Page 1

AN2269

Application Note

Using the ST8024 Smartcard Interface

Introduction

This application note provides information and suggestions for the optimal use and

performance of the ST8024 Smartcard Interface, including PCB layout, external component

placement, and connections (see

The ST8024 is a smart card interface designed to minimize microprocessor hardware and

software complexity in all applications that require a smar t card (e.g., Set Top Box,

Electronic Payment, Pay TV, and Identification cards). It was devel oped in accordance with

New Digital Systems (NDS) conditional access requirements, and implements all of the

blocks and procedures for card activation/deactivation and checking (see

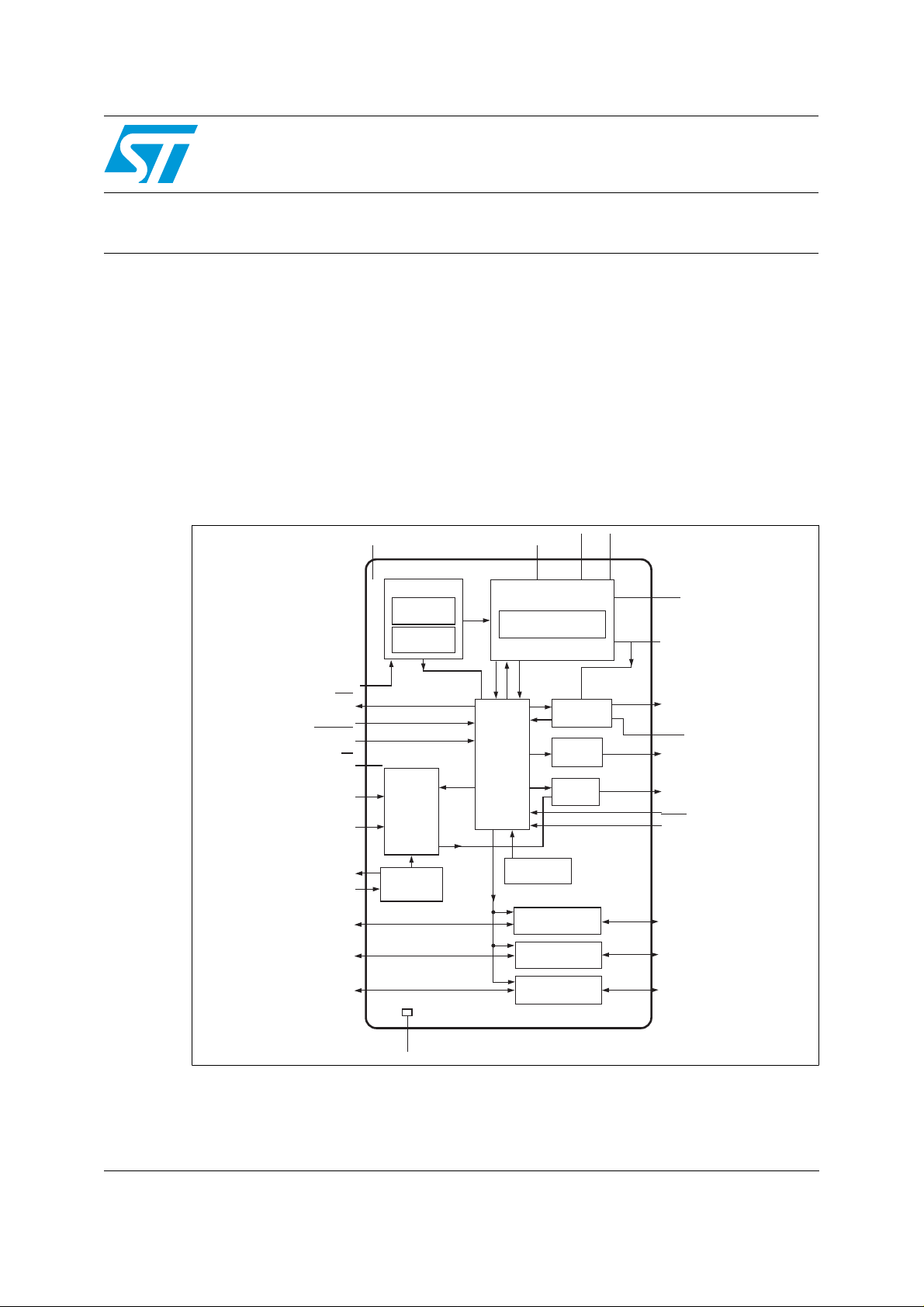

Figure 1. ST8024 Internal Block Diagram

ST8024 Application Hardware Guidelines on page 16

Figure 1

).

).

