Page 1

AN2334

Application Note

Complete car door module

Introduction

A car door module typically consists of a rubber-sealed carrier, onto which a variety of door

components such as the window lift mechanism, the wing mirror electric motor, the wiring

harness, the loud speaker, the door latch inner release cable, locks and various switches

are fitted, forming a “cassette”.

The trend in both Europe and the U.S. is to increase the complexity of the door module by

adding more electronic features needed to drive all door loads and functions, with the

possibility to connect the module to other car subsystems via standard automotive

communication protocols (LIN, CAN).

Among many of these automotive subsystems, the connectivity via a single wire,

decentralizing electronic modules, reduces the number of wires required and in turn reduces

wiring harness weight, contributes significantly to overall vehicle weight reduction. This is of

concern to auto manufacturers, who are constantly striving to reduce vehicle weight and to

improve fuel efficiency.

In this document, an electronic module is presented that controls all the car door functions,

including the window lift, all latching/locking operations, wing mirror movement, mirror turn

indicator light, defroster and some lamps. To reduce the risk of bodily injury, especially to

children, this module also includes an advanced trapping detection feature for the window lift

motor, which stops the window if a body member such as a finger, a hand or an arm is

introduced into the window climbing area during the window climbing process. A low-cost,

high performance, antipinch algorithm based on monitoring the window motor driver current,

has been developed.

April 2006 Rev 1 1/22

www.st.com

Page 2

Contents AN2334

Contents

1 Car door module description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Local Interconnect Network (LIN) messages . . . . . . . . . . . . . . . . . . . . 10

4 PC Keypad software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Hardware implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Appendix A Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22

Page 3

AN2334 List of tables

List of tables

Table 1. Door module actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2. Application Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3. FR RL RR data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4. Front Right Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. PC-VNH2 Diag. data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. Dashboard data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 7. PC - L9950 Diag. data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 8. Window and door lock coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 9. Mirror and door lock coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 10. L9950 Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 11. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3/22

Page 4

List of figures AN2334

List of figures

Figure 1. Door module block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. VNH2 PWM signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Simplified algorithm flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Master/slave diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. LIN bus message frame format diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. PC keypad screenshot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 7. Adjust thresholds screenshot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8. Board connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 9. Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. Board Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4/22

