Page 1

AN2050

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

APPLICATION NOTE

3-PHASE AUXILIARY POWER SUPPLY DESIGN BASED ON

EMITTER SWITCHED BIPOLAR TRANSISTORS (ESBTS)

1. INTRODUCTION

This document presents the results of a 3-Phase auxiliary power supply designed with the UC3845 PWM

driver and an ESBT, the new STC03DE170, as main switch. This work is supplemented by the release

of a 45W dual output SMPS demo board, widely used as auxiliary power supply in 3-phase motor drive

applications.

Moreover, the ESBT base driving circuit and some guidelines for the optimization of the power

dissipation are given. The influence of parasitic capacitance on ESBTs is also described in detail.

Furthermore, the slope compensation has been added in order to remove the oscillation during max

input voltage and min load. Accordingly, the discussion in theory is presented. Finally, the realization

methods of the output short circuit's protection function are provided.

For a complete design reference of an auxiliary power supply using an ESBT you may refer also to the

application note AN1889.

2. DESIGN SPECIFICATIONS AND SCHEMATIC DIAGRAM

The table below lists the converter specification data and the main parameters fixed for the demo board.

Table 1: Converter Specification Data and Fixed Parameters

Symbol Description

V

Rectified minimum Input voltage 450

inm in

Vin Rectified maximum Input voltage 850

V

Output voltage 1 15V/2A

out1

V

Output voltage 2 15V/1A

out2

P

Maximum Output Power 45W

out

η

F Switching frequency ≅ 100 kHz

Vfl Reflected fly back voltage 400 V

V

Max over voltage limited by clamping circuit 200 V

spike

Converter Efficiency >75%

Values

October 2004

1/20

Page 2

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

The power supply is based on a standard fly-back schematic including the RCD clamping network and

the TL431 plus opto-coupler for the secondary side regulation. The relevant schematic is reported in

figure 1.

Figure 1: Complete Schematic Diagram

J2

1

2

RF2

10K/0.5W

CF

0.1u/60V

6

RF 3

option

RF 1

2K/0.5W

D

C

B

A

54321

TR1

C3

1.5n/2KV

D7 BA159

D3 BY269

D4 BY269

TOR1

10/3

RG1

10K/0.25W

Lp=2.4uH, Np=160, Ns=5, lg=0.68mm

DDV2

STS20H100CT

DDV1

STS20H100T

R5

D8

12/0.5W

IN4148

1K/0.5W

Q1

ESBT

RS

1.4/1W

CV21

680u/50V

R6

D9 IN4148

C4

47u/50V

CV22

680u/50V

C5

100u/50V

FB

J3

1

2

1000u/50V

R8

10K/0.25W

CV11

RF4

810/0.5W

U2

PIC817

VREF

U3

R7

2.6K/0.25W

TL431

Title

Number RevisionSize

B

Date: 23-Jun-2004 Sheet of

File: C:\Documents and Settings\song liu\My Documents\esbt.ddbDrawn By:

CV12

1000u/50V

61

RF 5

1K/0.25W

8

D

D1

IN400 7

J1

F1

3

2

1

D2

C

B

A

IN400 7

Rb1

56K0.5W

U1 UC 3 8 4 5

7

VREF

CT

1n/60V

VCC

2

FB

1

COMP

8

VREF

4

RT/CT

RT

10K/0.25W

FB

Rco m

10K/0.25W

Cc o m

470p/60V

1 2 3 4 56

C1

150u/450V

R1

220K/0.5W

C2

150u/450V

Dz1

IN414 8

OUT

ISENSE

82K/2W

82K/2W

Dz2

IN4148

6

3

R3

R4

R2

220K/0.5W

Dz3

IN4148

Rb

RG

Rc s

1K/0.25W

CS

471/60V

C4

0.1u/60V

0.56/0.5W

22/0.5W

3. MEASUREMENTS

The board has a voltage doubler in the input stage to allow its testing with a standard main. The two

tables below report the efficiency measurement at full and minimum load.

