Page 1

AN2503

Application note

PDP Power Devices

Introduction

This application note discusses how to select o ptimal po we r de vices a nd contro l circuitry fo r

alternating plasma display panel applications, concentrating on power circuits used to

sustain plasma discharge on the panel.

Plasma Display Panels (PDP) are emerging as the leading candidate for large area wallhanging color TVs and HDTVs [1.]. Its large scr een, wide viewing angle, and thinness have

given it the edge over conventional displays. Scan, Energy Recovery (ERC) and Sustain

(discharge) circuits are important blocks that fulfill important energy saving requirements.

May 2007 Rev 1 1/30

www.st.com

Page 2

Contents AN2503

Contents

1 PDP Module structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 PDP basic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 PDP cell structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Panel memory characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 PDP driving sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 PDP Sustain circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Sustain circuit operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Positive pulse of Vyx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Positive discharge and clamping phase . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Vyx back to zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.4 Clamping to ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Symmetrical Y - X phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Reset phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 PDP Power Devices characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Power devices from ST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1 Measurement set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 Energy recovery section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.3 Discharge section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.4 Path section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.5 Set - reset section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Driving section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 Gate driver devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.1 Totem pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 Input buffer section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Bill of material and schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2/30

Page 3

AN2503 List of figures

List of figures

Figure 1. PDP module structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2. Cell structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. Memory effect - no charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. Memory effect - address phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5. Memory effect - Wall charges deposit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 6. Memory effect - discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 7. Memory effect - wall charges deposit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 8. Memory effect - discharge with reverse polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 9. Subfield structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 10. Subfield structure – expression of gray level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 11. Sustain circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 12. Circuit scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 13. Circuit scheme – positive pulse of V

Figure 14. Equivalent circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 15. Circuit scheme – positive discharge and clamping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 16. Circuit scheme – V

back to zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

yx

Figure 17. Circuit scheme – clamping to ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 18. Circuit scheme – negative pulse of V

Figure 19. Circuit scheme – negative discharge and clamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 20. Circuit scheme – V

back to zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

yx

Figure 21. Circuit scheme – clamping to ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 22. Circuit scheme – set and reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 23. Inductor current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 24. Gate driver topology with L6385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 25. Gate driver topology – L6388 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 26. STS01DTP06 Totem pole. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 27. Board schematic 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 28. Board schematic 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

yx

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

yx

3/30

Page 4

PDP Module structure AN2503

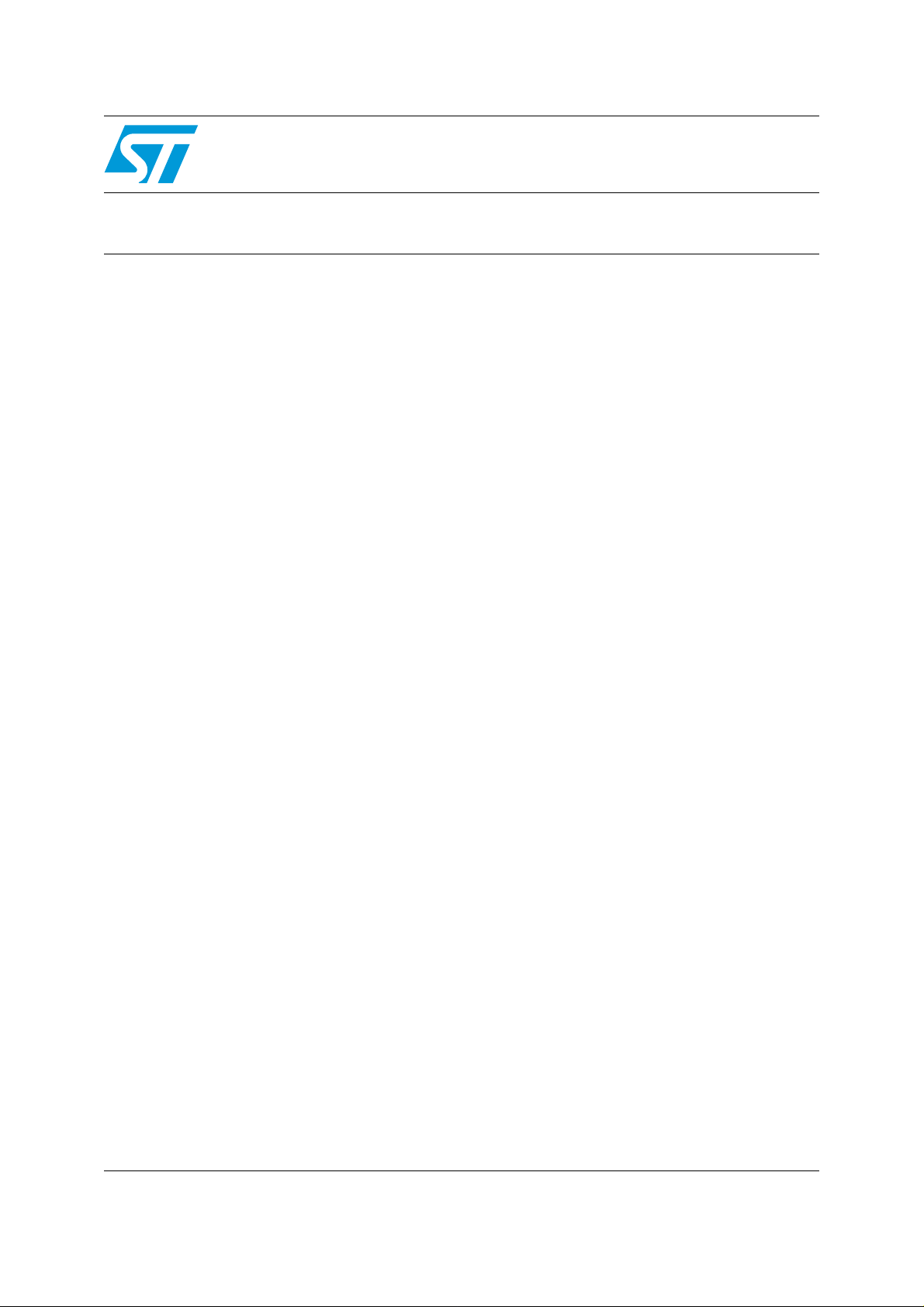

1 PDP Module structure

Po wer supply, address buffer, logic and scan buff er boards are the fundamental blocks of a

PDP. In particular, the energy recovery and sustain function are performed by the Y and X

drive boards. Power MOSFETs, IGBTs, Diodes and Drivers are key products for ERC and

sustain both in X and in Y drive boards. These products are also used for the path, set-reset

function in the Y drive board only. Path switches are mandatory to isolate ERC and Sustain

switches from the negative voltage applied to the display during the scan phase, while, set

and reset switches determine identical initial condition of the plasma cells before each

address cycle.

Figure 1. PDP module structure

ST's extensive portfolio covers the whole solutio n for an energy recovery circuit (ERC),

sustain circuit, path circuit, and set-reset circuit, both from a power device and IC driver

perspective.

The ST solution takes into account all fundamental requirements like cost, component

count, reliability and power consumption.

Reduced power losses and higher switching frequency are the main benefits of ST's

advanced technology.

4/30

Page 5

AN2503 PDP basic

2 PDP basic

Basic knowledge on Plasma Display Panel encompasses manufacturing issues in cell

structure, physics principle in the memo ry effect, and display algorithms needed to create a

range of colors.

2.1 PDP cell structure

Figure 2 shows the structure of a plasma display glass panel, [2.].

Figure 2. Cell structure

An AC PDP displa y is composed of front and rear glass substrates sandwiche d together and

then sealed. The air is vacuumed out and a mixture of inert gases (Ne and Xe) is injected

between the glass substrates . The separation between the two opp osing substrates is about

100um and the space between them is filled with a gas mixture of Ne and Xe. The front

glass substrate has a first electrode (X electrode) and a second electrode (Y electrode)

which operate as sustain electrodes. The X and Y electrodes are coated with bus

electrodes, dielectric layer, and MgO layer in sequence. The MgO protects the dielectric

from plasma damage and also aids the plasma in sustaini ng a discharge through secondary

electron emission from its surface. In addition, equivalent capacitor exists between the X

and Y electrodes. On the surface of the rear glass substrate, as opposed to the front glass

substrate, a third electrode operating as an address electrode (A electrode) is formed to be

orthogonal to the X and Y electrodes. Electrically, the entire assembly can now be

considered as a three-electrode capacitor. A cross point is formed where the X, Y and A

electrodes meet. Three adjacent red, blue and green cross points form a color picture

element (pixel) of the panel. In operation, an AC voltage sufficiently high will ionize the gas

to create the plasma. Then, the ultraviolet light from the plasma excites the phosphor to

create the color image.

Each pixel can be independently controlled and can assume different color gradations. The

number of pixels available determines the resolution of the glass panel vertically and

horizontally.

