Page 1

AN2304

Application note

LED driver for single flash

Introduction

This application note is dedicated to the design of a flash LED driver using STCF02, which

is a step-up/down current mode converter. Schematic and functional description,

recommendations for PCB Layout and external components selection are also evaluated.

This device is dedicated for driving a single LED with forward voltage range 2.7 to 5 V.

Photo of reference design board

February 2007 Rev 4 1/

www.st.com

Page 2

Contents AN2304

Contents

1 Schematic description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Selection of external components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Input and output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 LED selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 RFLASH selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 RTORCH selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 RMF selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 CCOMP selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8 NTC and Rx resistor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 PCB design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 PCB design rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Safety shutdown in flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2/

Page 3

AN2304 Schematic description

1 Schematic description

The Flash LED driver is based on STCF02 device with all necessary external components.

High operational frequency (1.8MHz) small size e xte rnal component usage, re sulting a v e ry

compact design of the Flash LED device. The device can operate in five modes:

● Shutdown mode

● Shutdown mode with activated NTC LED temperature sensing

● Torch mode

● Middle flash mode

● Flash mode

These modes can be selected by a combination of logic signals connected to enable pins.

Table 1. Truth table selection mode

EN1 EN2 EN3 ILED

00x 0 0 Shutdown

101 0 0 Shutdown+NTC

0

1

1

1

100 I

110 I

x

1

I

TORCH

MFLASH

= 160mV/(R

= f(I

FLASH

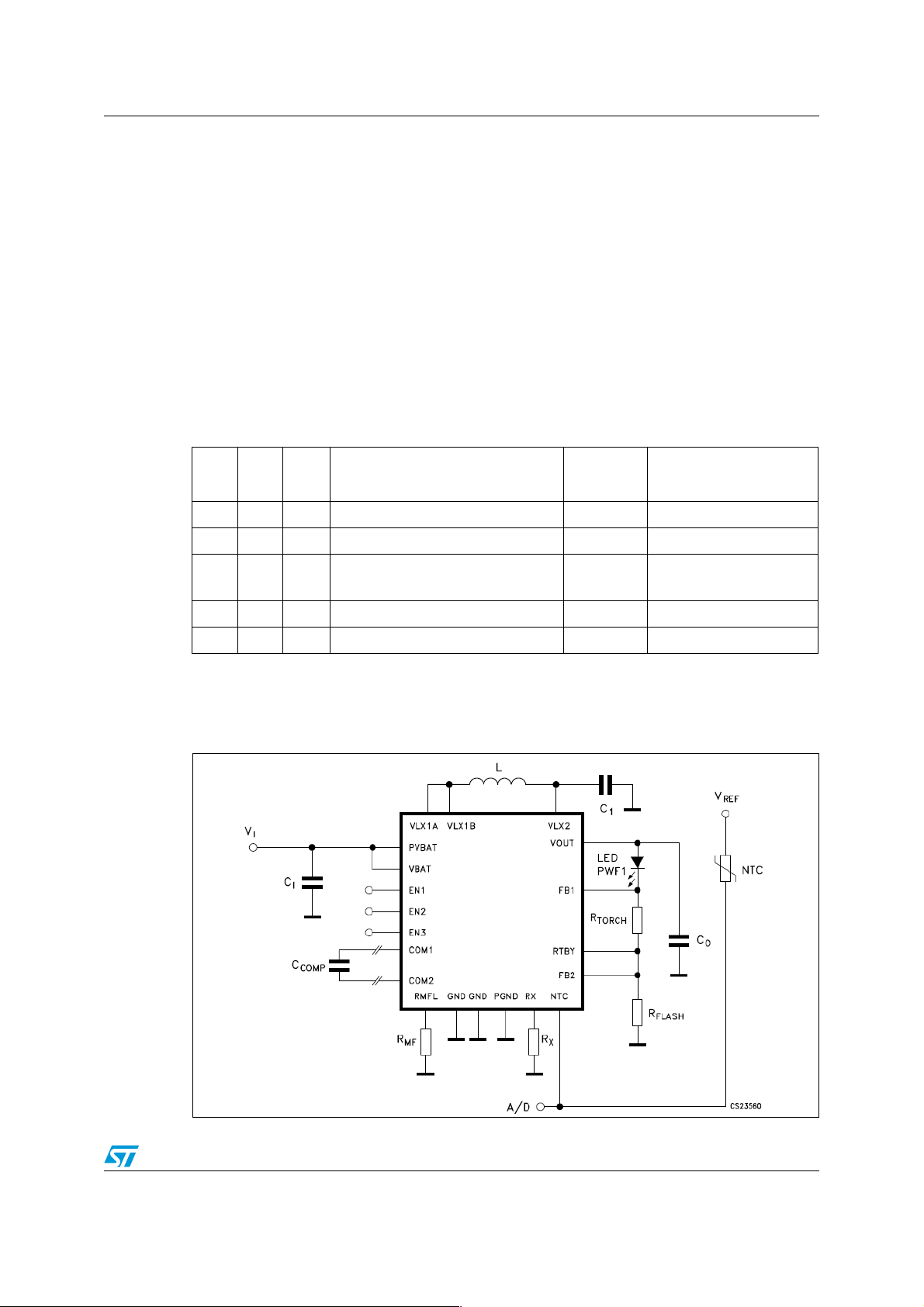

1.1 Application schematic

Figure 1. Typical application schematic

TORCH+RFLASH

, R

FLASH

= 160mV/R

MFLASH

FLASH

ILED_MAX

(mA)