PORADJ

OFF

RSTIN

CMDV

CC

5V/3V

CLKDIV1

CLKDIV2

XTAL1

XTAL2

AUX1UC

AUX2UC

I/O UC

V

DD

21 6 7

Supply

Internal

Reference

Voltage

Supervisor

Clock

Circuitry

Oscillator

Alarm

En4

CLK

18

23

20

19

3

1

2

24

25

27

28

26

V

REF

Sequencer

En3

V

DDP

ST8024

Oscillator 2.5MHz

En1

Thermal

Protection

S1

Step-up

Converter

Internal

CLKUP

En2

Generator

PV

CC

En5

RST

Buffer

En4

Clock

Buffer

I/O T ransceiver

I/O T ransceiver

I/O T ransceiver

S2

5

P

4

GND

V

8

UP

V

17

V

CC

CC

CGND

14

RST

16

CLK

15

PRES

10

PRES

9

AUX1

13

AUX2

12

I/O

11

22

GND

AI11884

February 2006 Rev 1 1/25

www.st.com

Page 2

Table of Contents AN2269 - Application Note

Table of Contents

1 Activation/Deactivation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Card Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Emergency Deactivation/Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 PORAD J VDD Undervoltage without External Resistor Bridge . . . . . . . . . 7

3.2 PORAD J V

3.3 Fault On Card Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 V

3.5 V

3.6 Over-Temperature Fault Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Short Circuit Fault Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CC

Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DDP

Undervoltage with External Divider . . . . . . . . . . . . . . . . . . . 9

DD

4 ST8024 Application Hardware Guidelines . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Power Supply Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Clock Section Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Smart Card Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/25

Page 3

AN2269 - Application Note List of Figures

List of Figures

Figure 1. ST8024 Internal Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. ST8024 Activation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Deactivation Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. CLKDIV Change Clock Duty Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5. ST8024 Automatic Deactivation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. External Resistor Bridge Applied to PORADJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. V

Figure 8. V

TH(ext) rise

TH(ext) fall

Figure 9. Card Extraction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. ST8024 Activation Sequence (after t

Figure 11. ST8024 Current Supply Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 12. I

Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SC

Figure 13. Deactivation Caused By V

Figure 14. ST8024 Application PCB Top Layer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 15. ST8024 Application PCB Bottom Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 16. Step-up Converter Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 17. ST8024 Application PCB Storage and Pumping Capacitors . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 18. ST8024 Application PCB Crystal (XTAL) Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 19. ST8024 Application PCB Smart Card Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 20. Ripple on V

Figure 21. ST8024 Application PCB Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

(External Rising Threshold Voltage on VDD) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

(External Falling Thres hold on VDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

debounce

Drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DDP

Output Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CC

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3/25

Page 4

Activation/Deactivation Sequence AN2269 - Application Note

1 Activation/Deactivation Sequence

The core of the ST8024 is the sequencer (shown in

coordinate the Enable signals for the activation and deactivation sequence as well as check

for possible fault conditions. This because the smart card is basically a microcontroller and

needs to be activated/deactivated by a correct sequence as required by the ISO/IEC7816

standard. The ST8024 activation and deactivation sequences are shown in

Figure 3 on page 5

Figure 2

goes low. The activation sequence starts and the first block to be enabled is the step-up

converter (V

allows the card software to start.

Figure 3

executes an automatic deactivation sequence, finishing in the inactive state after t

(deactivation time).

