Page 1

AN2206

Application note

Designing with L6920DB, high efficiency

syncronous rectifier step-up converter

Introduction

The L6920DB is a high efficiency monolithic step-up switching converter IC especially

designed for battery powered applications, thanks to its minimum start-up of 0.8 V, and a

minimum operating voltage of 0.6 V.

It requires only three external components to realize the conversion from battery voltage to

the selected output voltage.

It has a minimum output voltage of 1.8 V, which is enough to supply even the most advanced

ASICs and microprocessors. The high switching frequency allows users to choose small

inductors and output capacitors for their designs. Supervisory functions include Reference

Voltage, Low Battery Detection, and Shutdown, which are provided with overcurrent

protection.

March 2007 Rev 4 1/11

www.st.com

Page 2

Contents AN2206

Contents

1 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Output voltage selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Input capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Switching frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Low battery detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7 Layout guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Typical performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2/11

Page 3

AN2206 Application information

1 Application information

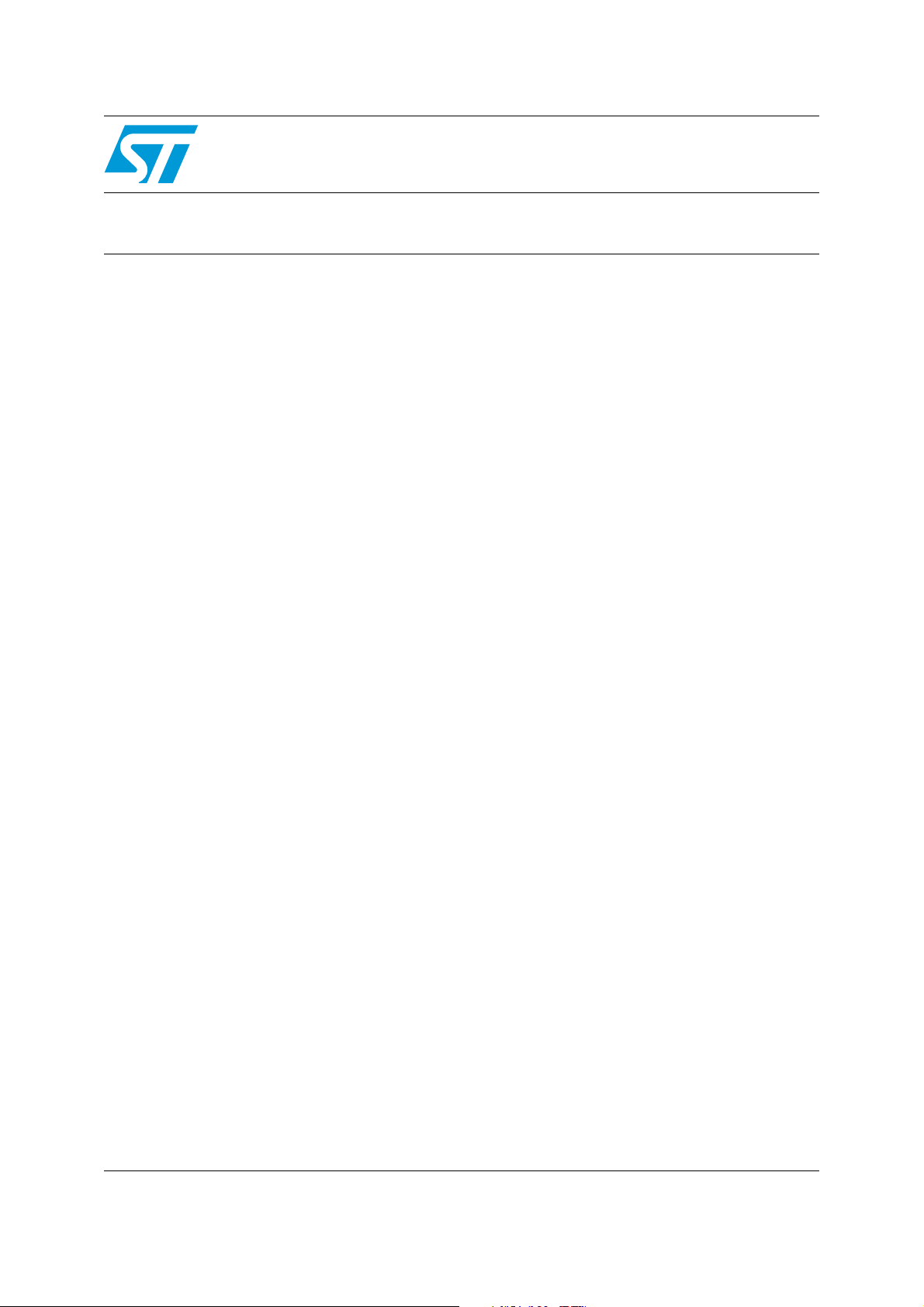

Figure 1. L6920DB Example of overall application size

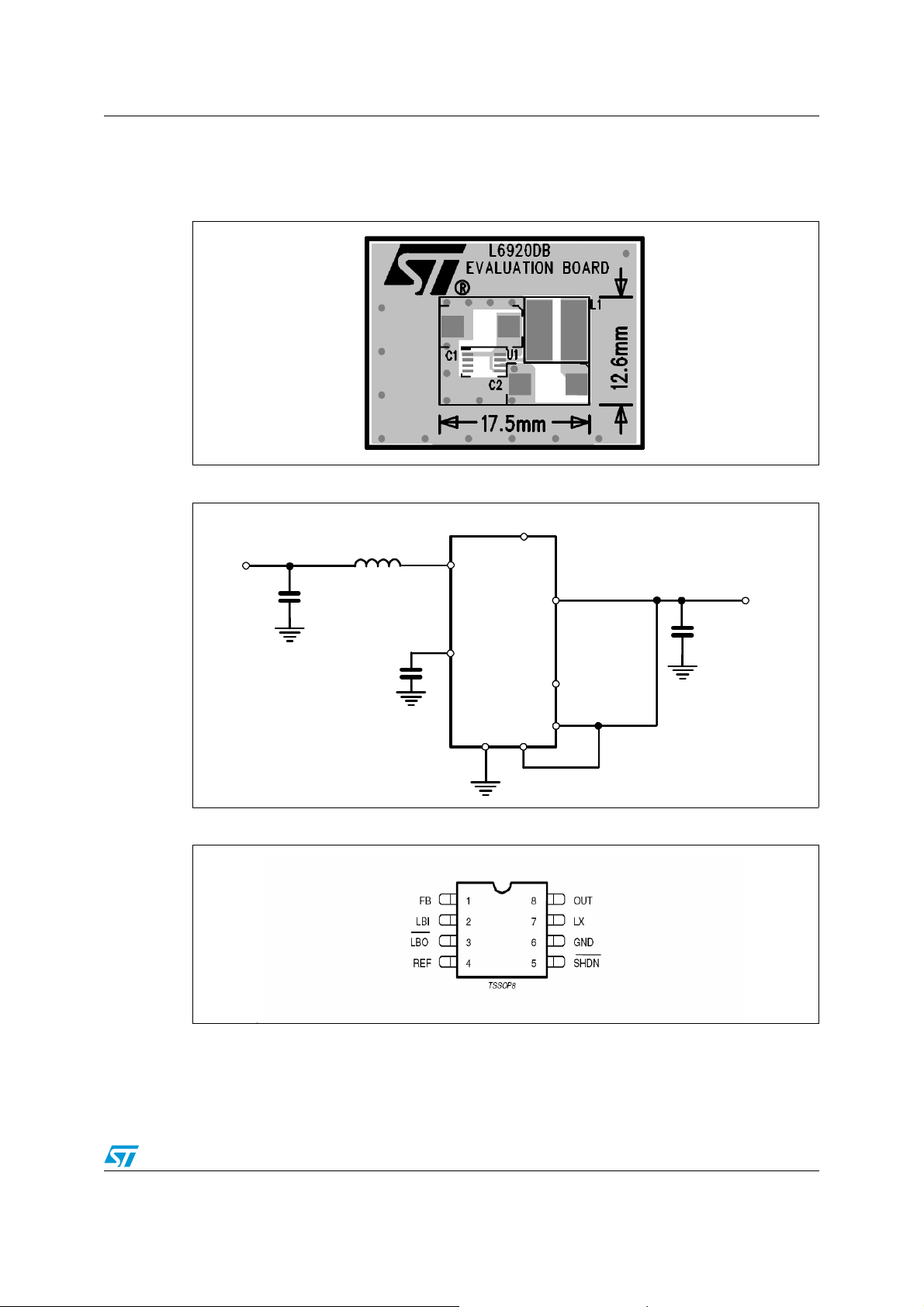

Figure 2. Application circuit

LBI

V

=2.5V

BATT

L1 10µH

C1

47µF

100nF

LX

V

REF

C4

4

GND

Figure 3. Pin connections (top view)

7

L6920D

6

2

5

8

3

1

_____

SHDN

V

___

LBO

FB

OUT

C1

47µF

=3.3V

V

OUT

3/11

Page 4

Application information AN2206

1.1 Output voltage selection

The output voltage must be selected by configuring the FB pin. Three choices are available:

● fixed 3.3 V

● fixed 5 V

● adjustable output set via an external resistor divider.

R4 and R5 should be selected in the range of 100 kΩ - 1 MΩ to minimize power consumption

