Page 1

AN2500

Application note

ST10 electric motor control library:

SPI drivers for MP49 power board

Introduction

STMicroelectronics provides a library of motor control functions that can be used as base

blocks for motor control applications.

This application note describes the set of API to simplify the usage of the MP49 motor

control power board. It provides ST10 compatible SPI drivers to configure the board and for

diagnostic purposes.

March 2007 Rev 1 1/18

www.st.com

Page 2

Contents AN2500

Contents

1 Functions set overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 MP49 to CPU board communication overview . . . . . . . . . . . . . . . . . . . . 6

2.1 SPI interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 SPI diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 Fault detection interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 API specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Function definition for motor power board configuration . . . . . . . . . . . . . . 9

3.1.1 SetCom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Function definitions for the motor power board diagnosis . . . . . . . . . . . . 10

3.2.1 ShortMotorDriver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 LowVoltPreDriver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.3 SPINGFailDetect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Type definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.1 DIAG1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.2 DIAG2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.3 DIAG3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2/18

Page 3

AN2500 List of tables

List of tables

Table 1. SPI master signal description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. SPI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. DIAG1 structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4. DIAG2 structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. DIAG3 structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3/18

Page 4

List of figures AN2500

List of figures

Figure 1. ST10 EMC library structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. SPI registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Fault signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4/18

