Page 1

AN2014

Application note

How a designer can make the most of STMicroelectronics Serial

EEPROMs

Introduction

Electrically erasable and programmable memory (EEPROM) devices are standard products,

used for the non-volatile storage of parameters and fine-granularity data.

There is no single memory technology (SRAM, DRAM, EEPROM, Flash Memory, EPROM,

ROM) that meets an application’s needs perfectly. Consequently, the designer needs to

know the particular strengths and weaknesses of each technology for optimal use in a given

application. He can then design the application to keep within the specification, for the best

performance, best reliability and lowest failure rates. Lately, this involves understanding at

least the general principles of how the devices, in the given technology, are constructed, and

how they work.

This document has been designed to give precisely this level of background understanding

for one of those technologies: EEPROM, from STMicroelectronics. It describes how

STMicroelectronics’ EEPROM is constructed, how it works, and gives useful guidelines for

achieving high reliability applications under some of the most stringent conditions, such as

those that are experienced in the automotive market.

March 2012 Doc ID 10701 Rev 8 1/69

www.st.com

Page 2

Contents AN2014

Contents

1 EEPROM cell and memory array architecture . . . . . . . . . . . . . . . . . . . . 7

1.1 Floating gate operation within an EEPROM cell . . . . . . . . . . . . . . . . . . . . 7

1.1.1 Reading the value stored in a memory cell . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.2 Writing a new value to the memory cell . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.3 Cycling limit of EEPROM cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2 Electrical architecture of ST serial EEPROM arrays . . . . . . . . . . . . . . . . 14

1.2.1 Memory array architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.2 Decoding architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.3 Intrinsic electrical stress induced by programming . . . . . . . . . . . . . . . . 15

2 Choosing a suitable EEPROM for your application . . . . . . . . . . . . . . . 17

2.1 Choosing a memory type suited to the task to be performed . . . . . . . . . . 17

2.2 Choosing an appropriate memory interface . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Choosing an appropriate supply voltage and temperature range . . . . . . 18

3 Recommendations to improve EEPROM reliability . . . . . . . . . . . . . . . 19

3.1 Electrostatic discharges (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.1 What is ESD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.2 How to prevent ESD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.3 ST EEPROM ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Electrical overstress and latchup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 What are EOS and latchup? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.2 How to prevent EOS and latchup events . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.3 ST EEPROM latchup protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Power supply considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.1 Power-up and power-on-reset sequence . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.2 Stabilized power supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3.3 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Hardware considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 I2C family (M24xxx devices) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.1 Chip enable (E0, E1, E2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.2 Serial data (SDA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.3 Serial clock (SCL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/69 Doc ID 10701 Rev 8

Page 3

AN2014 Contents

4.1.4 Write control (WC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1.5 Recommended I

2

C EEPROM connections . . . . . . . . . . . . . . . . . . . . . . 29

4.2 SPI family (M95xxx devices) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.1 Chip Select (S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.2 Write Protect (W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.3 Serial Data input (D) and Serial Clock (C) . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.4 Hold (HOLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.5 Serial Data output (Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.6 Recommended SPI EEPROM connections . . . . . . . . . . . . . . . . . . . . . . 33

4.3 MICROWIRE® family (M93Cxxx and M93Sxxx devices) . . . . . . . . . . . . . 35

4.3.1 Chip Select (S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3.2 Serial Data (D) and Serial Clock (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3.3 Organization Select (ORG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3.4 Serial Data output (Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3.5 Don’t use (DU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3.6 Recommended MICROWIRE EEPROM connections . . . . . . . . . . . . . . 37

4.4 PCB Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.1 Cross coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.2 Noise and disturbances on power supply lines . . . . . . . . . . . . . . . . . . . 38

5 Software considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1 EEPROM electrical parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Optimal Write control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.1 Page mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.2 Data polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3 Write protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3.1 Software write protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3.2 Hardware write protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4 Data integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4.1 The checksum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4.2 Data redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.4.3 Checksum and data redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.4.4 Extra redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5 Cycling endurance and data retention . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.5.1 Values specified in device datasheets . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.5.2 Optimal cycling with ECC (error correction code) . . . . . . . . . . . . . . . . . 48

Doc ID 10701 Rev 8 3/69

Page 4

Contents AN2014

5.5.3 Cycling and temperature dependence . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5.4 Defining the application cycling strategy . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.5 Overall number of write cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Power supply loss and application reset . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Application reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.1 I2C family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.2 SPI family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.1.3 MICROWIRE family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.2 Power supply loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2.1 Hardware recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2.2 Supply voltage energy tank capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2.3 Interruption of an EEPROM request . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.3 Robust software and default operating mode . . . . . . . . . . . . . . . . . . . . . . 62

7 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.1 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.2 Humidity and chemical vapors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.3 Mechanical stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4/69 Doc ID 10701 Rev 8

Page 5

AN2014 List of tables

List of tables

Table 1. Three serial bus protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 2. ESD generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 3. Typical POR threshold values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 4. Connecting the Ei inputs of I²C products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 5. Calculation rules for pull-up resistor on SDA

Table 6. Connecting WC inputs in I2C products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 7. Calculation for external pull-up and pull-down resistors in SPI products . . . . . . . . . . . . . . 34

Table 8. Calculating external pull-up and pull-down resistors in MICROWIRE products . . . . . . . . . 37

Table 9. Column and page address bits according to page length. . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 10. Application cycling profile evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 11. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

(1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Doc ID 10701 Rev 8 5/69

Page 6

List of figures AN2014

List of figures

Figure 1. Structure of an EEPROM floating gate transistor, and circuit symbol. . . . . . . . . . . . . . . . . . 7

Figure 2. MOSFET-like operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Floating gate reservoir full of electrons (Erased state) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Floating gate reservoir empty of electrons (Written state) . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Using the voltage on the control gate to determine the charge on the floating gate. . . . . . . 9

Figure 6. During erase, electrons go through the tunnel oxide into the floating gate. . . . . . . . . . . . . 10

