Page 1

AN2389

Application note

An MCU-based low cost non-inverting

buck-boost converter for battery chargers

Introduction

As the demand for rechargeable batteries increases, so does the demand for battery

chargers. There are different kinds of design solutions available for implementing battery

chargers. Some of them are dedicated hardware based solutions and some are

microcontroller based solutions.

In a microcontroller based solution, you have the flexibility of using the same hardware for

charging different batteries and making only slight changes in the software. But there are

still some challenges and one of the major challenges is to have a suitable input power

supply available. Generally the Buck converter topology is used as a DC- DC converter to

provide the controlled output power supply to the batteries. But in this case a problem may

arise, for example, if you want to charge a 4.2V Li-ion batteries from a 5V supply due to the

presence of the protection diode and other small drops across other components. This drop

is generally about 1V which makes it very difficult to provide 4.2V to the Li-ion batteries

using the buck converter topology.

This application note describes a simple technique for implementing a non-inverting buckboost converter which requires only one inductor. This converter is basically the result of

cascading a Buck converter with a Boost converter. This converter can be controlled by two

PWM signals from the microcontroller and can be used as a Buck converter or Boost

converter whenever required. So this solution combined with the flexibility of the ST7

microcontroller can be used to charge a wide range of the batteries using the same

hardware.

The example used in this application note is specific to battery chargers but this DC-DC

converter can be very useful for portable applications in general or any application which

uses rechargeable batteries.

August 2007 Rev 1 1/16

www.st.com

Page 2

Contents AN2389

Contents

1 Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Buck-boost implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Buck converter implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Boost converter implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Selection of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Application in battery charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Software flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Test environment and results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2/16