) 250 Torch+NTC

) 500 Medium Flash+NTC

600 Flash+NTC

MODE

3/

Page 4

Schematic description AN2304

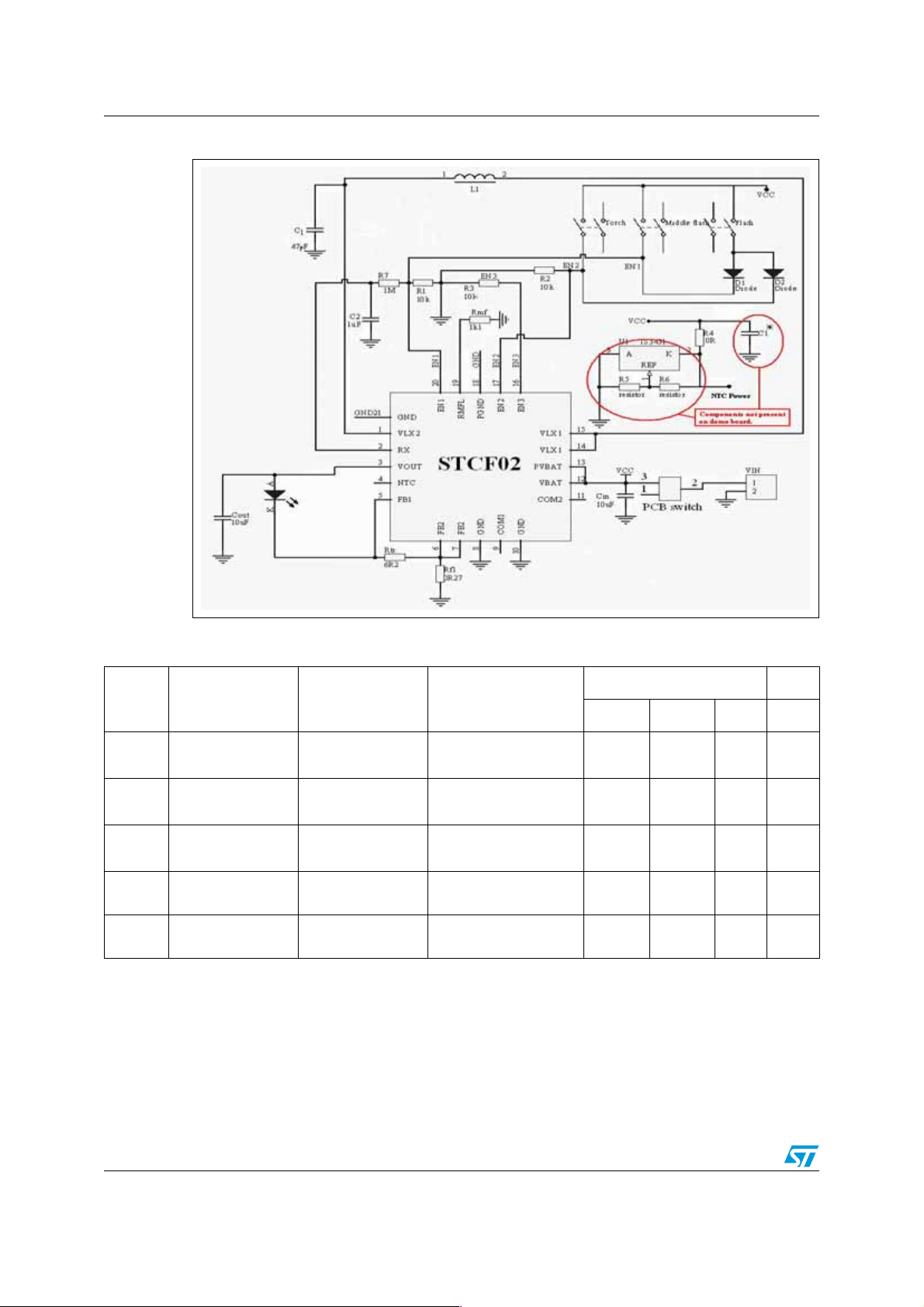

Figure 2. STCF02 Demo board electric schematic

Table 2. STCF02 Demo board BOM List

Symbol Parameter Type

R

FLASH

R

TORCH

R

MF

C

IN

C

OUT

Sensing flash

current resistor

Sensing torch

current resistor

Setting Resistor for

middle flash mode

Input filtering

capacitor

Output capacitor

Thick film type

(0805)

Thick film type

(0603)

Thick film type

(0402)

Ceramic type

(0603) 6.3 V

Ceramic type

(0603) 6.3 V

Supplier & part

number

ROHM

MCR10EZHFLOR27

ROHM

MCR03EZPJ6R20

ROHM

MCR01MZSF1K10

TDK

C1608X5ROJ106MT

TDK

C1608X5ROJ106MT

4

Typ. value Unit

Min Typ Max

0.27 Ohm

6.2 Ohm

1100 Ohm

10 2x10 µF

10 µF

4/

Page 5

AN2304 Selection of external components

Table 2. STCF02 Demo board BOM List (continued)

Symbol Parameter Type

Low profile inductor

L

