Page 1

AN2479

Application note

STA333ML demo board application note

Introduction

The purpose in this document is:

■ to describe how to connect the STA333ML demo board,

■ how to evaluate the demo board performance with electrical curve data,

■ how to avoid critical board and layout issues.

Application note can be configured to the 2.0 channels only. Both of the 2 channels are in

BTL mode. Each channel can deliver 20 W @ THD = 10% when Vcc = 18V and 8 load. It is

a total solution for the digital audio power amplifier in a TV application.

All the test items and graph data in this document are measured by audio precision

equipment. The test data shown in this document contains, for example, output power

versus Vcc, frequency response, THD+N versus frequency, THD+N versus output power,

FFT.

December 2006 Rev 1 1/42

www.st.com

Page 2

Contents AN2479

Contents

1 Test condition and connection of demo board . . . . . . . . . . . . . . . . . . . 3

1.1 Test condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.1 Jumper, power supply, signal and interface setting . . . . . . . . . . . . . . . . . 3

1.1.2 Output configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Equipment requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Connection method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 Speaker jack connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 PCB Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.1 Top view of PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.2 Bottom view of PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 BOM list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.1 Test connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Test curve report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 THD versus frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.1 THD versus output power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 FFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 Cross talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Design guideline for PCB schematic and layout . . . . . . . . . . . . . . . . . 28

3.1 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.1.1 Main driver for components selection . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2 Decoupling capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.1 Output filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3 Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2/42

Page 3

AN2479 Test condition and connection of demo board

1 Test condition and connection of demo board

1.1 Test condition

1.1.1 Jumper, power supply, signal and interface setting

1. JP1: format selection. 0

2. JP2: oversampling selection. 0 = 256 Fs, 1 = 384 Fs.

3. JP3: gain selection. 0 = 0 dB, 1 = +24 dB.

4. +3.3 V selection. Outer side = external +3.3 V, inner side = internal +3.3 V

5. Connect + voltage of 12 V DC power supply to +Vcc pin and negative to GND.

6. Connect + voltage of 3.3 V DC power supply to +3.3 V pin and negative to GND. If the

+3.3 V selection is set to the inner side, do not connect this wire.

7. Connect GUI AP interface board to the J3 connector of STA333ML demo board.

8. Connect the S/PDIF signal cable to the RCA jack on the interface board, The input

coming from the signal source such as Audio precision or DVD player.

9. The voltage range of the DC power supply for Vcc is from 5 V to 18 V.

(a)

= I2S, 1

(a.)

= left justified.

1.1.2 Output configuration

STA333ML demo board can be configured to 2.0 channels and do not require software

control. It is not necessary to connect the AP interface to the PC. When the power supply,

signal, interface and output have been setup, push the RESET button which allows the

STA333ML demo board to function.

1.2 Equipment requirement

● Audio Precision (System 2700) by AP Co., USA)

● DC power supply (With 5V to 18V)

● Digital oscilloscope (TDS3034B) by Tektronix

● PC

a. 0: connect to outer side, 1: connect to inner side.

3/42

Page 4

Test condition and connection of demo board AN2479

1.3 Connection method

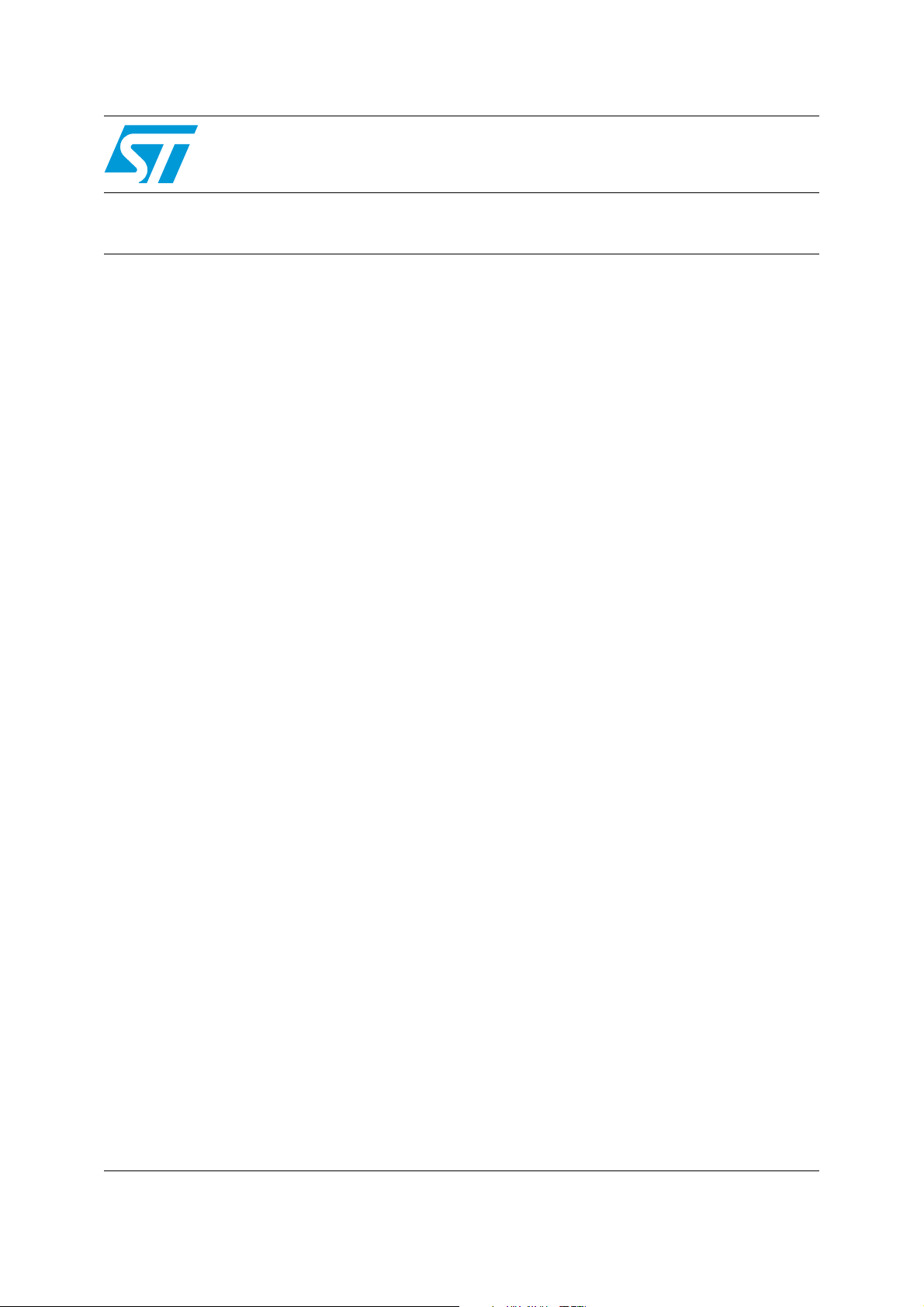

Top view of demo board.

Figure 1. Block diagram

External 3.3 V

(not required if +3.3 V

selection is set to internal)

+3.3 V

selection

Vcc (5-18 V)