5/30

Page 6

PDP basic AN2503

3

3

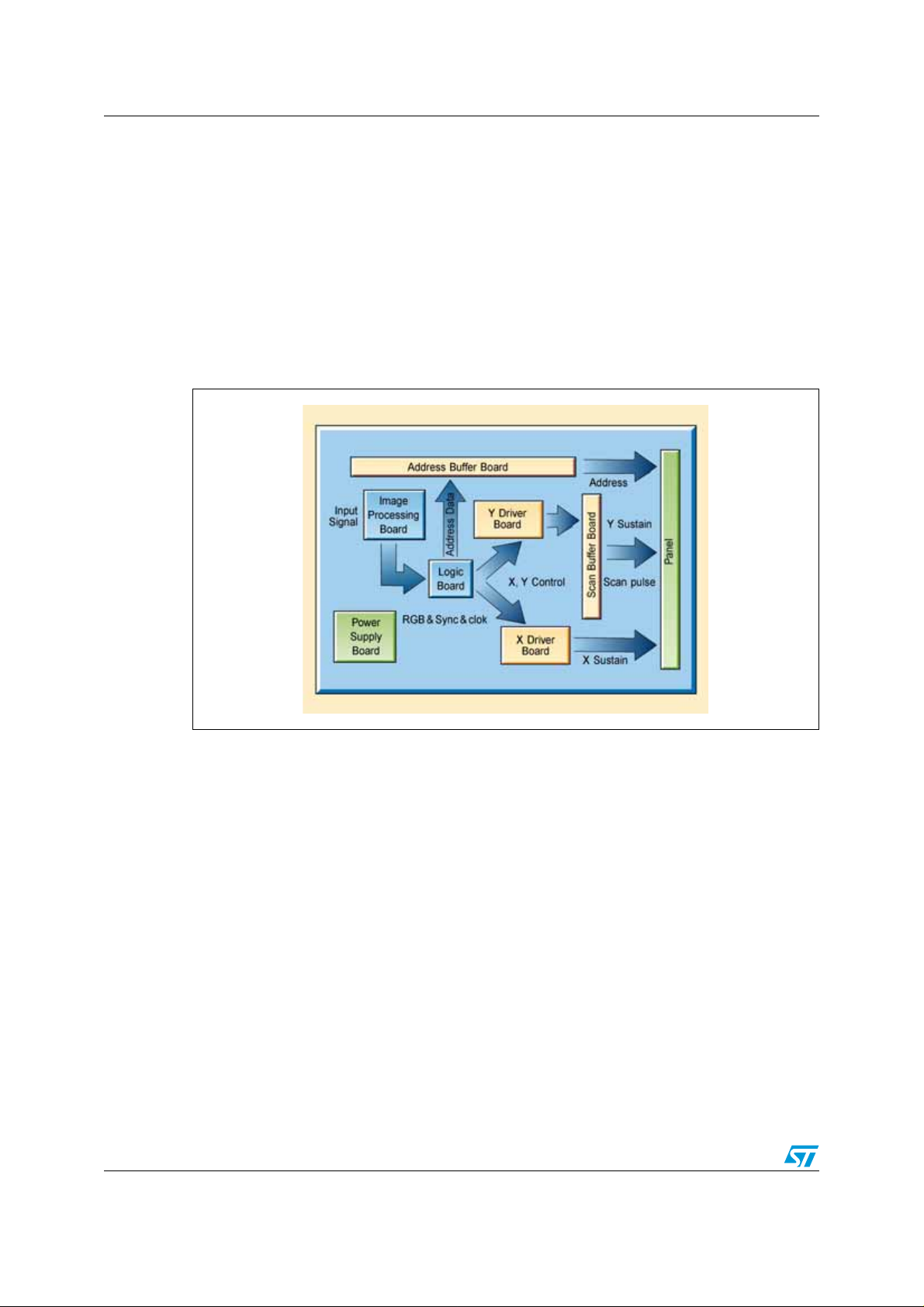

2.2 Panel memory characteristic

The AC PDPs provide inheren t memory characteristics [3.], [4.], as explained in the

following figures.

In general, the AC sustain square pulse voltage (V

), whose voltage Vs is smaller than the

xy

gas breakdown voltage Vbd, cannot initiate a discharge, as shown in Figure 3.

Figure 3. Memory effect - no charges

X = Vs Y = GND

Address = Vs/2

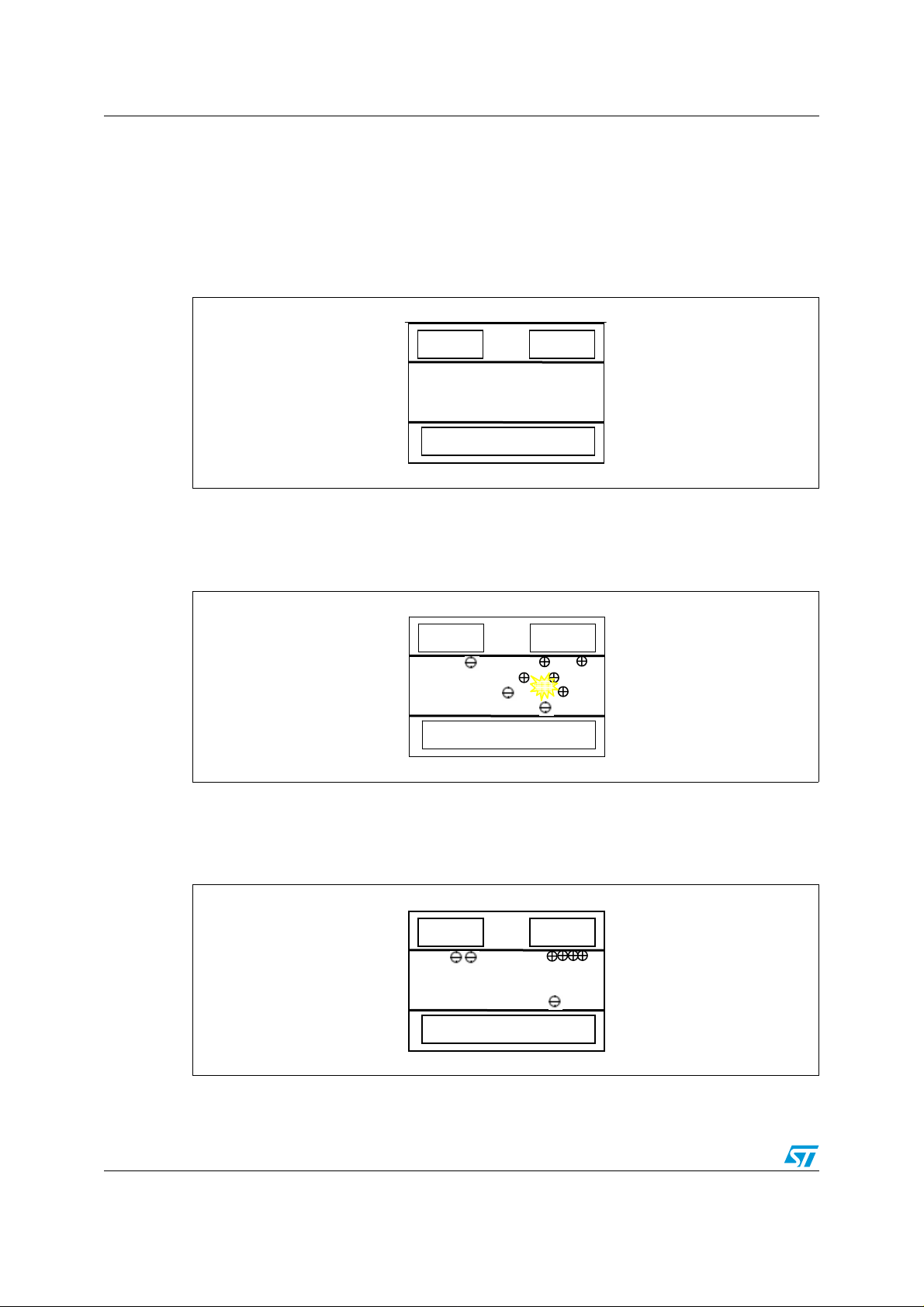

If data pulses Vd are applied to the address electrodes, while scan pulses -Vy are

sequentially applied to each Y electrode, the voltage (Vd + Vy) is higher than Vbd and a

weak discharge ignites, as shown in Figure 4.

Figure 4. Memory effect - address phase

X = Vk Y = -Vy

Charges, called wall charges (or w all voltage Vw), deposit on the dielectric lay er and reduce

the effective voltage across the gap. Then, the discharge ceases after a short time, as

shown in Figure 5.

