Page 1

AN2067

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

APPLICATION NOTE

VIPower: DIMMABLE WHITE LEDS

POWER SUPPLY WITH VIPer53

In the same way that LED manufacturers succeed

to realize blue LEDs, they now propose white

LEDs inside a monolithic chip, or so called “singlechip white ” LED s .

A current source is the mo re appropriate way to

drive LEDs. For a maximum of flexibility, a large

voltage range must be supported at the output due

to the large threshold of these white LEDs, and the

possible serial arrangement of them.

Furthermore, if these LEDs h av e to be dimmable,

they must be driven with a PWM (current

generator).

As a consequence, key features for this off-line

power supply is a current generator, which can

work as a Pulses Width M odulated mode, with a

wide output voltage range, and must also suite any

input voltage standard, and a galvanic isolation.

1. VIPer53 DESCRI PTION

VIPer53, the first multichip device of the VIPer

family has been chosen to fulfill the requirements.

It f eatures very l ow R

a typical power of 35W in wide range in a standard

DIP-8 package without a heatsink, answering the

of 1Ω allowing to deliver

dson

need for higher efficiency and reduced space

thanks to a lower power dissipation.

1.1. General features

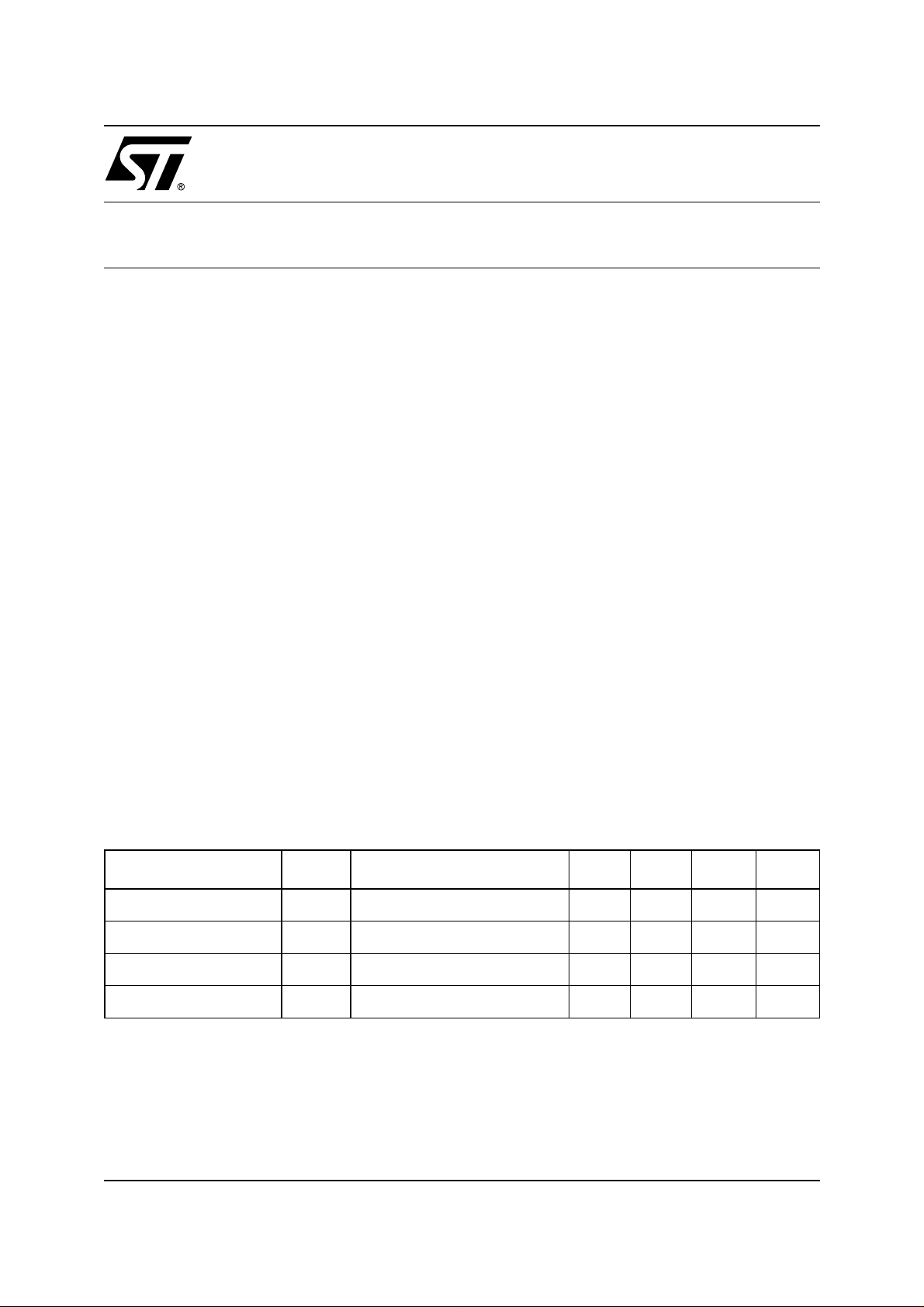

The block diagram is given on Figure 1. An

adjustable oscillator is driving a current controlled

PWM at a fixed switching frequency. The peak

drain current is set for each cycle by the voltage

present on the COMP pin. The useful range of the

COMP pin extends from 0.5V to 4.5V, with a

corresponding drain current range from 0A to 2A.

This COMP pin can be either used as an input

when working in secondary feedback

configuration, or as an output when the internal

error amplifier connected on the VDD pin is

operating in primary feedback to regulate the VDD

voltage to 15V.

The VDD under voltage comparator drives a h igh

voltage startup current source, which is switched

off during the normal operation of the device. This

feature together with the burst mode capability

allows to reach very low level of input power in

standby mode, when the converter is lightly

loaded.

Table 1. White LEDs Power Supply Specification

Parameter Name Conditions Min Typ Max Unit

V

Output current I

Output voltage V

Output Power P

Input Voltage V

OUT

OUT

OUT

IN

= 20V 200 1000 mA

OUT

I

= 1A 5 40 V

OUT

40 W

82 265 V

AC

Rev. 1

1/15November 2004

Page 2

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICATION N OTE

Figure 1. VIPer 5 3 bl oc k diagram

ON/OFF

OVERTEMP.

DETECTOR

OSC DRAIN

