Page 1

AN2451

Application note

ST7540 FSK powerline transceiver

design guide for AMR

Introduction

The ST7540 reference design has been developed as a useful tool to demonstrate how a

small, high-performance powerline node can be built using the ST7540 FSK transceiver.

With this reference design, it is possible to evaluate the ST7540 features, in particular, its

transmitting and receiving performances through actual communication on the power line.

The ST7540 reference design may be considered to be composed of three main sections:

● Power supply section, specifically tailored to match powerline coupling requirements

and to operate within a wide range of the input mains voltage

● Modem and crystal oscillator section

● Line coupling interface section

The coupling interface is designed to allow the ST7540 FSK transceiver to transmit and

receive on the mains using 72 kHz carrier frequencies, within the European CENELEC

standard A-band specified for automatic meter reading.

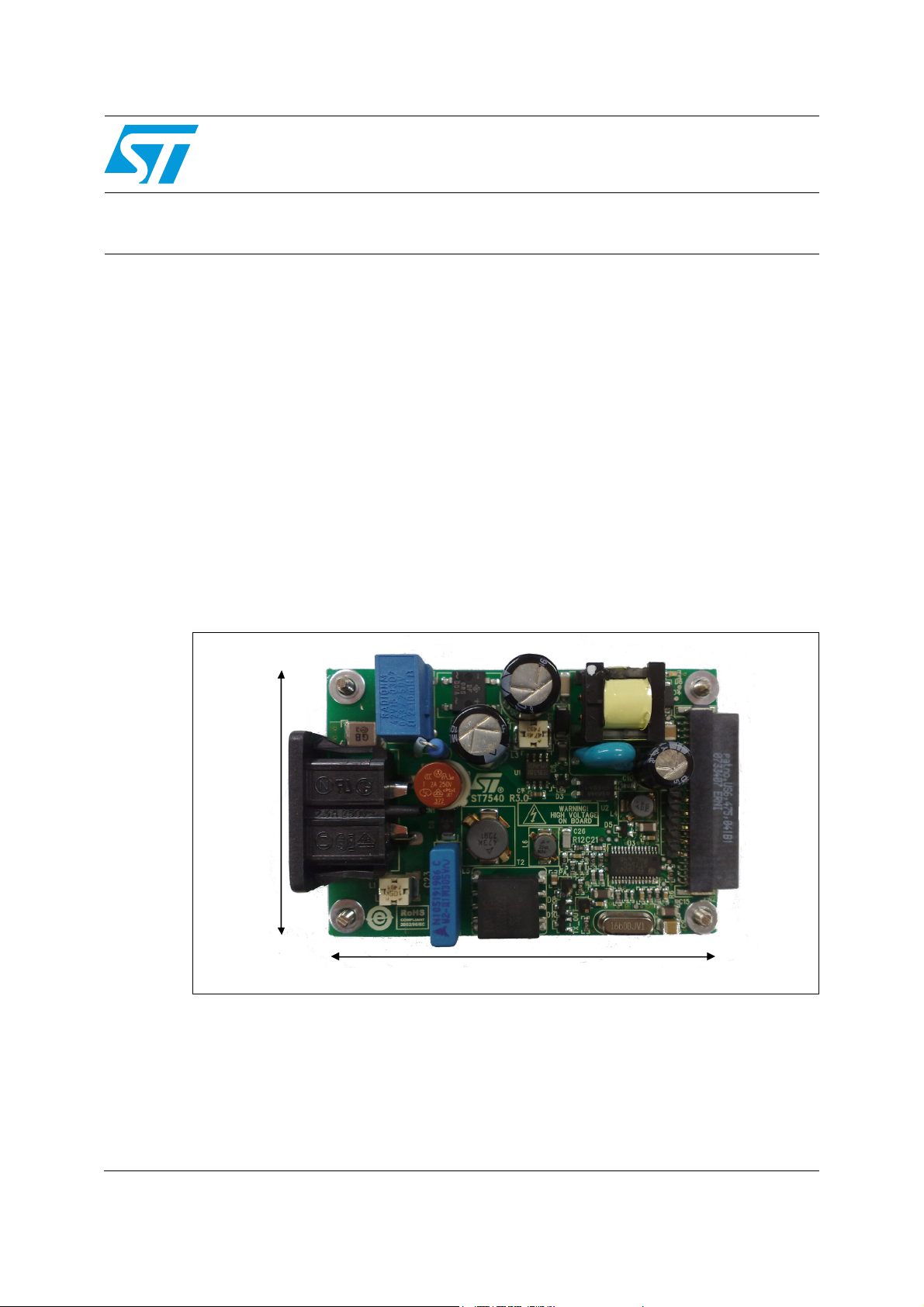

Figure 1. ST7540 reference design board with outline dimensions

52 mm

76 mm

As it can be seen from the picture above, a special effort has been made to obtain a very

compact reference design board, while keeping the focus on transmission and receiving

performances.

Note: The information provided in this application note refers to EVALST7540-2 reference design

board.

January 2010 Doc ID 12791 Rev 3 1/55

www.st.com

Page 2

Contents AN2451

Contents

1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 ST7540 FSK powerline transceiver description . . . . . . . . . . . . . . . . . . 10

4 Evaluation tools description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Board description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Coupling interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.1 Tx active filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.2 Tx passive filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1.3 Rx passive filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.4 Input impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Conducted disturbances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2.1 Conducted emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2.2 Noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3 Thermal design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 Oscillator section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.5 Surge and burst protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.6 50-pin connector for the EVALCOMMBOARD . . . . . . . . . . . . . . . . . . . . . 35

5.7 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Performance and ping tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Application ideas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Three-phase architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 Zero crossing detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.3 Received Signal Strength Indicator (RSSI) . . . . . . . . . . . . . . . . . . . . . . . 44

7.4 Non-isolated coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.5 DC powerline applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.6 110 and 132.5 kHz coupling circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2/55 Doc ID 12791 Rev 3

Page 3

AN2451 Contents

Appendix A Board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

List of normative references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Doc ID 12791 Rev 3 3/55

Page 4

List of figures AN2451

List of figures

Figure 1. ST7540 reference design board with outline dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Typical curve for output current limit vs. RCL value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

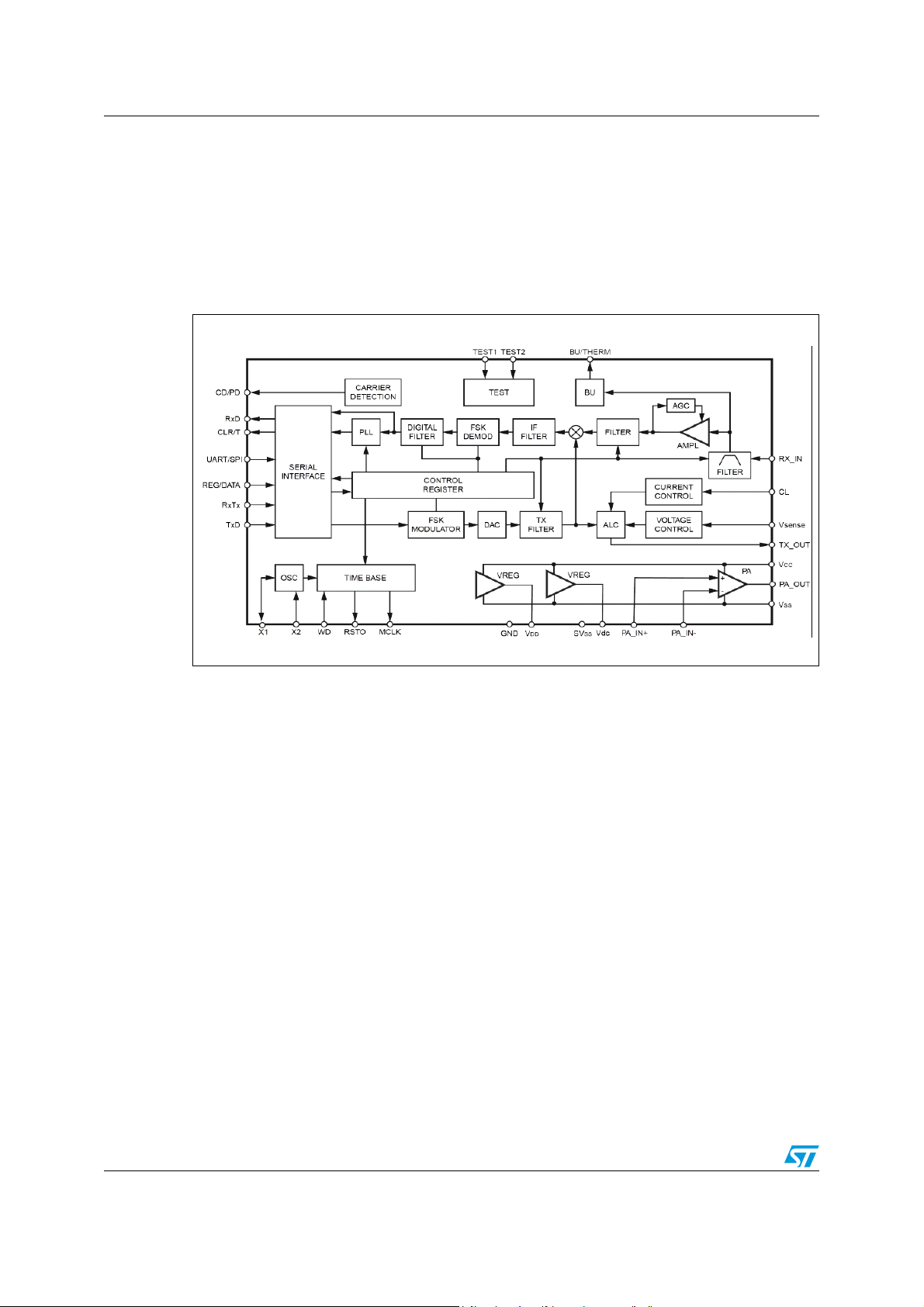

Figure 3. ST7540 Transceiver block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Complete evaluation system including a PC, an EVALCOMMBOARD and the EVALST7540-

2 board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

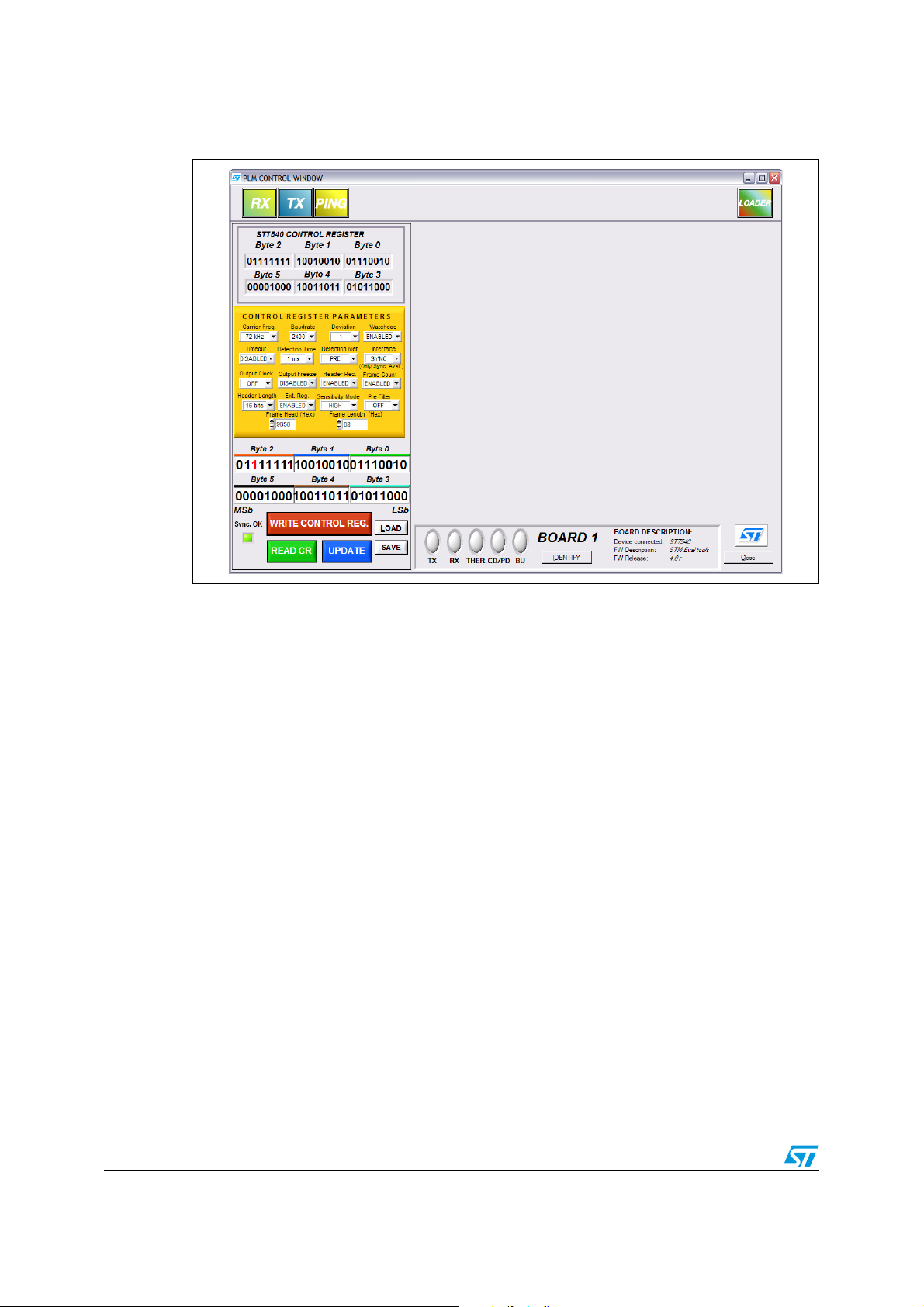

Figure 5. ST7540 powerline modem demonstration kit with control register window . . . . . . . . . . . . 12

