Page 1

AN2485

Application note

400 W FOT-controlled PFC pre-regulator with the L6563

Introduction

This application note describes an evaluation board based on the Transition-mode PFC

controller L6563 and presents the resu lts of th e be nc h evaluation. The board implemen ts a

400 W, wide-range mains input, a PFC pre-conditioner suitable for ATX PSU, or a flat

screen display. The chip is operated with Fixed-Off-Time control in order to use a low-cost

device like the L6563 which is usually prohibitive at this power level. Fixed-Off-Time control

allows Continuous Conduction Mod e operation which is normally achieved with more

expensive control chips and more complex control architectures.

L6563 400W FOT PFC Demo board (EVAL6563-400W)

March 2007 Rev 1 1/29

www.st.com

Page 2

Contents AN2485

Contents

1 Main characteristics and circuit description . . . . . . . . . . . . . . . . . . . . . 4

2 Test results and significant waveforms . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Harmonic content measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Inductor current in FOT and L6563 THD optimizer . . . . . . . . . . . . . . . . . 10

2.3 Voltage feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Start-up and RUN pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Start-up at light load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Open loop protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.7 Power management/housekeeping functions . . . . . . . . . . . . . . . . . . . . . . 17

3 Layout hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Audible noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Thermal measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Conducted emission pre-compliance test . . . . . . . . . . . . . . . . . . . . . . 22

7 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 PFC coil specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1 General description and characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.3 Mechanical aspect and pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2/29

Page 3

AN2485 List of figures

List of figures

Figure 1. EVAL6563-400W evaluation board: electrical schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. EVAL6563-400W compliance to EN61000-3-2 at 230 Vac-full load . . . . . . . . . . . . . . . . . . 7

Figure 3. EVAL6563-400W compliance to JEIDA-MITI at 100 Vac-full load . . . . . . . . . . . . . . . . . . . . 7

Figure 4. EVAL6563-400W compliance to EN61000-3-2 at 230 Vac-70 W load . . . . . . . . . . . . . . . . 7

Figure 5. EVAL6563-400W compliance to JEIDA-MITI at 100 Vac-70 W load . . . . . . . . . . . . . . . . . . 7

Figure 6. EVAL6563-400W Input current waveform at 100 V - 60 Hz - 400 W load . . . . . . . . . . . . . . 8

Figure 7. EVAL6563-400W Input current waveform at 230 V - 50 Hz - 400 W load . . . . . . . . . . . . . . 8

Figure 8. EVAL6563-400W Input current waveform at 100 V - 60 Hz - 200 W load . . . . . . . . . . . . . . 8

Figure 9. EVAL6563-400W Input current waveform at 230 V - 50 Hz - 200 W load . . . . . . . . . . . . . . 8

Figure 10. EVAL6563-400W Input current waveform at 100 V - 60 Hz - 70 W load . . . . . . . . . . . . . . . 8

Figure 11. EVAL6563-400W Input current waveform at 230 V - 50 Hz - 70 W load . . . . . . . . . . . . . . . 8

Figure 12. Power Factor vs. Vin and load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 13. THD vs. Vin and load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 14. Efficiency vs. Vin and load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 15. Static Vout regulation vs. Vin and load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 16. EVAL6563-400W Inductor current ripple envelope at 115 Vac - 60 Hz - full load . . . . . . . 10

Figure 17. EVAL6563-400W Inductor current ripple (detail) at 115 Vac - 60 Hz - full load . . . . . . . . . 10

Figure 18. EVAL6563-400W Inductor current ripple envelope at 230 Vac - 50 Hz - full load . . . . . . . 11

Figure 19. EVAL6563-400W Inductor current ripple (detail) at 230 Vac - 50 Hz - full load . . . . . . . . . 11

Figure 20. EVAL6563-400W Input mains surge from 90 Vac to 140 Vac - full load - C

Figure 21. L6562 FOT Input mains surge from 90 Vac to 140 Vac - full load - NO V

Figure 22. EVAL6563-400W Input mains dip from 140 Vac to 90 Vac - full load - C

Figure 23. L6562 FOT Input mains dip from 90 Vac to 140 Vac - full load - NO V

Figure 24. EVAL6563-400W Input current shape at 100 Vac-60 Hz vs. V

Figure 25. EVAL6563-400W Input current shape at 100 Vac-60 Hz vs. V

FF

FF

FF

ripple - CFF = 470 nF . . 14

ripple - CFF = 1.5 uF . . . 14

Figure 26. EVAL6563-400W start-up at 90 Vac-60 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 27. EVAL6563-400W start-up at 265 Vac-50 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 28. EVAL6563-400W start-up at 80 Vac-60 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 29. EVAL6563-400W Start-up at 265 V -50 Hz - 30 mA load. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 30. EVAL6563-400W start-up at 265 V -50 Hz - no load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 31. EVAL6563-400W open loop at 115 Vac-60 Hz - full load. . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 32. L6563 On/Off control by a cascaded converter controller via PFC_OK or RUN pin . . . . . 17

Figure 33. Interface circuits that let the L6563/A switch on or off a PWM controller . . . . . . . . . . . . . . 18

Figure 34. EVAL6563-400W PCB layout (not 1:1 scaled) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 35. Thermal map at 115 Vac-60 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 36. Thermal map at 230 Vac-50 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 37. 115 Vac and full load - phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 38. 115 Vac and full load - neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 39. 230 Vac and full load - phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 40. 230 Vac and full load - neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 41. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 42. Pin side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 43. Mechanic aspect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

= 470 nF . . 12

FF

input . . . . . . . 12

FF

= 470 nF . . . . 13

FF

input . . . . . . . . . 13

3/29

Page 4

Main characteristics and circuit description AN2485

1 Main characteristics and circuit description

The main characteristics of the SMPS are:

● Line voltage range: 90 to 265 Vac

● Minimum line frequency (f

● Regulated output voltage: 400 V

● Rated output power: 400 W

● Maximum 2f

● Hold-up time: 22 ms (V

● Maximum switching frequ ency: 85 kHz (@Vin=90 Vac, Pout=400 W)

● Minimum estimated efficiency: 90% (@Vin=90 Vac, Pout=400 W)

● Maximum ambient temperatur e: 50 °C

● EMI: in acc. with EN55022 Class-B

● PCB type and size: Single side, 70 um, CEM-1 , 148.5 x 132 mm

● Low profile design: 35 mm component maximum heigh t

output voltage ripple: 10 V pk-pk

L

The evaluation board implements a Power Factor Correc t ion (P F C) pr e- re gu la to r de livering

400 W continuous power on a regulated 400 V rail from a wide range mains voltage. The

board provides f or the reduction of the mains h armonics which allows meeting the standards

of the European norm EN61000-3-2 or the Japanese norm JEID A-MITI. This rail is the input

for the cascaded isol ated DC-DC converter that provides the output rails required by the

load.

): 47 Hz

L

after hold-up time: 300 V)

DROP

The board is equipped with enough heat sinking to allow full-load operation in still air. With

an appropriate airflow, and without any change in the circuit, the ev aluation board can easily

deliver up to 450 W.

The controller is the L6563 (U1), integrating all the functions needed to control the PFC

stage and to interface with the downstream con v erter . The L6563 controller chi p is designed

for Transition-Mode (TM) operation, where the boost inductor works next to the boundary

between Continuous (CCM) and Discontinuous Conduction Mode (DCM). However, with a

slightly different usage, the chip can operate so that the boost inductor works in CCM,

surpassing the limitations of TM operation in terms of power handling capability. The gatedrive capability of the L6563 is also adequate to drive the MOSFETs used at higher power

levels. This approach, which couples the simplicity and cost-effectiveness of TM operation

with the high-current capability of CCM operation, is the Fixed-Off-Time (FOT) control. The

control modulates the ON-time of the power switch, while its OFF-time is kept constant.

More precisely, the Line-Modulated FOT (LM-FOT), where the OFF-time of the power

switch is not rigorously constant but is modulated by the instantaneous mains voltage , will

be used. Please refer t o AN1792 (“De sign of Fixed-Off-Time-Controlled PFC Pre-regulators

with the L6562”) for a detailed description of this technique as indicated in Section 9:

References (point 2).

The power stage of the PFC is a conventional boost converter, connected to th e output of

the rectifier bridge D2. It includes the coil L4, the diode D3 and the capacitors C6 and C7.

The boost switch is represented by the power mosfets Q1 and Q2. The NTC R2 limits the

inrush current at switch on. It has been connect ed on the DC rail, in series to the output

electrolytic capacitor, in order to improve efficiency during low line operation. Additionally,

the splitting in two of output capacitors (C6 and C7) provides for managing the AC current

4/29

Page 5

AN2485 Main characteristics and circuit description

mainly by the film capacitor C7 which allows fo r a less costly ele ctrolytic to bear on ly the DC

part.

