Page 1

AN2141

Application note

LED array reference design board

Introduction

New high brightness LED (HB LED) applications such as displays, information panels,

signs, traffic signals, automotive lighting and advertising are becoming more and more

popular. For these applications new HB LED drivers with constant current outputs have

been designed. The constant LED current guarantees the same brightness for all LEDs and

provides a cost advantage in lighting system solutions, as there is no need for external

resistors for each individual LED. This document describes a simple design solution to drive

an array of high brightness LEDs, using the STP16CP05 and the STP16CPS05 LED

drivers.

Two reference design (one with 80 LEDs and another with 32 LEDs) are proposed to

provide a solution for driving high brightness LED arrays. The first has an array of 80 blue

HB LEDs arranged in a 5 x 16 matrix. This matrix of LEDs is driven by five 16-channel

STP16CPS05 drivers, with which it is possible to implement short, moving text. Also, all of

the LEDs in the display can be turned on simultaneously using a switch, in order to

demonstrate the uniformity in the brightness of the LEDs, which is achieved by applying the

same sink current to all channels. The second reference design is a smaller 4 x 8 LED

matrix driven by the STP16CP05 and the STP16CPS05, and includes a DC-DC converter

for supply voltages varying from 5 V up to 35 V. For this new 32 LED array reference design,

an evaluation board using OSRAM LEDs is available through order code STEVALILL003V2.

The new STP16CP05, STP08CP05 and STP16CPS05 LED drivers are monolithic, low

voltage 8-bit or 16-bit shift registers designed for driving LED and LED panel displays.

Thanks to these drivers the output LED current is constant and can be very precisely set

using just one external resistor to control the light intensity of the LEDs. The STPxxCx05

guarantees up to 20 V output driving capability, allowing designers to connect more LEDs in

series. The high 30 MHz clock frequency also satisfies the system requirement of high

volume data transmission. Both designs are controlled by the ST7Lite09 microcontroller,

which provides full text motion control, brightness regulation through PWM and control of

text speed. A 3.3 V supply voltage for the microcontroller and the drivers is provided by a

linear voltage regulator (the LE33 or L78L33).

The STP16CPS05 LED driver employs auto power saving to reduce power consumption.

January 2008 Rev 3 1/18

www.st.com

Page 2

Contents AN2141

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Reducing power dissipation on the chip . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Common drain outputs configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 LED array reference designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 80 LED array reference design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1.1 Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1.2 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 32 LED array reference design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.1 Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.2 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 The STP16CP05 vs. the STP16CPS05 . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 References and related materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2/18

Page 3

AN2141 List of figures

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2. Timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. General configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. Configuration with resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Common drain outputs configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. 80 LED array reference design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. 32 LED array reference design board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9. Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3/18