Figure 5. Memory effect - Wall charges deposit

X = Vk Y = -Vy

6/30

Address = Vd

Address = Vd

Page 7

AN2503 PDP basic

3

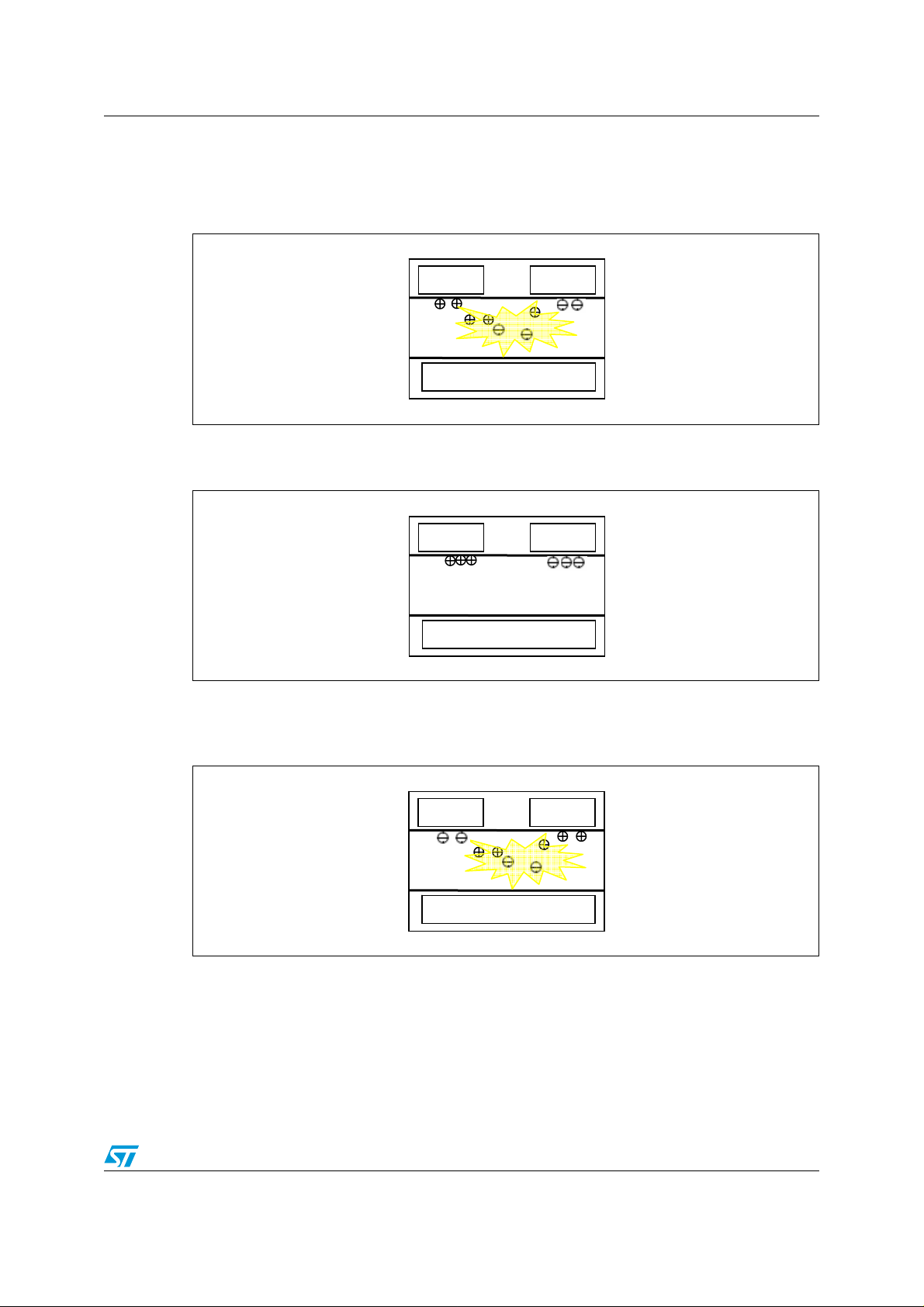

When the polarity of the sustain pulse is reversed, the potential difference across the gap

becomes larger than Vbd by an amou nt determined by the wall charges, and a new large

discharge of different polarity occurs, as shown in Figure 6.

Figure 6. Memory effect - discharge

X = GND Y = Vs

Address = Vs/2

The build-up of wall charges again terminates the discharge, as shown in Figure 7.

Figure 7. Memory effect - wall charges deposit

X = GND Y = Vs

Address = Vs/2

The next discharge starts as the polarity of the sustain pulse is reversed, as shown in

Figure 8.

Figure 8. Memory effect - discharge with reverse polarity

X = Vs Y = GND

Address = Vs/2

Once the discharge is initiated, it continues as long as the sustain pulse is applied. Due to

this memory characteristic of AC PDPs, lower sustain voltage (< Vbd) pulses can maintain

the ac PDPs to light.

In other words, the p rocess of panel image d ispla ying depends on a f ormer process of panel

addressing. In fact, during the address phase a small amount of charges (wall charges)

deposit on the selected electrodes without any visible light emission. This reduces the

7/30

Page 8

PDP basic AN2503

threshold voltage for discharge, and consequently, during sustain phase only selected cells

ignite and emit light.

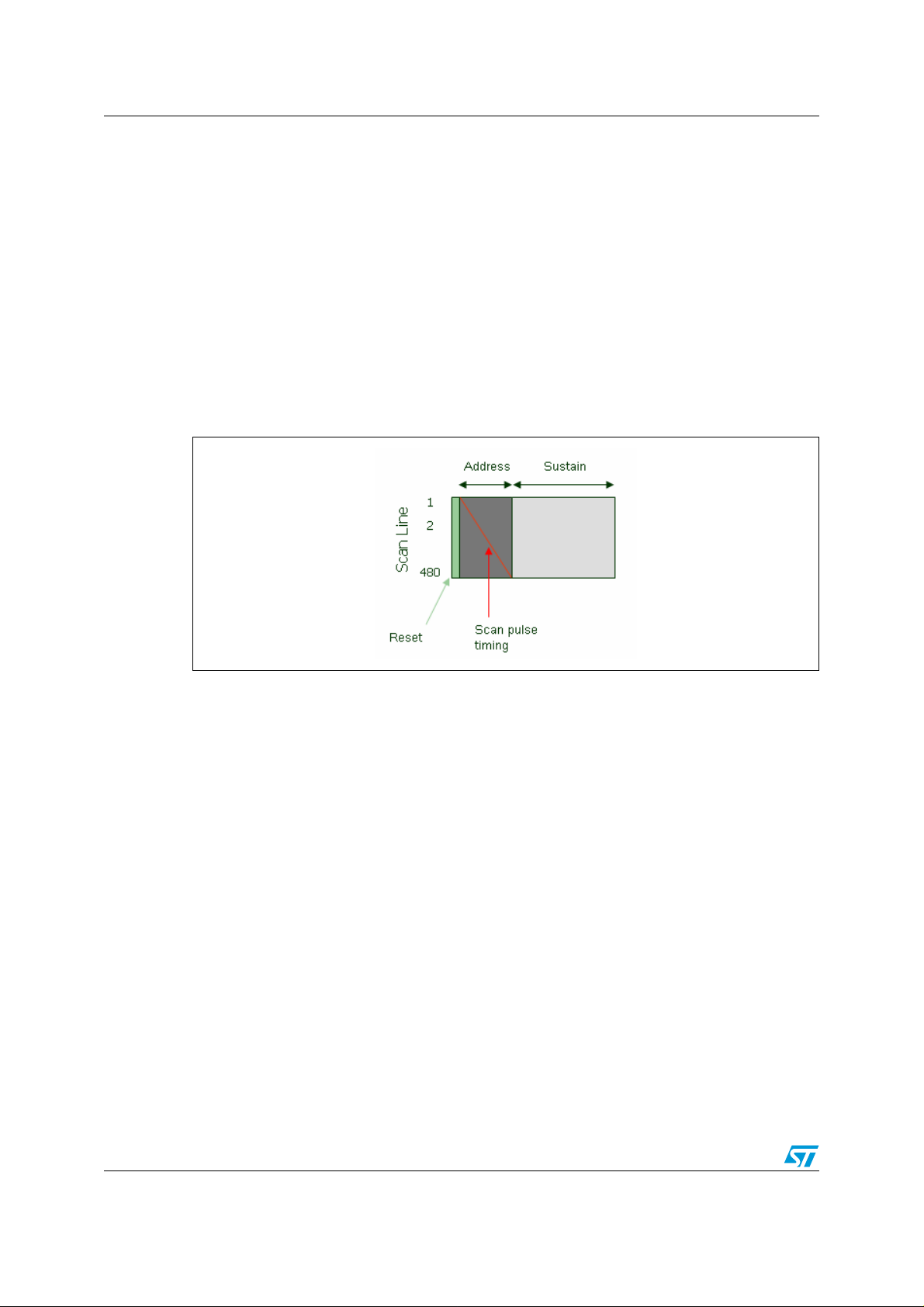

2.3 PDP driving sequence

The most common method of displaying one picture field is using the Address DisplaySeparation method (ASD).

All X electrodes are bused together and connected to a sustain driver, while the Y

electrodes are connected to susta in driver through seve ral scan ICs. One TV field is divided

into 10 subfields (SFs) in a 10-bit codification case, and each consists of a reset period, an

address period, and a display period (Figure 9).

On every subfield, each cell is addressed, sustained and erase d.

Figure 9. Subfield structure

During the reset period a slow ramping positive voltage up to 400 V followed by slow

ramping negative v oltage do wn to -150 V is applied across t he X and Y electrodes to put out

ionization and to set an identical initial condition for all the panel cells . In the address period,

the Y electrodes receive scan pulses, al ong with data pulses on the address electrodes, in

order to control wall charges in appropriate cells according to the image to be displayed .

Note that reset period and address period hav e the same dur ation in each subf ield, only the

number of sustain pulses varies among different subfields.