L_CH output

Connect to

interface board

Oversampling

selection

Gain

selection

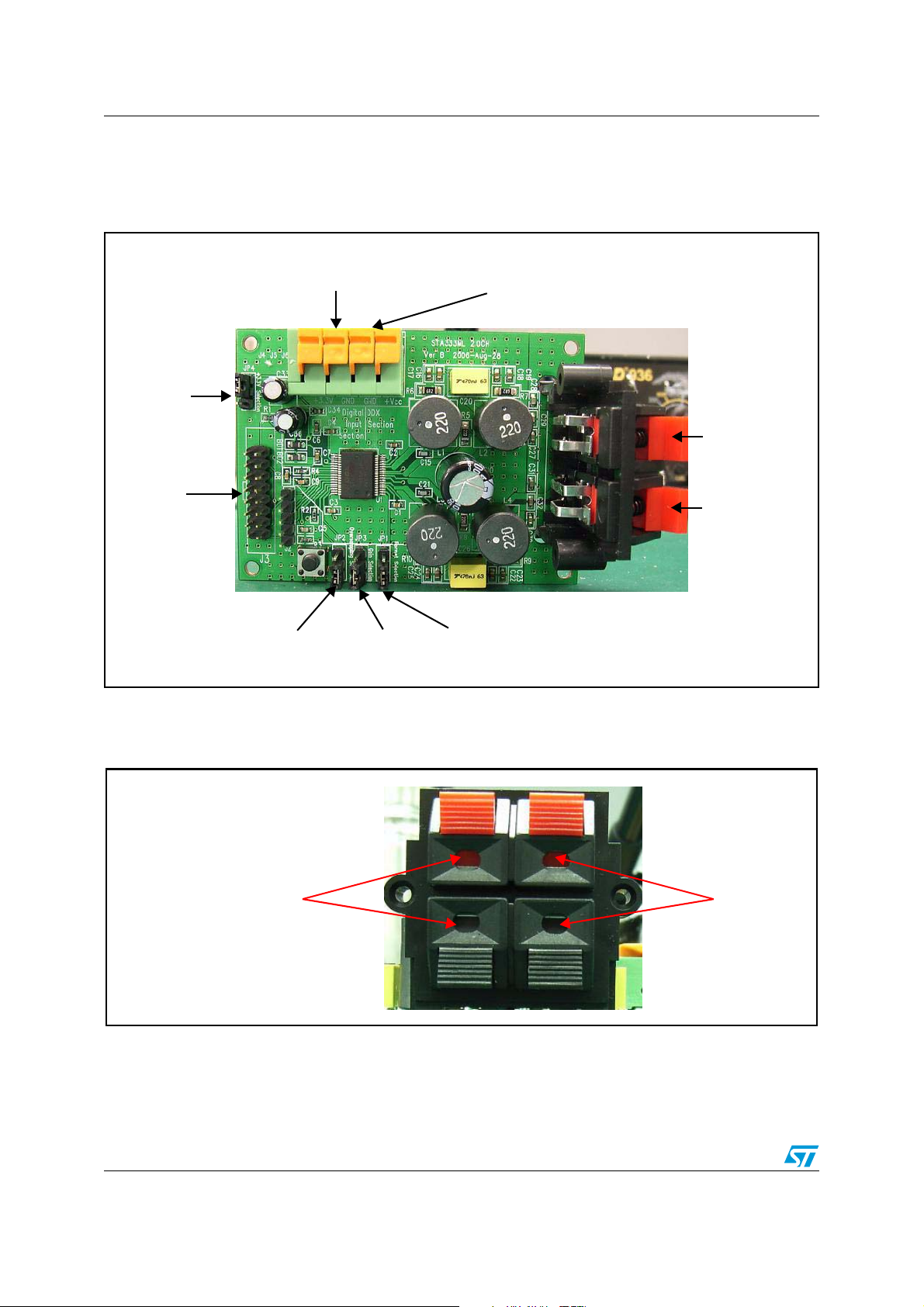

1.3.1 Speaker jack connection

Figure 2. Block diagram

R_CH output

Format

selection

L_CH outputR_CH output

4/42

Page 5

AN2479 Test condition and connection of demo board

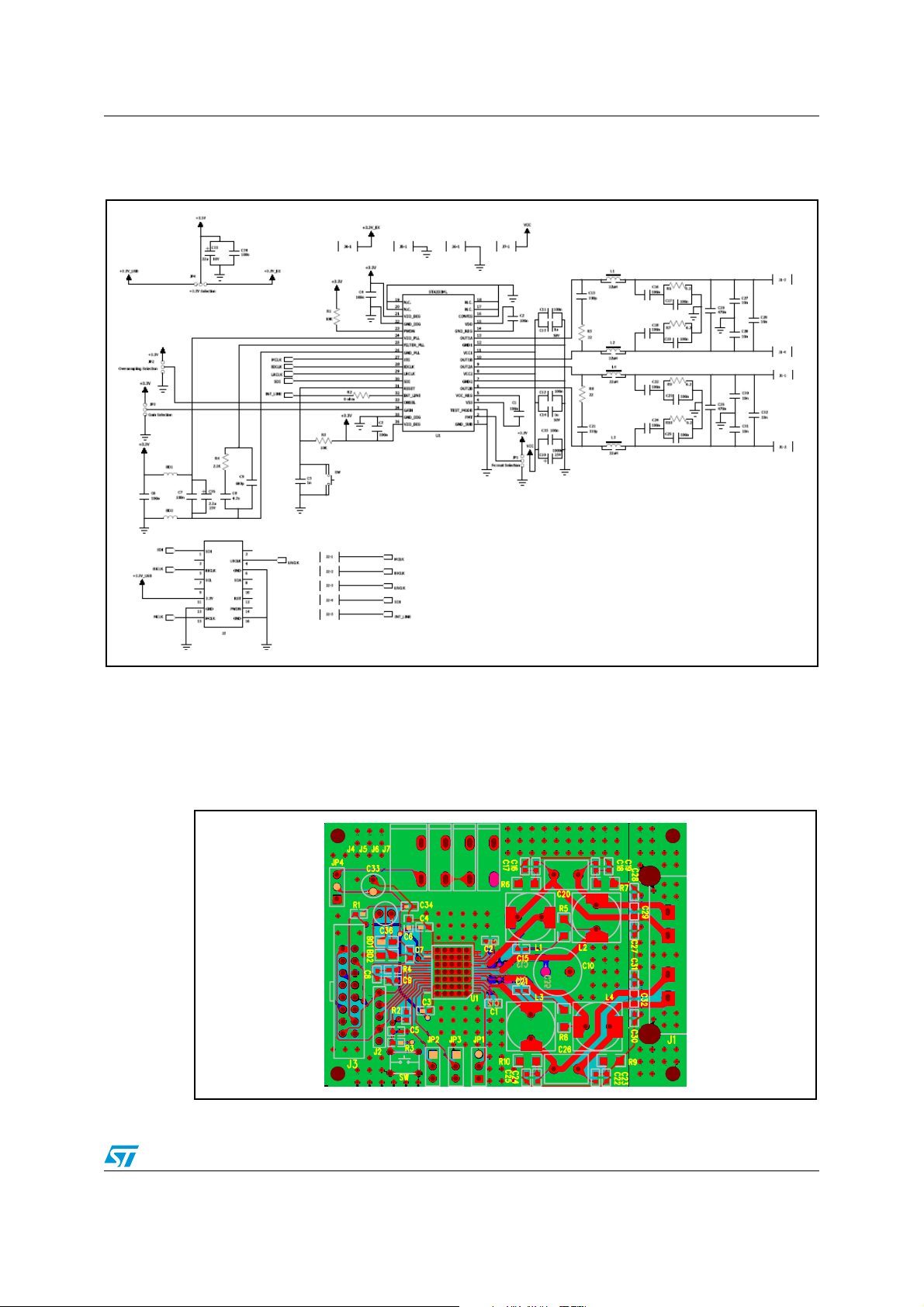

1.3.2 Schematic

Figure 3. Schematic diagram

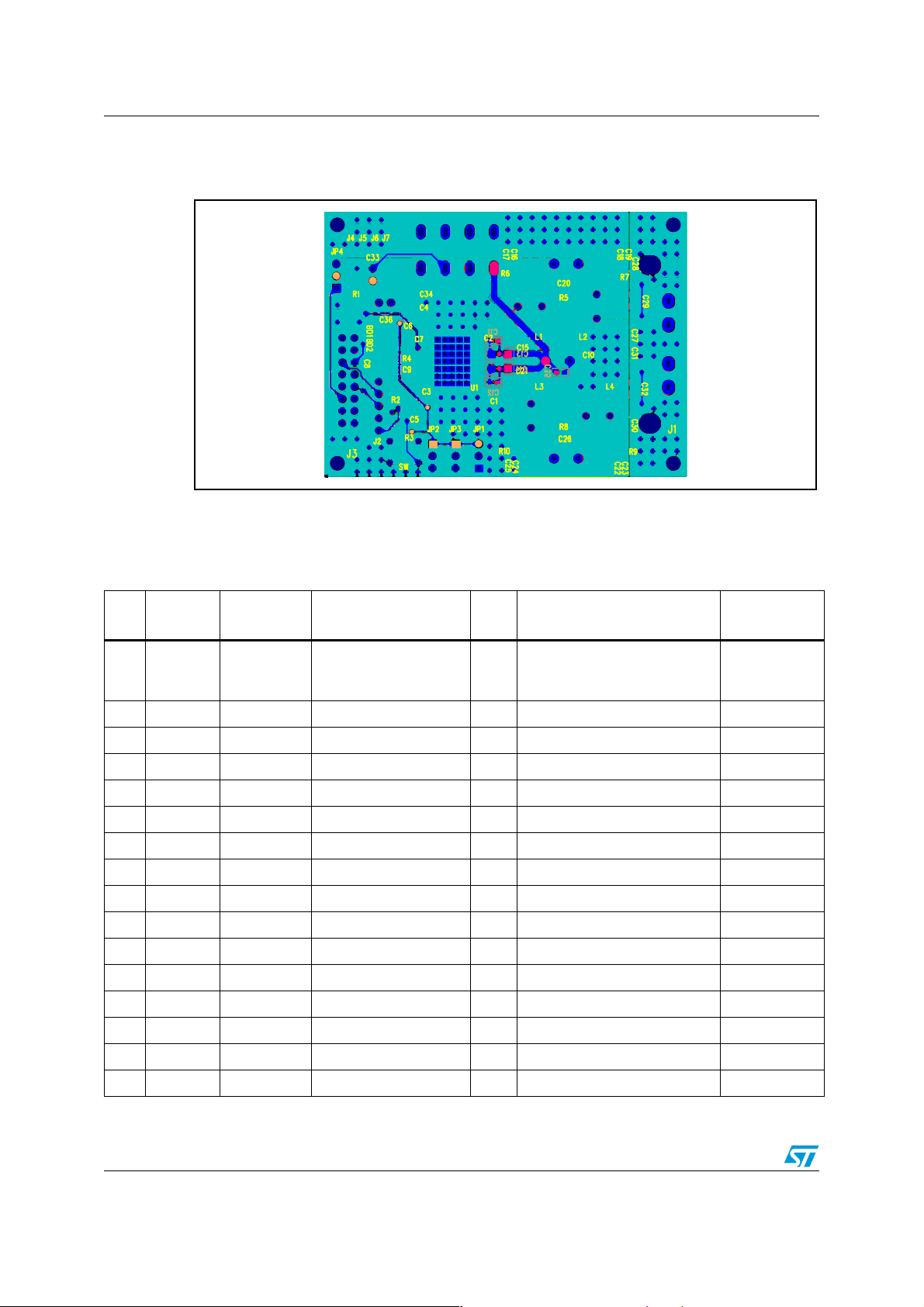

1.4 PCB Layout

1.4.1 Top view of PCB layout

Figure 4. Top layout

5/42

Page 6

Test condition and connection of demo board AN2479

1.4.2 Bottom view of PCB layout

Figure 5. Bottom layout

1.5 BOM list

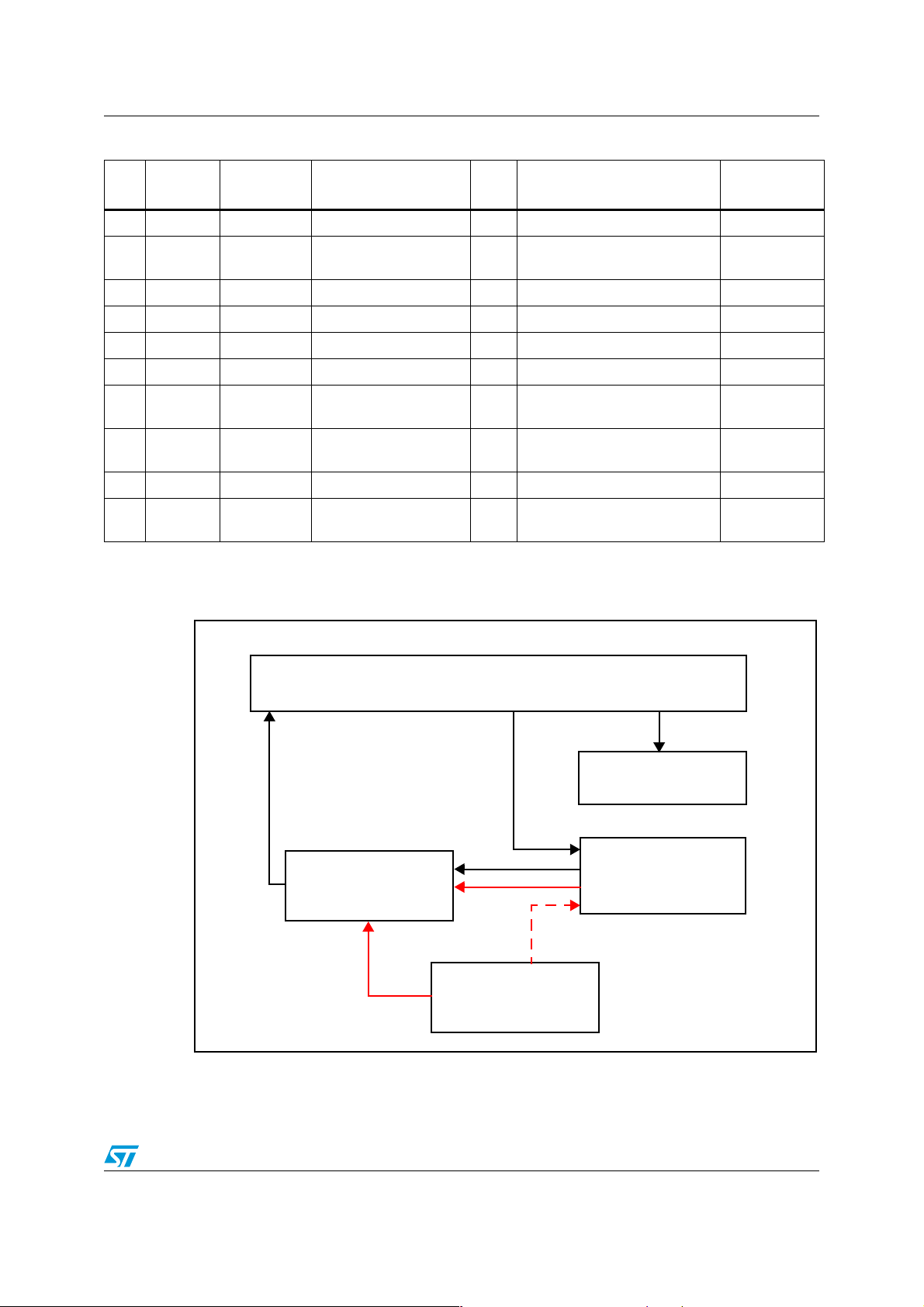

Table 1. BOM

Item

no.

1 CCAP CCAP0603 100 n, 50 V, +/- 10 % 18

2 CCAP CCAP0603 1 n, 50 V, +/- 10 % 1 C5 Murata

3 CCAP CCAP0603 4.7 n, 50 V, +/- 10 % 1 C8 Murata