Page 4

Block diagram AN2141

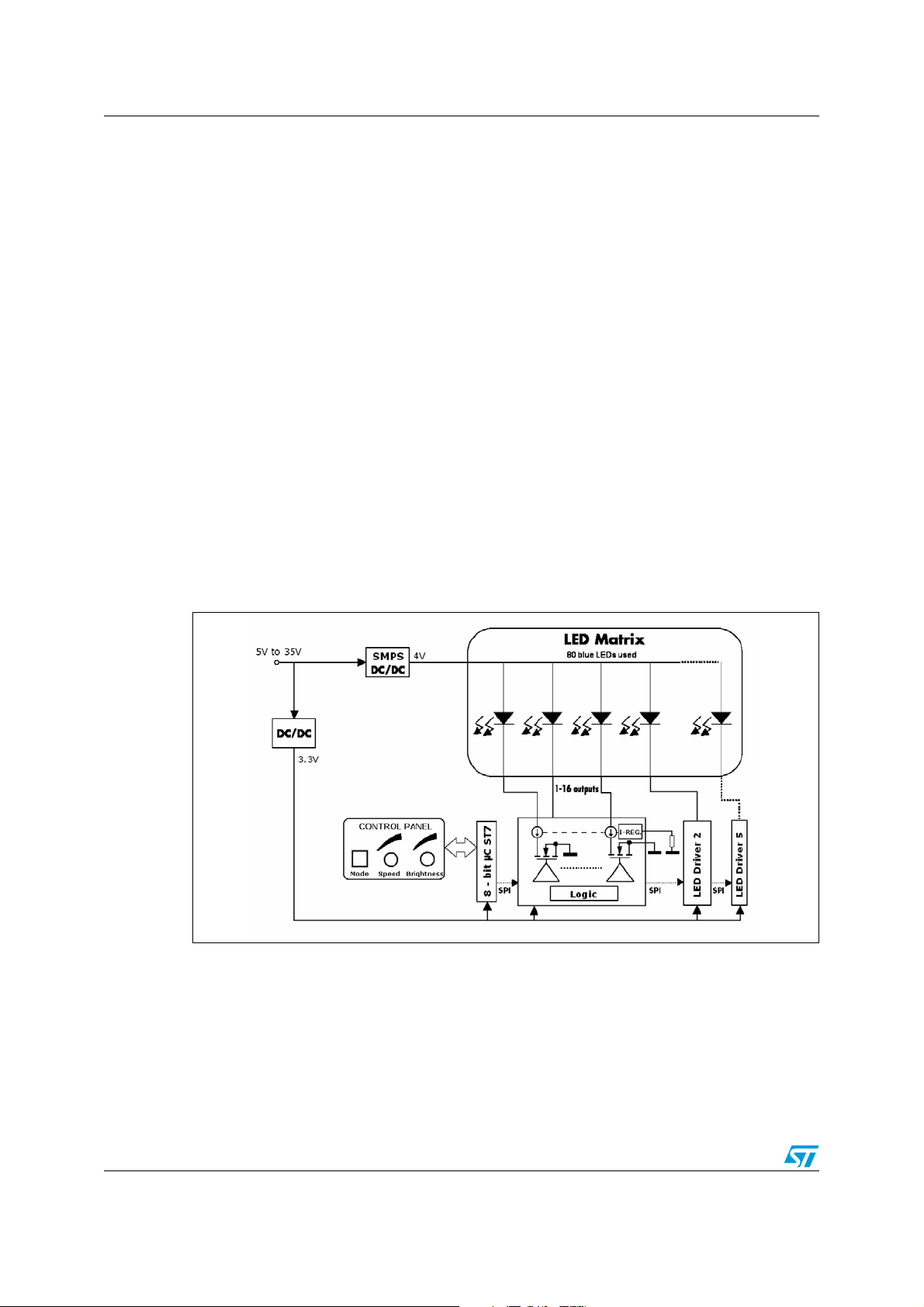

1 Block diagram

The block diagram of the LED array reference design board is shown in Figure 1. The

diagram shows a universal STMicroelectronics system solution for driving an LED array. The

number of LEDs can be increased by adding additional drivers in cascade. The input voltage

is connected to the anodes of all of the HB LEDs. The input voltage value is very important

due to the power dissipation in the drivers. A detailed explanation is described in Section 3:

Reducing power dissipation on the chip. The LED cathodes are connected to ground

through constant current sinks. The value of the constant current is set by only one external

resistor. The DC-DC converter is represented by a simple linear controller (LE33 or L78L33)

and provides 3.3 V supply voltage to the microcontroller and the LED drivers. The DC-DC

SMPS (switch mode power supply), using the L5970D step-down converter, is designed to

increase the efficiency, performance and supply voltage range (5 V up to 35 V). A detailed

description of the SMPS design can be found in the L5970D device datasheet.

The control unit in this application is a microcontroller which sends data through the serial

peripheral interface (SPI) to the shift registers. The data are shifted bit by bit to the next

driver with the falling edge of the clock frequency (the maximum communication frequency

for this driver is 30 MHz).

The control panel consists of the switch and two potentiometers. The switch changes the

modes and the potentiometers allow the changing of the brightness and the text speed

(blinking speed).

Figure 1.