Page 3

AN2389 Circuit diagram

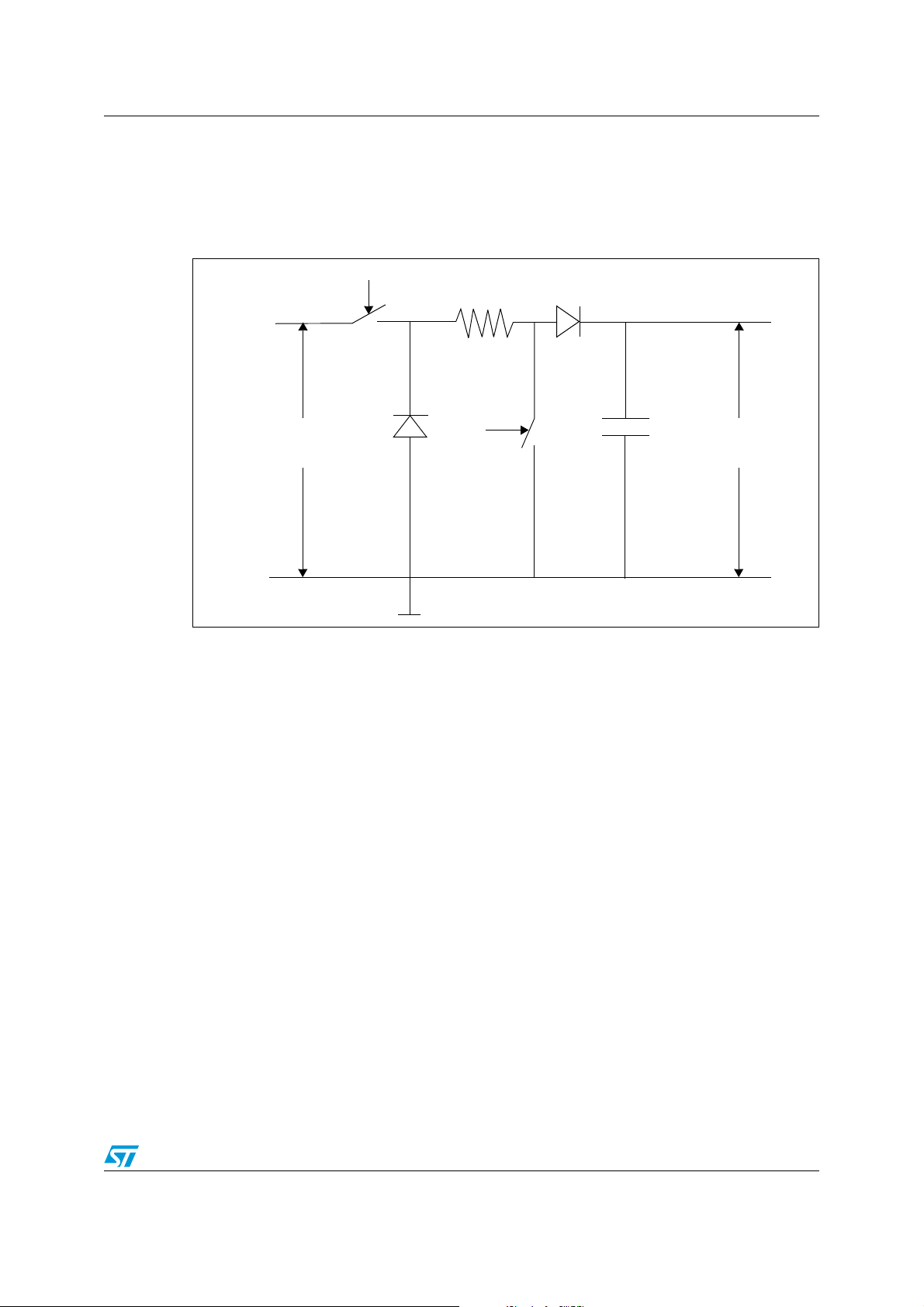

1 Circuit diagram

The diagram in Figure 1 shows the structure of the modified buck-boost converter.

Figure 1. Modified buck-boost converter

P+

P-

PWM1

SW1

d1

V

IN

L

PWM2

d2

SW2

C

V

OUT

3/16

Page 4

Theory of operation AN2389

2 Theory of operation

You can use this converter as buck-boost converter, as a buck converter or as a boost

converter by selecting different combinations of switches SW1 and SW2 driven by the

PWM1 and PWM2 signals output by the ST7 microcontroller.

2.1 Buck-boost implementation

This converter can be used as a non inverting buck-boost converter by selecting the

operating mode from Tabl e 1 which briefly describes the converter modes.

.

