Page 1

AN2131

APPLICATION NOTE

HIGH POWER 3-PHASE AUXILIARY POWER SUPPLY DESIGN

BASED ON L5991 AND ESBT STC08DE150

1. INTRODUCTION

This application note deals with the design of a 3Phase auxiliary power supply for 150W dual

output SMPS, using the L5991 PWM driver and

the STC08DE150 ESBT as main switch. The

combination of these ST's parts aims at obtaining

a high efficiency solution for high DC input voltage,

typical requirement of any three phase application.

The L5991 driver is an upgraded version of the

UC384X current mode PWM driver. It boasts

some very interesting additional features.

The necessity to handle both high output power

and wide input voltage leads to design a flyback

stage working in mixed operation mode:

discontinuous and continuous. The continuous

current mode introduces a right half plan zero in

the loop-transfer function which makes the

feedback stabilization difficult; the study on the

frequency response, reported in the present

document, has been carried out using MATLAB.

Furthermore, the slope compensation is

implemented and deeply explained. It is

necessary to remove sub-harmonic oscillations

when the duty cycle is higher than 50%.

Finally the experimental results are analyzed to

better understand the benefits given by the use of

the ESBT in this application.

2. DESIGN SPECIFICATIONS AND

PRELIMINARY REMARKS.

The table 1 lists the converter specification data

and the main parameters fixed for the demo board.

If we look at the specs, particularly at the power

and at the input voltage range, and a fter a brief

description of the differences between continuous

and discontinuous mode, it will s oon be clear that

it is very difficult and not conv enient to design a

flyback converter working in discontinuous mode.

Figure 1 shows a simplified schematic diagram of

a flyback converter.

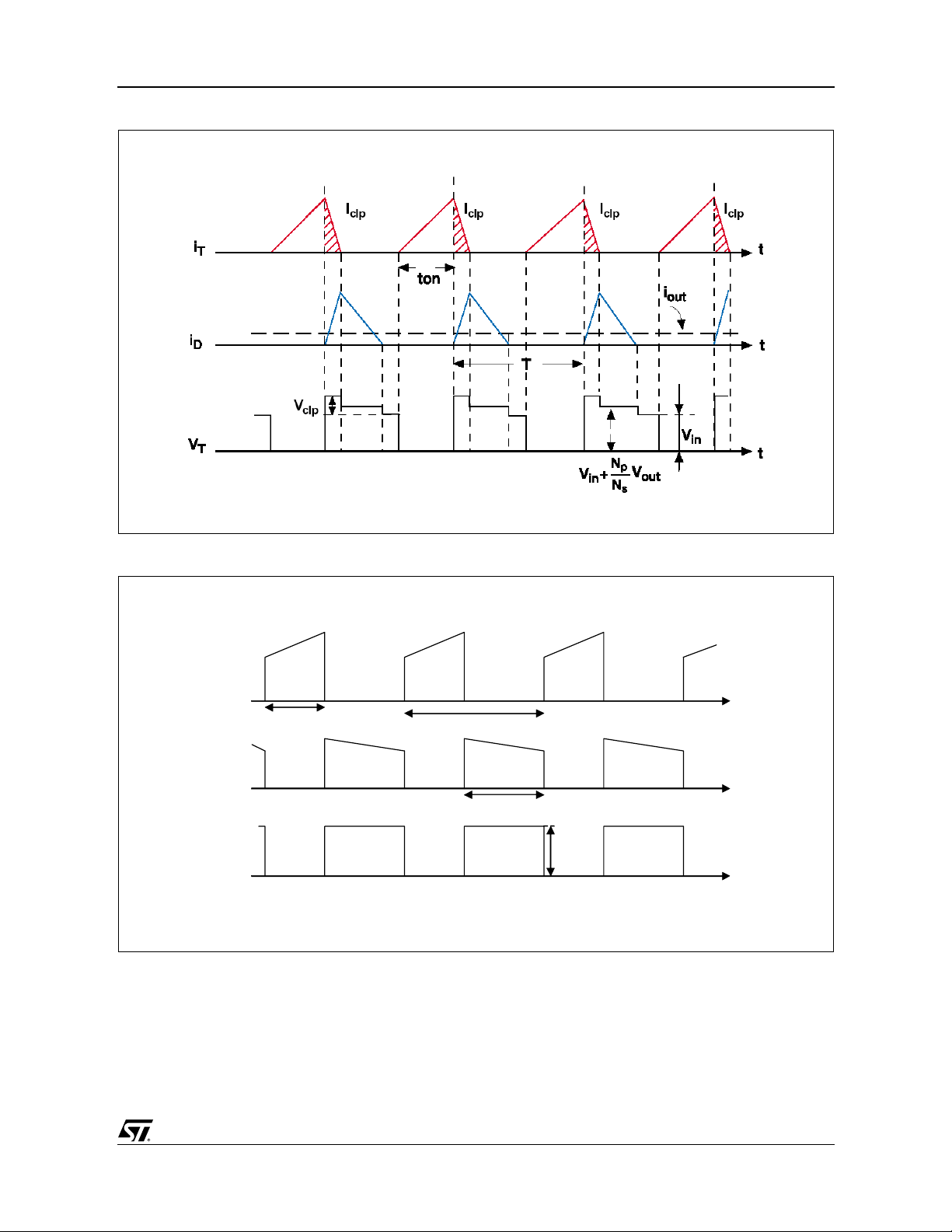

The discontinuous mode, shown in figure 2, has

no front-end step in its primary current, i

turn-off, the secondary current i

, is a decaying

D

, and at

T

triangle which drops to zero before the next turnon.

In the continuous mode, shown in figure 3, the

primary current i

characteristic appearance of a rising ramp on a

step. During the transistor off time (figure 3), the

secondary current has the shape of a decaying

triangle sitting on a step with the current still

remaining in the secondary at the instant of the

next turn-on. There is, therefore, still some energy

left in the secondary at the instant of next turn-on.

The two modes show significantly different

operating properties and usages. The

discontinuous mode responds more rapidly and

with a lower transient output voltage spike to

sudden changes in load current and input voltage.

On the other hand, discontinuous m ode provides

a secondary peak current in the range of two or

three times the continuous mode. This can be

easily understood by comparing figure 2 and figure

3.

The secondary current average v alue is equal to

the DC load current, as reported in both the above

mentioned figures. Assuming also closely equal

off time, it is obvious that the triangle in the

discontinuous mode must show a much larger

peak than the trapezoid of the continuous mode to

get the same average value. Therefore, in the

discontinuous mode, the larger secondary peak

current, at the beginning o f turn-off, will cause a

greater RFI problem.

Secondary rms current in the discontinuous mode

can be up to t wice that in the continu ous mode.

This requires larger secondary wire size and

output filter capacitors with larger ripple current

ratings for the discontinuous mode. Rectifier

diodes will a lso ha ve a high er tempe rat ure r ise in

the discontinuous mode because of the larger

secondary rms current.

Primary peak currents for the discontinuous mode

are about twice those in the continuous mode. As

a result, the discontinuous mode requires a higher

current rating and possibly a more expensive

power transistor. Also, the higher primary current

in the discontinuous mode results in a greater RFI

problem.

Despite all these relative disadvantages, the

discontinuous mode is much more used for low

has a front-end step and the

T

Rev. 1

1/27March 2005

Page 2

AN2131 - APPLICATION N OTE

power applications. This is due to two reasons.

Firstly, as mentioned above, the discontinuous

mode, with an inherently lower transformer

magnetizing inductance, responds more quickly

and with a lower transient output voltage spike to

rapid changes in output load current or input

voltage. Secondly, because the transfer function

of the continuous mode has a right half plane zero,

the error amplifier bandwidth must be drastically

consequence, the transient response is much

slower.