4 CCAP CCAP0603 680 p, 50 V, +/- 5 % 1 C9 Murata

5 CCAP CCAP0603 330 p, 50 V, +/- 10 % 2 C15, C21 Murata

6 CCAP CCAP0603 10 n, 50 V, +/- 10 % 6 C27, C28, C29, C30, C31, C32 Murata

7 CCAP CCAP1206 1 µ, 50 V 2 C13, C14 Murata

8 ECAP D = 10 mm 1000 µ, 25 V 1 C10 Rubycon

9ECAP D = 7mm22µ, 16 V 1 C33 Rubycon

10 ECAP D = 5 mm 2.2 µ, 25 V 1 C36 Rubycon

11 Chip bead L0805 600 ohm @ 100 MHz 2 BD1, BD2 Murata

12 CRES R0603 10 k +/- 5 % 2 R1, R3 Murata

13 CRES R0603 0 ohm +/- 5 % 1 R2 Murata

14 CRES R0603 2.2 k +/- 5 % 1 R4 Murata

15 CRES R1206 22 ohm +/- 5 % 2 R5, R8 Murata

Type Package Description Qty Reference code Manufacturer

C1, C2, C3, C4, C6, C7, C11,

C12, C16, C17, C18, C19, C22,

C23, C24, C25, C34, C35

Murata

16 CRES R1206 6.2 ohm +/- 5 % 4 R6, R7, R9, R10 Murata

6/42

Page 7

AN2479 Test condition and connection of demo board

Table 1. BOM

Item

no.