Block diagram

4/18

Page 5

AN2141 Timing diagram

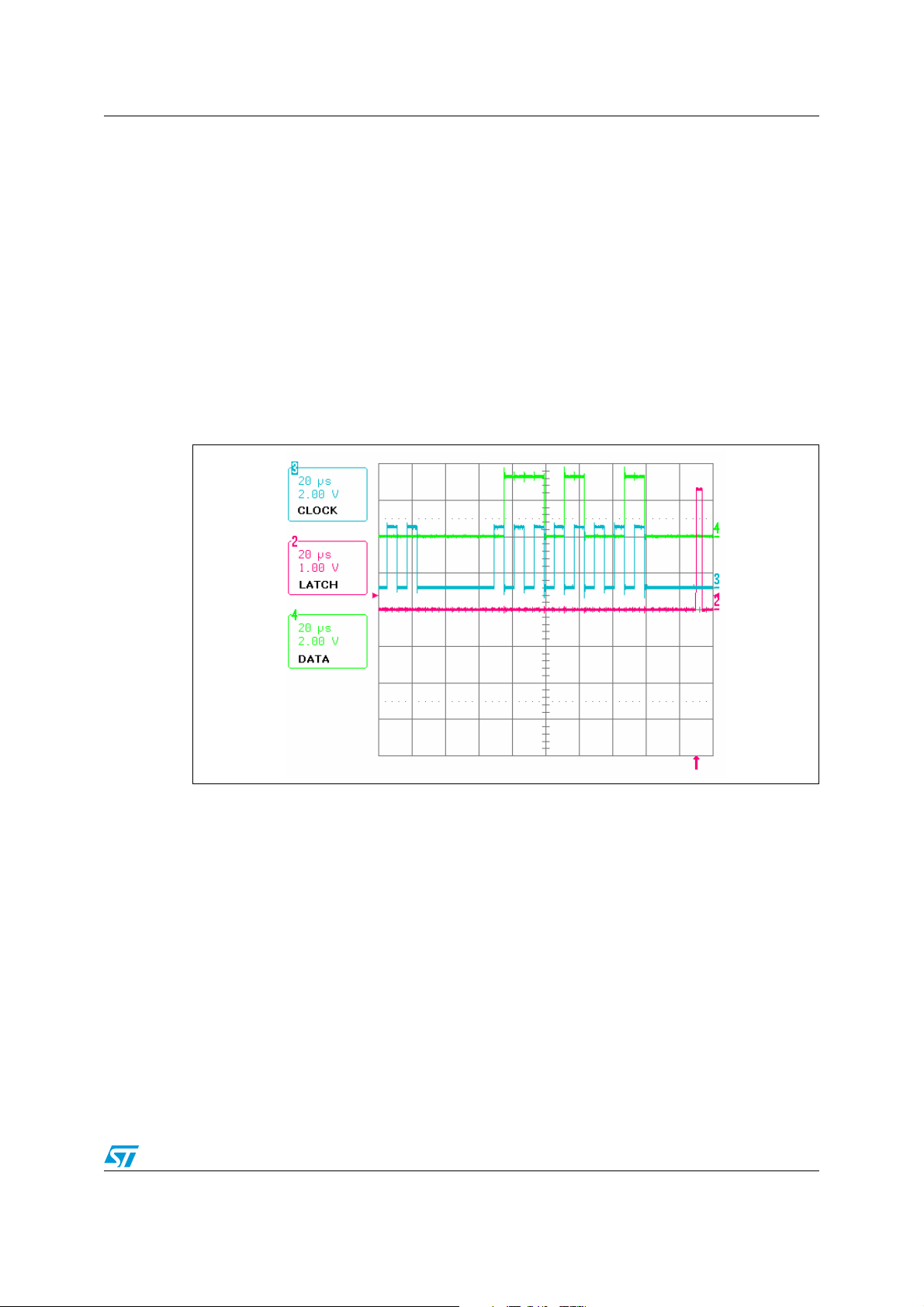

2 Timing diagram

The typical timing diagram is shown in Figure 2. The DATA, CLOCK and LATCH waveforms

are shown. The data are changed with the falling edge of the clock frequency. For example,

in Figure 2 one byte (01101001) can be seen. When all data are written to the drivers

through the SPI, the microcontroller sets the latch input terminal (LE) pin to “log 1" and

rewrites the data to the storage registers. In the next step the LE pin is grounded and thus

the following data can be transmitted to the shift registers without changes in the output

stage. The data in the storage registers are converted to the output constant current stages

by the output enable (EO) pin. Thanks to the output enable pin, the brightness can be

regulated through the PWM signal. Both LED array reference designs have adjustable delay

time via potentiometer after implementation of the “latch signal”. Thanks to this feature the

blinking speed can be regulated (time between sending data packets is changed).