At start-up the L6563 is powered b y the Vcc capacitor (C12) that is charged via the resistors

R3 and R4. The L4 secondary winding (pins #8-11) and the charge pump circuit (R5, C10,

D5 and D4) generate the Vcc voltage powering the L6563 during normal operations.

The divider R32, R33 and R34 provides the L6563 multiplier with the information of the

instantaneous voltage t hat is used to modula te the boost current. T he instantaneous v oltage

information is also used to get the average value of the AC line by the V

(Voltage Feed-

FF

Forward) pin . Divider R9, R10, R11, R12, and R13 is dedicated to sense output voltage

while divider R6, R7, R8, and R24 is dedicated to protect t he circuit in case of voltage loop

failures. The Line-Modu lated FOT is obtained by the timing generator components D6, C1 5,

R15, C16, R16, R31, and Q3.

The board is equipped with an input EMI filter designed for a 2-wire input mains plug. It is

composed of two stages, a Common Mode Pi-filter connected at the input (C1, L1, C2, C3)

and a Differential Mode Pi-filter afte r the input bridge (C4, L3, C5). The boar d also off ers the

possibility to easily connect a downstream converter and test the interface signals managed

by the L6563.

5/29

Page 6

Main characteristics and circuit description AN2485

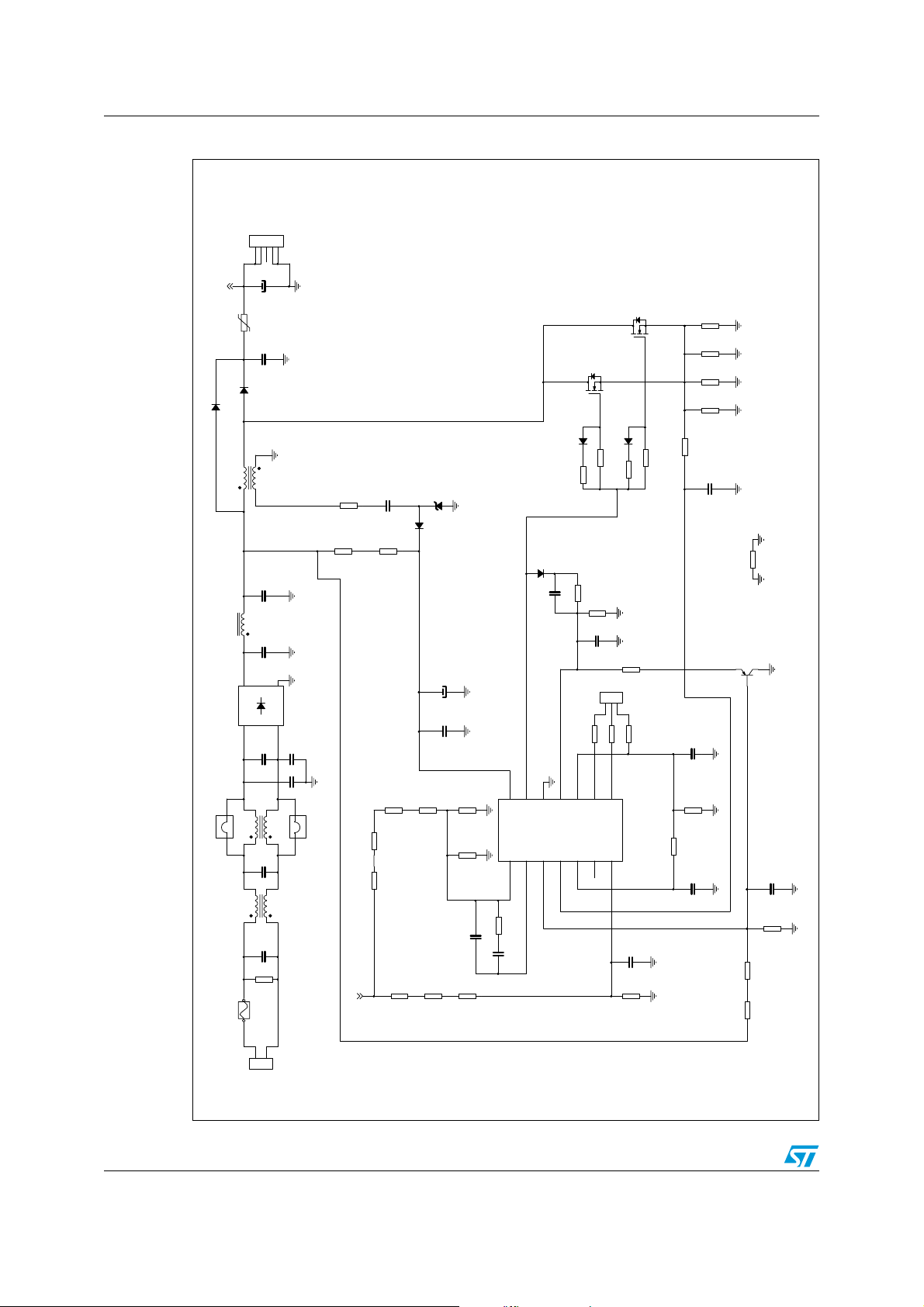

Figure 1. EVAL6563-400W evaluation board: electrical schematic

NC

RTN

RTN

+400Vdc

+400Vdc

J2

12345

+400Vdc

R2

NTC 2R5-S237

D3

STTH8R06

D1

1N5406

L4

PQ40-500uH

5-6 1-2

L3

DM-51uH-6A

+

D2

D15XB60

~

L2

RES

JP101

JUMPER

1 2

L1

CM-1.5mH-5A

F1

8A/250V

+400Vout

C7

330uF-450V

C6

470nF-630V

811

C5

470nF-630V

C4

470nF-630V

-

~

C3

680nF-X2

C9

RES

C8

RES

1 2

C2

470nF-X2

C1

470nF-X2

R1

1M5

Q2

STP12NM50FP

Q1

STP12NM50FP

D8

D7

LL4148

R36

3R9

C10

18N

D5

R5

47R

R3

180K

R4

180K

R102

JP102

JUMPER

R10

680k

R9

680k

+400Vdc

BZX85-C15

D4

LL4148

D6

LL4148

C15

100pF

C12

47uF/50V

C11

470nF/50V

10

12

0R0

R11

680k

R6

2M2

R7

2M2

14

R13

15k

VCC

U1

L6563

R12

82K

INV1COMP2MULT3CS4VFF5TBO6PFC-OK

R14

56k

C13

100nF

C14

1uF

R8

2M2

11

13

GD

ZCD

RUN

GND

LL4148

R17

6R8

R15

3K3

R16

R28

RES

9

PWM-STOP