and errors due to current sunk by FB pin (a few nA). See Figure 5

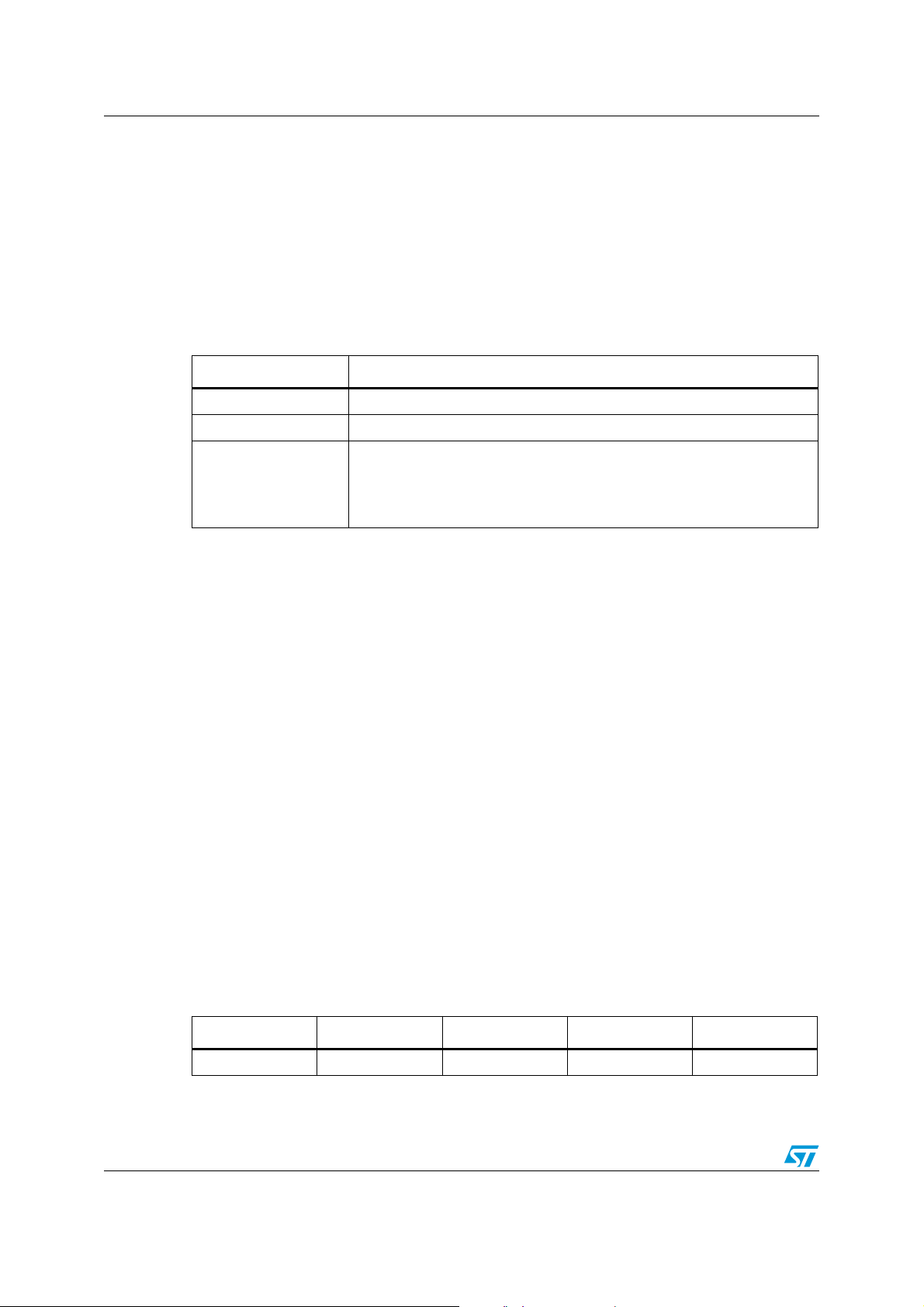

Table 1. Output voltage connection

Output voltage Feedback connection

=3.3 V FB Connected to OUT (See Figure 5)

V

OUT

V

=5 V FB Connected to GND (See Figure 5)

OUT

FB Connected to a resistor divider

R4

1.8 V=V

OUT

=5.2 V

V

OUT

1.23V 1

⎛⎞

------- -+

•=

⎝⎠

R5

1.2 Input capacitor selection

A minimum capacitance is usually added at the input to filter the current ripple. 10 µF are

enough for most of the applications.

Low-ESR Tantalum and Multilayer Ceramic Capacitors (MLCC) are good choices.

1.3 Output capacitor selection

The output capacitor affects both efficiency and output ripple, so its choice has to be

considered with particular care. The capacitance value should be in the range of about

10mF-100 µF. An additional, smaller, low Equivalent Series Resistance (ESR) capacitor can

be used (not mandatory) in parallel for high frequency filtering. A typical value is around

1 µF.

Note: For very high performance requirements (e.g., efficiency and output voltage ripple), a very

low ESR capacitor has to be used (e.g. MLCC capacitors).

Other possibilities include low-ESR tantalum capacitors, available from KEMET, and other

sources. POSCAP capacitors from SANYO and polymeric capacitors from PANASONIC are

also good choices (see Ta b l e 2 ).

Note: The cap values and rated voltages are only suggested possibilities.

Table 2. Distributor's capacitor main list

Manufacturer Series Cap value (µF) Rated voltage (V) ESR (mΩ)

