Page 1

AN2326

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Application note

Calibrating the RC oscillator of the

ST7ULTRALITE MCU using the mains

Introduction

The ST7ULTRALITE microcontroller contains an internal RC oscillator which can be

trimmed to a specific frequency with the required accuracy. The oscillator frequency has to

be calibrated by software using the RCCR register (RC Control Register) and the SICSR

register (System Integrity Control/Status Register). The value entered in the RCCR/SICSR

registers will switch ON a corresponding number of resistors that will modify the oscillator

frequency. Whenever the ST7ULTRALITE microcontroller is reset, the 10-bit value

contained in the RCCR/SICSR registers is restored to its default value (3FFh) i.e. the lower

possible frequency, so each time the device is reset, you have to load the calibration value in

the RCCR/SICSR registers. There are predefined calibration values stored in memory (refer

to the” Internal RC Oscillator Adjustment” section in the ST7ULTRALITE datasheet). You

can load one of these values in the RCCR/SICSR registers if one of the operating conditions

matches that in your application. Otherwise, you can define your own value, store it in non

volatile memory and load it in the RCCR/SICSR registers after each reset. However, if any

of the external conditions (temperature or voltage, for instance) changes too drastically, the

stored value may no longer produce the required accuracy. One solution is to recalculate the

RCCR/SICSR register values after each reset, based on an external reference.

The purpose of this application note is to present a software solution using the frequency of

the European standard mains (220V/50Hz) as a timebase to adjust the internal RC oscillator

of the ST7ULTRALITE to 8 MHz. The same approach can also be used for the US mains

standard (110V/60Hz).

The basic software takes less than 200 ms to calibrate the oscillator and uses less than128

bytes of program memory and five bytes of RAM for its simplest version. These RAM bytes

can be freed for other purposes when the calibration is done. Another example using

averages is given in this application note. This can be useful with noisy mains.

This application note also contains the diagram of a low cost circuit which converts the

mains into a 5 volt power supply and protects the microcontroller from overcurrent on the

input connected to the mains.

April 2006 Rev 1 1/20

www.st.com

Page 2

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Contents AN2326

Contents

1 Calibration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Software principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Basic version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Average version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Power supply and timebase delivery circuit . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Basic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Hardware protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Software examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Single alternance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.1 Main program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.2 Input capture interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.3 Timebase interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.4 Writing in non volatile memory for products without Data EEPROM . . . 12

4.1.5 Writing in non volatile memory for products with Data EEPROM . . . . . 13

4.1.6 Detailed basic version software flowchart . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Average version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.1 Main program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.2 Input capture interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.3 Timebase interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/20

Page 3

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Calibration software

1 Calibration software

1.1 Software principle

The software algorithm, described in the following flowchart (see Figure 3.), uses the mains

frequency as a timebase. This timebase allows the microcontroller to test if the RC oscillator

frequency is above or below the targeted frequency and repeatedly transforms it by

dichotomous analysis so that in 10 iterations the RCCR/SICSR registers are set to the

optimum value. In order to simplify the calculation, the calibration is done at 1MHz, the

8MHz internal RC is divided by 8 thanks to the AVTCHR register.

As the timer speed depends on the RC oscillator frequency, it is easy to determine if the

oscillator is too fast or too slow. The counted value can be obtained by the following

equation:

f

cpu

countedvalue

Since the frequency of the counter is the frequency of the oscillator divided by 32 (only the 8

MSbits are saved on the 13 bits of the counter), if the oscillator is at 1 MHz, the result of the

count between two edges (which have a 10 ms interval), is 138h for the European standard

(220V/50Hz). For the US standard (110V/60Hz) the right value is 104h. Since the goal of the

software is to set the RC oscillator frequency to 1 MHz it means obtaining 138h as the result

of the count. So if the result of the count is greater than 138h, it means that the frequency is

too high so the program increases the value of RCCR/SICSR registers in order to decrease

the RC oscillator frequency. And if the result is less than 138h, the RCCR/SICSR register

value is decreased in order to increase the RC oscillator frequency.

