Page 1

AN2456

Application note

Protection of single battery voltage SLICs for new networks in US market

Introduction

Despite the widespread proliferation of digital technologies, analog networks remain the

most commonly used telecommunication means in the world. Thanks to its simple and

cheap technology, POTS (plain old telephone set) are still utilized extensively.

Figure 1. Schematic of new networks

Central Office / LT

Central Office / LT

Central Office / LT

Central Office / LT

Long lines

Long lines

Long lines

Long lines

(Twisted pair)

(Twisted pair)

(Twisted pair)

(Twisted pair)

O

O

O

O

p

p

p

p

t

t

t

t

i

i

i

i

c

c

c

c

a

a

a

a

l

l

l

l

n

n

n

n

o

o

o

o

i

i

i

i

s

s

s

s

s

s

s

s

i

i

i

i

m

m

m

m

s

s

s

s

n

n

n

n

a

a

a

a

r

r

r

r

t

t

t

t

l

l

l

l

a

a

a

a

c

c

c

c

i

i

i

i

t

t

t

t

p

p

p

p

O

O

O

O

t

t

t

t

r

r

r

r

a

a

a

a

n

n

n

n

s

s

s

s

m

m

m

m

s

s

s

s

n

n

n

n

a

a

a

a

r

r

r

r

t

t

t

t

l

l

l

l

a

a

a

a

c

c

c

c

i

i

i

i

t

t

t

t

p

p

p

p

O

O

O

O

RCO

RCO

RCO

RCO

i

i

i

i

s

s

s

s

s

s

s

s

i

i

i

i

o

o

o

o

n

n

n

n

Short lines

Short lines

Short lines

Short lines

(Twisted pair)

(Twisted pair)

(Twisted pair)

(Twisted pair)

Optical

Optical

Network

Network

n

n

n

n

o

o

o

o

i

i

i

i

s

s

s

s

s

s

s

s

i

i

i

i

m

m

m

m

Unit

Unit

Co

Co

Co

Co

a

a

a

a

x

x

x

x

i

i

i

i

a

a

a

a

l

l

l

l

Central Office / LTCentral Office / LT

Central Office / LTCentral Office / LT

Figure 1 shows a schematic of modern telecom networks that are expected to keep

growing. These networks are essentially made up of two kinds of lines, classical long lines

(several kilometers long) that directly connect the Central Office (CO) to the subscriber, and

short lines (few tens of meters in length) that connect Remote Central Offices (RCO),

Optical Network Units (ONU) or Radio Network Units (RNU) to subscriber terminals. In

these networks SLICs can be present in either conventional Central Offices or any of the

above mentioned remote locations or in Remote Terminals (RT) in the customer premises

which connect to POTS through short lines. The link between these remote locations and

the CO is established by a long high speed digital link e.g. coaxial cable, fiber optic cable,

Wireless Local Loop (WLL). This disparity in line length has given rise to SLICs of two types.

Protection of both kinds of SLICs is a very important aspect in the design of the system. The

purpose of this application note is to propose a complete protection solution for short line

SLICs located in RT in customer premises.

November 2006 Rev 1 1/15

www.st.com

Page 2

Contents AN2456

Contents

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Telecom disturbances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 LCP152xx concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 SLIC protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Lightning surge protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Power crossing protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2/15