KEMET T510/T494/ T495 10 to 47 6 30 to 100

4/11

Page 5

AN2206 Application information

Table 2. Distributor's capacitor main list (continued)

Manufacturer Series Cap value (µF) Rated voltage (V) ESR (mΩ)

PANASONIC EEFCD 22 to 47 6.3 50 to 700

SANYO POSCAP TPA/B/C 22 to 230 6.3 40 to 80

1.4 Inductor selection

Usually, inductors ranging between 2 µH to 10 µH satisfy most application requirements.

However, small-value inductors are physically smaller and guarantee a faster response to

load transients.

Inductor size also affects the maximum current deliverable to the load. A low series

resistance is suggested if very high efficiency values are needed. In any case, the saturation

current of the choke should be higher than the peak current limit of the device (800 mA typ.).

Good surface-mount inductors are available from COILCRAFTS, COILTRONICS and other

sources (see Ta bl e 3 ).

Table 3. Distributor's inductor main list

Manufacturer Series Inductor value (µH) Saturation current (A)

Coilcraft

Coiltronics

Panasonic

LPO1704 2.2 to 10 0.9 to 1.6

LPO6610 2.2 to 10 0.9 to 1.5

ELL6SH 10 to 22 0.9 to 1.5

ELL6RH 5.1 to10 1.1 to 1.55

1.5 Switching frequency

The control loop of the L6920DB is based on a Minimum OFF-time and a Maximum ON-time

(see datasheet). This means that the switching frequency is not fixed, but changes in order

to keep the output voltage regulated. The maximum reachable value is approximately 1MHz.

The frequency value depends on the inductor value, input and output voltage, and the load.