Figure 2.

Timing diagram

5/18

Page 6

Reducing power dissipation on the chip AN2141

3 Reducing power dissipation on the chip

One of the most important considerations in this application is the calculation of the

maximum power dissipation on the driver chip. The maximum power consumption can be

calculated with the ambient temperature and the thermal resistance of the chip. The thermal

resistance depends on the type of package and can be found together with the maximum

allowed junction temperature in the datasheet for the device. The maximum allowable power

consumption of this device is calculated as follows:

Equation 1

T

–

P

dmax

● P

● T

● T

● R

- maximum power dissipation [W]

dmax

- ambient temperature [°C]

a

- maximum junction temperature [°C]

jmax

- thermal resistance junction to ambient [°C/W]

thja

The maximum forward current for each type of LED is provided in the datasheet and must

not be exceeded. Each output channel of the driver operates as a linear current sink. As the

sink current for each output of LED driver is set as constant by an external resistor, the

power dissipation of the chip depends on the value of LED supply voltage (V

forward voltage drop of the LEDs. To optimize the power dissipation of the chip, it is

recommended to use the lowest possible supply voltage for the LEDs. An example of how to

calculate the power dissipation of the chip is shown in Figure 3. The equation for this basic

connection is:

jmaxTa

-------------------------- -=

R

thja

) minus the

c

Equation 2

#outputs

P

totIcUc

● P

● I

● U

● I - constant LED current set by external resistor [A]

● #outputs - number of outputs

● V

● n

● V

- power dissipation of chip [W]

tot

- supply current for driver [A]

c

- supply voltage for driver [V]

c

- LED supply voltage [V]

c

- number of serial connected LED for each output

i

- LED forward voltage [V]

F

IVcniVF–()

+⋅=

∑

i1=

6/18

Page 7

AN2141 Reducing power dissipation on the chip

Figure 3. General configuration

STP16CPS05

When only one LED is connected to each output (the most common configuration used in

LED array reference boards) the equation can be simplified as follows:

Equation 3

P

totIc

#outputs

U⋅c–=

–()⋅⋅

IV

cVF

As previously stated, only the LED supply voltage V

an LED supply voltage V

about 0.5 V higher than VF or n*VF for n LEDs connected in

c

is variable. Thus the correct choice is

c

series.

If a PWM signal controls the brightness of the LEDs, the total power dissipation on the chip

is calculated as:

Equation 4

P

totIc

#outputs

U⋅c–=

IVcVF–()D⋅⋅ ⋅

where D is the duty cycle.

If there is no possibility to obtain the proper value of the LED supply voltage in an

application, an external resistor R in series with each LED must be connected to limit the

power dissipation on the chip as shown in Figure 4. The power dissipation on the chip is

consequently decreased as follows:

Equation 5

P

totIc

#outputs

U⋅c–=

IVcVFIR⋅–()–()⋅⋅

7/18

Page 8

Reducing power dissipation on the chip AN2141

Figure 4. Configuration with resistors

8/18

Page 9

AN2141 Common drain outputs configuration

4 Common drain outputs configuration

As mentioned above, the STPxxCx05 is focused on driving high brightness LEDs. The

maximum forward current of HB LEDs can vary from 20 mA to several hundred mA.

A typical current value for super HB LEDs is 350 mA. Thanks to the common drain

configuration the outputs can be connected together as shown in Figure 5. This increases

the performance and current capability of the driver. This configuration enables the driving of

several types of HB LEDs even with the limited current-per-output.