----------------------------=

32 f

×

mains

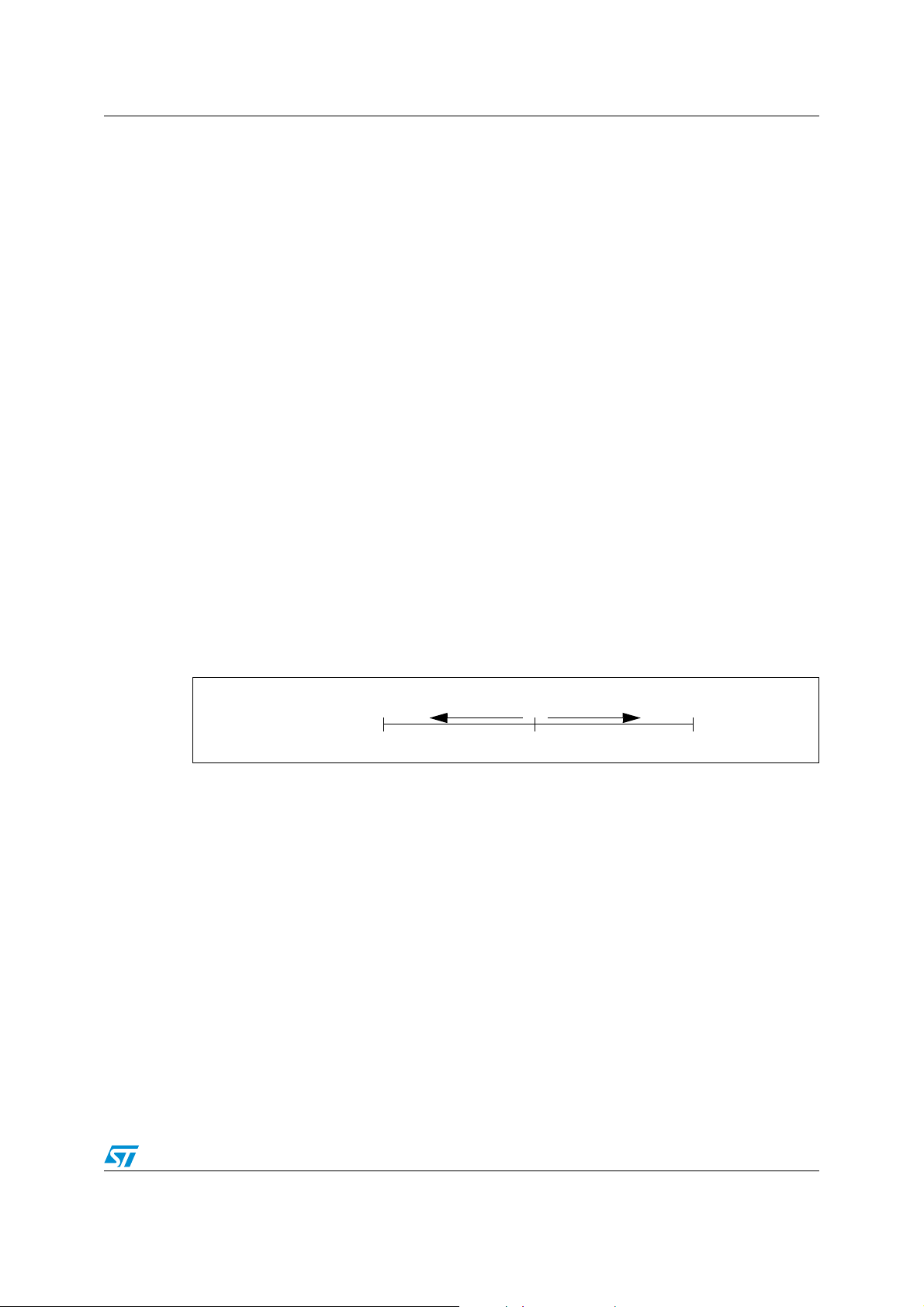

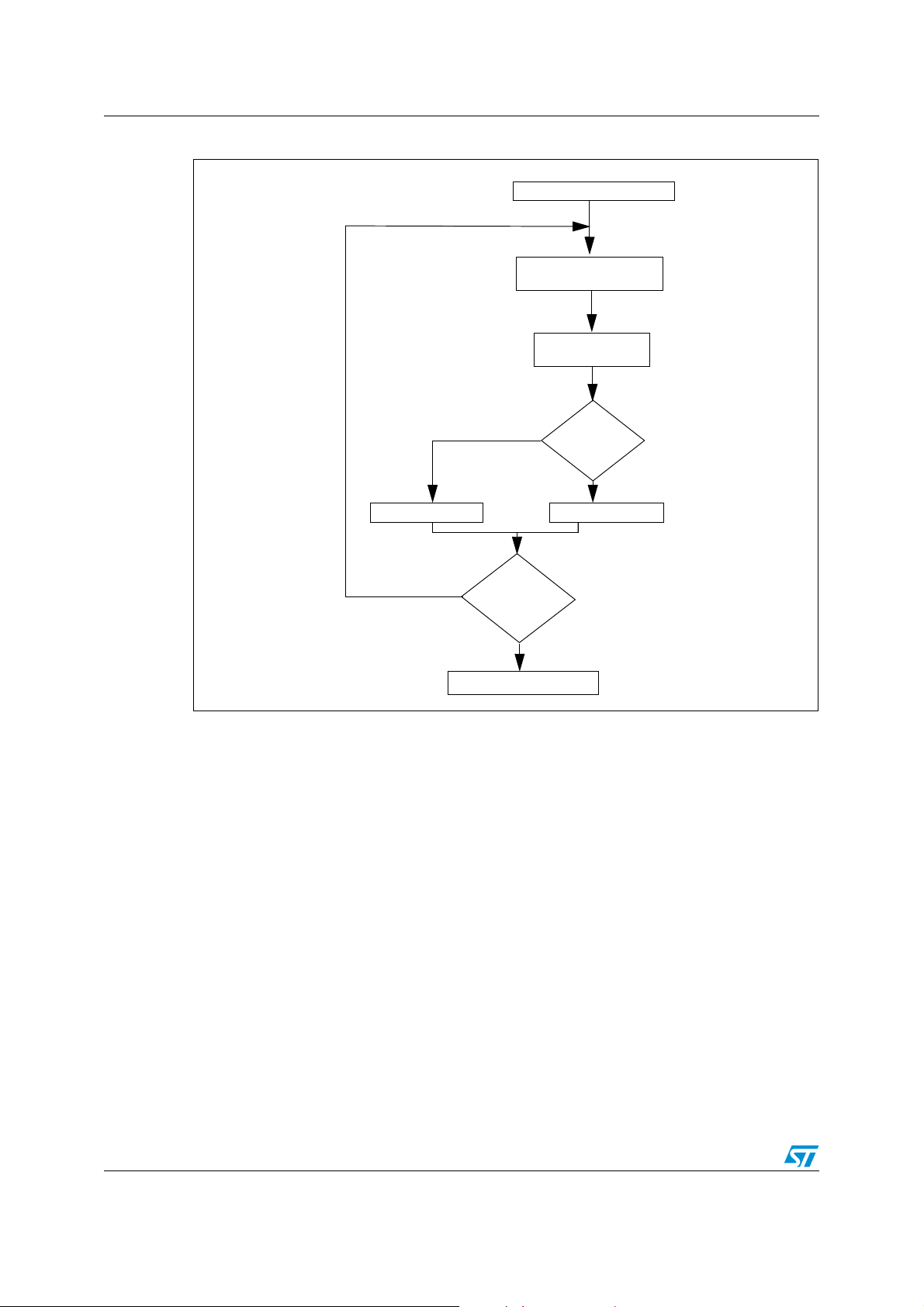

Figure 1. Dichotomous analysis of RCCR value

increase oscillator

frequency

RCCR Register

The RCCR register is set to 80h initially by the program, then the dichotomization starts by

adding or subtracting 40h and after each iteration the result is divided by two, so that after

10 iterations the value of RCCR is set with an accuracy of one bit.