Finally, referring to the power spec of our demo, it

is clear that the discontinuous mode cannot be

used because it would determine a very high

primary and secondary peak current with a higher

cost of all the main components involved: power

transistor, secondary diode and output capacitor.

reduced to stabilize the feedback loop. As a

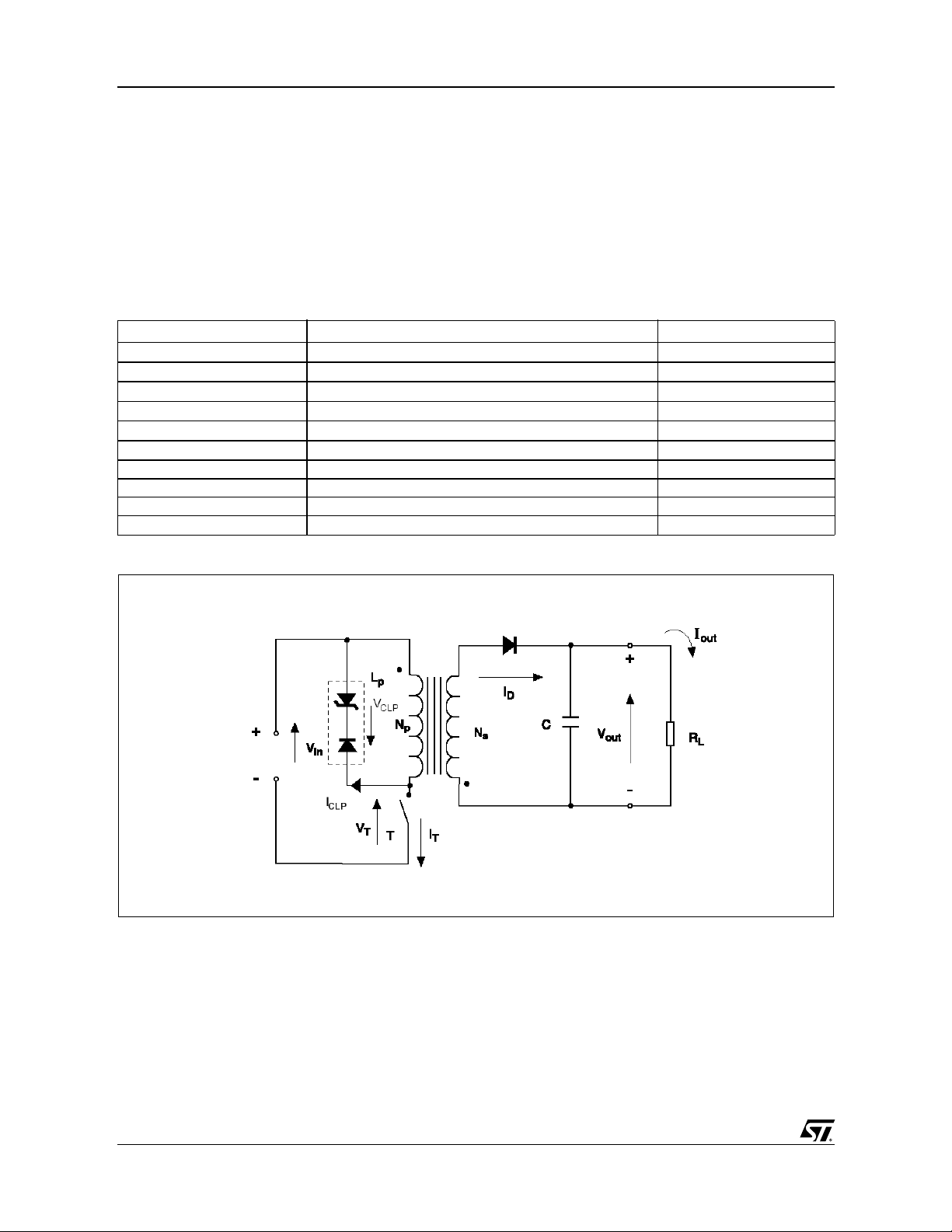

Table 1. Converter Specification data and Fixed Parameters

Symbol Description Values

V

inmin

V

inmax

V

out1

V

out2

V

aux

P

out

η Converter Efficiency >75%

F Switching frequency 90 kHz

Fsb Stand-by switching frequency 35 kHz

V

spike

Rectified minimum Input voltage 250

Rectified maximum Input voltage 850

Output voltage 1 24V/6.25A

Output voltage 2 5V/0.075A

Auxiliary Output voltage 15V/0.01A

Maximum Output Power 150W

Max over voltage limited by clamping circuit 200V

Figure 1. Simplified Schematic Diagram of a Flyback Converter

2/27

Page 3

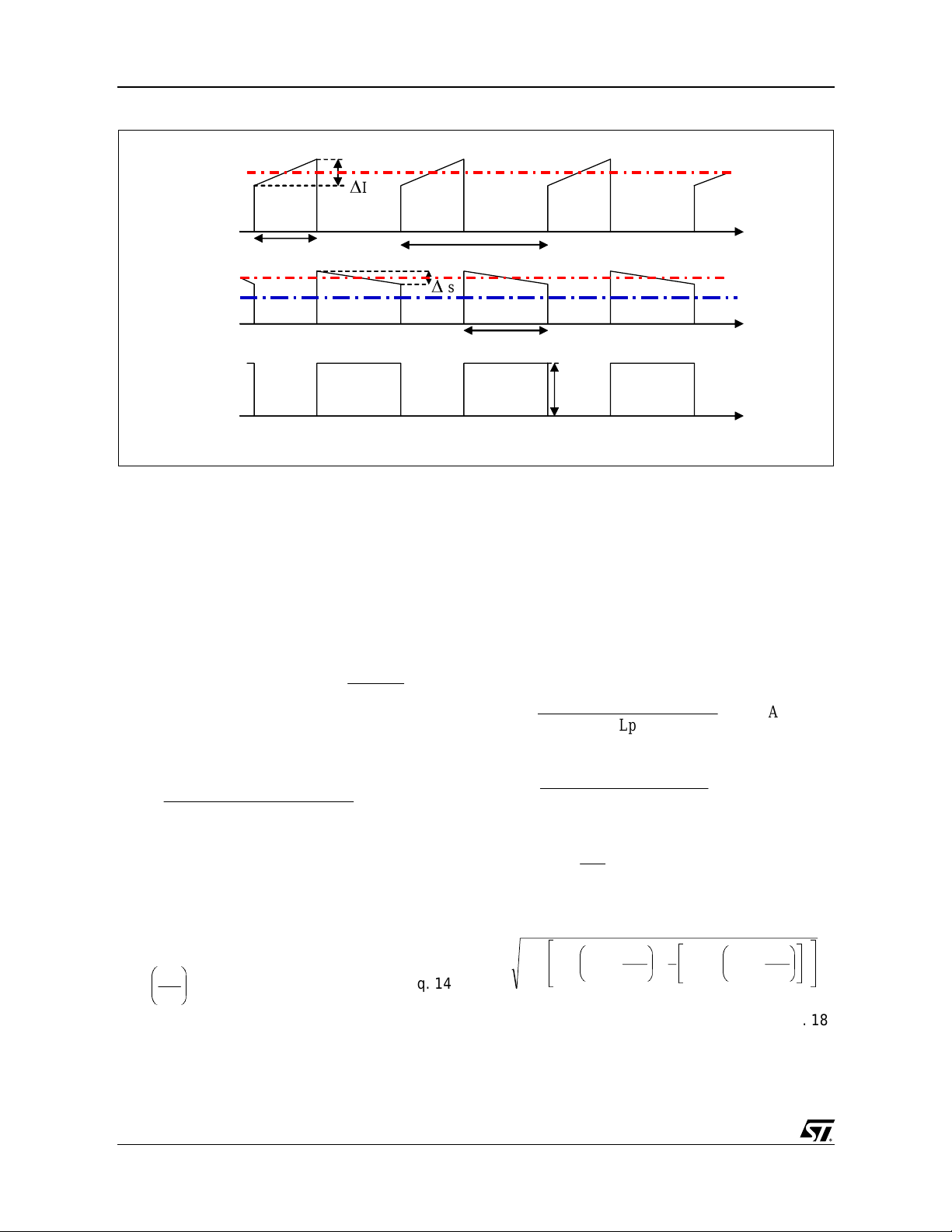

Figure 2. Discontinuous Mode Flyback Waveforms

t t

I

AN2131 - APPLICAT ION NOTE

Figure 3. Continuous Mode Flyback Waveforms

IT

t

D

VT

on

T

Ts

T

off

Vin+Vfly

3. FLYBACK CONTINUOS MODE WITH L5991

The minimization of the power drawn from the

mains under light load conditions (Stand-by,

Suspend or some o ther idle modes) i s an issue

that has recently become of great interest, mainly

because new and more severe standards are

coming into force.

The key point of this strategy is a low sw itching

frequency. It is well-known that many of the power

loss sources in a lightly loaded flyback waste

energy proportionally to the switching frequenc y,

hence this should be reduced as much as

possible. On the other hand, it is equally well-

3/27

Page 4

AN2131 - APPLICATION N OTE

D

V

D

N

V

known that a low switching frequency leads to

bigger and heavier magnetics and mak es filtering

more troublesome. It is then advisable to make the

system operate at high frequency und er nominal

load condition and to reduce the frequ ency when

the system works in a low-consumption mode.

This requires a special functionality of the

controller. It should be able to automatically

recognize the condition of light or heavy load and

then adequate its operating frequency

accordingly.

The L5991 PWM controller, with its "Stand-by

function", meets exactly this requirement. This

application note will deal with the design of a

flyback using L5991 PWM driver, while deeper

details about the driver itself can be foun d in the

dedicated application note AN1049.

The specifications table reports the two values of

the switching frequency, 90kHz for normal mode

and 35kHz for stand-by mode.