17 Test point Through hole 1 x 5 2.54 mm pitch 1 J2 Any source

18 Connector Through hole

19 Jumper Through hole 1 x 3 2.54 mm pitch 4 JP1, JP2, JP3, JP4 Any source

20 IC Through hole STA333ML 1 U1 ST

21 CAP Through hole 470 n 2 C20, C26

22 Connector Through hole WP4-15 1 J1 Song Cheng

23 Connector Through hole FFKDS/H1-5.08 3 J5, J6, J7

24 Connector Through hole FFKDSA1/H1-7.62 1 J4

25 COIL Through hole 22 µH 4 L1, L2, L3, L4 Kwang Sung

26

Type Package Description Qty Reference code Manufacturer

Ta c t

switch

2 x 8 2.54 pitch male

connector

Through hole 6 x 6 Tact switch 1 SW

1 J3 Any source

Phoenix

contact

Phoenix

contact

1.5.1 Test connection

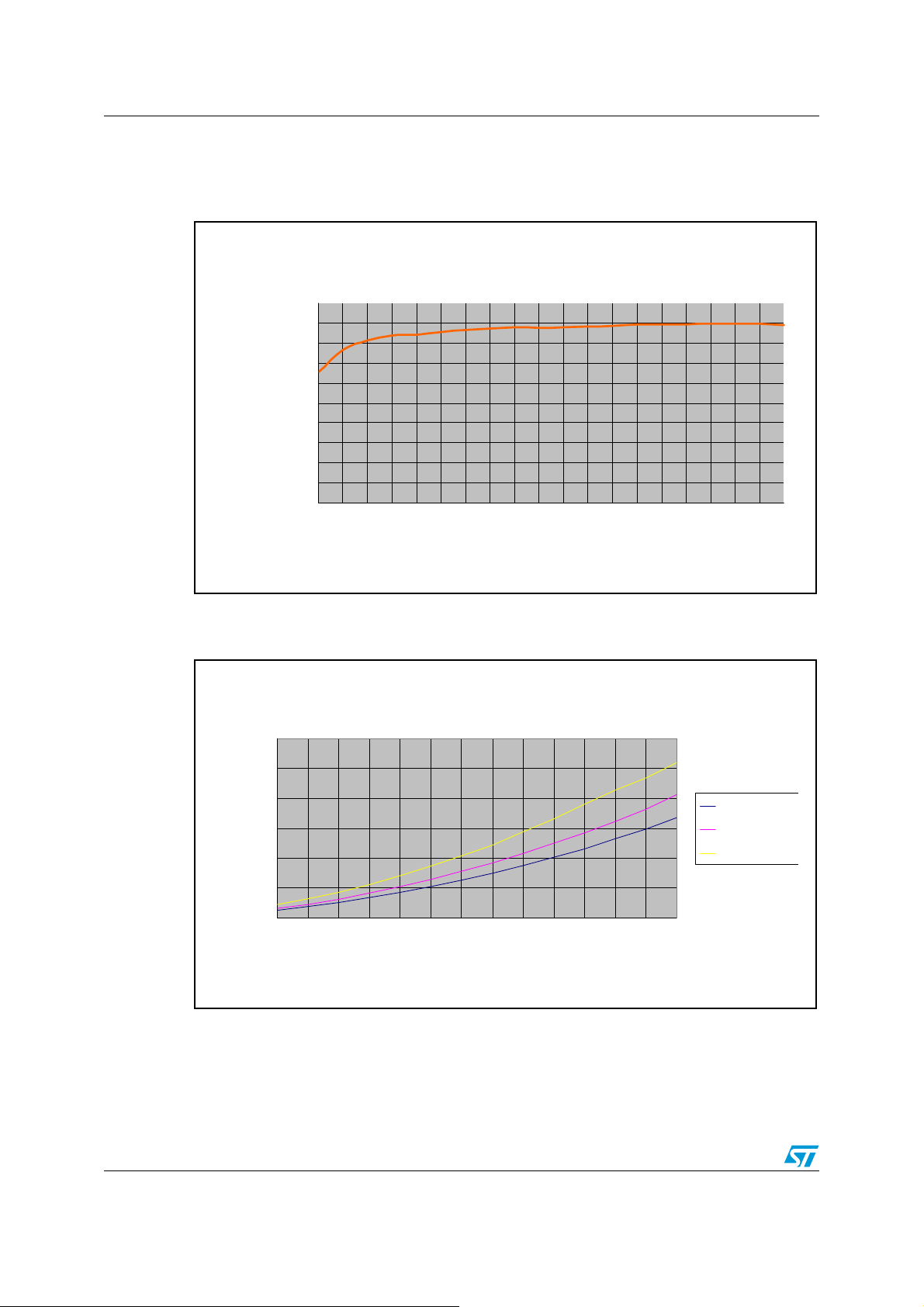

Figure 6. Block diagram of test equipment

Output

to AP

STA333ML

demo board

From 5 V to 18 V

Audio precision equipment

S/PDIF

signal

2

I

S signal

Digital oscilloscope

TDS3034B Tektronix

(DC3V3)

(DC7V)

7V for LPT B’D

DC power supply

Monitor

AP interface

7/42

Page 8

Test curve report AN2479

2 Test curve report

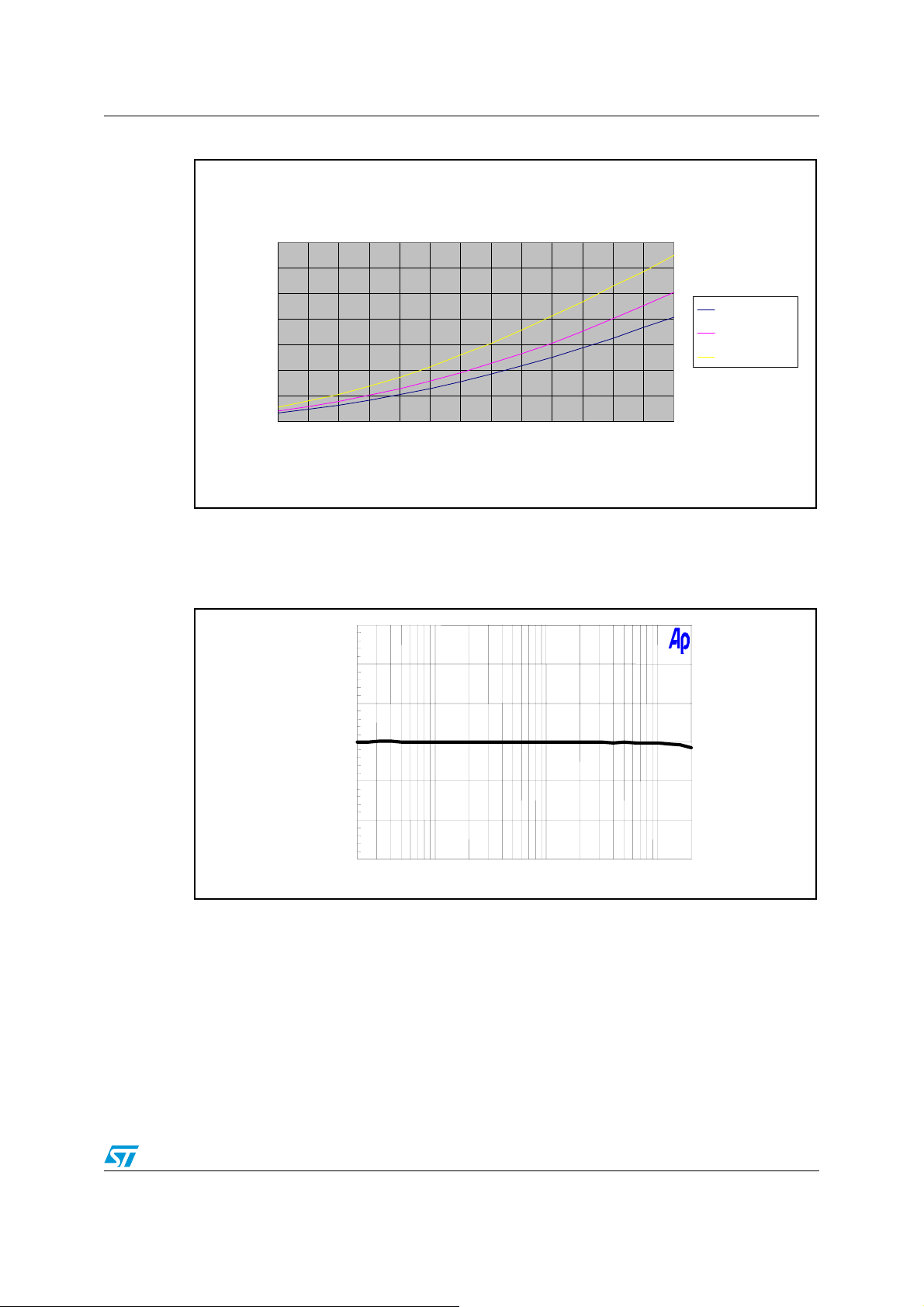

Figure 7. Efficiency versus output power

Efficiency

100.00

90.00

80.00

70.00

60.00

η(%)