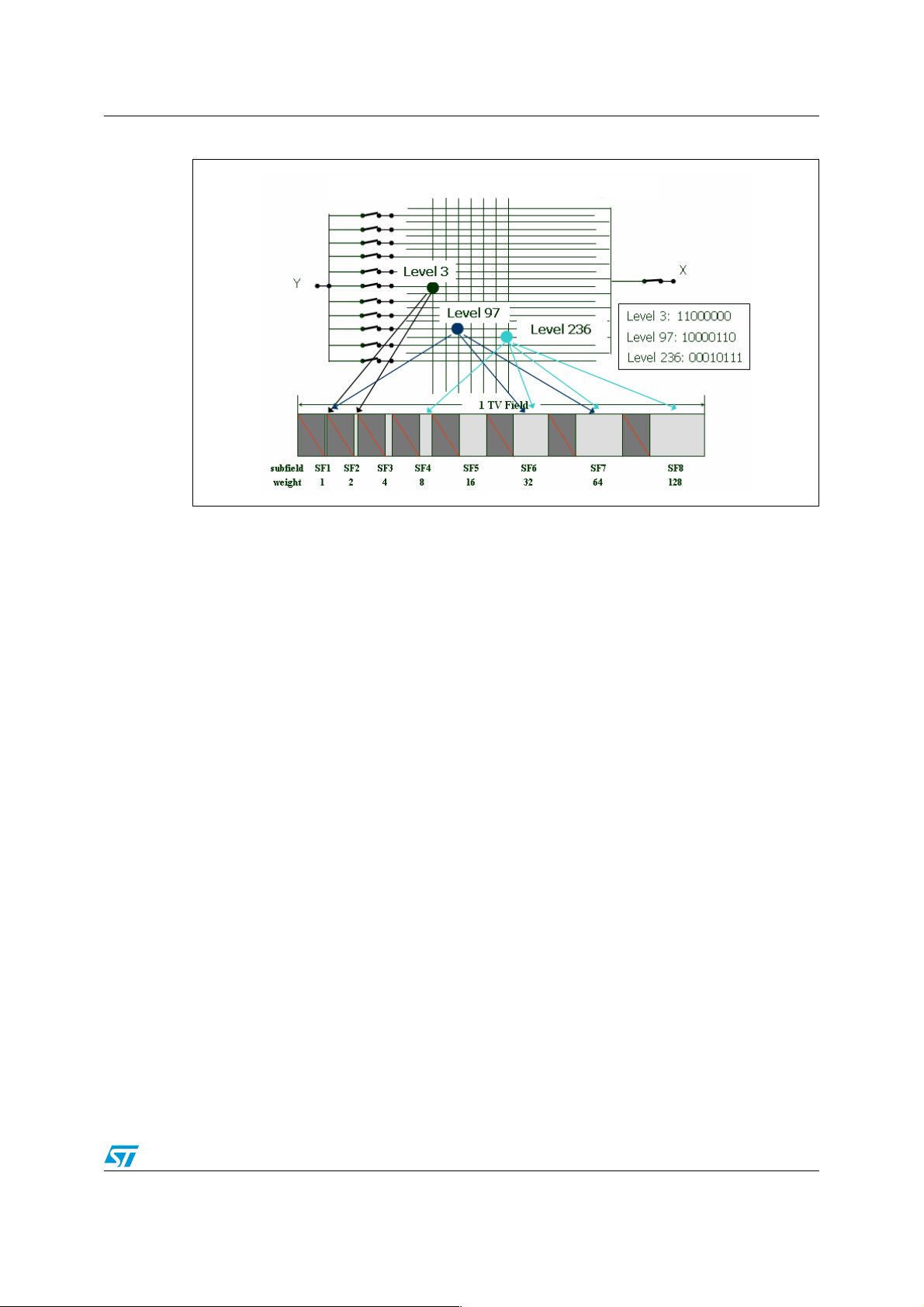

During sustain period, selected cells are sustained in order to display the whole image on

the panel. Gray scales are expressed by using the binary-coded light-emission-p e riod

method. The display periods are filled with trains of constant width and constant period

pulses, and their lengths are arranged according to the binary sequence, 1: 2: 4: 8: 16: 32:

64: 128: 256: 512. Therefore, gray levels of 2

expressed with an 10-bit sequence. This means that each color element has 1024 color

possible graduations and each pixel has 1024 x 1024 x 1024 = 1 billion colors. Figure 10

shows a simplified 8-bit system with 8 subfields. The subfields are weighted according to

their binary values and a typical TV field is 1/50 of a second.

10

for each color (R, G, and B) can be

8/30

Page 9

AN2503 PDP Sustain circuit

Figure 10. Subfield structure – expression of gray level

3 PDP Sustain circuit

In a Plasma Display Panel, frequent discharges are made to occur by alternately charging

each side of the panel to a critical voltage, allowing images to be displayed. This alternating

voltage is called the sustain voltage, and the sustain circuit (or sustainer) is needed to

provide it to the display [5.].

If a pixel has been driven "ON" during address period, the sustainer maintains the "ON"

state of that pixel by repeatedly discharging that pixel cell during the whole sustain period. If

a pixel has been driven "OFF" b y an a ddress driver, the voltage across the cell is nev er high

enough to cause a discharge, and the cell remains "OFF" during the sustain period.

The sustain circuit must drive all panel pixels at once. This means that the capacitance as

seen by the sustainer is typically v ery large. In a 42-inch panel with 852x480 pix e ls, th e total

capacitance of all the pixel cells, Cp, could be as much as 80 nF.

The key parameters in the sustainer study are:

● Cp - Panel equivalent capacitance

● Vs - Sustain Voltage

● f - Sustainer Switching frequency

● f

Conventional sustain circuit (half bridge topology) drives the panel directly, and thus

1/2C

ground.

- average sustainer switching frequency

av

2

f

PVS

is dissipated in the sustainer when the panel is subsequently discharged to

av

In a complete sustain cycle, each side of the panel is charged to Vs and subsequently

discharged to ground. Therefore, a total of 2CpVs

2

fav power is dissipated in a complete

sustain cycle.

9/30

Page 10

PDP Sustain circuit AN2503

Conventional sustain circuit (half bridge topology) drives the panel directly, and thus

1/2C

2

fav is dissipated in the sustainer when the panel is subsequently discharged to

PVS

ground.

In a complete sustain cycle, each side of the panel is charged to Vs and subsequently

discharged to ground. Therefore, a total of 2C

PVS

2

f

is dissipated in a complete sustain

av

cycle.

Figure 11. Sustain circuit

The power dissipation in the sustainer is th en 2C

2

fav, where fav is the average sustain

PVS

cycle frequency.

For Cp=80 nF, Vs =200 V, and f

= 100 kHz, the power dissipation in th e sustainer, resulting

av

from driving the capacitance of the panel, could be as high as 640 W.

If an inductor is placed in series with the panel, then Cp can be charged and discharged

through the inductor. This would ideally result in zero power dissipation since the inductor

would store all of the energy otherwise lost in the output resistance of the sustainer and

transfer it to or from Cp . Ho we v er , s wit ching de vices are neede d to control the flow of ene rg y

to and from the inductor, as Cp is charged and discharged, respectively, and this leads to

power losses.

The "ON" resistance, output capacitance, and switching transition time are characteristics of

these switching de vices that can result in significant energy loss. The amount of energy that

is actually lost due to these characteristics, and hence the efficiency, is determined largely

by how well the circuit is designed to minimize these losses. In addition to charging and

discharging Cp, the sustainer must also supply the large gas discharge current for the

plasma panel. This current, I, is proportional to the number of pixels that are "ON" in the

same TV frame. The resulting instan taneous power dissipation is I

resistance of the sustainer. Thus, the power dissipation due to the discharge current is

proportional to I

2

, or the square of the number of pixels that are simultaneously "ON".

2

R, where R is the output

There are two ways to minimize this dissipation. The first is to reduce the output resistance

of the sustainer by using very low resistance output drivers, and the second is to minimize

the number of pixels that are "ON" at any time.

The switching power losses due to the panel capacitance during sustain period in AC PDP

driving system can be minimized using a specific energy recovery circuit. The most common

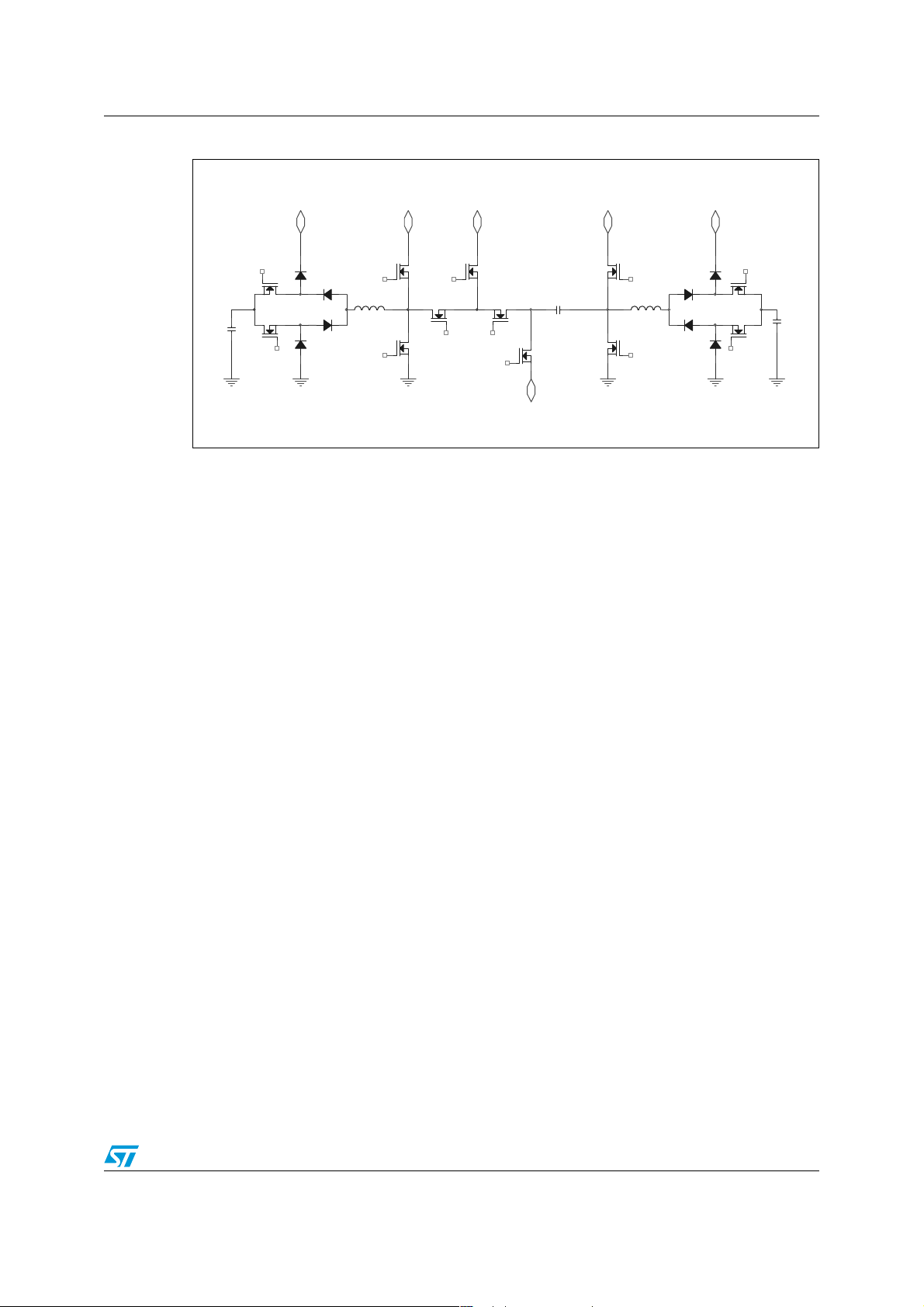

sustain/energy recovery circuit topology refers to Weber topology (Figure 12).