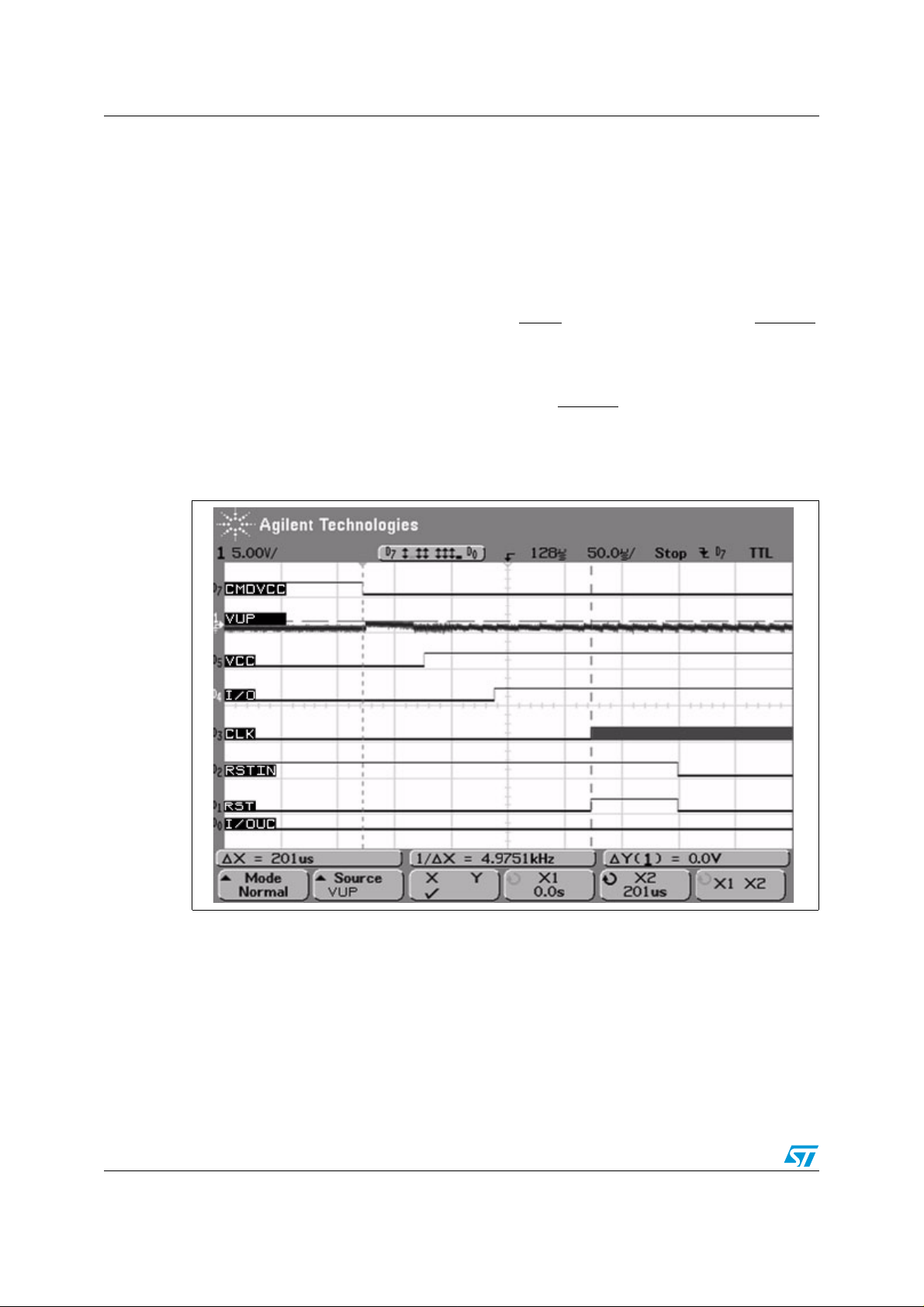

Figure 2. ST8024 Activation Sequence

shows that the PRES condition is true (PRES = low or PRES = high), and CM DVcc

shows the deactivation sequence (when the CMDVcc goes high). The circuit

, respectively. Please refer to the ST8024 datasheet for details.

), linked to En1 (see

UP

Figure 1

), while the last enabled signal is the RST that

Figure 1 on page 1

) that must

Figure 2

de

and

4/25

Page 5

AN2269 - Application Note Activation/Deactivation Sequence

Figure 3. Deactivation Sequence

5/25

Page 6

Card Clock AN2269 - Application Note

2 Card Clock

The card clock signal (CLK) is present on the CLK pin when the ST8024 is activated; it is

linked with the internal En4 signal (see

according to the settings in

Table 1

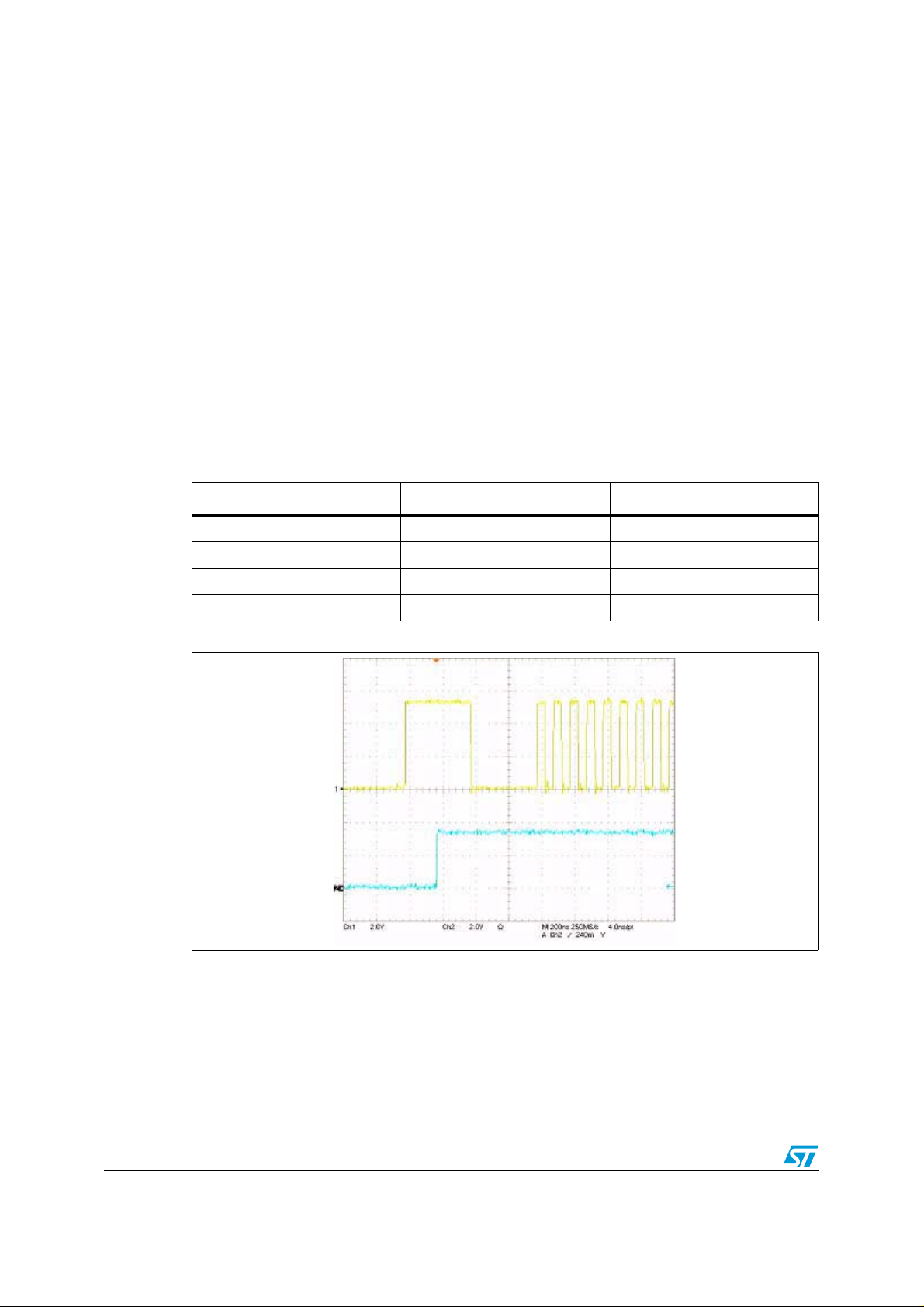

According to the ISO/IEC7816 specifications, the CLK duty cycle must be guaranteed