Page 5

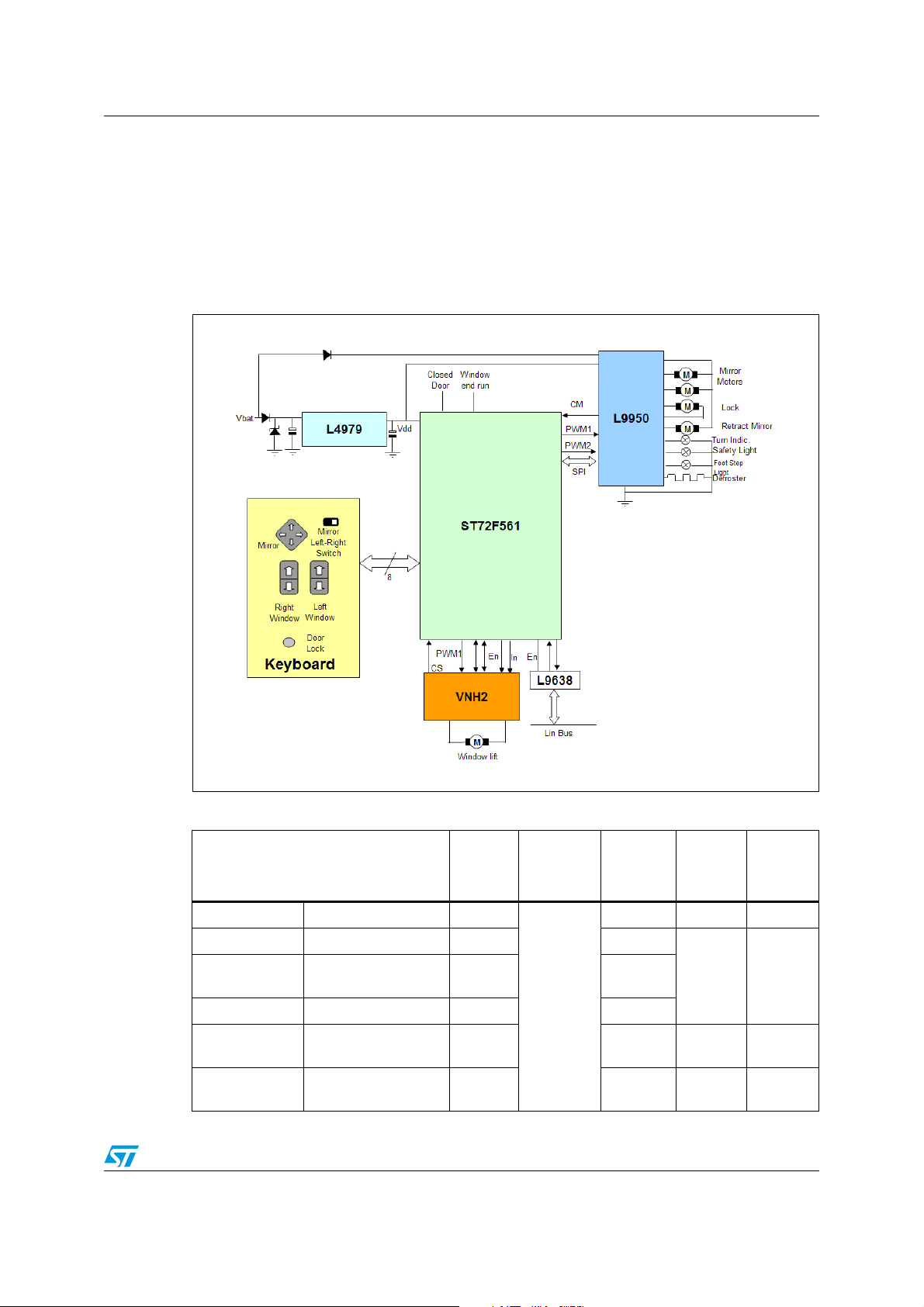

AN2334 Car door module description

1 Car door module description

This note describes a complete electronic module used to drive all loads in a car door,

connected via a LIN bus to the dashboard and to other doors, and via a parallel port to a PC

(for demonstration purposes). The block diagram in Figure 1 shows the system

configuration.

Figure 1. Door module block diagram

Table 1. Door module actuators

Actuators P

Window Lift 1 DC motor

Door lock 1 DC motor

Mirror axis

control

Mirror fold 1 DC motor

Mirror defroster

Light bulbs

2 DC motors

1 grounded resistive

load

4 grounded resistive

loads

nom

100W

5W

5/22

Wor ki ng

voltage

12 V

Load

speed

(Typ)

>78 rpm <2.5A <20A

Load

current

(Typ)

<2A <10A

current

Stall

Page 6

Car door module description AN2334

The microcontroller is the ST72F561, a member of the ST7 microcontroller family, designed

for mid-range applications with CAN (Controller Area Network) and LIN (Local Interconnect

Network) interfaces. It is based on an industry standard 8-bit core, featuring an enhanced

instruction set. The enhanced instruction set and addressing modes of the ST7 offer both

power and flexibility to software developers, enabling the design of highly efficient and

compact application codes. In addition to standard 8-bit data management, all ST7

microcontrollers feature true bit manipulation, 8x8 unsigned multiplication and indirect

addressing modes.

The voltage regulator is the L4979 which offers high precision output voltage and a

programmable watchdog timer with an external capacitor. The programmable watchdog

timer allows microcontroller auto-recovery from software runaway failures.

The L9638 performs LIN-bus interface functions between the protocol handler in the

microcontroller and the physical bus in automotive applications. It has a Sleep mode that

allows the lowest current consumption of the transceiver. It is possible to wake up the

transceiver through LIN-bus, Enable input or Wake-up input.

The new VNH2SP30 window power bridge driver provides a smooth and fully-protected

motor drive via 20 kHz PWM. A current sense (CS) output is used to monitor motor torque

that provides an antitrap function via the ADC inputs of the microcontroller.

Finally, the L9950 actuator driver controls mirror adjustment and fold-in/-out, as well as an

advanced locking system, driving the door latch and the dead bolt motor. Five intrinsic highside drivers are available to control various lamps or LEDs, including the mirror defroster,

and sophisticated diagnostic algorithms allow digital and analog load status to be monitored

by reading fold, lock motors and defroster currents.

6/22

Page 7

AN2334 Algorithms

2 Algorithms

After turn on or resetting, the microcontroller initializes all used peripherals (I/Os, Timers,

ADC and LIN-SCI) and variables, drives the L9950 to open the left wing-mirror and sends a

LIN message to do the same for the right wing-mirror. Afterward, it starts an infinite loop that

can be stopped only by resetting or turning off the board.