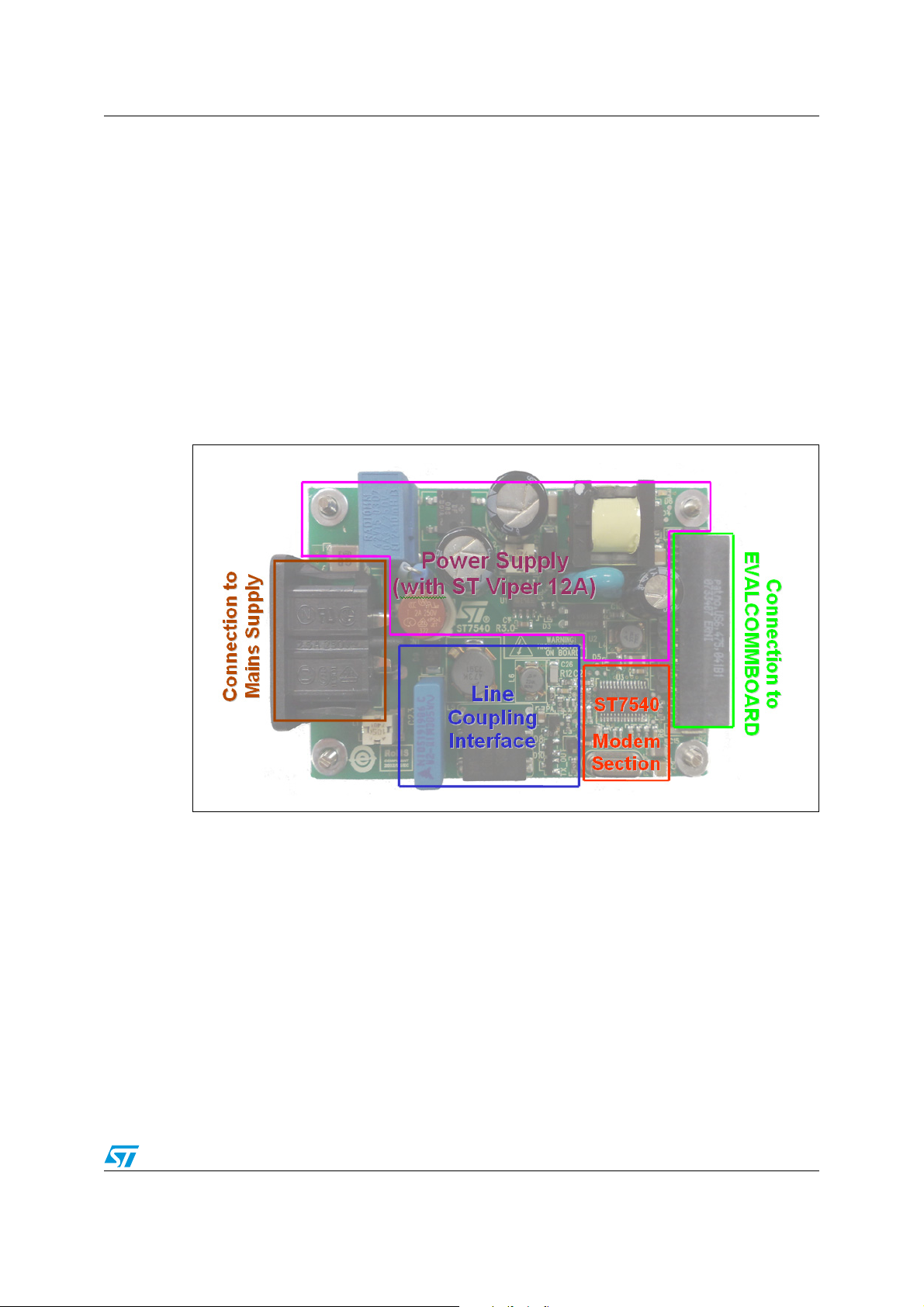

Figure 6. Positioning of the various sections of the board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

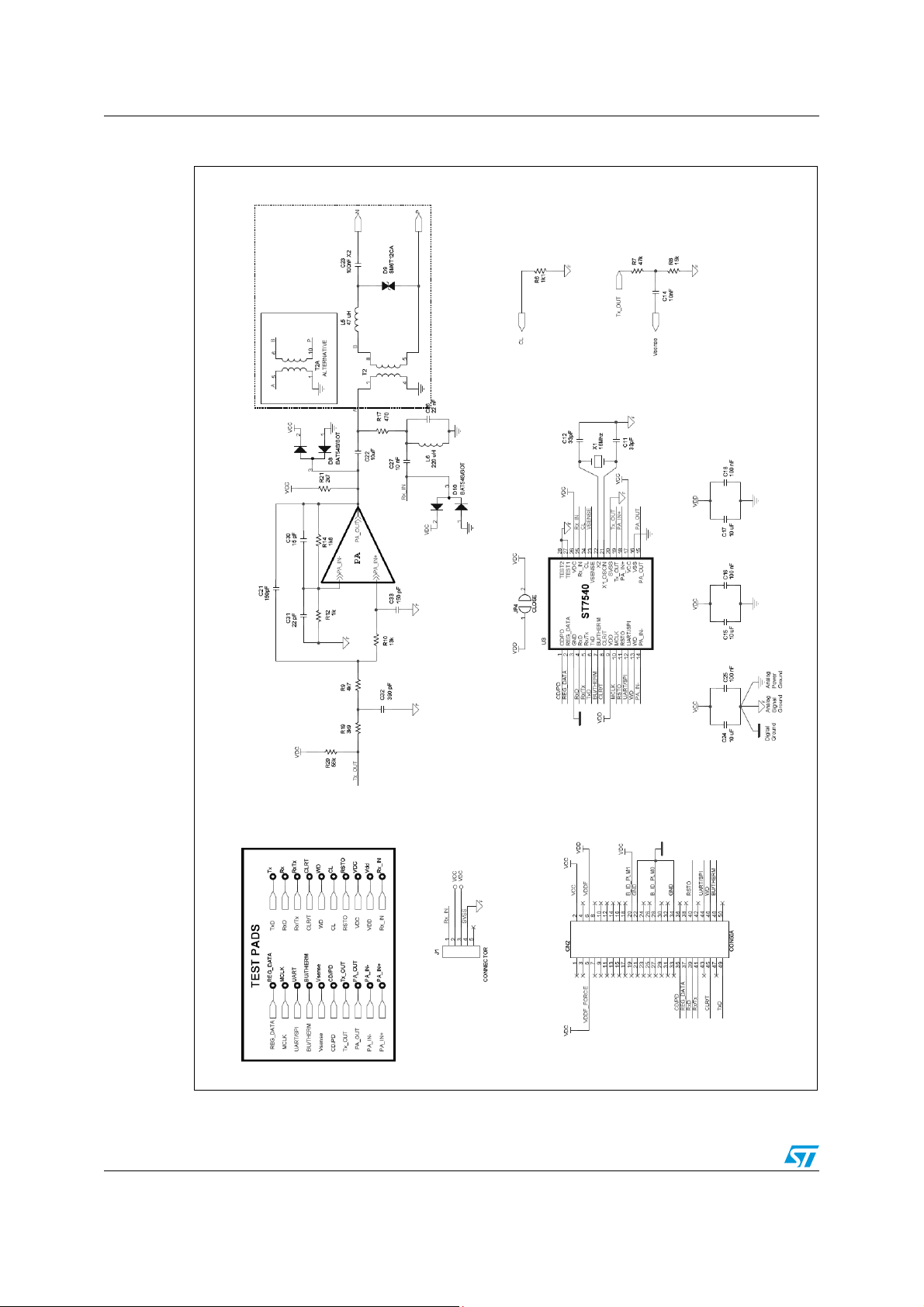

Figure 7. Modem and coupling interface schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. Power supply schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 9. Schematic of Rx and Tx filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. Measured frequency response of the Tx active filter (typical curve) . . . . . . . . . . . . . . . . . . 20

Figure 11. Simulated frequency response of the Tx active filter with components tolerance effect. . . 20

Figure 12. Measured frequency response of the Tx active + passive filters connected to the CISPR net-

work (typical curve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 13. Simulated frequency response of the Tx active + passive filters connected to the CISPR network with the components tolerance effect22

Figure 14. Measured frequency response of the Rx passive filter (typical curve) . . . . . . . . . . . . . . . . 23

Figure 15. Simulated frequency response of the Rx passive filter with components tolerance effect . 24

Figure 16. Measured input impedance magnitude of coupling interface in Tx mode (typical curve) . . 25

Figure 17. Measured input impedance magnitude of coupling interface in Rx mode (typical curve). . 25

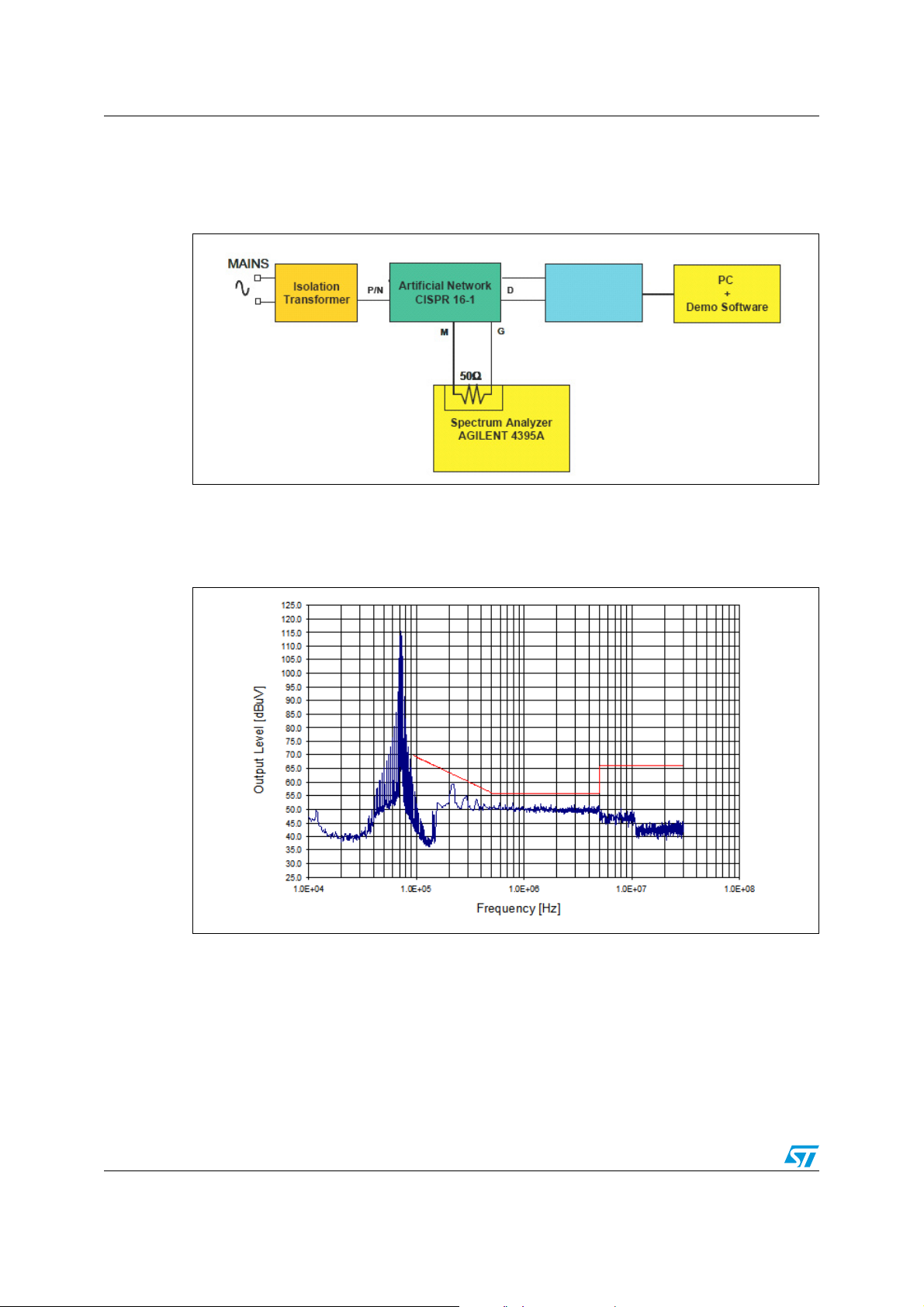

Figure 18. Conducted emissions test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 19. Output spectrum (typical) at 72 kHz, 2400 baud, deviation 1, mains 220Vac . . . . . . . . . . 26