1.6 Low battery detection

The L6920DB includes a low battery detection comparator. The threshold is V

and a hysteresis is added to avoid oscillations when input crosses the threshold slowly. The

Low Battery Output (LBO

use. Adding a resistor divider at the Low Battery Input (LBI) pin gives the user the ability to

set at which value of V

) is an open drain, so a pull-up resistor, R3, is required for proper

the (LBO goes high. The relationship is showed below:

BATT

SD10 2.2 to 6.2 0.9 to 1.6

SD12 3.3 to 10 0.85 to 1.4

voltage

REF

Equation 1

V

BATT TH–

1.23V 1

⎛⎞

•=

⎝⎠

R1

--------+

R2

5/11

Page 6

Application information AN2206

L1 10

µ

If a Low battery voltage detection than 1.23 V is required, it is possible using a resistor

divider between V

OUT

and V

, showed in the Figure 4.

BATT

In this case the relationship is the following:

Equation 2

V

BATT TH–

1.23

V

⎛⎞

---------------------------------

⎝⎠

OUT

1.23–

R

R

2

1•–=

In order to keep the efficiency high, the resistors of this divider must be chosen with a value

higher than 100 KΩ.

Figure 4. Schematic for low battery voltage detection below the 1.23 V voltage

reference

Figure 5. Demoboard schematic

V

BATT

N.C

C4

100nF

R1

N.C

R2

LBI

V

REF

GND

2

L6920D

4

6

LX

FB

7

V

OUT

8

R3

N.C

___

LBO

3

_____

SHDN

5

1

H

J1

1

2

3

1

2

3

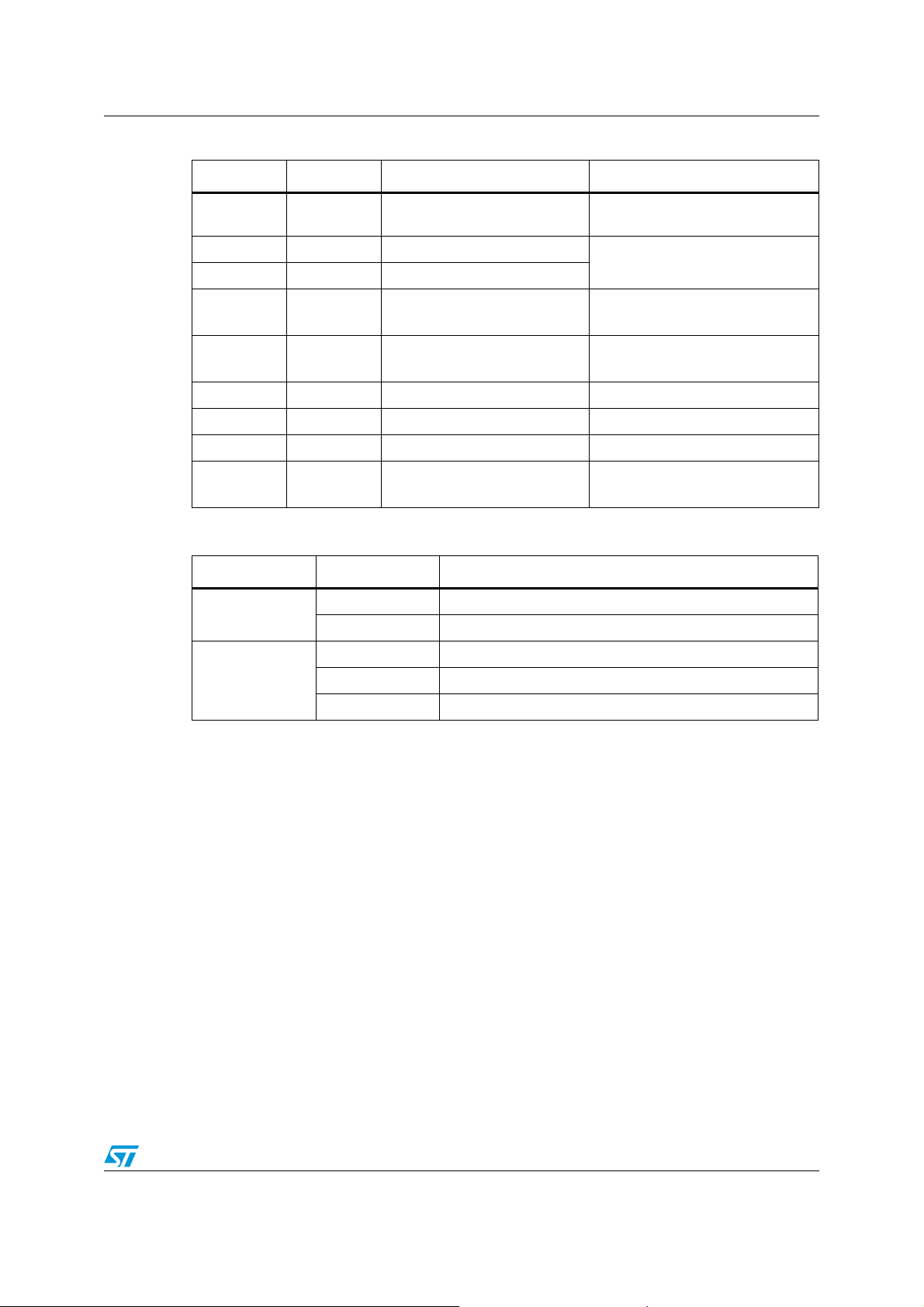

Table 4. Demo board components description

J2

C3

N.C

R4 N.C.

R5 N.C.

C2

47µF

C1

47µF

V

BATT

GND

V

OUT

GND

___

LBO

_____

SHDN

Name Value Manufacturer Description

R1 N.C

Low battery Input resistor divider

R2 N.C

6/11

Page 7

AN2206 Application information

Table 4. Demo board components description (continued)

Name Value Manufacturer Description

R3 N.C

R4 N.C

R5 N.C

C1 47 µ

C2 47 µ

C3 1 µ

C4 100

U1 L6920DB

L1 10 µH

F

F

F High frequency filter capacitor

nF V

PANASONIC

EEFCDJ470R

PANASONIC

EEFCDJ470R

PANASONIC

ELL6RH100M

Table 5. Jumper connections

Jumper Position Function

J1

1-2 Device enabled

2-3 Device disabled