R1 Anti bump resistor

R2 Anti bump resistor

R3 Anti bump resistor

R4 Resistor

R7

C1 Filtering Capacitor Ceramic (0603) TDK C1608C0J1H470J 47 pF

C2

D1 Schottky diode STPS1L40M

D2 Schottky diode STPS1L40M

4.5(L) x 4.7 (W) x

1.4 (L)

Safety shutdown

resistor

Safety shutdown

capacitor

shielded

DCR 0.12 Ohm

Isat 1.7 A

Thick film type

(0402)

Thick film type

(0402)

Thick film type

(0402)

Thick film type

(0402)

Thick film type

(0402)

Ceramic type

(0603) 6.3 V

Supplier & part

number

TDK VFL5014A-4R7

ROHM

MCR03EZPJ10KR00

ROHM

MCR03EZPJ10KR00

ROHM

MCR03EZPJ10KR00

ROHM

MCR03EZPJ1R00

ROHM

MCR03EZPJ1MR00

TDK

C1608X5ROJ105MT

Typ. value Unit

Min Typ Max

4.7 µF

10 KOhm

10 KOhm

10 KOhm

0Ohm

1MOhm

1µF

LED Luxeon LED PWF1 LXCL-PW1

2 Selection of external components

2.1 Input and output capacitor selection

For input and output capacitors it is recommend ed to use a cer amic capacitor with lo w ESR.