OSCILLATOR

PWM

LATCH

S

R1

FF

R2

R3 R4 R5

Q

BLANKING TIME

SELECTION

1V

H

COMP

CURRENT

AMPLIFIER

VDD

8.4/

11.5V

15V

18V

UVLO

COMPAR ATOR

ERROR

AMPLIFIER

OVERVOL TAGE

COMPAR ATOR

0.5V

4.35V

STANDBY

COMPAR ATOR

OVERLOAD

COMPAR ATOR

150/400ns

BLANKING

4V

4.5V

0.5V

PWM

COMPAR ATOR

8V

125k

TOVL COMP SOURCE

converter, the output power is first limited by the

1.2. Overload protection

A threshold of 4.35V typical has been

implemented on the COMP pin. This overload

threshold is 150mV below the clamping voltage of

4.5V which corresponds to the current limitation of

the device. In case of a COMP v oltage exc eedi ng

the overload threshold, the pull up resistor on the

TOVL pin is released and the external capacitor

connected on this pin begins to charge. When

reaching a value of 4V typical, the device stops

switching and remains in this state until the VDD

voltage reaches V

, or resumes normal

DDoff

operation if the COM P voltage returns t o a value

below the overload threshold.

The drain current that the device is able to deliver

without triggering the overload threshold is called

“current capability”, specified as I

in the data

Dmax

sheet. This value must be used to size correctly

the converter versus its max imum output power.

When an overload occurs on secondary side of the

current limitation of the device. If this overload is

lasting for more than a time constant defined by a

capacitor connected on the TOVL pin, the device

is reset, and a new restarting sequence is initiated

by turning on the startup current source. The

capacitors on the VDD pin and on the TOVL pin

will be defined together in order to insure a correct

startup and a low res tart d uty cycle in ov erload or

short circuit operation. Here are the typical

corresponding formulas:

C

C

C

Where t

OVL

VDD

VDD

12.56–×10 tss⋅>

1

84×10

I

>

--------------------------

V

and D

ss

---------------- 1–

D

RST

⋅

DD1tss

DDhyst

are respectively the time

RST

C

⋅

OVLIDDch2

-------------------------------------------⋅⋅>

V

DDhyst

needed for the output voltages to pass from 0V to

2/15

Page 3

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICAT ION NOTE

their nominal values at startup, and the restart duty

cycle in overload or short circuit condition. A

typical value of 10 % is generally set for this last

parameter, as it insures that the output diodes and

the transformer don’t overheat. The other

parameters can be found in the data sheet of the

device.

As the VDD capacitor has to respect two

condition s, the max imu m valu e will b e ret ained to

define its value.