between 45% and 55%, even when the status of CLOCKDIV1 or CLOCKDIV2 changes.

Figure 4

shows how the ST8024 ensures duty cycle accuracy by waiting for completion of a

whole clock cycle before changing the frequency (CLKDIV1 change, rising edge of CH2).

The output Duty Cycle is 50%±5%, even if the Clock Division changes.

The card clock signal (CLK) can be obtained by connecting a crystal (“XTAL”) between the

XTAL1 and XTAL2 pins, or by an external signal applied to the XTAL1 pin. In this case the

XTAL2 pin must be left floating. The external signal voltage level must be limited between

GND and V

Table 1. CLK Division Factor

voltage.

DD

Figure 1 on page 1

.

) and its frequency is obtained

CLKDIV1 CLKDIV2 f

0 0 1/8 f

011/4 f

1 1 1/2 f

10f

Figure 4. CLKDIV Change Clock Duty Cycle

clk

Xtal

XtalL

Xtal

Xtal

Legend:

1. CH1 = Output CLK Waveform

2. CH2 = CLKDIV1 Pin

3. Conditions: V

4. Mode: ACTIVE

5. f

= 10MHz; CLKDIV2 = 0V

XTAL

= 3.3V; V

DD

6/25

= 5V; 5/3V = H

DDP

Page 7

AN2269 - Application Note Emergency Deactivation/Fault Detection

3 Emergency Deactivation/Fault Detection

ST8024 is equipped with a fault detection circuitry which monitors the following conditions

(see

Figure 1 on page 1

● V

● Fault on card removal,

● V

● V

● Over-Temperature protection.

undervoltage,

DD

Short circuit protection,

CC

drop, and

DDP

3.1 PORADJ VDD Underv oltage without External Resistor Br idge

The ST8024 logic circuitry is supplied by VDD. In order to avoid voltage spikes that could

cause damage, or malfunction of the device and/or card, a voltage supervisor block is

embedded (see

(Falling Threshold Voltage on V

deactivation sequence and V

As V

goes higher than V

DD

100mV, typ), after a certain amount of time (t

reset pulse width, 8ms typ, see

sequence starts and V

to GND to avoid noise capture is recommended.

Figure 1

):

). This block monitors VDD and when it gets lower than V

, 2.45V, typ), the supervisor immediately starts the

DD

goes low.

CC

+ V

TH2

Figure 5 on page 8

goes high. The PORADJ pin can be left floating, but connecting it

CC

HYS2

, (V

is the Hysteresis of threshold voltage,

HYS2

+ t

w

debounce

, where tw is the internal power-on

), CMDVcc goes low. The activation

TH2

Note: See

Fault On Card Removal on page 12

for t

debounce

feature details.

7/25

Page 8

Emergency Deactivation/Fault Detection AN2269 - Application Note

Figure 5. ST8024 Automatic Deactivation Sequence

Note: Deactivation: V

Activation: As V

Legend:

1. CH1 = CMDVcc

2. CH2 = V

3. CH3 = OFF

4. CH4 = V

5. Conditions: VDD = 3.3V; V

6. Mode: ACTIVE

7. f

CC

DD

= 10MHz; CLKDIV2 = 0V

XTAL

≈ 2.393V.

TH2

≥ V

DD

+ V

TH2

= 5V; 5/3V = H

DDP

(≈ 2.498V) AND CMDVcc goes low, VCC goes high.

HYS2

8/25

Page 9

AN2269 - Application Note Emergency Deactivation/Fault Detection

3.2 PORADJ VDD Undervoltage with External Divider

In this case, a resistor bridge is applied to the PORADJ pin (see

V

TH(ext) fall

Voltage on V

are the External Rising Threshold Voltage and the External Falling Threshold

, respectively. They are the voltages on pin PORADJ that switch the device

DD

Figure 6

). V

TH(ext) rise

and

ON and OFF. By knowing these values and using the formula:

V

PORADJ

R2R1R2+⁄()VDD×=

Where:

it is possible to set R

device ON and OFF (R

In particul a r, R

1

and R2 in order to get suitable values for VDD in order to turn the

1

= 100kΩ typ).

1+R2

and R2 have to be set so that, when VDD is getting low, before turning the

microcontroller off, the smart card has to be switched off properly as well. The same goes

for microcontroller start-up. The smart card has to be turned on after the microcontroller.

Figure 7

and

Figure 8 on page 11

show the V

TH(ext) rise

and V

TH(ext) fall

on the PORADJ pin

(0.21V and 1.15V, respectively).