Table 2: Full Load: 15V@2A, 15V@1A, Vin: 160Vac, 220Vac, 300Vac (with Voltage Doubler)

PARA METER LOW LINE=160Vac NO MLINE=220Vac HILINE =300Vac SPEC.LIMIT

I/P Power (W ) 57.5 57.7 55.3

O/P Power ( W ) 45.5 45.5 45.5

Efficiency ( % ) 79.2% 79% 82.3% 75%

Table 3: Min Load: 15V@0.2A, 15V@0.1A Vin: 160Vac, 220Vac, 300Vac (with Voltage Doubler)

PARAMETER LOWLINE=160Vac NOMLINE=220Vac HILINE=300Vac SPEC.LIMIT

I/P Power (W ) 10.2 9.8 9.7

O/P Power ( W ) 4.6 4.6 4.6

Efficiency ( % ) 45 % 47% 47%

2/20

Page 3

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

®

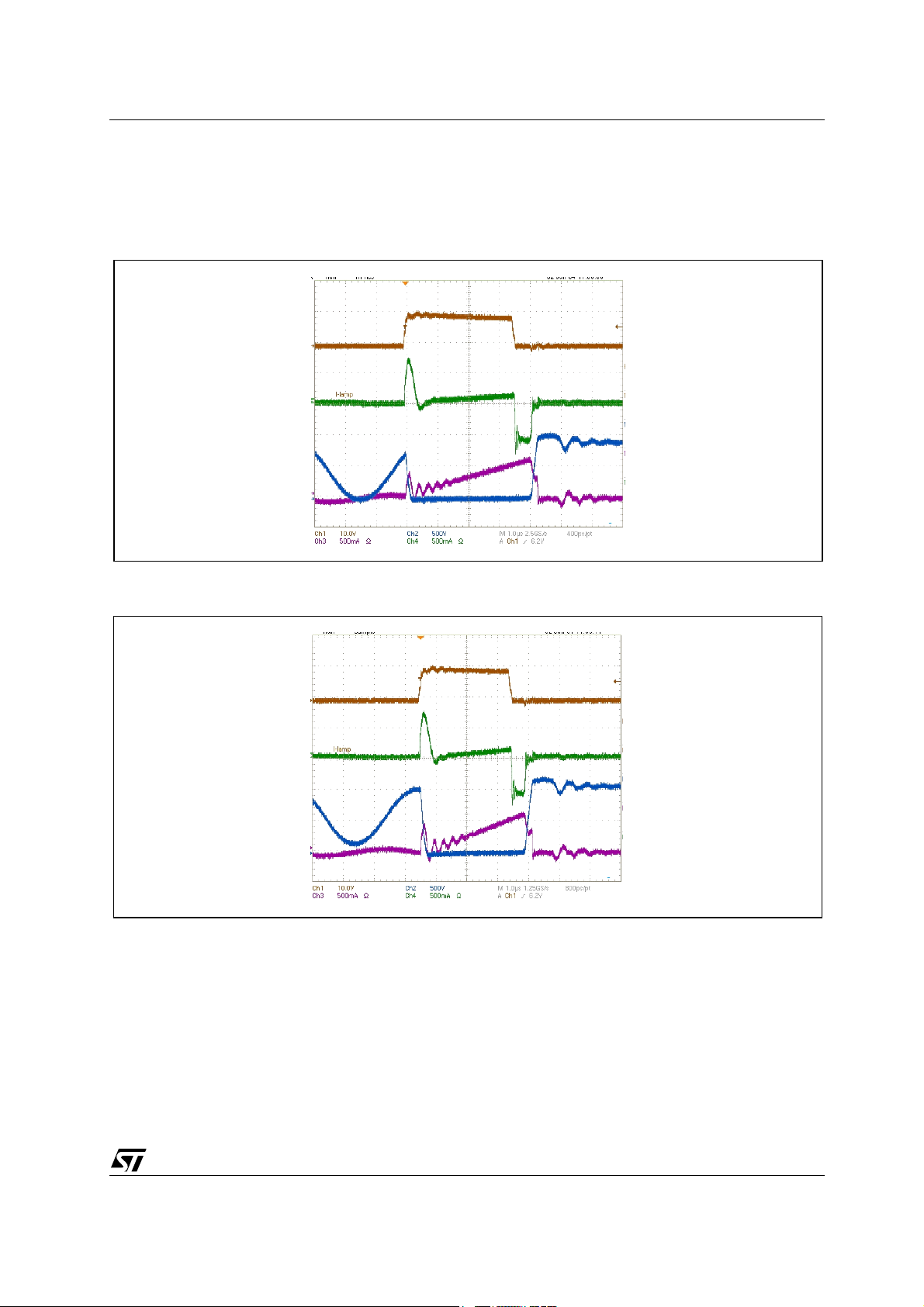

The main waveforms in steady state condition at full load are reported below. It is worth noticing the

behavior of the base current with an initial high peak pulse needed to minimize the effect of the dynamic

saturation voltage.