1.3. Stand-by operation

On the opposite load config uration, the converter

is lightly loaded and the COMP voltage is

decreasing until reaching the shutdown threshold

at typically 0.5V. At this point, the switching is

disabled and no more energy is passed on

secondary side. So, the output voltage is

decreasing and the regulation loop is rising again

above the shutdown threshold, thus resuming the

normal switching operation. A burst mode with

pulse skipping is taking place, as long as the

output power is below t he one corresponding to

the minimum turn on of the device. As the COMP

voltage is working around 0.5V, the peak drain

current is very low (it is actually defined by the

minimum turn on time of the d evice, and by the

primary winding of the transformer) and no audible

noise is generated.

In addition, the minimum turn on time depends on

the COMP voltage. Below 1V (V

blanking time increases to 400ns, whereas it is

150ns for higher voltages. The minimum turn on

time resulting from these values are respectively

600ns and 350ns, when taking into account the

internal propagation time. This feature brings the

following benefit:

• This brutal change induces an hysteresis

between normal operation and burs t mode which

is reached sooner when the output power is

decreased.

• A short value in normal operation insures a good

drain current control in case of short circuit on

secondary side.

• A long value in standby operation reinforces the

burst mode by skipping more switching cycles,

thus decreasing switching losses.

More details regarding the stan dby operation c an

be found in the data sheet. See also the prac tical

COMPbl

), the

results obtained in the corresponding section of

this document.