Page 5

AN2500 Functions set overview

1 Functions set overview

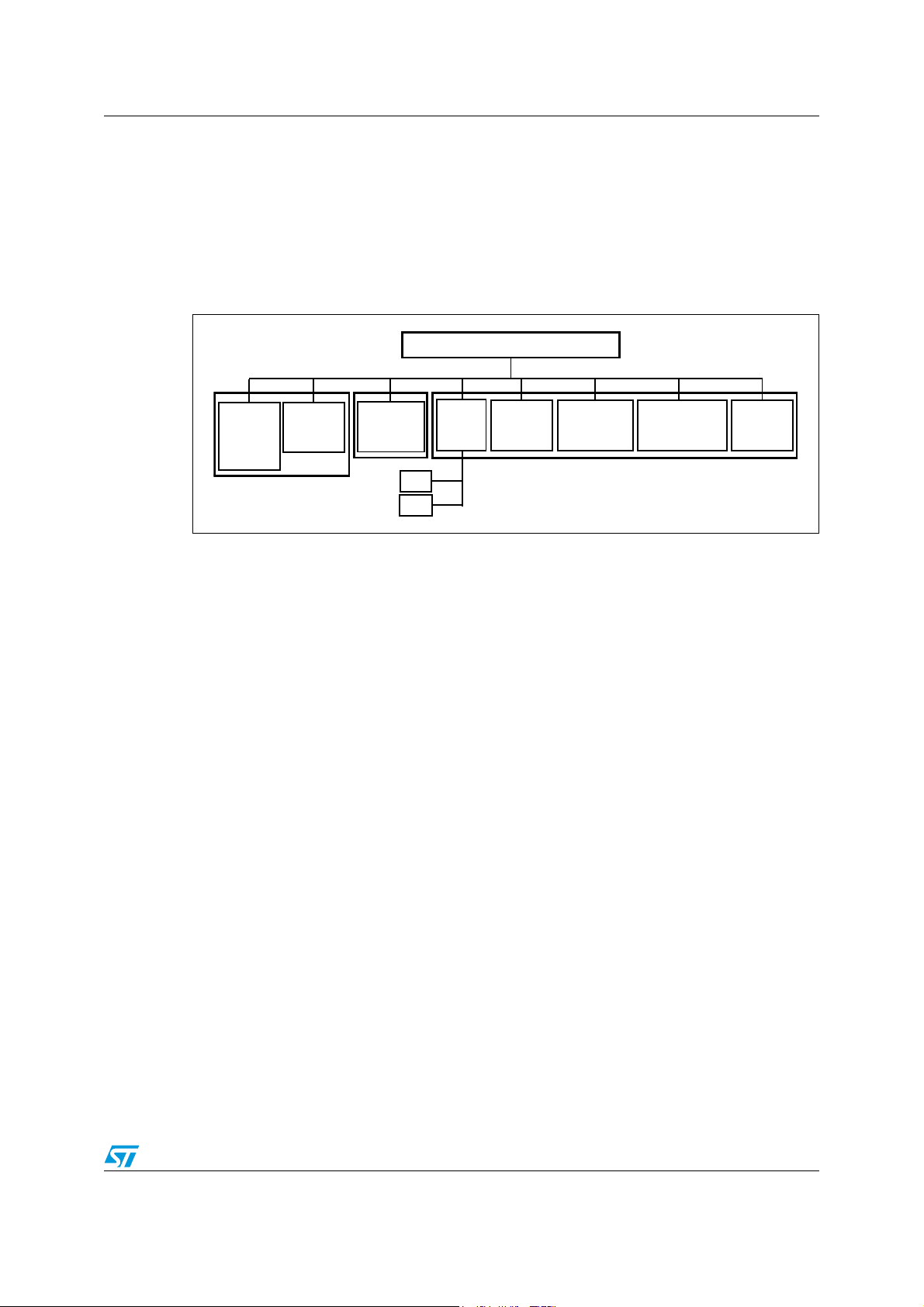

The SPI_FS is a set of functions included in ST10 electric motor control library (see

Figure 1). It uses the ST10 peripheral SSC configured like SPI interface to allow the full

duplex communication with MP49 (slave) and to set a specific MP49 parameters

configuration or diagnosis requests, see Tabl e 2.

Figure 1. ST10 EMC library structure

ST10 EMCL

Flux

Oriented

Control

Sinusoidal

Control

Observer

Leunberger

spi.c

spi.h

SPI

Driver

Encoder

Driver

Hall sensors

Driver

Current sensing

Driver

PWM

Driver

The communication between the CPU board and the motor power board is based on SPI

interface with a chip select (4 signals in total).

The exchanged data set some parameters and the command to read the status of the motor

power board. The configuration command allows to choose the shape of fault pin output

signal. Another subset of commands allows to send diagnosis requests to read the status of

the inverter driver and of the powerMOS.

5/18

Page 6

MP49 to CPU board communication overview AN2500

2 MP49 to CPU board communication overview

The MP49 motor power board communicates with the CPU board using an SPI interface

and using a fault signal to report to the CPU faults as soon as they are detected.

The MP49 requires only to be configured after reset and the CPU does not need any action

after initialization as long as the fault pin is not active.