Figure 2: VinDC = 450V Full Load

Figure 3: VinDC 600V Full Load

3/20

Page 4

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

Figure 4: : VinDC = 850V Full Load

Table 4: Measurement Results

Power Dissipation

4.37 W

5.39 W

3.71 W

ESBT

Component Measured T emperature

160 Vac

220 Vac

300Vac

68.7

78.9

62.1

Major differences in power dissipation are mainly due to turn-on operation, and are strongly correlated to

the parasitic capacitance of the transformer, and the output capacitance of the ESBT in parallel with the

heat-sink package parasitic capacitance. This issue will be treated deeply in paragraph 5.

4. BASE DRIVING CIRCUIT DESIGN

In practical applications, such as SMPS, where the load is variable, the collector current varies as well.

As a consequence, it is very important to provide a base current to the device that is correlated to the

collector current in order to avoid the over saturation of the device at low load and to optimize its

performance in terms of power dissipation. One common method to do this is the proportional driving

method provided by a current transformer as shown in Figure 1. As already stated in the previous

chapter, it is recommended to provide a short current pulse to the base to make the turn-on as fast as

possible and to reduce the dynamic saturation phenomenon. This pulse is achieved by using the

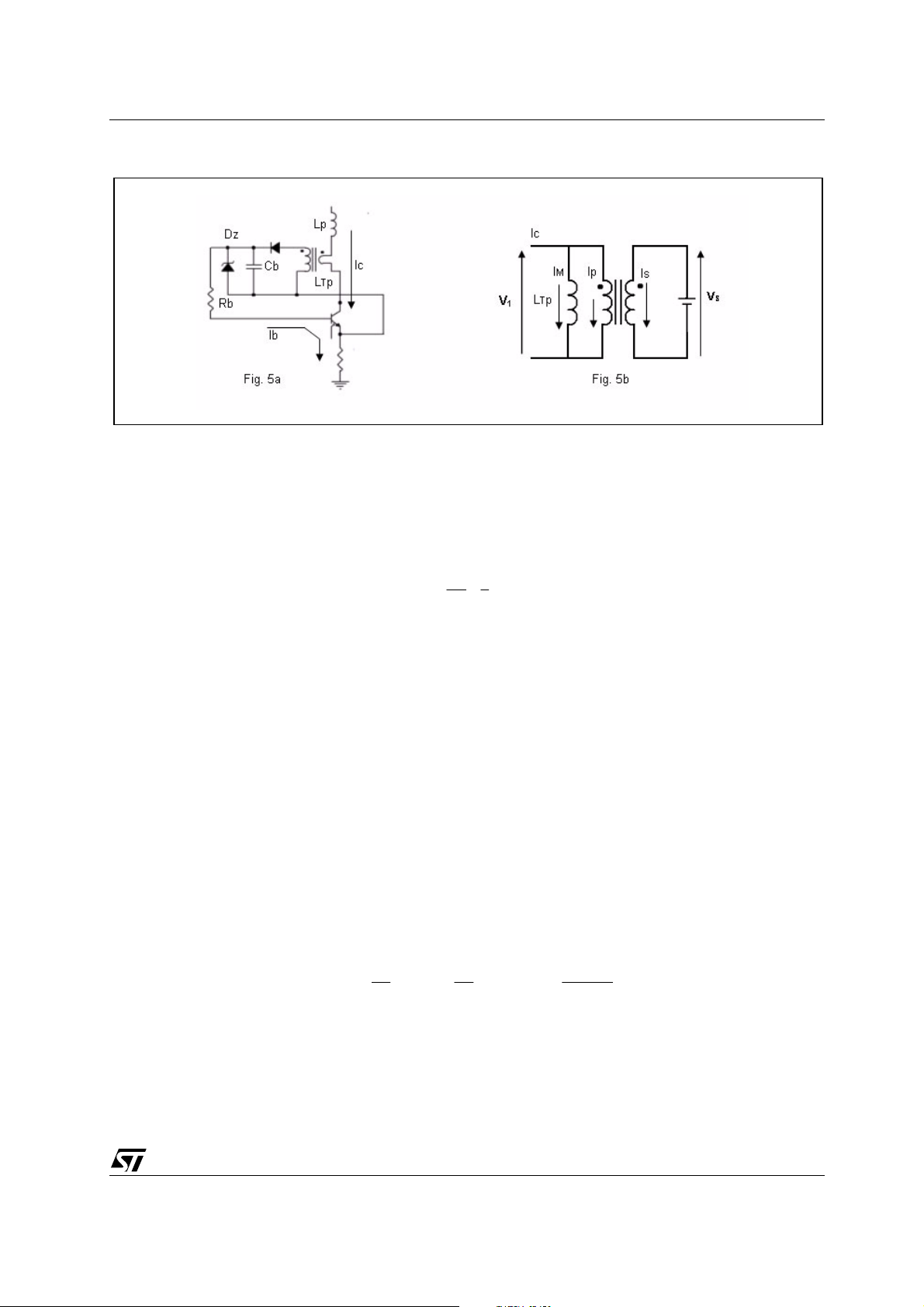

capacitor and the zener diode in figure 5.

4/20

Page 5

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

®

⋅

∆

ϕ

Figure 5: Proportional Driving Schematic and its Equivalent Circuit

The current transformer turn ratio imposes a zone in the current characteristics with fixed IC/IB, its turn

ratio has to be designed according to the characteristics of the chosen transistors and in particular to its

gain. As an example, the STC03DE170 exhibits h

=5 at IC=1.8A, VCE=5V, so that in order to ensure the

fe

right saturation level of the transistor at full load operations we can fix at first a turn ratio:

1

N

P

=

5

N

S

A correct design of the current transformer has to take into consideration some constraints that, being in

contrast each other, lead to a few iterative design steps. The magnetic permeability of the core of the

current transformer has to be as high as possible in order to minimize the magnetization current Im that is

a fraction of the primary current that flows in the core and is not transferred to the secondary side (see

figure 5b). On the other end, too high a permeability core may lead to the saturation even with a very

small magnetization current unless the number of primary turns as well as the size of the core is