10/30

Page 11

AN2503 PDP Sustain circuit

Figure 12. Circuit scheme

Vs Vs VsVset

L1

T3

T6 T5

T4

Y-Electrode

Cp

T9

X-Electrode

T10

D8

D5

T11

L7

T12

D7

D6

CS2

T7

T8

-Vreset

CS1

Vs

D2

T2

T1

D3

D1

D4

Weber topology provides a new sustainer circuit that recovers the energy otherwise lost in

charging and discharging the panel capacitance , Cp . The efficiency with which the sustainer

recovers this energy is defined as the "recovery" efficiency. In particular, when Cp is

charged to V

2

C

.

PVS

and then discharged to zero, the energy that flows into and out of Cp is E =

s

The recovery efficiency is defined by:

Equation 1

2

E

–

Eff 100

C

PVS

-----------------------------------------

CPV

LOST

2

S

⎛⎞

E

LOST

----------------- -–

•=•=

100 1

⎜⎟

⎝⎠

CPV

2

S

where E

is the energy lost in charging and discharging Cp in the sustain circuit without

LOST

energy recovery.

It is worth noting that the recovery efficiency is not the same as the conventional power

efficiency defined in terms of the power delivered to a load, since no power is delivered to

the capacitor Cp. It is simply charged and then discharged. The recovery efficiency is a

measure of the energy loss in the sustainer, and could reach a value higher than 90%.

Summarizing, the panel's pixels are connected in parallel and can be represented as an

equivalent panel capacitor Cp. A proper switching sequence, together with the energy

recovery circuit, allows this circuit to produce an AC voltage required to illuminate, recover

residual energy and reset the cells of the panel.

Referring to the schematic in Figure 12, Power de vices in the Sustain circuit top ology can be

grouped into four circuit sub-functions:

1. Energy recove ry circuit (ERC) which consists of T1, T2, T11, T12, D1, D2, D3, D4, D5,

D6, D7, D8

2. Sustain circuit (discharge circuit or sustainer) which consists of T3, T4, T9, T10

3. Path circuit which consists of T5, T6

4. Set and Reset circuit which consists of T7, T8

11/30

Page 12

PDP Sustain circuit AN2503

3.1 Sustain circuit operations

Sustain circuit operations describe the way to generate a square wa veform on the panel

capacitor. This section describes how t o charge and dischar ge the pa nel capacit or in or der

to perform the sustain phase.

3.1.1 Positive pulse of V

After the reset period, we can suppose that all cells on the panel have been already

addressed during the address period. This means that the cells to be displayed have

accumulated enough wall charge to be ignited, due to cell memory effect. We can assume

also that CS1 and CS2 have already their steady state voltage value, this means they have

initial voltage of V

In order to produce a positive voltage across the panel (V

are turned ON and D1 is forward biased. CS1 charges and raises the voltage across the

panel capacitor Cp in a resonant way. This step is a part of the energy recovery phase since

it recovers the energy stored in the capacitor CS1 from previous sustain cycles back to the

panel.

Figure 13. Circuit scheme – positive pulse of V

T2

CS1

T1

/2 from previous sustain cycles.

s

Vs

D2

D3

D1

D4

yx

L1

Vs Vs VsVset

T3

T6 T5

T4

positive), T1, T5, T6 and T10

yx

yx

T7

Y-Electrode

T8

T9

X-Electrode

Cp

L7

T10

D8

D5

T11

T12

D7

D6

CS2

The equivalent circuit during the LC resonant period of the energy recovery circuit is:

Figure 14. Equivalent circuit

In Figure 14, R represents the parasitic resistance including on-resistances of switches and

V

represents the diode forward drop. Based on this figure, the panel voltage V

ON

obtained as follows:

Equation 2

V

s

⎛⎞

V

12/30

------ V

yx

–

ON

⎝⎠

2

-Vreset

t

-- -–

τ

⎛⎞

1e

–=

⎝⎠

R

------

ωtcos

ωL

ωtsin+

can be

yx

Page 13

AN2503 PDP Sustain circuit

Where

If (2L/R)

ωR

⎛⎞

τ

=

⎝⎠

2

and (ωR/L) can be ignored, t he equation (Equation 2) can be simply re-written as:

-------

and

L

ω

1

⎛⎞

-----------

⎝⎠

LCp

R

⎛⎞

------ -

–=

⎝⎠

2L

2

Equation 3

t

---

τ

1e

ωcos–= t

Where

If ω’ =

ω

∏ then the peak value is:

1

-----------=

’

LCp

V

------ VON–

yx

⎝⎠

2

V

s

⎛⎞

Equation 4

C

πR

p

-------

V

s

V

yx pk,

⎛⎞

------ VON–

⎝⎠

2

1e

–=

------–

2

L

Equation 4 states that an increase of the parasitic resistance ca uses the reco very efficiency

to be degraded. Naturally, it is necessary to reduce the parasitic resistance by desig ning the

circuit board optimally as well as choosing s witching devices with small on-resistance and

low on-drop voltage to minimize the hard-switching stress and improve the recovery

performance. On the other hand, reduction of the inductor value produces similar results

and, thus, using a too small value of L is not desirable with respect to driving loss.

3.1.2 Positive discharge and clamping phase

Figure 15 shows both panel discharge and the camping current paths. In the f irst phase t he

ionized gas could be represented as a non linear resistor and the peak current during this

period is higher than that during energy recovery. The worst condition is represented when

all cells in the panel must be ignited (full white screen condition), and in this case the

discharge current could be higher th an 120 A f or a standa rd definition (SD) 4 2-inch PDP set.

Further increase in the current value is expected in HD PDP as the number of pixels

increases.

Figure 15. Circuit scheme – positive discharge and clamping

Vs Vs VsVset

L1

T3

T6 T5

T4

T7

-Vreset

CS1

Vs

D2

T2

T1

D3

D1

D4

Y-Electrode

Cp

T8

T9

X-Electrode

T10

D8

D5

L7

D7

T11

T12

D6

CS2

13/30

Page 14

PDP Sustain circuit AN2503

The discharge current has also a sinusoidal profile , and is conduct ed b y T3, T6, T5, Cp , and

T10. Once the panel is charged to Vs and visible light is emitted, current stops flowing and

the gas inside the glass stops ionizing. (Note that th e us e of I GBTs in the discharg e section

requires extra care; indeed power devices requires freewheeling diodes to carry reverse

current due to the tank circuit formed between the panel capacitor Cp, L1 and the bus

capacitance).

At this time D1 is reverse biased and its reverse cur rent charges the inductance L1. The

energy stored in the ind uctance is rem oved through the clamping current, and the clampin g

current path is carried out by T3, D3, and D2. In this phase the re v erse curren t of D1 is a ke y

parameter in power loss re duction. In f act, a lower clampi ng current means lower conduction

losses in T3, D2 and D3. Depending on the topology used, and in particular the clamping

diode's position, the time spent to evacuate the energy stored in the inductance can vary

significantly.

3.1.3 Vyx back to zero

The next phase consists of bringing back to zero the pane l capacitor v oltage and re v erse the

polarity of the voltage across Y-X electrodes.

In order to efficiently decrease the voltage on the panel capacitor, the energy stored in Cp

could be recovered bac k in the recovery capacitor CS1.This can be done by turning ON T2,

T6, T5, and T10.

The current path is shown in Figure 16. This current stops flowing when the voltage across

the panel capacitance V

is half sinusoidal and its direction is from the panel Cp back to CS1.

Figure 16. Circuit scheme – V

Vs

D2

D3

T2

CS1

T1

D1

D4

3.1.4 Clamping to ground

In order to bring completely to zero the panel capacitance, T10, T5, T6, and T4 are turned

ON, creating a current path across the panel through the equivalent resistances of power

devices and parasitic elements of the circuit.

and CS1 reach the same value (Vs/2). The profile of this current

yx

back to zero

yx

Vs Vs VsVset

T3

L1

T6 T5

T4

T7

Y-Electrode

T8

-Vreset

T9

X-Electrode

Cp

L7

T10

D8

D5

T11

T12

D7

D6

CS2

14/30

Page 15

AN2503 PDP Sustain circuit

Figure 17. Circuit scheme – clampin g to ground

Vs

Vs Vs VsVset

T3

T6 T5

T4

CS1

D2

D3

T2

T1

D1

D4

L1

3.2 Symmetrical Y - X phase

A similar switching sequence is applied in order to re ve rse the polarity across Y-X electrodes

(X electrode more positive than Y electrode)

In particular, this can be briefly described as:

a) Energy recovery, path and discharge switches, T12, T5, T6, and T4 are turned

ON, and the current flows from CS2 to Cp.

Figure 18. Circuit scheme – negative pulse of V

Vs Vs VsVset

L1

T3

T6 T5

T4

CS1

Vs

D2

T2

T1

D3

D1

D4

T7

Y-Electrode

T8

-Vreset

T9

X-Electrode

Cp

L7

T10

D8

D5

T11

T12

D7

D6

CS2

yx

Y-Electrode

Cp

T9

X-Electrode

T10

D8

D5

L7

D7

T11

T12

D6

CS2

T7

T8

-Vreset

b) Discharge and Clamp phases: T9, T4, T5, T6 are turned ON and the current flow s

from Vs to Cp and through T9, L7, D7, D8.