decrease oscillator

frequency

80h

Start Value

FFh0h

3/20

Page 4

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Calibration software AN2326

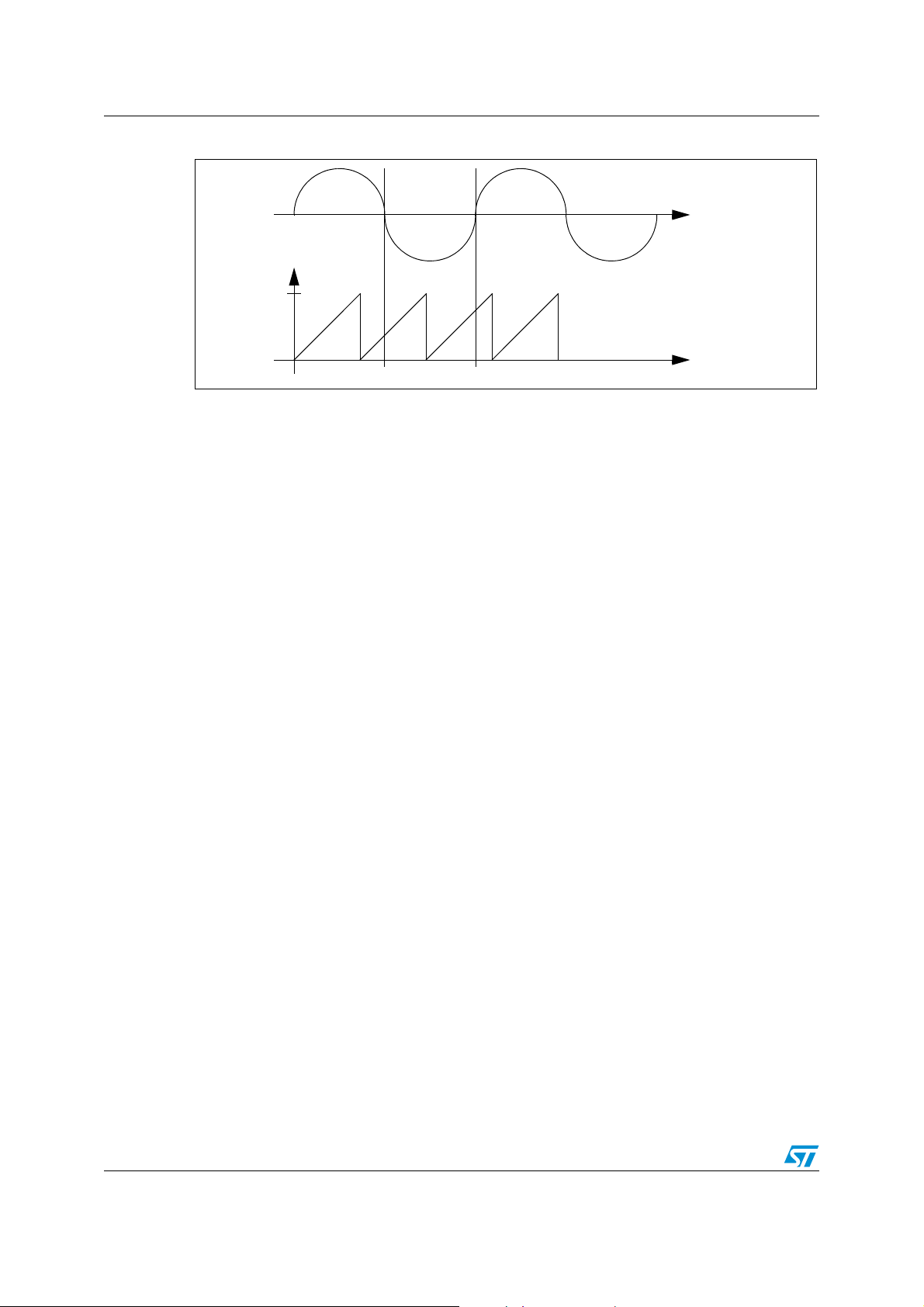

Figure 2. Using the timer input capture to measure the mains frequency

Mains

F9h

0h

To measure the frequency, the software uses the Lite Timer input capture (LTIC) so that on

each edge of the mains the value of the free running counter is stored as shown in Figure 2..

Then the microcontroller calculates the elapsed time between the two edges of the mains.

This time is given by the following equation:

where nbover represents the number of counter overflows during the measurement, capture

1 and capture 2 are the values captured on the free running counter when an edge occurs

on the mains and F9h is the overflow value of the free running counter.

If the RC oscillator frequency is equal to 1 MHz, the result time will be 138h for European

standard (220V/50Hz) or 104h for US standard mains (110V/60Hz), so these are the

reference values.

This measurement result is compared to the reference value and, depending on the result of

the comparison, the microcontroller adds to or subtracts from the current RCCR/SICSR

register values.

Overflow

Free-running

Counter

Capture 1 Capture 2

time nbover F9h capture2 capture1–+×=

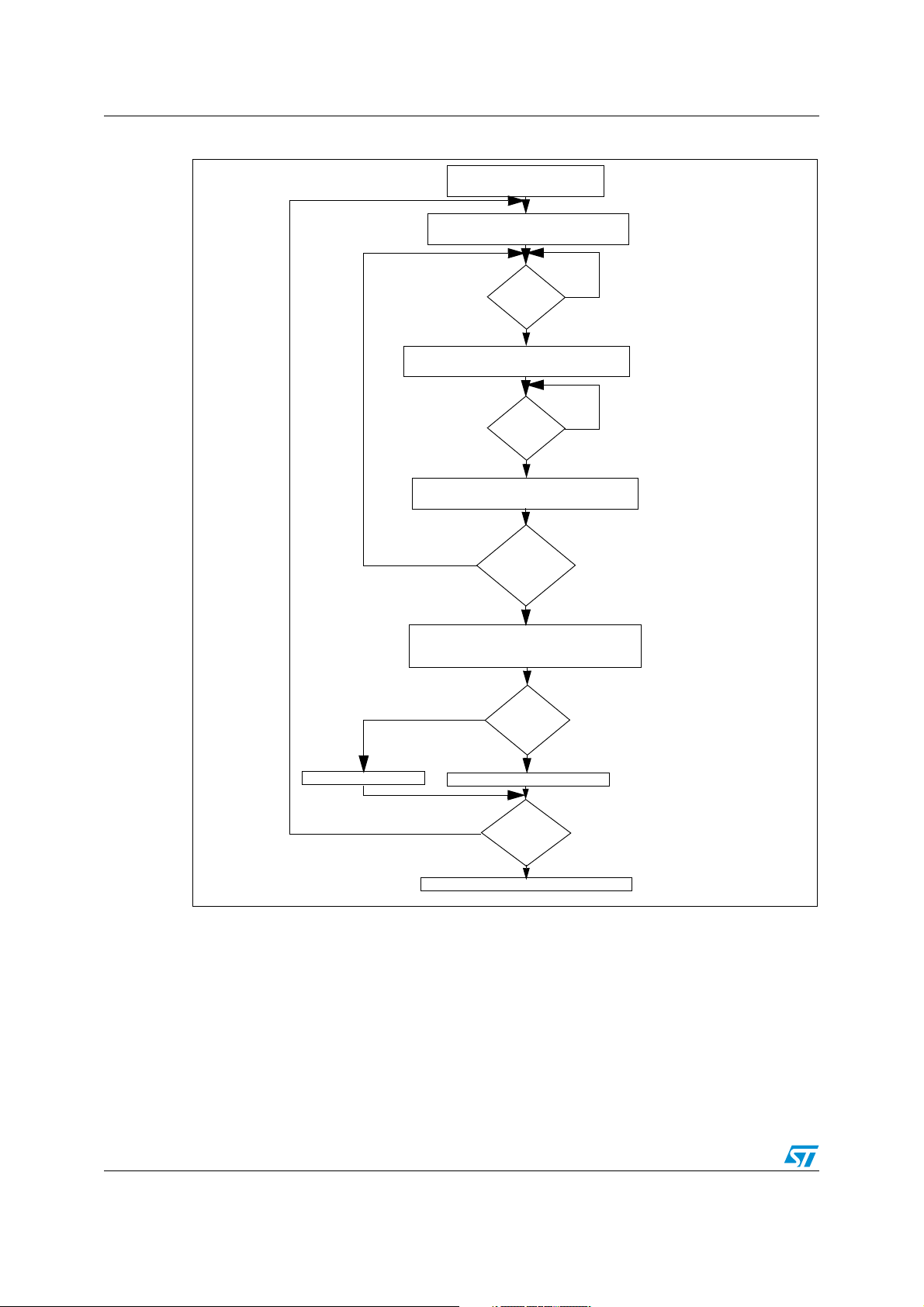

1.2 Basic version

In this version the measurement is done only once for each dichotomization step. This