Figure 7. During write, electrons go through the tunnel oxide out of the floating gate . . . . . . . . . . . . 11

Figure 8. VPP signal applied to EEPROM cells

(HiV is the output of the charge pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. Accumulation of negative or positive charges in the tunnel oxide . . . . . . . . . . . . . . . . . . . 13

Figure 10. Architecture of the memory array (showing the grouping in bytes). . . . . . . . . . . . . . . . . . . 14

Figure 11. Decoding block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 12. Latchup mechanism and protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13. Latchup test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 14. Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 15. Local EEPROM supply filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 16. Chip Enable inputs E0, E1, E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 17. Serial Data input/output SDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 18. SDA bus conflict with push-pull buffers (NOT RECOMMENDED) . . . . . . . . . . . . . . . . . . . 26

Figure 19. Serial Clock input SCL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 20. Write Control input (WC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 21. Recommended I²C connections – safe design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 22. Recommended I²C connections – robust design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 23. Chip Select, Clock, Data, Hold input pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 24. Write Protect input W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 25. Output pin tri-state buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 26. Recommended SPI connections - safe design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 27. Recommended SPI connections - robust design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 28. Chip Select, Clock, Data input pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 29. Organization input ORG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 30. Recommended MICROWIRE connections - safe design . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 31. Recommended MICROWIRE connections - robust design . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 32. PCB decoupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 33. I

Figure 34. SPI data polling algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 35. MICROWIRE data polling algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 36. .Recommended use of the WC pin in I²C products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 37. Recommended use of the W pin in SPI products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 38. Example of how to duplicate data safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 39. Write cycling versus temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 40. I

Figure 41. SPI bus enters the high impedance state (Master reset) . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 42. MICROWIRE bus enters the high impedance state (Master reset) . . . . . . . . . . . . . . . . . . 56

Figure 43. EEPROM power backup capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 44. Emergency sequence I

Figure 45. Emergency sequence SPI products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 46. Emergency sequence MICROWIRE products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2

C data polling algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2

C bus enters the high impedance state (Master reset) . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2

C products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6/69 Doc ID 10701 Rev 8

Page 7

AN2014 EEPROM cell and memory array architecture

AI10227

Tunnel Oxide

Control Gate

Floating Gate

Source

Drain

Gate Oxide

Oxide

Channel Region

Drain

Source

Control Gate

Floating Gate

!)B

6

G

)

D

6

!

$RAIN

3OURCE

6

G

)

D

1 EEPROM cell and memory array architecture

1.1 Floating gate operation within an EEPROM cell

From the user’s point of view, this EEPROM device is a circuit for storing digital information.

To interface with the EEEPROM device a set of standard instructions are used. Behind this

simple interface, however, there are a number of sensitive analog and physical processes.