Page 3

AN2456 Telecom disturbances

1 Telecom disturbances

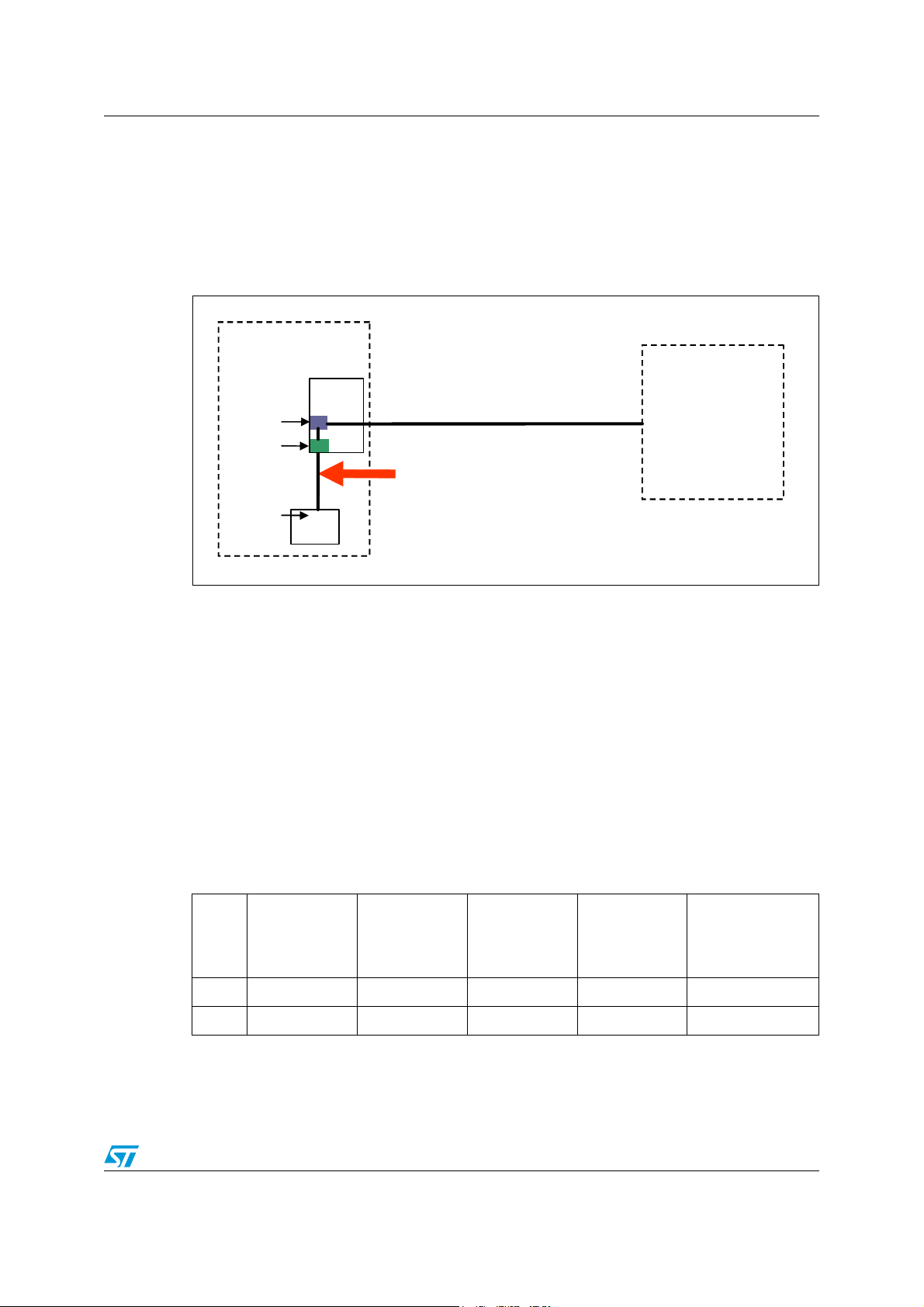

Figure 2 shows the different disturbances that may appear on the telecom line. Among

these, lightning and power crossing are the main considerations for wireline applications.

These disturbances are well defined in the country standards.

Figure 2. Line disturbance causes

Subscriber

Location

Remote

Terminal

SLIC

Protection

Protection

Short

line

POTS

Atmospheric effects (Lightning)

50/60Hz mains disturbances

Electrostatic discharges

Central office

As the purpose of this application note is to illustrate the protection topology needed for

short line SLICs located in RT in customer premises in the US, the standard to be

considered for lightning and power crossing tests is the Telcordia GR1089 Intrabuilding

(equipment port type 4).

The Telcordia GR1089 specifies two acceptance criteria:

● First level: the equipment shall continue to operate properly after the test.

