CHANNEL POWER MOSFET STMicroelectronics

Q2 STP12NM50FP TO220FP N-CHANNEL POWER MOSFET STMicroelectronics

Q3 BC857C SOT23 SMALL SIGNAL PNP TRANSISTOR STMicroelectronics

Q5 STP14NK50Z TO220FP N-CHANNEL POWER MOSFET STMicroelectronics

Q6 STP14NK50Z TO220FP N-CHANNEL POWER MOSFET STMicroelectronics

TF3524 SERIES COMMON MODE TOROIDAL

INDUCTOR

TDK

Q7 BC547C TO92 SMALL SIGNAL PNP TRANSISTOR STMicroelectronics

Q8 BC847C SOT23 SMALL SIGNAL PNP TRANSISTOR STMicroelectronics

25/37

Page 26

Bill of materials AN2509

Table 7. Bill of materials (continued)

Item Part Description Supplier

Q9 BC857C SOT23 SMALL SIGNAL PNP TRANSISTOR STMicroelectronics

Q10 BC847C SOT23 SMALL SIGNAL NPN TRANSISTOR STMicroelectronics

Q11 BC547C TO92 SMALL SIGNAL PNP TRANSISTOR STMicroelectronics

R1 1M5 VR25 TYPE HIGH VOLTAGE RESISTOR BC COMPONENTS

R2 NTC 2R5-S237 NTC RESISTOR 2R5 S237 SERIES EPCOS

R3 680 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R4 47 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R5 2M2 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R6 680 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R7 2M2 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R8 680 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R9 2M2 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R10 100 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R11 15 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R13 56 k 1206 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R14 3k3 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R15 6R8 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R16 5k1 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R17 15 k 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R18 6R8 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R19 1K0 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R20 1k0 STANDARD METAL FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R21 0R39 PR02 POWER RESISTOR BC COMPONENTS

R22 0R39 PR02 POWER RESISTOR BC COMPONENTS

R23 0R39 PR02 POWER RESISTOR BC COMPONENTS

R24 0R39 PR02 POWER RESISTOR BC COMPONENTS

R25 30 k 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R26 150 k 1206 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R28 240 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R29 1k5 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R30 620 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R31 620 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R32 10 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R33 0R 0805 SMD STANDARD FILM RES 1/8 W BC COMPONENTS

R34 2k7 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

26/37

Page 27

AN2509 Bill of materials

Table 7. Bill of materials (continued)

Item Part Description Supplier

R35 47 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R36 0R 0805 SMD STANDARD FILM RES 1/8 W BC COMPONENTS

R37 2M2 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R38 47 STANDARD METAL FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R39 0R 0805 SMD STANDARD FILM RES 1/8 W BC COMPONENTS

R40 47 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R41 16 k 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R42 10 1206 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R43 150 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R45 82R 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R46 1k5 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R47 10 k 1206 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R48 56 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R49 56 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R50 56 k 1206 SMD STANDARD FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R52 3k3 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R53 75 k 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R54 1k5 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R56 1k0 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R58 75 k 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R59 1k0 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R60 6k2 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R61 2k7 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R62 47 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R64 1k6 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R66 1k0 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R67 1k0 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R68 22 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R69 0R 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R70 22R 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R71 10 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R72 10 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R73 8k2 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R74 10 k 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R75 150 k 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

27/37

Page 28

Bill of materials AN2509

Table 7. Bill of materials (continued)

Item Part Description Supplier

R76 150 k 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R77 4k7 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R79 2k2 0805 SMD STANDARD FILM RES 1/8 W 5% 200 ppm/°C BC COMPONENTS

R80 30 k 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R81 30 k 0805 SMD STANDARD FILM RES 1/8 W 1% 100 ppm/°C BC COMPONENTS

R82 100 k 1206 SMD STANDARD FILM RES 1/4 W 1% 100 ppm/°C BC COMPONENTS

R83 1M0 VR25 TYPE HIGH VOLTAGE RESISTOR BC COMPONENTS

R84 150 k STANDARD METAL FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R86 470R STANDARD METAL FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R87 220R STANDARD METAL FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