Figure 5. Common drain outputs configuration

9/18

Page 10

LED array reference designs AN2141

5 LED array reference designs

Two LED array reference designs have been developed: one with 80 LEDs using the

STP16CPS05 LED driver, and another with 32 LEDs using the STP16CP05 and

STP16CPS05 LED drivers. In the following sections these two designs and their differences

are briefly described.

5.1 80 LED array reference design

An example of the 80 LED array reference design proposal (no evaluation board is currently

available for this design) is shown in Figure 6. Its block schematic description is provided in

Section 1: Block diagram. The only simplification in this reference design is that it does not

include an SMPS DC-DC converter. Therefore the supply voltage should be in the range of

4 V to 5 V.

Figure 6. 80 LED array reference design

5.1.1 Application schematic

A detailed application schematic of this design is shown in Figure 7. Five STP16CPS05 LED

drivers with 16 outputs are controlled by the ST7Lite09 microcontroller. The microcontroller

provides the clock frequency (SCK pin), the serial data (MOSI pin), the PWM signal (PWM

pin) and the latch signal (PA0 pin). The clock frequency in this application is 633 KHz and

the PWM signal for brightness regulation is 619 Hz. Resistors R1 to R5 (one for each driver)

set the constant current for all outputs. Their value is 1.3 kΩ and they set the constant sink

current to approximately 10 mA (for more information, please refer to the STP16CP05 and

STP16CPS05 datasheets). The analog voltage values from the trimmers R6 and R8 are

measured and converted by the microcontroller’s ADC to the digital reference signal. The

microcontroller sets the PWM signal for brightness and the data time delay for text speed

control accordingly.

10/18

Page 11

AN2141 LED array reference designs

5.1.2 Bill of material

Table 1. Bill of material

Item Quantity Reference Part

1 8 C1, C2, C3 C4 C5 C7, C8, C9 100 nF

2 1 C6 10 µF

3 1 C10 2.2 µF

480 D1 - D80 LED

5 5 J1, J2, J3, J4, J5 STP16CPS05

6 1 J6 ICP

7 1 J7 Connector

8 5 R1, R2, R3, R4, R5 1k3

9 3 R6, R7, R8 10 k

10 1 SW1 SW push button

11 1 U1 ST7Lite09

12 1 U2 LE33/SO

11/18

Page 12

LED array reference designs AN2141

Figure 7. Application schematic

STP16CPS05 STP16CPS05

STP16CPS05

STP16CPS05

STP16CPS05

12/18

Page 13

AN2141 LED array reference designs

5.2 32 LED array reference design

The 32 LED array reference design board is shown in Figure 8 and its block schematic

description corresponds to Section 1: Block diagram. All components are placed on the top

side of the board. This board includes an SMPS DC-DC converter using the L5970D stepdown switching regulator for input voltages from 5 V to 35 V. The order code for this

reference design board is STEVAL-ILL003V2.

Figure 8. 32 LED array reference design board

5.2.1 Application schematic

The detailed application schematic of this design is shown in Figure 9. Two LED drivers

(STP16CP05 and STP16CPS05) with 16 outputs each are controlled by one ST7Lite09

microcontroller. Resistors R1 and R2 (one for each driver) set the constant current for all

outputs. Their value is 1.2 kΩ and they set the constant sink current to 16 mA for each output

(for more information, please refer to the STP16CP05 and STP16CPS05 datasheets). Six

blinking modes are programmed in this application. The first switches the entire display

ON/OFF. The second is a "harmonic" lighting effect, as the light is moved from the margin to

the center of the display and back. During the third mode the numbers from one to nine are

moved on the display. The fourth and fifth modes are implemented to show differences

between the STP16CP05 and the STP16CPS05 LED drivers (as described below). Since

the constant current LED drivers are used in this design, the brightness for each LED must

be the same. Therefore, during the sixth mode, all LEDs are simply turned ON for LED

brightness checking. All features and functions (communication, brightness regulation,

blinking speed regulation, etc.) are similar to the 80 LED array reference design board, with

exception of the addition of an SMPS DC-DC converter. Its output voltage is 4 V and its

maximum current is 1 A (L5970D device). For more details on this converter design, please

refer to the L5970D datasheet. The clock frequency in this application is 83.6 KHz and the

PWM signal for brightness regulation is 654 Hz.