Figure 20. Narrow-band conducted interference test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 21. Measured BER vs. SNR curve (typical), white noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 22. SNR vs. frequency curve (typical) at BER = 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 23. PCB copper dissipating area for ST7540 reference design board . . . . . . . . . . . . . . . . . . . 29

Figure 24. Packet-fragmented transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 25. Equivalent model of the thermal impedance qJA of the HTSSOP28 package with exposed

pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 26. Output current vs. supply current typical curve for ST7540 in Tx mode . . . . . . . . . . . . . . . 31

Figure 27. Dissipated power vs. load impedance modulus typical curve for ST7540 reference design

board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 28. A recommended oscillator section layout for noise shielding . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 29. Common mode disturbances protection - positive disturbance . . . . . . . . . . . . . . . . . . . . . 33

Figure 30. Common mode disturbances protection - negative disturbance . . . . . . . . . . . . . . . . . . . . . 34

Figure 31. Differential mode disturbances protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 32. Scheme of the connector for the EVALCOMMBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 33. Typical waveforms at 230 Vac: open load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 34. Typical waveforms at 230 Vac: full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 35. Typical waveforms at 265 Vac: short-circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 36. Typical waveforms at 265 Vac: startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 37. Load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 38. SMPS efficiency curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 39. ST7540 powerline modem demonstration kit window for the master board . . . . . . . . . . . . 41

Figure 40. Scheme of principle for three-phase architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 41. Schematic of a zero crossing detection circuit for non-isolated coupling . . . . . . . . . . . . . . 43

Figure 42. Schematic of a zero crossing detection circuit for isolated coupling. . . . . . . . . . . . . . . . . . 44

Figure 43. ZC_OUT vs. AC mains waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4/55 Doc ID 12791 Rev 3

Page 5

AN2451 List of figures

Figure 44. Peak detector electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 45. Measured DC_OUT Vs. AC_IN peak detector response . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 46. Example schematic for non-isolated solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 47. Line coupling interface for 110 kHz channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 48. Line coupling interface for 132.5 kHz channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 49. PCB layout - component placing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 50. PCB layout - top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 51. PCB layout - bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Doc ID 12791 Rev 3 5/55

Page 6

List of tables AN2451

List of tables

Table 1. Electrical characteristics of the ST7540 reference design . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Output voltage level setting through Vsense partitioning - typical values . . . . . . . . . . . . . . . 8

Table 3. Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 4. ST parts on the ST7540 reference design board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 5. Line coupling transformer specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 6. Noise immunity test settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 7. 50-pin connector digital signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 8. 50-pin connector analog signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 9. 50-pin connector power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 10. SMPS specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 11. SMPS transformer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 12. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6/55 Doc ID 12791 Rev 3

Page 7

AN2451 Electrical characteristics

1 Electrical characteristics

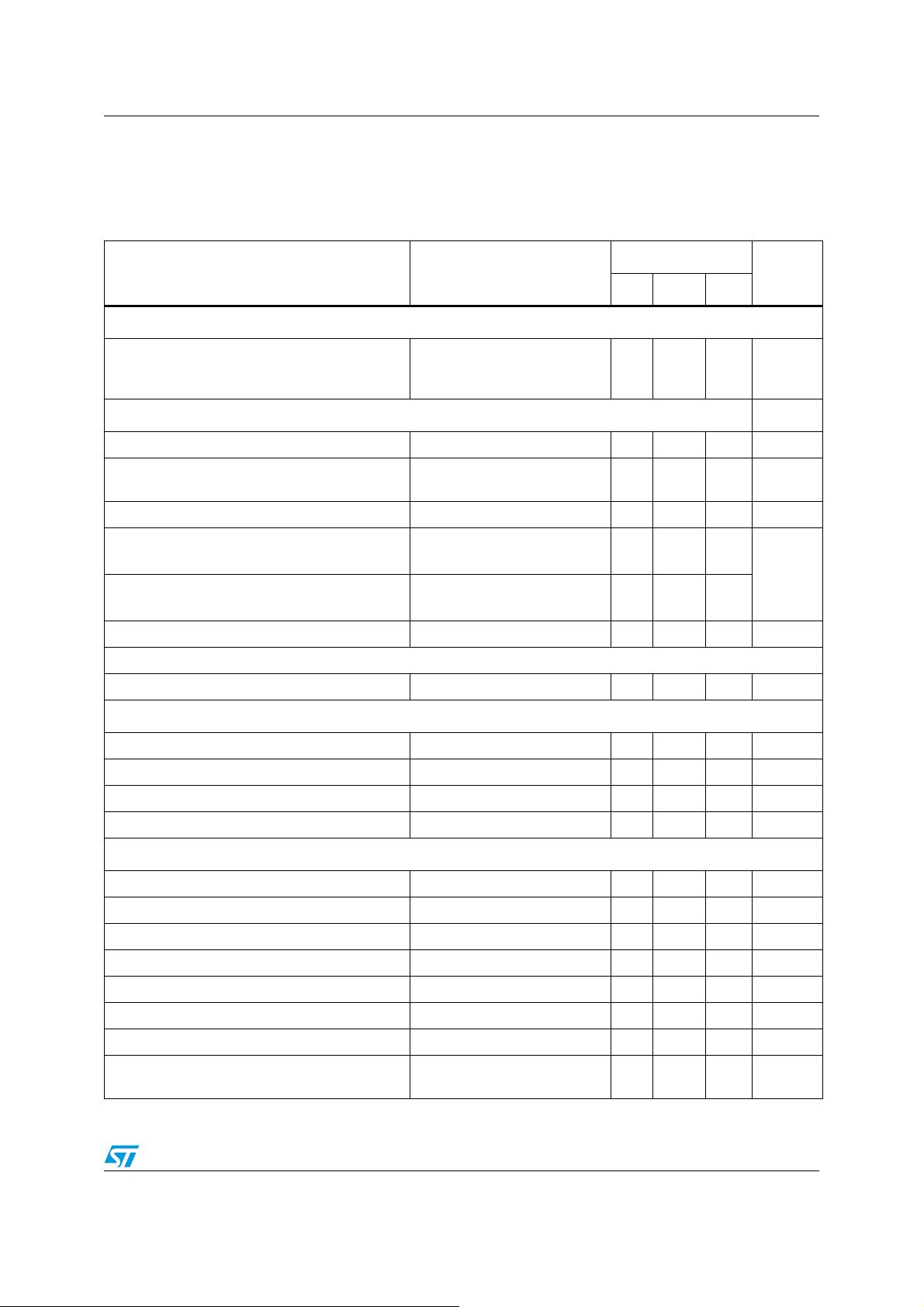

Table 1. Electrical characteristics of the ST7540 reference design

Val ue

Parameter Test conditions

Min Typ Max

Operating conditions

If ST7540 junction temperature

Ambient operating temperature

Transceiver section transmitting specifications (Tx mode)

Selected channel frequency FSK carrier 72 kHz

Transmitting output voltage level at mains output

Transmitting output current limit R6=1.1kΩ – See Figure 2 500 mA rms

nd

2

harmonic distortion

at mains output

3rd harmonic distortion

at mains output

exceeds 180 °C device shuts

down

R7 = 47kΩ, R8 = 15kΩ – See

Table 2

Loaded with CISPR 16-1

network

Loaded with CISPR 16-1

network

85 °C

22.25 V rms

-55

-61

Unit

dB

C

50Hz attenuation 100 dB

Receiving specifications (Rx mode)

-3

Minimum detectable Rx signal BER<10

Auxiliary supply

5 V regulated voltage ST7540 internally generated -5% 5.05 +5% V

5 V current capability 50 mA

3.3 V regulated voltage ST7540 internally generated -5% 3.3 +5% V

3.3 V current capability 50 mA

Power supply section

AC mains voltage range 85 265 V

Mains frequency 50-60 Hz

Output voltage Green led ON -10% 12.3 +10% V

Output voltage ripple Iout = 500 mA, Vin=85 Vac 1 %

Peak output current 500 mA

Output power 5.6 W

Efficiency at Pout=3.5W 70 %

Nominal transformer isolation*

Primary to secondary/

secondary to auxiliary

, negligible noise 48 dBµV rms

4 kV

Doc ID 12791 Rev 3 7/55

Page 8

Electrical characteristics AN2451

Table 1. Electrical characteristics of the ST7540 reference design (continued)

Val ue

Parameter Test conditions

Min Typ Max

Number of holdup cycles 0

Input power 100 mW

Switching frequency Transceiver section in Tx mode -10% 65 +10% kHz

Switching frequency

Transceiver section in Rx

mode

-10% 21 +10% kHz

Unit

Table 2. Output voltage level setting through V

V(PA_OUT)

[V

]

P-P

V(PA_OUT)

[V

]

RMS

V(PA_OUT)

[dBuV

RMS

]

partitioning - typical values

sense

R

7

[kΩ]

2.830 1.000 120 16 15

3.170 1.120 121 20 15

3.560 1.260 122 24 15

3.990 1.410 123 27 15

4.470 1.580 124 33 15

5.030 1.780 125 39 15

5.660 2.000 126 47 15

6.340 2.240 127 51 15

7.100 2.510 128 56 15

7.980 2.820 129 68 15

Figure 2. Typical curve for output current limit vs. RCL value

R

[kΩ]

8

8/55 Doc ID 12791 Rev 3

Page 9

AN2451 Safety precautions

2 Safety precautions

The board must be used only by expert technicians. Due to the high voltage (220 V ac)

present on the parts which are not isolated, special care should be taken with regard to

people's safety.

There is no protection against high voltage accidental human contact.

After disconnection of the board from the mains, none of the live parts should be touched

immediately because of the energized capacitors.

It is mandatory to use a mains insulation transformer to perform any tests on the high

voltage sections (see circuit sections highlighted in Figure 7 and Figure 8) in which test

instruments like Spectrum Analyzers or Oscilloscopes are used.

Do not connect any oscilloscope probes to high voltage sections in order to avoid damaging

instruments and demonstration tools.

Warning: ST assumes no responsibility for any consequences which

may result from the improper use of this tool.

Doc ID 12791 Rev 3 9/55

Page 10

ST7540 FSK powerline transceiver description AN2451

3 ST7540 FSK powerline transceiver description

ST7540 transceiver uses frequency shift keying (FSK) modulation to perform a half-duplex

communication on a powerline network. It operates from a 7.5 to 13.5 V single supply

voltage (Vcc) and integrates a power amplifier (PA), which is able to drive low line

impedance, and two linear regulators providing 5 V and 3.3 V.

Figure 3. ST7540 Transceiver block diagram

The ST7540 can communicate using eight different communication channels (60, 66, 72,

76, 82.05, 86, 110, 132.5 kHz), four baud rates (600, 1200, 2400, 4800) and two deviations

(1 and 0.5). Additional functions are included, such as watchdog, automatic control on PA

output voltage and current, carrier/preamble detection and band-in-use signaling,

transmission time-out, and thermal shutdown.