● Second level: the equipment may be damaged, but should not become a fire or

electrical hazard.

For intrabuilding equipment, however, only first level acceptance criterion need to be

satisfied for lightning tests.

Ta bl e 1 and Tab le 2 give the list of lightning and power crossing tests in the Telcordia

GR1089 intrabuilding standard for equipment port type 4.

Table 1. Telecordia GR1089 intrabuilding lightning tests

Voltage and

Surge

Peak voltage

(V)

1 ±800 100 2/10 1 M (on tip and ring)

2 ±1500 100 2/10 1 L

1. M: metallic; L: longitudinal

Peak current

(A)

current

waveforms

(µs)

Repetitions of

each polarity

Tes t

configuration

(1)

3/15

Page 4

Telecom disturbances AN2456

Table 2. Telecordia GR1089 2nd level intrabuilding power crossing test

(equipment port type 4)

Tes t Tes t for

Voltage

(V

rms

Current

)

(A

rms

)

Duration

Test

configuration

(1)

1 Secondary contact 120 25 15 minutes M (on tip and ring), L

1. M: metallic; L: longitudinal

Table 3. IEC61000-4-2 ESD surge standard

Contact discharge Air discharge

Level Test voltage (kV) Level Test voltage (kV)

1212

2424

3638

48415

(1)

X

1. “X” is a level to be defined.

Special X

(1)

Special

Ta bl e 3 shows the most commonly used worldwide standard for ESD. Generally, Level 4 is

required. Such tests appear in the Telcordia GR1089 standard and do apply to equipment

port type 4.

The next section presents the protection concept of the LCP152xx used to protect short line

SLICs with a single battery voltage.