4. FLYBACK STAGE DESIGN

The continuous mode operation, as any switching

topology, is identified by observing the steady

state behavior of the energy storage compon ent.

In the flyback topology, the storage element is

represented by the magnetization transformer

inductance, which is charged by the primary

winding during the on time, and discharged by the

secondary winding during the off time. The flyback

topology will hence be working in continuous

mode if the secondary wind ing current does not

reach zero at the end of the off time.

As previously said, the mixed mode implies a

discontinuous mode operation for low load and/or

higher input voltage. The boundary depends on

the output power for a given input voltage. The

higher is the input voltage th e hig her is t he ou tput

power when the continuous mode starts.

Theoretically, there isn't any restriction to fix the

boundary between continuous and discontinuous

mode. It will be given by imposing design equation

for others relevant circuit parameters.

The maximum duty cycle , that in a discontinuous

mode flyback is imposed to prevent the continuous

mode operation, in this case must be fixed

establishing a good trade-off between primary and

secondary side performance. There are two

opposite effects: by inc reasing the duty cy cle the

rms current at primary side can be reduced , while

the rms current at secondary side will be

increased. This means that a higher duty cycle

imposes a less stressful cond ition to any part s in

the primary path, and a more stressful condition to

the secondary path. In the same way, to decrease

the duty cycle causes an optimization of

secondary side and a deterioration of primary side

performances.

The higher duty cycle is a further help to easily

design the flyback stage for a wi de range voltage

input. On the other hand, the higher duty cycle

implies a higher reflected voltage to promptly

demagnetize the flyback transformer.

For such a high power flyback stage, an important

parameter to monitor is the current ripple at

secondary side; it is needed either t o lower rms

current or to reduce RFI. Further consideration

concerns the reflected flyback voltage which is

imposed in order not t o overcome the maximum

breakdown of the power switch.

The above consideration plus some cost issues

generate a clear figure of how to impose design

equations. Moreover, since design specifications

imply a high power output only, the following

calculation will consider the influe nce of both low

power and auxiliary outputs negligible.

In continuous operation mode the relationship

between input and output voltage is only

dependent on the duty cycle and not on the

frequency. The relationship is given by the

following formula:

N

Out

V

in

D

S

11

−⋅=1

N

P

Eq. 1

Eq. 1 is ideal and does not take into consideration

real effects such as the voltage drops on the

power switch and on the output diode. I ncluding

these two voltage drops it is possible to get the first

design equation and calculate the turn ratio

between input and the higher power output

(Vout1).

N

P

=

N

S

1

Where, V

CSon

−

+

and V

VcsVin

on

VdVout

D

⋅

111

−

fw

are respectively the

d1fw

Eq. 2

voltage drop on the power switch and on the

secondary side diode. Eq. 2 is valid for any input

voltage. The second des ig n eq uat ion co mes from

the maximum power switch breakdown, defining

first V

, the flyback reflected voltage, and then

fly

calculating the maximum switch breakdown

voltage.

P

fly

()

N

S

VdVout

111+⋅=

fw

Eq. 3

4/27

Page 5

AN2131 - APPLICAT ION NOTE

in

V

0

s

V

V

3

8.

mVVVBV

arg

+++=

inspikefly

max

Eq. 4

Eq. 4 also includes the safe design margin and the

allowed voltage spike f ixed by clamping network

design. By combination of Eq. 3 and Eq. 4, the

maximum primary/secondary turn ratio is finally

obtained.

inmVVBV

arg

⇒

inmVVBV

Eq. 5

−−−≤

inspikefly

max

N

P

≤

N

S

1

inspike

+

arg

−−−

max

VV

fwdOu t

11

For 150W power output, the proposed power

switch is STC08DE150, with BV=1500V.

Assuming V

=1V. From Eq. 5 results:

V

d1fw

N

P

1

N

1≤S

From Eq. 2, imposing V

=200V, margin=200V and

spike

in=Vinmin

=220V, Np/Ns =

Eq. 6

10, and considering the normal mode switching

frequency, the maximum duty cycle and the maximum on time are:

N

P

=

N

Vfly

15=

+

VdVaux

fwaux

Eq. 10

The next transformer design step is to fix the

primary and/or secondary magnetization

inductances. There are several criteria: the first

one is to select the primary in duc tance in o rder to

ensure continuous mode operation from full load

to minimum load. This method, since a bigger

primary magnetization inductance is requested,

assures a very low output current ripple,

increasing transformer primary turns.

Furthermore, it makes the RHP zero lower, so that

the loop stabilization will be more complicated.

The second alternative criterion is to calculate

primary and secondary inductances by defining

maximum secondary ripple current. This last

method fixes a limit fo r the rms current and do es

not require such a high primary magnetization

inductance, but it may lead to a transition m ode

operation.

max

TonD

=

⇒

µ

87.5max%8.52

=

Eq. 7

It is worth noticing that the v al ue of t he duty cycle

calculated by Eq. 7 is a good trad e-off to optimi ze

both primary and secondary side performances.

By the way, it must be pointed out that being

>50%, slope compensation may be

D

max

necessary. This subject will be deeply analyzed in

paragraph 7.

Once fixed t he turn ratio between input a nd the

higher power output, the flyback reflected voltage

is fixed by Eq. 3 as well.

N

P

fly

()

N

1

S

VdVout

25011

=+⋅=

fw

Eq. 8

It is now possible to calculate the two turn ratios

referred to the slave Vout2 and to the auxiliary

outputs.

N

P

=

N

2

Vfly

2

3

=

+

VdVout

fwS

Eq. 9

5/27

Page 6

AN2131 - APPLICATION N OTE

t t

I

1

()

A

5

A

A

Figure 4. Waveforms and Nomencla ture of the Continuous Mo de Flyb ack Desi gn

Ipcs

∆

Ips

Ip

on

T

∆

Is1

s1

VT

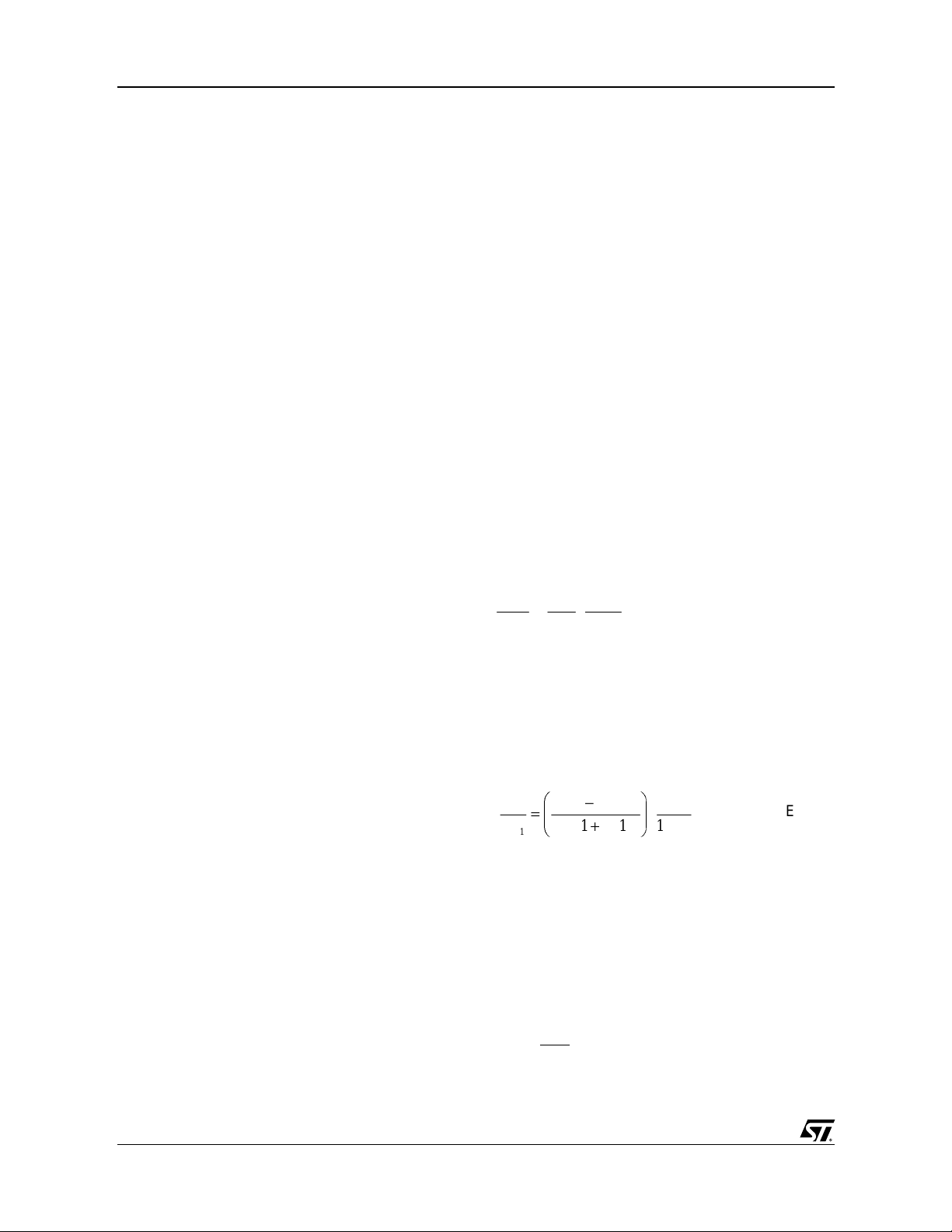

Figure 4 reports the most significant waveforms

and relevant nomenclature to further proceed in

the flyback design. From figure 4, we define IPCS

the primary average current value and ∆

primary current variation during the on time, I

the secondary average current value and ∆

secondary current variation during the off time and

the secondary average current.