Figure 19. Circuit scheme – negative discharge and clamping

Vs Vs VsVset

L1

T3

T6 T5

T4

T7

Y-Electrode

T8

-Vreset

T9

D8

D5

X-Electrode

Cp

L7

T10

D7

D6

CS1

Vs

D2

D3

T2

T1

D1

D4

T11

T12

CS2

15/30

Page 16

PDP Sustain circuit AN2503

2

c) Energy Recovery phase: T4, T5, T6, and T11 are tu rned ON, and the current flo ws

from Cp to CS2.

Figure 20. Circuit scheme – V

Vs

D2

D3

T2

S1

T1

D1

D4

L1

back to zero

yx

Vs Vs VsVset

T3

T6 T5

T4

T7

-Vreset

d) Zero voltage Clamp, T4, T5, T6, T10 are turned ON.

Figure 21. Circuit scheme – clampin g to ground

V

D

T T T

CS

D

D

V V VVse

L

T

T

Y

E

l

e

c

Y-Electrode

Cp

T8

C

T

T9

X-Electrode

L7

T10

T

X-Electrode

L

T1

D8

D5

T11

T12

D7

D6

D

D

D

T1

T1

D

CS

CS

It can be noted that during sustain phase, path switches T5 and T6 are always turned ON,

and they see both energy recovery current and discharge current which explains the need

for low voltage drop devices.

3.3 Reset phase

At the end of each subfield, the cells are reset a pplying a positive ramp v oltage f ollow ed by a

negative one.

During positive reset, T10, T5, T7 are turned ON. During negative reset T10 and T8 are

turned ON.

16/30

Page 17

AN2503 PDP Power Devices characteristics

Figure 22. Circuit scheme – set and reset

Vs Vs VsVset

L1

T3

T6 T5

T4

T7

X-Electrod e

Y-Electrod e

Cp

T8

-Vreset

CS1

Vs

D2

T2

T1

D3

D1

D4

4 PDP Power Devices characteristics

A clear idea of circuit operation will help us to highlight the main features of the devices

involv ed. In particular the analysis can be split in power de vices analysis and driving devices

analysis, in order to address specific characteristics of each device.

4.1 Power devices from ST

T9

L7

T10

D8

D5

D7

T11

T12

D6

CS2

Power devices in PDP have common characteristics that range from high peak current

capability and low forward voltage drop to fast turn-ON capability. The current both in the

Energy Recovery Circuit (ERC) and in the Discharge Circuit (DC) follows a half sinusoidal

pattern. ERC and DC could be simply classified as soft switching converters. In fact, the

circuit can be considered as a series resonant LCR circuit, so the current at turn-ON is zero

(zero current switching) and the voltage at turn-OFF is zero (zero voltage switching).

Since a MOSFET has an intrinsic body diode across it, a MOSFET does not require an antiparallel diode when selected as power devices on the discharge circuit, while an IGBT

needs a specific freewheeling diode. For ER circuit, the Power Switch does not require an

anti-parallel diode since re verse current is blocked by the diodes in series with the devices

(D1, D3, D5 and D7), thus MOSFET or IGBT can be used as power devices on the ER

circuit.

Diodes D2, D4, D6 and D8 provide additional pr otection clamping the voltage on the

inductors avoiding damage to devices on the ER circuit.

Path circuit has to carry both ER and Discharge currents , thus it is required to hav e v ery low

voltage drop. It can be noted that during ER and Discharge cycles, the pass circuit remains

on. The Path circ uit switches on and off only during reset period which happens at the end

of each subfield, which means that the maximum frequency is in the range of 1 kHz. The

Path circuit is a bidirectional circuit, so a MO SFET, that can carry current in both directions,

could be used for this circuit.

ST has a broad range of products covering the power section ranging from MOSFET and

IGBT to dedicated Diodes.

17/30

Page 18

PDP Power Devices characteristics AN2503

4.1.1 Measurement set-up

Po wer losses and thermal analysis measurements were performed based on an average

switching frequency. In fact, switching performances have to be related to the maximum

frequency in the system, usually 250 kHz, whereas power losses a nd thermal management

have to be related to an average frequency. The Average Switching frequency takes into

account the fact that during a picture time , the po w e r devices do not switch at the maximum

frequency for the whole time, but only during the sustain phases. The sust ain duration, and

consequently the number of sustain pulses , increases starting from subfield 1 to su bfield 10.

Average frequency can be calculated starting from sustain duty ratio.

Table 1. 10 subfield / single scan

Scan speed VGA 480 XGA 768 HD 1080

3 µsec - - -

2.5 µsec 0.130 - 2 µsec 0.274 - -

1.5 µsec 0.418 0.159 1 µsec 0.562 0.389 0.202

Table 2. 10 subfield / dual scan

Scan speed VGA 480 XGA 768 HD 1080

3 µsec 0.418 0.158 -

2.5 µsec 0.490 0.274 0.040

2 µsec 0.562 0.389 0.202

1.5 µsec 0.634 0.504 0.364

1 µsec 0.706 0.620 0.526

Note: Sustain duty = picture time - reset period x SF - N x SF x scan speed [

Picture time = 16.67 ms

Reset period = 250

µsec

SF = number of sustain pulses

N = number of lines

The sustain duty ratio is carried out for a 10 subfield case in b oth single scan and dual scan

operations, varying the scan speed duration (time needed to scan a single line in the

display), for VGA (480 lines), XGA (768 lines) and HD (1080 lines).

According to the following formula,

f

av=fswitching

For a VGA display

x SustainDuty

→ SustainDuty = 0.27 ÷ 0.56 → f

= 68 ÷ 140 kHz

av

This means that power devices in ERC and discharge circuit need to be designed for an

average frequency of 140 kHz (maximum) in terms of power losses and thermal

management. Clearly peak current and peak v o ltage r ating do not chang e when w e perf o rm

this averaged analysis.

µs / line]

18/30

Page 19

AN2503 PDP Power Devices characteristics

Typical voltage requirements for a PDP are:

● Sustain voltage Vs = 200 V

● Set voltage Vset= 400 V

● Reset voltage Vreset= -150 V

4.1.2 Energy recovery section

For Energy recovery circuit, the maximum voltage stress is Vs/2 ≈ 100 V, and the current

stress depends on the device. The clamping diodes have to withstand a current lower than

10 A, whilst the ERC switches and the ERC diodes have to be able to handle a resonant

half-sinusoidal current up to 100 A peak.

The typical current waveform in the Energy recovery circuit is shown in Figure 23. The key

parameters of the DERC diode for the energy reco very circuit have been optimized in order

to decrease power losses.

Figure 23. Inductor current

ERC

current

T1

Clamping

current

T3

D2

D3

For ER circuit new devices with low voltage drop and very fast turn ON hav e been

developed.

● Energy recovery diodes STTH60P03, STTH40P03

Energy recovery diodes (D1, D3, D5, and D7) have been tailored on this application

optimizing key parameters to reduce power losses [6.], [7.]. They have the ability to handle

large repetitive peak current ( Irp), in conjunction with a lower r e v erse current (I

forward voltage (V

FP

).

) and peak

RM

Table 3. STTH60P03 Features

Symbol Parameter Test conditions Min. Typ Max. Unit

I

S

V

RM

factor

FP

Reverse

recovery current

T

= 100°C

j

Softness factor 0.5

Peak forward

voltage

= 25°C

T

j

= 60 A VR =

I

F

100 V

/dt = 200 A/µs

dI

F

I

= 60 A

F

dIF/dt = 400 A/µs

67.5A

2.5 3.5 V

19/30

Page 20

PDP Power Devices characteristics AN2503

● Clamping diodes STTH2003, STTH1003

Diodes D2, D4, D6, and D8 provide additiona l protection to clamp the voltage on the

inductors [8], [9]. Overvoltage is due to ER diodes reverse current that store energy in the

inductors. The fa ct that reverse current I

of ERC diodes stores energy in the inductors

RM

(and can cause ov ervoltage if we do not use clamping diodes D2, D4, D6, and D8),

demonstrates that the I

I

causes power losses both in Clamping diodes and Discharge switches.

RM

in ERC diodes is a key parameter to take into account. In fact,

RM

Table 4. Clamping diodes features

P/N IF [A] V

STTH1003 10 300 13 175 0.9 DPAK, TO-220FP, D

STTH2003 2x10 300 35 175 1 DPAK, TO-220FP, D

● Energy recovery MOSFET ST75N20

T1, T2, T11, and T12 are the power switches used in the Energy recovery circuit. Due to the

reactive nature of the load, th e voltage across the power switch falls rapidly followed by a

rapid rise in the current. This explains why a fast turn-ON is needed, and low conduction

losses (low drop) can be achieved only reducing the R

MOSFET in proprietary STripFET

charge is perfectly tailored for the application [9.].

Table 5. ERC MOSFET features

P/N V

ST75N20 200 0.028 75/300 300 TO-247, TO-220, D

DSS

[V] R

4.1.3 Discharge section

When the panel discharges, a sinusoidal shaped current will go through the discharge

switches. The curre nt could reach a peak value higher than 120 A in worst condition (full

white screen), thus low R

Maximum voltage stress for discharge circuit is Vs = 200 V

● Discharge MOSFET STW52NK25Z

The STW52NK25Z Power MOSFET in property superMESH

low R

and low gate charge is perfectly tailored on the application [10.].

DSON

[V] Trr [ns] Tj[C] VF[V] Package

RRM

. The STW75N20 Power

TM

technology, thanks to its low R

[Ω] ID/I

DSON

and fast turn-ON are required.