15K

C16

220pF

123J3RES

R29

RES

8

7

R18

6R8

R35

3R9

R31

1k5

R30

RES

PWM-LATCH

R26

C17

10nF

R24

36K

R23

0R39-1W

R22

0R39-1W

R21

0R39-1W

R20

0R39-1W

R19

1K0

C20

330pF

R101

0R0

Q3

BC857C

C19

2nF2

R27

240k

150k

C21

C18

470nF

10nF

R34

10k

R33

620k

R32

620k

1

2

J1

90 - 265Vac

6/29

Page 7

AN2485 Test results and significant waveforms

2 Test results and significant waveforms

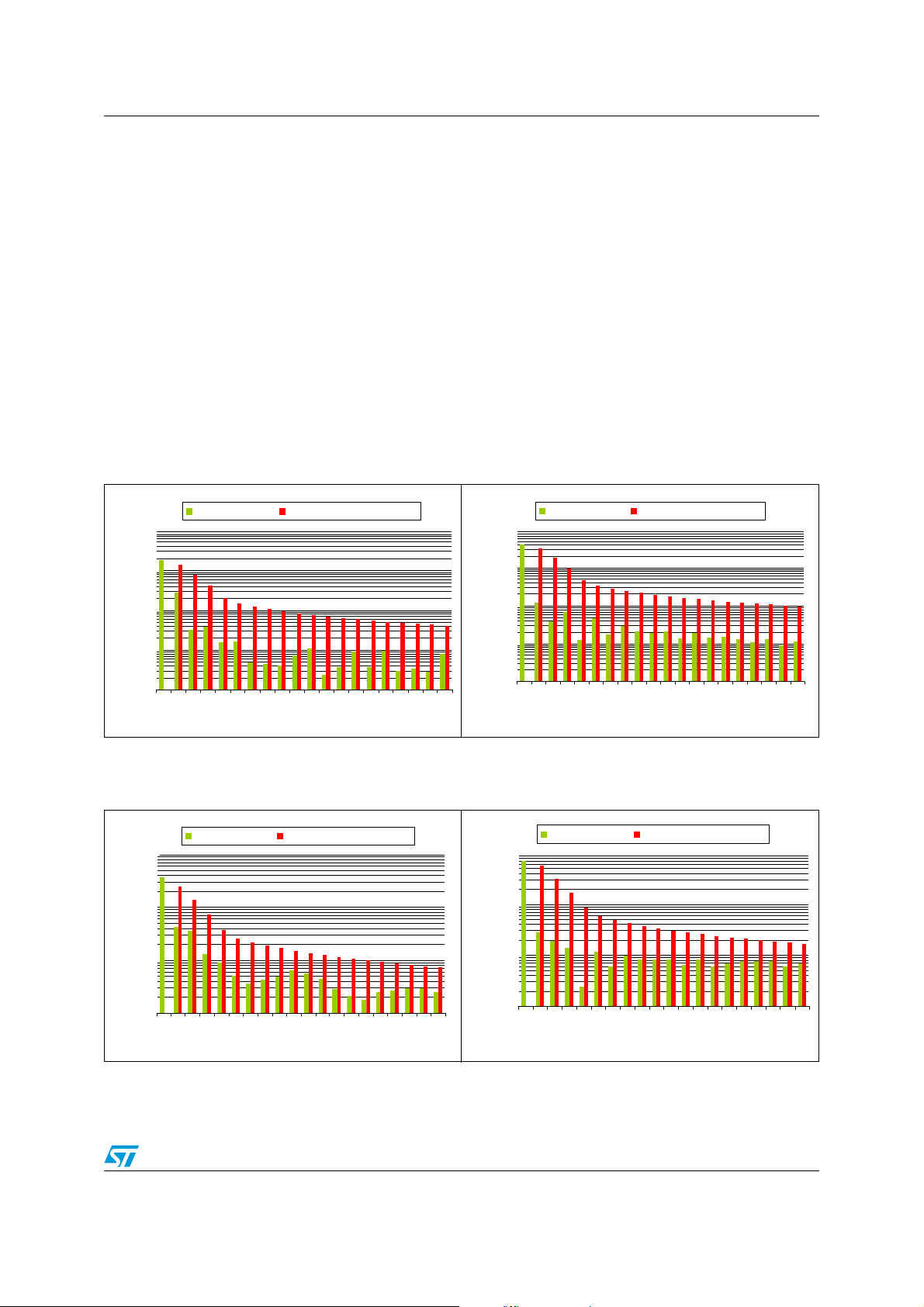

2.1 Harmonic content measurement

One of the main purposes of a PFC pre-conditioner is the correction of input current

distortion, decreasing the harmonic contents below the limits of European and Janapese

regulations. The board has been teste d according to Europ ean norm EN61000-3-2 Class-D

and Japanese norm JEIDA-MITI Class-D, at full load and 70 W output power, at both the

nominal input voltage mains.

As shown in Figure 2, 3, 4, and 5, the circuit is able to reduce the harmonics well below the

limits of both regulations from full load down to light load. 70 W of output power has been

chosen because it is almost the lower power limit at which the harmonics must be limited

according to these international norms.

Figure 2. EVAL6563-400W compliance to

10

1

0.1

0.01

Harmo nic Curr en t [A]

0.001

EN61000-3-2 at 230 Vac-full load

Measured value EN61000-3-2 Cla ss-D limits

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

Harmoni c Order [n]

Figure 4. EVAL6563-400W compliance to

1

0.1

EN61000-3-2 at 230 Vac-70 W load

Measured value EN61000-3-2 Class-D lim i ts

Figure 3. EVAL6563-400W compliance to

JEIDA-MITI at 100 Vac-full load

Measured value JEIDA-MI T I Cla ss-D lim its

10

1

0.1

0.01

Harmoni c Current [A]

0.001

1 3 5 7 9 111315171921232527293133353739

Harmonic Order [n]

Figure 5. EVAL6563-400W compliance to

JEIDA-MITI at 100 Vac-70 W load

Measured value JEIDA-MI T I Class-D lim i ts

1

0.1

0.01

Harmo nic Cu r r ent [A]

0.001

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

Harmonic Order [n]

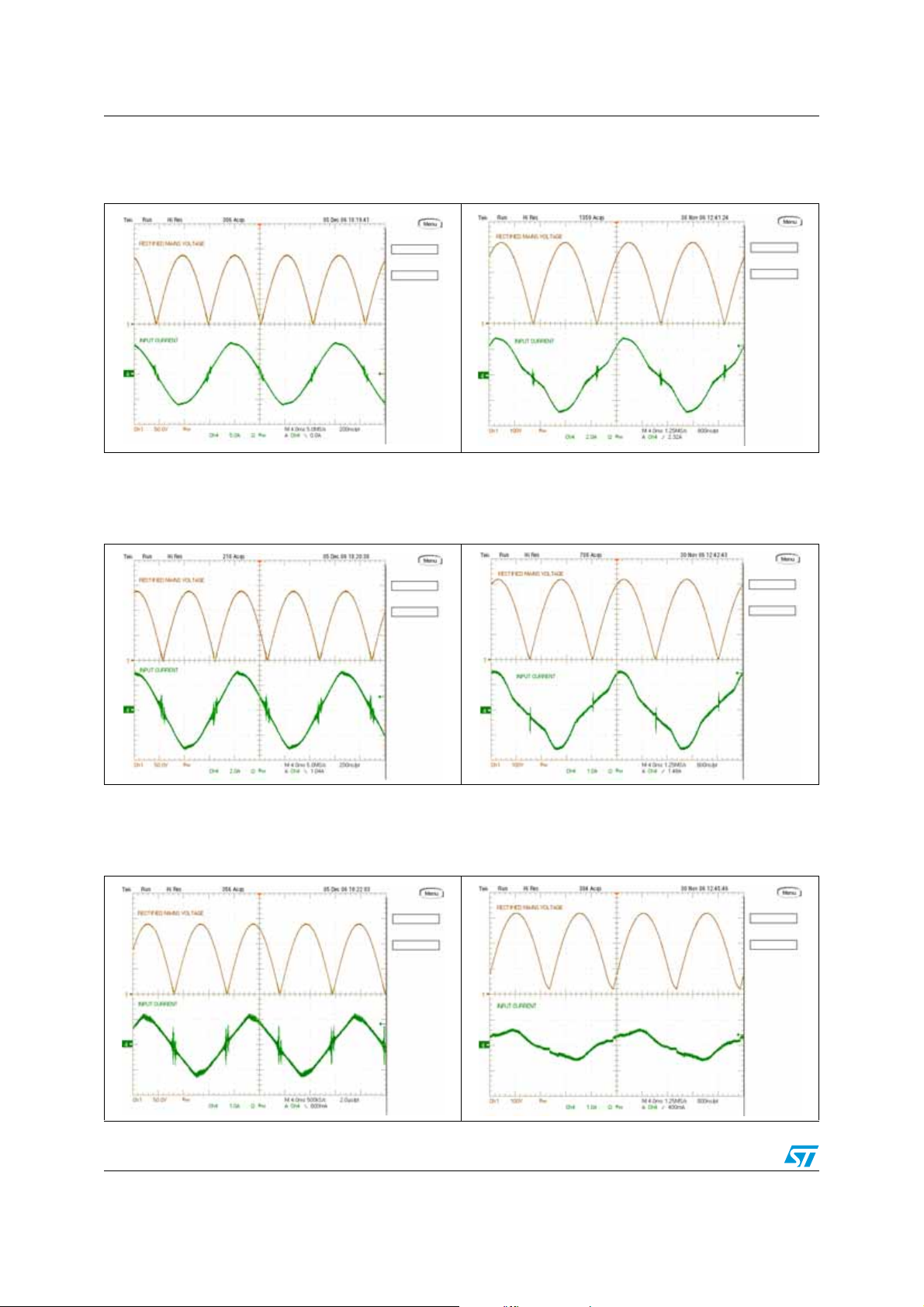

For user reference, waveforms of the input current and voltage at the nominal input voltage

mains and different load conditions are given in Figure 6, 7, 8, 9, 10, and 11.