As long as V

for t

+ t

w

debounce

gets the proper start-up value (so that V

DD

by the CMDVcc

16ms (while OFF

(tw ≈ 16ms, in this case). During this time, the device can not be turned on

TH(ext) rise

. To turn th e device on, CMDVcc must go low at least by the end of about

is high).

= 1.196V), OFF goes low

Figure 6. External Resistor Bridge Applied to PORADJ

V

DD

GND

R1

To PORADJ

R2

AI11885

9/25

Page 10

Emergency Deactivation/Fault Detection AN2269 - Application Note

Figure 7. V

Legend:

1. CH1 = CMDVcc

2. CH2 = V

3. CH3 = OFF

4. CH4 = V

CC

TH(ext) rise

TH(ext) rise

(External Rising Threshold Voltage on VDD)

10/25

Page 11

AN2269 - Application Note Emergency Deactivation/Fault Detection

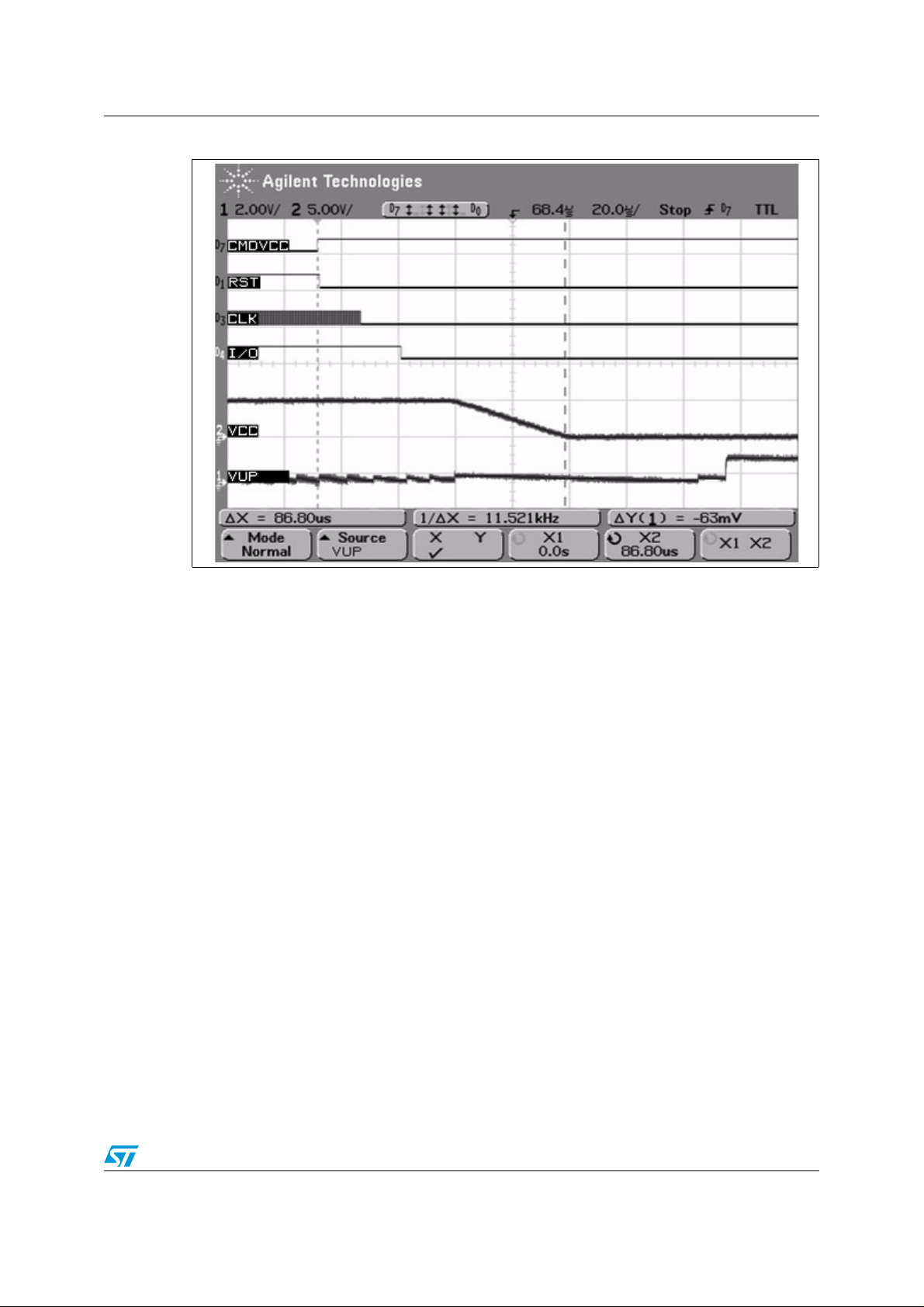

Figure 8. V

Note: As V

Legend:

1. CH1 = CMDVcc

2. CH2 = V

3. CH3 = OFF

4. CH4 = V

TH(ext) rise

CC

TH(ext) fall

TH(ext) fall

(External Falling Threshold on VDD)

= 1.155V, the device starts switching OFF and VCC goes low.