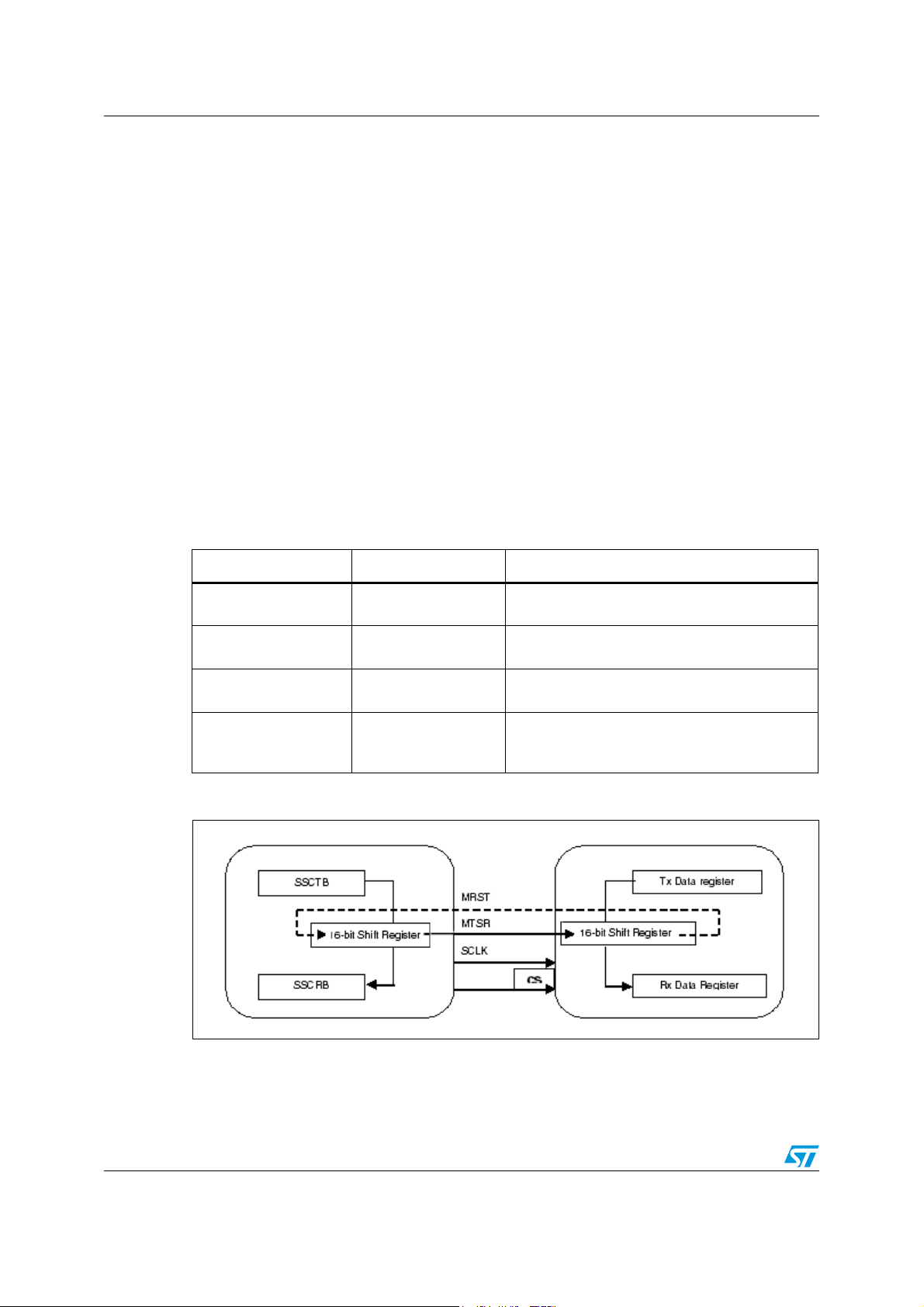

2.1 SPI interface

The SPI interface provides a full-duplex, synchronous serial communication between

microcontrollers and peripherals. It is based upon a Master-Slave protocol where the master

is the device that drives the serial clock signal (SCLK), used to synchronize the

communication.

The SPI bus consists of four wires, Serial Clock signal (SCLK), Master Transmit / Slave

Receive (MTSR), Master Receive / Slave Transmit (MRST), and Chip Select (CS), which

carry information between the devices connected to the bus (see Figure 2).

Table 1. SPI master signal description

Name Direction Description

MTSR Output

MRST Input

SCLK Output

CS Output

Figure 2. SPI registers

SPI Serial Data Output. Serial data output from

the SPI Master to a SPI slave.

SPI Serial Data Input. Serial data input from a

SPI slave to the SPI Master.

SPI Serial Clock. Normally high, and the correct

clock pulse number is sixteen.

SPI Slave Selects. Normally high, this input

signal starts the communication when it is forced

low (for selecting the MP49 board use pin P2.7).

The SCLK control line is driven by the SPI Master and regulates the flow of data bits, so that

data is shifted on falling edge of SCLK and is sampled on the opposite edge when the data

is stable.

6/18

Page 7

AN2500 MP49 to CPU board communication overview

This input signal to the MP49 is normally high and the correct clock pulse number is sixteen

with a maximum clock frequency of 4MHz. The master may transmit data at a variety of

baud rates.

Note: SPI messages shall be separated by a wait time of 5us minimum. This shall be guaranteed

by CPU software.

2.2 SPI diagnostic

The MP49 circuitry includes SPI diagnostic circuitry. The CPU must follow the commands

defined in the library. In case of improper command, a fault reporting a SPI diagnostic will be

generated.

2.2.1 Fault detection interface

The fault pin from the MP49 board is activated (low level) as soon as at least 1 fault

condition occurs.

The CPU then can use status read commands to read the status registers to diagnose the

system.

The fault pin is released after the CPU has read the register showing the fault and when

there is no more fault condition (continuous hardware detection).

The detected faults are Motor Pre-Driver diagnosis, Thermal Detection, PowerMOS short

circuit, Current Regulator diagnosis, LCHG pin diagnosis and SPI communication diagnosis.

When there is no fault, the signal on the fault pin can be configured to be a static high signal

or to be a 4ms period signal (pulses).

By default, the fault pin is set to be a 4ms pulse signal (see Figure 3).