2. WHITE LEDS POWER SUPPLY

2.1. Schematic

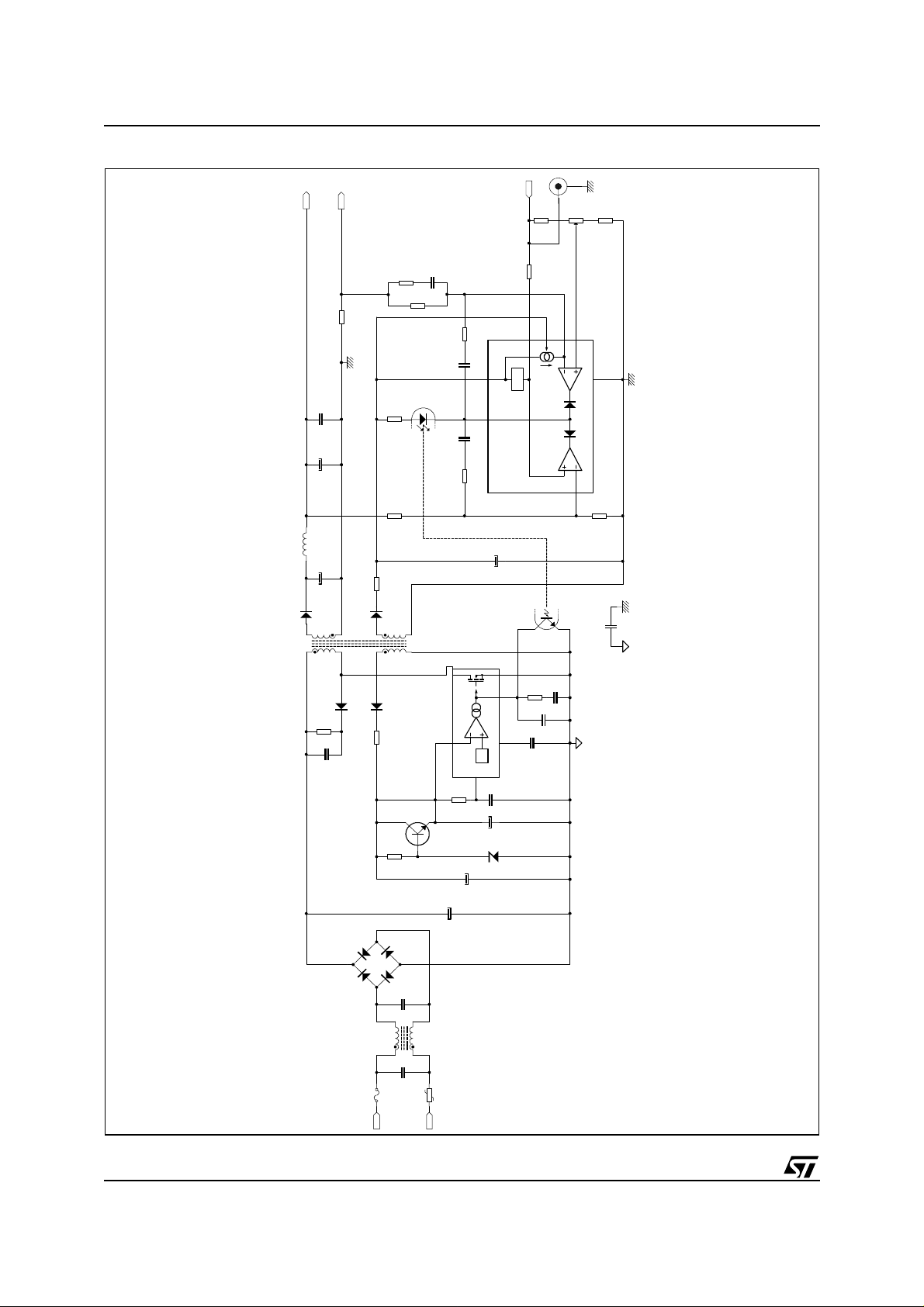

The power topology is an off-line fly-back, working

at a fixed frequency of 66KHz.

The overall schematic is presented on Figure 2.

2.1.1. Primary section

On the left hand side of the schematic, there is the

fuse F1, inrush current limiter CTN1, input filter T1,

followed by the rectifier BR1 and its bulk

capacitance C3.

R4, C4 and D4 built the RCD clamper, for

discharging the leakage inductance of the

transformer.

D2, R2 and C5 is the rectifier and filtering of the

primary auxiliary winding, used in forward mode

(refer to Section 3). This generates a voltage

supply from 21 V up to 80 V, proportional to turns

ratio between main primary winding and au xiliary

primary winding, and versus input voltage range

(110 V

A serial voltage regulator is required to supply the

VIPer 53 with the correct voltage (around 12 V). It

is built with R14, DZ14, Q1 and C12. Notice that

the V

80 V. This transistor may also dissipate 0.7 W

when input voltage is 250 V

The COMP pin filter is done using C8, R9 and C9.

2.1.2. Transformer

By definition, a current generator may have a large

output voltage variation, according to the output

load.

Then, if auxiliary winding is used in fly-back mode,

there could be a large voltage variation on

auxiliary winding as it is proportional to the

reflected voltage. So, it will be used in forward

mode in order to limit the voltage variation for

supplying the VIPer53.

In order to guaranty the functionality even with low

output voltage load, an auxiliary winding at

secondary side has been added, instead using the

main secondary output to supply the regulation

loop and the voltage limitation (using the

TSM 101). For similar reasons, this auxiliary

winding will be also used in forward mode.

up to 250 VAC).

AC

of this transistor must be higher than

CE0

.

AC

3/15

Page 4

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICATION N OTE

Figure 2. Current Generator Schem at i c

1A OUTPUT

J107

VREF INPUT

P101

1KA

2.2K

R103

0

R107

R131

2.2K

C131

10nF

R101

12K

0.25

R100

6.8K

R107

C113

22nF

C111

100nF

C110

10uF/63V

L101

10µH

C112

220uF/63V

D101

STTH302

R102

680

U2A

C114

100nF

PC817

R108

100K

R106

10K

3.3

R122

D122

BAS21

1K

R109

1

2

345

8

Vref

VCC

GND

6

TSM101

U103

C121

22uF/40V

7

330

R105

U2B

PC817

C_YCAP

2.2nF/2KV

T2

DRAIN

SOURCECOMP

D2

BAS21

D4

EBR44-600

R4

47K/4W

R2

10

C4

1nF/250V

R14

3.3K/0.5W

VIPER53

TOVL

VDD

15V

OSC

C11

4.7nF

R5

5.1K

Q1

2N5550

C12

22uF/25V

DZ14

12V/0.5W

C9

470nF

R9

6.8K

C8

4.7nF

C10

100nF

C5

C3

100uF/400V

1uF/100V

BR1

1A/600V

C2

100nF/400V

T1

COMMON

MODE

F1

0.5A

FILTER

C1

<0

T

C

100nF/400V

CTN1

AC INPUT

4/15

Page 5

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICAT ION NOTE

2.1.3. Secondary section

On the right hand side of the schematic, the

secondary winding is used in fly-back mode.

D101, C112 are respec tively the rectifying di ode

and its filtering. L101 and C110 bui ld another low

pass filter.

The auxiliary sec ondary winding used in forw ard

mode (refer to Section 3) in association with R122,

D122 and C121 built the rectifier and filtering for

the supply of the regulation loop, using a

dedicated component (TSM101). This supply is

independent from the load voltage.