allows the calibration software to be light and fast. It requires only 128 bytes of program

memory and 5 bytes of RAM during calibration. The calibration takes less than 200 ms to be

completed.

The software works as shown in the following flowchart. The assembly code and a more

detailed flowchart can be found in Section 4.

4/20

Page 5

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Calibration software

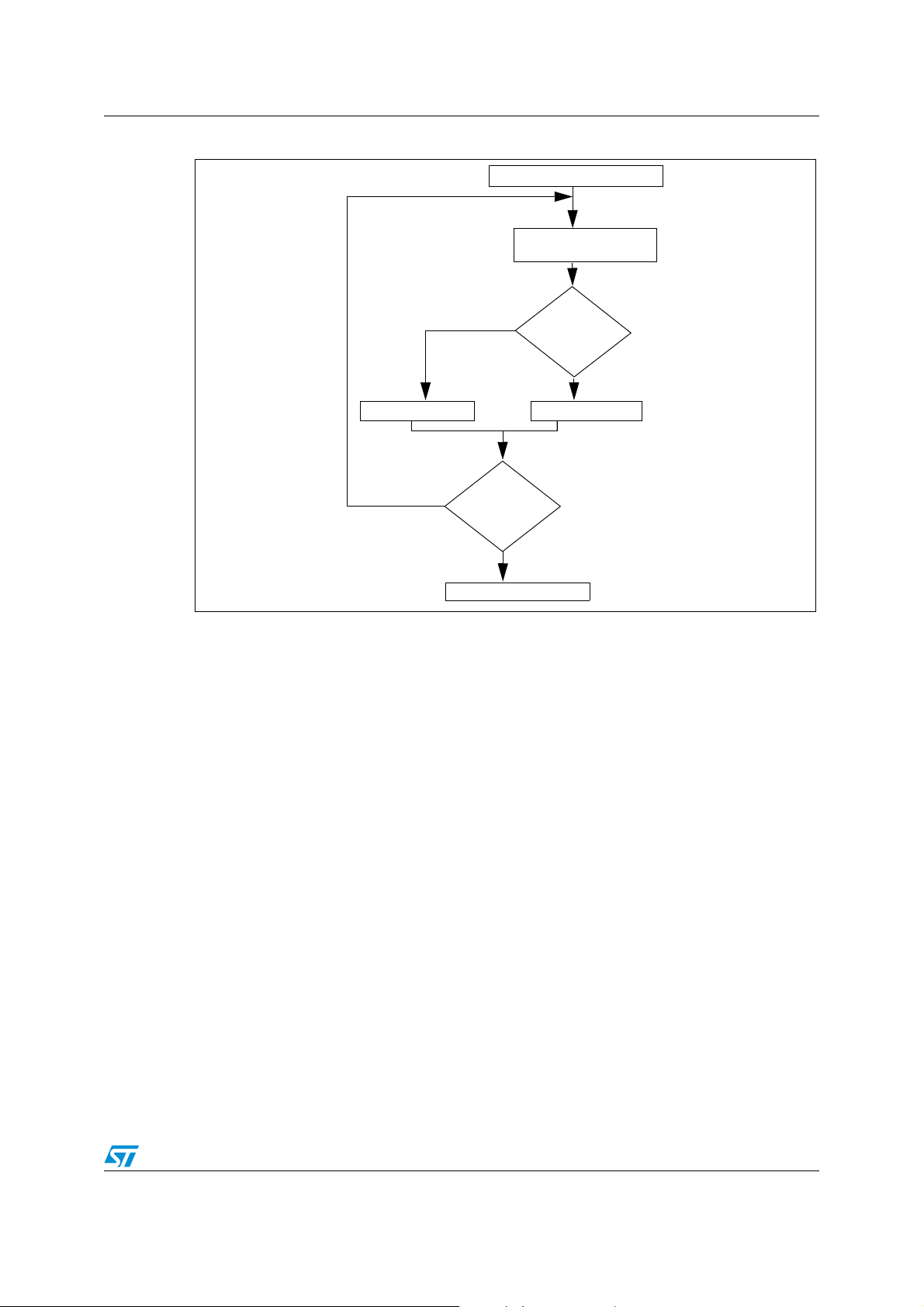

Figure 3. Basic software flowchart

Initialization of Lite Timer

Measurement and

calculation

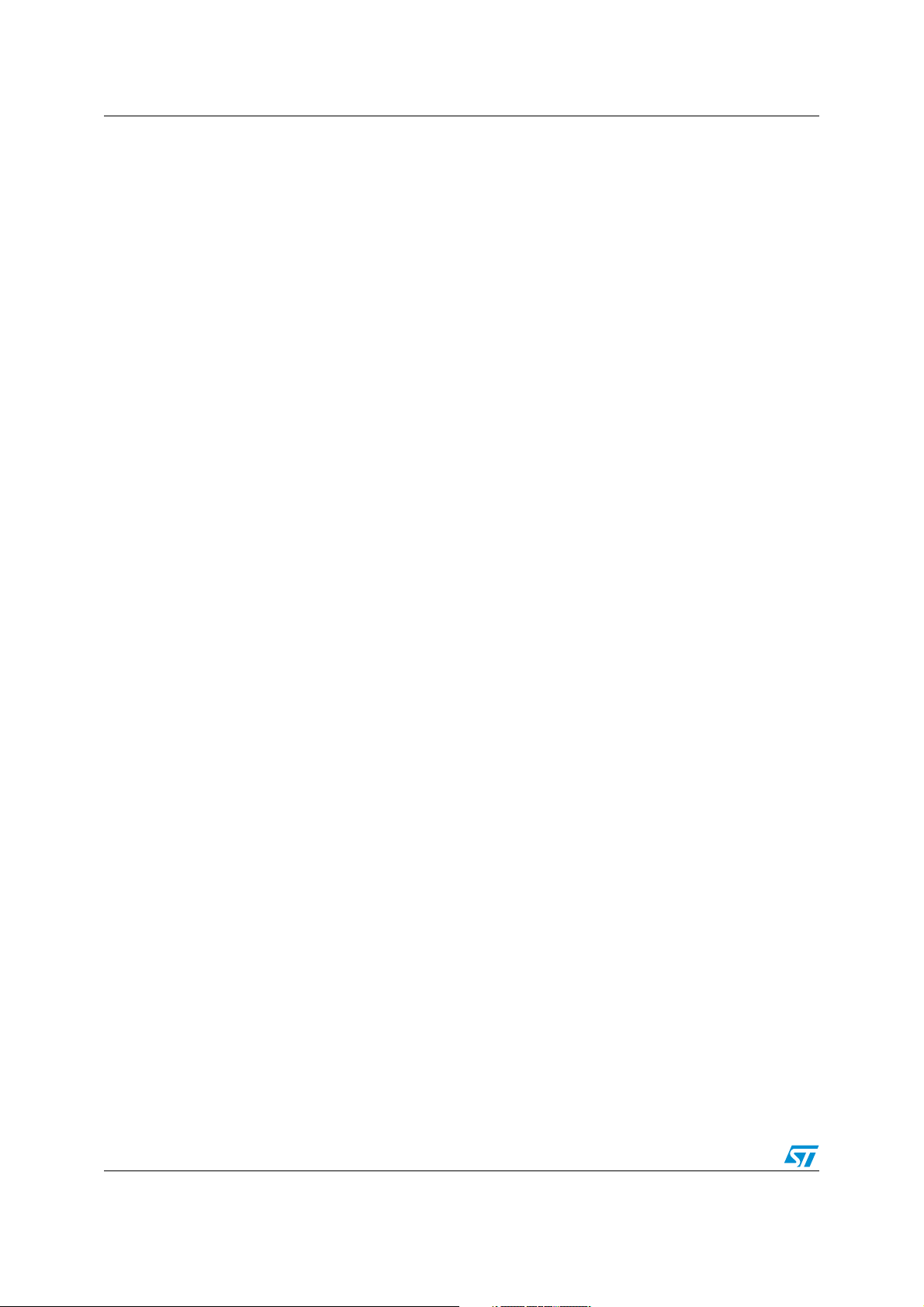

1.3 Average version

This version uses the method described in Section 1.1 except it performs four measurements and uses

their average for each dichotomization step. It is useful when the mains is noisy. For instance, when a

motor starts it generates a tension pick and this can be considered as a mains edge.

This version is safer than the basic one but it requires more resources. It uses 136 bytes of program

memory and 11 bytes of RAM during calibration. The calibration takes less than 800 ms to be completed.

The average version works as shown in the following flowchart. The assembly code can be found in

Section 4.

smaller

no

Dichotomization

finished?

yes

Clock is set to 1 MHz

Compare

result with

reference

greater or equal

Increase RCCRDecrease RCCR

5/20

Page 6

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Calibration software AN2326

Figure 4. Average software flowchart

Initialization of Lite Timer

4 measurements and

calculation

Average

smaller

Decrease RCCR

no

Clock is set to 1 MHz

Dichotomization

finished?

yes

Compare

result with

reference

greater or equal

Increase RCCR

6/20

Page 7

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Power supply and timebase delivery circuit

2 Power supply and timebase delivery circuit

The following figures show circuits which will provide 5V DC to the ST7ULTRALITE and

protect the input capture from overcurrent. If no power supply is needed, the only

component to keep is the resistor on the LTIC input, which is mainly to protect from

overcurrent.

2.1 Basic circuit

This circuit contains a capacitive power supply which converts the 220V/50Hz of the mains,

as well as the 110V/60Hz of the US mains, into 5V DC.

Warning: be aware that this kind of power supply cannot be used if there are

big current variations.

It also inputs 220V/50Hz to the Lite Timer Input Capture pin (LTIC/PA2) protected by resistor

R2.

The incoming alternating signal on the LTIC input pin is 220V/50Hz. Because of the

clamping diode on the input of the ST7ULTRALITE, the input signal can be considered as a

0-5V square signal.