The transceiver, which is dedicated only to physical communication, operates with a

microcontroller whose aim is to manage the communication protocol stack. A reset output

(RSTO) and a programmable clock (MCLK) can be provided to the microcontroller by the

ST7540 in order to simplify the external logic and circuitry.

The host controller can exchange data with the transceiver through a serial interface,

programmable to operate either in UART (CLR/T data clock not used) or in SPI mode.

Communication on the power line can be either synchronous or asynchronous to the data

clock that is provided by the transceiver at the programmed baud rate.

When in transmission mode (i.e. RxTx line at low level), the ST7540 samples the digital

signal on the TxD line at the programmed baud rate and modulates it in a FSK sinusoidal

output on the Tx_OUT line. This signal is then externally fed into the power amplifier to add

current capability. The power amplifier can also introduce gain and active filtering to the

signal, just using few external passive components. The resulting signal on the PA_OUT line

is coupled to the power line.

When in receiving mode (i.e. RxTx line at high level), an incoming FSK signal on the Rx_IN

line is demodulated and the digital output is available for the microcontroller on the RxD pin.

10/55 Doc ID 12791 Rev 3

Page 11

AN2451 Evaluation tools description

The device also recovers the synchronism of the received signal using an internal PLL. The

recovered clock is present on CLR/T output.

The ST7540 operating parameters can be set by means of an internal control register,

accessible only through the SPI host interface.

4 Evaluation tools description

The complete evaluation system for the ST7540 powerline communication consists of:

● a PC using the "ST7540 power line modem demo kit" software tool

● one EVALCOMMBOARD hosting the ST7 microcontroller

● one ST7540 reference design board (EVALST7540-2).

The correct procedure for connecting the EVALST7540-2 and the EVALCOMMBOARD is as

follows:

1. Connect the EVALST7540-2 and the EVALCOMMBOARD

2. Connect the ac mains cable to the EVALST7540-2 and the USB cable to the

EVALCOMMBOARD

3. Connect the EVALST7540-2 to the ac mains supply

4. Connect the EVALCOMMBOARD to the PC via the USB cable.

Warning: Follow the connection procedure to avoid damaging the

boards.

Figure 4. Complete evaluation system including a PC, an EVALCOMMBOARD and

the EVALST7540-2 board

B /

UUSSB

RS232

Doc ID 12791 Rev 3 11/55

Page 12

Evaluation tools description AN2451

Figure 5. ST7540 powerline modem demonstration kit with control register window

The complete chain, controlled by the ST7540 powerline modem demonstration kit, can set

up real communication at bit level, simply by sending or receiving a user-defined bit stream.

It is possible to establish a half-duplex communication with two of these communication

nodes (two chains) connected to each other. In order to better evaluate communication

between two nodes, the ST7540 powerline modem demonstration kit has some particular

features, including:

● Frame synchronization: a byte synchronization header can be added to the to the

exchanged data to set up a simple protocol, intended to test the capability of the

system to correctly receive the exact transmitted bit sequence. This can be done in two

ways: via the ST7540 control register settings (the internal configuration register of the

modem has a frame header field, in which an 8- or 16-bit header can be set) or via the

Rx panel of the ST7540 powerline modem demonstration kit (setting a synchronization

at SW level). A bit synchronization can be introduced as a simpler feature by enabling

the preamble detection method in the control register panel and then inserting at least

one “0101” or one “1010” sequence at the beginning of the transmitted bit stream.

● Ping session: a master-slave communication with automatic statistics calculation can

be very useful to test a point-to-point or a point-to-multipoint powerline communication

network, thus providing a method to evaluate reachability of each node in the network.

For further details about the ST7540 powerline modem demonstration kit, please refer

to the user manual UM0239 “ST7540 power line modem demo kit graphical user

interface”.

12/55 Doc ID 12791 Rev 3

Page 13

AN2451 Board description

5 Board description

The ST7540 reference design is composed of the following sections:

● Power supply section, based on ST’s VIPer12A-E IC

● ST7540 modem and crystal oscillator section

● Line coupling interface section, with three subsections:

– Transmission active filter

– Transmission passive filter

– Receiving passive filter.

The board also has two connectors, which allow the user to plug the mains supply on one

side of it and the I.B.U. communication board on the other side.

Figure 6. Positioning of the various sections of the board

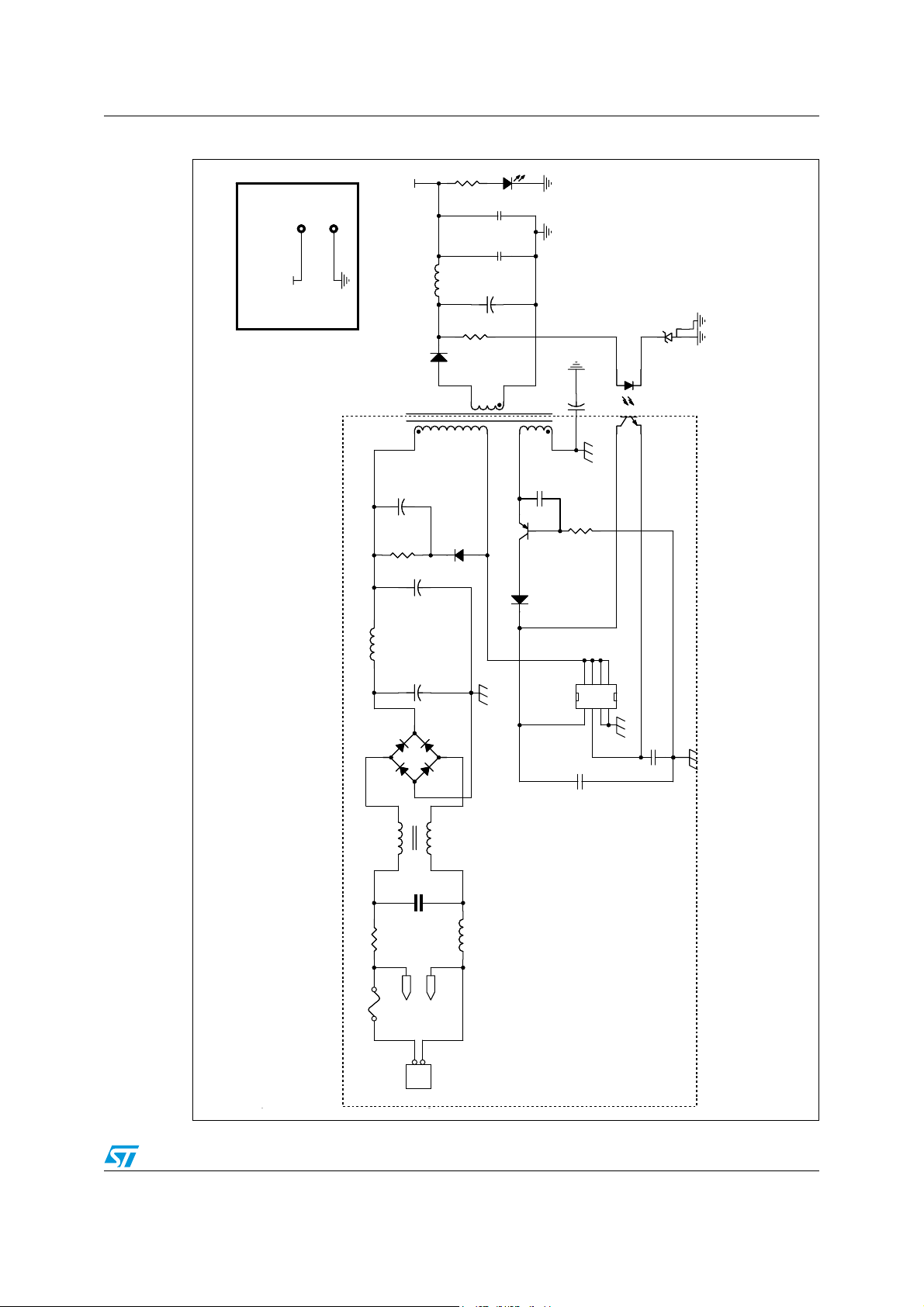

The schematics of the whole reference design appear in Figure 7 and 8. Figure 7 shows

the modem and the coupling Interface circuits, while Figure 8 represents the power supply

circuit. In both the schematics, high voltage regions are highlighted.

Ta bl e 3 lists the components used to develop the reference design board. All parts have

been selected to give optimal performances.

The layout of the printed circuit is given in Appendix A - Figure 49, Figure 50 and Figure 51.