11/25

Page 12

Emergency Deactivation/Fault Detection AN2269 - Application Note

3.3 Fault On Card Removal

If the smart card is pulled out from its socket (PRES goes high or PRES goes low), the

deactivation sequence starts. The OFF

Figure 9

). In order to avoid bouncing on the PRES (or PRES) signal at card insertion or

extraction, as the card is inserted again, OFF

If CM DVcc

and CMDVcc

Figure 10 on page 12

goes low before this time, after card insertion, the device does not turn itself on

must wait for t

debounce

shows the start of the activation sequence after t

Figure 9. Card Extraction

pin goes low and the device switches off (see

goes high just after a period t

debounce

(≈ 8ms).

before going low enough to switch the device on.

debounce

is elapsed.

Figure 10. ST8024 Activation Sequence (after t

12/25

debounce

)

Page 13

AN2269 - Application Note Emergency Deactivation/Fault Detection

3.4 VCC Short Circuit Fault Protection

The ST8024 is able to supply the card with current pulses of about 140mA f or no longer than

5.5µs, typical (see

Short circuit protection is an important interface feature that warns the sequencer block if

the output current becomes higher than the short circuit current li mit (≈120mA) for too much

time. This characteristic allows the de vice to supply the card with current pulses higher than

the maximum allowed, if their lengths are not too long. If the current pulses last for more

than 5.5µs, the deactivation sequence starts to protect the card. The OFF

as to warn the microcontroller about the overcurrent fault. The sequence in

page 14

shows how the current pulse becomes long enough to make the short circuit

protection happen.

Figure 11. ST8024 Current Supply Sequence

Figure 11

and

Figure 12 on page 14

).

pin goes low so

Figure 12 on

Legend:

1. CH1 = CMDVcc

2. CH2 = ISC Pulse

3. CH3 = V

4. CH4 = OFF

CC

13/25

Page 14

Emergency Deactivation/Fault Detection AN2269 - Application Note

Figure 12. ISC Short Ci rcuit Protection

14/25

Page 15

AN2269 - Application Note Emergency Deactivation/Fault Detection

3.5 V

The voltage supervisor also controls the V

(≈2.578V, in this case, see

Figure 13. Deactivation Caused By V

Legend:

1. CH1 = V

2. CH2 = CMDVcc

3. CH3 = V

4. CH4 = OFF

DDP

Drop

DDP

CC

Figure 13

Drop. As it reaches the minimum value

DDP

, the OFF pin goes low and the VCC drops.

Drop

DDP

3.6 Over-Temperature Fault Protection

Over-Temperature protection is another impor ta nt interface feature that warns the

sequencer block of fault events. If the temperature is higher than the shutdown temperature

(150°C, typ), the deactivation sequence starts to protect the card. The OFF

as to warn the microcontroller about the over-temperature fault.

pin goes low so

15/25

Page 16

ST8024 Application Hardware Guidelines AN2269 - Application Note

4 ST8024 Application Hardware Guidelines

This section contains some optimization guidelines concerning PCB la yout as well as

external component placement and connections. The referenced application board in

Figure 14

application NDS requirements.

The PCB layout provides completely separate supply and GND copper planes, which allow

each plan to act as a shield for each group of noise-sensitive device pins. The PGND, and

CGND and GND planes share a common point on bottom layer of the PCB (see top,

Figure 15 on page 17

Figure 14. ST8024 Application PCB Top Layer

and

Figure 15 on page 17

).

has two layers, and uses these guidelines to meet

16/25

Page 17

AN2269 - Application Note ST8024 Application Hardware Gu idelines

Figure 15. ST8024 Application PCB Bottom Layer

17/25

Page 18

ST8024 Application Hardware Guidelines AN2269 - Application Note

4.1 Power Supply Optimization

The ST8024 can drive both 3V and 5V cards by the supply voltage selector pin 5/3V (pin 3)

as shown in

and if the 5/3V is connected to V

A step-up converter supplied by V

input voltage V

● 5/3V=H and V

● 5/3V=H and V

● 5/3V=L and V

● 5/3V=L and V

The S1 and S2 pins are used for duplicating the supply voltage V

pumping capacitor (C4). The charge pump output pin (V

storage capacitor (C5) to stabilize the voltage.

Figure 16. Step-up Converter Block Diagram

Figure 1 on page 1

or follows it, depending on the 5/3V and V

DDP

> 5.8 V; voltage follower

DDP

< 5.7 V; voltage doubler

DDP

> 4.1 V; voltage follower

DDP

< 4.0 V; voltage doubler

DDP

. If the 5/3V pi n is connected to GND, the VCC voltage is 3V,

, the VCC voltage is 5V.

DD

is used for the VCC voltage generation. It doubles the

DDP

values:

DDP

by using the 100nF

DDP

) has to be connected to a 100nF

UP

100nF

100nF

S1 S2

65

ON/OFF

Step-up

Mode

Selector

ST8024

EN2

PV

CC

7

OUTPUT

L

V

CC

Regulator

1

7

PGND

V

UP

100nF

V

CC

AI11894

18/25

Page 19

AN2269 - Application Note ST8024 Application Hardware Gu idelines

A small amount of noise is introduced into the design because of the switching circuitry. In

order to reduce it and improve the efficiency of the step-up converter, the capacitors must be

connected as closely as possible to the pins (see

Figure 17

). An Equiva lent Series

Resistance (ESR) of lower than 100mΩ at 100kHz is recommended.