4/15

Page 5

AN2456 LCP152xx concept

2 LCP152xx concept

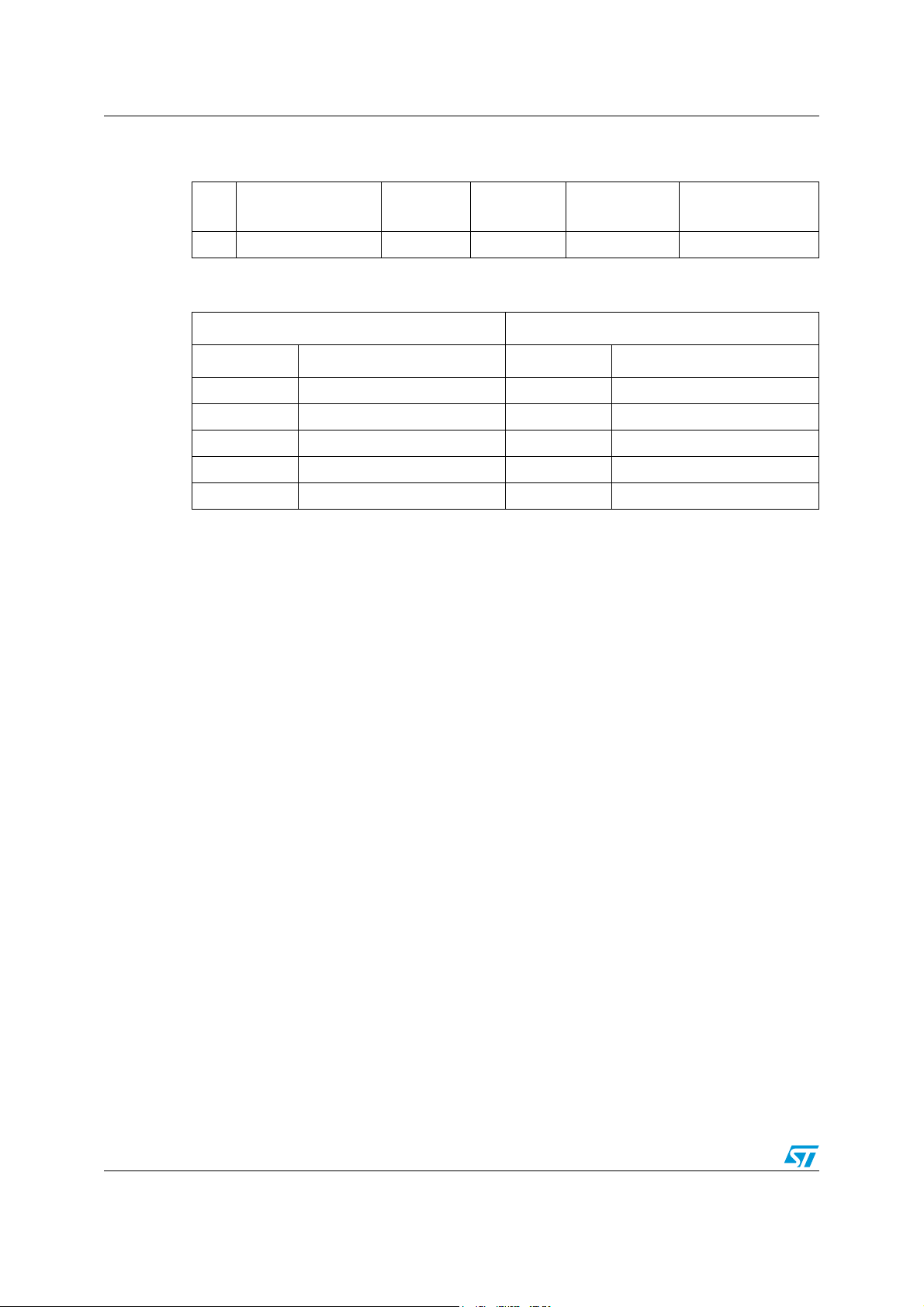

Figure 3. LCP152xx concept behavior

GND

GND

L 1

L 1

L 2

L 2

Fuse1

Fuse1

-Vbat

-Vbat

Fuse2

Fuse2

TIP

TIP

ID1

T1

IG

IG

Gate

Gate

C

C

T1

Th1

Th1

RING

RING

D1

D1

ID1

GND

GND

V Tip

V Tip

V Ring

V Ring

Figure 3 shows the protection circuit using the LCP152xx crowbar concept that can be used

for protection of single battery high voltage SLICs. It’s noteworthy that the schematic does

not show series resistors that would normally be used on wires L1 and L2. This

configuration permits the negative firing threshold V

of the LCP152xx to be programmed at

g

the negative battery voltage of the SLIC (up to -150 V), while the positive clamping threshold

is at the GND.

Figure 4. LCP152xx electrical characteristics

I

I

Vg

Vg

Vf

Vf

Ih

Ih

V

V

It can be seen from the characteristics of the device (shown in Figure 4) that the device

operates asymmetrically.

Under normal operating conditions i.e. when the voltage on the line is between 0 and –V

the LCP152xx is transparent to the application.

For positive surges on either wire (e.g. L1), the diode D1 clamps the surge voltage to its

forward voltage (Vf).

5/15

bat

,

Page 6

LCP152xx concept AN2456

When there is a negative surge voltage bigger than –V

, on either wire (e.g. L1), a current

bat

IG flows through the base of transistor T1 and is injected into the gate of thyristor Th1. This

current causes Th1 to fire and the entire surge current is bypassed to GND. As soon as the

surge current flowing through Th1 drops below the holding current Ih, Th1 switches off.

Figure 5. Example of recommended PCB layout for protection with LCP1521S

LCP1521S

LCP1521S

GND

To Line

To Line

side

side

GND

220nF

220nF

To SLIC

To SLIC

side

side

Figure 5 represents the PCB layout that would typically be used to optimize SLIC protection

using LCP1521S which is in SO-8 package. The LCP152xx is also available in QFN 3x3 6

lead package, and is called LCP152DEE.

A capacitor is connected between the gate of the LCP1521S and the ground in order to

speed up the firing of this device during fast edge surges. As shown in Figure 5 the

capacitor needs to be placed as close as possible to the LCP1521S gate pin and also to the

reference ground track (or plane). Please note that the capacitor is generally present around

the –V

pin of the SLIC. The optimized value for the capacitor is 220 nF.

bat

Such a layout is recommended for the QFN package as well.