Doc ID 12791 Rev 3 13/55

Page 14

Board description AN2451

Figure 7. Modem and coupling interface schematic

HIGH

VOLTAGE

SECTION

14/55 Doc ID 12791 Rev 3

Page 15

AN2451 Board description

Figure 8. Power supply schematic

VccVcc

VssVss

Vcc

TEST PADS

L3

470uHL3470uH

T1T1

C4

C4

R2

220kR2220k

Vcc

L4

33 uHL433 uH

D4D4

2 1

1

470pF 630V

470pF 630V

+

+

C2

C2

10uF 400V

10uF 400V

R5

1k5R51k5

D6

LEDD6LED

C29

C29

47uF 16V

47uF 16V

C9

C9

47uF 16V

47uF 16V

C8

470uF 16V

C8

470uF 16V

+

+

R4

560R4560

8

5

4

3

2

C5

220 pFC5220 pF

23

D2D2

Q1Q1

13

R3

1

D3D3

DC OUTPUT

C10

2.2 nF

C10

2.2 nF

10 KR310 K

12 V dc

1

3

D5

10VD510V

2

1 3

24

U2U2

R1

F1

D1

D1

4

10R 1WR110R 1W

T - 2AF1T - 2A

BRIDGE

BRIDGE

6

5

CN1CN1

C3

10uF 400V

C3

10uF 400V

+

+

1

3

-+

-+

2

10

L2L2

1

L1

1 mHL11 mH

N

P

C1

1

33nF X2C133nF X2

2

AC INPUT

85 V ac to 256 V ac

U1U1

578

DRAIN

FB

Vdd

3 6

C6

10 uFC610 uF

S

241

C7

47 nFC747 nF

HIGH

VOLTAGE

SECTION

Doc ID 12791 Rev 3 15/55

Page 16

Board description AN2451

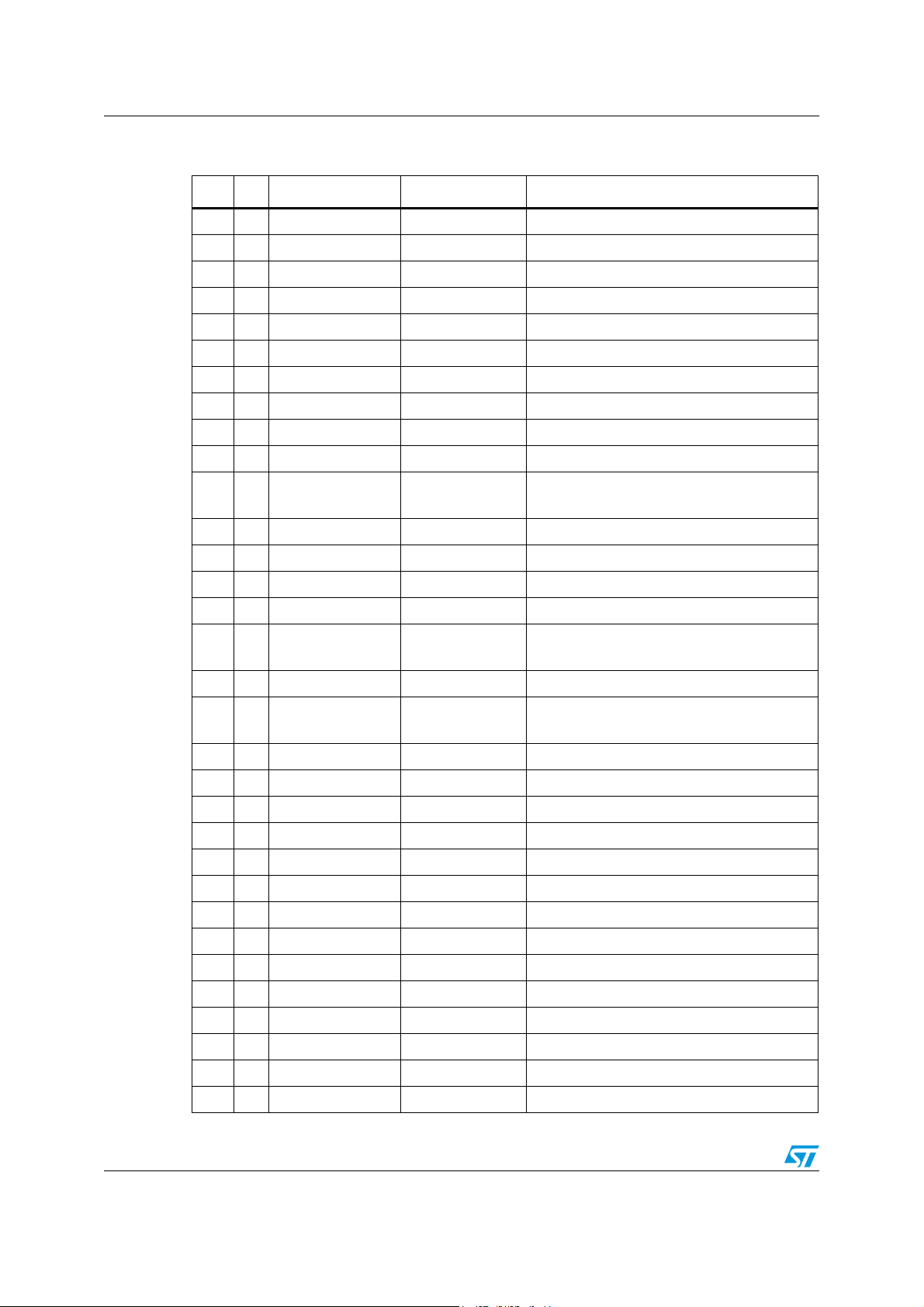

Table 3. Bill of materials

Item Qty Part Value Description

1 1 CN1 HEADER 2 Mains supply connector

2 1 CN2 CON50A 50 pins SMT right angle female p=1.27mm

3 1 C1 33nF X2 Murata GA355XR7-GB333K

4 2 C2,C3 10uF / 400V Yageo SE-K / Nichicon VK 20%

5 1 C4 470pF / 1kV TDK C4520X7R-3A471K

6 1 C5 220pF / 50V TDK C0603C0G-1E220J

7 4 C6,C15,C17,C24 10uF / 16V TDK C3216X7R-1C106MT

8 1 C7 47nF / 25V Murata GRM188R7-1E473K

9 1 C8 470uF / 16V Rubycon 3M0319 / Yageo SE-K 20%

10 2 C9,C29 47uF / 16V Murata GRM32ER6-1C476K

11 1 C10 2.2nF Y1

12 2 C11,C12 33pF TDK C1005C0G-1H330J

13 2 C14,C27 10nF Murata GRM188R7-1H103K

14 4 C16,C18,C19,C25 100nF TDK C1608X7R-1H104K

15 2 C21,C33 150pF Murata GRM1885C-1H151J

16 1 C22 10uF

17 1 C23 100nF X2 EPCOS B32922-A2104K

18 1 C26 22nF

19 1 C30 15pF Murata GRM1555C-1H150J

20 1 C31 22pF Murata GRM1555C-1H220J

21 1 C32 390pF Murata GRM1885C-1H391J

22 1 D1 DF06S 600 V - 1.5 A bridge rectifier

23 1 D2 STTH1L06A SMA ultra-fast Schottky diode

24 1 D3 BAS16 / BAS21 SOT23

25 1 D4 STPS1H100 SMA Schottky diode

TDK CD12-E2GA222MYNS /

Murata DE1E3-KX222M

Murata GRM21BR6-1A106K /

TDK C2012X5R-0J106K

Murata GRM21B5C-1H223J /

TDK C3216C0G1H223J

26 1 D5 BZX84C10 SOT23 10V zener diode

27 1 D6 LED Green LED

28 2 D8, D10 BAT54S SOT23 low drop Schottky diode

29 1 D9 SM6T12CA 12V bidirectional transil diode

30 1 F1 2A - T Time-lag fuse

31 1 JP4 CLOSE

32 1 J1 CONNECTOR

16/55 Doc ID 12791 Rev 3

Page 17

AN2451 Board description

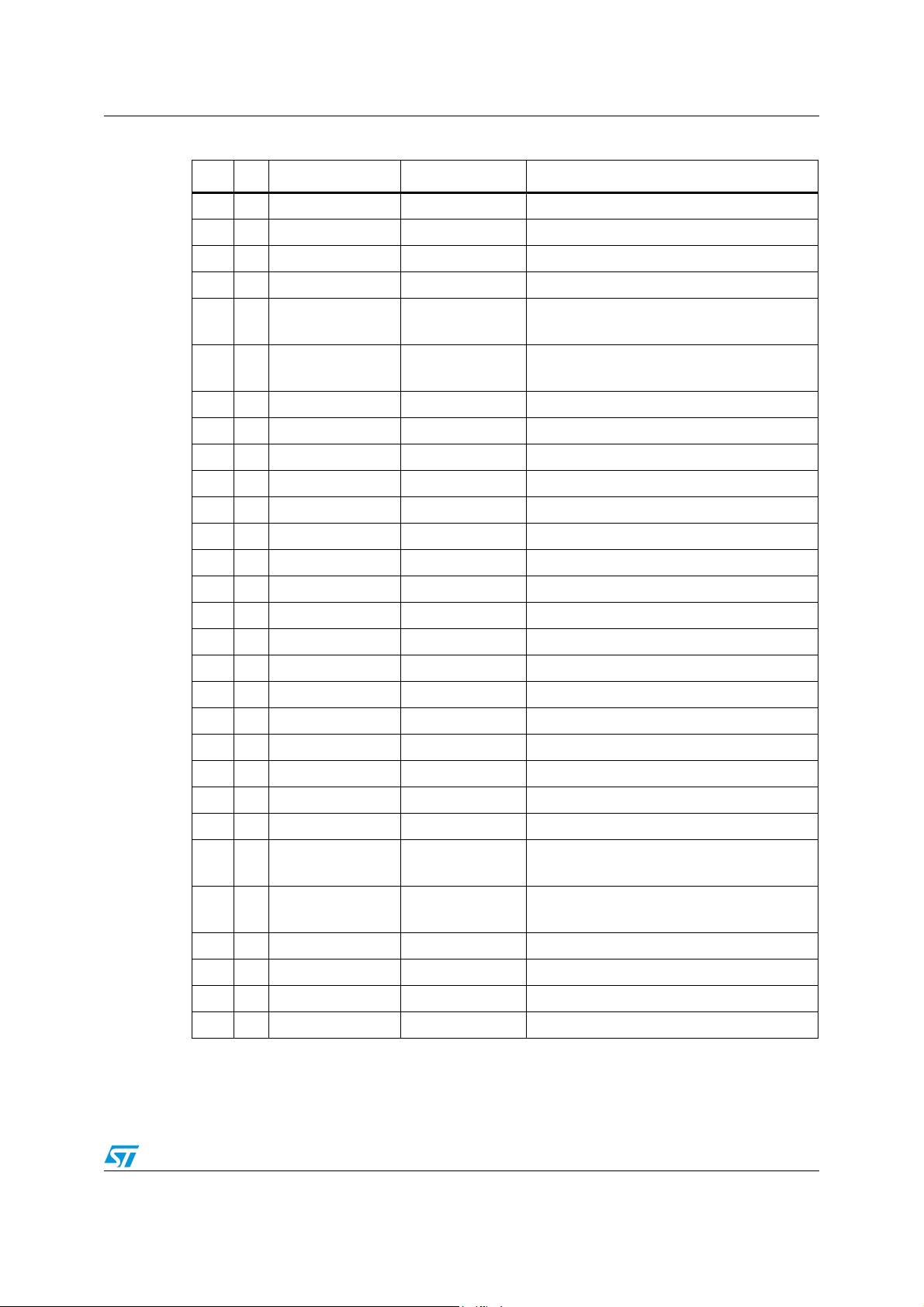

Table 3. Bill of materials (continued)

Item Qty Part Value Description

33 1 L1 1mH Epcos B82442-H1105K

34 1 L2 2x10mH 0.3A Radiohm 42V15

35 1 L3 470uH Epcos B82442-A1474K

36 1 L4 33uH Epcos B82462-A4333K

37 1 L5 47uH

38 1 L6 220uH

39 1 Q1 BC857BL SOT23

40 1 R1 10R 1W Metal oxide type - radial

41 1 R2 220K 0603 1%

42 1 R3 10K 0603 1%

43 1 R4 560 0603 1%

44 1 R5 1K5 0603 1%

45 1 R6 1K1 0603 1%

46 1 R7 47K 0603 1%

47 1 R8 15K 0603 1%

48 1 R9 4K7 0603 1%

49 1 R10 12K 0603 1%

50 1 R12 1K 0603 1%

51 1 R14 1K8 0603 1%

52 1 R17 470 0603 1%

Epcos B82464-A4473K /

WE 744-775-147

Epcos B82462-A4224K /

WE 744-774-222

53 1 R19 3K9 0603 1%

54 1 R20 56K 0603 1%

55 1 R21 2K7 0603 1%

56 1 T1

57 1 T2

58 1 U1 VIPER12AS SMPS controller / switch

59 1 U2 SFH610-A Opto-switch

60 1 U3 ST7540 Powerline transceiver

61 1 X1 16 MHz

SMPS

transformer

Line

transformer

Doc ID 12791 Rev 3 17/55

TDK SRW12.6EF-E07H013 /

WE S06-100-057

VAC T60403-K5024-X044 /

Radiohm 69H14-2101

Page 18

Board description AN2451

Table 4. ST parts on the ST7540 reference design board

Value Description

ST7540 Powerline transceiver

VIPER12AS SMPS controller / switch

STTH1L06A Ultrafast diode

STPS1H100 Schottky diode

SM6T12CA 12V bidirectional transil diode

5.1 Coupling interface

The mains coupling interface is composed of three different filters: the Tx active filter, the Tx

passive filter and the Rx passive filter.

All three filters are described in the sections Section 5.1.1, 5.1.2, and 5.1.3. In each section,

calculations and measured frequency responses are given.

The filters are quite sensitive to the components' value tolerance. Actual components used

in the ST7540 reference design have the following tolerances:

● +/- 10% for coils and for the X2 capacitor

● +/- 1% for SMD resistors

● +/- 5% for SMD ceramic capacitors.

To evaluate sensitivity of the filters to the tolerances listed above, the following sections

include simulated responses of the filters with Montecarlo statistical analysis. Statistical

simulation helps understanding the relationship between components' value tolerance and

variations on the responses of the filters. In simulation curves, the ideal response is drawn in

blue, while red curves indicate statistical variations generated through simulation.

18/55 Doc ID 12791 Rev 3

Page 19

AN2451 Board description

Figure 9. Schematic of Rx and Tx filters

5.1.1 Tx active filter

The Tx active filter is based on the ST7540 internal power amplifier (PA), whose input and

output pins are available externally to allow a filtering network to be tailored around the

amplifier.

For the ST7540 reference design board, a 3-pole low-pass filter has been developed by

cascading a simple R-C low-pass stage and a Sallen-Key 2-pole cell with 9dB gain. The

R19-C32 low-pass stage is aimed at introducing attenuation starting from approximately an

octave above the transmission channel frequency.

The transfer function of the 2

nd

order Sallen-Key cell is:

Equation 1

A

As()

-------------------------------------------- -=

s

----------

ω

R

14

where and

⎛⎞

A

1

0

⎝⎠

---------+

R

12

---------------------------------------------------------=,=

ω

C

R

1

• C33• C21•

9R10

0

2

s

----------------- - 1++

2

ω

C

C

Q•

R

• C33• C21•

Q

--------------------------------------------------------------------------------------- -=

R

9R10

9C33R10C21R9C21

1A

–()++

0

The corner frequency may be calculated as:

Equation 2

----------------------------------------------------------------------

f

c

2π R

Figure 10 represents the measured transfer function of the Tx active filter. It shows good

rejection on both the 2

nd

and 3rd harmonic frequencies for the 72 kHz signal.

1

• C33• C21••

9R10

135.7k Hz==

Doc ID 12791 Rev 3 19/55

Page 20

Board description AN2451

Figure 10. Measured frequency response of the Tx active filter (typical curve)

Simulation of the Tx active filter response against components' tolerance, depicted in

Figure 11, shows +/- 1 dB variation in gain module at 72 kHz.

Figure 11. Simulated frequency response of the Tx active filter with components

tolerance effect

5.1.2 Tx passive filter

Coupling to the power line requires some passive components in addition to the active

filtering stage. In particular, Tx passive filter section is made of the decoupling capacitor

C22, line transformer T2, inductor L5 and X2 safety capacitor C23.