The evaluation board is equipped with MURATA GRM31M 7U1H104JA01B capacitors.

However, other capacitors with an ESR of up to 100mΩ at 100kHz are good enough to work

within the specifications. They just may be more sensitive to the la yout optimization process.

Figure 17. ST8024 Application PCB Storage and Pumping Capacitors

19/25

Page 20

ST8024 Application Hardware Guidelines AN2269 - Application Note

4.2 Clock Section Optimization

Recommendations for the PCB design clock area include:

● The XTAL should be connected as closely as possible to the XTAL pins to reduce signal

reflections, especially for high frequency applications (see

● Two compensation capacitors (C9 and C10), each of 15pF (typ) are suggested to

improve the oscillator start-up performances. Even without those additional capacitors

the CLK Duty Cycle is guaranteed between 45% and 55% (according to the NDS

specifications), with frequencies up to 26MHz.

Figure 18. ST8024 Application PCB Crystal (XTAL) Connection

Figure 18

).

20/25

Page 21

AN2269 - Application Note ST8024 Application Hardware Gu idelines

4.3 Smart Card Connections

In typical applications, a 100nF filter capacitor (C3) is connected to the VCC output towards

GND/CGND, near the ST8024 pins. A second 100nF capacitor (C8) is connected between

the card socket pins C1 (V

to reduce noise and avoid coupling effects, the wire length between the ST8024 and card

should be as short as possible.

Another recommendation is to keep the CLK track far away from the other signal tracks to

limit coupling with the transceiver lines. Further decoupling is gained if the clock track is

shielded by a GND/CGND plane or track on the PCB.

Keeping the PGND and GND/CGND planes as large as possible improves power supply

noise rejection. With this in mind, the board design should connect these planes with a large

number of vias between the top and bottom board layers (3-4 vias per cm

) and C5 (CGND), near the card slot (see

CC

Figure 19

2

).

). In order

The V

applied with V

Figure 20 on page 22

applied and the measured ripple is lower than 160mV

spikes are much lower than 350mVPP, even when a pulsed load of up to 80mA is

CC

= 5V, or up to 65mA with VCC = 3V, as specified b y the NDS requirements.

CC

shows a typical VCC output waveform where an 80mA pulsed load

.