0.01

Harm o n ic Cur r e n t [A]

0.001

1 3 5 7 9 111315171921232527293133353739

Harmonic Order [n]

7/29

Page 8

Test results and significant waveforms AN2485

Figure 6. EVAL6563-400W Input current

waveform at 100 V - 60 Hz - 400 W

load

Figure 8. EVAL6563-400W Input current

waveform at 100 V - 60 Hz - 200 W

load

Figure 7. EVAL6563-400W Input current

waveform at 230 V - 50 Hz - 400 W

load

Figure 9. EVAL6563-400W Input current

waveform at 230 V - 50 Hz - 200 W

load

Figure 10. EVAL6563-400W Input current

waveform at 100 V - 60 Hz - 70 W

8/29

load

Figure 11. EVAL6563-400W Input current

waveform at 230 V - 50 Hz - 70 W

load

Page 9

AN2485 Test results and significant waveforms

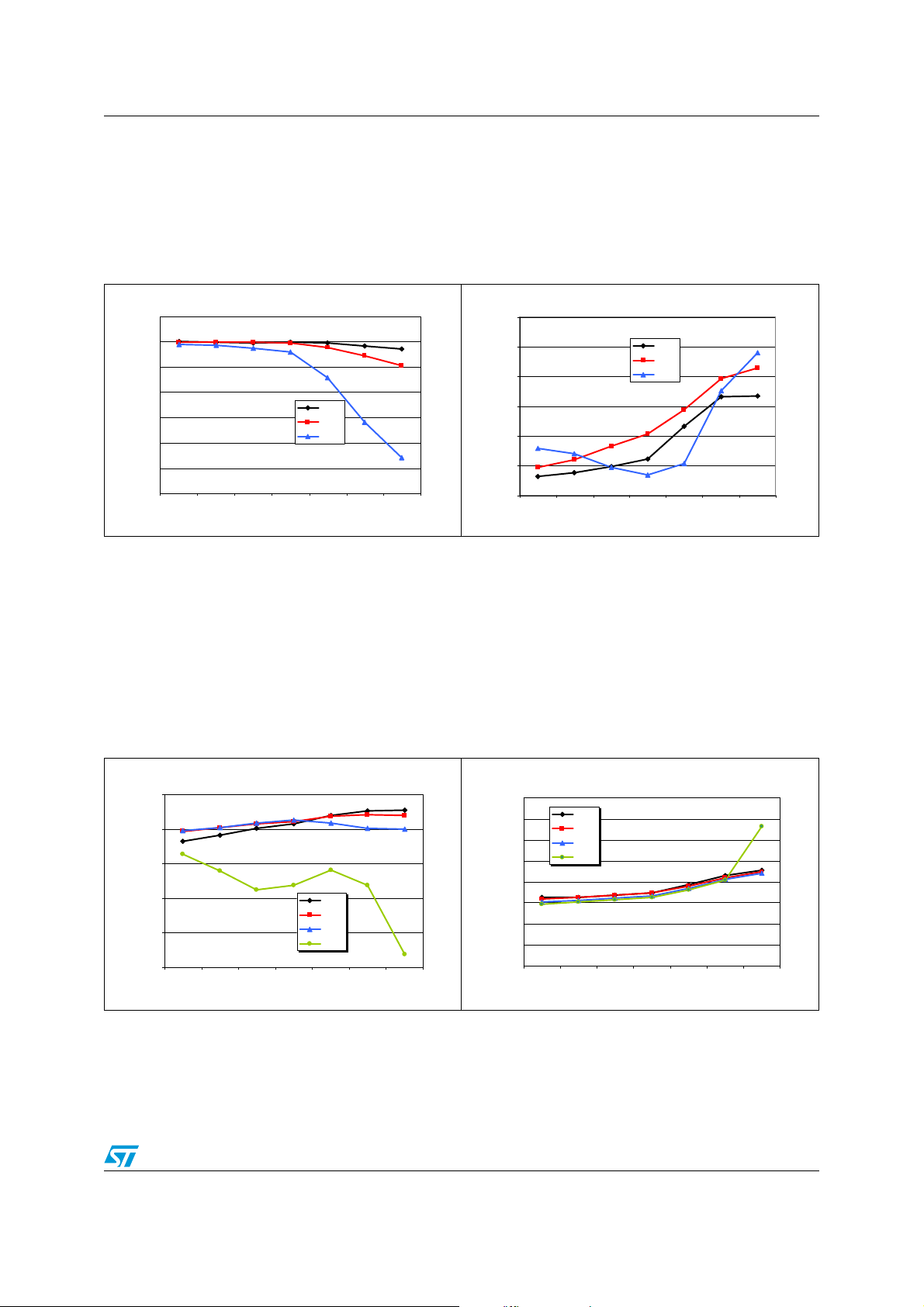

The Power Factor (PF) and the Total Harmonic Distortion (THD) have been measured too

and the results are reported in Figure 12. and Figure 13. As shown, the PF at full load and

half load remains close to unity throughout the input voltage mains range while it decreases

at high mains range when the circuit is deliv ering 70 W. THD is low, remaining within 25% at

maximum input voltage .

Figure 12. Power Factor vs. Vin and load Figure 13. THD vs. Vin and load

PF

1.05

1

0.95

0.9

RMS

400W

200W

70W

]

0.85

0.8

0.75

0.7

90 100 115 130 180 230 265

VIN [V

THD [%]

30

V

IN [VRMS

400W

200W

70W

]

25

20

15

10

5

0

90 100 115 130 180 230 265

Efficiency is very good at all load and line conditions. At full load it is always significantly

higher than 90%, making this design suitable for high efficiency power supply.

The measured output voltag e v ariation at different line and load conditions is given in Figure

15. As shown, the voltage is perfectly stable over the input vo lta ge r ang e d ue to th e Voltage

Feed-Forward function embedded in the L6593. Only at 265 Vac and light load, there is a

negligible deviation of 1 V due to the intervention of the burst mode (for the "static OVP")

function.

Figure 14. Efficiency vs. Vin and load Figure 15. Static Vout regulation vs. Vin and

Eff [%]

100%

95%

90%

85%

80%

75%

90 100 115 130 180 230 265

VIN [V

RMS

400W

200W

70W

15W

]

404

403.5

403

402.5

402

401.5

401

400.5

400

load

V

[VDC]

OUT

400W

200W

70W

15W

90 100 115 130 180 230 265

VIN [V

]

RMS

9/29

Page 10

Test results and significant waveforms AN2485

2.2 Inductor current in FOT and L6563 THD optimizer

Figure 16, 17, 18, and 19 show the waveforms relevant to the inductor current at different

voltage mains. As shown in Figure 16. and Figure 18., the inductor current wavef orm over a

line half-period is very similar to that of a CCM PFC. It is also possible to note the transition

angle from DCM to CCM that occurs closer to the zero crossing of the current sine wave at

low mains and move toward the top if the circuit is working at high mains. In Figure 17. and

Figure 19. the magnification of the waveforms at the peak of the sine wave, shows the

different ripple current and Off-times, which is modulated by the input mains voltage.

Figure 16. EVAL6563-400W Inductor current

ripple envelope at 115 Vac - 60 Hz full load

CH1: Q1/Q2 Drain voltage

CH2: MULT voltage - pin #3

CH4: L4 inductor current ripple envelope

On both the drain voltage traces reported in Figure 16. and Figure 18., close to the zero

crossing points of the sine wave, it is possible to note the action of the THD optimizer

embedded in the L6563. It is a circuit that minimiz es the conducti on dead-angle occurring to

the AC input current near the z ero-crossings of the line voltage (crossover distortion). In this

way, the THD (Total Harmonic Distortion) of the current is considerably reduced. A major

cause of this distortion is the inability of the system to transfer energy effectively when the

instantaneous line voltage is very low. This effect is magnified by the high frequency filter

capacitor placed after the bridge rectifier, which retains some residual voltage that causes

the diodes of the bridge rectifier to be reverse-biased and the input current flow to

temporarily stop. To overcome this issue the device forces the PFC pre-regulator to process

more energy near the line voltage zero-crossings as compared to that commanded by the

control loop.

Figure 17. EVAL6563-400W Inductor current

ripple (detail) at 115 Vac - 60 Hz full load

CH1: Q1/Q2 Drain voltage

CH2: MULT voltage - pin #3

CH4: L4 inductor current ripple envelope

The result is both a minimization of the time interval where energy transfer is lacking and a

full discharge of the high-frequency filter capacitor after the bridge. Essentially, the circuit

artificially increases the ON-time of the power switch with a positive offset added to the

output of the multiplier in the proximity of the line voltage zero-crossings. This offset is

reduced as the instantaneous line voltage increases, so that it becomes negligible as the

line voltage moves toward the top of the sinusoid. The offset is modulated by the voltage on

10/29

Page 11

AN2485 Test results and significant waveforms

the VFF pin, so as to have little o ffset at low line, where energy transfer at zero crossings is

typically quite good, and a larger offset at high line where the energy transfer gets worse.

In order to maximize the benefit from the THD optimizer circuit, the high-frequency filter

capacitors after the bridge rectifier should be minimized, compatible with EMI filtering

needs. A large capacitance in fact introduces a conduction dead-angle of the AC input

current in itself thus reducing the eff ectiveness of the optimizer circuit.