Fuse1 and Fuse 2 in Figure 3 are necessary in order for the equipment to be protected from

power crossing disturbances. These are defined in the different country standards. The

fuses shouldn’t open for First level tests, while they must open safely for Second level tests

where the LCP152xx will fail.

6/15

Page 7

AN2456 SLIC protection

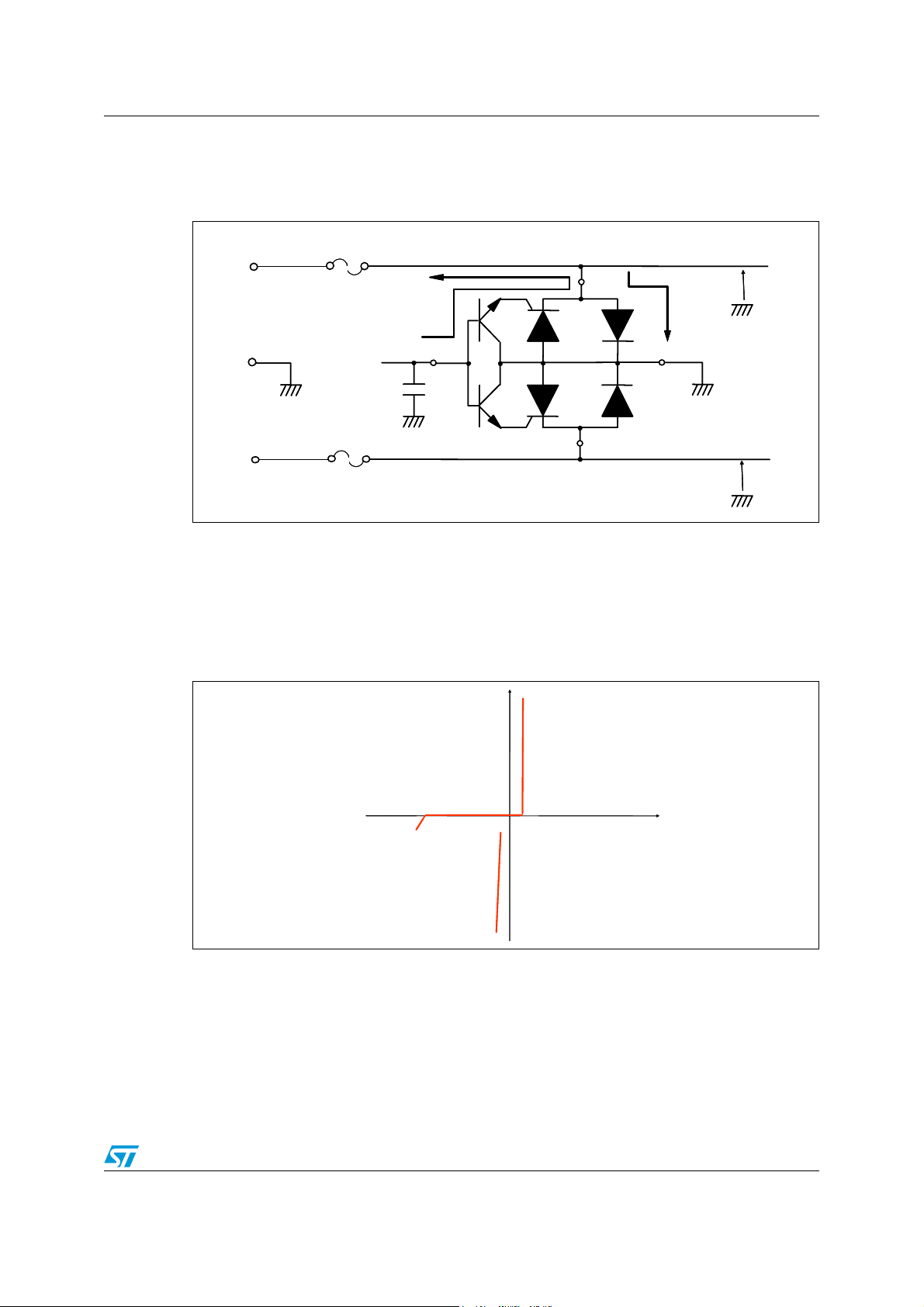

3 SLIC protection

Figure 6. Protection diagram for short line SLICs like STLC3055N located in remote