increased. On the contrary, by choosing a core with a very small magnetic permeability, it is possible to

reduce the number of primary turns and the core size, but the consequent small permeability would not

ensure the necessary current on the secondary side because almost all of the primary current would be

used as magnetization current. Among some possible choices, a ferrite ring with 12.5mm diameter and

relative permeability in the range of 4500 ÷ 7000 has been selected.

Starting from the preliminarily fixed turn ratio (N=0.2), we must determine the minimum primary turns

needed to avoid the core saturation. By applying the Faraday's law and imposing the maximum flux

Bmax equals to Bsat/2:

d

NV

1

dt

B

AN

⋅⋅≅=

t

∆

N

TPeTPTP

TV

on

=⇒

max1

2

BA

sate

⋅

Where, Bsat is the saturation flux of the core and depends on its magnetic permeability.

Looking at figure 5b the equivalent schematic diagram of the transformer has been modeled with its

secondary closed with a voltage generator, whose value can be calculated doing some consideration on

the circuit in fig. 5a. In fact, during the conduction time, the junction base-emitter of ESBT can be seen as

a forward biased diode, to this we have to add the voltage drop on both diode D and resistor R

in series

B

5/20

Page 6

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

≅++

=

−

=

with the base of the ESBT (the Vdson of the mosfet can be neglected). In this way the voltage source at

secondary side Vs is given by:

VVVVV

5.2

RBDBEonS

Since the magnetization inductance cannot be neglected, only I

, a fraction of the total collector current,

P

will be transferred to the secondary. As a result, the magnetization current has to be firstly as low as

possible. Meanwhile, the value of the magnetization inductance must be taken into account for the

proper calculation of the transformer primary turns and turns ratio. The magnetization voltage drop, that

is, the voltage at the primary of the current transformer, can be now easily calculated:

N

T

1

VV

S

1

N

T

2

1

5.2

5

[]

V

5.0

=⋅==

The magnetization current will be:

TV

ON

=

max1

L

TP

results relatively high; obviously the core must

Mmax

I

M

max

The number of primary turns should be increased if I

have a window area large enough to hold both primary and secondary windings. Once both core material

and size are fixed, the turn ratio must be adjusted to get the desired I

ratio according to the below

C/IB

equation:

I

P

N

==

eff

I

B

II

maxmaxCMC

I

5

where I

is the max magnetization current.