Figure 18. EVAL6563-400W Inductor current

ripple envelope at 230 Vac - 50 Hz full load

CH1: Q1/Q2 Drain voltage

CH2: MULT voltage - pin #3

CH4: L4 inductor current ripple envelope

2.3 Voltage feedforward

The power stage gain of PFC pre-regulators v aries with the square of the RMS input v oltage

as well as the crossover frequency fc of the overall open-loop gain because the gain has a

single pole characteristic. This leads to large trade-offs in the design. For example, setting

the gain of the error amplifier to get fc = 20 Hz at 264 Vac means having fc = 4 Hz at 88 Vac,

which results in sluggish control dynamics. Additionally, the slow control loop causes large

transient current flow during rapid line or load changes that are limited by the dynamics of

the multiplier output. This limit is considered when selecting the sense resistor to let the full

load power pass under minimum line voltage conditions, with some margin. A fixed current

limit allows excessive power input at high line, whereas a fixed power limit requires the

current limit to vary inversely with the line voltage.

Figure 19. EVAL6563-400W Inductor current

ripple (detail) at 230 Vac - 50 Hz full load

CH1: Q1/Q2 Drain voltage

CH2: MULT voltage - pin #3

CH4: L4 inductor current ripple envelope

Voltage Feedforward can compensate for the gain variation with the line voltage and

provides a solution to the above-mentioned issues. It consists of deriving a voltage

proportional to the input RMS voltage, f eeding this v oltage into a squarer/d ivider circuit (1/V

corrector) and providing the resulting signal to the multiplier that generates the current

reference for the inner current control loop. In this way a change of the line voltage will

cause an inversely proportional change of the half sine amplitude at the output of the

multiplier so that the current reference is adapted to the new operating conditions with

(ideally) no need for invoking the slow dynamics of the error amplifier. Additionally, the loop

gain will be constant throughout the input voltage range, which improves significantly

dynamic behavior at low line and simplifies loop design.

11/29

2

Page 12

Test results and significant waveforms AN2485

The L6563 achieves Voltage Feedforward with a technique that makes use of just two

external parts and limits the feedforward time constant trade-off issue to only one direction.

A capacitor C

(C18) and a resistor RFF (R26 + R27), both connected to the VFF pin (#5),

FF

complete an internal peak-holding circuit that provides a DC voltage eq ual to the peak of the

rectified sine wave applied on pin MULT (pin #3). R

when the line voltage decreases. In this way, in case of sudden line voltage rise, C

provides a means to discharge CFF

FF

FF

is

rapidly charged through the low impedance of the internal diode and no appreciable

overshoot is visible at the pre-regulator's output. In case of line voltage drop, C

discharged with the time constant R

· CFF, which can be in the hundred ms to achieve an

FF

FF

is

acceptably low steady-state ripple and have low current distortion. The dynamics of the

voltage feed-forward input is limited downwards at 0.5 V, that is, the output of the multiplier

no longer increases if the voltage on the V

pin is below 0.5 V. This helps to prevent

FF

excessive power flow when the line v oltage is lower than the minimum specified value.

The behavior of the EVAL6563-400W demo board in case of an input volt age surge fro m 90

to 140 Vac is shown in Figure 20. The graph shows that the V

function provides for the

FF

stability of the output voltage which is not affected b y the input voltage surge. In f act, thanks

to the V

function, the compensation of the input voltage variation is very fast and the

FF

output voltage remains perfectly stable at its nominal value. The opposite is confirmed in

Figure 21. which shows the behavior of a PFC using the L6562 working in FOT and

delivering a similar output power. In case of a mains surge the controller cannot compensate

for it, and the output voltage stability is guaranteed b y the feedback loop only. Unfortunately ,

as previously stated, its bandwidth is poor therefore the output voltage has a significant

deviation from the nominal value.

The circuit has the same behavior in case of mains surge at any input voltage, and it is not

affected if the input mains surge happens at any point on the input sine wave.

Figure 20. EVAL6563-400W Input mains surge

from 90 Vac to 140 Vac - full load C

= 470 nF

FF

CH1: Output voltage

CH2: Input rectified mains voltage

CH3: V

voltage - pin #5

FF

CH4: Input current

Figure 21. L6562 FOT Input mains surge from

90 Vac to 140 Vac - full load - NO

VFF input

CH1: Output voltage

CH2: Input rectified mains voltage

CH3: V

voltage - pin #5

FF

CH4: Input current

12/29

Page 13

AN2485 Test results and significant waveforms

Figure 22. shows the circuit be ha vior in case of main s dip . As pr e viously described, the time

constant of the V

pin provides a very fast compensation in case of surge, which is the

FF

most critical transition, and a slower compensation in case of mains dip. As shown, in that

case the output voltage changes, but in few mains cycles it returns to the nominal value. A

controller without the V

function will instead perform differently. In Figure 23. the behavior

FF

of a PFC using the L6562 working in FOT and delivering a similar output power is shown. In

case of a mains dip, the output voltage variation is larger and the ou tput voltage requires

more time to return to the or ig ina l value.

Figure 22. EVAL6563-400W Input mains dip

from 140 Vac to 90 Vac - full load C

= 470 nF

FF

CH1: Output voltage

CH2: Input rectified mains voltage

CH3: V

voltage - pin #5

FF

CH4: Input current

Deriving a voltage proportional to the RMS line voltage implies a form of integration, which

has its own time constant. If the time constant is too small the voltage generated will be

affected by a considerable amount of ripple at twice the mains frequency so causing

distortion of the current reference ( resulting in high THD and poor PF). If the time constant is

too large there will be a considerable delay in setting the right amount of feedforward,

resulting in excessive overshoot or undershoot of the pre-regulator's ou tput voltage in

response to large line voltage changes. Clearly, a trade-off is required.

Figure 23. L6562 FOT Input mains dip from 90

Vac to 140 Vac - full load - NO V

FF

input

CH1: Output voltage

CH2: Input rectified mains voltage

CH3: V

voltage - pin #5

FF

CH4: Input current

For reference, Figure 24. and Figure 25. compare the input current shape and the

measurement of the THD and 3

shows that increasing 3 times the C

RD

Harmonic amplitude for different CFF values. Figure 25.

capacitor improves the current shape and both the

FF

THD and the third harmonic current are also decreased, but not very significantly. The time

constant used for V

(CFF = 470 nF, RFF = 150 K+240 K) is a good compromise.

FF

13/29

Page 14

Test results and significant waveforms AN2485

Figure 24. EVAL6563-400W Input current

shape at 100 Vac-60 Hz vs. V

ripple - C

THD [%]: 3.39% - 3

CH3: V

voltage - pin #5

FF

= 470 nF

FF

RD

harmonic: 0.126 A

FF

CH4: Input current

2.4 Start-up and RUN pin

Figure 25. EVAL6563-400W Input current

shape at 100 Vac-60 Hz vs. V

ripple - C

THD [%]: 2.75% - 3

CH3: V

voltage - pin #5

FF

= 1.5 uF

FF

RD

harmonic: 0.109 A

FF

CH4: Input current

Figure 26. and Figure 27. detail the waveforms during the start-up of the circuit, at mains

plug-in. The Vcc voltage rises to the turn-on threshold, and the L6563 starts the operation.

For a short time the energy is supplied by the Vcc capacitor, then the auxiliary winding and

the charge pump circuit take over. At the same time, the output voltage rises from peak

value of the rectified mains to the nominal value of the PFC output voltage. The good

margin phase of the compensation network allows a clean start-up, without any large

overshoot that would trigger the Dynamic and Static over voltage protection.

Figure 26. EVAL6563-400W start-up at 90 Vac-

60 Hz - full load

CH1: Output voltage

CH2: Pin #14 - Vcc voltage

CH3: Pin #10 - RUN

CH4: Pin #13 - Gate drive

Figure 27. EVAL6563-400W start-up at 265

Vac-50 Hz - full load

CH1: Output voltage

CH2: Pin #14 - Vcc voltage

CH3: Pin #10 - RUN

CH4: Pin #13 - Gate drive

14/29

Page 15

AN2485 Test results and significant waveforms

g

A dangerous event for any PFC is the operation during an undervoltage of the mains. This

condition may cause overheating of the primary power section due to an excess of RMS

current. To prevent th e PF C fr om t his a bno rmal opera tio n a b rownout protection is needed.