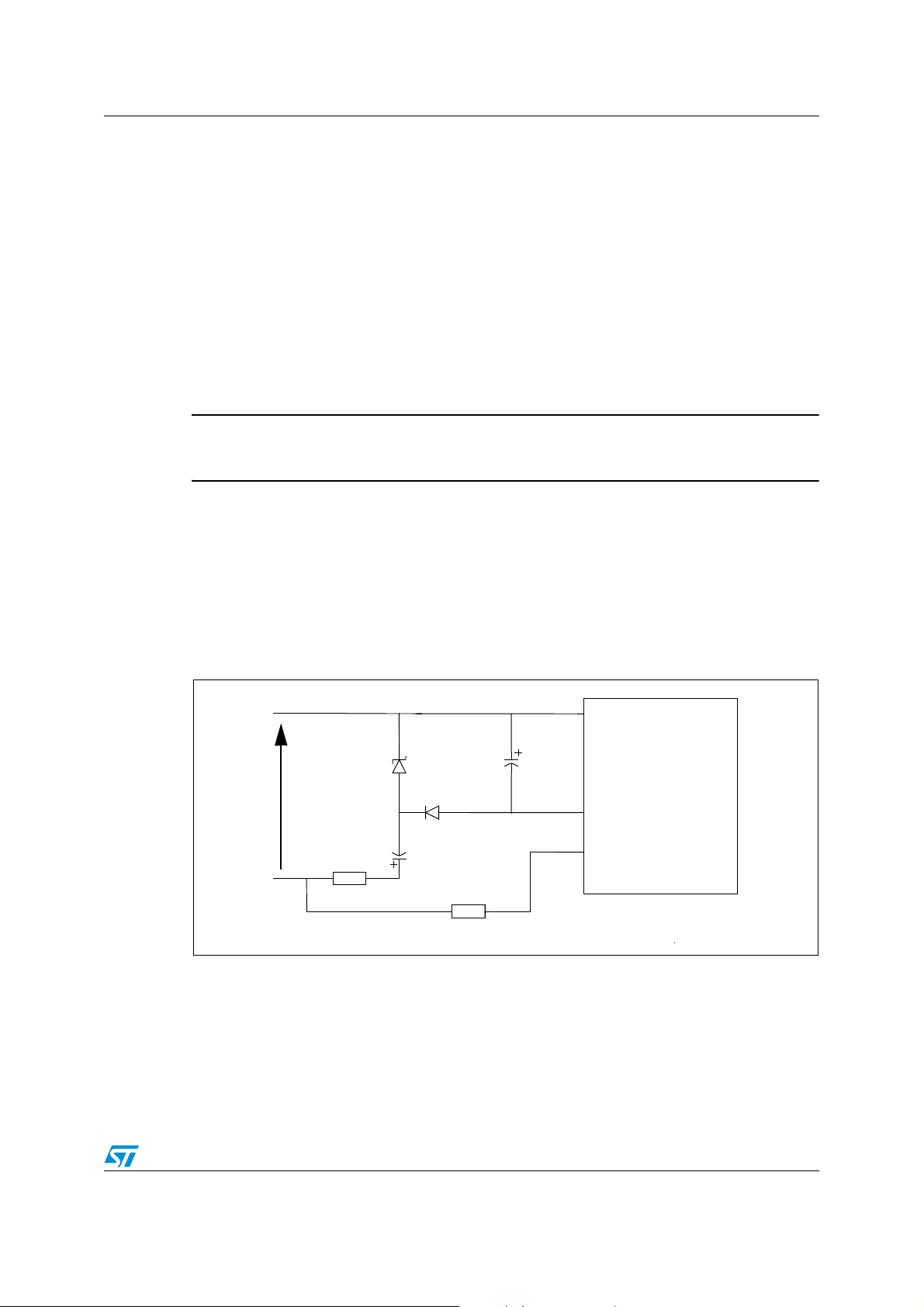

Figure 5. Power supply and timebase delivery circuit diagram

V

DD

C1

220µF/16V

ST7ULTRALITE

GND

LTIC

Mains

(220V/50Hz)

R1 47R/0.5W

zener

5.6V

1N4148

C2

C2

220nF/400V

R2 470k/0.5W

The maximum current available in the microcontroller depends on the C2 value. Table 1

gives the maximum average current versus the capacitor value. The average current follows

the equation below:

Imax Vmax 2 f C⋅⋅⋅=

In the case above, C2 is equal to 220nF so the available current is limited to 4.9 mA in the

case of a European mains. To have the same current levels in the case of the US mains

7/20

Page 8

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Power supply and timebase delivery circuit AN2326

(110V/60Hz), C2 must be multiplied by two. A 440nF capacitor will limit the current to 4.9

mA.

For the US standard, R2 must be divided by two in order not to limit the current too much on

the LTIC input. A 220kΩ resistor is enough in this case.

Table 1. Maximum MCU current

Capacitor C2 Maximum Current

220nF 4.9mA

330nF 7.3mA

470nF 10.4mA

680nF 15mA

1µF 22.1mA

2.2 Hardware protection

To prevent bad measurements due to noisy mains, a filter can be added between the mains

and the input capture of the ST7ULTRALITE. The following figure shows one example of a

filter. This filter is a pass band centered on the mains frequency in order to reject all

frequency which could be understood by the microcontroller as a mains edge.

Please note that this is just a second order filter and that this may not be enough if the mains

is really noisy. Any kind of filter can be added on the LTIC.

Figure 6. Band pass filter

mains

C1

470nF/400V

The pass band filter above must be tuned to mains frequency. The value of the resistors for

this filter is given in the table below.

Table 2. Resistor values

resistors 50Hz/220V 60Hz/110V

R1 6.8K/0.5W 5.6K/0.5W

R2 6.8K/0.5W 5.6K/0.5W

R3 470K/0.5W 220K/0.5W

R1 R2

C2

470nF/400V 470nF/250V

R3

C2

LTIC

8/20

Page 9

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Conclusion

3 Conclusion

This system allows you to have a power supply for the microcontroller and an auto

adjustable clock set to 1, 2, 4 or 8MHz, selected by prescaler, with the required accuracy

whatever the external conditions.

This solution also offers the advantage of being less expensive than a solution with a

transformer and requires less space.

It requires a small amount of space in program memory (less than 128 bytes) in its smallest

version.

9/20

Page 10

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Software examples AN2326

4 Software examples

A zip file attached to this application note contains the complete software of this calibration

method.

4.1 Single alternance

This version performs only one count between two edges and changes the value of the

RCCR/SICSR registers according to this measurement. This can lead to bad tuning if there

is noise on the reference signal.

4.1.1 Main program

;All the bytes from locations 80h to 85h are used by this software to store values or as control

registers but they can be reused safely after the clock has been set.

;dichotomy value

.value equ $81 ;this byte contains the value which will be added or

subtracted to/from the RCCR last value at the end of each round

;capture values

.capture1 equ $82

.capture2 equ $83 ;these two bytes contain the two values of the counter captured on

the edge of the mains, they are used to calculate the time elapsed between the two edges

;number of overflows

.nbover equ $84 ;this byte contains the number of counter overflows during the

measurement

;control register

.cr equ $85 ;this byte is used as a control register for the measurement. Its

bits allow or not the interrupts and show which step of the count is the current one.

.strtstp equ 1 ;this is set to start the count and reset to stop it

.lsb_RCCR equ 7 ;this bit is set when the first capture has occurred. It allows

the overflows to be counted

;address to program in NVM (optional)

.E2ADDR equ $86

.RAM equ $88

.main

ld A, #$63

ld AVDTHCR, A ; set internal clock to fRC/8 meaning 1MHz targeted

clr SICSR ;

ld A, #$80 ;value containing the value which will be

ld value, A ;add or subs to/from RCCR during the dichotomy

ld RCCR, A ;RCCR is set to the middle of its range of value

clr cr ;clear the byte use as control register for the count

next

clr nbover ;clear the byte containing the number of timer overflow

ld A, LTICR ;clear the ICF bit

count

btjt cr, #strtstp, count; wait for the end of count

rim ;interrupts enable

bset LTCSR,

bset cr,#strtstp ;set the start-stop bit of cr: count can start

clr LTCSR ;lite timer interrupts disable

srl value ;dichotomy value divided by 2

ld A,#$F9 ;these lines calculate this equation:

ld X,nbover ;

mul X,A ;(nbover*$F9)+ capture2 - capture1

add A, capture2 ;

jrnc nocarry ;this equation is calculated with 16 bits

inc X ;

clear the 2 lowest significant bits located in this register

#7 ;enable input capture interrupt

10/20

Page 11

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Software examples

nocarry

sub A, capture1 ;MSB are in register X

noneg

cp X, #$01 ;if mains frequency is 50Hz the reference value is $138

compare cp A, #$38 ;value is smaller than the reference the program jump to

plus

plus_lsb

btjt value, #5, p_lsb0

btjt value, #4, end

ld A, value

ld SICSR, A ;add value if counted value is greater than ref

jra next

p_lsb0

minus

btjt cr,#lsb_RCCR,minus_lsb

ld A, RCCR

jra new

minus_lsb

btjt value,#5, m_lsb0

btjt value, #4, clr_lsb0

bres RCCR,#0 ;reset the LSb of RCCRH

ld A, value

ld SICSR, A ;substract value if counted value is smaller tha n ref

jra next

m_lsb0

clr_lsb0

new

bset cr, #lsb_RCCR

ld A, #$80

ld value, A

jra next

.end_calibration ; end of the calibration

; at this point the Fcpu is set to 1MHz

; the last operation is to set the clock to the targeted value by setting the prescaler register

jrnc noneg ;

dec X ;and LSB in register A.