terminals

TIPL

RINGL

10 W

10 W

TCP500 mA

220 nF

220 nF

TCP500 mA

LCP1521S

G

G

50 W

VTip

50 W

VRing

-Vbat

TIP

TIPS

S

SLIC

SLI

C

STLC3055N

STLC3055

N

RING

RINGS

S

-Vba

-Vbat

Rin

Ring

g

Gen

Gen

.

.

Figure 6 gives the protection circuit of a single battery voltage short line SLIC located in RT

in the US. In this particular application note the STLC3055N has been chosen as an

example of a single battery high voltage SLIC. High voltage SLICs like this, are well suited to

short line applications that require smaller battery and ringing voltages, as compared to long

line applications. Since the ringing signal is smaller, it is generated by the SLIC itself

(without external ring generator). These SLICs are capable of higher voltages (~ -70 V

during ringing) than classical long line SLICs (which generate ~ -56.6 V constant) and are

therefore called high voltage SLICs.

At any given time the line card could be in one of three operating modes i.e. idle mode,

ringing mode or speech mode. The protection circuit used must protect the line card during

all three operating modes. During idle mode there is only the battery voltage on the line and

when in speech or ringing mode the corresponding signal is superimposed on the battery

voltage. The LCP1521S assumes this protection function for all three operating modes.

The fuse TCP500mA from Cooper-Bussman along with a 10 Ω resistor is the serial

protection used to protect the LCP1521S and the EUT against power crossing disturbances.

The 50 Ω resistor is used to limit the current entering the SLIC.

7/15

Page 8

SLIC protection AN2456

Figure 7. STLC3055N evaluation board used to perform tests

Mode select

switches

(D0, D1, D2)

D2 Toggle input

TIP

RING

STLC3055N

LCP1521S

GND

-Vbat

+9V

Figure 7 shows the STLC3055N evaluation board (Ref.:WT546) used to perform the tests.

Please note that, as only lightning protection is managed on this board (by the LCP1521S),

both fuses and 10 Ω resistors have to be added externally in order to assume protection

against power crossing disturbances. The mode the SLIC operates in is selected by the

mode select switches. These switches are single pole, double throw switches, that connect

the pins D0, D1 or D2 to either Ground or V

i.e. logic level 0 or 1 respectively. The D2

CC

toggle input is connected to a square wave at the ring frequency when the SLIC is in ringing

mode. All the results shown here under were from tests performed on this board. The tests

are performed only in Active mode Normal Polarity and Ringing mode as these two modes

test the performance of the protection for both possible battery voltage levels.

Figure 8 shows the voltage on TIP, RING and –V

where TIP is at -3.5V and RING is at -44.5 V (-V

(i.e. TIP = -44.5 V and RING = -3.5 V) by switching D2. Figure 9 shows the TIP, RING and

–V

voltages in the Ringing mode. The voltage on each wire swings between -2.1 V and

bat

-66.4 V (-V

8/15

= -70.9 V) at the ring frequency of 20 Hz.

bat

during Active mode Normal Polarity

bat

= -50.9 V). The polarity can be reversed

bat

Page 9

AN2456 SLIC protection

Figure 8. Tip, ring and –V

mode)

Figure 9. TIP, RING and –V

voltages during active mode normal polarity (ANP

bat

V

Tip

V

Ring

-V

bat

voltages during Ringing mode

bat

V

(20 V/div)

Tip

V

Ring

(20 V/div)

0

(20 V/div)

(20 V/div)

(20 V/div)

3.1 Lightning surge protection

Since the application is dedicated to US, the protection has to be Telcordia GR1089

compliant. Also because it is only meant for intrabuilding SLICs located in RT, this protection

needs only to be able to handle a 100 A (2/10 µs) current surge. Telcordia GR1089

Intrabuilding standard requires the EUT to meet First level compliance criterion for lightning

tests.