PP

Figure 19. ST8024 Application PCB Smart Card Connections

21/25

Page 22

ST8024 Application Hardware Guidelines AN2269 - Application Note

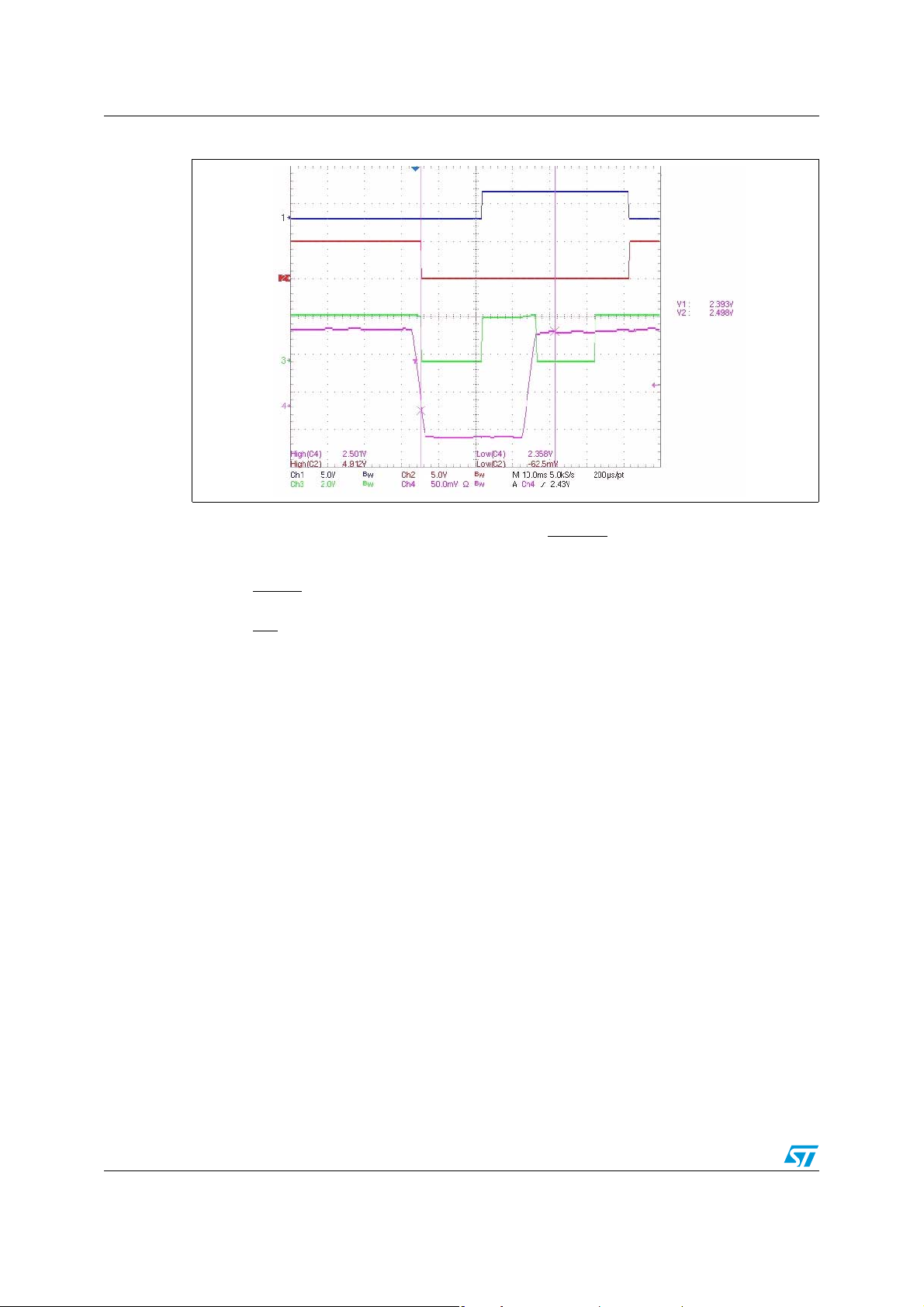

Figure 20. Rippl e on VCC Output Voltage

Legend:

1. VDD = 3.3V

DDP

= 5V

CC

CC

2. V

3. CH2 = 80mA Pulsed Current I

4. CH4 = Ripple on VCC Output Voltage

5. 5V Offset on V

22/25

Page 23

AN2269 - Application Note ST8024 Application Hardware Gu idelines

Figure 21. ST8024 Application PCB Schematic

A

1

of

1

Wednesday, June 22, 2005

ST8024 Evaluation Board

A4

Title

Size Document Number Rev3Date: Sheet

N.C. or N.O. switch is included in the Smartcard connector.

Please select JP17 as specified in the PRES configuration.

2 - 3

1 - 5

J7

100nF

1 - 4

2 - 5

T.P. card K

B

2

1

VCC

100nF

C8

U1

6

5

Pin 2 of JP17 to J8

RST

4

3

CLK

AUX1

K2

K1

AUX2

I/ONCGND

7

SMARTCARD CONNECTOR

8

9

10

J6

U2

XTAL GND Jumper

10pF

10MHz

AUX2UC

CLKDIV1

C

C1

C10

Y1

25

262728

I/OUC

AUX1UC

CLKDIV2

5V/3V

4

321

C4

24

XTAL2

GNDP

5

XTAL1

S2

23

6

100nF

10pF

22

OFF

VDDP

7

100nF

C5

GND

S1

VCC

19

20

15

16

21

17

18

CLK

RST

VCC

VDD

RSTIN

PORADJ

CMDVCC

C3

VUP

9

8

PRES

10

100nF

PRES

11

CGND

AUX1

AUX2

I/O

ST8024

14

13

12

J1 pins J2 pins

D

6

54321

J3

J2

2.7V - 6.5V

VDD

GND

3

2

1

J14

–OFF

3

2

1

J12

VTHSEL

3

2

1

J11

CMDVCC

3

2

1

J10

RSTIN

+

47µF

C6

C9

J8

J7

J6

J5

J4

J3

I/OUC

AUX1UC

AUX2UC

CLKDIV1

CLKDIV2

5/3V

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

J1

4V ÷ 6.5V

VDDP

VUP

47µF

330nF

C12

2

1

+

C7

JP18

D

C2

100nF

+PRES (SW N.C.)

–PRES (SW N.O.)

PRES conf.

and SW kind

PRES config (JP17)

Please connect the 2 jumpers as follows:

10KΩ

R6

4

5

3

2

1

JP17

J8

GND-PRES

C

PRES

No Switch

B

J5

T.P. card K

1 2 3 4 56

AI11898

A

23/25

Page 24

Revision History AN2269 - Application Note

5 Revision History

Table 2. Document Revision History

Date Revision Changes

10-Feb-2 006 1 Initial re le a s e.

24/25

Page 25

AN2269 - Application Note

y

y

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at an

time, with out notice.

All ST products are sold purs uant to ST’s terms and conditions of sale.

Purchase rs are solely r esponsible for the choice, se l ection and us e of the ST prod ucts and serv i ces described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party product s or services it s hall not be deeme d a license grant by ST for the use of such third part y products

or services , or any intel lec tual pro per ty cont aine d ther ein or con sidere d as a warra nty c overi ng th e use i n any mann er w hats oever of such

third party products or servi ces or any intellectual property cont ai ned therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPRO VED IN W RITING B Y AN AUTHORIZE REPRESE NTATIVE O F ST, ST PRODU CTS ARE N OT DESI GNED,

AUTHOR I Z ED OR WARRANTED FOR USE IN MILITARY , AIR CRAFT , S PACE, LIF E S AVING, OR L IF E SUSTAINI NG APPLIC AT I O NS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warran ty gr anted by ST fo r the ST produc t or se rvice d es cribed he rein and shall not c reat e o r extend in a ny mann er wha tsoe ver, an

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMi croelectronic s - A l l rights reserved

STMicroelectronics grou p of companies

Austra l i a - Be l gi um - Brazil - Cana da - China - Czech Rep ubl i c - Finland - Franc e - Germany - Hong Kong - India - Israel - It aly - Japan -

Malaysi a - M al ta - Morocco - Sin gapore - Spain - Sweden - Switzerlan d - United Kingdom - Uni ted States of America

www.st.com

25/25

Loading...

Loading...