The microcontroller starts polling on both key pins (for driving window lift) and the keypad.

As soon as a load is turned on, the L9950 Enable Bit is set to switch the device into active

mode, turning on the Charge Pump Output. This output drives the gate of an external nchannel power MOS used for reverse polarity protection. This action, guaranteeing the

reverse battery protection, needs about 300µs, which is the activation delay for every load.

When no load is driven, the Enable Bit is cleared and the device goes into standby mode for

power saving.

It is possible to drive the window lift by using both the PC keypad and board keys (#4 / #5 -

Figure 9). The "Up key" and "Down key" pins are configured in the input pull-up mode, so

they are normally at a high value (5V); if the UP or DOWN buttons are pressed, two different

behaviors are shown, depending on the duration of the pressing time. If the button is

pressed for less than 100 ms, the glass moves up or down (depending on the key pressed)

until the top or bottom part of the window is reached; if the pressed time exceeds 100 ms,

the window moves up or down following the touch temporization. The same behavior occurs

when a PC software keypad is used.

The "Window Up switch" pin (#9 - Figure 9), also configured in input pull-up mode, must be

connected using a mechanical switch that senses the window end run, indicating that the

door upper limit has been reached.

The PWM 8-bit Autoreload Timer is used to perform a task temporized at 1 ms.

This task is in charge of all temporized events:

– It counts 250 ms before sending a LIN request message to the dashboard

– In case of window lift activation, it manages current sampling

– It also controls the mirror folding, locking and turn indicator light on and off

switching timings

When either the Down or Up key (both in the board or on the PC keypad) are pressed, the

Window_Lift routine is called:

– VNH2 InA and InB pins are, then, set or reset, depending on the key pressed, to

lift the window up or down and,

– the 16-bit Timer is used to provide to the VNH2 a PWM signal with 20 kHz

frequency and 30% duty cycle

– during a 1 ms task, the current sense voltage is acquired via ST7 ADC; the

acquisition is averaged over a 10 ms period to eliminate noise. Motor power is

calculated by multiplying the current sense by the estimated angular velocity. This

value is averaged over 100 ms, providing a delayed signal compared to the

original. The difference between power and averaged power must be compared

with a threshold to determine whether a pinch event occurs. This threshold

depends on the motor status (soft start up or steady state conditions).

Unless a Down/Up key is pressed or a pinch occurs, the duty cycle increases linearly until

100% is reached and the PWM becomes a constant (steady state phase, see Figure 2.)

7/22

Page 8

Algorithms AN2334

Figure 2. VNH2 PWM signal

PWM

5V

At this point the system waits for any event: A pressed key or a pinch.

If a key is pressed, the motor is stops, resetting VNH2 PWM and setting InA and InB for

braking to Vbatt the motor and stopping the glass.

In case of a pinch event, the Window Up switch is first checked. If this switch is closed

(upper limit reached), the glass is locked driving the motor up for 800 ms.

Otherwise, if the glass moves up, it is driven down for 800 ms to release the pinched object;

if it goes down the motor is stopped immediately.

When an abnormal condition is detected (Open Load, Short circuit or thermal shutdown), a

LIN message is sent to the PC VNH2 diagnostic node. Open Load is detected by current

sense voltage monitoring (value) while a short circuit and thermal shutdown are detected

using the VNH2 DIAGx pin. When DIAGx pin is reset, while INx is set, the status pin

indicates a thermal shutdown; otherwise, if INx is reset the status pin detects a short circuit.

For further information about antipinch algorithms, please refer to “AN2095 - VNH2 for

window lift with antipinch routine”.

Duty

Cycle

30%

Duty

Cycle

50%

Soft Start

Duty

Cycle

70%

Duty

Cycle

100%

t

When a command for L9950 loads is detected through keypad input pins, the

microcontroller drives such loads through the L9950 SPI bus. Serial data for controlling

outputs and for receiving status registers is sent via this bus.

For example, if one of the over-current bits is set, the corresponding driver is disabled. If the

over-current recovery bit of the output is not set, the microcontroller must clear the overcurrent bit to enable the driver again.

If the thermal shutdown bit is set, all drivers go to high impedance state. Again, the

microcontroller must clear the bit to enable the drivers.

When the Fold Mirror motor is activated, the relevant motor is driven for 4 seconds with a

fully charged battery and for 6 seconds in other cases. Since the OUT1 is common to all

mirror motors, it is impossible to drive two or more mirror motors at the same time.