I

Out1

By adopting the second design method, we now fix

the maximum secondary ripple current ∆

following equations:

I

max1

Out

⋅∆⋅=⋅∆⋅=∆

IIII

SCSSSS

122D

−

max

where ∆

Ι

s1max

variation and ∆

1max1

is the maximum secondary current

Ι

is the ripple current. Therefore

s

we have:

TTVdV

−⋅−

L

()

=

1

S

where L

S1

inductance. Imposing ∆

I

∆

max!

S

is the secondary magnetization

max1

ONSfwOut

Ι

%= ±30% from Eq. 11

s

and Eq. 12 results:

IPS

IS1

Ι

% in the

s

Eq. 1

Eq. 12

the

S1CS

the

Ts

T

off

Once fixed turn ratios an d t he primary inductance

value, some extra calculation is needed to choose

either the transformer or the external components

for flyback stage. Since design specifications request one high power output only, while the slave

and the auxiliary outputs need a very small power,

for designing the transformer we can only consider

a single output. Based on this supposition the relevant design parameters are here below reported.

Fixed N

Primary Winding:

Ip

Ipcs

Is1cs

Iout1

Vin+Vfly

= 10 and Lp = 1.6 mH.

p/Ns

−

=∆ Eq. 1

on

max*)min(

TonVcsVin

8.0

=

Lp

Po

=

min

IpIp

+= Eq. 17

cspk

max

DVcsVin

η

max)(

⋅⋅−

on

Ip

∆

88.12=

48.1

=

t

Eq. 16

HL

µ

S

while the primary magnetization inductance is:

L

P

6/27

17.161= Eq. 13

2

N

P

=

N

S

S

1

Ip

=

rms

max

HL

µ

1617

=⋅

1

Eq. 14

=

A

08.1

∆

IpIpD

−=

cspk

I

1

P

2

IpIp

−−+

cspk

2

I

∆

P

=

23

Eq. 18

Page 7

AN2131 - APPLICAT ION NOTE

A

A

0

A

Is

1

5

1

Master Secondary Winding:

I

Out

Is

1

=

CS

=∆ Eq. 2

Is

1

1

=

Is

rms

()

29.9

=

max1

D

max1

−

IsIs

11 =

+=

CSpk

max

A

24.13

=

−⋅+

TTVdVout

)()1(

ONFW

max

Ls

1

∆

9.18

=

2

∆

I

1

IsIsD

111

s

−−=

cspk

3

2

IsIs

Eq. 19

7.9

Eq. 21

2

∆

I

11

s

−−+

11

cspk

2

Eq. 22

Above calculation have been made c onsidering a

continuous mode operation. This condition is

assured by imposing ∆I

%< 100%. According to

s

the reported design parame ters, the transformer

has been designed by Cramer and all remaining

power parts have been chosen as reported in ST's

application note AN1889.

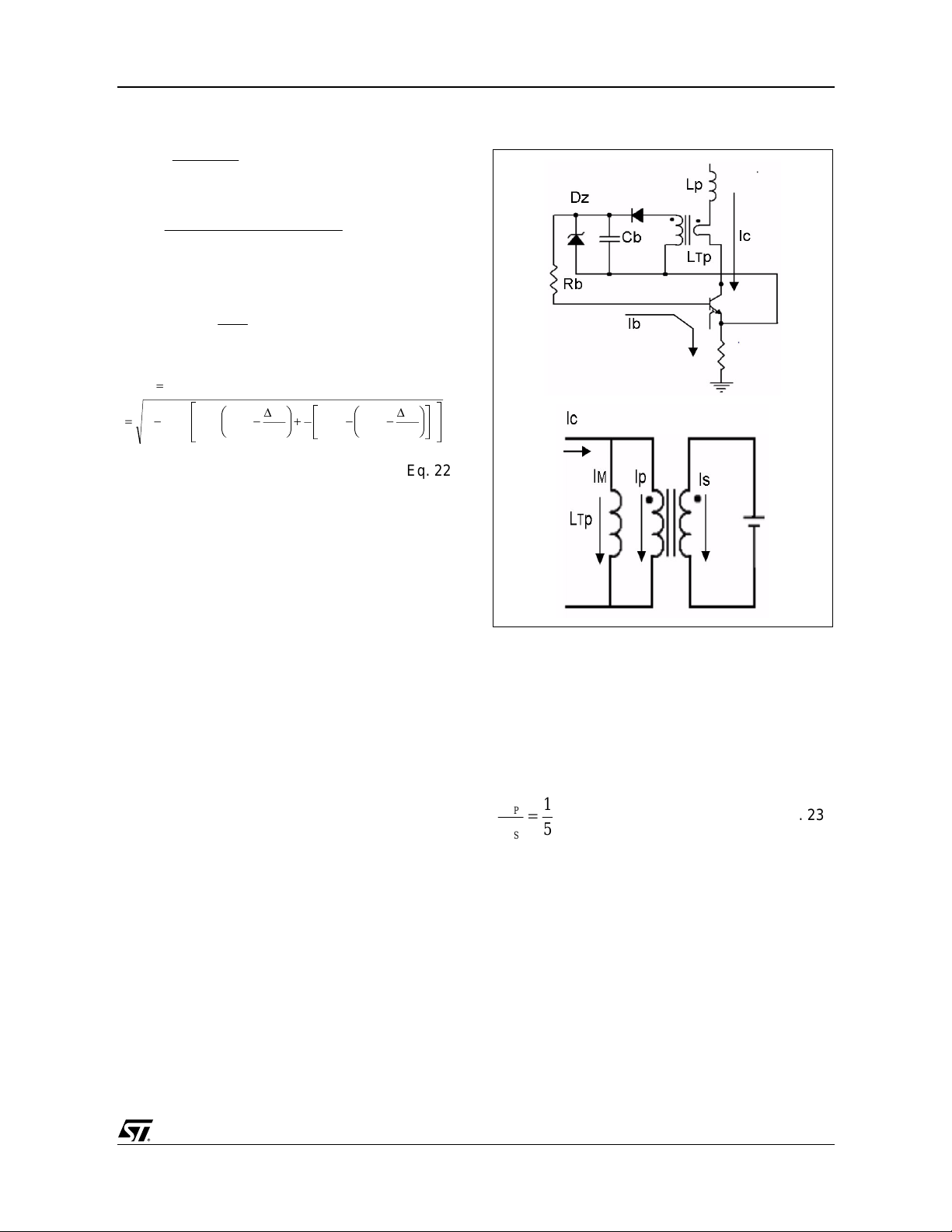

Figure 5. The Pro portional Driv in g Schematic

and its Equivalent Cir cuit

=

5. BASE DRIVING CIRCUIT DESIGN

In practical applications, such as SMPS, where the

load is variable, the collector current is variable as

well.

As a consequence, it is very important to provide

a base current to the device which i s r elated to the

collector one. In this way, it is possible to avoid the

device over saturation at low load and to optimize

the performance in terms of power dissipation.

The best and simplest way to do this is the

proportional driving method provided by the

current transformer, in figure 5.

At the same time, as already stated, it is very

useful to provide a short pulse to the base to make

the turn-on as fast as pos sible and to reduc e the

dynamic saturation phenomenon.

The pulse is achieved by using the capacitor and

the zener in figure 5.

The driving network guarantees a zone with f ixed

ratio that results imposed once the current

I

C/IB

transformer turn ratio h as been chosen. F rom the

ESBT STC08DE150 dat asheet, and in particular

looking at the st orage time characterization, it is

clear that a turn ratio equal to 5 is a good value to

ensure the right saturation of ESBT at I

= 2A, so

c

that in the current transformer we can fix at first:

N

P

=

N

S

Eq. 23

The core magnetic permeability of the current

transformer has to be as high as possible in order

to minimize the magnetization current I

(that is

m

not transferred to the secondary side but only

drives the core into saturation). On the contrary,

too high a permeability core may lead the core into

saturation even with a very small magnetization

current. To avoid that i t is necessary to increase

the number of primary turns and the size of the

core as well. On the other hand, if a core with a

very small magnetic permeability is chos en, it is

possible to reduce the number of primary turns

and the core size, but if the permeability is too

small we may not have current on t he secondary

side because almost all the collector current

7/27

Page 8

AN2131 - APPLICATION N OTE

TV

V

V

V

V

I

5

b

()

V

()

becomes magnetization current. As a compromise

a ferrite material with a relative permeability in the

range of 4500 ÷ 7000 is the best choice.