TSM 101 has been design for voltage and current

controller, which can be used for the control of a

current generator, in association with a voltage

limitation. It includes its own reference voltage

(bandgap), and two operational amplifiers.

2.1.4. Current regulation loop

The output current is sensed through the shunt

resistor R100. The shunt voltage is amplified using

R101 and R107 in association with one OPamp of

the TSM 101, building the error amplifier. The

current target is set through the trimmer P101.

R103 and P101 provide a fraction of the reference

voltage provided by the TSM 101 (U103).

There is also another way to set the current target,

using the connector J107 for dimming (see

Section 2.2).

C113 with R107 is the integrator network of this

amplifier, in order to cancel the static error of the

regulation loop.

Then, the regulation loop continue with the opt ocoupler U2 (diode and transistor). This set the

level of the COMP pin filter, which set the peak

drain current VIPer53’s power cell (current control

mode). Thus, the energy stored inside the

transformer during each cycles is transferred on

the secondary side, which supply the output

current.

R131 and C131 is a phase lead net work in order

to compensate the phase delay due to L101/C110

filter, for whole loop stability purpose.

2.2. Dimming

2.2.1. Dimming purpose

The main purpose of this application is to supply

“single-chip white LEDs”, and to dim the

brightness of these LEDs.

Because the white color is obtained from two

peaks in the spectrum (a blue ray and a yellow

ray), there is a dependency between the driving

current and the white color spectrum.

2.2.2. Dimming in the application

This application do not propose any PW M and its

oscillator circuitry, which can be easily found in

dedicated literature. The way to proceed is to

apply an external PWM signal on the node

VREF_INPUT.

Provided that output impedance of the generator is

not higher than 50 Ω, the input voltage is forced by

the external generator instead of the DC reference

voltage of the TSM 101.

The low level voltage of this PWM signal must be

0V, and high level voltage must be around 1 V.

Then, the peak current of the PWM generator can

be set using the trimmer P101, a s in DC mode,

from 0 up to 1 A.

The maximum frequency allowed is limited by

dynamic behavior of the PWM current generator

(refer to Section 2.2.4). The best way to use this

power supply, is to set the lowest frequency

convenient for human eye versus flicker. The

highest the period, the highest the dimming range.

2.2.3. Audible noise

When using the power supply with a P WM signal,

some audible noise may be heard, especially if the

frequency of the external signal is inside the

audible range.

This noise is emitted by the core of the

transformer, and is a normal way to work. This

noise is proportional to the output power

transferred through it.

This noise can be reduced by optimiz ation of the

transformer.

5/15

Page 6

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICATION N OTE

2.2.4. Dynamic behavior of the current

regulation loop

As explain above, the power supply must be ab le

to generates a PWM current, at a sufficient

frequency in order to avoid flicker, with the

possibility to adjust the duty cycle. The shortest

the time response of the regulation loop, the more

linear will be the 0 % up to 100 % characteristics

of the dimming range.

Thanks to the threshold of LED, it is possible to

pulse its current instead to pulse its voltage. Then,

the voltage can be maintained, it a void to charge

and discharged the output capacitances. This

helps a lot for dynamic behavior of the current

generator, since the output filtering capacitance

are quite large.

The dynamic behavior of this current generator is

limited by several root causes in the whole

schematic.

First origin of limitation is the RC couple R101 +

R107 / C113. When the reference level is

changing on the error amplifier (TSM 101-pin 5),

the OPamp must move to this new operating point,

by charging the node TSM 101-pin 3. This is

limited by the charging of the capacitor C113

through the resistor R101 + R107.

Secondly, the filtering c apacitance C121 must be

large enough in order to properly sustain the

supply voltage of the OPamp and the resistor

R102. Effectively, during a transient, the OPamp

has to compensate its output level for loop

stabilization. Then, the dynamic behavior is limited

by the (dis)charging of the capacitor C113 through

the resistor R102, once t he supply voltage of the

amplifier is stable during that transient.

Third, the serial resistance of the load, plus the

shunt resistance R100, and t he serial resistor of

the capacitor C112 are limiting the time res ponse

of the current generator. When switching the

output current from O FF (low current le vel) t o ON

(high current level), the output voltage has to

increase of:

∆Vout ∆I

But, the output current capability will be limited for

a while, until the charging of the capacitance C112

is not completed. When this capacitor is charged,

then the current capability is then available for the

load itself.

outRsloadRshunt

+()⋅=

2.2.5. Voltage limitation

The output voltage limitation is built around R106,

R105, R108, C114 and the corresponding OPamp

of the TSM 101.