Mmax

Particular care must be taken in order to ensure the insulation between primary and secondary sides

since the voltage on the primary side during the off time can exceed 1500V.

Next step is to select the zener diode, the capacitor Cb and the resistor Rb. The turn-on performance of

ESBT is related to the initial base peak current and its duration t

CRt 3

bbpeak

that is approximately given by:

peak

A suitable value for Rb that gets rid of the ringing on the base current after the peak, and at the same

time generates negligible power dissipation is 0.56

The t

in mind that in practical applications it should never be lower than 200ns. The value of C

easily calculated since the values of t

The I

6/20

value can be determined once the minimum on time is set upon the operating frequency. Bear

peak

and Rb were chosen.

peak

amplitude must be limited in order to avoid an extra saturation of the device. This action is

peak

Ω.

can be now

b

Page 7

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

®

(

)

+

(

)

=

made by the zener diode Dz that clamps the voltage across the small capacitor Cb. The zener must be

chosen according to the following empiric formulas and within the range of V

Zmin

and V

Zmax

:

=

max

The base peak current will be higher with higher clamp voltage (Dz) or smaller capacitance (Cb), which in

turn will lead to shorter duration of the peak time.

The higher and longer is the base peak current, the lower is the power dissipation during turn-on, on the

other hand it is necessary to limit the Ib peak both in terms of amplitude and time duration, otherwise at

low load a very high saturation level may occur with consequent long storage time that may lead the

device to an excessive power dissipation during turn-off. Moreover, longer storage times can also lead to

oscillations especially at high input voltage. To overcome these problems it is advisable to fix the peak

duration to 1/3 the minimum duty cycle.

5. PARASITIC CAPACITANCE BETWEEN ESBT COLLECTOR AND GROUND

The parasitic capacitance between the ESBT collector and ground is mainly due to three components as

shown in figure 6: C1 that is the primary inter-winding capacitance, C2 that represents the intrinsic

capacitance of the ESBT between its collector and source, C3 that is the parasitic capacitance between

the collector of the ESBT and the heat-sink. Usually ESBT is assembled on a heat-sink and is insulated

from it by interposing an insulation layer. The heat-sink should be grounded to minimize the RFI and also

for safety reasons. In this way C3 results in parallel with C1 and C2. The resulting total parasitic

capacitance C equal to C1+C2+C3 could result sufficiently large to produce additional not negligible turnon power dissipation and to origin ringing and noise problems. The influence of this parasitic capacitance

will be worst at higher input voltage like those observed in three-phase auxiliary power supply.

12

RIV

bpeakZ

min

RIV 2

bpeakZ

Figure 6: Small Signal Equivalent Circuit

The fly-back converter of the demo is operated in DCM, so, before the end of the off time, the secondary

of the transformer has completely discharged all the energy stored into the primary inductance during the

previous cycle. At that time, the magnetization inductance and the total parasitic capacitance C resonate

as it is evident from figure 7. The power supply has been tested at full load and different input voltages.

The highest temperature on the ESBT has been experienced at about 600V bus voltage when the

7/20

Page 8

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

heat-sink is grounded and the isolation material is ceramic. Looking at figure 7, it can be noted that ESBT

turns on at maximum voltage (about 1100V) and that the test frequency is about 100kHz. Under the

same conditions, with the heat-sink not grounded, the temperature on the ESBT results considerably

lower. Finally, in figure 8 the current which flows trough the package-heatsink parasitic capacitance is

also showed. The power dissipation caused by the parasitic capacitance between the ESBT collector

and the heat-sink can be calculated by using the formula: P

different values of C

Lower power dissipation can be achieved at a lower value of the capacitance C3 by increasing the

insulation distance between the heat-sink and ESBT collector and using plastic instead of ceramic

material for the insulation pad. However, this will increase the thermal resistance between the package of

the ESBT and the heat-sink, leading the device to operate at a higher working temperature. So the right

value of C3 is a right compromise between the thermal resistance and turn-on losses.