-V

bat

0

(20 V/div)

9/15

Page 10

SLIC protection AN2456

g

Figure 10 shows the setup used to perform lightning tests in longitudinal mode. To perform

lightning tests in metallic mode, the set up is similar except that one of the wires (TIP or

RING) is connected to ground and the surge is applied only on the other wire.

Figure 10. Lightning measurement set up for longitudinal tests

50Ω

50Ω

EUT

VTip

VRin

-Vbat

Lightning

Generator

Current probe

Voltage probe

I Surge

Oscilloscope

TIP

RING

TCP500mA

220 nF

TCP500mA

10Ω

10Ω

LCP1521S

Figure 11. +800 V - 100 A (2/10 µs) - Metallic on ring - ringing mode

V

0

V

TIP

STLC3055N

RING

-Vbat

(20 V/div)

Tip

(20 V/div)

Ring

SLIC

Ring

Gen

10/15

-V

I

Surge

bat

(20 V/div)

(20 A/div)

Page 11

AN2456 SLIC protection

Figure 12. -800 V - 100 A (2/10 µs) - Metallic on tip - ANP mode

V

(20 V/div)

Tip

0

V

Ring

-V

bat

I

Surge

(20 V/div)

(20 V/div)

(20 A/div)

Figure 11 and Figure 12 show the behavior of the protection for positive and negative

surges in Ringing mode and ANP mode respectively. The lightning surge is applied in

metallic configuration and is 2/10 µs – 800 V – 100 A per the Telcordia GR1089 Intrabuilding

standard. In both cases it is seen that the peak current is only about 40 A. This is because of

the two 10 Ω resistors on the line (800 V/ (8 Ω +10 Ω) ~ 40 A).

In the case of Figure 11 it is seen that the diode of the LCP1521S on the Ring wire clamps

the voltage to GND when a positive surge is applied to RING. The protection behavior would

be similar if the surge was applied on TIP. We also see that there is little effect of the surge

on V

and –V

Tip

. After the surge, VRing returns to the operating voltage.

bat

Figure 12 shows that the thyristor structure inside the LCP1521S on the TIP wire fires when

a negative surge of higher magnitude than –V

, is applied. When the current through the

bat

thyristor drops below its holding current, the voltage on TIP returns to the operating voltage.

Figure 13. +1500 V - 100 A (2/10 µs) - longitudinal - ANP mode

V

(20 V/div)

Tip

0

(20 V/div)

V

Ring

(20 V/div)

-V

bat

I

(20 A/div)

Surge

11/15

Page 12

SLIC protection AN2456

Figure 14. -1500 V - 100 A (2/10 µs) - longitudinal - ringing mode

0

(20 V/div)

V

Ring

V

(20 V/div)

Tip

-V

(20 V/div)

bat

(20 A/div)

I

Surge

Figure 13 and Figure 14 also show the behavior of the protection for positive and negative

surges in ANP mode and Ringing mode respectively. The lightning surge is applied in

longitudinal configuration and is 2/10 µs – 1500 V – 100 A per the Telcordia GR1089

Intrabuilding standard. In both cases it is seen that the peak current is only about 55 A. This

is because of the two 10 Ω resistors on the line (1500 V/ (15 Ω +10 Ω) ~ 55 A).

The behavior of the protection for the 1500 V surge is the same as it is for the 800 V surge,

the only difference being that the protection on both wires act, due to the longitudinal

application of the pulse.

Although, the protection solution was tested for all lightning tests required by the Telcordia

GR1089 Intrabuilding standard, for reasons of brevity, only some of them are illustrated

above. All results are available upon request. The SLIC returned to its initial operating

conditions after the surge application for all tests, i.e. the protection solution provides the

SLIC, Telcordia GR1089 First level compliance.