When a ferrite ring with some diameter has been

selected, the minimum primary turns is determined

to avoid the core saturation from the preliminarily

fixed turn ratio N with 0.2. By applying the

Faraday’s law and imposing the maximum flux

equals to B

B

max

N

1

d

ϕ

dt

sat

/2:

AN

B

∆

⋅⋅≅=

t

∆

⇒

N

TPeTPTP

⋅

on

2

=

max1

BA

sate

⋅

Eq. 24

Where, B

is the saturation flux of the core and it

sat

depends on the magnetic permeability.

During the conduction time, the junction base-

emitter of ESBT can be seen as a f orward b iased

diode. To complete the secondary side l oad loop

the voltage drop on both diode D and resistor R

must be added in series with the base of the

ESBT. The equivalent secondary side voltage

source is given by:

VVV

RBDBEonS

5.2≅++=

Eq. 25

Since the magnetization inductance cannot be

neglected, only I

, a fraction of the total collector

P

current, will be transferred to the secondary. As a

result, the magnetization current has to be first as

low as possible. Meanwhile, the value of the

magnetization inductance must be taken into

account for a proper calculation of transformer

primary turns and turns ratio. The magnetization

voltage drop, that is, the voltage at the primary of

the current transformer, can be now easily

calculated:

adjusted to get the desired I

ratio according to

C/IB

the equation below:

N

eff

where I

I

P

==

I

B

is the maximum magnetization

Mmax

II

−

maxmaxCMC

I

current.

The insulation between primary and secondary

should be considered since the voltage on the

primary side during the off time can overstep

1500V.

Next step is to select the zener diode, the

capacitor C

and the resistor Rb. The turn-on

b

performance of ESBT is related to the initial base

peak current and its duration t

approximately given by:

CRt3=

bpeak

B

A suitable value for R

is 0.56. It can eliminate the

b

ringing on the base current af ter the peak, and at

the same time, it generates negligible power

dissipation.

The value t

can be determined once the

peak

minimum on time is set based on the operation

frequency. Bear in mind that in practical

applications it should never be lower than 200ns.

The value of Cb can be counted since the values

of t

I

and Rb are known.

peak

must be limited in order to avoid an extra

peak

saturation of the device. This action is made by the

zener diode Dz that clamps the voltage across the

small capacitor Cb. The zener must be chosen

according to the following empirical fo rmulas and

bpeakZ

Zmin

12

+=

and V

Zmax

inside the range of V

max

RI

peak

:

Eq. 28

that is

Eq. 29

N

T

1

V

S

1

N

T

2

1

5.2

5

[]

V

5.0

=⋅==

The magnetization current will be:

Eq. 26

min

=

RIV2

bpeakZ

The base peak current will be higher with higher

Eq. 30

clamp voltage (Dz) o r smaller capacitanc e (Cb),

TV

ON

=

M

max

max1

L

TP

Eq. 27

which in tu rn will le ad to a shor ter dur ation of th e

peak time.

The higher and longer the base p eak current, the

lower the power dissipation during turn-on. But

The number of primary turns should be increased

if I

is relativ ely hig h. But the core mu st hav e

Mmax

window area enough to hold all primary and

secondary windings. Othe rwise it is necessary to

choose a bigger core size. Once both core

material and size are fixed, the turn ratio must be

you need to limit the Ib peak both in terms of

amplitude and time duration otherwise at low load

a very high saturation level may result. If the

device is over-saturated the storage time is too

long with higher power dissipation during turn-off.

Moreover a long storage time can also cause

output oscillation especially at high inpu t voltage.

8/27

Page 9

AN2131 - APPLICAT ION NOTE

G

1

)

)

G

2

To overcome the above mentioned problems it is

recommended to fix the peak duration to 1/3 the

minimum duty cycle.

6. CONTINUOS CURRENT MODE LOOP

STABILIZATION

It is well known from literature that the transfer

function of the continuous current mode (CCM)

flyback converter is given by:

sv

)(

1

out

s

)(

1

()

sCR

C

⋅

where N = N

electrolytic capacitor series resistance.

It is worth noticing that the transfer function has

one pole and two zeros, whose on e on the right

half plane. The RHP zero is very difficult if not

==

sv

)(

11

−+

2

sCR

1

+

D

+

, R is the load, RC is the

p/Ns

−⋅⋅

DRN

1(

⋅

+⋅⋅

DR

1(3

Scomp

DsL

p

2

()

1

−

DRN

Eq. 31

impossible to compensate and therefore must be

kept well beyond the closed-loop bandwi dth. As a

result, the transient response o f such system wi ll

be not extremely fast.

Considering now, the transfer function in the

following form:

)(

sv

out

comp

1

)(

sv

)(

s

1

⋅==

k

1

s

−

11

z

s

1

−

p

Substituting the values of this design in case of low

input voltage (worst case), we obtain the

frequency response reported in the following

figure 6. Poles and zeros are reported in the below

equations:

P11= -202/rad=-32.1Hz

= -23Krad/s=-3.79KHz

Z

11

Z

= 88Krad/s=14.1KHz

12

s

−

z

1211

Eq. 3

11

Eq. 33

9/27

Page 10

AN2131 - APPLICATION N OTE

G

G

s

G

1

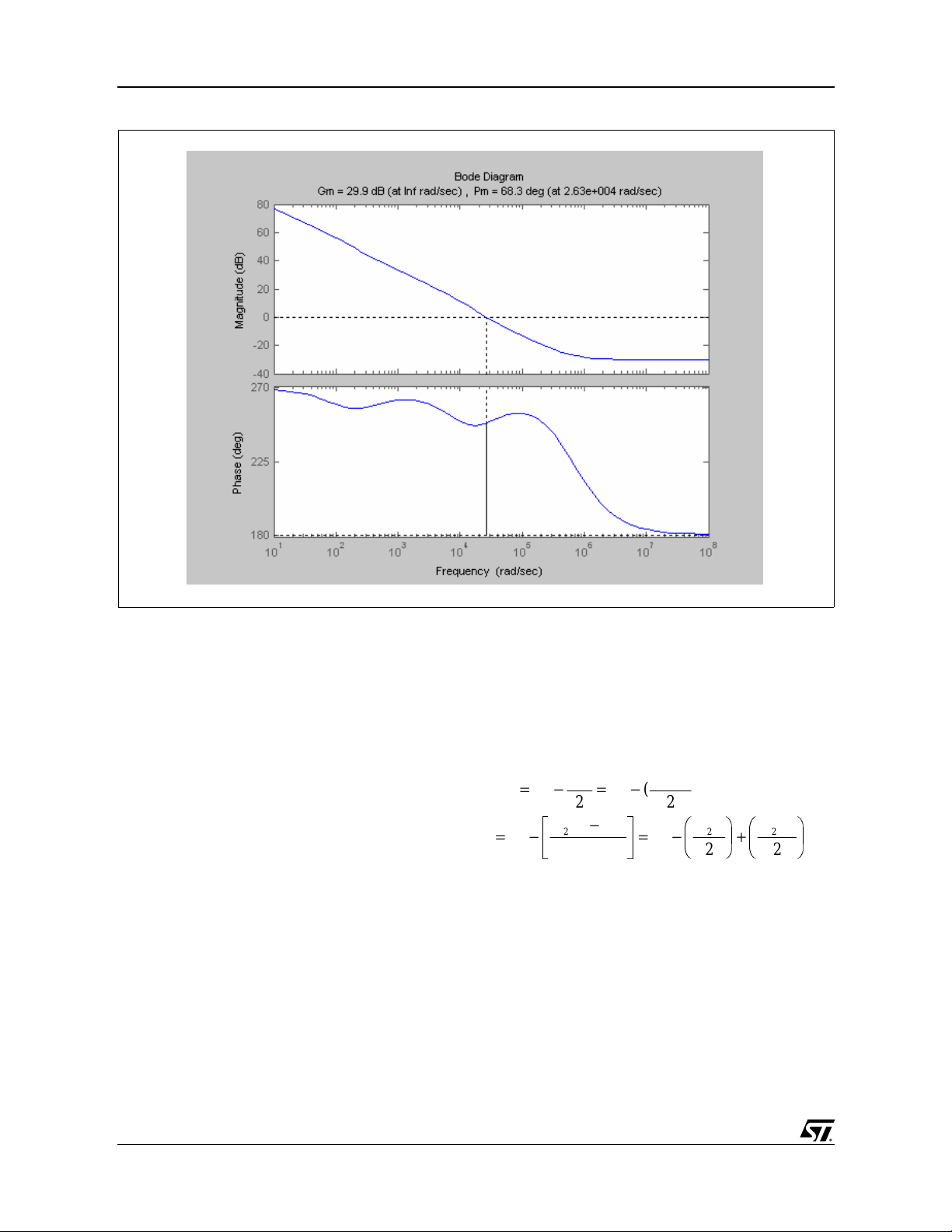

Figure 6. Flyback Frequency Response at Minimu m Input Voltage

A good line and load regulation implies a high DC

gain, thus the open loop gain should have a pole

at the origin. Normally, in this case we need a

feedback network like the one in figure 7. Its

transfer function is given by:

sv

s

)(

2

out

==

sv

)(

)(

comp

or:

sv

)(

comp

s

)(

out

sv

)(

RCTR

COMP

max

FHB

−

1

1

k

==

22

s

1

−

()