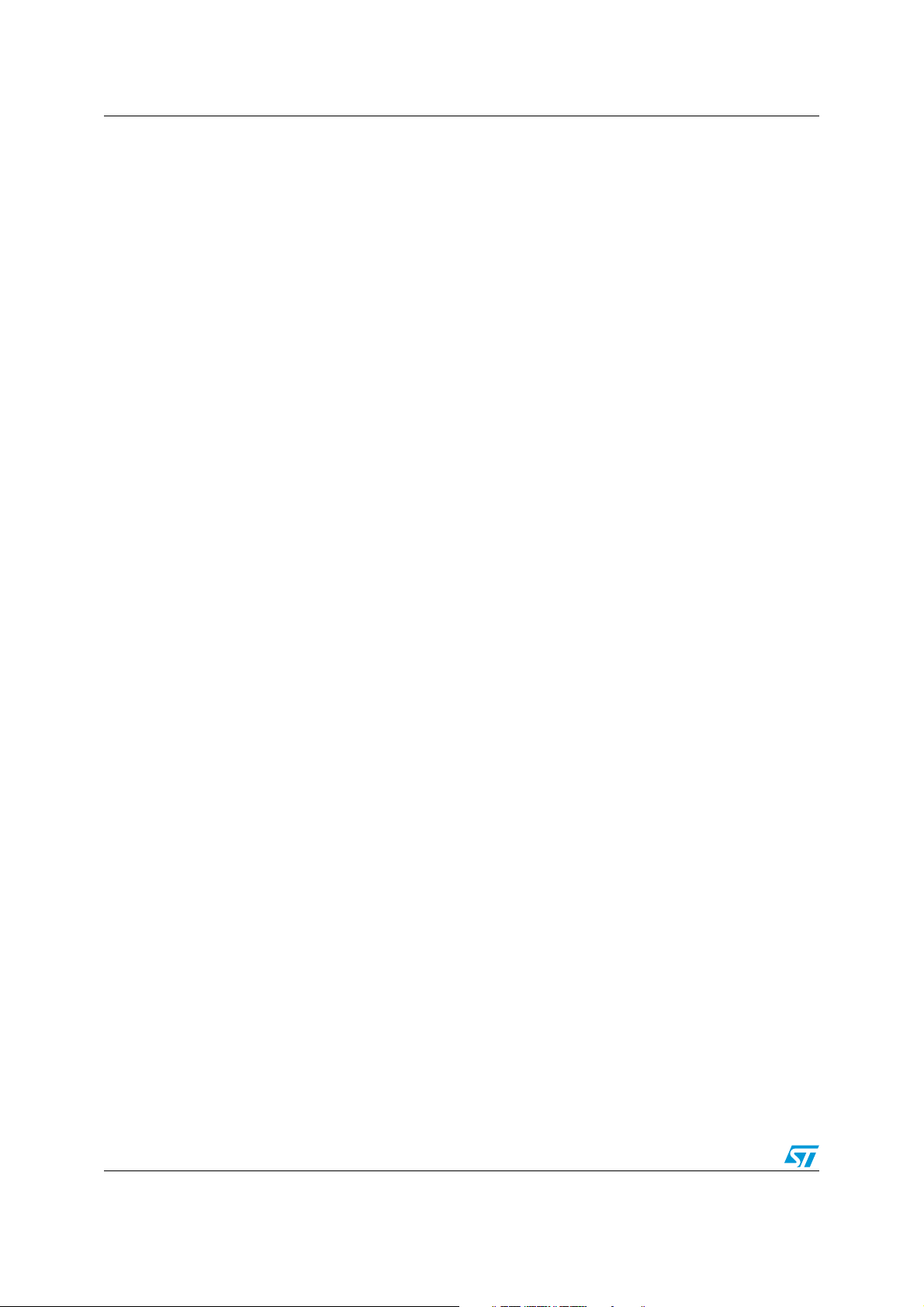

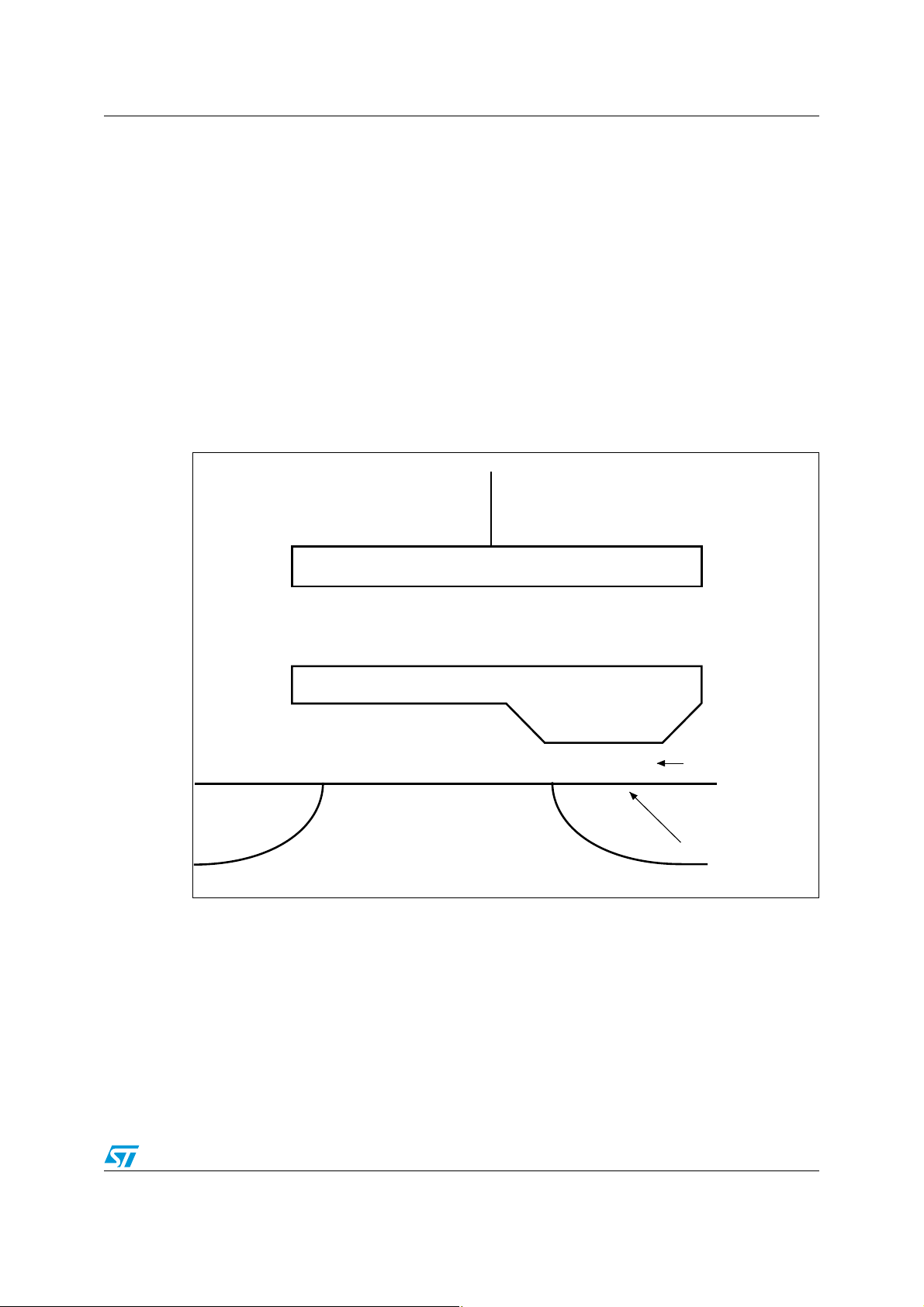

Figure 1. Structure of an EEPROM floating gate transistor, and circuit symbol

Figure 1. shows the key component of a single EEPROM cell, the floating gate transistor

(also known as a FLOTOX transistor). Figure 2. shows how it can be considered to be just

like any other type of MOSFET device. As the voltage, V

electrode, so the current flowing through the drain, I

, is increased on the Control Gate

g

, increases in proportion. For the

d

present, we can assume that this is a fairly linear relationship.

Figure 2. MOSFET-like operation

Figure 3 shows what happens if the Floating Gate can be made more negatively charged,

by filling it with extra electrons. This is used for the Erased state of the EEPROM cell.

Figure 4 shows what happens if the Floating Gate can be made less negatively charged, by

emptying it some of its normal electrons. This is used for the Written state of the EEPROM

cell.