13/18

Page 14

LED array reference designs AN2141

5.2.2 Bill of material

Table 2. Bill of material

Item Qty Reference Part Description Order code

1 1 CONNECTOR1 ICC Programming connector

2 5 C1,C2,C3,C5,C6 100 nF SMD cap. 0805

3 1 C4 10 nF SMD cap. 0805

4 1 C7 220 pF SMD cap. 0805

5 1 C8 22 nF SMD cap. 0805

6 1 C9 10 µF/35 V SMD tantal. cap.

7 1 C10 100 µF/16 V SMD tantal. cap.

8 1 C11 220 µF/16 V Electrolytic cap.

932 D1 - D32

10 1 D33 SMD green LED Green SMD LED

11 1 D34 STPS340U Schottky diode STPS340U

OSRAM SMD blue

LED

LB T68C-P2S1-35 OSRAM - Q65110A1978

12 1 IO1 ST7LITE09 Microcontroller ST7FLite09Y0M6

13 1 I02 STP16CP05 LED driver STP16CP05MTR

14 1 IO3 STP16CPS05 LED driver STP16CPS05MTR

15 1 IO4 78L33 Voltage regulator L78L33ACD

16 1 IO5 L5970D DC-DC converter L5970D

17 4 J1,J2,J3,J4 CON1 Not connected

18 1 J5 CON3 Input connector

19 1 L1 33 µH Inductor Coilcraft - DO3316P-333

20 2 P1,P2 10 k Potentiometer

21 2 R1,R2 1K2 SMD 1206 resistor

22 1 R3 10 k SMD 1206 resistor

23 1 R4 560 Ω SMD 1206 resistor

24 1 R5 6k8 SMD 1206 resistor

25 1 R6 3 k SMD 1206 resistor

26 1 R7 4k7 SMD 1206 resistor

27 1 S1 Switch Button

14/18

Page 15

AN2141 LED array reference designs

Figure 9. Application schematic

15/18

Page 16

The STP16CP05 vs. the STP16CPS05 AN2141

6 The STP16CP05 vs. the STP16CPS05

The STP16CPS05 LED driver includes an additional feature called “auto power saving”,

which minimizes the quiescent current if no active data is detected on the latches, and

automatically powers-up the device at the first active data latched. The fourth and fifth

blinking modes are designed on the 32 LED reference design board STEVAL-ILL003V2 to

measure the supply current for the STP16CP05 and STP16CPS05, when no active data is

detected and when active data is latched.

Ta bl e 3 shows that the STP16CPS05 has much lower current (0.067 mA) than the

STP16CP05 (3.11 mA) if no active data is detected. Therefore for large panels it is possible

to save a significant amount of energy using the STP16CPS05 LED drivers with the auto

power saving feature.

Table 3. Current consumption for the STP16CP05 and STP16CPS05 measured on

the STEVAL-ILL003V2

Data status STP16CP05 STP16CPS05

Active data is detected (all outputs are turned ON) 3.03 mA 3.07 mA

No active data is detected (all outputs are turned OFF) 3.11 mA 0.067 mA

16/18

Page 17

AN2141 References and related materials

7 References and related materials

1. STP16CP05 and STP16CPS05 datasheets

2. ST7Lite0 datasheet

3. L5970D datasheet

8 Revision history

Table 4. Document revision history

Date Revision Changes

28-Apr-2005 1 Initial release.

17-Nov-2005 2

22-Jan-2008 3

Added information about new LED driver STP16CP596. Modified

Ta bl e 2 and Figure 9.

Document reformatted. Replaced references to part numbers

STP16CP596, STP16CL596 and STP08CL596 throughout the

document with the new, improved devices STP16CP05,

STP16CPS05 and STP08CP05, respectively. Added Section 6: The

STP16CP05 vs. the STP16CPS05. Added the order code for the 32

LED reference design board STEVAL-ILL003V2. Clarified that no

board is commercially available for the 80 LED reference design in

Section 5: LED array reference designs

17/18

Page 18

AN2141

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

18/18

Loading...

Loading...