Figure 7: Overall Working Waveforms

are shown in Table 5.

3

= C3V

D

2

f/2. The relevant results at

CS

Figure 8: Discharging and Charging Current of C3

8/20

Page 9

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

®

The values for the capacitance C3 reported in table 5 are calculated as follows:

1) First the dv/dt of the collector voltage has to be measured with the heat-sink not grounded

2) Knowing that the current available to charge the total parasitic capacitance Cout during turn-off

is the IC peak current, from the formula i=Cdv/dt we can calculate Cout1=C1+C2.

3) Now the heat-sink has to be grounded to redo the measure of the dv/dt

4) Repeat step number 2, where now, Cout2=C1+C2+C3

5) Finally make the difference between Cout2 and Cout1 that is equal to C3

It is strongly recommended using a passive voltage probe whose parasitic capacitance contribution is

negligible.

Table 5: Influence of Parasitic Capacitance

C3 Capacitance (pF) power dissipation(W)

1 insulation plastic pad

2 insulation plastic pads

1 insulation c eramic pad

28 1.4

17 0.85

35 1.75

6. OSCILLATION AT MINIMUM LOAD AND MAXIMUM INPUT VOLTAGE

The fly-back power supply tends to oscillate at minimum load and maximum input voltage. The resistor

Rs in series with the ESBT in Figure 9(a) has the function of a current sense. The current waveform will

often have a large spike at its leading edge as shown in Figure 9(b). This is due to the discharge of the

parasitic capacitance C2 & C3 and the charge of the parasitic capacitance C1 as mentioned in the

previous chapter. A simple RC filter is usually adequate to suppress this transient spike that could cause

a premature end of the output pulse, as shown in Figure 10. The RC time constant should be

approximately equal to the current spike duration usually a few hundred nanoseconds; the values used in

the demo board are Rcs=1K, Cs = 560pF.

Figure 9: Current Sense Circuit (a) and Waveform of Sense Resistor (b)

UC 38 4 5

VCC

FB

COMP

VREF

RT/CT

OUT

ISENSE

6

3

Vc s Vr s

ES BT

Rc s

Spike

Vr s

Cs

Rs

(a) (b)

9/20

Page 10

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

Figure 10: Normal Operation Waveforms of Output Pulse and Current Spike

In case of maximum input voltage and minimum load, the current spike duration and the pulse width

could stand the same order of magnitudes. In this case the RC filter will not be effective, as shown in

Figure 11. A bigger capacitance could not solve the problem; furthermore, as a consequence, the

increasing of the delay imposed by the current sense may lead the magnetic core of the transformer to

go into saturation since the current continues to rise up during this delay period. This can more easily

happen during start-up and output short circuit.

Figure 11: Output Waveforms and Current Spike at Minimum Load and Maximum Input Voltage

Moreover, if the filter capacitance is too big it is possible that the minimum duty cycle is not reachable

with consequent oscillations and instabilities. On the contrary, if the filter capacitance is too small, some

instability can occur as well. The reason can be explained by the following consideration. The energy

transferred from primary to secondary side results small if the output pulse is prematurely terminated

during the switching cycle. If this happens for several pulses the feedback loop will act increasing the

error signal and producing a higher energy that will be transferred to the secondary side. Accordingly, a

higher output pulse will be generated and again prematurely ended. Another disadvantage of choosing a

too small filter capacitance is that the power supply could not be able to start-up at full load and minimum

input voltage. It is possible to mitigate both of the above mentioned problems just reducing the parasitic

10/20

Page 11

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

®

capacitance between collector and ground with the effect of smoothing the current spike during turn-on.

Normally, using an ESBT as a main switch, it is not possible to reach a very low minimum duty cycle

because of its storage time; as a consequence, if the minimum load is very low, it is not possible to

completely eliminate the oscillations. In the applications where turn-on can occur at a very high voltage,

like in auxiliary power supplies, the great amount of energy stored in the parasitic capacitances leads to

high peak currents and oscillations. In this situation, small slope compensation can help to completely

remove this problem; note that normally the slope compensation is used to prevent sub harmonic

oscillations when the converter is operated at a duty cycle higher than 50%. The slope compensation can

be implemented by adding a positive going ramp to the signal coming from the sensing resistor (see

figure 12).