Doc ID 10701 Rev 8 7/69

Page 8

EEPROM cell and memory array architecture AN2014

AI10228

Tunnel Oxide

Control Gate

- - - - - - - - - - - - - - - -

Source

Drain

Gate Oxide

Oxide

V

g

V

g

I

d

- - - - - -

V

th.erase

Channel Region

AI10229

Tunnel Oxide

Control Gate

+ + + + + + + + + + + + +

Source

Drain

Gate Oxide

Oxide

V

g

V

g

I

d

+ + + + +

V

th.write

Channel Region

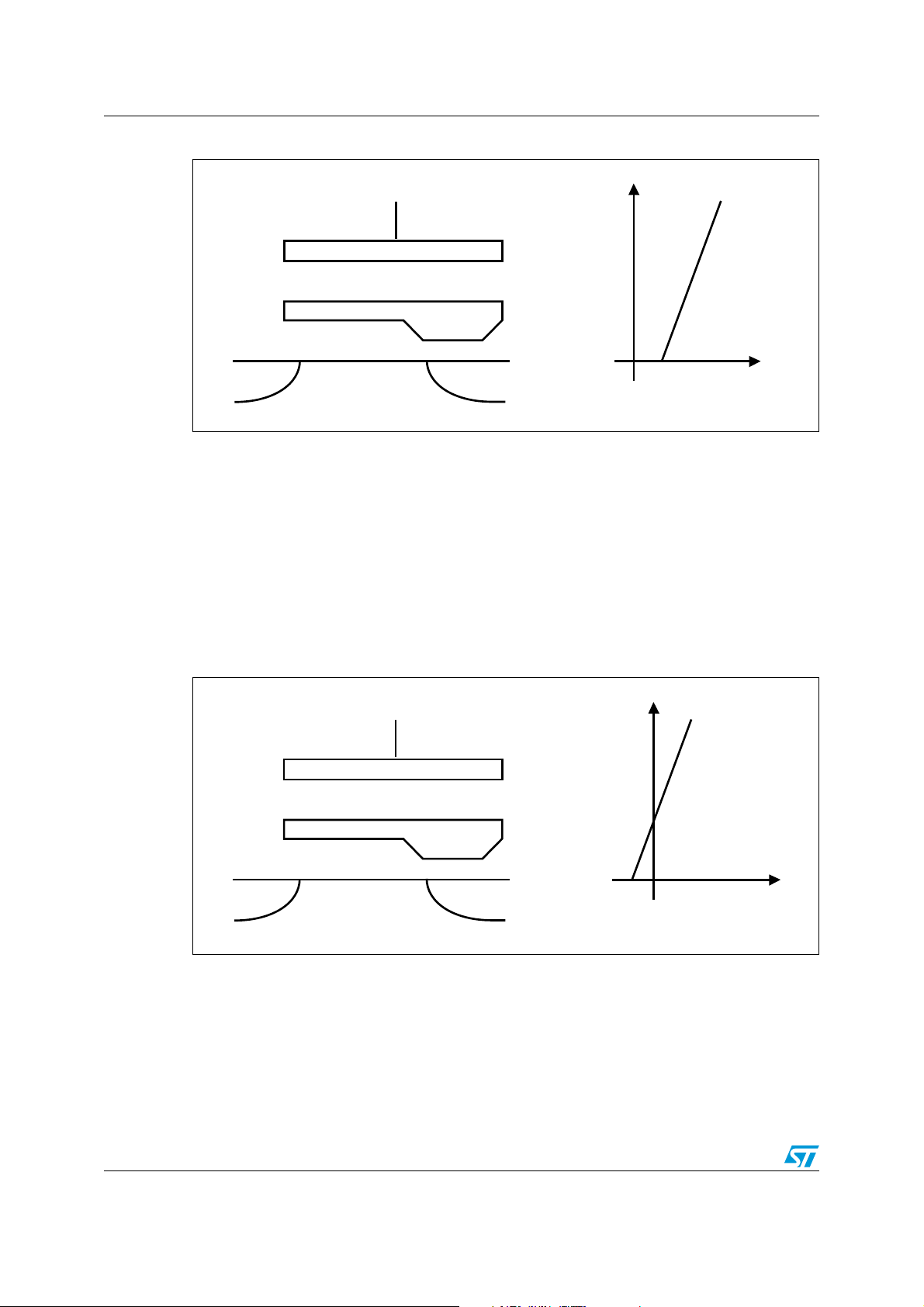

Figure 3. Floating gate reservoir full of electrons (Erased state)

1. Control Gate threshold value (V

= f(Vg) characteristic shows Id=0 for Vg<V

2. I

d

th.erase

) is positive.

th.erase

.

The effect, as viewed from the channel region of the transistor, is that the Control Gate

voltage, V

, is offset by an extra negative or positive amount. Viewed from the outside,

g

black-box electrical behavior of the device, the charge on the Floating Gate has the effect of

moving the threshold MOSFET voltage, V

, at which the linear conduction region begins. In

th

other words, a FLOTOX transistor is a MOS transistor with a variable Control Gate threshold

value, V

.

th

The Floating Gate acts as the storage element, and, being completely surrounded by

insulating oxide, as shown in Figure 1, keeps its charge even when there is no power supply.

Figure 4. Floating gate reservoir empty of electrons (Written state)

1. Control Gate threshold value (V

=f(Vg) characteristic shows Id=0 for Vg<V

2. I

d

8/69 Doc ID 10701 Rev 8

th.write

) is negative

th.write

.