It is basically a not-latched shutdown function that must be activated when a conditi on of

mains under voltage is detected. The L6563 has a dedicated inhibit pin (RUN, #10),

embedding a comparator with hysteresis, stopping the L6563 operation if the voltage

applied is below its threshold. Because the L6563 V

pin delivers a voltag e signal

FF

proportional to the input mains, the complete brownout function can be easily implemented

using a simple resistor divider connected between the V

and the RUN pins. In this demo

FF

board, the divider resistors setting the turn-on threshold are R26 and R27 on the sche matic

in Figure 1. In Figure 28. a start-up tentative below the threshold shows that the RUN pin

does not allow the IC operation.

Figure 28. EVAL6563-400W start-up at 80 Vac-60 Hz - full load

2.5 Start-up at light load

Figure 29. EVAL6563-400W Start-up at 265 V -

CH1: Q1/Q2 drain voltage

CH2: Output voltage

CH3: Pin #13 - Gate drive

CH4: Pin #14 - Vcc voltage

50 Hz - 30 mA load

Figure 30. EVAL6563-400W start-up at 265 V -

50 Hz - no load

CH1: Q1/Q2 drain voltage

CH2: Output voltage

CH3: Pin #13 - Gate drive

CH4: Pin #14 - Vcc volta

e

15/29

Page 16

Test results and significant waveforms AN2485

The board, as is, is able to properly handle an output load as low as 12 W. With lower load

levels the system will not start up correctly at high line because burst pulses last so long that

the Vcc voltage drops below the UVLO of the L6563. In that condition, if the load increases

suddenly, the PFC output voltage drops until the IC resumes normal operation. Supplying

the L6563 from an external source (typically it's the auxiliary voltage powering the controller

of the downstream converter or of an auxiliary power supply), the minimum load that can be

properly handled goes to virtually zero.

2.6 Open loop protection

Figure 31. EVAL6563-400W open loop at 115 Vac-60 Hz - full load

CH1: Q1/Q2 drain voltage

CH2: Output voltage

CH3: Pin #7 - PFC_OK

CH4: Pin #8 - PWM_LATCH

The L6563 is equipped with an OVP, which monitors the current flowing through the

compensation network and entering in the error a mplifier (pin COMP, #2). When this current

reaches about 18 µA, the output vo ltage of the multiplier is f orced to decrease , thus reducing

the energy drawn from the mains. If the current exceeds 20 µA, the OVP is triggered

(Dynamic OVP), and the external power transistor is switched off until the current falls

approximately below 5 µA. However, if the overvoltage persists (in case the load is

completely disconnected, for example), the error amplifier eventually saturates low and

triggers an internal comparator (Static OVP) that keeps the external power switch turned off

until the output voltage returns close to the regulated value.

The OVP function is able to handle "normal" overvoltage conditions, that is , those resulting

from an abrupt load/line change or occurring at start-up. It cannot handle the overvoltage

generated, fo r instance , when the uppe r resistor of t he output divid er f ails open. The vo ltage

loop can no longer read the information on the output voltage and forces the PFC preregulator to work at maximum ON-time , causin g the out put voltage to rise with no control. A

pin of the L6563 (PFC_OK, #7) is dedicated to providing an additional monitoring of the

output voltage with a separate resistor divider (R6, R7, R8 high, R24 low, see Figure 1.).

This divider is selected so that the voltage at the pin reaches 2.5 V if the output voltage

exceeds a preset value, usually larger than the maximum Vo that can be expected (including

worst-case load/line transients).

If V

= 400 V, Vox = 460 V, select R6+R7+R8 = 6.6 MΩ. Three resistor in series have been

O

chosen according to their voltage rating, so R24 = 6.6 MΩ ·2.5/(460-2.5) = 36 KΩ.

When the OVP f unction is triggered, the gate drive activity is immediately stopped, the

device is shut down, its quiescent consumption is reduced below 250 µA , and the condition

16/29

Page 17

AN2485 Test results and significant waveforms

L6668

PFC_STOP14

16

Vcc

10 kΩ

BC557

2.2 kΩ

L6563

L6563A

Vcc

14

8.2 V

L6563

L6563A

(RUN)

PFC_OK

BC547

L6668

14 PFC_STOP

7

(10)

2.2 kΩ

8

VREF

100 kΩ

L6599

PFC_STOP14

L6563

L6563A

(

RUN

)

PFC_OK 7

(10)

is latched as long as the supply voltage of the IC is abo ve the UVLO threshold. At the same

time the pin PWM_LATCH (pin #8) is asserted high. PWM_LATCH is an open source output

able to deliver 3. 7 V min. with 0.5 mA load, inte nded f or tripping a latched sh utdown fun ction

of the PWM controller IC in the cascaded DC-DC converter, so that the entire unit is latched

off. To restart the system, it is necessary to recycle the input power , so that the Vcc v oltages

of both the L6563 and the PWM controller go below their respective UVLO thresholds.

The PFC_OK pin doubles its function as a not-latched IC disable. A voltage below 0.2 V

shuts down the IC, reducing its consumption below 1 mA. In this ca se both PWM_ST OP and

PWM_LATCH keep their high impedance status. To restart the IC simply let the voltage at

the pin go above 0.26 V.

Note that this function off ers a complete pro tection against no t only f eedbac k loop f ailure s or

erroneous settings, but also against a failure of the p rotection itself. Either resistor of the

PFC_OK divider failing short or open (or the PFC_OK (#7) pin is floating) results in shutting

down the L6563 and stopping the pre-re gulator.

The eve nt of an open loop is shown in Figure 31. The protection intervention stops the

operation of the L6563 and the activation of the PWM_LATCH pin.

2.7 Power management/housekeeping functions

A special feature of the L6563 is that it facilitates the implementation of the "housekeeping"

circuitry needed to coordinate the operation of the PFC stage to that of the cascaded DCDC

converter. The housekeeping circuitry functions ensure that transient conditions like powerup or power down sequencing or failures of power stage are properly handled. The L6563

provides some pins for these functions.

One communication line between the L6563 and the PWM controller of the cascaded DCDC converter is the PWM_LATCH pin (#8), which is normally open when the PFC works

properly. It goes high if the L6563 loses control of the output v olt age (because of a f ailur e of

the control loop) or if the boost inductor saturates. Its aim is to latch off the PWM controller

from the cascaded DC-DC converter as well. A second communication line can be

established via the disable function included in the RUN pin. Typically, this line is used to

allow the PWM controller of the cascaded DC-DC con verter to shut down the L6563 in case

of light load, in order to minimize the no-load input consumption of the power supply.

Figure 32. L6563 On/Off control by a cascaded converter controller via PFC_OK or

RUN pin

17/29

Page 18

Layout hints AN2485

(

)

(10)

The third communication line is the PWM_STOP pin (pin #9), which works in conjunction

with the RUN pin (pin #10). The purpose of the PWM_STOP pin is to inhibit th e PWM

activity of both the PFC stage and the cascaded DC-DC converter.

The PWM_STOP pin is an open collector, normally open, that goes low if the device is

disabled by a voltage lower than 0.52 V on the RUN pin (#10). It is important to point out that

this function works correctly in systems where the PFC stage is the master and the

cascaded DC-DC converter is the slave or, in o ther w or ds, where the PFC stage starts first,

powers both controllers and enables/disables the operation of the DC-DC stage. This

function is quite flexible and can be used in different ways. In systems comprising an

auxiliary converter and a main converter (e.g. desktop PC's silver box or Hi-end Flat-TV or

monitor), where the auxiliary converter also powers the controllers of the main converter, the

pin RUN (#10) can be used to start and stop the main converter. In the simplest case, to

enable/disable the PWM controller th e PWM_STOP (#9) pin can be connected to either the

output of the error amplifier or, if the chip is provided with it, to its soft-start pin.

The EV AL6563-400W off ers the possibility to test the housekeeping functions b y connecting

them to the cascaded converter via the serie s re sistors R28, R29, R30. Regarding the

PWM_STOP (#9) pin that is an open collector type, if it needs a pull-up resistor, connect it

close to the cascaded PWM for better noise imm unity.

Figure 33. Interface circuits that let the L6563/A switch on or off a PWM controller

BC557

100 kΩ

VREF

8

L6668

2.2 kΩ

14 PFC_STOP

PFC_OK

(RUN)

BC547

7

(10)

L6563

L6563A

Vcc

16

L6668

10 kΩ

8.2 V

2.2 kΩ

PFC_STOP14

Vcc

14

L6563

L6563A

L6599

3 Layout hints

The layout of any converter is a very important phase in the design process which may not

always ha ve the necessary attention required by the engineers. Even if it the layout phase

appears time-consuming, a good la yout does sav e time during the functi onal debugging and

the qualification phases. Additionally, a power supply circuit with a correct layout needs

smaller EMI filters or less filter stages and subsequently provides consistent cost savings.