R88 560 K STANDARD METAL FILM RES 1/4 W 5% 200 ppm/°C BC COMPONENTS

T-RES-ER49-

T1

T2 T-FLY-AUX-E20 86A-6079-R TYPE FLYBACK TRANSF. E20 CORE DELTA

U1 L6563 ADVANCED TRANSITION MODE PFC CONTROLLER STMicroelectronics

400W

86H-5408B TYPE RESONANT TRANSFORMER ER49 DEL TA

U2 L6599 HIGH VOLTAGE RESONANT CONTROLLER STMicroelectronics

U3 SFH617A-2 63-125% CTR SELECTION OPTOCOUPLER STMicroelectronics

U4 TL431 TO92 PROGR. SHUNT VOLTAGE REGULATOR STMicroelectronics

U5 VIPER12A LOW POWER OFF LINE SMPS PRIMARY SWITCHER STMicroelectronics

U6 SFH617A-2 63-125% CTR SELECTION OPTOCOUPLER INFINEON

U7 TL431 TO92 PROGR. SHUNT VOLTAGE REGULATOR STMicroelectronics

U8 SFH617A-2 63-125% CTR SELECTION OPTOCOUPLER INFINEON

Note: Q9 and R72: mounted by reworking on PCB

Q11, Q12, R83, R84, R86, R87, R88, C58, C59, C60 and C61: added by reworking on PCB

28/37

Page 29

AN2509 PFC coil specification

6 PFC coil specification

● Application type: consumer, home appliance

● Inductor type: open

● Coil former: vertical type, 6+6 pins

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

6.1 Electrical characteristics

● Converter topology: FOT PFC Preregulator

● Core type: PQ40-30 material grade PC44 or equivalent

● Max operating freq: 100 KHz

● Primary inductance: 500 µH ±10% @1 KHz-0.25 V (see Note: 1)

● Primary RMS current: 4.75 A

Note: 1 Measured between pins 2-3 and 10-11.

Figure 26. Electrical diagram

2 The auxiliary winding is not used in this design, but is foreseen for another application.

Table 8. Winding characteristics

Start PINS End PINS

11 8 5 (spaced) Single Ø 0.28 mm Bottom

5 - 6 1 - 2 65 Multistrand – G2 Litz Ø 0.2 mm x 30 Top

Turn

number

Wire type Wire diameter Notes

6.2 Mechanical aspect and pin numbering

● Maximum height from PCB: 45 mm

● Cut pins: 9-12

● Pin distance: 5 mm

● Row distance: 45.5 mm

● External copper shield 15 x 0.05 (mm) connected to pin 11 by tinned wire

29/37

Page 30

Resonant power transformer specification AN2509

Figure 27. Pin side view

● Manufacturer: DELTA ELECTRONICS

● P/N: 86H-5410

7 Resonant power transformer specification

● Application type: consumer, home appliance

● Transformer type: open

● Coil former: horizontal type, 7+7 pins, 2 slots

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

● Mains insulation: ACC. with EN60065

7.1 Electrical characteristics

● Converter topology: half-bridge, resonant

● Core type: ER49 - PC44 or equivalent

● Min. operating frequency: 75 Khz

● Typical operating freq: 120 KHz

● Primary inductance: 240 µH ±10% @1 KHz - 0.25 V [see Note 1]

● Leakage inductance: 40 µH ±10% @1 KHz - 0.25 V [see Note 1] - [see Note 2]

Note: 1 Measured between pins 1-3

2 Measured between pins 1-3 with the secondary windings shorted

30/37

Page 31

AN2509 Resonant power transformer specification

Figure 28. Electrical diagram

14

SEC. A

13

1

PRIM.