Page 9

AN2014 EEPROM cell and memory array architecture

AI10234

V

g

I

d

V

g.ref

I

d.ref

I

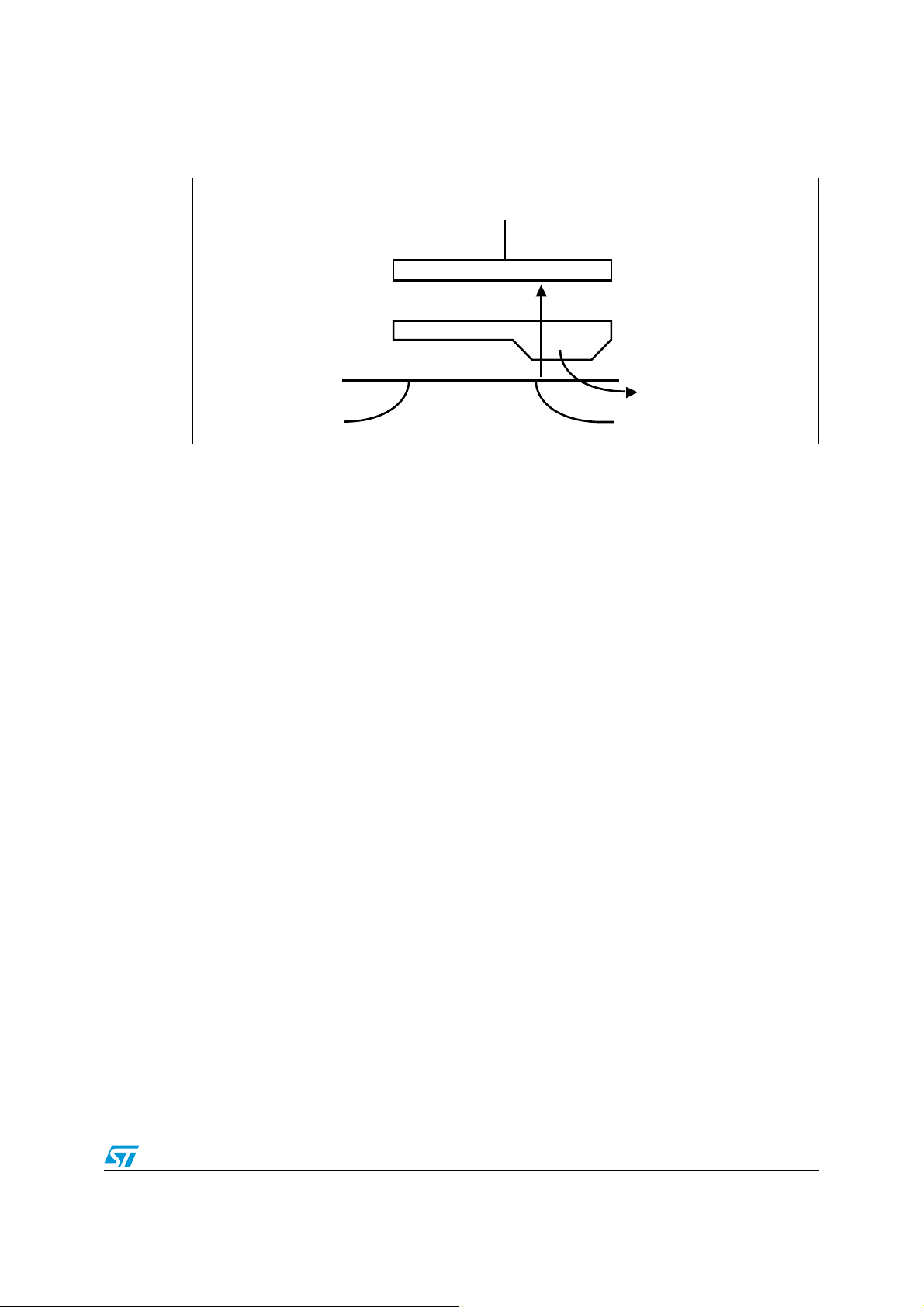

1.1.1 Reading the value stored in a memory cell

Figure 5 puts the three curves together, by way of comparison. It shows that for a given

Control Gate voltage, V

higher or lower than that of the neutral device, depending on whether the reservoir of

electrons on the Floating Gate has been filled up, or emptied. This, then, is the basis of how

the memory cell can be read.

Figure 5. Using the voltage on the control gate to determine the charge on the

floating gate

, the current that flows through the drain, Id, will be detectably

g

1. A written cell draws a current IµA (where IµA > I

); an erased cell does not draw any current (0µA).

d.ref

In most of ST EEPROM products, a predetermined biasing condition on the Control Gate

and the drain makes it possible to compare the current absorbed by the FLOTOX transistor

with a reference. Basically, with the predetermined biasing condition an erased FLOTOX cell

is not able to sink as much current as the reference (ideally the transistor is off). On the

other hand, a written FLOTOX cell sinks a current that is superior to the reference (the

transistor is on). By comparing to a reference current, the device is able to retrieve the

stored information as a digital signal on the output pins of the memory device.

Doc ID 10701 Rev 8 9/69

Page 10

EEPROM cell and memory array architecture AN2014

AI10232

Vg=+18V

Vd=0V

Electric Field

Tunneling Electrons

Control Gate

Source

Drain

Gate Oxide

Oxide

Channel Region

Floating Gate

e

-

1.1.2 Writing a new value to the memory cell

The next question, of course, is how the charge can be changed on the Floating Gate, given

that it is so well insulated by oxide, and keeps its charge even when there is no power

supply. The answer is that the Tunnel Oxide, shown in Figure 1, is very thin, and can be

used to transfer charge, when much higher voltages are applied than those normally used

during Read operations.

Filling the Floating Gate reservoir with negative charges (electrons) is called erase. After

erase, the FLOTOX transistor is in the Erased State (see Figure 3). Pulling out negative

charges from the Floating Gate is called Program. After Program, the FLOTOX transistor is

in the Written State (see Figure 4). One state is used to represent logic-0, and the other

logic-1, but the exact choice is manufacturer and product-type dependent).

Both operations use the Fowler-Nordheim tunneling effect. For this, a high electric field

(1 million V/mm, or more) is needed to make electrons pass through the thin Tunnel Oxide.

For a Tunnel Oxide thickness of 100Å, the high voltage needs to be at least 10V. In fact,

higher voltages, in the range 15 to 18V, are normally used, to reduce the time taken for the

operation. Voltages higher than this cannot be used, since they would damage the thin

Tunnel Oxide.

For erase, the cell Control Gate is made positive, and the source-drain region is grounded

(as shown in Figure 6). The electric field makes electrons move from the substrate towards

the Floating Gate, thereby filling the reservoir, and increasing the characteristic threshold

voltage of the transistor (as shown in Figure 3).

Figure 6. During erase, electrons go through the tunnel oxide into the floating gate

1. Characteristic threshold Vth increases and becomes positive as shown in Figure 3

For write, the Control Gate is grounded and the source-drain region is made positive (as

shown in Figure 7). The electric field is the opposite of that for erase, and so electrons move

out from the Floating Gate, thereby emptying the reservoir, and decreasing the

characteristic threshold voltage of the transistor (as shown in Figure 4).