L5 has been accurately chosen to have a high saturation current (>1 A) and a very low

equivalent series resistance (<0.2 Ω), to limit distortion and insertion losses even with heavy

line load. Center frequency for the series resonance is calculated as:

+/‐1 dB

Equation 3

f

-------------------------------- -=

c

2π L

20/55 Doc ID 12791 Rev 3

1

•

5C23

Page 21

AN2451 Board description

provided that the dc-decoupling capacitor C22 is much greater than C23 (in this case, 100

times greater) and that parasitic components of the transformer have negligible effects on

the filtering action.

Particular attention has been paid in choosing the line transformer. The required

characteristics are listed in Ta bl e 5.

In order to have a good power transfer and to minimize the insertion losses, it is

recommended to choose a transformer with a primary (shunt) inductance greater than 1mH

and a series resistance lower than 0.5 Ω.

Another important parameter is the leakage inductance. If it has a relevant value (10 to 50

uH), this can be used to design the coupling filter without inserting series inductance (L5,

L6). The drawback, however, is the poor accuracy of this parameter, which can lead to a

shift of the filter response and to bad coupling. Consequently, a low leakage inductance

value (<1 µH) has been chosen, fixing the series inductance through a discrete component

with greater accuracy.

The last specified parameter, the 4 kV insulation voltage requirement, is described and

coded in the EN50065-4-2 CENELEC document.

Table 5. Line coupling transformer specifications

Parameter Value

Turn ratio 1:1

Magnetizing inductance >1 mH

Leakage inductance <1 µH

DC resistance <0.5 Ω

DC saturation current >2 mA

Interwinding capacitance < 50 pF

Withstanding voltage 4 kV

Figure 12 shows the measured response of the Tx active and passive filters, loaded with the

CISPR network. The figure highlights a further filtering effect added by the passive L-C

series resonant combined with the CISPR reactive load.

Doc ID 12791 Rev 3 21/55

Page 22

Board description AN2451

Figure 12. Measured frequency response of the Tx active + passive filters

connected to the CISPR network (typical curve)

Figure 13. Simulated frequency response of the Tx active + passive filters

connected to the CISPR network with the components tolerance effect

5.1.3 Rx passive filter

The Rx filter is made up of a resistor in series with a parallel L-C resonant. The transfer

function of the filter can be written as:

Equation 4

Rs()

--------------------------------------------------------------------------------------------- -=

R17RLC26L6+

2

---------------------------------------

s

R

sL6RL+•

--------------------------- -

R

17L6C26

17L6C26

+/‐1dB

s

R17RL+

------------------------- -+•+

R

17L6C26

where R

is the DC series resistance of the inductor (in our case, about 2 Ω). The center

L

frequency and the quality factor of the filter can be expressed as:

22/55 Doc ID 12791 Rev 3

Page 23

AN2451 Board description

Equation 5

R

1

------

fc

2π

1

------

ωC•

2π

+

17RL

------------------------- -

R

17L6C26

1

---------------------------

2π L6C

26

The simplification made on fc formula is possible because R

quality factor and filter selectivity depend not only on R

produces a lower steepness of the resonance, while a higher R

R

17L6C26

---------------------------------------

Q

R17RLC26L6+

17>RL

, but also on RL. A higher RL

17

17

•=,≅==

ω

C

. Consequently, the

gives a higher selectivity.

Actual values of the components give a Q equal to 4.3.

The R

between R

Rs()

value impacts in a clearer way on insertion losses. To evaluate the relationship

L

and the losses on the received signal, the following simplified expression of

L

at f=f

may be used:

c

Equation 6

Rj 2πf

•()Q

CL6

-------------------

•

c

R

----------------------------------------------- -=≅

17

1R

1

•

LR17

C

26

---------

•+

L

6

•

ω

With actual values of the components, we get a loss of about 1 dB. The same calculation

gives unitary transfer if R

is set to zero.

L

Looking at the first way to express the module of the transfer function, it is possible to notice

that a higher value of Q can help keeping the losses small. Nevertheless, a high value of Q

would bring a higher sensitivity of the filter to the components tolerance.

Figure 14 shows the measured frequency response of the Rx passive filter. The filter has an

actual -3 dB bandwidth equal to 17 kHz and an attenuation of about 1 dB at center

frequency, just as expected.

Figure 14. Measured frequency response of the Rx passive filter (typical curve)

Figure 15 represents a simulation of the response of the Rx passive filter with the

components tolerance effect. A worst case loss of nearly 1.5 dB can be observed at 72 kHz

due to a shift on center frequency.

Doc ID 12791 Rev 3 23/55

Page 24

Board description AN2451

Figure 15. Simulated frequency response of the Rx passive filter with components

tolerance effect

5.1.4 Input impedance

The input impedance of a powerline communication node is another critical point. Figure 16

and Figure 17 show the input impedance magnitude vs. frequency curves in both Tx and Rx

mode. In both figures channel impedance point and the minimum impedance point are

indicated.

‐ 1. 5 dB

The impedance magnitude values prove that the ST7540 reference design board is

compliant with the EN50065-7 document, which sets the following minimum impedance

constraints for this kind of equipment:

● Tx mode:

– free in the range 3 to 95 kHz

–3 Ω

● Rx mode:

from 95 to 148.5 kHz

– 10 Ω from 3 to 9 kHz

– 50 Ω between 9 and 95 kHz only inside signal bandwidth (free for frequencies

outside signal bandwidth)

–5 Ω from 95 to 148.5 kHz

24/55 Doc ID 12791 Rev 3

Page 25

AN2451 Board description

Figure 16. Measured input impedance magnitude of coupling interface in Tx mode

(typical curve)

Figure 17. Measured input impedance magnitude of coupling interface in Rx mode

(typical curve)

5.2 Conducted disturbances

5.2.1 Conducted emissions

The EN50065-1 standard describes the test setup and procedures for testing conducted

emissions.

The conducted emissions measurements have been taken with 220 V

test pattern consists of a continuous transmission of a “1010” continuous sequence at 2400

baud, deviation 1. The output signal measured at the CISPR artificial network has a value of

120 dBuV

which means a signal of 2 V

RMS

Doc ID 12791 Rev 3 25/55

on the mains output.

RMS

mains voltage. The

ac

Page 26

Board description AN2451

The spectrum analyzer performs a peak measurement instead of a quasi-peak

measurement, as specified by EN50065-1. For continuous sinusoidal signals the two types

of measurement give the same result.

Figure 18. Conducted emissions test setup

EVALST7540-2

Figure 19 shows the results for the output spectrum measurement. The EN50065-1

disturbance limits mask (traced in red) may be compared to the typical output spectrum of

the ST7540 reference design board.

Figure 19. Output spectrum (typical) at 72 kHz, 2400 baud, deviation 1, mains 220V

5.2.2 Noise immunity

The tests on immunity against white noise and narrow-band conducted interferences are

based on two ST7540 reference design boards performing a simplex (unidirectional)

communication. The first board transmits a given bit sequence, while the receiving board

passes the received bit stream to a BER tester software on a PC, which evaluates the

percentage of correctly received bits.

ac

26/55 Doc ID 12791 Rev 3

Page 27

AN2451 Board description

The noise (white noise or sinusoidal interferer) is produced by a waveform generator and

injected into the artificial network through an AC coupling circuit. Figure 20 shows the test

environment used to perform noise immunity tests.

Figure 20. Narrow-band conducted interference test setup

PC with

Demo SW

ST7540

PC with

BER Tester

SW

Spectrum Analyzer

AGILENT

4395A

ST7540 Board

STIMULUS

ST7540 Board

Under Test

Coupling

Circuit

Ta bl e 6 reports the parameters for the test conditions settings.

The received signal and noise levels are measured at the mains connector of the board

under test. The 3 kHz resolution bandwidth chosen for the Spectrum Analyzer allows

measurement of the actual signal and noise levels as seen by the receiving ST7540 internal

circuitry, programmed for 2400 baud.

Table 6. Noise immunity test settings

Parameter Value

Received signal 86 dBuVrms

Frequency 72 kHz

Baud rate 2400

Deviation 1

Detection method Carrier with conditioning

Detection time 3 ms

Sensitivity High

Input filter Off

Transmitted sequence AACC h

S.A. resolution BW 3 kHz

Figure 21 represents the BER vs. SNR curve in the presence of white noise. It may be noted

that a BER of 10

-3

corresponds to a SNR around 12 dB, as expected from a nonideal FSK

demodulator.

Doc ID 12791 Rev 3 27/55

Page 28

Board description AN2451

Figure 21. Measured BER vs. SNR curve (typical), white noise

BER vs. Signal to Noise Ratio

1.00E-01

S/N @ CISPR

S/N @ Rx_IN

1.00E-02

1.00E-03

BER

1.00E-04

1.00E-05

1.00E-06

6.0 7.0 8.0 9.0 10.0 11. 0 12.0 13.0 14. 0 15.0 16.0 17.0 18.0

S/N

For narrow-band interference tests, two types of interfering noise have been used: a pure

sinusoidal tone and an amplitude-modulated signal (modulating signal 1 kHz, modulation

depth 80%). In both cases, the amplitude of the noise signal (of the carrier, for modulated

signal) has been decreased until the measured BER was lower than 10

-3

(one error every

1000 transmitted bits).

Figure 22 shows SNR vs. frequency curves for both a pure sinusoidal and an AM modulated

interferer.

Figure 22. SNR vs. frequency curve (typical) at BER = 10

15

10

5

0

-5

-10

-15

-20

-25

SNR [dB]

-30

-35

-40

-45

-50

-55

30 40 50 60 70 80 90 100 110 120

frequency [kHz]

-3

No modulation

AM 1kHz 80%

28/55 Doc ID 12791 Rev 3

Page 29

AN2451 Board description

5.3 Thermal design

All heat dissipation is based on the heat exchange between the ST7540 IC, the PCB and the

surrounding environment.

A large PCB copper area under the device is recommended to make an easier heat transfer

from the ST7540 to the environment. The metallic slug under the device (exposed pad of

HTSSOP28 package) must be properly soldered to the copper area on the PCB top side, as

recommended in the datasheet.

The large ground layer on the bottom side of the board must be connected to the top side

layer through multiple via holes.

In the case of ST7540 reference design, an area of about 0.2 cm

for exposed pad soldering, while ground layer dissipating area on the bottom side is nearly

2

1.5 cm

.

Figure 23. PCB copper dissipating area for ST7540 reference design board

Top layer Bottom layer

2

is put on the PCB top side

Copper area

Even if the ST7540 features a built-in thermal shutdown circuitry which turns off the power

amplifier (PA) when the die temperature (T

not to exceed 125 °C during normal operating conditions to ensure the functionality of the

IC.

The relationship between junction temperature T

transmission P

D

Equation 7

where T

is the ambient temperature (from -45 to +85 °C) and θJA is the junction to ambient

A

thermal impedance of the ST7540 IC, which is related to the length of the transmission (t

and to the duty cycle d = t

as illustrated by Figure 24.

Soldering area

Multiple Via Holes Large GND layer

) exceeds 170 °C. It is however recommended

J

and power dissipation during

J

is described by the following formula:

TJtTXd,()TAPDθJA• tTXd,()–=

PKT

/ (t

PKT

+ t

), assuming a packet-fragmented transmission

IDLE

TX

)

Doc ID 12791 Rev 3 29/55

Page 30

Board description AN2451

3

P

Figure 24. Packet-fragmented transmission

Transmission

in progress

Idle

state

t

PKT

t

IDLE

t

TX

When soldered to a proper copper area on the PCB as explained above, the IC is

characterized by a steady-state thermal impedance of about 35 °C/W. The transient of the

thermal impedance θ

can be estimated by simulating a 6-cell equivalent model, as shown

JA

in Figure 25. The simulated curve vs. the transmission duration and the duty cycle is also

given. It can be noticed that the transient of θ

takes several hundreds of seconds, after

JA

which the static value of 35 °C/W is reached.

Figure 25. Equivalent model of the thermal impedance

θ

of the HTSSOP28

JA

package with exposed pad

40

, d) [ºC/W]

TX

(t

JA

ș

30

20

10

0

1E-1 1 1E1 1E21E-2 1E

tTX [s]

d = 100%

d = 75%

d = 50%

d = 25%

R1

0.4

C1

5e-4

R4

D

11

C4

0.09

R2

1

C2

6e-3

R5

9.5

C5

0.8

R3

8

C3

17e-3

R6

6

C6

15

R ĺ °C/W

C ĺ W*s/°C

T

A

This means that during the transient phase (i.e. if the transmission time t

or even less) the IC is able to dissipate power that is well above the one sustainable at

steady state. For this reason, a complete thermal analysis requires taking into account the

characteristics of the transmission, i.e. duty cycle and duration, determining the value

reached by the thermal impedance and then the allowed power dissipation.