The L6563 does not need any special attention to the layout, but the general layout rule for

any power converter must be applied carefully. Basic rules using the EVAL6563-400W

schematic as a reference are listed below. They can be used for other PFC circuits having

any power level, working either in FOT or TM control.

1. Keep power and signal RTN separate d. Connect the return pins of components

carrying high current such as C4, C5, sense resistors, C6 and C7 as close as p ossib le .

18/29

PFC_STOP14

PFC_OK 7

RUN

L6563

L6563A

Page 19

AN2485 Layout hints

This point is the RTN star point. A downstream converter must be connected to this

return point.

2. Minimize the length of the traces relevant to L3, boost inductor L4, boost rectifier D4

and output capacitor C6 and C7.

3. Keep signal components as close as possible to L6563 pins. Keep the tracks relevant

to the pin #1 (INV) net as short as possible. Components and traces relevant to the

Error Amplifier must be placed far from traces and connections carrying signals with

high dv/dt like Mosfet Drains (Q1 and Q2).

4. Connect heat sinks to Power GND.

5. Add an external shield to the boost inductor and connect it to Power GND.

6. Connect the RTN of signal components including the feedback, PFC_OK and MULT

dividers close to the L6563 pin #12 (GND).

7. Connect a ceramic capacitor (100÷470 nf) to pin #14 (Vcc) and to pin #12 (GND), close

to the L6563 connect this point to the RTN star point (see point 1.).

Figure 34. EVAL6563-400W PCB layout (not 1:1 scaled)

19/29

Page 20

Audible noise AN2485

4 Audible noise

Differential mode currents in a circuit with high frequency and low frequency components

(like in a PFC) may produce audible noise due to inter-mod ulation between operating

frequency and mains line frequency.

The phenomenon is produced because of mechanical vibration of reac tive components like

capacitors and inductors. Current flowing in the winding can cause vibration of wires or

ferrite which produces buzzing noise, therefore, to avoi d this boost and filter inductors have

to be wound with correct wire tension, and the component has to be varnished or dipped.

Frequently, X-Capacitors and Filter Capacitors after bridge gene rate acoustic noise beca use

of AC current that causes the electrodes to vibrate and produce buzzing (noise). Thus,

minimize AC current inserting a differential mode, Pi-filter between the bridge and the boost

inductor helps to reducing the acoustic noise and additionally the EMI filter will benefit too.

Such actions decrease significantly the ripple current that otherwise has to be filtered by the

EMI filter. The capacitors selected are polypropylene, preferably dipped type, because

boxed ones are generally more at risk to generate acoustic noise.

The acoustic noise can also be due to an incorrect circuit behavior for an abnormal current

modulation. It can be due to the Dynamic OVP intervention that stops the IC switching

cycles which consequently creates a discontinuity of the input line current shape that can

produce vibrations as described above, occurring typically at light load. In this case, only a

board re-layout can help, taking into consideration the points outlined in Section 3: Layout

hints. In addition, grounding the boost inductor may help, because in this ca se w e decrease

the emissions from the most efficient "antenna" of our circuit. In fact, in case of improper

layout some pi cofarads of layout parasitic capacitance together with the very high dV/dt of

the MOSFET Drain voltage may inject noise somewhere in the circuit.

5 Thermal measures

In order to check the design reliability, a thermal mapping by means of an IR Camera was

done. Figure 35. and Figure 36. show thermal measures on board component side at

nominal input voltages and full load. Captions visible on the pict ures placed across key

components show the relevant temperat ure. Table 1. provides the correlation between

measured points and components for both thermal maps. The ambient temperature during

both measurements was 27°C. According to these measurement results all components of

the board are working within their temperature limit s.

20/29

Page 21

AN2485 Thermal measures

6

9

2

5

8

4

7

9

9

2

6

0

3

7

0

4

8

Figure 35. Thermal map at 115 Vac-60 Hz - full load

80.

°C

73.

67.

60.

53.

47.1

40.

33.

26.

Figure 36. Thermal map at 230 Vac-50 Hz - full load

79.

°C

73.

66.

60.

53.

46.

40.

33.

26.

Table 1. Measured temperature table at 115 Vac and 230 Vac - full load

Point Component Temperature @115 Vac Temperature @230 Vac

A D2 64.7°C 51.3°C

B Q2 76.5°C 62.0°C

C Q1 74.1°C 61.9°C

D D3 72.8°C 65.6°C

E C7 41.0°C 41.5°C

F L1 58.5°C 43.5°C

G L3 59.2°C 50.6°C

H L4 – CORE 57.0°C 56.5°C

I L4 - WINDING 65.1°C 60.9°C

21/29

Page 22

Conducted emission pre-compliance test AN2485

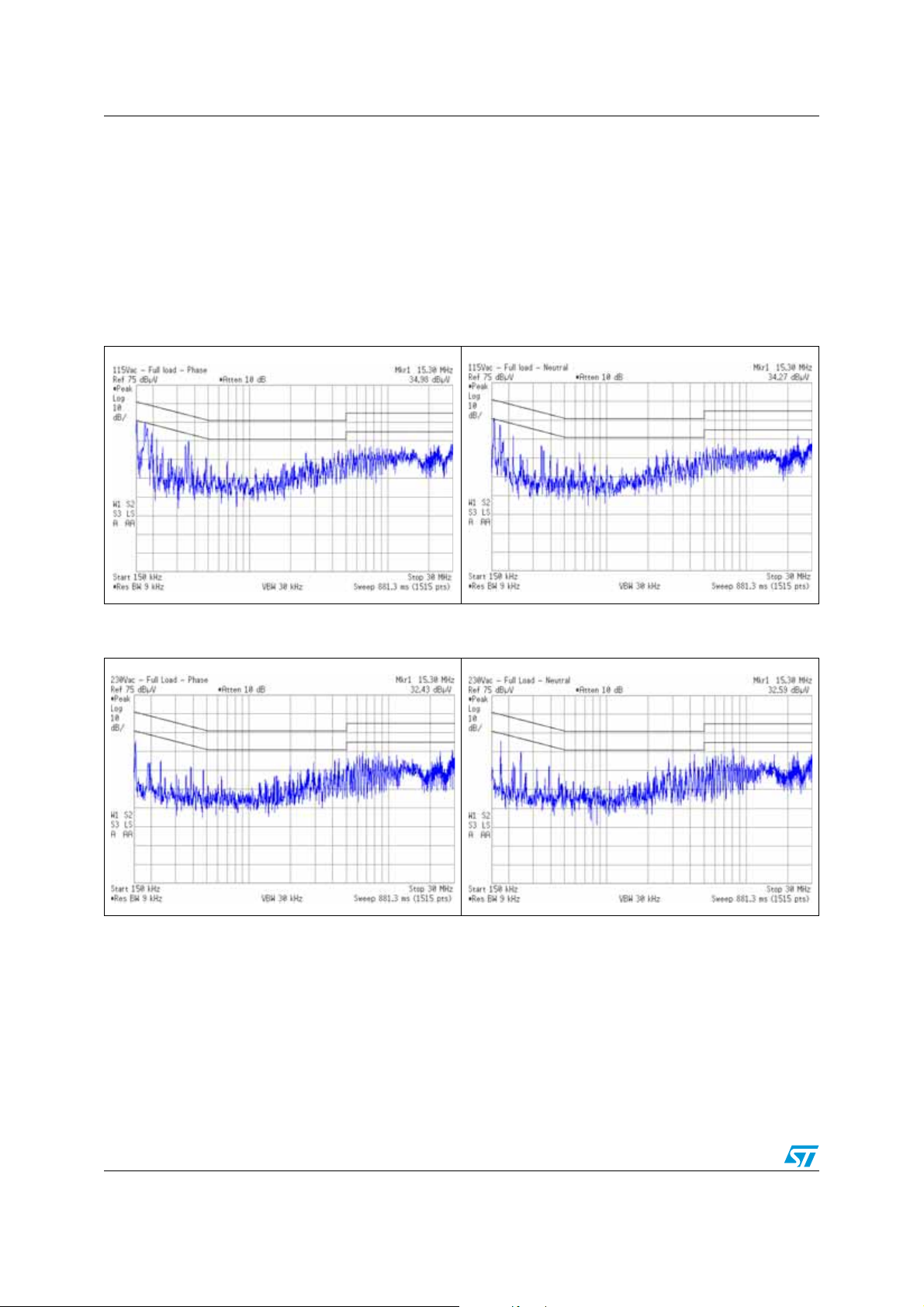

6 Conducted emission pre-compliance test

Figure 37, 38, 39, and 40 show the peak measurement of the conduct ed noise at full load

and nominal mains voltages. The limits shown on the diagrams are EN55022 Class-B,

which is the most common norm for domestic equipment using a two- wire mains

connection. As shown on the graphs, under all test conditions there is a good margin of the

measures with respect to the limits.