10/69 Doc ID 10701 Rev 8

Page 11

AN2014 EEPROM cell and memory array architecture

AI10233

Vg=0V

Vd=+18V

Electric Field

Tunneling Electrons

Control Gate

Source

Drain

Gate Oxide

Oxide

Channel Region

Floating Gate

e

-

Figure 7. During write, electrons go through the tunnel oxide out of the floating

gate

1. Characteristic threshold decreases and becomes negative as shown in Figure 4

Typically EEPROM erase/write cycles require a high voltage of about 15 to 18V for

approximately 5ms. As EEPROM devices use a single supply voltage, the high voltage must

be generated and managed internally. A set of analog circuits is available to generate and

control the high voltage from the single external power supply:

● voltage and current references to control oscillators and timings

● a regulated charge pump that generates a stable 15 to 18V voltage, HiV, from the

single external power supply

● a ramp generator that, from the stable HiV voltage, makes the specific waveform

(shown in Figure 8) that is to be applied to the cells

V

is the high voltage that is directly applied to the FLOTOX cell, as described earlier. The

PP

precise shape of the V

voltage waveform is critical, and has a direct effect on the reliability

PP

and endurance of the memory cells. The slope, plate time and maximum level are

parameters that are very carefully controlled.

Writing new data in an EEPROM array triggers an auto-erase of all the addressed bytes,

resets them all to the Erased state, and then selectively programs those bits that should be

set to the Written state.

Doc ID 10701 Rev 8 11/69

Page 12

EEPROM cell and memory array architecture AN2014

AI10235

V

PP

5ms

t(ms)

HiV

18V

Auto-Erase

Program

Write Cycle = Auto-Erase + Program

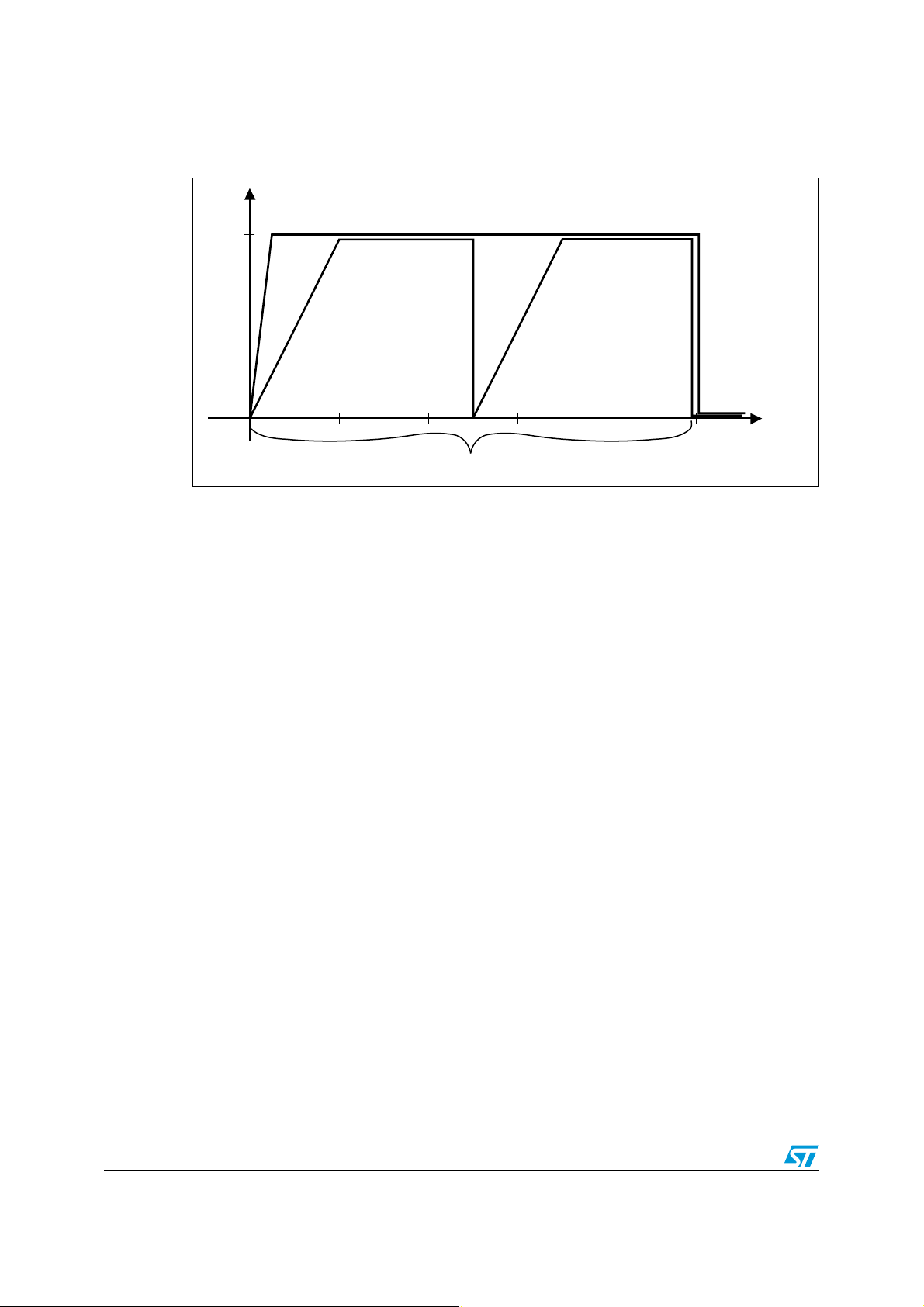

Figure 8. VPP signal applied to EEPROM cells

(HiV is the output of the charge pump)

To summarize: Binary information is coded by means of a FLOTOX transistor. The Floating

Gate is a reservoir filled with negative electric charges that modify its electrical

characteristics. The electric charges can be made to migrate into or out of the reservoir by

applying a high voltage to a thin Tunnel Oxide. The binary information is read by comparing

the cell (FLOTOX transistor) current to a reference.