Actual dissipated power P

can be calculated as:

D

Equation 8

PDPINP

where P

IN=VCC*ICC

and POUT=V

OUT rms * IOUT rms

receiving circuitry and linear regulators is considered negligible for thermal analysis

purposes. The relationship between current absorption from the power supply (I

output current to the load (I

) is shown in Figure 26. The value of Vin can be deduced

OUT

from the load regulation curve of the SMPS, given in Figure 37.

30/55 Doc ID 12791 Rev 3

is some seconds

TX

–=

OUT

. Note that power consumption by

) and PA

CC

Page 31

AN2451 Board description

Figure 26. Output current vs. supply current typical curve for ST7540 in Tx mode

The transmission output level V

OUT rms

fixed for the ST7540 reference design, correspond to a maximum output power P

of 2 V and the current limit I

OUT rms(LIMIT)

of 500 mA,

of 1 W

OUT

over a 4 Ω load. In these conditions, the required dissipation results equal:

Equation 9

P

D LIMIT()PIN LIMIT()POUT LIMIT()

Figure 27 shows the curve of P

and I

OUT rms(LIMIT)

set for the ST7540 reference design.

vs. the load impedance modulus according to the V

D

11.7V 0.25A•()2V 0.5A•()2W≅–≅–=

OUT rms

Figure 27. Dissipated power vs. load impedance modulus typical curve for ST7540

reference design board

Referring to the relationship between dissipated power and temperature, it can be proven

that in a continuous transmission, i.e. with θ

at its steady-state value of 35 °C/W, a 2 W

JA

dissipation can be sustained in safe conditions if the ambient temperature remains below 55

°C. Instead, supposing a transmission time t

to the graph of Figure 25 the θ

would be 15 °C/W only. In this case a power dissipation of

JA

of 1 s and a duty cycle d of 50%, according

TX

2.7 W (corresponding to a 1 Ω load) is allowed over the entire ambient temperature range of

the ST7540.

Doc ID 12791 Rev 3 31/55

Page 32

Board description AN2451

5.4 Oscillator section

The ST7540 crystal oscillator circuitry is based on a MOS amplifier working in inverter

configuration.

This circuitry requires a crystal with a maximum load capacitance of 16 pF and a maximum

ESR of 40 Ω.

It is very important to keep the crystal oscillator and the load capacitors as close as possible

to the device.

The resonant circuit should be far away from noise sources such as:

● Power supply circuitry

● Burst and surge protections

● Mains coupling circuits

● Any PCB track or via carrying a signal.

To properly shield and separate the oscillator section from the rest of the board, it is

recommended to use a ground plane on both sides of the PCB, filling all the area below the

crystal oscillator and its load capacitors. No tracks or vias should cross the ground plane

except for the crystal connections.

It is also recommended to use a large clearance on the oscillator related tracks, to minimize

humidity problems (see Figure 28).

Connecting the case to ground is also a good practice to reduce the effect of radiated

signals on the oscillator.

Figure 28. A recommended oscillator section layout for noise shielding

5.5 Surge and burst protection

The specific structure of the coupling interface circuit of the application is a weak point

against high voltage disturbances that can come from the external environment. In fact an

efficient coupling circuit with low insertion losses consequently allows a very low impedance

path from the mains to the powerline interface of the device.

For this reason it is recommended to add some specific protection devices on the mains

coupling path, to prevent high energy disturbances coming from the mains from damaging

the internal circuitry of the ST7540.

32/55 Doc ID 12791 Rev 3

Page 33

AN2451 Board description

The possible environments for this kind of application can be both indoor and outdoor:

residential, commercial and light-industrial locations. To verify the immunity of the system to

environmental electrical phenomena, a series of immunity specification standards and tests

must be applied to the powerline application.

The requirements for ac-connected ports, fixed by the EN50065-2-3 document (part 7immunity specifications), include EN610000-4-4 (electric fast transients), EN610000-4-5

(surges), EN610000-4-6 (RF out-of-band disturbances), EN610000-4-11 (voltage dips).

In particular, surge tests are specified as both common and differential modes at level +/- 4

kV, with pulse shape 1.2 x 50 µs. Fast transient burst tests are specified at level +/- 2 kV, with

pulse shape 5 x 50 ns and pulse frequency 5 kHz.

Figure 29, Figure 30 and Figure 31 illustrate the protection criteria implemented in the

ST7540 reference design.

Figure 29 and Figure 30 show the protection against common mode disturbances. The

BAT54S diodes are intended to prevent the voltage on PA_OUT and Rx_IN lines from going

above the supply rail (Vcc for PA_OUT and VDC for Rx_IN) or below ground, with a

tolerance equal to the forward voltage of the diodes, that is nearly 0.3 V.

Figure 31 describes the protection intervention in case of differential mode disturbances. A

differential voltage higher than 12 V is shorted by the bidirectional power transil, which is the

most robust protection and also the one capable to absorb most of the energy of incoming

disturbances.

Figure 29. Common mode disturbances protection - positive disturbance

Doc ID 12791 Rev 3 33/55

Page 34

Board description AN2451

Figure 30. Common mode disturbances protection - negative disturbance

Figure 31. Differential mode disturbances protection

34/55 Doc ID 12791 Rev 3

Page 35

AN2451 Board description

5.6 50-pin connector for the EVALCOMMBOARD

Figure 32. Scheme of the connector for the EVALCOMMBOARD

VDC

VDDF_FORCE

CD/PD

REG_DATA

RxD

Rx/Tx

CLR/T

Tx D

CN2

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

CON50A

Vcc

VDDF

ANALOG_IN

B_ID_PLM1

GND

B_ID_PLM0

GNDGND

RSTO

UART/SPI

WD

BU/THERM

Vcc

Vdd

VDC

The ST7540 transceiver requires external digital control to communicate. This is done

through an ST7 microcontroller which is accommodated on the EVALCOMMBOARD (see

Chapter 4 on page 11). Communication with the ST7 microcontroller involves several

signals, which can be gathered into 3 groups: Digital signals, Analog signals and Power

connections. The signals for each group are listed in Ta bl e 8 , Tab l e 9 and Ta b le 1 0. Besides

the ST7540 input and output signals, the link to the EVALCOMMBOARD includes:

● A 2-bit (B_ID_PLM_1 and B_ID_PLM_0) Board Identification Code, which identifies the

hosted powerline transceiver. The microcontroller is able to recognize the ST7540

reference design board through a “10” binary configuration of this code.

● An Analog Input (ANALOG_IN), which is a line intended to implement a Received

Signal Strength Indicator (a peak meter used to give an Rx signal level estimation).

● A VDDF_FORCE signal, which forces the microcontroller to refer digital interface levels

to the VDDF (VDD) supply voltage provided by the ST7540 reference design board.

This way both the modem and the microcontroller “talk” on the same digital levels.

Table 7. 50-pin connector digital signals

Pin number Signal name Description Generated by

20 B_ID_PLM_1 Board ID for PLM applications (MSB) PLC Board (VDC)

28 B_ID_PLM_0 Board ID for PLM applications (LSB) PLC Board (GND)

35 CD/PD Carrier or preamble detected signal Modem

37 REG_DATA Data communication or register access µC

39 RxD Serial data output Modem

40 RSTO Reset output Modem

Doc ID 12791 Rev 3 35/55

Page 36

Board description AN2451

Table 7. 50-pin connector digital signals

Pin number Signal name Description Generated by

41 RxTx Receiving or transmission selection µC

44 UART/SPI Host Interface selection µC

45 CLR/T Serial data clock Modem

46 WD Watchdog timer reset µC

48 BU/THERM

49 TxD Serial data input µC

Table 8. 50-pin connector analog signals

Pin number Signal name Description Generated by

8 ANALOG_IN Analog input (for μC processing) -

Table 9. 50-pin connector power connections

Pin number Signal name Description Generated by

2 PLM_10 V 12 V power supply PLC Board

4 VDD 3.3 V / 5 V power supply Modem

5 VDDF_Force Force microcontroller digital level to VDDF PLC Board (VDC)

6 VDDF Digital power supply Modem (VDD)

22,34 GND Ground -

5.7 Power supply

- Rx mode: band-in-use detection signal

- Tx mode: thermal event signal

Modem

The ST7540 reference design includes a specifically designed Switching Mode Power

Supply (SMPS) circuit, based on the ST VIPer12AS-E device.

The VIPer12AS-E is a smart power device with a current mode PWM controller, a startup

circuit and protections integrated in a monolithic chip using VIPower M0 technology. It

includes a 27 Ω Mosfet with 730 V breakdown voltage and a 400 mA peak drain current

limitation. The switching frequency is internally fixed at 60 kHz, in order to provide a good

compromise between EMI performances and magnetic parts dimensioning.

The internal control circuit offers the following benefits:

● large input voltage range on VDD pin accommodates changes in supply voltage

● automatic burst mode in low-load condition

● overload and short-circuit protection in hiccup mode

The power supply is designed in isolated flyback configuration. Secondary regulation,

implemented through an optocoupler and a Zener diode, takes the requested output

tolerance for the specified application into account.

The main specifications are listed in Ta bl e 1 0.

36/55 Doc ID 12791 Rev 3

Page 37

AN2451 Board description

Table 10. SMPS specifications

Parameter Value

Input voltage range, V

Output voltage, V

Peak output current, I

in

OUT

OUT(MAX)

85-265 V

12 V±10%

500 mA

ac

In the input stage, an EMI filter is implemented (C1-L2 plus C3-L3-C2) for both differential and

common mode noise, in order to fit the requested standard.

The blocking diode D

inductance voltage spike, assuring reliable operation of the VIPer12AS-E. D

and the clamping network (R2-C4) clamp the peak of the leakage

2

must be very

2

fast recovery and very fast turn-on to avoid additional drain overvoltage. The clamp

capacitor C

must be low-loss (with polypropylene or polystyrene film dielectric) to reduce

4

power dissipation and prevent overheating, since it is charged with high peak currents by the

energy stored in the leakage inductance.

A Leading Edge Blanking (LEB) circuit for leakage inductance spikes filtering has also been

implemented (Q

- C5 - R3). It blanks the spike appearing at the leading edges of the voltage

1

generated by the self-supply winding, greatly improving short circuit behavior.

The output rectifiers have been selected to take the maximum reverse voltage and the RMS

secondary current into account. A STPS1H100 Power Schottky rectifier has been chosen

for this purpose.

A LC filter has been added on the output (consisting of L

, C9 and C29) in order to filter the

4

high frequency ripple without increasing the output capacitors size or quality.

The transformer used for this application has three windings, since one of them is needed to

supply the VIPer12AS-E. The primary inductance has been chosen as 2.7 mH and the

reflected voltage has been set to 80 V.

A layer type has been chosen with EF12.6 or E13/7/4 core.

The characteristics are listed in Tab l e 11 .

Table 11. SMPS transformer specifications

Parameter Value

Core geometry SRW12.6ES or E13/7/4

Primary inductance 2.7 mH±10%

Leakage inductance 180 μH max

N

P

N

AUX

N

SEC

Withstanding voltage 4 kV

224 turns – 0.1 mm

39 turns – 0.1 mm

31 turns – 0.2 mm (TEX-E wire)

RMS

Some significant waveforms are represented in the following figures. Figure 33 and

Figure 34 show typical waveforms in both open-load and full-load conditions.

Doc ID 12791 Rev 3 37/55

Page 38

Board description AN2451

In any SMPS, protection against an output short-circuit is very important. All tests have been

done by shorting the SMPS output at maximum input voltage. The results are given in

Figure 35.

The main parameters are the drain-source voltage (V

supply voltage (V

DD

).

The output current is an important parameter to be checked during shorts. Although the

output current peaks are quite high, the mean value is very low, thus preventing component

melting for excessive dissipation. In this way, the output rectifier, transformer windings and

PCB traces don't get overstressed. This assures system reliability against long-term shorts.

In case of device overheating, the integrated thermal protection stops the device operation

until the device temperature falls.

The startup phase could be critical for the SMPS. Output overshoot occurs if the circuit is

not properly designed. Care must be taken in designing a proper clamp network in order to

prevent voltage spikes, due to leakage inductance, from exceeding the breakdown voltage

of the device (730 V minimum value).

The startup transient is shown in Figure 36. It may be noted that the maximum drain-source

voltage doesn't exceed the minimum breakdown voltage BV

margin.

Finally, load regulation is presented in Figure 37, for different input voltages. With 230V

the output voltage ranges from 12.3V to 11.1 V, within the requested tolerance.