50.00

40.00

30.00

20.00

10.00

0.00

1 2 3 4 5 6 7 8 9 1011121314151617181920

Condition: R LOAD =8 ohm; VCC=18 V

Figure 8. Output power versus Vcc

Output Power@1%THD vs. Vcc

30

25

20

15

10

5

Output Power (W)

0

5 6 7 8 9 10 11 12 13 14 15 16 17 18

Vcc (V)

Output Power (W)

Rl=8 Ohm

Rl=6 Ohm

Rl=4 Ohm

8/42

Page 9

AN2479 Test curve report

A

k

k

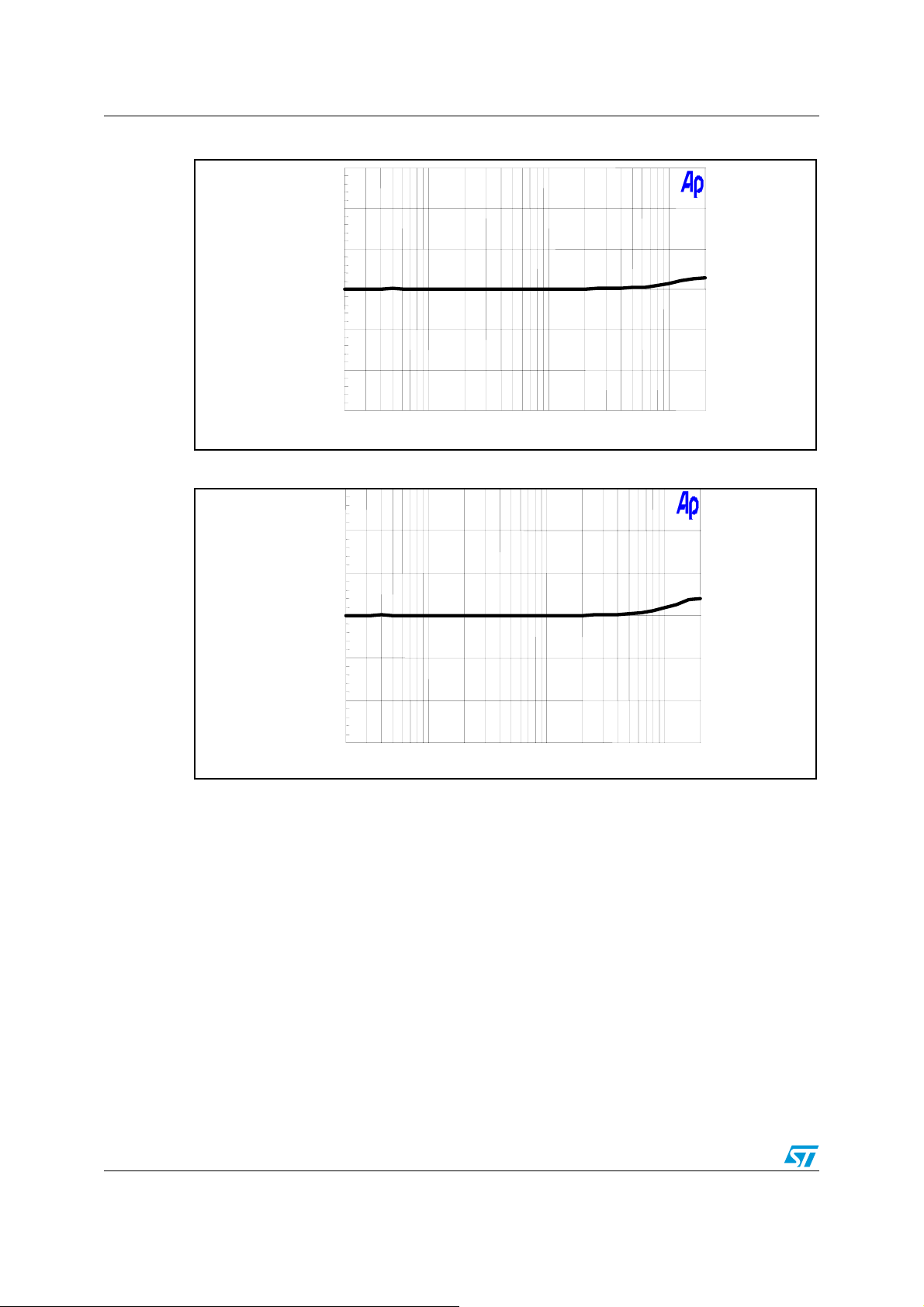

Figure 9. Output power@10% THD vs. supply voltage

Output Power@10%THD vs. Vcc

35

30

25

20

15

10

5

Output Power (W)

0

5 6 7 8 9 101112131415161718

Vcc (V)