The turn indicator and the defroster are driven using PWM2 and PWM1 respectively.

For all lights, the over-current Recovery Enable bit is set by the microcontroller; this

automatically reactivates the output after a delay time, resulting in a PWM modulated

current with a programmable duty cycle.

The over-current recovery feature is intended for loads which have an initial current higher

than the over-current limit of the output (for example, cold light bulbs).

The described algorithm, including LIN message managing, is stored in less than 10 kB on

the microcontroller Flash memory.

8/22

Page 9

AN2334 Algorithms

Figure 3. Simplified algorithm flowcharts

Reset

Reset

Init

Ext. WDG reload

Ext. WDG reload

Paral. Port and keys read

Paral. Port and keys read

Key or keypad

Key or keypad

Load turn ON/OFF

Load turn ON/OFF

NO

NO

Send LIN Msg to PC

Send LIN Msg to PC

Init

Pushed

Pushed

Diagnostic

Diagnostic

NO

NO

Window Lift Routine

Window Lift Routine

Load Turn ON/OFF

Load Turn ON/OFF

Turn On Charge Pump

Turn On Charge Pump

VNH2 or

VNH2 or

L9950

L9950

LOAD ?

VNH2 L9950

VNH2 L9950

LOAD ?

SPI send MSG

SPI send MSG

250 ms Task

250 ms Task

LIN Msg Request to Dashboard

LIN Msg Request to Dashboard

Receive Data

Receive Data

Defroster

Defroster

ON

NO

NO

NO

NO

ON

Turn Light ON

Turn Light ON

YES

YES

PWM1 On

PWM1 On

SPI send Msg

SPI send Msg

YES

YES

PWM2 On

PWM2 On

SPI send Msg

SPI send Msg

9/22

Page 10

Local Interconnect Network (LIN) messages AN2334

3 Local Interconnect Network (LIN) messages

Created by the LIN Consortium (a collection of automotive, software and semiconductor

manufacturers), LIN is a low speed bus with a maximum speed of 20kbaud. The most

significant advantage offered by LIN bus is the low cost of implementation. Implementing a

LIN node costs approximately half of an equivalent CAN bus node.

The LIN bus protocol is based on the common UART byte interface. Any microcontroller with

a UART interface can be used as a node on the LIN bus since the basic transmission uses

the UART format. The LIN bus protocol specification 1.2 defines three standard baud rates:

2400 baud, 9600 baud and 19200 baud. Communication is based on a master/slave

mechanism.

The bus is composed of one master node (Driver door) and five slave nodes (All Doors,

Front Right Door, Dashboard, PC VNH2 Diagnostic and PC UH22/L9950 Diagnostic). All

arbitration and collision management takes place in the master node to further simplify and

lower the cost of the slave nodes.

Figure 4. Master/slave diagram

CAN Bus

SLAVE

All Doors

MASTER

Driver Door

SLAVE

Front Right Door

SLAVE

Dashboard

SLAVE

PC-VNH2 Diag

LIN Bus

SLAVE

PC-UH22/L9950 Diag

– All Doors is used for locking/unlocking all doors

– Front Right Door is the slave node in the front right door that receives all

messages for mirror positioning (X-Y and fold) and for front right window lift

– Dashboard is questioned from the master node each 250 ms in order to give

information for turning on/off turn indicator and defroster

– PC-VNH2 is used for demonstration purposes to send VNH2 diagnostic

information to PC

– PC-UH22/L9950 is also used for demonstration purposes to send L9950

diagnostic information to PC

All communications on the bus take the form of messages, which have a defined format

known as the message frame. A diagram showing the format of the message is shown in

Figure 5. The message frame is composed of a header and a response. The header is

further broken down into three fields:

– The synchronization break field, composed of 13 dominant bits (0) and at least

one recessive bit (1), which indicates the beginning of a frame.

– The synchronization field, which allows a slave to be synchronized on the current

master baud rate.

– The identifier field, which identifies the requested message and the length of the

response field.

10/22

Page 11

AN2334 Local Interconnect Network (LIN) messages

Figure 5. LIN bus message frame format diagram

Only the master node can initiate a message by sending a header field that is received by all

nodes. Each slave node analyses the header and must be ready to send or receive data

during the response field of the frame. The identifier field within the header informs all slave

nodes in the network of the appropriate action to take. Such actions include:

– Receiving bytes transmitted in the response field

– Transmitting bytes in the response field

– Doing nothing

ST72F561 has a flexible microcontroller architecture that makes the implementation of LIN

bus communication much easier than on other devices.