1

1

sCRR

1

s

z

21

++

+

CsR

compCOMP

Eq. 34

Eq. 35

s

p

21

CRRs

To properly design the feedback loop, let us

consider first the following transfer function and its

bode plots (figure 8):

s

)(1⋅

FFH

It is preferable that the RHP zero is well bey ond

the closed loop cut off freq uency . To make it, first

of all, a gain is ne eded. Then, f rom figure 8, a 90

degrees phase margin could be achieved fixing

both zero and pole of G

pole p

get a phase margin of 90 degrees with a well

defined gain. Observe t hat a high phase margin ,

making the system response quite slow, could

help avoid undesired frequency changes. By the

way, to assure a not too slow trans ient response,

it is advisable to choose ab out 60 degrees phase

margin. Referring to this real case, we can fix both

zero and pole in order not to exactly cancel p

and z21.

and zero z21 of G1. In this case, we i deally

11

to cancel respectively

2

Eq. 36

11

10/27

Page 11

AN2131 - APPLICAT ION NOTE

Z

According to the previous argument we fix the pole

and zero as Eq. 37.

= -11.1krad/s = -1.77kHz

P

21

= -245rad/s = -39Hz

21

Eq. 37

Figure 10 reports the overall open loop transfer

function G1*G2.

Phase margin is very close to the desired value

and it assures a good stability and quite fast

Figure 7. Converter Feedback Network

transient response. Finally, it is interesting to

check the loop stability for the highest input

voltage and maximum output load. Under this

condition, the frequency response of the system is

shown in figure 11.

From figure 12, as expected, the phase m argin is

higher and hence the system stability margin is

improved.

11/27

Page 12

AN2131 - APPLICATION N OTE

Figure 8. Flyback Frequency Response at Vinmin Adding a Pole at the Origin

Figure 9. Fre quency Response of the Feed bac k-transfer Function

12/27

Page 13

AN2131 - APPLICAT ION NOTE

Figure 10. St abi li ze d Op e n Lo op-transfer Function at Mini m um Input Voltage

Figure 11. Flyback Frequency Response at Maximum Input Voltage

13/27

Page 14

AN2131 - APPLICATION N OTE

Figure 12. Stabilized Open Loop-transfer Function at Maximum Input Voltage

voltage and which may continue for some time.

7. SLOPE COMPESATION FOR

SUBHARMONICS SUPPRESSION

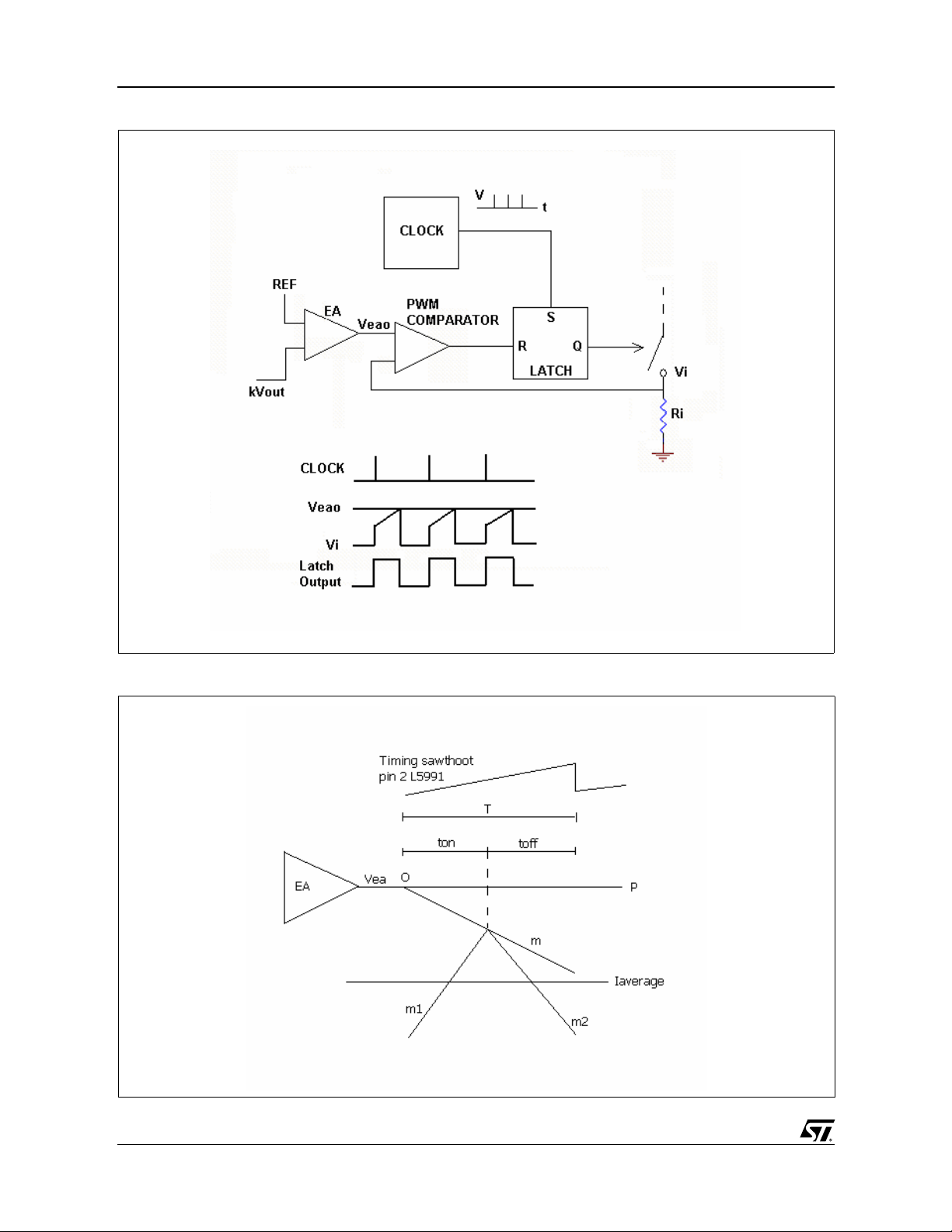

The L5991, as many PWM drivers for SMPS,

applies a current mode control. This control

method keeps the power transistor current peak

constant at the needed level to supply the DC load

with DC output voltage dictated by the voltage

error amplifier. This is equal to keep cons tant the

current peak at secondary side winding. The

average current at secondary side is the DC load

current and, however, to keep the current peak

constant does not mean to keep the average

current constant.

Because of this, in the unmodified current mode

scheme, changes in the DC input voltage will

cause momentary changes in the DC output

voltage. The output voltage change will be

corrected by the voltage error amplifier outer

feedback loop, as this is t he l oop which ultimately

sets the output voltage.

Again, however, the inner loop, while keeping

peak inductor current constant, does not supply

the correct average current and output voltage

changes again. The effect is then an oscillation

which commences at every change in input

The mechanism can be better understood from an

examination of the upslope and do wnslope of the

output inductor currents.

In figure 13, it can be seen that the average

primary side current at low DC input is higher than

the high DC input case. This can be seen

quantitatively as:

dI

2

II

−=

I

p

I

ppav

2

()

−

tTm

on

tm

2

off

=−=−=

(

)

2

Tm

I

−=

p

tm

on

222

222

Eq. 38

+

14/27

Page 15

AN2131 - APPLICAT ION NOTE

Figure 13. Average Primary Side Current at

Low and High DC Input

Since the voltage feedback loop keeps the product

of V

constant, at lower DC input voltage,

dcton

where the on time is higher, the average output

inductor current I

is higher, as can be seen from

av

equation 38 and figure 13.

Furthermore, since the DC output voltage is

proportional to the average, not to the peak,

inductor current, as DC input goes down, DC

output voltage will go up.