3

SEC. B

12

11

SEC. C

10

9

SEC. D

8

Table 9. Winding characteristics

Pins Winding RMS current N° turns Wire type

1 - 3 PRIMARY 2.90 A

14 - 13 SEC. A

13 - 12 SEC. B

11 - 10 SEC. C

9 - 8 SEC. D

1. Secondary windings A and B must be wound in parallel

2. Secondary windings C and D must be wound in parallel

(1)

(1)

(2)

(2)

RMS

1.7 ARMS 11 Litz Ø 0.2 mm x 10

1.7 ARMS 11 Litz Ø 0.2 mm x 10

1.15 ARMS 7 Litz Ø 0.2 mm x 20

1.15 ARMS 7 Litz Ø 0.2 mm x 20

19 Litz Ø 0.2 mm x 20

Figure 29. Mechanical aspect and pin numbering

Note: Cut PIN 7

● Manufacturer: DELTA ELECTRONICS

● P/N: 86H-5408

31/37

Page 32

Auxiliary flyback power transformer AN2509

Table 10. Mechanical dimensions

ABCDEF

Dimensions

(mm)

39.0 max 3.5 ± 0.5 41.6 ± 0.4 51 max 7.0 ± 0.2 51.5 max

Figure 30. Winding position on coil former

PRIMARY

SECONDARY

8 Auxiliary flyback power transformer

● Application type: consumer, home appliance

● Transformer type: open

● Winding type: layer

● Coil former: horizontal type, 4+5 pins

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

● Mains insulation: ACC. with EN60065

COIL FORMER

8.1 Electrical characteristics

● Converter topology: flyback, DCM/CCM mode

● Core type: E20 - N67 or equivalent

● Operating frequency: 60 Khz

● Primary inductance: 4.20 mH ±10% @1 KHz - 0.25 V [see Note 1]

● Leakage inductance: 50 µH MAX @100 KHz - 0.25 V [see Note 2]

● Max. PEAK primary current: 0.38 Apk

● RMS primary curre n t: 0. 2 A

Note: 1 Measured between pins 4-5

2 Measured between pins 4-5 with secondary windings shorted

32/37

RMS

Page 33

AN2509 Auxiliary flyback power transformer

A

Figure 31. Electrical diagram

5

PRIM

4

2

UX

1

● Manufacturer: DELTA ELECTRONICS

● P/N: 86A - 6079 - R

6

+5V

7

8

+3.3V

10

Table 11. Winding characteristics

Pins: start - end Winding RMS current N° turns Wire type

4 - 5 PRIMARY 0.2 A

2 - 1 AUX 0.05 A

8- 10 3.3 V 1.2 A

6 - 7 5 V 1 A

RMS

RMS

RMS

RMS

140 G2 - Ø 0.25 mm

29 G2 - Ø 0.25 mm

7 TIW Ø 0.75 mm

3 TIW Ø 0.75 mm

Figure 32. Auxiliary transformer winding position on coil former

INSULATING TAPE

COIL FORMER

3.3V / 5V

AUX

PRIMARY

33/37

Page 34

Board layout AN2509

9 Board layout

Figure 33. Copper tracks

34/37

Page 35

AN2509 Board layout

Figure 34. Thru-hole component placing and top silk screen

Figure 35. SMT component placing and bottom silk screen

35/37

Page 36

References AN2509

10 References

1. "L6563/L6563A advanced transition-mode PFC controller" Datasheet

2. "Design of Fixed-Off-Time-Controlled PFC Pre-regulators with the L6562", AN1792

3. "L6599 high-voltage resonant controller" Datasheet

4. "LLC resonant half-bridge converter design guideline", AN2450

11 Revision history

Table 12. Revision history

Date Revision Changes

13-Mar-2007 1 First issue

20-Mar-2007 2 Minor text changes

23-Apr-2007 3

– Cross references updated

– Table 7: Bill of materials modified

36/37

Page 37

AN2509

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale .

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services descri bed herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE S T DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR P URPOSE (AND THEIR E QUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all informa tion previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Ita ly - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

37/37

Loading...

Loading...