The LIN bus transmission of a master node, as this demoboard, has three distinct phases:

– Synchronization break field transmission: The length of this field is 13 dominant

bits and 1 recessive bit

– Data byte transmission: The synchronization field, the identifier field, the data

fields and the checksum field are each one byte fields.

– Data byte reception: The data fields and the checksum field are also transmitted in

a byte wise manner.

The LIN bus protocol uses a standard baud rate: 19200 baud. In case of microcontroller

debugging, when CPU frequency is divided by two, a 9600 baud protocol is also possible.

The software PC allows users to change the baud rate.

It is necessary to define a specific ID (6 bits long) for each message, which is used for

reception or transmission. The message ID is written in a hexadecimal format with the parity

bits included. According to the LIN specification, the data field can be 1 to 8 bytes long (for

LIN 1.2 and newer).

The parity bits P0 and P1 are calculated as follows:

P0=ID0 ⊕ ID1 ⊕ ID2 ⊕ ID4

P0=ID1 ⊕ ID3 ⊕ ID4 ⊕ ID5

Because the application is for demonstration purposes, it uses two LIN messages for

transmission with PC (2 bytes long for VNH2 diagnostic and 8 bytes long for L9950

diagnostic).

11/22

Page 12

Local Interconnect Network (LIN) messages AN2334

Table 2. Application Messages

Message ID

LinMsg1

(0xc1)

LinMsg2

(0x42)

LinMsg4

(0x73)

LinMsg3

(0xC4)

LinMsg5

(0x11)

Table 3. FR RL RR data

Slave

response

source

Driver Door (M)

Driver Door (M)

Driver Door (M)

Driver Door (M)

Slave response

destination

FR RL RR

Doors (S)

Front Right

Door (S)

PC-L9950

Diag (S)

PC-VNH2

Diag (S)

Dashboard (S) Driver Door (M) 2 See Ta ble 6 Master data request

Description Data Value

Unlock Doors 0x01

Lock Doors 0x02

Table 4. Front Right Door

N.transmit

[bytes]

2See Ta bl e 3

2See Ta bl e 4

Message

Data

Description

Master transmit doors lock / unlock

command

Master transmit FR Door

commands

8See Ta bl e 7 Master transmit diagnostic signals

2See Ta bl e 5

Master transmit RL Door

commands

Description Data Value

Front Right Mirror Dx 0x01

Front Right Mirror Sx 0x02

Front Right Mirror Up 0x03

Front Right Mirror Down 0x04

Front Right Mirror Close 0x05

Front Right Mirror open 0x06

Front Right Window Up 0x07

Front Right Window Down 0x08

Table 5. PC-VNH2 Diag. data

Description Data Value

No diag err 0x01

Therm. Shutdown Leg A 0x27

Therm. Shutdown Leg B 0x28

Short Circ. Leg A 0x29

Short Circ. Leg B 0x2A

Open Load 0x2B

12/22

Page 13

AN2334 Local Interconnect Network (LIN) messages

Table 6. Dashboard data

Description

Data Value

No action 0x01

Defroster turn on 0x02

Turn light turn on 0x03

Defroster and Turn light turn on 0x04

Table 7. PC - L9950 Diag. data

Data0 Data1 Data2 Data3 Data4

Bit Description Bit Description Bit Description Bit Description Bit Description

VS Over

0

Voltage

VS Under

1

Voltage

Thermal

2

Shutdown

Temperature

3

Warning

Out 2 HS

0

Over Current

Out 3 LS

1

Over Current

Out 3 HS

2

Over Current

Out 4 LS

3

Over Current

Out 6 HS

0

Over Current

Out 7 HS

1

Over Current

Out 8 HS

2

Over Current

Out 9 HS

3

Over Current

Out 2 LS

0

Open Load

Out 2 HS

1

Open Load

Out 3 LS

2

Open Load

Out 3 HS

3

Open Load

Out 6 LS

0

Open Load

Out 6 HS

1

Open Load

Out 7 HS

2

Open Load

Out 8 HS

3

Open Load

4N.U. 4

Out 1 LS

5

Over Current

Out 1 HS

6

Over Current

Out 2 LS

7

Over Current

5

6

7

Out 4 HS

Over Current

Out 5 LS

Over Current

Out 5 HS

Over Current

Out 6 LS

Over Current

Out 10 HS

4

Over Current

Out 11 HS

5

Over Current

Out 1 LS Open

6

Load

Out 1 HS Open

7

Load

Out 4 LS

4

Open Load

Out 4 HS

5

Open Load

Out 5 LS

6

Open Load

Out 5 HS

7

Open Load

Out 9 HS

4

Open Load

Out 10 HS

5

Open Load

Out 11 HS

6

Open Load

N.U.