Figure 12: Slope Compensation Network and Related Waveforms

Practically, the slope compensation is realized by connecting a resistor between pin 4 and pin 3. In fig.

12b the positive going ramp, added to the voltage on the sense resistor, is shown. The positive effect of

this method is clear if you look at fig 12c where the output signal is correct. If the resistance value to be

inserted is too small (the same order of magnitude of Rt) the switching frequency will be affected by both

Rt and Rslope. To avoid this problem an emitter follower could be interposed between pin 4 and Rslope,

as shown in figure 13.

11/20

Page 12

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

Figure 13: Modified slope compensation network with emitter follower

The slope compensation can be also achieved by using a small capacitor in place of the resistor as

shown in figure 14. In this case the following relations must be taken into account:

C du

Cs du

Where C = Ct+ Cs Cslope/(Cs + Cslope).

/ dt =( Vref - uCt )/Rt (1)

Ct

/ dt = Cs d(uCt - u

CS

) = Cslope du

Cslope

Cslope

/dt (2)

The capacitive slope compensation does not need the use of a small signal transistor as emitter follower,

but from the equations 1 and 2 above, it is clear that, positive going ramp can be achieved only if the

voltage slope at pin 4 is higher than the voltage slope of the voltage at pin 3 and this could not be verified

in every working condition.

Figure 14: Capacitive Slope Compensation

12/20

Page 13

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

®

Anyway, in both cases (resistive or capacitive slope compensation), the values have to be chosen in

order to add a voltage ramp that is high enough to solve the oscillation problem. On the other hand the

ramp amplitude cannot be arbitrarily high, otherwise the peak of the ramp will be very high and the

maximum collector current will be reduced accordingly.

Noises can be anyway greatly reduced, paying particular attention to the layout: as an example using

copper ground plane and separate return lines for high and low current paths. The use of 0.1µF

capacitors from Vcc and Vref pins to ground can provide low-impedance paths for high frequency

transients. Some noises are often generated by the output of PWM IC (pin 6) being it pulled down below

the ground at turn-off by the influence of external parasitic inductances. A clamping diode in the pin 6 (to

ground) will prevent such output noise.

Note that there are significant oscillations in figure 15 at min load and max input voltage with the heatsink grounded (high parasitic capacitance). VIS is the waveform of the pin3 of UC3845.

Figure 15: Minimum Load Maximum Input Voltage, Heat-sink Grounded

Note that in Figure 16 the oscillations are slightly decreased at min load and max input voltage when the

heat-sink is not grounded (lower parasitic capacitance).

Figure 16: Minimum Load Maximum Input Voltage, Heat-sink not Grounded

13/20

Page 14

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

E

Vb

Note that oscillations are completely removed in Figure 17 at min load and max input voltage when the

slope compensation is added and the heat-sink is not grounded.

But it is worth noticing that the working conditions are not particularly stressful during turn-on as it occurs

when the collector voltage is relatively low.

Figure 17: Minimum Load Maximum Input Voltage, Heat-sink not Grounded plus Slope

Compensation

7. THE PROTECTION FOR OUTPUT SHORT CIRCUIT

The self-supply circuit of PWM IC is shown in Figure 18 where the popular 1N4148 or UF4003 can be

used as bias rectifiers. The UC384X family realizes the function of an output short circuit protection by

using the Under-Voltage-Lock-Out function through the Vcc pin (UVLO function). When the output is

short circuited, the auxiliary winding output and consequently the Vcc voltage will drop to zero: once the

Vcc voltage reaches a value lower than the under voltage lockout, the PWM IC stops operating. Then the

power supply will start again and will be stopped by the UVLO function for several cycles till the short

circuit is removed.