Rl=8 Ohm

Rl=6 Ohm

Rl=4 Ohm

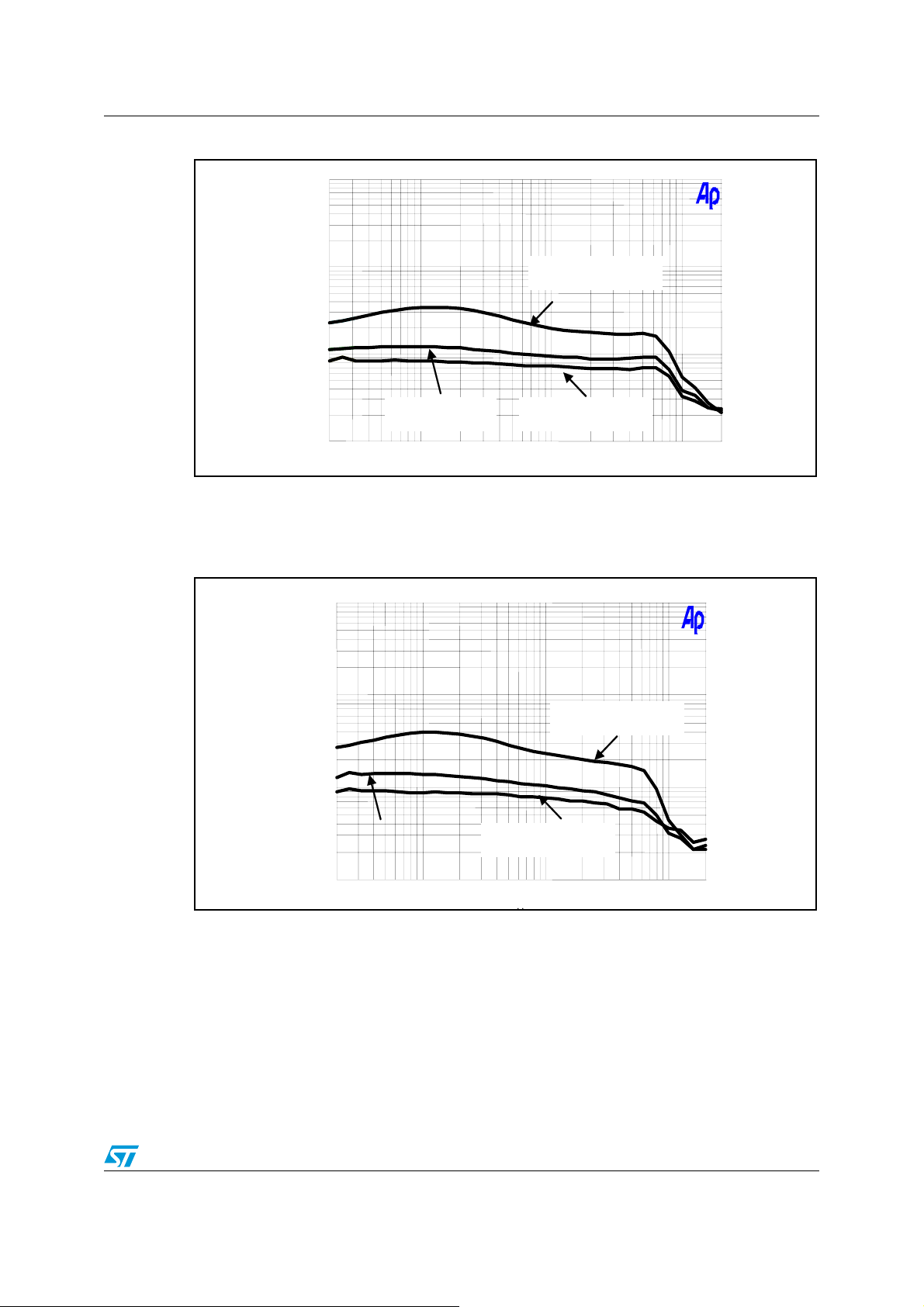

2.1 Frequency Response

Figure 10. 18 V 4 ohm 0 dB: Pout = 1 W@ 1 KHz filter: L = 10 uH, C = 1 uF

+3

+2

+1

d

B

+0

r

-1

-2

-3

20

50 100 200 500 1k 2k 5k 10

20

Hz

9/42

Page 10

Test curve report AN2479

r

A

k

k5k10k

z

+3

A

k

Figure 11. 18 V 6 Ohm 0 dB: Pout = 1 W @ 1 KHz filter: L = 15 uH, C = 680 nF

+3

+2

+1

d

B

+0

-1

-2

-3

20 20

50 100 200 500 1k2

H

Figure 12. 18 V 8 Ohm 0 dB: Pout = 1 W @ 1 KHz filter: L = 22 uH, C = 470 nF

+2

+1

d

B

+0

r

-1

-2

-3

20

50 100 200 500 1k 2k 5k 10k

20

10/42

Page 11

AN2479 Test curve report

020k

k2k5k10k

k

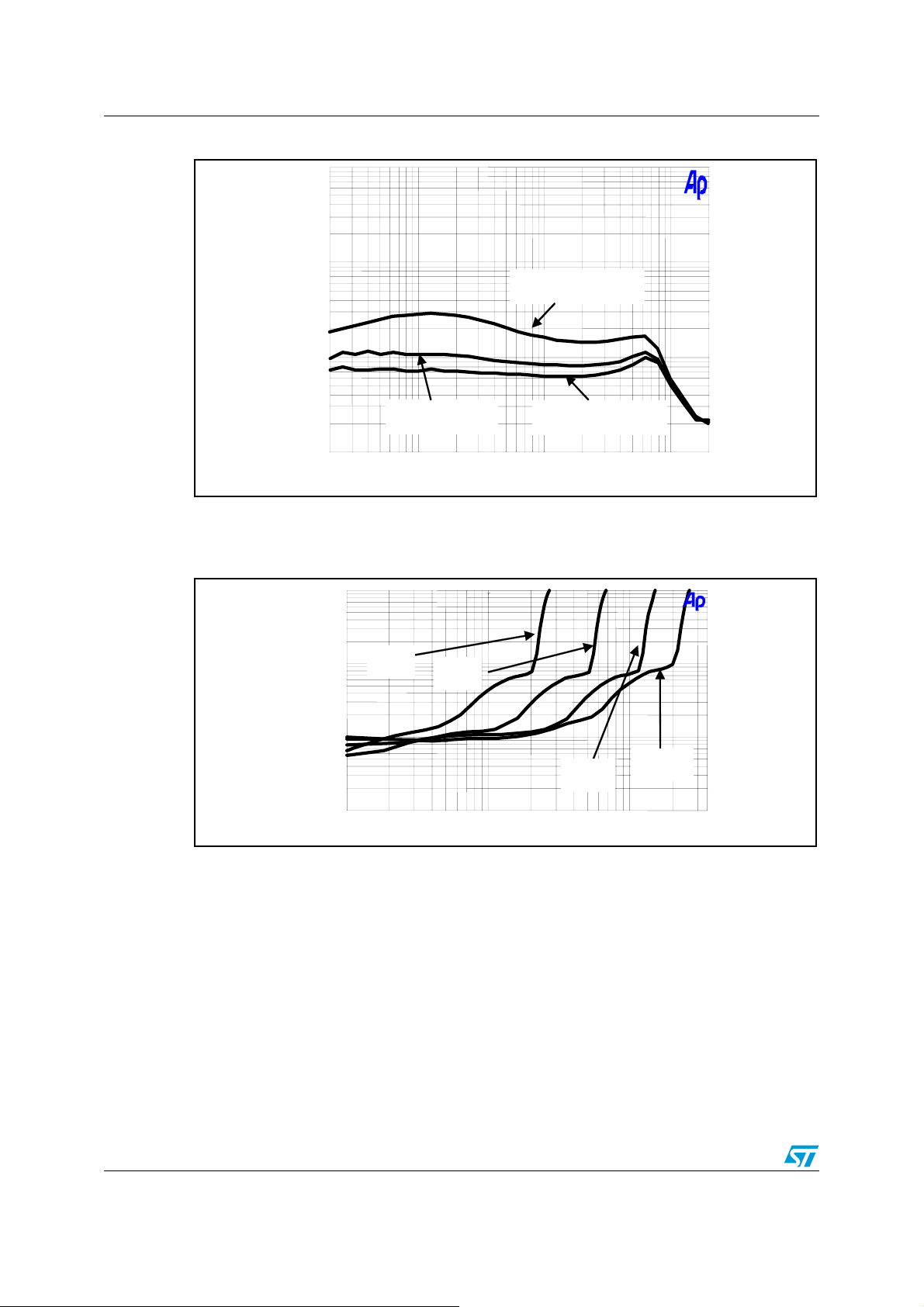

Figure 13. 6 Ohm Pout = 1 W

10

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

2

50 100 200 500 1

Vcc=5 V

Vcc=18 V Vcc=12 V

2.2 THD versus frequency

Figure 14. 4 Ohm Pout = 1 W

10

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

20 20

50 100 200 500 1k 2k 5k 10k

Vcc=5 V

Vcc=18 V

11/42

Page 12

Test curve report AN2479

0

5

20.5125%

m30

m

51020

W

Figure 15. 8 Ohm Pout = 1 W

10

5

2

1

0.5

Vcc=5 V

%

0.2

0.1

0.05

0.02

Vcc=12 V

0.01

20 20k50 100 200 500 1k 2k 5k 10k

2.2.1 THD versus output power

Figure 16. 4 Ohm (1/2)

1

5V

0.