7

13/22

Page 14

PC Keypad software AN2334

4 PC Keypad software

Before switching on the board, the PC “Keypad” software must be run, defining the parallel

port base address (see Windows Device Manager) and the COM serial port to be used.

PC software has four different functions: Keyboard, dashboard, LIN analyzer, VNH2 and

L9950 diagnostic view.

– Keyboard is connected to the microcontroller via a parallel port and provides to

the microcontroller an 8-bit word that encodes all possible user actions as

described in the following Table 8 and Tabl e 9 :

Table 8. Window and door lock coding

Window Door

Parallel Port

Up Left Down Left Up Right Down Right Lock / Unlock

00 0 0 0 192

00 0 1 0 194

01 0 1 0 202

01 0 0 0 200

00 1 0 0 196

10 1 0 0 212

10 0 0 0 208

00 0 0 1 193

00 0 1 1 195

01 0 1 1 203

01 0 0 1 201

00 1 0 1 197

10 1 0 1 213

10 0 0 1 209

14/22

Page 15

AN2334 PC Keypad software

Table 9. Mirror and door lock coding

Mirror Door

Open Close

00 0 0 0 0 0 0 0

10 0 0 0 0 0 0 128

01 0 0 0 0 0 0 64

10 1 0 0 0 0 0 160

01 1 0 0 0 0 0 96

00 0 1 0 0 0 0 16

00 0 0 1 0 0 0 8

00 0 0 0 1 0 0 4

00 0 0 0 0 1 0 2

00 1 1 0 0 0 0 48

00 1 0 1 0 0 0 40

00 1 0 0 1 0 0 36

00 1 0 0 0 1 0 34

Left /

Right

Up Down Left Right

Lock /

Unlock

Parallel Port

00 0 0 0 0 0 1 1

10 0 0 0 0 0 1 129

01 0 0 0 0 0 1 65

10 1 0 0 0 0 1 161

01 1 0 0 0 0 1 97

00 0 1 0 0 0 1 17

00 0 0 1 0 0 1 9

00 0 0 0 1 0 1 5

00 0 0 0 0 1 1 3

00 1 1 0 0 0 1 49

00 1 0 1 0 0 1 41

00 1 0 0 1 0 1 37

00 1 0 0 0 1 1 35

– Dashboard is a LIN slave node and is used to switch on or off the turn indicator

light and the defroster.

– LIN Analyzer “sniffs” all LIN messages that flow through bus.

– VNH2 and L9950 diagnostic graphically shows the LIN messages addressing

VNH2 and L9950 diagnostic nodes.

Figure 6 displays the program main window snapshot.

15/22

Page 16

PC Keypad software AN2334

Figure 6. PC keypad screenshot

Keyboard

Keyboard

Dashboard

Dashboard

LIN analyzer

LIN analyzer

VNH2 and L9950

VNH2 and L9950

diagnostics

diagnostics

16/22

Page 17

AN2334 PC Keypad software

PC software can also change the thresholds for the window lift routine. Any threshold

change modifies the motor torque in a pinch state. For further details, please refer to

“AN2095 - VNH2 for window lift with antipinch routine”.

Figure 7. Adjust thresholds screenshot

17/22

Page 18

Hardware implementation AN2334

5 Hardware implementation

The voltage regulator, which provides the required 5V during normal mode, is enabled by

the LIN transceiver through Inhibit Output pin INH. To reset the microcontroller with the

watchdog timer in case of a missing pulse, a jumper must be installed in the Voltage

Regulator Reset connector (#1 - Figure 8).

The jumper must be removed in case of microcontroller reprogramming; in fact, in this

phase, the microcontroller cannot provide pulses to the voltage regulator that should provide

a low level reset. Moreover, during the programming phase, to enable the Voltage regulator

a jumper must be installed in the Voltage Regulator Enable connector (#2 - Figure 8)

because in this case the LIN bus interface L9638 cannot provide the enabling voltage.

In summary, the microcontroller can be reprogrammed using the ICP connector (#10 -

Figure 8) by removing the Reset jumper (#1 - Figure 8) and settling the Enable jumper (#2 -

Figure 8). See the ST72F561 datasheet for more details.