DSON

[A] P [W] Package

DMAX

DSON

DSON

TM

technology, and due to its

2

PAK

2

PAK, TO220

and low gate

2

PAK

Table 6. Sustain MOSFET features

P/N V

STW52NK25Z 250 0.033 52/208 300 TO-247 STW52NK25Z

STW54NK30Z 300 0.060 54/200 300 TO-247 STW54NK30Z

DSS

[V] R

DSON

[Ω] ID/I

4.1.4 Path section

For Path circuit, MOSFET is the preferred device since this circuit is required to conduct

current in both directions. The switching frequency is low, and the RMS current through this

20/30

[A] P [W] Package P/N

DMAX

Page 21

AN2503 PDP Power Devices characteristics

circuit is very large since it has to conduct both ER and discharge currents. Both

STripFET

TM

and superMESHTM Power MOSFETs technologies from ST are ideal for this

application since they allow the die to have very high current density and therefore reduce

the number of paralleled devices required to maintain very low voltage drop [9.], [10.], [11.],

[12.].

For path s witch in T6 position, the maximu m v oltage st ress is (Vs + Vset) / 2 ≈

for path switch in T5 position, the maximum voltage stress is (Vset + |Vreset|) / 2 ≈ 275 V.

Table 7. Path MOSFET features

P/N V

ST60NK30ZD1 300 0.045 60/240 450 Die or MAX247

STW52NK25Z 250 0.033 52/208 300 TO-247

ST75N20 200 0.028 75/300 300 TO-247, TO-220, D

ST40N20 200 0.045 40/160 160

DSS

4.1.5 Set - reset section

The set and reset circuit applies asymmetrical AC voltage across the panel in order to

evacuate any remaining surface charge from the cells. This is usually done at the end of

each subfield (or the beginning of the next subfield), and the power devices on this circuit

operate in the linear mode. This mea ns that the voltage drop is very large but the current

through the device is relatively low. Due to the requirement of asymmetrical Set and Reset

voltages, Power switches in the set and reset circuits have to block up to 600 V. Typical

voltage value for Set function is 400 V and for Reset function is -150 V. This means that the

maximum voltage stress for Set circuit T9 is (Vs + Vset) = 600 V while the maximum voltage

stress for reset circuit T10 is Vset + |Vreset| = 550 V.

[V] R

DSON

[Ω] ID/I

[A] P [W] Package

DMAX

TO-247 TO-220 D

300 V, while

TO220FP

2

PAK

2

PAK

ST offers two families of products for this section both appreciable for their ruggedness for

linear applications.

Example device is STGP10NB60S in the IGBT Planar technology [13.]:

Table 8. Set – reset IGBT features

P/N V

STGP10NB60S 600 1.7 10 D

[V] V

CES

[Ω] IC [A] Package

CE(SAT)

2

PAK

Further examples of devices are superMESHTM devices as follows [14.], [15.].

Table 9. Set-reset MOSFET features

P/N V

ST9NK70Z 700 1 7.5/30 115 W TO-220 D

ST14NK60Z 600 0.5 13.5/54 160 W TO-220 D

DSS

[V] R

DSON

[Ω] ID/I

[A] P [W] Package

DMAX

2

PAK TO220FP

2

PAK TO220FP

21/30

Page 22

PDP Power Devices characteristics AN2503

4.2 Driving section

Driving section devices range from gate driver devices to input buffer ones. Gate driver

function is carried out by a gate driver IC and a push pull amplifier.

Driving section can be split in:

● Gate driver section: L6385 or L6388

● Push pull section: STS01DTP06

● Input buffer section 74VHCT541

4.3 Gate driver devices

ST offers the widest series among the High Voltage Half-Bridge Gate Drivers (the L638x

series), manufactured with BCD"OFF-LINE" technology. They are able to work in

applications with with voltages to 600 V. In the L638x series the two selected drivers are the

L6388 [16.] and the L6385 [17.], which can drive two Power MOSFETs or IGBTs, one highside and one low-side, in a Half-Bridge or different topology. L6388 is especially effective in

applications where logic input must be compatible with 3.3 V Logic. Another key feat ure of

the L6388 is that it provides effective anti-shoot-through circuitry which prevents two Power

MOSFETs or IGBTs from being turned ON at the same time. This is achie v ed by introd ucing

a 200 ns time interval, a "dead time" between the moment one of the components is turned

OFF and the other is turned ON. L6385 is able to drive asymmetrical half bridge, but its

logic input is not compatible with 3.3V Logic.

The main features of these HV Gate Drivers are:

● dV/dt immunity +- 50 V/nsec in full temperature range

● Driver current capability:

– 400 mA source

– 650 mA sink

● Switching time 50/30 nsec rise/fall with 1 nF load

● Under voltage lock-out on lower and upper driving section

● Internal bootstrap diode

● Outputs in phase with inputs

Due to different char acteristics, the to pologies used in Ene rgy Recovery Circuit and Sustain

Circuit depend on the driver used as shown in Figure 24 and Figure 25.

22/30

Page 23

AN2503 PDP Power Devices characteristics

Vcc

HIN

LIN

GND

1

3

2

4

OUT

HVG

Vboot

8

7

6

5

LVG

VCC

L638x

VCC

TO PLASMA

Vs

Vs

Vs

Vs

Vcc

HIN

LIN

GND

1

3

2

4

OUT

HVG

Vboot

8

7

6

5

LVG

VCC

L638x

VCC

Vs/2

Vs/2

PP

PP

PP

PP

pgy

Vs

Figure 24. Gate driver topology with L6385

Figure 25. Gate driver topology – L6388

Vs

Vs

L638x

GND

8

Vboot

LIN

HVG

HIN

OUT

Vcc

LVG

PP

7

6

5

VCC

Vs/2

TO PLASMA

PP

VCC

1

2

3

4

L638x

GND

8

Vboot

LIN

HVG

HIN

OUT

Vcc

LVG

PP

7

6

5

VCC

VCC

1

2

3

4

PP

Due to current value in bootstrap charge, the internal diode cannot be used, thus external

diode SMBY01-400 [20.] must be used. Further details on L6585 and L6588 application can

be found in [18.] and [19.].

4.3.1 Totem pole

In order to match inherent power devices characteristics, (as high gate charge) with drivers

current capability, totem pole STS01DTP06 [21.] in a push pull configuration is used in the

application. The STS01DTP06 is housed in the SMD dual island SO-8 package and allows

an optimized electronic solutions, b y impro ving circuit efficie ncy, saving space and reducing

component count on the board.

The STS01DTP06 is a hybrid complementary NPN and PNP bipolar transistor

manufactured using the latest low voltage planar technology. Extremely efficient

performance is obtained by combining high pulse cur rent, excellent gain and fast speed,

23/30

Page 24

PDP Power Devices characteristics AN2503

resulting in low losses in high frequency applications. The STS01DTP06 offers a 30 V NPN

and PNP combination supporting a continuous collector current of 3 A and the minimum

gain of the two transistors is 100 at 1 A collector current. The transistor elements are fully

independent so that higher assembly flexibility is guaranteed. Concerning PDPs, this means

that the turn-ON and the tu rn-OFF resistors could be different.

Figure 26. STS01DTP06 Totem pole

The STS01DTP06 main features are summarized in Table 10:

Table 10. STS01DTP06 Features

Part number

[V] Ic[A] P

V

NPN PNP

STS01DTP06 30 3 1.6 100 0.7 2 100

CEO

4.4 Input buffer section

The 74VHCT541 is an advanced high-speed CMOS OCTAL BUS BUFFER (3-STATE)

fabricated with sub-micron silicon gate and double-layer metal wiring C2MOS technology,

available in TSSOP package [22.].

In order to enhance PC board layout, the 74VHCT541 offers a pin-out having inputs and

outputs on opposite sides of the package. The device is characterized by high speed and

low power dissipation. Power down protection is provided on all inputs and 0 to 7 V can be

accepted on inputs with no regard to the supply voltage. This device can be used to

interface 5 V to 3 V. All inputs and outputs are equipped with protection circuits against static

discharge, giving them 2KV ESD immunity and t ransient excess voltage.

[W] hFEmin VCE(sat)@ MAX [V] Ic[A] IB[mA]