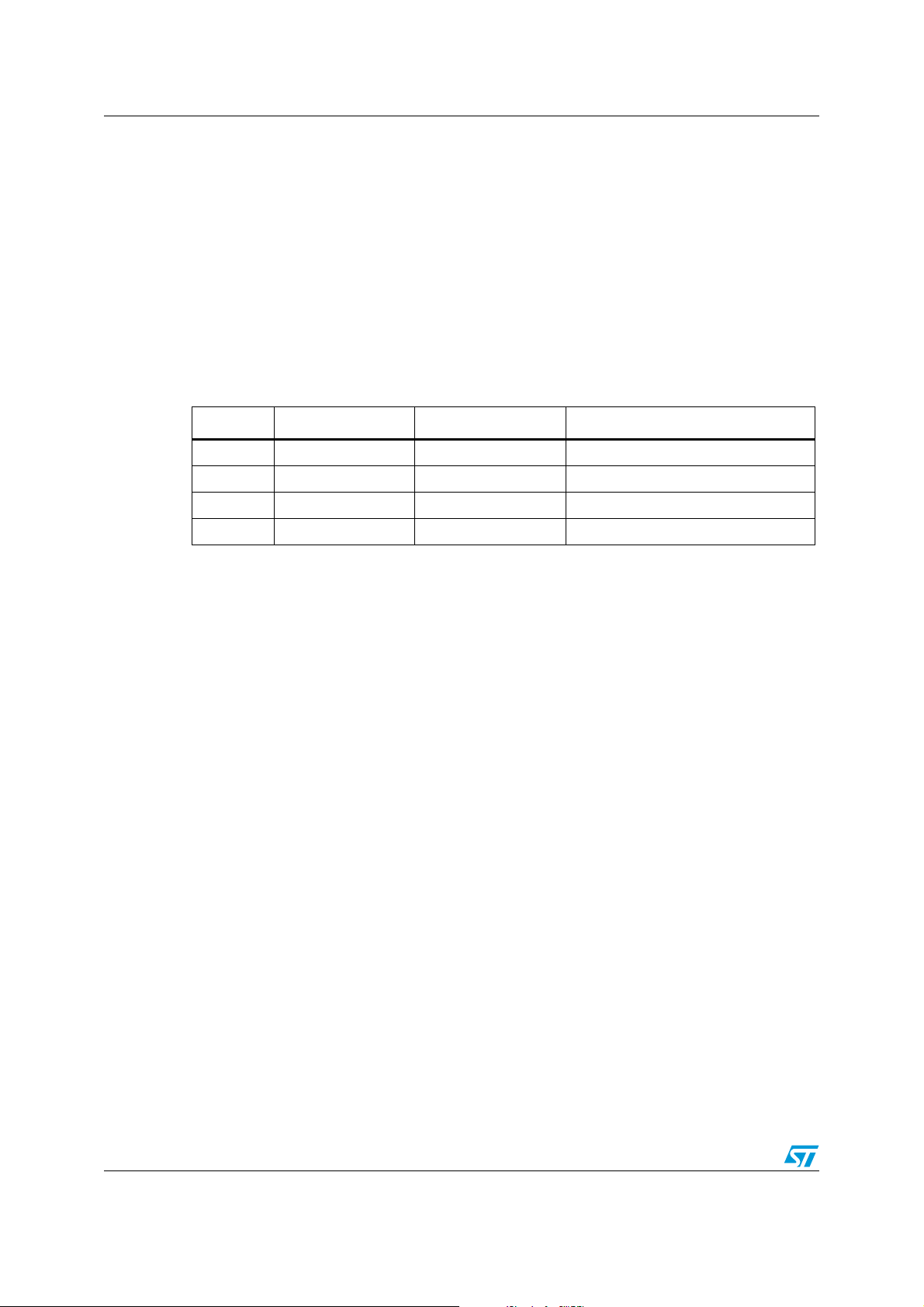

Table 1. Operating modes based on switch combinations

Phase SW1 (PWM1) SW2 (PWM2) Operating modes

1OFF OFF BUCK

2OFF ON N/A

3ON OFF BUCK-BOOST

4ON ON BOOST

If we look at phase 2 in Ta bl e 1 , here the switch SW1(PWM1) is OFF and switch SW2

(PWM2) is ON. This condition never occurs either in a buck converter or in boost converter.

So you should always take care in your software that this condition must not happen. To

avoid this, if we assume that initially both switches are in OFF condition then you should use

the following guidelines to manage the PWM signals driving the two switches.

1. Keep the frequency of both PWM signals the same, to better control when

synchronizing the two PWM signals using the next three guidelines.

2. The duty cycle D1 of control signal PWM1, must be greater than the duty cycle D2 of

control signal PWM2.

3. PWM1 should be enabled before the PWM2 signal.

4. PWM1 should be disabled after the PWM2 signal.

4/16

Page 5

AN2389 Theory of operation

Figure 2. Timing diagram for two PWM signals

Phase 3

PWM1

PWM2

Phase 1Phase 4

Figure 2 shows a timing example for the two PWM signals based on the above guidelines.

Here phase 2 does not occur.

– If the duty cycles of the two PWM signals driving SW1(PWM1) and SW2 (PWM2)

are D1 and D2 respectively and

– if we exclude the saturation voltage of the switches from our calculation and

– if the drop across the diodes is V

and Vd2 respectively,

d1

– then the output voltage Vout is given by the following formula:

= [ Vin * D1 - V

V

out

* ( 1 - D1) ] / ( 1 - D2) - V

d1

d2

As mentioned in [2], theoretically this converter works linearly over a gain range of 0 - 200%

of the input voltage.