A jumper on CB4 connector (#8 - Figure 8) allows using the board without using the LIN

Interface as detailed in Section 3: Local Interconnect Network (LIN) messages.

The board connector locations are given in Figure 8.

Figure 8. Board connectors

1 Reset

1 Reset

2 Enable

2 Enable

12 Power

12 Power

Supply

Supply

13 L9950

13 L9950

Outputs

Outputs

3 L9950 Outputs

3 L9950 Outputs

1

1

2

2

4 Down Key

4 Down Key

3

3

4

4

5

5

6

6

7

7

8

8

5 Up Key

5 Up Key

11

9

9

10

10

11

12 14

12 14

6 - CB5 / 7 – CB3 / 8 - CB4

6 - CB5 / 7 – CB3 / 8 - CB4

9 - Window Up Switch

9 - Window Up Switch

15

13

13

15

16

16

10 ICP Conn

10 ICP Conn

11 Window

11 Window

Motor

Motor

16 LIN Conn.

16 LIN Conn.

15 Wake Up

15 Wake Up

14 Parallel

14 Parallel

Port

Port

18/22

Page 19

AN2334 Hardware implementation

The L9950 loads are shown in the following table:

Table 10. L9950 Loads

L9950 Outputs Load

OUT1 Common Mirror Motors

OUT2 X Mirror Motor

OUT3 Y Mirror Motor

OUT4 Lock Motor

OUT5 Lock Motor

OUT6 Mirror Fold Motor

OUT7 Exterior Light

OUT8 Footstep Light

OUT9 Safety Light

OUT10 Turn Indicator

OUT11 Defroster

The input signals INA and INB are directly interfaced with the microcontroller to select the

motor direction and the brake condition. The DIAGA/ENA or DIAGB/ENB, connected to the

I/O microcontroller and configured as input pull-up, enable the legs of the bridge. They also

provide a digital diagnostic signal. The CS pin allows monitoring the motor current by

delivering a current proportional to its value. The PWM, up to 20 KHz, allows control of the

motor speed in all possible conditions.

The reverse polarity protection MOSFET needs a zener diode and a resistor between gate

and source to protect against ISO pulses and for proper turn off in static reverse polarity.

In master node application, a LOW ohmic resistor must be connected externally between

LIN and battery to allow the maximum transmission rate.

Finally, all outputs need a 10nF capacitor to protect the module against 8 kV ESD events.