tot

24/30

Page 25

AN2503 Bill of material and schematics

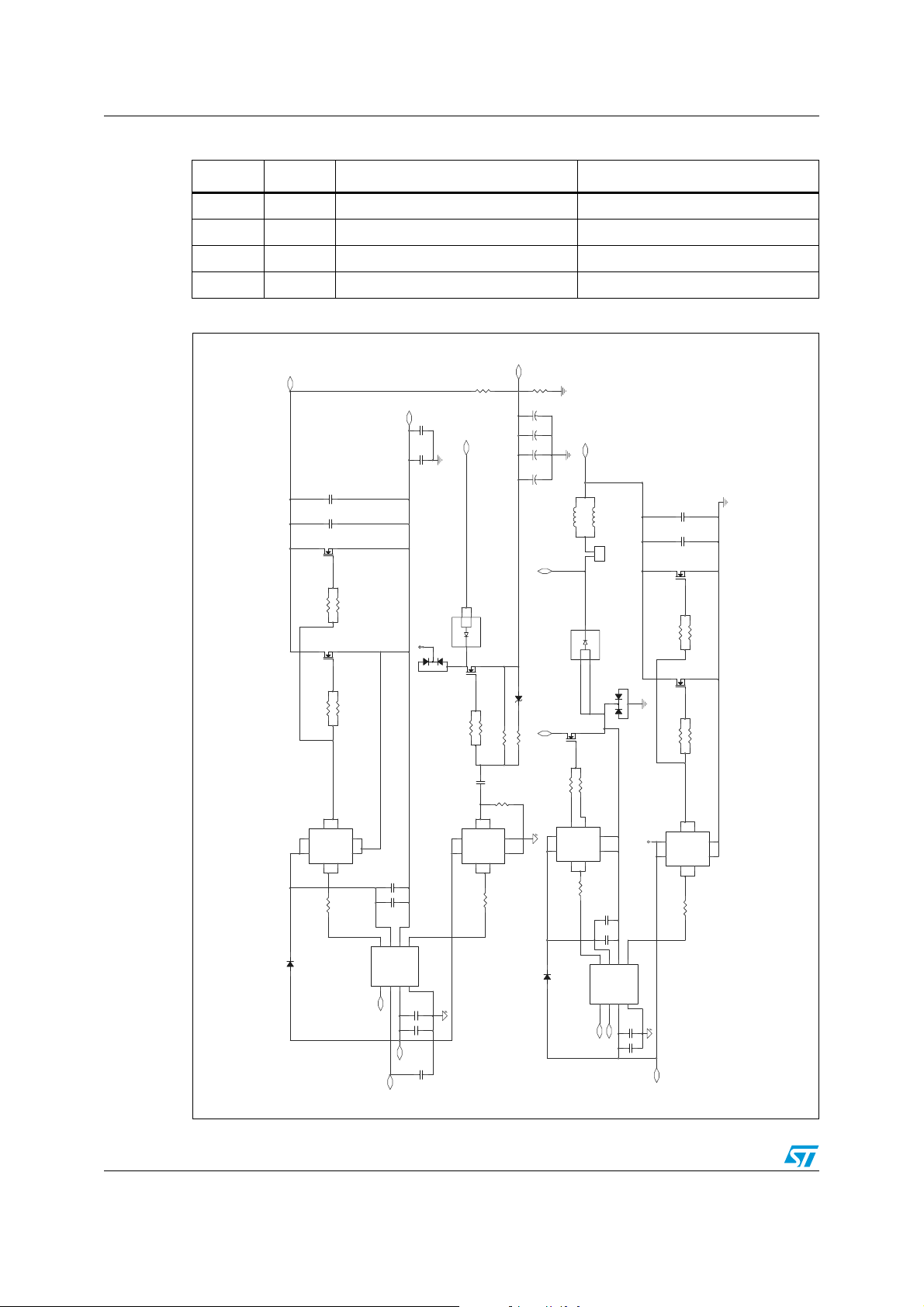

5 Bill of material and schematics

Table 11 gives the BOM and the schematics of the demo board.

Table 11. Bill of material

Item Qty Reference Value & comment

1 5 C1,C4,C23,C26, C44 2.2 µF 50 V

2 5 C2,C3,C24,C25,C45 100 nF 50 V

3 4 C5,C6, C20,C21 2.2 nF 400 V

4 4 C16,C17,C18,C19 3.3 µF 250 V

5 1 C22 104 K 250 V

6 8 C27,C28,C29,C30,C48,C49,C50,C51 100 µF 250 V

7 2 C35,C36 100 µF 25 V

8 7 C37,C38,C39,C40,C41,C42,C43 100 pF 10 V

9 2 C46,C47 X1 Capacitor modeling the panel

10 4 D1,D7 SMBY01-400

11 2 D2,D10 STTH60P03SW

12 3 D3,D8 STTH2003CG

13 3 D14 DIODE Z.16 V

14 1 F1 5A 250 V Fuse

15 2 F2,F3 1A 125 V

16 1 J1 HEADER 9

17 2 J4,J13 Connector 2 PINS

18 1 J7 GND-STAR Connector

19 1 J18 HEADER 30

20 2 L5,L6 500 nH inductor

21 2 L12,L14 10 µH inductor

22 2 R2,R19 2,2 Ω SMD resistor

23 8 R7,R8,R9,R10,R17,R18,R21,R22 3.9 Ω SMD resistor

24 2 R1, R20 36 Ω SMD resistor

25 5 R35,R36,R37,R38,R39 200 Ω SMD resistor

26 4 R50, R51 100 KΩ SMD resistor

27 6 R3, R4, R23, R24, R25 1 Ω SMD resistor

28 6 R26,R40,R41,R42,R43,R44 100 Ω SMD resistor

29 3 R27 10 KΩ SMD resistor

30 2 U1,U5 L 6385

31 4 U2,U3,U6,U7 STS01DTP06

25/30

Page 26

Bill of material and schematics AN2503

V sustainV sustain

VCC

C26

22uF-50V

U16

STW52NK25Z

U6

STS01DTP06

12

34

5

6

7

8

E1B1

E2B2

C2

C2

C1

C1

C25

100nF

C47

X1

C21

2.2nF

C19

3.3uF 250v

C16

3.3uF 250v

R27

10K

D14

DIODE Z.16v

R17

3.9

R51

100K

U7

STS01DTP06

12

34

5

6

7

8

E1B1

E2B2

C2

C2

C1

C1

U5

L 6385

123

4 5

678

LIN

HIN

VCC

GND LGV

VOUT

HGV

Vboot

U15

STW75N20

C23

22uF-50V

C17

3.3uF 250v

C31

33pF

R19

2.2

D10 STTH60P03SW

A1KA2

R20

36

R24

1

C22

104K 250V

C18

3.3uF 250v

R21

3.9

C24

100nF

R26100

U14

STW52NK25Z

D8

STTH2003CG

R50

100K

C20

2.2nF

R251K

R231

R22

3.9

D7

SMBYT01-400

C46

X1

R18 3.9

U11

STW52NK52Z

R7 3.9

R4 1

R3 1.

U13

STW75N20

C4

22uF-50V

D1

SMBYT01-400

R9

3.9

C3

100nF

R2

2.2

R8 3.9

C6

2.2nF 400v

J4

CON2

1

2

D2

STTH60P03SW

123

A1KA2

C2

100nF

C1

22uF-50V

U3

STS01DTP06

12

34

5

6

7

8

E1B1

E2B2

C2

C2

C1

C1

D3

STTH2003CG

U2

STS01DTP06

12

34

5

6

7

8

E1B1

E2B2

C2

C2

C1

C1

L6 500nH

C5

2.2nF 400v

R10

3.9

U12

STW52NK25Z

L5 500nH

U1

L 6385

123

4 5

678

LIN

HIN

VCC

GND LGV

VOUT

HGV

Vboot

R1

36

LIN U4005

V sustain/2

V sustain

HIN U4005

Display

VCC

Res IND

VCC

Display

Res INDV sustain/2

HIN U4004

LIN-U4004

T11

T10T10

T12

T9 T9

Table 11. Bill of material (continued)

Item Qty Reference Value & comment

32 1 U8 74VHCT541

33 4 U11,U12,U14, U16 STW52NK25Z

34 2 U13,U15 STW75N20

35 3 J15, J16, J17 Connector 17 pins

Figure 27. Board schematic 1

26/30

Page 27

AN2503 Bill of material and schematics

Figure 28. Board schematic 2

J15

123456789

F3

FUSErid

C42

100pF

C36

100uF 25v

VCCVDD

10111213141516

V sust ain

CONN SOCKET 17

J16

123456789

17

C51

C50

C49

C48

10111213141516

Display

Xs

LIN U4005

R44

100

R39

200

Xr

CONN SOCKET 17

J17

17

Xg

LIN-U4004

R40

100

R37

VDD

123456789

Xr

HIN U 4004

R41

100

200

Xf

R36

C44

22uF25v

C45

100nF

U8

1

2

J13

ENABLE

Xs

R42

200

19

20

18

19

20

18

123456789

123456789

XrXbXf

Xs

Xg

10111213141516

Xb

HIN U 4008

100

R35

200

11121413151617

10

Xg

CONN SOCKET 17

17

Xf

HIN U 4005

R43

100

R38

200

11121413151617

st74v hct 541

10

Xb

C43

100pF

C37

100pF

C38

100pF

C39

100pF

C40

100pF

C41

C35

100uF 25v

L12

10uH

F2

FUSErid

Vb

123456789

J1

C28 C29 C30

C27

R30

1K

R31

1K

R32

1K

R33

1K

100uF250V

L14

INDUCTOR

F1

FUSErid

1234567891011121314151617181920212223242526272829

HEADER 9

1

2

J7

GND-STAR

J18

100pF

R34

1K

30

HEADER 3 0

27/30

Page 28

Conclusions AN2503

6 Conclusions

ST offers its customers a complete product portfolio covering the whole PDP. ST's system

approach helps customers design effective energy recover (ERC) and Sustain circuits,

improving their time-to-market. PDP power consumption is greatly reduced using ST's

dedicated products.

7 References

1. "Plasma displays," IEEE Trans. Plasma Sci., vol. 19, pp. 1032-1047, Dec. 1991.

2. "Cell structure and driving method of a 25-in (64 cm) diagonal high-resolution color ac

plasma display," in Proc. Symp. Society for Information Display, vol. 29, 1998, pp. 279-

282.

3. "Charge spreading and its effect on AC plasma panel operating margins," IEEE Trans.

Electron Devices , vol. ED-24, pp. 870-872, July 1997.

4. "Measurement of wall charges in a surface discharge AC-PDP," in Proc. Int. Display

Workshops, 1997 , pp. 527-530.

5. " Power efficient sustain drivers and address drivers for plasma panel," U.S. Patent 4

866 349, Sept. 1989 and U.S. Patent 5 081 400, Jan. 1992.

6. STTH60P03SW Datasheet

7. STTH40P03SW Datasheet

8. STTH2003CG Datasheet

9. STW75N20 Datasheet

10. STW52NK25Z Datasheet

11. STP40N20 Datasheet

12. ST60NK30ZD1 Datasheet

13. STGP10NB60S Datasheet

14. STP9NK70Z Datasheet

15. STB14NK60Z Datasheet

16. L 6388 Datasheet

17. L 6385 Datasheet

18. AN994 - L6384, L6385, L6386, L6387 Application guide

19. AN1299 - L6384, L6385, L6386, L6387: TIPS & TRICKS

20. SMBY01-400 Datasheet

21. STS01DTP06 Datasheet

22. 74VHCT541 Datasheet

28/30

Page 29

AN2503 Revision history

8 Revision history

Table 12. Revision history

Date Revision Changes

02-May-2007 1 First issue

29/30

Page 30

AN2503

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sal e.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all info rmation previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

30/30

Loading...

Loading...