3.2 Power crossing protection

The test setup used to perform the power crossing tests is exactly the same as the setup for

lightning tests (shown in Figure 10 on page 10), with the AC surge generator connected

instead of the lightning surge generator.

As seen in Tab le 2 ., the Telcordia GR1089 Intrabuilding standard requires the equipment

(Port type 4) to meet Second level compliance criterion for 120 V

crossing test.

rms

, 25 A

, 15 min power

rms

12/15

Page 13

AN2456 SLIC protection

Figure 15. 120 V

Figure 16. 120 V

rms

rms

- 25 A

- 25 A

- 15 min. - metallic on tip - ANP mode

rms

- 15min. - longitudinal - ringing mode

rms

0

V

(20 V/div)

Tip

V

Ring

-V

bat

I

Surge

V

(20 V/div)

Tip

(20 V/div)

(20 V/div)

(20 A/div)

0

(20 V/div)

V

Ring

(20 V/div)

-V

bat

I

(20 A/div)

Surge

Figure 15 and Figure 16 show the protection behavior in ANP mode and Ringing mode

when the power cross is applied in metallic configuration on TIP and in Longitudinal

configuration respectively. The current is 11.3 A

11.3 A

). It is seen that the power is engaged on the wire for 1.5 to 2 cycles before the fuse

pk

(120 V

pk

/ (4.8 Ω+10 Ω) ~ 8.1 A

rms

rms

~

opens. During this time it is noted that the voltage is clamped to GND by the diode inside

LCP1521S for the positive half cycles. During the negative half cycles, the thyristor structure

inside LCP1521S fires when the voltage exceeds –V

. We see some disturbance in –V

bat

bat

voltages but it returns to initial condition after the test. In Figure 15 the protection on Ring

doesn’t react because the power cross is only applied on TIP. But however there is a small

disturbance on VRing during the surge due to the disturbance on -V

bat

.

13/15

Page 14

Conclusion AN2456

The protection solution was tested for all configurations, but only two are illustrated for

brevity. All other test results are available upon request. The TCP 500 mA fuse opened

safely in all cases (i.e. without smoke or fire) and ensured Telcordia GR1089 Second level

compliance. There was no damage to the SLIC or even the LCP1521S after the power cross

tests. Although not required by the Telcordia standard, this sort of co-ordination of serial and

parallel protection reduces the system down time and keeps system recovery costs low after

a power cross in the field.

4 Conclusion

The purpose of this application note was to propose a complete protection solution for single

battery voltage SLICs located in remote terminals, at customer premises, in the US.

Therefore, the standard that has been considered for lightning and power crossing tests in

order to validate this protection solution is the Telcordia GR1089 Intrabuilding (equipment

port type 4).

The protection solution consists of programmable overvoltage protection and fuses for

overcurrent protection. The overvoltage protection device is an ST product based on the

crowbar concept (LCP1521S). While the series protection is mainly done using fuses TCP

500 mA from Cooper-Bussman. There is a 10 Ω resistor on each wire that makes the fuses

TCP500mA compatible with the LCP1521S and makes the solution compliant with the

Telcordia GR1089 Intrabuilding standard.

All the tests mentioned in the tables of the Telcordia GR1089 Intrabuilding standard were

performed on the STLC3055N evaluation board shown in Figure 7 on page 8, with both

external fuses and 10 Ω resistors. All test results are available upon request. These results

showed that there was no impact on either of the fuses during lightning tests, while they

opened safely, in time to protect the SLIC and the LCP1521S, during power crossing tests.

The presented protection topology is an effective protection solution for single battery

voltage SLICs located at remote terminals in the US. The application note is intended only

as a guideline. While the STLC3055N is a good example of a single battery voltage SLIC

that one might see in a remote terminal, SLIC designs are excessively variant and therefore

exact implementation of the above circuitry for a different SLIC may or may not be the most

efficient solution.

5 Revision history

Date Revision Changes

03-Nov-2006 1 Initial release.

14/15

Page 15

AN2456

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

15/15

Loading...

Loading...