jrmi minus ;if it is 60Hz the reference is $104.the program first

jreq compare ;compares MSB with $01 and then compare LSB with

jp plus ;$38 for 50Hz and $04 for 60Hz. if the calculated

jrmi minus ;minus to decrease RCCR else it increase RCCR

btjt cr,#lsb_RCCR,plus_lsb

ld A, RCCR

add A, value ;add value if counted value is greater than ref

jra new

bset SICSR,#5 ;add value if counted value is greater than ref

jra next

sub A, value ;subtract value if Y

bres SICSR,#6

bset SICSR,#5 ;subtract value if Y is smaller

jra next

bres SICSR,#5 ;reset the LSb of RCCRL

jra end

ld RCCR,A ;enter the new value in RCCR

btjf value, #0,

ld A, #$03 ; set clock to fRC meaning 8MHz

; ld A, #$23 ; set prescaler to fRC/2

; ld A, #$43 ; set prescaler

; ld A, #$63 ; set prescaler to fRC/8

ld AVDTHCR,A ; in the three cases AVD is set off

next;stop after 7 rounds

is smaller

to fRC/4

4.1.2 Input capture interrupt

ld A, LTICR ;load captured value in A

btjt LTCSR, #4, finish ;test if it is first or second capture

overflows

finish ld capture2, A ;if it is the second capture, captured value is stored in

capture2

bset LTCSR, #4 ;allow timebase interrupt in order to count the number of

ld capture1, A ;captured value is stored in capture1

jp endit1

clr cr ;clear cr to end the count

11/20

Page 12

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Software examples AN2326

endit1

iret

4.1.3 Timebase interrupt

ld A, LTCSR ;clear TB bit

endit2

inc nbover ;increment number of overflows

iret

4.1.4 Writing in non volatile memory for products without Data EEPROM

To store the final value of RCCR/SICSR registers in non volatile memory, the following lines must be

added after the timer interrupts have been disabled in the main program. As Data EEPROM is not embedded in the ST7ULTRALITE, the storage is done in program memory, so the sector 0 size must be

0.5k (selected by option byte). The programmation routine must be executed from RAM, so it is first

loaded in RAM and then called. Both RCCR and SICSR registers are saved.

; Content of RCCR and SICSR is saved at FC00h and FC01h

; < RESET_FCSR >

LD A,#$56 ; Enter RASS keys to unlock FCSR register

LD FCSR,A

LD A,#$AE

LD FCSR,A

; < LOAD_RAM >

LD X,#$3F ; Copy programming software driver 32 bytes = 4 lines

.RAM_Copy

LD A,(RAM_Driver,X)

LD (RAM,X),A

DEC X

JRPL RAM_Copy

; < USER_APPLICATION_PROGRAM >

; < FIRST_PROG >

LD A,#$FC ; High address

LD X,A ;

clr Y ; define FC00 as destination address

LD {E2ADDR},X ; Address high to be programmed (0081h) is in X

LD {E2ADDR+1},Y ; Address low to be programmed (0082h) is in Y

CALL RAM ; Call the programming driver located into RAM

JP USER_APPLICATION

; ----------------------------------------------------------------------------; ROUTINE: XemulE2_ByteProg

; DESCRIPTION: Emulated data EEPROM byte

; BEFORE: A = data to be programmmed

; X:Y = address where it has to be programmed [FC00h..FDFFh]

; -----------------------------------------------------------------------------

; into RAM from address 0083h

programming driver routine

.RAM_Driver

BSET FCSR,#LAT ; Enable Emul. EEPROM latches

LD A,FCSR

CLR X

LD A, RCCR

LD ([E2ADDR.w],X),A; Set address/data to be programmed

inc X

A, SICSR

LD

LD ([E2ADDR.w],X),A; Set address/data to be programmed

BSET FCSR,#PGM ; Launch the Emul. EEPROM programming

12/20

Page 13

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Software examples

.EEPROM_Prog

BTJT FCSR,#PGM,EEPROM_Prog; Wait end of programming (~5ms)

RET

4.1.5 Writing in non volatile memory for products with Data EEPROM

To store final value of RCCR/SICSR registers in EEPROM, add theses lines after disabling the timer interrupts in the main program.

ld RCCR, A

bset EECSR,#1 ;start to enter value in the EEPROM

ld $1003,A ;load value of the RCCR in EEPROM

ld A, SICSR

ld $1004,A ;load value of the SICSR in EEPROM

wait btjt EECSR,#0,wait ;wait for the end of writing in EEPROM

bset EECSR,#0 ;start to write in the EEPROM

13/20

Page 14

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Software examples AN2326

4.1.6 Detailed basic version software flowchart

STORE STARTING VALUE

80H --> VALUE

80H --> RCCR

CLEAR RAM BYTES

ENABLE INPUT CAPTURE INTERRUPT

(NBOVER, CR)

EDGE

ON LTIC

INPUT

YES

STORE CAPTURED VALUE IN CAPTURE 1

ENABLE TIMEBASE INTERRUPT TO

START TO COUNT TIMER OVERFLOWS

EDGE

EDGE

ON LTIC

ON LTIC

INPUT

INPUT

STORE CAPTURED VALUE IN CAPTURE 2

DISABLE TIMEBASE AND INPUT CAPTURE

NBOVER X F9 + CAPTURE 2 - CAPTURE 1

GREATER

SUBTRACT VALUE TO RCCRADD VALUE TO RCCR

YES

INTERRUPTS

DIVIDE VALUE BY 2

CALCULATION OF:

COMPARE

RESULT WITH

138H

SMALLER

NO

NO

NO

RC OSCILLATOR IS TRIMMED TO 1 MHZ

IS THE

DICHOTOMY

FINISHED?

YES

14/20

Page 15

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Software examples

4.2 Average version

This version performs the count between two edges four times and changes the value of the

RCCR/SICSR registers according to the average of these measurements. This method

allows to perform a better tune of the RC oscillator especially in noisy environment.

4.2.1 Main program

;All the bytes from locations 80h to 8Bh are used by this software to store values or as control

registers but they can be reused safely after the clock has been set.