12/69 Doc ID 10701 Rev 8

Page 13

AN2014 EEPROM cell and memory array architecture

AI10251

Control Gate

Source

Horizontal electric barrier

disturbing erase and write

Oxide

- - + - - -

Channel Region

+

+

Vertical electric path

leading to leakage

Gate Oxide

Floating Gate

1.1.3 Cycling limit of EEPROM cells

When a cell is cycled (repeatedly erased and programmed) two common phenomena occur

and are amplified during the memory cell lifetime. When tunneling, negative charges can

either be trapped in some imperfection of the oxide or damage the Tunnel Oxide:

1. Charge trapping

The accumulation of negative charges in the thin Tunnel Oxide creates an electric

barrier in the Tunnel Oxide. The high voltage needed for the tunneling effect becomes

even higher: programming high voltages are no more able to move enough charges to

program the cell properly. The Erased and Written states become undifferentiated.

2. Stress on oxide

When the Tunnel Oxide deteriorates, a positive charge path may appear, that facilitates

undesirable leakage through the Tunnel Oxide. The Floating Gate is no more 100%

insulated, and loses its charges, and so the data retention time drops drastically.

Figure 9. Accumulation of negative or positive charges in the tunnel oxide

Charge trapping and oxide damage are accelerated at high temperatures. They are directly

involved in cell cycling and endurance limitations.

Permanent digital information storage has to cope with physical phenomena and analog

nonlinear behaviors that have natural limits and are sensitive to wear-out and improper use

conditions.

Doc ID 10701 Rev 8 13/69

Page 14

EEPROM cell and memory array architecture AN2014

Cg-Line 0

8 Bit-Line Latches

Cg line

Bit line

Bit line

Bit line

8 Select

transistors

8 FLOTOX

transistors

Row-

Line 0

b07 b06 b00

Cg-Line i

8 Bit-Line Latches

bi7 bi6 bi0

Control

Gate

transistor

Row-

Line n

AI10224b

Column 0 Column i

Byte

Select

transistor

FLOTOX

transistor

Memory Cell

1.2 Electrical architecture of ST serial EEPROM arrays

In the previous section, the EEPROM functionality was considered at the single bit level.

We will now zoom out of the memory cell to the full EEPROM array, in order to give an

overview of the architecture of an EEPROM device.

1.2.1 Memory array architecture

An EEPROM device is made of an array of memory cells whose organization allows byte

granularity, the automatic erasing of the addressed bytes (Erased state), and the

programming of only those bits that are to be changed to ‘1’ (Written state). The array (as

shown in Figure 10) is organized as follows:

● Each memory cell consists of one Select transistor in series with a FLOTOX transistor

and each byte is made up of eight memory cells and a Control Gate transistor with a

drain that is common to the control gates of all eight FLOTOX transistors.

● Rows (in the horizontal direction) are made up of 16 bytes (or more, depending on the

memory size (the number of bytes within each row being a function of the array size).

For each row, all Select transistors and all Control Gate transistors are connected to the

Row line.

● Columns are grouped by eight bit-lines and one Cg-line. This is then repeated as many

times as the number of bytes in a row.

● A bit-line is common to all the drains of the Select transistors of each memory cell in the

column. A Cg-line is common to all the sources of the Control Gate transistors of the

column.

Figure 10. Architecture of the memory array (showing the grouping in bytes)

14/69 Doc ID 10701 Rev 8

Page 15

AN2014 EEPROM cell and memory array architecture

AI10225

Address Shift Register

Column

Decoder

Bit-line and Cg-line Latches: RAM Buffer

Row

Decoder

Array

Cg-lines and Bit-lines

Row-lines

Read/Write Analog

Voltages

Serial Input

MSB Address Bits LSB Address Bits

1.2.2 Decoding architecture

To address a single byte in a full array, decoding circuits are necessary. One logical address

is associated with one byte location. The address bits are inserted serially into a Shift

Register. Then, with parallel output, the decoding structures receive all of the bits at the

same time, to perform the decoding and addressing. The row decoder decodes and brings

correct biasing to a single row line. As one or more bytes of the same row can be

programmed at the same time, the column decoder decodes one or more column(s), and a

RAM buffer memorizes the data to write, and enables the right path for Cg-line and Bit-line

biasing.

Figure 11. Decoding block diagram

1.2.3 Intrinsic electrical stress induced by programming

Whatever kind of data must be programmed and whether the request is made by byte or

page, all high-voltage circuits are stressed by HiV (a high voltage ranging between 15 and

18V). In particular, the internal nodes of the charge pump can see voltages equal to

HiV + V

regulation, decoding, latches) are submitted to higher stress than active low voltage

transistors. The overall time during which the high voltage circuits are active is relatively

short compared to the product lifetime (10ms x 1Mcycles = 10000 seconds => less than 3

hours).

A standard ST EEPROM device has a few hundred high voltage transistors, for low memory

density products (1Kbit). This number can rise to a few thousand for high memory density

products (1Mbit).

Consider, by way of example, the stress induced on the array elements when programming

one single byte in a 1Kbit EEPROM, organized as 128 x8 bit. The memory array is

composed of 8 pages (or rows) of 16 bytes (or columns).

(that is as much as 23 V). All circuits that receive and carry HiV (ramp generator,

CC

Doc ID 10701 Rev 8 15/69

Page 16

EEPROM cell and memory array architecture AN2014

Erase cycle: the complete row (page) that contains the addressed byte receives the VPP

signal, on the selected Row-line, as does the complete column, on the selected Cg-line:

● Control Gates of all the Select transistors in the given row: 1 row x 16 bytes x 8 bits

=128

● Control Gates of all the Control Gate transistors in the given row: 1 row x 16 bytes = 16

● Drains of all the Control Gate transistors that are connected to the given Cg-line: 1

column x 8 rows = 8

The Bit-lines of the addressed bytes are floating.