For a good stability of the device supplied by a low input voltage of 2.7 V at maximum

ratings, it is recommended to use 10 uF/6. 3 V as a minim um v a lue of input capacitor and 10

uF/6.3 V as a minimum value of output capacitor.

Note: See recommended components in Table 2.

2.2 Inductor selection

Shielded thick inductor with low DC series resistance of wiring is recommended for this

application. For good efficiency it is recommended to use an inductor with series DC

resistance R

DCL<RD

/10, [Ω, Ω,1] where RD is dynamic resistance of LED.

5/

Page 6

Selection of external components AN2304

For nominal operation, the peak inductor current can be calculated by this formula:

Equation 1

2

I

PEAK

⎛⎞

I

----------- -

⎜⎟

⎝⎠

OUT

n

V

–()V

OUTVin

--------------------------------------------------- -+

2L• F• V

•

•

OUT

IN

V

OUT

--------------

•=

V

2

IN

Where:

–I

–I

Peak inductor current

PEAK

Current sourced at the VOUT pin

OUT

– n Efficiency of the STCF02

–V

–V

Output voltage at the pin Vout

OUT

Input voltage at the pin Vin

IN

– L Inductance value of the inductor

– F Switching frequency

Note: See recommended components in Table 2.

2.3 LED selection

Any LED with forw ard voltage from 2.7 V to 5 V is f easib le for use with device STCF 02. LED

forward voltage must include the voltage spread of this value. It is possible to set the LED

current in the three different operating modes (torch, medium flash, high flash) through three

external sensing resistors.

Note: See recommended components in Table 2.

2.4 R

R

P

FLASH

FLASH

RFLASH=RFLASH*IFLASH

selection

resistor can be selected by equations R

2

, where PRFLASH is the dissipated power on R

recommended to use thick metal film resistor 0603 package size with 1% tolerance.

Maximum flash LED current for STCF02 device is 600mA in battery voltage range from 2.7

V to 5.5 V.

2.5 R

R

TORCH

TORCH

selection

resistor can be selected by equations:

Equation 2

160mV I

R

TORCH

-----------------------------------------------------------------------------=

=160mV/I

FLASH

•()–

TORCHRFLASH

I

TORCH

FLASH

and

FLASH

resistor. It is

Equation 3

P

RTORCHRTORCH

6/

=

I2•

TORCH

Page 7

AN2304 Selection of external components

where P

RTORCH

is the dissipated power on R

metal film resistor with 1% or 5% tolerance. Maxim um torch LED current f or STCF02 device

is 250 mA in voltage range from 2.7 V to 5.5 V.

2.6 RMF selection

With this resistor it is possible to set the LED current value in middle flash mode. The value

of R

resistor is defined by equation:

MF

Equation 4

where I

package size.

2.7 C

This component could optionally be used if the error amplifier bandwidth, which is set to

2kHz default, has to be decreased in case of unstable function of driver, which could cause

the use of different inductor and output capacitor values. It is recommended to use a

ceramic capacitor in 0402 package size.

COMP

is middle flash LED current. It is recommended to use thick film resistor in 0402

MF

selection

I

MF

resistor. It is reco mme nded t o use thick

TORCH

5–

10

⎛⎞

-----------

=

3000

⎝⎠

R

FL

13000 R

--------------------------------- -+

13000 R

•

+

MF

MF

2.8 NTC and Rx resistor selection

The NTC resistor for sensing LED temperature and the Rx resistor create the voltage

divider. Output of this divider is compared to the internal voltage reference 1.192 V. When

the voltage of the voltage divider output is increased over the reference, the logic will switch

off the power circuit.

The maximum current, which could flow through the NTC pin is 1mA. Voltage divider must

be supplied from an external voltage source.