Figure 3. Fault signal

Fault condition

Fault s ign al

Fault ou tp ut (normal mode)

Fault output (pulse m ode)

4m s

7/18

Page 8

API specification AN2500

3 API specification

The following APIs allow easy access to set a specific configuration or read the status of the

motor power board.

The use of these functions eliminates the need to access directly ST10 registers.

Available functions:

● SetCom()

● ShortMotorDriver()

● LowVoltPreDriver()

● SPINGFailDetect()

described in the following.

The communication between the ST10 microcontroller and the MP49 power board through

the SPI interface uses a set of four commands, listed in Tabl e 2 , to set a specific MP49

parameters configuration or a diagnosis request.

Table 2. SPI commands

Item Definition

COMMAND configuration of a parameters set

DIAG_READ1 Motor Driver Short Diagnosis

DIAG_READ2 Pre Driver VGS Low Voltage

DIAG_READ3 SPI Diagnosis

The command to set the MP49 board configuration sends back the echo of the

configuration. Note that when the diagnosis requests are read from the microcontroller, each

flag of the Tx data register from MP49 board is cleared.

In the following the functions that allow to set a specific configuration, read the echo from

MP49 power board, and send a specific diagnosis request are listed

(see file spi.c in the sw library).

8/18

Page 9

AN2500 API specification

3.1 Function definition for motor power board configuration

In the following the function for setting a specific MP49 parameters configuration is specified

(see file spi.c in the sw library).

3.1.1 SetCom

Prototype definition:

UINT16 SetCom( UINT16 command )

Parameters:

Parameter Description

command

Command to set the

Define command value using OR-ing of constants defined in spi.h

MP49 power board.

Return value:

Return value Description / meaning

OK no errors

FAIL_REGWRITE_

FAIL_

MP49 read data is different from sent one

MP49 wrong keyword

Description:

Set the command to MP49 and check the echo from MP49.

Example:

SetCom(COMMAND | PSA_ON | FAULT_OUT_NORMAL)

See predefined constants in spi.h.

9/18

Page 10

API specification AN2500

3.2 Function definitions for the motor power board diagnosis

In the following the functions for the diagnosis are specified, (see file spi.c).

3.2.1 ShortMotorDriver

Prototype definition:

UINT16 ShortMotorDriver( struct DIAG1*p_ diag_1 )

Parameters:

Parameter Description

p_diag_1 pointer to diagnosis structure

Return value:

Return value Description/meaning

OK no short

FAIL _

MP49_DIAG found short

MP49 wrong keyword

FAIL_

Description:

Set the command to MP49 power board and read the status of short diagnosis of the motor

driver.

3.2.2 LowVoltPreDriver

Prototype definition:

UINT16 LowVoltPreDriver( struct DIAG2* p_diag_2 )

Parameters:

Parameter Description

p_diag_2 pointer to diagnosis structure

Return value:

Return value Description/meaning

OK normal

FAIL _

MP49_DIAG found fail

MP49 wrong keyword

FAIL_

Description:

Set the command to MP49 power board and read the status of low voltage diagnosis of the pre-

driver.

10/18

Page 11

AN2500 API specification

3.2.3 SPINGFailDetect

Prototype definition:

UINT16 SPINGFailDetect( struct DIAG3* p_diag_3 )

Parameters:

Parameter Description

p_diag_3 pointer to the diagnosis structure

Return value:

Return value Description/meaning

OK normal

FAIL _MP49_DIAG_SPING found fail

MP49 wrong keyword

FAIL_

Description:

Set the command to MP49 power board and read the status of diagnosis of SPI.

11/18

Page 12

API specification AN2500

3.3 Type definitions

There are three different structures, here defined, to store the status of diagnosis for each

request command, used in functions of diagnosis (e.g. DIAG1 for short diagnosis of the

MOTOR DRIVER).

3.3.1 DIAG1

Table 3. DIAG1 structure

Type: struct

Each field of the structure stores short diagnosis on motor driver:

Description:

3.3.2 DIAG2

Table 4. DIAG2 structure

Type: struct

WL,WH,VL,VH,UL,UH.

See the file spi.h

Description:

3.3.3 DIAG3

Table 5. DIAG3 structure

Type: struct

Description:

Each field of the structure stores low voltage diagnosis on pre driver VGS:

W LV, W HV, V LV, V H V, UL V,U H V.

See the file spi.h.

The structure stores the Fail:

SPING

See the file spi.h.