None Adjustable using R4 and R5 (not mounted)

Pull-up resistor. Connected

between VOUT and LBO pins.

Output voltage resistor divider

Output capacitor

Input capacitor

filter capacitor

REF

Inductor

J2

1.7 Layout guidelines

The board layout is very important in order to minimize noise, high frequency resonance

problems and electromagnetic interference. It is essential to keep the high switching current

circulating paths as small as possible to reduce radiation and resonance problems. The

output and input cap should be very close to the device.

The external resistor dividers, if used, should be as close as possible to the FB and LBI pins

of the device, and as far as possible from the high current circulating paths, to avoid pick-up

noise.

Large traces for high current paths and an extended ground plane help reduce noise and

increase the efficiency.

For an example of recommended layout see the following evaluation board.

1-2 3.3 V output voltage

2-3 5 V output voltage

7/11

Page 8

Application information AN2206

Figure 6. Demoboard layout (top view)

Figure 7. Demoboard layout (bottom view)

8/11

Page 9

AN2206 Typical performance

2 Typical performance

Figure 8. Efficiency vs. output current at Vout = 3.3 V

Figure 9. Efficiency vs. output current at Vout = 5 V

Figure 10. Start-up voltage vs. output current at Vout = 5 V

VStart up vs. output current

1600

1500

1400

1300

1200

1100

1000

VStart up (mV

900

800

700

600

0.1 1 10 100 1 00 0

Output current (mA)

9/11

Page 10

Revision history AN2206

Figure 11. Start-up voltage vs. output current at Vout = 3.3 V

VStart up vs. output curren t

1600

Vout=3.3V

1500

1400

1300

1200

1100

1000

VStart up (mV

900

800

700

600

0.1 1 10 100 1000

Output current (mA)

3 Revision history

Table 6. Revision history

Date Revision Changes

05-Dec-2005 1 First issue

09-Feb-2006 2 Text modification

- New template

05-Oct-2006 3

26-Mar-2007 4 - Ta b le 4 modified

- Equation 2 modified

- Figure 4 modified

10/11

Page 11

AN2206

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

11/11

Loading...

Loading...