Figure 37. 115 Vac and full load - phase Figure 38. 115 Vac and full load - neutral

Figure 39. 230 Vac and full load - phase Figure 40. 230 Vac and full load - neutral

22/29

Page 23

AN2485 Bill of material

7 Bill of material

Table 2. Bill of material

Ref.

des.

C1 470 nF-X2 DWG X2 FILM CAPACITOR R46-I 3470--M1- ARCOTRONICS

C10 18 N 1206 100V SMD CERCAP - GEN. PURPOSE AVX

C11 470 nF/50 V 1206 50V SMD CERCAP - GEN. PURPOSE AVX

C12 47 uF/50 V DIA6.3X11 ALUMINIUM ELCAP - YXF SERIES - 105°C RUBYCON

C13 100 nF 0805 50V SMD CERCAP - GEN. PURPOSE AVX

C14 1 µF 1206 50V SMD CERCAP - GEN. PURPOSE AVX

C15 100 pF 0805 50V SMD CERCAP - GEN. PURPOSE AVX

C16 220pF 0805 50V SMD CERCAP - GEN. PURPOSE AVX

C17 10 nF 0805 50V SMD CERCAP - GEN. PURPOSE AVX

C18 470 nF 1206 50V SMD CERCAP - GEN. PURPOSE AVX

C19 2 nF2 0805 50V SMD CERCAP - GEN. PURPOSE AVX

C2 470 nF-X2 DWG X2 FILM CAPACITOR R46-I 3470--M1- ARCOTRONICS

C20 330 pF 0805 50V SMD CERCAP - GEN. PURPOSE AVX

C21 10 nF 1206 50V SMD CERCAP - GEN. PURPOSE AVX

C3 680nF-X2 DWG X2 FILM CAPACITOR R46-I 3680--M1- ARCOTRONICS

C4 470 nF-630 V DWG FILM CAPACITOR MKP - B32653A6474J EPCOS

C5 470 nF-630 V DWG FILM CAPACITOR MKP - B32653A6474J EPCOS

C6 470 nF-630 V DWG FILM CAPACITOR MKP- B32653A6474J EPCOS

Part typepart value

Case/

package

Description Supplier

C7 330 µF-450 V DIA35x35 ALUMINIUM ELCAP - LLS SERIES - 85°C NICHICON

D1 1N5406 DO-201 STD RECOVERY RECTIFIER VISHAY

D2 D15XB60 DWG RECTIFIER BRIDGE SHINDENGEN

D3 STTH8R06 TO-220FP ULTRAFAST HIGH VOLTAGE RECTIFIER STMicroelectronics

D4 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D5 BZX85-C15 MINIMELF ZENER DIODE VISHAY

D6 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D7 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

D8 LL4148 MINIMELF FAST SWITCHING DIODE VISHAY

F1 8 A/250 V 5x20MM 8A MAINS INPUT FUSE WICKMANN

J1

J2

3-PINS CONN. (CENTRAL REM.) P 3.96 KK

SERIES

5-PINS CONN. (CENTRAL REM.) P 3.96 KK

SERIES

MOLEX

MOLEX

23/29

Page 24

Bill of material AN2485

Table 2. Bill of material (continued)

Ref.

des.

JP101 JUMPER WIRE JUMPER

JP102 JUMPER WIRE JUMPER

L1 1.5 mH-5A DWG CM CHOKE - LFR2205B DELTA ELECTRONICS

L3 DM-51 µH-6 A DWG FILTER INDUCTOR - LSR2306-1 DELTA ELECTRONICS

L4 PQ40 -500 µH DWG PFC INDUCTOR - 86H-5410B DELTA ELECTRONICS

Q1 STP12NM50FP TO-220FP N-CHANNEL POWER MOSFET STMicroelectronics

Q2 STP12NM50FP TO-220FP N-CHANNEL POWER MOSFET STMicroelectronics

Q3 BC857C SOT-23 SMALL SIGNAL BJT - PNP VISHAY

R1 1 M5 AXIAL HV RESISTOR BC COMPONENTS

R10 680 K 1206 SMD STD FILM RES - 1% - 250ppm/°C BC COMPONENTS

R11 680 K 1206 SMD STD FILM RES - 1% - 250ppm/°C BC COMPONENTS

R12 82 K 0805 SMD STD FILM RES - 1% - 250ppm/°C BC COMPONENTS

R13 15 K 0805 SMD STD FILM RES - 1% - 250ppm/°C BC COMPONENTS

R14 56 K 0805 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R15 3K3 0 805 SMD STD FILM RES - 1% - 100ppm/°C BC COMPONENTS

R16 15 K 0805 SMD STD FILM RES - 1% - 100ppm/°C BC COMPONENTS

R17 6R8 0805 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

Part typepart value

Case/

package

Description Supplier

R18 6R8 0805 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R19 1K0 1 206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R2 NTC 2R5-S237 DWG NTC RESISTOR 2R5 S237 EPCOS

R20 0R39-1 W AXIAL AXIAL RES - 5% - 250ppm/°C BC COMPONENTS

R21 0R39-1 W AXIAL AXIAL RES - 5% - 250ppm/°C BC COMPONENTS

R22 0R39-1 W AXIAL AXIAL RES - 5% - 250ppm/°C BC COMPONENTS

R23 0R39-1 W AXIAL AXIAL RES - 5% - 250ppm/°C BC COMPONENTS

R24 36 K 0805 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R26 150 K 1206 SMD STD FILM RES - 1% - 250ppm/°C BC COMPONENTS

R27 240 K 0805 SMD STD FILM RES - 1% - 100ppm/°C BC COMPONENTS

R3 180 K 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R31 1K5 0 805 SMD STD FILM RES - 1% - 100ppm/°C BC COMPONENTS

R32 620 K 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R33 620 K 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R34 10 K 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R35 3R9 0805 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R36 3R9 0805 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

24/29

Page 25

AN2485 Bill of material

Table 2. Bill of material (continued)

Ref.

des.

R4 180 K 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R5 47R 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R6 2M2 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R7 2M2 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R8 2M2 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R9 680 K 1206 SMD STD FILM RES - 1% - 250ppm/°C BC COMPONENTS

R101 0R0 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

R102 0R0 1206 SMD STD FILM RES - 5% - 250ppm/°C BC COMPONENTS

U1 L6563 SO-14 ADVANCED TM PFC CONTROLLER STMicroelectronics

Part typepart value

Case/

package

Description Supplier

25/29

Page 26

PFC coil specification AN2485

8 PFC coil specification

8.1 General description and characteristics

● Application type: consumer, home appliance

● Inductor type: open

● Coil former: horizontal type, 6+6 pins

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

8.2 Electrical characteristics

● Converter topology: Boost PFC Preregulator, FOT control

● Core type: PQ40-30 material grade PC44 or equivalent

● Max operating freq: 100 KHz

● Primary inductance: 500 µH ±10% @1 KHz-0.25 V (see Note: 1 )

● Primary RMS current: 4.75 A

Note: 1 Measured between pins #1-2 and #5-6

Figure 41. Electrical diagram

Table 3. Winding charactericstics

Start PINS End PINS

11 8 5 (spaced) Single Ø 0.28 mm Bottom

5 - 6 1 - 2 65 Multistrand – G2 Litz Ø 0.2 mm x 30 Top

Number

of turns

Wire type

Wire

diameter

Notes

26/29

Page 27

AN2485 PFC coil specification

8.3 Mechanical aspect and pin numbering

● Maximum Height from PCB: 31 mm

● Ferrite: two symmetrical half cores, PQ40-30

● Material grade: PC44 or equivalent

● Central leg air gap: to be defined, in order to get the required inductance value

● Coil former type: vertical, 6+6 pins

● Pin distance: 5 mm

● Row distance: 45.5 mm

● Cut pins: #9-12

● External copper shield: not insulated (for EMI reasons), connected to pin #11 (GND)

Figure 42. Pin side view

Figure 43. Mechanic aspect

● Manufacturer: DELTA ELECTRONICS

● P/N: 86H-5410B

27/29

Page 28

References AN2485

9 References

1. "L6563 Advanced transition-mode PFC controller" Datasheet

2. "Design of Fixed-Off-Time-Controlled PFC Pre-regulators with the L6562", AN1792

3. "EVAL6562-375W Evaluation Boar d L6562-based 375W FOT-controlled PFC Preregulator" AN1895

4. "L6561, Enhanced Transition-Mode Power Factor Corrector", AN966

10 Revision history

Table 4. Revision history

Date Revision Changes

22-Mar-2007 1 First issue

28/29

Page 29

AN2485

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale .

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all informa tion previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

29/29

Loading...

Loading...