0.1

0.0

0.02

0.01

100

200

8V

500m12

Vcc=18 V

12V

16V

12/42

Page 13

AN2479 Test curve report

0

2

5

20.51 2 5

%

m30

m

m12

51020

W

0

2

5

20.51 2 5

%

m

m

2

51020

W

0

0

2

5

20.51 2 5

%

m30

m

m12

51020

W

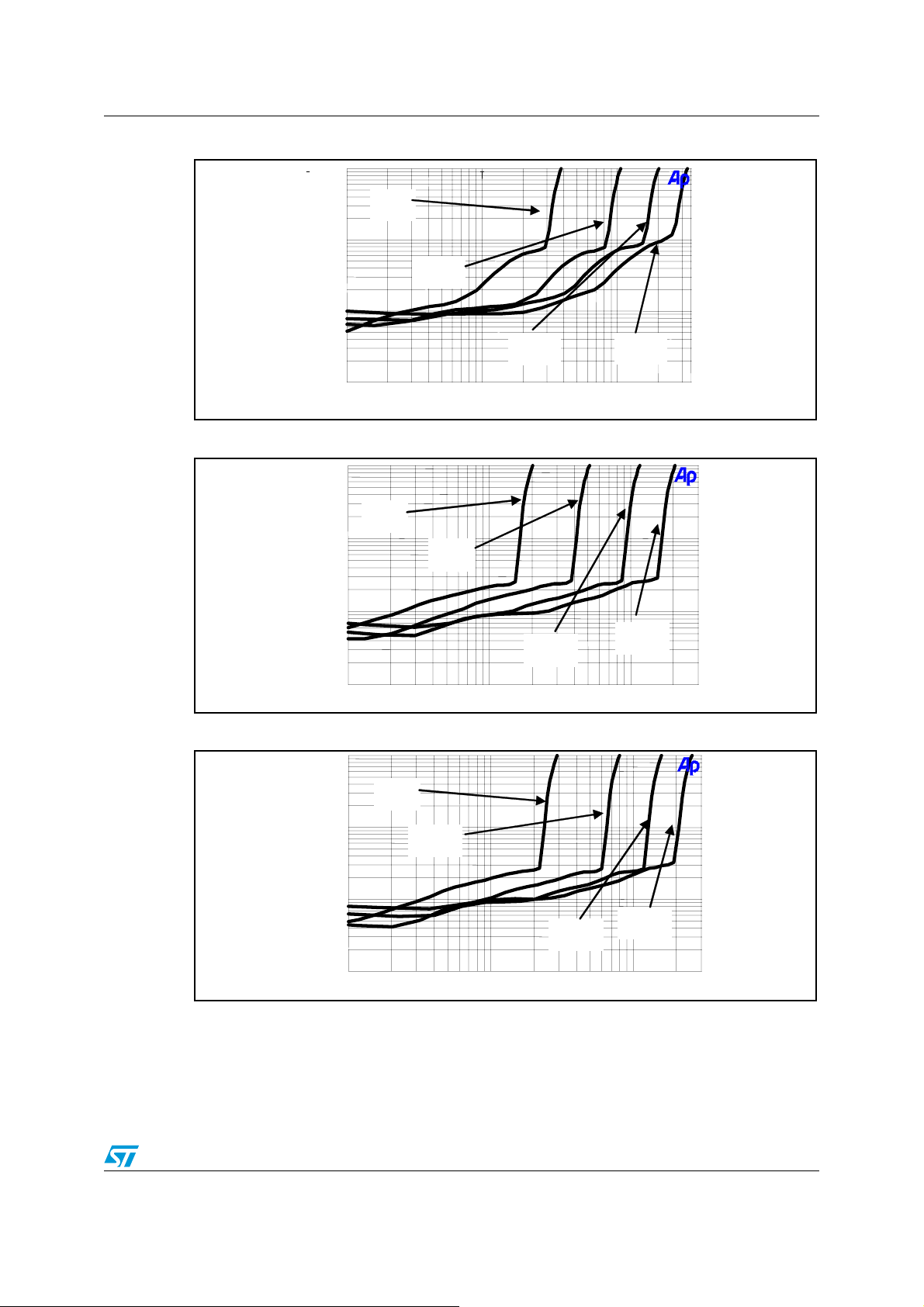

Figure 17. 4 Ohm (2/2)

1

6V

10V

0.

0.1

0.0

0.0

0.01

100

14V

500

18V

200

Figure 18. 6 Ohm (1/2)

1

5V

0.

0.1

0.0

0.0

0.01

100m200

Figure 19. 6 Ohm (2/2)

1

0.

0.1

0.0

0.0

0.01

100

6V

200

500

10V

8V

500

12V

1

14V

16V

18V

3

13/42

Page 14

Test curve report AN2479

0

2

5

20.51 2 5

%

m30

m

m12

51020

W

0

2

5

20.51 2 5 %

m30

m

m12

51020

W

A

Figure 20. 8 Ohm (1/2)

1

5V

0.

0.1

0.0

0.0

0.01

100

Figure 21. 8 Ohm (2/2)

1

0.

0.1

0.0

0.0

0.01

100

200

6V

200

8V

500

10V

500

12V

14V

16V

18V

2.3 FFT

Figure 22. 0 dBFS@ 1 KHz 5 V 4 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-10 0

-11 0

-12 0

-13 0

-14 0

-15 0

20 20k50 100 200 500 1k 2k 5k 10k

14/42

Page 15

AN2479 Test curve report

A

10

A

A

Figure 23. -60 dBFS@ 1 KHz 5 V 4 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20 20k50 100 200 500 1k 2k 5k 10k

Figure 24. 0 dBFS@ 1 KHz 5 V 6 ohm

+

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20 20k50 100 200 500 1k 2k 5k 10k

Figure 25. -60 dBFS@ 1 KHz 5 V 6 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20 20k50 100 200 500 1k 2k 5k 10k

15/42

Page 16

Test curve report AN2479

A

A

Figure 26. 0 dBFS@ 1 KHz 5 V 8 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20 20k50 100 200 500 1k 2k 5k 10k

Figure 27. -60 dBFS@ 1 KHz 5 V 8 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20 20k50 100 200 500 1k 2k 5k 10k

16/42

Page 17

AN2479 Test curve report

A

10

A

Figure 28. 0 dBFS@ 1 KHz 12 V 4 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-15 0

20

Hz

20k50 100 200 500 1k 2k 5k 10k

Figure 29. -60 dBFS@ 1 KHz 12 V 4 ohm

+

+0

-10

-20

-30

-40

-50

-60

d

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20

20k50 100 200 500 1k 2k 5k 10k

17/42

Page 18

Test curve report AN2479

A

A

Figure 30. 0 dBFS@ 1 KHz 12 V 6 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-10 0

-11 0

-12 0

-13 0

-14 0

-15 0

20 50 1 00 200 500 1k 2k 5k 10k

Hz

20k

Figure 31. -60 dBFS@ 1 KHz 12 V 6 ohm

+10

+0

-10

-20

-30

-40

-50

-60

d

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-15 0

20

Hz

20k50 100 200 500 1k 2k 5k 10k

18/42

Page 19

AN2479 Test curve report

A

10

A

Figure 32. 0 dBFS@ 1 KHz 12 V 8 ohm

+10

+0

-10

-20

-30

-40

-50

-60

d

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20 20k50 100 200 500 1k 2k 5k 10k

Hz

Figure 33. -60 dBFS@ 1 KHz 12 V 8 ohm

+

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20

Hz

20k50 100 200 500 1k 2k 5k 10k

19/42

Page 20

Test curve report AN2479

A

10

A

Figure 34. 0 dBFS@ 1 KHz 18 V 4 ohm

+10

+0

-10

-20

-30

-40

-50

-60

d

B

-70

r

-80

-90

-100

-

110

-120

-130

-140

-150

20

Hz

20k50 100 200 500 1k 2k 5k 10k

Figure 35. -60 dBFS@ 1 KHz 18 V 4 ohm

+

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20

Hz

20k50 100 200 500 1k 2k 5k 10k

20/42

Page 21

AN2479 Test curve report

A

A

Figure 36. 0 dBFS@ 1 KHz 18 V 6 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20

Hz

20k50 100 200 500 1k 2k 5k 10k

Figure 37. -60 dBFS@ 1 KHz 18 V 6 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20

Hz

20k50 100 200 500 1k 2k 5k 10k

21/42

Page 22

Test curve report AN2479

A

A

Figure 38. 0 dBFS@ 1 KHz 18 V 8 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20

Hz

20k50 100 200 500 1k 2k 5k 10k

Figure 39. -60 dBFS@ 1 KHz 18 V 8 ohm

+10

+0

-10

-20

-30

-40

-50

d

-60

B

-70

r

-80

-90

-100

-110

-120

-130

-140

-150

20

Hz

20k50 100 200 500 1k 2k 5k 10k

22/42

Page 23

AN2479 Test curve report

r

A

k

k5k10k

r

A

k

k

k

2.4 Cross talk

Figure 40. 5 V 4 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

-60

-70

-80

-90

-100

20 20

50 100 200 500 1k2

Figure 41. 12 V 4 ohm 1 W @ 1 KHz

Hz

d

B

-100

+0

-10

-20

-30

-40

-50

-60

-70

-80

-90

20

50 100 200 500 1k2

Hz

5k 10

20

23/42

Page 24

Test curve report AN2479

A

k

r

A

k

k5k

Figure 42. 18 V 4 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

r

-60

-70

-80

-90

-100

20

50 100 200 500 1k 2k 5k 10k

Hz

20

Figure 43. 5 V 6 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

-60

-70

-80

-90

-100

20

50 100 200 500 1k 2

Hz

10k

20

24/42

Page 25

AN2479 Test curve report

r

A

k

k5k

r

A

k

k5k

Figure 44. 12 V 6 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

-60

-70

-80

-90

-100

20

50 100 200 500 1k 2

Hz

10k

20

Figure 45. 18 V 6 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

-60

-70

-80

-90

-100

20

50 100 200 500 1k 2

Hz

10k

20

25/42

Page 26

Test curve report AN2479

r

A

k

k5k

r

A

k

k5k

Figure 46. 5 V 8 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

-60

-70

-80

-90

-100

20

50 100 200 500 1k 2

Hz

10k

20

Figure 47. 12 V 8 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

-60

-70

-80

-90

-100

20

50 100 200 500 1k 2

Hz

10k

20

26/42

Page 27

AN2479 Test curve report

r

A

k

k5k

Figure 48. 18 V 8 ohm 1 W @ 1 KHz

+0

-10

-20

-30

-40

d

B

-50

-60

-70

-80

-90

-100

20

50 100 200 500 1k 2

Hz

10k

20

27/42

Page 28

Design guideline for PCB schematic and layout AN2479

3 Design guideline for PCB schematic and layout

3.1 Schematic

3.1.1 Main driver for components selection

● Absolute maximum rate: 20 V.