5/16

Page 6

Theory of operation AN2389

2.2 Buck converter implementation

If you keep SW2 always in OFF condition and drive SW1 (PWM1) with a PWM signal from

the microcontroller then the circuit works like a buck converter, except that you have an

additional diode drop V

Figure 3. Buck converter implementation

due to diode d2.

d2

P+

P-

PWM1

d1

V

IN

L

OFF

d2

SW2

C

V

OUT

If the duty cycle of the PWM signal driving SW1 (PWM1) is D1, the output voltage will be

given by:

V

= Vin * D1 - Vd1 ( 1 - D1) - V

out

d2

6/16

Page 7

AN2389 Theory of operation

2.3 Boost converter implementation

Again if you keep switch SW1 (PWM1) always in ON condition and drive the Switch SW2

(PWM2) with a PWM signal generated by the microcontroller, then the combination works as

a boost converter except that you have an additional free wheeling diode D1 which you can

ignore.

Figure 4. Boost converter implementation

P+

V

IN

P-

If the input voltage is V

across the diode d2 is V

= Vin / ( 1 - D2) - V

V

out

ON

SW1

d1

, the duty cycle of the PWM signal driving PWM2 is D2 and the drop

in

, then the output voltage V

d2

d2

L

PWM2

d2

SW2

is given by:

out

C

V

OUT

7/16

Page 8

Selection of components AN2389

3 Selection of components

The inductor and capacitor can be selected using the formulae given below.

3.1 Inductor selection

The minimum value of the inductor can be selected by choosing the maximum of the values

given by the following two formulae:

T * [ ( Vin - V

2 * I

Lmin =

are the saturation voltages of the two switches SW1 and SW2.

Here V

sat1

and V

Lmin =

sat2

Iout and Vout are the maximum output current and voltage respectively.

V

and Vd2 is the drop across diodes d1 and d2.

d1

The duty cycles of the PWM signals driving SW1 and SW2 are D1 and D2 respectively.

3.2 Capacitor selection

The minimum of the capacitor value can be selected by using the following formula ,

assuming a variation in Vout of 1% or less

In practice, we take inductor and capacitor values that are larger than the values calculated

using the above formulae.

out

T * [ Vd1 + V

2 * I

Cmin =

) * D1 - V

sat1

out

100 * I

V

out

out

out

* D2 - V

sat2

] * ( 1 - D1)

* (1 - D1) * T

* (D1 - D2)]

out

(1)

(2)

(3)

8/16

Page 9

AN2389 Application in battery charger

4 Application in battery charger

We can use the modified non-inverting buck-boost converter in a combination of different

modes as required by the application.

4.1 Theory of operation

The DC-DC converter uses a combination of buck-boost converter and boost converter

mode to charge the Li-ion battery. In case of Li-ion, the constant current constant voltage

(CC CV) charging algorithm is used to charge the battery. Here we have chosen the input

voltage just enough to show the functionality of the converter in buck-boost mode and boost

mode.

Initially the converter works in Buck-Boost converter mode to charge the battery in constant

current mode by keeping the duty cycle of PWM2 constant and varying the duty cycle of

PWM1. As soon as there is an overflow condition for the duty cycle of PWM1. The converter

switches from buck-boost converter mode to boost converter mode. And then duty cycle of

PWM2 is varied to follow the algorithm while SW1 remains in ON condition. Following

section shows the software flow chart for this combination.

9/16

Page 10

Application in battery charger AN2389

4.2 Software flowchart

There are many ways in which you can control the operation of this circuit. An example

algorithm which can be used for in Li-ion battery charger is given below-

Figure 5. Li-ion battery charger flowchart

INITIALIZE THE PWM

SIGNALS WITH DUTY

CYCLE D1 AND D2.

WORKS IN BUCK-BOOST MODE. KEEP D2

FIXED AND VARY D1 TO KEEP THE CURRENT

CONSTANT.

IS THERE

A OVERFLOW IN

D1?