12/18

Page 13

AN2500

Appendix A

The following table is showing the commands available to configure the MP49 power board.

Configuration command

1514131211109876543 2 10

000001XX00001FAULT00

Name Bits Value Description

Command field 15 to 10

dummy bits 9, 8 x

reserved bit field1 7,6,5,4 0000

reserved bit field2 3 1

must be

“000001”

Command key word

Dummy bits

The value of those bits is ignored.

Reserved

The software must always write those bits as 0

Reserved

The software must always write those bits as 1

FAULT pin signal selection

FAULT 2 0

1

reserved bit field3 1,0 00

pulse mode (default value after reset)

level mode (no-fault = high-level; fault = low-level)

Reserved

The software must always write those bits as 0

Motor driver short diagnosis read command

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

001000

Name Bits Value Description

XXx

xxxxx xx

Read DIAG_READ1 key word

Command field 15 to 10

must be

“001000”

On the next command, the MP49 board will

send the Motor driver short register on the

SPI.

dummy bits 9 to 0 x

Dummy bits

The value of those bits is ignored.

Predriver’s low voltage diagnosis read command

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

010000XXxxxxx x xx

13/18

Page 14

Name Bits Value Description

Read DIAG_READ2 key word

Command field 15 to 10

must be

“010000”

On the next command, the MP49 board will

send the Predriver’s low voltage register on the

SPI.

AN2500

dummy bits 9 to 0 x

Dummy bits

The value of those bits is ignored.

SPI communication diagnosis read command

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

011000XXxxxxx x xx

Name Bits Value Description

Read DIAG_READ3 key word

Command field 15 to 10

must be

“011000”

On the next command, the MP49 board will

send the SPI communication register on the

SPI.

dummy bits 9 to 0 x

Dummy bits

The value of those bits is ignored.

The following table is showing the meaning of the status registers of the MP49 power board.

Motor driver short diagnostic

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

x001000xUHULVHVLWHWL00

Name Bits Value Description

Command echo field 14 to 9 001000

UH 7

UL 6

VH 5

14/18

Read DIAG_READ1 command key word

this bit field is echoing the command field of

the read DIAG_READ1 command

PowerMOS UH short diagnostic

0 = normal

1 = short

PowerMOS UL short diagnostic

0 = normal

1 = short

PowerMOS VH short diagnostic

0 = normal

1 = short

Page 15

AN2500

Name Bits Value Description

PowerMOS VL short diagnostic

VL 4

0 = normal

1 = short

PowerMOS WH short diagnostic

WH 3

0 = normal

1 = short

PowerMOS WL short diagnostic

WL 2

0 = normal

1 = short

dummy bits 1,0

Reserved

Those bits are always 0.

PREdriver low voltage diagnostic

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

x011000xUHVULVVHVVLVWHVWLV00

Name Bits Value Description

Command echo field 14 to 9 010000

UHV 7

ULV 6

VHV 5

VLV 4

WHV 3

WLV 2

dummy bits 1,0

Read DIAG_READ2 command key word

this bit field is echoing the command field of

the read DIAG_READ2 command

UHV predriver short diagnostic

0 = normal

1 = under voltage

ULV short diagnostic

0 = normal

1 = under voltage

VHV short diagnostic

0 = normal

1 = under voltage

VLV short diagnostic

0 = normal

1 = under voltage

WHV short diagnostic

0 = normal

1 = under voltage

WLV short diagnostic

0 = normal

1 = under voltage

Reserved

Those bits are always 0.

15/18

Page 16

AN2500

SPI communication diagnostic

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

x011000xxxSPINGxx x x0

Name Bits Value Description

Read DIAG_READ3 command key word

Command echo field 14 to 9 011000

dummy bits 8,7,6

SPING 5

this bit field is echoing the command field of

the read status3 command

Reserved

Those bits should be ignored (either 0 or 1).

SPI diagnostic

0 = normal

1 = SPI error (non valid command in

command bit field or less than 16 clock

periods in an SPI frame.

dummy bits 4,3,2,1

dummy bits 0

Reserved

Those bits should be ignored (either 0 or 1).

Reserved

This bit is always 0.

16/18

Page 17

AN2500 Revision history

4 Revision history

Table 6. Document revision history

Date Revision Changes

09-Mar-2007 1 Initial release.

17/18

Page 18

AN2500

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

18/18

Loading...

Loading...