R 106, R 105 create a bridge divider of the output

voltage, in order to compare that fraction to the

reference voltage of the TSM 101. The voltage

limit is set by the formula:

R105 R106+

-------------------------------- -

Vout Vref

If the voltage limit is reached, the cable AND of the

TSM 101 allow the voltage limitation circuit to

force the whole loop to reduce the output power.

The stability of the voltage limitation loop i s done

with R108 and C114.

For human body protection against electrical

shocks, this limit has been set to around 40 V, as

advise in safety standards.

2.3. No load operation

The design of the VIPer53 is intended to enter into

burst mode when output see a low load. The

application designer must avoid to en ter in hiccup

mode (or bad burst mode) when no load is

connected.

The resistors R106 and R105 has been designed

in the application in order to have the VIPer53 in

burst mode when no load is connected. A

sufficient current is drawn into R106 and R105,

dissipating the few power transferred to the

secondary side of the transformer during the burst

mode, using the minimum turn-on time (see Figure

7, Figure 9 and Section 4.8, Figure 17 for

measurements).

2.4. Short circuit operatio n

Due to current generator structure, there is no

malfunction or damage when used in short circuit

condition. The current is by definition lim ited. The

output power is low in that condition (refer to

Section 4.8 and Figure 18 for measurements).

2.5. Low Voltage Load

When using very low voltage load (less than 4

volts at output), some instability problem may

appears, depending of t he load ty pe (inductive or

capacitive load, etc.).

⋅=

R105

6/15

Page 7

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICAT ION NOTE

Poles and zeros vary too much, which lead to

make instable the whole transfer function.

This instability may be associated with audible

noise due to some low frequency oscillations. The

user must avoid using loads which have a voltage

below than 4V, in order to ensure a correct

operation of the power supply.

3. Transformer des ign

3.1. Primary Inductance

The primary inductance has been set to 0.5mH,

according to the output power required, and the

(minimum specification of) current capability of the

VIPer53.

The VIPer software helps to define the number of

turns of the primary inductance. It provides a result

of 52 turns, in 2 wires. A diameter of 0.4mm has

been chosen.

3.2. Primary Auxiliary winding

The VIPer53 must be supplied with at least 12.8 V,

for a correct operation. This winding is also used

in forward mode. The turn rat io between primary

winding and primary auxiliary winding according to

the minimum input voltage (100 V

A value of 0.21 will be used with 11 turns on

auxiliary. At maximum input voltage (400 V

auxiliary supply then will be 85 V. This will provide

constraint on the voltage regulator for the VIPer53.

) is 0.18.

DC

DC

), the

3.4. Summary of transformer

Table 2 summarise the spec ification of the power

supply transformer.

4. Measurements

The measurements done on the application board

has been performed at room temperature (27° C),

using an open application board, in still air

condition.

Static measurements have been performed us ing

a programmable electronic load, used as a voltage

generator (so called “static load”).

In order to be as close as possible of the LEDs

load, dynamic measurements have been done

using a discrete voltage generator, as described in

Figure 3 (so called “dynamic load”). This present a

similar load as LEDs according to serial resistance

and parasitic capacitance.

Figure 3. Discrete Voltage Load

3.2.1. Secondary wind in g

The output voltage may vary from 4 V up to 40 V,

and the reflected voltage must n ot exceed 100 V.

The turn ratio should be 0.5 (26 turns) in order to

avoid current mode instability.

A diameter of 0.7mm is provided by VIPer

software.

3.3. Secondary Auxiliary winding

This secondary auxiliary output must guaranty a

voltage from minimum 6 V up to m aximum 32 V

(supply voltage range of the TSM 101). The turn

ratio is 0.077 (4 turns). This provide a supply

voltage from 7.7V up to 30.8 V, which is in line with

the specification of the TSM 101.

4.1. Switching cycle

Figure 4 and Figure 5 show the drain voltage and

drain current respectively in discontinuous mode

and continuous mode, with a 40 Watts static load,

and input voltage respectively at 400 V and 100 V.

Figure 7 and Figure 9 present Drain voltage, Drain

current, V

The output (static) load is 4 Watts (40 Volts,

100 mA), and input voltage is respectively at

100 V and 400 V .

COMP

and V

voltage in burst mode.