● Bypass capacitor 100 nF in parallel to 1 µF for each power Vcc branch. Preferable

dielectric is X7R.

● Vdd and ground for PLL filter separate of the power supply.

● Coil saturation current compatible with the peak current of the application.

3.2 Decoupling capacitors

There are two different ways to use the decoupling capacitors:

● shared among the channels: the best practise layout route must be used for the board,

● one decoupling system per channel: it is mandatory that the decoupling capacitor must

be as close as possible to the IC pins.

3.2.1 Output filter

Figure 49. Output filter

INxA

INxB

● The key function of a snubber network is to absorb energy from the reactance in the

power circuit. The purpose of the snubber RC network is in order to avoid the high

pulse energy (such as spikes) in the power circuit which can be dangerous to the

system. When using the snubber network, the energy is be transferred to and from the

snubber network, ensuring the system can work safely.

L11

C90

330p

R36

20

L13 22u

22u

C89

100n

C95

100n

C101

100n

C105

100n

R34

6.2

R37

6.2

C98

470n

Damping networkMain filterSnubber

C91

1000p

C103

1000p

C99

1000p

J7

1

2

CON2

28/42

Page 29

AN2479 Design guideline for PCB schematic and layout

● The purpose of the main filter is to remove frequency higher than audible range of

20 KHz. The main filter uses the Butterworth formula to define the cut off frequency,

which must be higher than 20 KHz, otherwise the frequency response is affected.

● The purpose of the damping network is to avoid high frequency oscillation on the output

circuit. After using the damping network the THD can be improved, and can also avoid

the inductive copper on the PCB route when the system is working in high frequency

with PWM or PCM.

Snubber filter

The snubber circuit must be optimized for the application. Starting values are 330 pF in

series to 22 ohm. The power can be defined by the following formula which considers the

power supply, frequency and capacitor value:

P=C*f*(2*V)^2

This power is dissipated in series resistance.

Figure 50. Snubber filter

INxA

C126

330p

R44

22

INxB

Damping network

The C-R-C is a damping network. It is mainly intended for high inductive loads.

Figure 51. Damping filter

C du mp - S

C du mp - P

C du mp - P

C du mp - S

R dump

Rdump

Main filter

The main filter is an L and C based Butterworth filter. The cut-off frequency must be chosen

between the upper limit of the audio band (20 KHz) and the carrier frequency (384 KHz).

29/42

Page 30

Design guideline for PCB schematic and layout AN2479

d

Figure 52. Main filter

C

load

-----------------------------------------------------------------=

22 Π f

L

load

---------------------------------------------------=

2 Π 2× f

F

cutoff

---------------------------------------------------------------------- -=

2 Π× 2C

Recommended values

Rload

Lload

Cload

C dump-S

C dump-P

R dump

8 ohm 4 ohm

22 µH10µH

470 nF 1 µH

100 nF 220 nF

220 nF 220 nF

6.2 2.7

1

cutoff

1

R

load

load

×××

××

×××

R

load

cutoff

L

load

Lload

INxA

C load

Rlo a

INxB

Lload

Recommended power up and power down sequence

Figure 53. Main filter

Vcc

5 V

0V

Vlogic

0V

Reset

0V

Play

30/42

Page 31

AN2479 Design guideline for PCB schematic and layout

3.3 Layout

1. Solder snubber network as close as possible to the IC related pin.

Figure 54. Snubber network

Snubber network

2. Use electrolytic capacitor first to separate the Vcc branches.

Figure 55. Separate the Vcc branches

Separate from the E-cap

3. Minimize the path between Vcc pins and ground pin in order to avoid inductive paths.

Figure 56. Minimized paths between Vcc and GND

GND

Vcc

4. To dissipate the thermal with a ground plane.

31/42

Page 32

Design guideline for PCB schematic and layout AN2479

Figure 57. Dissipate thermal

GND

Big ground plane

5. Solder PLL filter as close as possible to the FILT pin.

Figure 58. PLL filter

6. For differential application create symmetrical paths for the output stage.

PLL filter

32/42

Page 33

AN2479 Design guideline for PCB schematic and layout

Figure 59. Dissipate thermal

Symmetrical

output paths

7. Separate the coil and the neighboring coil are vertical to avoid crosstalk.

33/42

Page 34

Design guideline for PCB schematic and layout AN2479

Figure 60. Avoiding crosstalk

Ver t ical

Ver t ical

8. It is better to use a polyester filter capacitor.

Figure 61. Filter capacitor

Separate the coils to avoid

crosstalk

Filter capacitors should be metal or polyester

9. Consider ground layout. To avoid interference between ground power and small signal

ground, it is necessary to divide the grounding as shown in Figure 62.

34/42

Page 35

AN2479 Design guideline for PCB schematic and layout

Figure 62. Ground layout

Channel ground plane

Power ground plane

10. Thermal layout with large ground (1 of 2 for top and bottom layers).

Figure 63. Thermal layout (1 of 2)

Thermal layout on

the top layer

Thermal layout on

the bottom layer

11. Thermal layout with big ground (2 of 2 for thermal and soldering holes).

The thermal resistance junction at the bottom of the STA333ML to the ambient

obtainable with a ground copper area of 4 x 4 cm and with 35 via holes (see Figure 64).

Figure 64. Thermal layout (2 of 2)

35 via holes ϕ:1.0 mm

12. VCC routing.

The best route for the Vcc supply is one which avoids interference between different

signals (for example, part A is idle whilst part B is working at full load).

35/42

Page 36

Design guideline for PCB schematic and layout AN2479

Figure 65. Vcc routing

Best method to isolate the two channels

amplifiers are isolated from each other

Good Vcc routing

13. Vcc filter for high frequency.

The PWM system works with a fast switch (frequency of 340 KHz approximately) which

means the copper wire works as a coil. In order to avoid this, a ceramic capacitor

should be used to balance resistance. It is a mandatory requirement that ceramic

capacitors are placed as close as possible to the related pins. The distance between

the capacitor and their respective pins should be less then 5 mm in order to minimize

inductive coil effect generated by the copper wire.

36/42

two amplifiers are daisy chained

Bad Vcc routing

Page 37

AN2479 Design guideline for PCB schematic and layout

Figure 66. Vcc filter

Vcc capacitor filter as close to the related pins as

possible. The ceramic capacitors on the bottom

of the PCB close to the IC due to SMD mounting

limitations.

14. Decoupling capacitors.

Solder decoupling capacitors as close as possible to their respective IC pin. This

reduces the inductive coil effect.

Figure 67. Decoupling capacitors

Good amplifier bypassing

capacitors are properly placed

Bad amplifier bypassing, capacitors are

out of order and ground connection is indirect

15. Snubber filters for high frequency spike protection on the PWM.

37/42

Page 38

Design guideline for PCB schematic and layout AN2479

Figure 68. Snubber filter placement

Place snubber circuit as close

as possible to the appropriate

IC pins, and the - and + for

each channel.

Figure 69. Examples of snubber filter placement

Good common mode snubber placement

Good differential snubber placement

Caution: A spike can occur if there > 3 mm distance between the snubber network and the pins. This

can cause damage to the IC. Therefore the distance must be kept below 3 mm.

16. Output routing

38/42

Page 39

AN2479 Design guideline for PCB schematic and layout

Figure 70. Output routing

Good output routing

traces grow wider as space allows

Good output routing

area between outputs is small

Bad output routing

area between outputs is large

17. Thermal layout

Note: The thermal pad must be connected to ground in order to properly set the IC references. It is

necessary to allow the heat to flow freely to all sides of the board including top and bottom.

For optimum heat dissipation it is recommended that the PCB has some solder via holes.

39/42

Page 40

Design guideline for PCB schematic and layout AN2479

Figure 71. Output routing

Good thermal layout (top)

heat can flow freely to the sides

Good thermal layout (bottom)

plenty of copper area

Bad thermal layout (top)

heat flow cut off by the snubbers

Bad output routing (bottom)

little copper area on 3 sides

40/42

Page 41

AN2479 Revision history

4 Revision history

Table 2. Document revision history

Date Revision Changes

06-Dec-2006 1 Initial release.

41/42

Page 42

AN2479

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

42/42

Loading...

Loading...