;dichotomy value

.value equ $81 ;this byte contains the value which will be added or

subtracted to/from the RCCR last value at the end of each round

;capture values

.capture1 equ $82

.capture2 equ $86 ;these bytes contain the values of the counter captured on the

edge of the mains, they are used to calculate the time elapsed between the two edges

;number of overflows

.nbover equ $8A ;this byte contains the number of counter overflows during the

measurement

;control

.cr equ $8B ;this byte is used as a control register for the measurement. Its

bits allow or not the interrupts and show which step of the count is the current one.

.strtstp equ 1 ;this is set to start the count and reset to stop it

.lsb_RCCR equ 7 ;this bit is set when the first capture has occurred. It allows

the overflows to be counted

;address to program in NVM (optional)

.E2ADDR equ $86

.RAM equ $88

.main

next

clr nbover ;clear the byte containing the number of timer overflow

ld A, LTICR ;clear the ICF bit

capture

rim ;interrupts enable

count

calcul

add A, (capture2,Y) ;

nocarry

sub A, (capture1,Y) ;MSB are in register X

noneg inc Y

register

ld A, #$63

ld AVDTHCR, A ; set internal clock to fRC/8 meaning 1MHz targeted

ld A, #$80 ;value containing the value which will

ld value, A ;add or subs to/from RCCR during the dichotomy

ld RCCR, A ;RCCR is set to the middle of its range of value

clr cr ;clear the byte use as control register for the count

clr Y

bset LTCSR, #7 ;enable input capture interrupt

bset cr,#strtstp ;set the start-stop bit of cr: count can start

btjt cr, #strtstp, count; wait for the end of count

clr LTCSR ;lite timer interrupts disable

inc Y

cp Y,#4 ;repeat the capture four time to make an average

jrne capture

srl value ;dichotomy value divided by 2

clr Y

ld A,#$F9 ;these lines calculate this equation for the four

ld X,nbover;measures:

mul X,A ;(nbover*$F9)+ capture2 - capture1

jrnc nocarry ;this equation is calculated with 16 bits

inc X ;

jrnc noneg ;

dec X ;and LSB in register A.

cp Y,#4

be

15/20

Page 16

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Software examples AN2326

jrne calcul

srl A ;these lines calculate the average of the last four

srl X ;measures by dividing their total by 4. It is done by

jrnc carry1 ;two consecutive right shift on the 16 bit result.

carry1

srl A

carry2

cp X, #$01 ;if mains frequency is 50Hz the reference value is $138

compare

cp A, #$38 ;value is smaller than the reference the program jump to

plus

plus_lsb

btjt value, #5, p_lsb0

btjt value, #4, end

ld A, value

ld SICSR, A ;add value if counted value is greater than ref

jra next

p_lsb0

minus

btjt cr,#lsb_RCCR,minus_lsb

ld A, RCCR

jra new

minus_lsb

btjt value,#5, m_lsb0

btjt value, #4, clr_lsb0

bres RCCR,#0 ;reset the LSb of RCCRH

ld A, value

ld SICSR, A ;substract value if counted value is smaller

jra next

m_lsb0

clr_lsb0

new ld RCCR,A ;enter the new value in RCCR

next_near

.end_calibration ; end of the calibration

; at this point the Fcpu is set to 1MHz

; the last operation is to set the clock to

add A,#$80

srl X

jrnc carry2

add A,#$80

jrmi minus ;if it is 60Hz the reference is $104.the program first

jreq compare;compares MSB with $01 and then compare LSB with

jp plus ;$38 for 50Hz and $04 for 60Hz. if the calculated

jrmi minus ;minus to decrease RCCR else it increase RCCR

btjt cr,#lsb_RCCR,plus_lsb

ld A, RCCR

add A, value ;add value if counted value is greater than ref

jra new

bset SICSR,#5 ;add value if counted value is greater than ref

jra next

sub A, value ;subtract value if Y is smaller

than ref

bres SICSR,#6

bset SICSR,#5 ;subtract value if Y is smaller

jp next

bres SICSR,#5 ;reset the LSb of RCCRL

jra end

btjf value, #0, next_near;stop after 7 rounds

bset cr, #lsb_RCCR

ld A, #$80

ld value, A

jp next

ld A, #$03 ; set clock to fRC meaning 8MHz

; ld A, #$23 ; set prescaler to fRC/2

; ld A, #$43 ; set prescaler to fRC/4

; ld A, #$63 ; set prescaler to fRC/8

ld AVDTHCR,A ; in the three cases AVD is set off

the targeted value by setting the prescaler register

4.2.2 Input capture interrupt

ld A, LTICR ;load captured value in A

btjt LTCSR, #4, finish ;test if it is first or second capture

16/20

Page 17

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Software examples

overflows

finish

capture2

endit1 iret

bset LTCSR, #4 ;allow timebase interrupt in order to count the number of

ld (capture1,Y), A ;captured value is stored in capture1

jp endit1

ld (capture2,Y), A ;if it is the second capture, captured value is stored in

clr cr ;clear cr to end the count

4.2.3 Timebase interrupt

ld A, LTCSR ;clear TB bit

endit2

inc nbover ;increment number of overflows

iret

17/20

Page 18

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Software examples AN2326

Table 3. Detailed average version software flowchart

STORE STARTING VALUE

80H --> VALUE

80H --> RCCR

CLEAR RAM BYTES

ENABLE INPUT CAPTURE INTERRUPT

(NBOVER, CR)

EDGE

ON LTIC

INPUT

YES

STORE CAPTURED VALUE IN CAPTURE 1.X

ENABLE TIMEBASE INTERRUPT TO

START TO COUNT TIMER OVERFLOWS

EDGE

ON LTIC

INPUT

STORE CAPTURED VALUE IN CAPTURE 2.X

DISABLE TIMEBASE AND INPUT CAPTURE

NBOVER X F9 + 4(CAPTURE2.X - CAPTURE1.X)

RESULT DIVIDED BY 4 TO AVERAGE IT

EQUAL OR GREATER

YES

INTERRUPTS

FOUR

MEASUREMENTS

DONE?

CALCULATION OF:

DIVIDE VALUE BY 2

COMPARE

RESULT WITH

138H

NO

NO

YES

ADD VALUE TO RCCR

SMALLER

SUBTRACT VALUE TO RCCR

NO

RC OSCILLATOR IS TRIMMED TO 1 MHZ

IS THE

DICHOTOMY

FINISHED?

YES

18/20

Page 19

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2326 Revision history

5 Revision history

Table 4. Document revision history

Date Revision Changes

03-April-2006 1 Initial release.

19/20

Page 20

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Revision history AN2326

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

20/20

Loading...

Loading...