OUT

7/15

Page 8

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICATION N OTE

Table 2. Transformer specification

Parameter

Primary inductance Lprim: 0.5mH

Primary auxiliary winding 0.211 11 1 ~0.2 <0.1

Secondary winding 0.5 26 1 0.7 1

Secondary auxiliary winding 0.077 4 1 ~0.2 <0.1

Figure 4. Discontinuous mode (40W/V

Prim. Induct.

or Turn Rati o

Lleak < 4µH (0.8%)

Core: E25H

=400V)

IN

Number

of Turns

52 2 0.4 2.3

Figure 6. Burst mode (P

Number

of Wires

Wire diam.

(mm)

=4W; VIN=100V)

load

Max Current

(A)

Figure 5. Con t in uo us m od e (40 W /V

=100V)

IN

Figure 7. Burst mode (P

=4W; VIN=400V)

load

8/15

Page 9

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICAT ION NOTE

Figure 8. Dynamic response 50% duty cycle at

100Hz

4.2. Dynamic response

4.2.1. Discrete load

An external signal has been applie d on c onne ctor

J107 (node VREF_IN), in order to replace the

static internal reference voltage of the TSM101

with a PWM signal.

The amplitude of this signal is 0 V (low level) - 1 V

(high level) in order to get the full range 0 up to 1 A.

The frequency of this signal is around 100 Hz. The

generator allow to adjust the duty cycle of this

(PWM) signal from 10% up to 90%.

The load used during these measurements is a

discrete load (dynamic load).

Figure 9. Dynamic response 10% duty cycle at

100Hz

Figure 8, Figure 9 and Figure 10 show the

dynamic response of the current generator, when

used in PWM mode, respectively with 50%, 10%

and 90% of duty cycle.

10% and 90% of duty cycle at 100 Hz, is roughly

the minimum and maximum du ty c ycle allowed to

get an acceptable shape for the current pulse.

The minimum turn on/off time is around 1 ms. This

provide a maximum frequency of 500 Hz (2 ms

period).

Figure 10. Dynamic response 90% duty cycle

at 100Hz

4.2.2. LEDs load

Figure 11 and Figure 12 represent the dynamic

response on real load, respectively on 4 white

LEDs, and 1 white LED.

The dynamic response is worst than using discrete

load. It is also worst using 4 LEDs than using 1

LED. This typically shows the LED serial

resistance limitation, as explain below in Section

2.2.4.

The poor dynamic response on LEDs load is

because it has been o ptimized u sing the discrete

load, which have different serial resistance.

There is a room for im provement on LEDs load,

until the signal V

maximum value (4.5V). Poles and zeros may be

tune in order to improve the dynamic response of

COMP

, and then I

V

still do not reach its

COMP

.

OUT

9/15

Page 10

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICATION N OTE

Figure 11. Dynamic response on 4 White LEDs

Figure 12. Dynamic response on 1 White LED

4.4. Load regulation

The regulation versus the load is represented in

Figure 14. The regulation is around 0.4 %.

Figure 14. Lo ad R egulation

1050

1040

1030

1020

1010

1000

990

Iout (mA)

980

970

960

950

010203040

Vout ( V)

4.5. Voltage limitation

Figure 15 is the extension of the load regulation in

Figure 14 (up to the voltage limit). Then, the

voltage limitation act on the output power through

the whole regulation l oop, and the output curren t

then decrease down to 0.

Note: Since the bridge divider has been slightly

tune, the voltage limit may be different than these

measures according to R10 5 and R106 standard

values.

Figure 15. Voltage Limitation

1200

1000

4.3. Line regul a tio n

Figure 13 presents the output current variation

versus AC line input voltage. It shows a variation

of 0.4 %.

Figure 13. AC Li ne R egulation

1050

1040

1030

1020

1010

1000

Iout (mA)

990

980

970

960

950

100 150 200 250 300 350 400

Vin ( V)

800

600

Iout (mA)

400

200

0

0 10203040

Vout (V)

4.6. Power Supply Efficiency

Figure 16 shows the efficiency of the power supply

when output power increases from 0 up to

40 Watts, using several input voltage. Output

voltage vary while output current is 1A.

The efficiency is lower than what could have been

expect for an off line converter. This is mainly due

10/15

Page 11

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICAT ION NOTE

to the current generator structure of this

application, which impose to have the supply of

the VIPer53 connected on a fo rward windi ng, and

because of its associated serial voltage regulator.

Figure 16. Efficiency (I

100.0

90.0

80.0

70.0

n (%)

60.0

50.0

40.0

5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0

Pout (W )

4.7. Efficiency Vs. output power (V

OUT

=1A)

=100V)

IN

Vin=100V

Vin=200V

Vin=300V

Vin=400V

Main contributors in the power budget are the

transformer, the inrush current limiter, primary and

secondary rectifier, and the clamper.