DC output voltage will then be corrected by the

outer feedback loop and a seesaw action or

oscillation will occur.

A second problem whi ch generates oscillation in

current mode is shown in figures 14 and 15.

From these figures, it can be seen that, at a fixed

DC input voltage, if for some reason there is an

∆I

initial current disturbance

, after a first

1

downslope the current will be displaced by an

∆I

amount of

.

2

Figure 14. Current Disturbance Effects at Duty

Cycle <50%

Figure 15. Current Disturbance Effects at Duty

Cycle >50%

Furthermore, if the duty cycle is less than 50%

(m

) as in figure 14, the output disturbance ∆I

2<m1

will be less than the input disturbance ∆I1, and

after some cycles, the disturbance will die out. But

if the duty cycle is greater than 50% (m

2>m1

) as in

figure 15, the output disturbance after one cycle is

greater than the input disturbance.

This can be seen quantitatively from figure 14. For

∆I

a small current displacement

, the current

1

reaches the original peak val ue earlier in time by

∆I

an amount dt where dt =

. On the inductor

1/m1

downslope, at the end of the on time, the current is

lower than its original value by an amount

∆I

where

m

2

Now with m

IdtmI ∆==∆

122

m

1

grea ter tha n m1, the disturbances will

2

Eq. 39

continue to grow but eventually will decay, causing

an oscillation.

Both current-mode problems mentioned above

can be corrected as shown in figure 16, where the

original, unmodified output of the error amplifier is

shown as the horizontal voltage level OP. The

scheme for correcting the previous problems

(slope compensation) consists of adding a

negative voltage slope of magnitude m to the

output of the error amplifier. By a proper selection

of m in the way discussed below, the inductor

average DC current can b e made independent of

the power transistor on time. This corrects the

problems indicated in both equations 38 and 39.

Figure 17 shows the upslope m1 and the

downslope of the output inductor current.

Remember that in current mode, the power

transistor on time starts at every clock pulse and

ends at the instant the output of the PWM

comparator reaches equality with the output of the

voltage error amplifier as shown in figure 16.

2

2

15/27

Page 16

AN2131 - APPLICATION N OTE

Figure 16. PWM with Current Mode Control

Figure 17. Implementation of Slope Compensation

16/27

Page 17

AN2131 - APPLICAT ION NOTE

n

i

R

V

)

V

0

0

n

V

In slope compensation, a negative voltage slope of

magnitude m=dV

added to the error amplifier output. The magnitude

of m is, therefore, calculated.

In figure 17, the error-amplifier output at any time

after a clock pulse is

t

on

eaea

0

where V

to zero.

The peak voltage V

sensing resistor R

is the error amplifier output at ton equal

ea0

==

where Ipp and Isp are the primary and secondary

currents respectively. But I

is the average secondary or average output

inductor current and dI

inductor current change during the off time (m

Then

II −+=+=

sasp

Then

N

s

i

N

Equating eq. 40 and 41, which is wh at the PWM

comparator does, we obtain

N

s

N

p

N

s

−

N

p

IR

p

m

2

R

i

2

/dt starting at clock time is

ea

mtVV−=

o

across the primary current-

i

in figure 16 is

i

N

s

IRI

spippi

N

p

+ dI2/2, where I

sp=Isa

, in figure 13, is the

2

tm

2

off

m

2

(

I

tT

22

m

2

()

2

tVIR

0

oneasai

T

−+=

tT

onsai

N

N

m

2

s

R

p

−+=

i

2

Eq. 40

Eq. 41

sa

2toff

Eq. 42

onsa

Eq. 43

−

m

Eq. 44

This, then, corrects the two above mentioned

problems arising from the fact that without

compensation, current mode maintains the peak

constant, and not the average, output inductor

current.

The same effect is obtained by adding a positivegoing ramp to the output of the current-sensing

resistor V

voltage unmodified.

Adding the positive-going ramp to V

is the most usual approach. Let us suppose that

the slope of the ramp is dV/dt.

When the PWM driver finds the equality of its two

inputs, the output terminates the on time. Then

+(dV/dt)ton=V

V

i

N

s

N

p

Then

).

N

s

N

p

t

From the above, it can be seen that if the slope dV/

dt of the voltage added to V

N

p)Rim2

relation vanish and the secondary average voltage

is independent of the on time.

I

sa

In the L5991 chip, a positive going ramp starting at

every clock pulse is available at the top of the time

capacitor (pin 2 in figure 18).

The voltage at that pin is:

osc

and leaving the error-amplifier output

i

subs titute Vi from e q . 4 1 :

ea0

IR

dV

on

dt

/2, the terms involving ton in the preceding

∆

=

∆

m

2

()

−+

IR

tT

2

N

sai

N

N

−+

N

V

t

o

t

m

s

p

s

p

2

R

R

T

i

2

m

2

2

dV

dt

++

V

=

eai

is equal to (Ns/

i

is simple and

i

Vt

=+

eaononsai

Eq. 46

Eq. 47

Eq. 48

It can be seen in this relation that if

N

N

then the coefficient of the t

average output inductor current is independent of

the on time.

m

s

p

2

R

i

2

m

dV

ea

==

dt

term is zero and the

on

Eq. 45

where

∆V = 2V and ∆t = 0.693*R

tCt

.

17/27

Page 18

AN2131 - APPLICATION N OTE

n

V

Figure 18. Slope Compensation by Simple Resistance

As seen in figure 18, a fraction of that voltage

whose slope is ∆V/∆t is added to V

(the voltage

i

across the current-sensing resistor). That slope is

set at (N

s/Np)Ri(m2

/2) by the Rcs, R

Thus in figure 18, since R

is much less than Rcs,

i

slope

resistors.

the voltage delivered to the current sensing

terminal (pin 13) is:

R

+

i

CS

RR

+

slopeCS

VV

iosc

R

+=

CS

RR

+

V

∆

t

o

t

∆

slopeCS

Eq. 49

and setting the slope of that added voltage equal

=

slopeCS

+ R

/2), we obtain

mRNN

()()

).

tCt

drain current off the top of the

slope

2//

iPS

2

tV

∆∆

Eq. 50

to (N

s/Np)Ri(m2

R

CS

RR

+ /

where ∆V/∆t = 2/(0.693R

Since R

CS

timing capacitor, the operating frequency

changes.

Then either R

CS

+ R

is made large enough so

slope

that the frequency change is small or an emitter

follower is interposed between pin 2 and the

resistors as shown in figure 19.

Figure 19. Slo pe C om pensation by E m itte r

Follower Stage

We choose the second option for two reasons: the

first one is due to the fact that it is difficult to avoid

frequency changes with typical R

values. The

CS

second reason, related to the L5991 characteristics, is a little bit more complicated and it will be

now explained.

In our design, after choosing R

R

CS

+

RR

()()

=

slopeCS

iPS

∆∆

/

= 1kΩ we have:

CS

mRNN

2//

2

tV

k

9.6

Ω≅

Eq. 51

18/27

Page 19

AN2131 - APPLICAT ION NOTE

V

The closest value available is R

= 6.8kΩ.

slope

Therefore, first of all, to keep the frequencies

established originally, the oscillator res istors can

be chosen accordingly, and more important, since

the valley value of the oscillator is about 1V, we

have a voltage shift of:

R

CS

=∆

V

i

+

1 =

RR

slopeCS

1

=

VV

+

8.61

m

1281

Eq. 52

As already stated in the previous paragraphs, the

PWM driver used in our design has a special

feature. We can externally fix two different

operating frequencies in order to improve the

system power efficiency.

As mentioned in both AN1049 and

L5991datasheet, the level at which the operating

frequency changes is es tablished by Vcomp, the

error amplifier output voltage. Two thresholds are

used to guarantee a hysteresis, avoiding

Figure 20. Final Slope Compensation Schematic

uncertainty when switching from low to high

frequency and vice-vers a. As explained in the

AN1049 the two values can be referred to the

current sensing (pin 13) voltage. The upper level is

0.867V while the lower level is 0.367V.

If a simple resistance is used to ma ke the slope

compensation, a voltage shift is also introduced

and its value computed in eq.52 is too high. In fact,

to make the system work at low frequency it is

necessary to undergo 0.367V and it may happen

that the lower frequency is never reached.

With the emitter follower of figure 19, besides

avoiding any alteration in the oscillator

functionality, we get about 0.5V voltage shift

respect to pin2, and hence a consequent reduction

of the ∆V

previously calculated. To obtain ∆Vi = 0

i

and assure the correct behavior of the PWM driver

in the SMPS a diode in series with the emitter has

been introduced as shown in figure 20.