YES

WORKS IN BOOST MODE. KEEP SW1

ALWAYS ON AND VARY THE D2 TO

CONTINUE THE ALGORITHM BY KEEP

-ING THE CURRENT OR VOLTAGE

CONSTANT AS REQUIRED.

END

No

10/16

Page 11

AN2389 Test environment and results

5 Test environment and results

We used this buck-boost converter in the universal battery charger evaluation board

described in AN2390. Figure 6 below shows the general battery charger circuit using the

non-inverting buck-boost converter circuit mentioned in this application note. For simplicity,

this figure does not show all the connections.

Figure 6. General circuit-based battery charger

P+

P-

PWM1

SW1

d1

V

IN

L

PWM2

d2

SW2

I

BAT

C

V

OUT

V

BAT

Battery

R

S

Sense resistor

Here some results are shown for charging the Li-ion battery using this converter in buckboost mode. The above charger is is intended for charging a single Li-ion or two NiMH in

series using a 5V supply input. Details on the implementation are given in AN2390 where

you can find results for NiMH batteries as well as for a charger used simply in buck

converter mode.

Some parameter values are as follows:

V

= 5V, Iin (MAX) = 2A, V

in

sat1

= V

= 0.3V, Vd1 = V

sat2

= 0.5V. and PWM frequency for both

d2

PWM1 and PWM2 = 16KHz.

Also let’s say the maximum value of V

= 5.5V and I

out

= 1.2A and the maximum duty cycle

out

of D1 is 95% and D2 is equal to 30%.

Then using the formulas given in Section 3:

Lmin = 21 uH (from equation 1) or 10 uH (from equation 2). So we should choose a value

larger than 21 uH.

Cmin = 70uF (from equation 3). So we need to choose a value higher than 70 uF.

In this example, L = 75 uH, C = 470 uF are taken, which are larger than the values

calculated using the formulas hence will support the application.

The following table shows some of the readings taken for different values of the duty cycles

D1 and D2.

11/16

Page 12

Test environment and results AN2389

I

Table 2. Input vs output

Sl No Vin (V) Iin (A) V

(V) I

out

out

(A)

1 5 1.23 3.9 1.05

2 5 1.33 4.14 1.05

3 5 1.36 4.2 1.05

4 5 1.27 4.2 0.975

5 5 0.97 4.2 0.80

6 5 0.85 4.2 0.712

7 5 0.65 4.15 0.55

8 5 0.33 4.15 0.28

9 5 0.31 4.15 0.26

10 5 0.16 4.10 0.129

In above results, we have not added V

(0.3V), diode drop (0.5V) and the drop across the

sat

series resistor (connected to measure battery current) as shown in Figure 6 to get the actual

output voltage of the non-inverting buck-boost converter.

For example it is given that V

(battery voltage) = 4.2V,

out

but the actual output voltage of the converter is equal to:

V

4.2V (Battery Voltage V

out

) + 0.3V(Switch Drop V

bat

)+ 0.5V(Protection Diode Vd2)+

sat1

0.4V (Drop across Sense resistor) = 5.4V.

So we are able to achieve 5.4V from a 5V supply thus validating the concept.

12/16

Page 13

AN2389 Conclusion

6 Conclusion

This application note describes a simple but very useful technique for implementing a

microcontroller controlled low cost non-inverting buck-boost converter. This converter can

be used as a buck converter or as a boost converter or as a buck-boost converter. The

example shows the application of this converter in a battery charger. However it can also be

used in other portable applications or any application getting its power from a rechargeable

battery. Or you could use this technique to make a USB charger to charge Li-ion batteries or

3 or more NiMH Cells in series.

13/16

Page 14

References AN2389

7 References

[1] AN2390: “A flexible universal battery charger”, STMicroelectronics

[2] “A noninverting buck-boost converter with reduced components using a microcontroller”

by Robert S. Weissbach and Kevin M. Torres, IEEE members.

14/16

Page 15

AN2389 Revision history

8 Revision history

Table 3. Document revision history

Date Revision Changes

21-Aug-2007 1 Initial release.

15/16

Page 16

AN2389

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

16/16

Loading...

Loading...