When output load increase, the ratio between the

dissipated power of these main contributors and

the output power decrease. This is because power

of main contributors is quite cons tant versus the

output load.

Figure 18. In put power in Shor t Circuit mode

3.0

2.5

2.0

1.5

Pin (W)

1.0

0.5

0.0

100 150 200 250 300 350 400

Vin (V)

Figure 19 presents Drain, COMP pin, Output

voltage and Drain current during short circuit

condition. Notice that the converter is in

continuous mode (V

Figure 19. Short circuit con di tio n ( V

=100V).

IN

=100V)

IN

4.8. Extreme load conditions

Figure 17 and Figure 18 show the po wer supply

consumption respectively when no load is

connected at the output and in short circuit

condition.

5. Boa rd description

Figure 17. Input power in No Load mode

1.2

1.0

0.8

0.6

Pin (W)

0.4

0.2

0.0

100 150 200 250 300 350 400

Vin (V)

5.1. Printe d Circuit Board

Figure 20 to Figure 22 present the PCB of the

application. They respectively show all the layers

of the PCB, the BOTTOM layer of the PCB, and

then the TOP OVERLAY layer of the PCB.

11/15

Page 12

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICATION N OTE

Figure 20. All layers (not in scale)

Figure 21. Bottom layer (not in scale)

Figure 22. Top Overlay layer (not in scale)

12/15

Page 13

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICAT ION NOTE

6. Bill of material

The Table 3 presents the bill of material of the

application.

Table 3. Bill Of Material

Symbol Description Quantity

BR1 1A/500V 1

C1 100n/400V 1

C2 100n/400V 1

C3 100u/400V/159 PUL-SI 1

C4 1nF/250V 1

C5 1µF/100V/RLI135 1

C8 4.7nF 1

C9 470nF 1

C10 100nF 1

C11 4.7nF 1

C12 22µF/25V 1

C104 NC 1

C105 NC 1

C107 NC 1

C110 10uF/63V 1

C111 100nF 1

C1 12 220uF/63V/RLI 135 1

C113 22nF 1

C114 100nF 1

C121 22uF/40V 1

C131 10nF 1

COR1 CORNER 1

COR2 CORNER 1

COR3 CORNER 1

COR4 CORNER 1

COR5 CORNER 1

COR6 CORNER 1

CTN1 1

C_YCAP 2.2n/2KV 1

D2 BAS21 1

D4 EBR44-600 1

D101 STTH302 1

D122 BAS21 1

DZ14 12V/0.5W 1

13/15

Page 14

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICATION N OTE

F1 FUSE 1

J1 1

J2 1

J3 1

J101 1

J102 1

J103 1

J107 Vref_in 1

L101 10uH 1

P101 1K 1

P1011 1K 1

Q1 BC546/VCEO=100V/1W 1

R2 10 1

R4

R5

R9

R14

R100

R101

R102

R103

R104

R105

R106

R107

R108

R109

R122

R131

TR1 LN_FILTER 1

TR2 E25 1

U1 STMicroelectronics VIPer53DIP 1

U2 PC817 1

U101 STMicroelectronics TSM1 01A 1

47KΩ/4W

5.1KΩ

6.8KΩ

3.3KΩ/0.5W

0.25Ω

12KΩ

680Ω

2.2KΩ

1Ω

1.8KΩ

56KΩ

6.8KΩ

100KΩ

1KΩ

3.3Ω

1.8KΩ

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

14/15

Page 15

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2067 - APPLICAT ION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such i nformat ion nor for a ny infr ingement of patents or other right s of third par ties whi ch may res ults from its use. No license is

granted by i m plication or otherwise under any patent or pat ent rights o f ST M i croelectronics. Specif i cations mentioned in this public at i on are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical compone nts in lif e support de vices or syste ms without express wri tt en approval of STMicroelectronics.

The ST logo is a registered trademark of STM i croelectr onics.

All other nam es are the pr operty of their respecti ve owners

Austra l i a - B el gi um - Brazil - Canada - China - Czech Republic - Finland - France - Germa ny - Hong Kong - India - Israel - Italy - Japan -

Malaysi a - M al ta - Morocco - S i ngapore - Spain - Sweden - Switzerland - United Kingdom - Unite d States of Am erica

2004 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

www.st.com

15/15

Loading...

Loading...