Figure 18: Self-Supply Circuit of PWM IC

us

Rs tart

Cv c c

7

2

1

8

4

U1

UC 3 8 4 5

VCC

FB

COMP

VREF

RT/CT

D1

OUT

ISENSE

IN4148

6

3

R1

CS

T

Rb

Rg

Rc s

Rg s

14/20

Page 15

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

®

The resistor R1 in figure 18 has the function to filter the voltage spikes due to the parasitic inductances,

appearing on the positive edge of the voltage that causes the Vcc voltage to increase at the increasing of

the output load. The optimum value can be found empirically taking into account that its max value has to

ensure the start-up of the power supply at min load and min input voltage, while the min value must

ensure the filtering of the voltage spike at full load and max voltage. It is recommended to design the turn

ratio of the self-supply winding in order to get a voltage approximately in the middle of the two boundary

conditions described before. A small and inexpensive axial inductor in the range of 1 to 10uH may be

used instead of R1, with even better results.

Sometimes, only adjusting the value of the resistance might not be enough to solve the problem. So

other actions, like those listed below, should be taken:

1. Use diode IN4007 instead of 1N4148 or UF4003.

Thanks to the higher recovery time shown by the IN4007, the energy stored in the capacitance of Vcc

can be discharged through the diode and auxiliary winding during the recovery period. This will help

reduce the voltage of Vcc (see figure 19).

Figure 19: Vcc Capacitance Discharging

2.

The auxiliary winding should be twisted tightly on the outermost layer and concentrated on the middle

of the bobbin.

The effect of that is a lost of magnetic coupling between auxiliary winding and primary winding, which, in

turn, helps increase the leakage inductance and the delay making inefficient the transfer of energy from

primary to the auxiliary winding. The auxiliary winding should couple better with the secondary winding.

3. Connect a resistor between PWM IC pin3 and Vbus.

It is very effective when short circuit protection cannot be realized at high input voltage.

4. Remove the bead in series with the secondary diode.

The bead can reduce the current slope rate. Take EMI into account before doing it.

5. Increase current sense resistor.

The current sense resistor connected between the source pin and the ground should be big as soon as

possible on the condition that power supply must start-up normally at full load and min input voltage.

6. Decrease the capacitance of RC filter.

Noise immunity and starting up of power supply at full load and min input voltage must be ensured.

15/20

Page 16

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

Table 6: Bill of Material

Part Type Designator

1 C1 150u/450V

2 C2 150u/450V

3 C3 1.5n/2KV

4 C4 0.1u/60V

5 C5 100u/50V

6 Ccom 470p/60V

7 CS 471/60V

8 CF 0.1u/60V

9 CT 1n/60V

10 CV11 1000u/50V

11 CV12 1000u/50V

12 CV21 680u/50V

13 CV22 680u/50V

14 R1 220K/0.5W

15 R2 220K/0.5W

16 R3 82K/2W

17 R4 82K/2W

18 R5 12/0.5W

19 R6 1K/0.5W

20 R7 2.6K/0.25W

21 R8 10K/0.25W

22 RG 22/0.5W

23 RG1 10K/0.25W

24 Rb 0.56/0.5W

25 Rb1 56K/0.5W

26 RS 1.4/1W

27 Rcs 1K/0.25W

28 RT 10K/0.25W

29 Rcom 10K/0.25W

30 RF1 2K/0.25W

31 RF2 10K/0.25W

32 RF3 Option

33 RF4 810/0.5W

34 RF5 1K/0.25W

35 D1 IN4007

36 D2 IN4007

37 D3 BY269

38 D4 BY269

39 D5 IN4148

40 D6 IN4148

41 Dz IN4148*3

42 Db BA159

43 DDV1 STS20H100CT

44 DDV2 STS20H100CT

45 F1 FUSE1

46 U1 UC3845

47 U2 PIC817

48 U3 TL431

49 TR1 Lp = 2.4uH, Np = 160, Ns = 5

50 TOR1 Turn Ratio:12/3

16/20

Page 17

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

®

Figure 20: Picture of Demo board

AN2050 - APPLICATION NOTE

ESBT:

STC03DE17

Figure 21: PCB Picture Bottom View

17/20

Page 18

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

Figure 22: PCB Picture Top View

18/20

Page 19

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

®

8. REVISION HISTORY

Table 7: Revision History

Date Revision Description of Changes

15-Oct-2004 1 First Release

AN2050 - APPLICATION NOTE

19/20

Page 20

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN2050 - APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

20/20

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

© 2004 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

www.st.com

Loading...

Loading...