Figure 33. Typical waveforms at 230 V

load

: open

ac

), the output current (I

DS

, with a reasonable safety

DSS

) and the

OUT

ac

Figure 34. Typical waveforms at 230 Vac: full

load

,

V

DS

Ch1 freq - 9.62 kHz (black)

Ch2 mean - 9.90 V (green)

V

DD

V

DD

I

OUT

I

OUT

V

DS

Ch1 freq - 57.71 kHz (black)

Ch2 mean - 13.79 V (green)

Ch4 max - 503 mA (light blue)

38/55 Doc ID 12791 Rev 3

Page 39

AN2451 Board description

Figure 35. Typical waveforms at 265 V

short-circuit

ac

:

Ch1 freq - 23.50 Hz (green)

Ch4 max - 2.08 A (light blue)

Ch4 mean - 383 mA (light blue)

Figure 37. Load regulation

12.5

12.4

12.3

12.2

12.1

12

11.9

11.8

11.7

Vout [V]

11.6

11.5

11.4

11.3

11.2

11.1

11

0 100 200 300 400 500

Figure 36. Typical waveforms at 265 Vac:

startup

V

DS

V

DD

I

OUT

Ch1 max - 702 V (black)

Ch2 mean - 19.72 V (green)

Ch4 max - 500 mA (light blue)

185 V ac

230 V ac

265 V ac

Iout [mA]

Doc ID 12791 Rev 3 39/55

Page 40

Board description AN2451

Figure 38 shows the efficiency vs. output current curve. Minimum efficiency occurs at low-

load condition, as expected from any SMPS. This is not an issue for our application, since

low efficiency corresponds also to low power consumption and thus to low dissipation.

On the other hand, at output current values over 500 mA (full-load condition), both the

transformer and the VIPer are forced to operate close to their current limitations and thus the

efficiency is reduced.

In general, efficiency is affected by the losses which are due to R1 (series input resistor

limiting in-rush current) and to the filtering on both the primary and secondary side. Filtering

is more important than efficiency because a powerline communication appliance has very

restrictive EM disturbance limits and it is also highly sensitive to noise coming from the

power supply.

Figure 38. SMPS efficiency curve

0.73

0.71

0.69

0.67

0.65

Ș

0.63

0.61

0.59

0.57

50 100 150 200 250 300 350 400 450 500

Iout [mA]

40/55 Doc ID 12791 Rev 3

Page 41

AN2451 Performance and ping tests

6 Performance and ping tests

Our evaluation system includes a ping test embedded into the ST7540 powerline modem

demonstration kit and the FW of the EVALCOMMBOARD. This feature allows the user to

perform in-field communication tests and to evaluate reachability of PLC network nodes.

A ping session is based on a master board sending a sequence of messages to one or more

slave boards. if the messages are correctly received by the slave boards, they are resent

one by one to the master.

The PC connected to the master keeps statistics of the messages sent and correctly

received by the slave boards, thus making it possible to get a numerical evaluation of the

reachability of each node corresponding to a slave.

Figure 39 represents the ping window of the ST7540 powerline modem demonstration kit for

the master node. The main characteristics of this tool are indicated in red.

Figure 39. ST7540 powerline modem demonstration kit window for the master board

Number of

Slaves

(up to 255)

Repetition

Control

Medium

Access

Last

Message

Status

Number of

Messages

Graphical

Statistics

Numerical

Statistics

Special controls are included in the ping test:

● Repetition control: may be used to improve communication reliability. When repetition

control is enabled, a message not responded by a slave is resent up to three times

before sending a new message

● Medium access control: defines what type of medium access has to be used. Choices

are “none”, “BU” or “PD”. In the last two cases, messages are sent to the slave only if

the BU or CD/PD lines of the ST7540 modem are not active. If the PD setting is

selected, the content of the ST7540 internal control register is changed to select

“Preamble” as the detection method.

For further details about ST7540 powerline modem demonstration kit, please refer to the

user manual UM0239 “ST7540 power line modem demo kit graphical user interface”.

Doc ID 12791 Rev 3 41/55

Page 42

Application ideas AN2451

7 Application ideas

7.1 Three-phase architecture

Figure 40. Scheme of principle for three-phase architecture

PA _OU T

VDC

2

1

VCC

R21

2k7

Rx_IN

3

D10

BAT54S/SO T

3

D8

BAT54S/SO T

C22

10uF

C27

10 nF

L6

220 uH

2

1

VCC

R17

47 0

C26

22 n F

C36

100 nF X2

L5

47 uH

T2

1

8

4

5

C23

15 0nF X2

D9

SM6T12CA

C34

100 nF X2

C35

100 nF X2

P1

P2

P3

N

The ST7540 modem can be used to communicate on a three-phase network. The coupling

solution depicted in Figure 40 can be used.

In that topology, the total impedance that the ST7540 power amplifier is required to drive is

equal to the parallel of the impedance seen on each of the three phases, so probably the

device will be required to force an higher output current.

For concentrator nodes in metering networks (usually put at the low voltage substations),

the impedance per each phase is higher, so the suggested solution will give better

performance.

7.2 Zero crossing detector

Often, in AMR (Automatic Meter Reading) applications, it is necessary to know which phase

each meter is placed on. This information is mainly useful at system level in order to check

for unexpected losses on the distribution line due to failures or energy theft.

Since the three phases on the mains are sinusoidal waveforms with a phase shift of 120°

from each other (equal to 6.67 ms at 50 Hz / 5.5 ms at 60 Hz), the simplest way to associate

the meter to its correct phase is to synchronize the transmission to the phase itself. To do

that, the meter should always start its transmission synchronously with zero voltage

transitions on its phase and the concentrator should measure the delay between the

beginning of the incoming frame and the transition on its reference phase. The act of

detecting the zero voltage transitions on the mains phase is called zero crossing detection.

42/55 Doc ID 12791 Rev 3

Page 43

AN2451 Application ideas

Figure 41 and Figure 42 show two possible zero crossing detector circuit implementations.

N and P mean neutral and phase lines respectively at the meter/concentrator side, while

ZC_OUT is a digital output to the application microcontroller.

Particular attention should be paid to current rating (see solution in Figure 42) The

maximum allowable current for 1W dissipation, sustainable by two ½ W resistors in a series,

is 4.5 mA rms = 6.4 mA peak.

Such a current flowing into the LED of the optocoupler can minimize the delay between the

actual zero crossing of the mains voltage and the edge of the ZC_OUT signal, if the

optocoupler has been chosen to have an activation current I

about 10 times smaller than

F

the peak current.

Figure 43 shows the behavior of the ZC_OUT digital signal versus the AC Mains Input for

both circuits.

Warning: The circuit in Figure 41 is only applicable to a non-isolated

board topology. It is not possible to implement it directly on

the ST7540 reference design.

Figure 41. Schematic of a zero crossing detection circuit for non-isolated coupling

VDC

R1

N

470k

R2

220k

P

D1

BZX79C12A

1 3

Q1

BS170F/SOT

R3

450

ZC_OUT

Doc ID 12791 Rev 3 43/55

Page 44

Application ideas AN2451

A

Figure 42. Schematic of a zero crossing detection circuit for isolated coupling

VDC

R1A

N

25k 1/2W

P

R1B

25k 1/2W

If<1m A

21

D1

1N4148

Figure 43. ZC_OUT vs. AC mains waveforms

54

ISO1

OPTOCOUPLER

ZC_OUT

R2

100k

5V

7.3 Received signal strength indicator (RSSI)

In many application fields, measuring the strength of the incoming signal is useful to:

● Evaluate the SNR (signal to noise ratio) at the node

● Choose the best routing through the network (if repeaters are allowed)

One possible implementation for the received signal strength indicator (RSSI) is the one

depicted in Figure 44, where a peak detector is used to measure the amplitude of the

incoming signal.

C Mains

ZC_out

ZC OUT

44/55 Doc ID 12791 Rev 3

Page 45

AN2451 Application ideas

Figure 44. Peak detector electrical schematic

5V

R4

4.7k

R3

D1

1N4148

C1

100n

DC_OUT

Rx_IN

R1

100k

8

3

2

U1A

+

-

1

4

LM393

R2

18k

82k

The schematic above is based on a simple diode-capacitor (D1-C1) circuit improved with an

LM393 comparator so that:

● The comparator eliminates the diode reverse voltage.

● The feedback network (R3/R2) introduces a gain of 4 to improve performance against

low amplitude signals.

In the end this circuit gives, on DC_OUT line, a DC voltage proportional to the AC peak-topeak level at the input. Figure 45 shows the measured behavior of this circuit with a given

pure sinusoidal waveform at the input. The DC_OUT signal should be converted through an

integrated A/D converter by the application microcontroller.

Figure 45. Measured DC_OUT Vs. AC_IN peak detector response

3000

2500

2000

1500

DC_OUT [mV ]

1000

500

0

0 200 400 600 800 1000 1200

7.4 Non-isolated coupling

A possible alternative solution for line coupling is a non-isolated circuit. An example is

shown in Figure 46, in which the transformer T2 has been substituted with the shunt

inductor L7. The value of the inductor has been chosen to give about 100 dB rejection to the

mains voltage through a C23-L7 high pass filter. Advantages arising from non-isolated

Doc ID 12791 Rev 3 45/55

AC_IN [mVpp]

Page 46

Application ideas AN2451

topologies mainly include cost optimization, eliminating the need for isolation components,

and circuit simplicity.

Figure 46. Example schematic for non-isolated solution

PA_O UT

VDC

VCC

3

R21

2k7

D8

BAT 54S/ SOT

C22

10uF

C27

Rx_IN

2

1

D10

BA T54S /SOT

10 nF

L6

220 uH

3

2

1

VCC

R17

47 0

C26

22 n F

L7

1 mH

L5

47 uH

C23

10 0nF

D9

S M6T12 C A

N

P

7.5 DC powerline applications

The ST7540 reference design can be adapted to communicate over a DC power line. In this

case, the schematic of Figure 46 has to be referred to as line coupling, with two

modifications: L7 can be removed and the C23 capacitor can be substituted with a lower

voltage ceramic component.

A DC-DC converter will substitute the ac-dc SMPS. For example, the L5970 DC-DC stepdown switching regulator can be used in case of 24 V bus to obtain the 12 V supply for the

ST7540 device.

7.6 110 and 132.5 kHz coupling circuit

In this paragraph application circuits for CENELEC band B and C are provided. The 110 and

132.5 kHz channels of the ST7540 transceiver are suitable for home automation

applications and in general for applications not subject to the European AMR regulations.

Figure 47 and Figure 48 show the schematics for the line coupling interface tuned

respectively to the 110 and 132.5 kHz channels.

46/55 Doc ID 12791 Rev 3

Page 47

AN2451 Application ideas

Figure 47. Line coupling interface for 110 kHz channel

Doc ID 12791 Rev 3 47/55

Page 48

Application ideas AN2451

Figure 48. Line coupling interface for 132.5 kHz channel

48/55 Doc ID 12791 Rev 3

Page 49

AN2451 Troubleshooting

8 Troubleshooting

In this section the most frequently asked questions are described.

1. Problem: the ST7540 reference design board does not work at all.

What to check:

a) Check that the AC mains supply cable is well connected to CN1.

b) Check if the green LED D6 is on.

c) Check the voltage on the Vcc test pad. The value must be about 12 V.

2. Problem: the ST7540 reference design board is not responding.

What to check:

a) Check the VDC voltage. The value must be about 5 V. In a noisy environment,

spurious voltage spikes could compromise the internal linear regulator startup.

b) If Vdd is not externally connected to the VDC line, verify the Vdd voltage. The

value must be about 3.3 V.

c) Check if the MCLK selected frequency is present.

d) Check the connection between the reference design board and the

EVALCOMMBOARD and the connection between the EVALCOMMBOARD and

the PC.

3. Problem: the ST7540 reference design board does not transmit.

What to check:

a) Check the voltage on the PA_OUT test pad with the oscilloscope ground probe

connected to the SVss signal ground. The programmed carrier frequency must be

present on the PA_OUT line.

b) Check there is no short-circuit impedance on the mains at the transmitting

frequency.

c) Check the CL voltage. It fixes the current limiting threshold. It has to be lower than

1.9 V, otherwise the IC is put in current-limit mode.

If the current-limit mode is forced on the transceiver, modify the value of the R6 feedback

resistor to exit from limitation according to the actual load forced by the mains network.

4. Problem: the ST7540 reference design board transmits only for a short time.

What to check:

a) Check the transmission timeout setting. It has to be disabled for continuous

transmission.