Figure 9. Board Layout

ICP

Reset

Reset

Enable

Enable

+12

+12

Down

Out4

Out6

Out6

Gnd

Gnd

Out4

Out5

Out3

Out5

Out7

Out7

Out3

Out3

Out3

Out2

Out2

Out10

Out10

Out8

Out9

Out8

Out9

Down

Out1

Out1

Out1

Out1

Up

Up

Gnd

Gnd

Parallel Port

Out11

Out11

Parallel Port

Connector

Connector

ICP

Connector

Connector

Wake Up

Wake Up

Window

Window

A

A

Window

Window

B

B

Gnd

Gnd

+12

+12

Lin

Lin

19/22

Page 20

Schematic AN2334

m

Appendix A Schematic

Figure 10. Board Schematic

1234567

10nF

C9

10nF

C7

10nF

C10

26

GNDA28GNDA27GNDA

VCC4VCC12VCC13VCC3VCC

C5

100uF

C4

100nF

RESE T

ICCDATA

ICCCLO CK

12

13

RESE T

ICCCLK / AI N 0/ P B4

ICCDATA/AI N1/P B5

18

21

23

Ext Wdg

41

PE4

8

CON8

10nF

C14

Mirr o r R et ra ct Mot o r

10nF

C13

Lock Mot. B

10nF

Common Mi rror Mo to rs

10nF

Lock Mot. A

MOTOR D C

17

18

25

30

OutA1OutA2OutA

GNDB

GNDB20GNDB19GNDB

PWM

VCC22VCC24IN A5IN B11PWM8DiagA/En A6DiagB/EnB

7

R17

R19

R18

10K

10K

Master in-Slave out

Mast er o ut- Sl ave i n

R61K

R71K

TxD

26

10

19

17

14

11

43

MCO/ PB3

PD6/AI N10

PC6/SPI_MOSI27PC5/SPI_MISO

T8_I CA P1 / P B2

PD5/linSCL2_TDO

T16_ICAP2/( HS)/PC1

T16_OCMP1/AIN2/P B6

PD1/linSCL1_RD1

PWM3/PA35T16_ICAP1/AI N4/PC0

PWM0/PA13PWM1/(HS)P A24ARTIC2/(HS)PA6

PWM3/PA46ARTCLK/(HS)PA57PD2/linSCL1_TDO

8

32

33

R31KR41KR51KR101KR141KR111KR121KR13

1K

123456789

J2

+5V

R1

4.7k

C12

C8

10nF

C26

J5

10nF

C27

14

21

OutB

OutB15OutB16OutB

OutA

CSens

Multi Power SO30

9

10

R22

2.2K

R21

R35

R20

10K

10K

2.7K

2.7K

PWM1

EN

RxD

36

28

9

35

T8_O CMP 1 /P B 1

PD4/linSCL2_RDl

PD3(HS)/ linSCL2_ SCK

T16_OCMP2/AIN3/P B7

PC4/CAN_TX

PD7/AI N11

24

44

CM

10

to PC Parallel Port

10k

R9

Spi Cl ock

PC7/SPI_SCK

PD0/SPI_ss/AIN629PF1/AIN7

1K

R15

CSN

Vpp/ICCSEL

22

38

Vs s _0

ICCSEL /Vpp

PC3/CAN_RX

T1 6 _ E XTCL K / ( H S ) /P C 220PE6/AI N5

PF5

23

30

34

33nF

C28

R16

10 K

15

37

Vs s 2

Vs s a

PF2/AIN8

31

25

J3

10nF

C6

Left - Rig ht Mi rr o r Mot o r

Common Mi rror Moto rs

Up-Down Mi rror Mot or

Common Mi rror Mo to rs

29

GNDA

VNH 2 SP 3 0

VBAT

R8

47K

+5V

Vd d

10nF

C3

+5V

39

16

40

42

Vd d 2

Vd d A

Vdd_0

Osc1

Osc2

ST72F561

1

2

C2

18pF

XT1

16 MHz

C1

Osc1

18pF

VBAT

R2

10k

1234567

J9

Exte ri ou r Li ght

TQFP44

Close d Door

CB5

PF1

CB4

CB3

PE6

M2

M1

CB2

Win dow Up Sw itch

CON7

10nF

C19

Defroster

10nF

C18

Turn Indicator

10nF

C16

Safet y Li gh t

10nF

C17

Footst ep Ligh t

10nF

C11

Common Mi rror Moto rs

Up- Do wn Mir ro r Mot or

Left-Right Mirror Motor

5

Out13Out24Out3

Out416Out4

Vs28Vs

Vs

L9950

25

29

32

VBAT

123

J6

100Ohm

VBAT1

R27

10nF

R25

500 Ohm

VBAT

INH

7

8

6

5

Vs

LIN

INH

GND

RxD1EN2WUP3TxD

L9638D

4

EN

TxD

RxD

R24

1k

VBAT

2

3

J7

123456789

J4

ICCDATA

Lock Mot. B

Safet y Li gh t

Lock Mot. A

Turn Indicator

Footst ep Ligh t

Exteriou r Light

Mirror Retract Motor

2

17

C15

Wake Up

35

22

31

33

Out520Out521Out6

Out730Out8

Out9

Out1034Out11

Vs6Vs

Vs14Vs

Vs23Vs24Vs

CP

Tab

7

15

26

Tab

CP

Master in-Slave out

CON3

SO8

R26

1KOhm

10

ICC P rog ra

Vd d

Osc1

RES ET

ICCCLO CK

Vp p / ICC S EL

C29

CM

33nF

PWM1

R34

R32

2.7k

R36

50k

10k

Defroster

Out11

Di8CSN10DO11Vcc

CSN

Master out-Sl ave in

VBAT

CP

R33

27

PWM1

12

L4979D

R23

INH

10k

13

9

Spi Cl oc k

Clk

CM/P W M2

GND

GND18GND

GND

Power SO36

1

19

36

C25

10nF

+5V

10nF

C24

+5V

RES ET

C23

U5

Ext Wdg

Wi6Vo

Vs8En1Ground

100uF

47nF

7

5

C22

Vcw

Vcr

SO8

2

4

C21

1nF

100uF

C20

R31

100k

D2

BATTERY

J8

D1

R29 10 0K

CB1

3

Res out

J1

1K

R30 10 K

10k

R28

20/22

Page 21

AN2334 Revision history

Revision history

Table 11. Document revision history

Date Revision Changes

07-Apr-2006 1 Initial release.

21/22

Page 22

AN2334

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22

Loading...

Loading...