7/

Page 8

PCB design AN2304

3 PCB design

3.1 PCB design rules

STCF02 is a powerful switched device, the PCB must be designed in line with rules for

designing switched supplies. It is recommended to use at least four layers PCB to save the

area on application PCB. The pow er wirings must be as short as possible and wide,

because of large current. Place all external components close to the STCF02. High-energy

switched loops should be as small as possible to reduce EMI. Most of LEDs need cooling,

which could be done by defi ned area of copper on the PCB. Use t he ref erence guide of each

LED to design the heatsink. Place the RFLASH resistor as close as po ssible to pin 8. When

the change of PCB layer is needed, use enough vias. Place the NTC resistor as close as

possible to LED for good temperature sensing. Direct connection of GND and PGND is

needed to achieve correct value of outp ut current. The Led current should not flow through

this track! Sensing of the v oltage on the Rflash resistor has to be done with a wire from pin 7

directly connected to Rflash resistor, no current flows through this track. Pin 6 and pin 7

have to be connected on the pin of Rflash resistor. Expose pad has to be connected to the

PGND with a track as wide as possible.

Figure 3. PCB layout

+

-

Input supply range = 2.7 V to 5.5 V

● Torch mode selection: pushing the Torch button, we will have 25 mA current flowing

through the WLed, no time limit is present. Is possible to reach up to 250 mA of torch

current calculating the R

Equation 5

8/

resistor using this formula:

torch

I

TORCH

16mV

------------------------------------------------- -=

R

+

TORCHRFLASH

Page 9

AN2304 Safety shutdown in flash mode

● Medium Flash mode selection: pushing the Medium Flash button, we will ha ve 150 mA

current flowing through the WLed, safety shutdown is active and after maximum 0.5

sec. the WLed will be turned off. Is possible to reach up to 500 mA of medium Flash

current calculating the Rmflash resistor using this formula:

Equation 6

5–

I

--------------------------------------------------------------------------------- -=

MF

R

FL

● Full Flash mode selection: pushing the Full Flash button, we will have 600 mA current

10

•

13000 R

⎛⎞

3000

----------------------------------

+•

⎝⎠

13000 R

MF

+

MF

flowing through the WLed, safety shutdown is active and after maximum 0.5 sec. the

WLed will be turned off. Is possible to reach up to 600 mA of full Flash current

calculating the Rflash resistor using this f ormula:

Equation 7

I

FLASH

160mV

-------------------- -=

R

FLASH

4 Safety shutdown in flash mode

Alternatively to NTC temperature sensing and protection, it is possible to properly drive all

the STCF02 features with only the EN1 and EN2 pins and include the safety shutdown

mode. This feature has to be active only for Mid Flash and Full Flash operating mode

because in Torch mode there is no risk of burning the LED because of the low current

flowing through it.

The purpose of this specific application is to avoid LED burning if the microcontroller does

not work properly (this means EN1 and/or EN2 are pins stu c k in a hig h logic level). If EN2 is

stuck at high level while EN1 still in low level, the selected mode is Torch, and the safety

shutdown in not needed.

If EN1 is stuck at high level, the STCF02 is in Mid/Full Flash mode and the LED should be

protected from long time operation at high peak current. In this condition, after an RC

defined time, the LED automatically go es off and sta ys off wait ing fo r EN1/EN2 pin resuming

at low level.

After the microcontroller reset, both EN pins will go at low lev el (device enters "All off" mode)

and the capacitor is discharged. At this point, the STCF02 is ready to resume the normal

operating mode.

In typical operating conditions safety shutdown time is about 500msec. This is possible by

applying an RC filter with R=1 MOhm and C=0.47 uF.

9/

Page 10

Safety shutdown in flash mode AN2304

Figure 4. Safety shutdown RC circuit

Figure 5. Safety shut down graphics

Operation for RC filter R=1M Ohm, C=1.0 uF; VLX1 switching voltage (dark blue), during

flash mode with EN1 voltage in high level (light blue). The RX pin voltage (violet) increases

and the output current (light green) goes down after one second (1.192 V threshold

reached).

10/

Page 11

AN2304 Revision history

5 Revision history

Table 3. Revision history

Date Revision

26-Jan-2006

04-Apr-2006

25-May-2006

06-Feb-2007

Changes

1

2

3

First issue

- Pictures changed

- New values added in table “Bill of Material“

- Pictures changed

- Pictures changed

4

- BOM changed

- Minor text changes

11/

Page 12

AN2304

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all informatio n previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

12/

Loading...

Loading...