19/27

Page 20

AN2131 - APPLICATION N OTE

5A

8. PROTOTYPE IMPLEMENTATION AND EXPERIMENTAL RESULTS

Figure 21. Prot otype Schematic

24V @ 6.2

1

2

J2

H2

C13

1nF

22

R27

0.5W

T1

1000uF

50V

C15

+

1000uF

50V

C14

+

D9

STTH3002CT

16

15

9

10

CSM 39-07 1 B

1

7

3

D7

STTH108

D6

1.5KE400A

D5

STTH108

6.8nF/1250V

C9

47k

R20

2W

47k

R21

2W

24k

R31

18k

R29

4k7

R28

PC817

U2A

1

2

1

2

J3

5V @ 0.05A

C17

100nF

Vout

GND

Vin

U3

L78L05

C16

+

47uF 25V

D10

STTH102

14

12

4

5

47uF

25V

STTH102

D8

+

C11

D4

1N4148

2k7

R30

C18

150nF

TL4 31 A C

U4

C12

1nF/Y1

H1

0.56

R26

STC08DE150

46

T2

1

STTH 102

.22uF

D2

Q1

R25

T34 8 36

3

D3

R22

C10

0.56

3.9V

R11

56k

0.56

R23

R24

1k

22

20/27

470pF

R10

240k

0.5W

R9

240k

400V

240kR30.5W

0.5 W

820k

R6

1

2

Vin 250VDC to 850VDC

820k

R7

R8

R17

220uF

400V

C2

+

R1

F1

R18

-t

6k8

8k2

10/3.7A

T1A

5k6

R15

R14

NU

D1

1N4148

14

16

13

15

12

dis

isen

St-by

sync2rct3dc

U1

1

R16

Q2

6k8

R13

sgnd

dc-lim

vref5vfb

4

12k

PN2222A

910k

910kR5910k

R4

220uF

C1

+

240kR20.5W

J1

C8

9

11

10

vc

out

pgnd

22

R19

vcc

comp

L5991A

47uF

C6

C5

C4

C3

43

U2B

50V

C7

+

NU

3.3nF

100nF

10nF

PC817

6

7ss8

470

R12

Page 21

AN2131 - APPLICAT ION NOTE

The theoretical design has been further improved

by bench verification getting the final schematic

reported in figure 21. The board has been

successfully tested according to design

specifications previously reported and additional

features have been also verified.

At that time there is still current flowing through it

and therefore forces a hard turn-off which caus es

ringing on the reverse recovery.

By adding a snubber based on a capacitance

higher than the diode junction capacitance and a

resistor tuned to the ringing of the leakage

inductance and the diode c apacitance, the peak

D6 Snubber Circuit

This topology works both in discontinuous and

continuous mode.

The output diode turns off at zero current when

operating in discontinuous mode after the core is

discharged. In continuous mode the diode turns off

when Q1 is turned on.

reverse voltage spike and the ringing can be

minimized.

The ringing often causes EMI issues and adds

noise to sensitive PWM circuits. Figure 22 shows

the diode at 6 amps.

The blue waveform is the diode recovery without

snubbing, while the green one is the diode

recovery after adding the snubber.

The resistor dissipates 0.23 watts in this example.

Figure 22. D6 Diode Recovery Time Effects with and without Snubber

21/27

Page 22

AN2131 - APPLICATION N OTE

Short Circui t

During an output overload or short circuit, the

primary current ramps up higher and higher. This

current is sensed by R8 which is turned into a

voltage, filtered by R17 and C10 and fed to pin 13

of U1 (I sense). When this voltage reaches 1 volt

the pulse is terminated. This is known as pulse by

pulse current limit. The unit is protected against

overstressing the main switch and output diode. In

other words by choosing R8 we can limit the power

of the unit. During short circuit the output power is

limited to this value. Depending on the transformer

coupling an output short should reflect a lower

voltage to the auxiliary voltage supplying the

L5991. When this voltage falls below the under

voltage lockout of 8.4 volts, the L5991 shuts down

and initiates a restart. In most cases because of

the insulation in a transformer, it is difficult to

achieve such results. As shown in figure 23, when

the output is overloaded the transformer voltage

falls to about 3 to 4 volts due to the drop of the

diode traces and the output inductor. The 24 volts

winding has 10 turns and the Vcc one has 6, so the

voltage at the transformer pin of Vcc should be

around 2.2 volts. The problem is the leakage

inductance causing spikes and ringing whose

peak charge the Vcc cap. as seen in figure 23

(violet waveform).

Figure 23. Output Waveforms without Short Circuit Protection

22/27

Page 23

AN2131 - APPLICAT ION NOTE

By adding a 22uH inductor in series with the Vcc

winding and D3 we are a ble to filter out the s pike

and ringing to achieve Vcc to collapse below the

under-voltage shutdown and re-initiate a start up.

In this mode the high-cup mode is reached

dissipating less power and keeping the thermal

stresses low.

By adding a 22uH inductor in series with the Vcc

winding and D3 we are a ble to filter out the s pike

and ringing to achieve Vcc to collapse below the

under-voltage shutdown and re-initiate a start up.

In this mode the high-cup mode is reached

dissipating less power and keeping the thermal

stresses low.

The shutdown is shown in the Figure 25 at 300V

input. The hiccup mode duty cycle is 45ms on and

370ms off. As the input voltage is increased, the

start up through resistors R25 becomes faster

decreasing the off time. At 850 volt in the duty

cycle is decreased to 50% protecting the power

devices.

The most meaningful wavefo rms at different load

and input conditions are reported in figures 26, 27,

28, 29.

Figure 24. Output Waveforms with Short Circuit Protection

Figure 25. Hic cup Mode with Short Ci rc ui t Pro t ec tio n

23/27

Page 24

AN2131 - APPLICATION N OTE

Figure 26. Steady State Vin=850V Pout=150W

Figure 27. Steady State Vin=850V Pout=150W

Figure 28. Steady State Vin=250V Pout=150W

Figure 29. Steady State Vin=250V Pout=150W

Figure 26, 27, 28, and 29 show the prototype

steady state behavior, by reporting the gate

voltage (violet waveform), the ba se current (blue

waveform), and the collector current (yellow

waveform) signals. The collector voltage signal

has been not caught under maximum load

condition because the probe parasitic capacitance

generates an inner loop noise causing some

undesirable oscillations.

TM

Of course, safe operation for the ESBT

in terms

of maximum voltage spike on the collector has

been also verified.

The switching frequency under maximum load

condition is about 85Khz. The base current

waveform highlights as the ESBT

TM

storage time

is about 600ns, indicating the correct device

saturation level and hence its optimal working

condition.

Next waveforms will show the low l oad condition

where the switching frequency is appreciably

reduced to optimize, even in this condition, the

power supply efficiency.

24/27

Page 25

AN2131 - APPLICAT ION NOTE

Figure 30. Steady State Vin=850V Pout=25W

Figure 31. Steady State Vin=850V Pout=25W

Figure 33. Steady State Vin=250V Pout=25W

Figure 30, 31, 32 and 33 show the steady state

behavior for the low load condition. I n this case the

switching frequency is about 37KHz, and the

collector voltage signal (green waveform) has

been added sin ce in this less stressful con dition

the probe doesn't affect the system stability. From

figure 31 is possible to see the very high voltage

applied on the collector (1184V) during a normal

working condition.

Figure 32. Steady State Vin=250V Pout=25W

25/27

Page 26

AN2131 - APPLICATION N OTE

9. PCB LAYOUT

Figure 34. Prot otype PCB Lay o ut

The printed circuit board is reported in figure 34,

while the relevant bill of material is listed in the

schematic of figure 21.

REFERENCES:

- STMicroelectronics application note AN1889

"ESBT STC03DE170 IN 3-PHASES AUXILIARY POWER SUPPLY"

- STMicroelectronics application note AN1049

"MINIMIZE POWER LOSSES OF LIGHTLY

LOADED FLYBACK CONVERTERS WITH

THE L5991 PWM CONTROLLER "

- STMicroelectronics L5991 datasheet

- STMicroelectronics STC08DE150 datasheet

- Abraham I. Pressman, "Switching Power Supply

Design", McGraw-Hill, Inc.

26/27

Page 27

AN2131 - APPLICAT ION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or oth erwise under any patent or patent righ ts of STMicroele ct ronics. Spe ci f i cations menti oned in this publication are subjec t

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authori zed for use as criti cal components in life supp ort devices or s ys tems without express writt en approval of S T M i croelectronics.

The ST logo is a register ed t rademark of STMicroelec tr onics.

All other nam es are the property of their respective owners

© 2005 STMi croelectroni cs - All rights reserved

STMicroelectronics group of companies

Australi a - Belgium - Brazil - Canad a - China - Czech Republic - Finl and - France - Germany - Hong Kong - India - Israel - Italy - Ja pan -

Malaysia - M al ta - Morocco - Singapore - Sp ai n - S weden - Swit zerland - Uni te d Kingdom - Un i ted States of A m eri ca

www.st.com

27/27

Loading...

Loading...