Write cycle: the complete row (page) that contains the addressed byte receives the V

PP

signal, on the selected Row-line:

● Control Gates of all the Select transistors in the given row: 1 row x 16 bytes x 8 bits

=128

● Control Gates of all the Control Gate transistors in the given row: 1 row x 16 bytes = 16

● The Cg-line of the addressed byte is held at ground voltage

● The Bit-lines are left floating or receive V

case is when FFh is to be written, and all Bit-lines receive the V

● Drains of all the Select transistors sharing the same 8 Bit-lines: 1 column x 8 rows x 8

depending on data to be written. The worst

PP

PP

signal

bits = 64

This example shows how one single byte, being erased or programmed, incurs a lot of High

Voltage stress on elements that are on the same row, column and bit-line as the one

addressed. For a 1Kbit EEPROM, programming one single byte to FFh induces stress on

128 Select transistors and 24 Control Gate transistors during auto-erase, and 192 Select

transistors and 16 Control Gate transistors during the write cycle, even though only 17

transistors (8 Select transistors, 8 FLOTOX transistors, 1 MOS transistor) were really being

addressed for the data change.

The bigger the memory array, the larger the number of additional transistors that are

involved. This is why when high cycling performance is required, it is recommended to

gather cycled data in contiguous blocks and use the write page mode as much as possible.

16/69 Doc ID 10701 Rev 8

Page 17

AN2014 Choosing a suitable EEPROM for your application

2 Choosing a suitable EEPROM for your application

ST "Automotive Grade" EEPROM products are made to meet automotive’s stringent

requirements. They are produced by a longstanding process and benefit from being tested

continuously for quality as well as specific test strategies like Statistical Bin Limits,

Parametric Average Testing and qualification following the AEC Q100, specific product

buffer stocks, etc.

Nevertheless, the reliability on EEPROM products are also closely linked to the way they are

designed in Applications.The aim of this part of the document is to provide our automotive

customers with a set of practical recommendations for achieving immediate improvements

in application reliability and robustness.

In the case of automotive applications, ST strongly recommends the use of products that

are classified as automotive grade. These devices are designed to satisfy the most stringent

requirements of automotive, sensitive and safety applications. "Grade 3" and Automotive

Grade EEPROMs are tested with STMicroelectronics’ High Reliability Certified Flow

(described in Quality Note, QNEE9801) insuring a very high level of quality.

2.1 Choosing a memory type suited to the task to be performed

EEPROM devices are particularly suited to the tasks of code traceability and parameter

storage. The Serial protocol offers the best compromise of performance versus cost where

the access time is not critical.

2.2 Choosing an appropriate memory interface

ST is specialized in Serial Access EEPROMs, which are based on three main protocols: I²C,

SPI and MICROWIRE (see Ta bl e 1 ).

Fundamental requirements such as noise immunity, ESD, latchup and cycling Endurance

are basic features of each ST Serial EEPROM device (independent from the protocol used).

The choice of the most appropriate Serial EEPROM depends mainly on the hardware

resources of the master and on the architecture built around it. See the following:

● The I

● The SPI bus and MICROWIRE bus are 4-wire protocols allowing higher communication

Data Write protection is different for each protocol family and is also a key factor when

selecting the memory interface. I

and MICROWIRE products provide both hardware and software protection. Refer to

Section 5.3: Write protection.

2

C bus offers a 2-wire protocol working at a maximum clock rate of 400 kHz and

so, is preferred when the hardware resources are limited and the data rate is not a

constraint at all. The multiple slave configuration requires no extra hardware and is

managed by software.

speed (speed is determined by each manufacturer design and technology). The

number of slaves is unlimited but each slave requires an additional master resource for

the chip select line. Both SPI and MICROWIRE can be used with only 3 wires providing

that the D and Q pins are tied together to a bidirectional I/O.

2

C products offer only hardware Write protection while SPI

If none of the standard products exactly meets all the requirements to produce an

Application Specific Memory (as described in AN1292), customizing is also possible.

Doc ID 10701 Rev 8 17/69

Page 18

Choosing a suitable EEPROM for your application AN2014

Table 1. Three serial bus protocols

I2C SPI MICROWIRE

®

ST Families M24Cxx, 1 Kb to 2 Mb M95xxx, 1 Kb to 2 Mb

Interface 2 wires: Single I/O line, clock

Clock Rate

(max)

Data

Management

Specific

Features

Page: 16 bytes to 256 bytes

Up to 8 devices cascadable

1 Mb/s Up to 20Mb/s 2 Mb/s

Byte

Global write control

on the same bus

4 wires: data in, data out,

clock & CS

Byte

Page: 16 bytes to 256 bytes

Hold mode (input pin)

Write control for 4 blocks

M93Cxx, 1 Kb to 16 Kb

M93Sxx, 1 Kb to 4 Kb

4 wires: data in, data

out, clock & CS

Byte or word

Page: 4 words

Block write protection

defined by software for

M93Sxxx family

2.3 Choosing an appropriate supply voltage and temperature range

These are essential parameters that will define the device reliability when operating in the

application. The V

within the limits defined in ST datasheets.

values and the temperature values of the application must always stay

CC

18/69 Doc ID 10701 Rev 8

Page 19

AN2014 Recommendations to improve EEPROM reliability

3 Recommendations to improve EEPROM reliability

3.1 Electrostatic discharges (ESD)

ESD damage can happen any time during the product lifetime, from the moment it is

delivered to the final field service operation. ESD damage can be destructive or latent. In the

first case, a simple functional test can screen faulty devices; in the second case, the part is

partially damaged and may be able to operate correctly, but its operating life may be

drastically reduced, causing the device to fail prematurely in field service.

3.1.1 What is ESD?

Static Electricity results from the contact and separation of two bodies, which creates an

unbalance in the number of electrons at the surface of the bodies. Practically, the bodies

become charged to a specific electrical potential that depends on the material from which

they are made (see Tab l e 2 ). An electrostatic discharge is defined as the transfer of charges

between two bodies at different electrical potentials. It is instantaneous (a few nanoseconds)

and thus induces high energy peaks which are very difficult to control and predict.

3.1.2 How to prevent ESD?

An ESD can be managed if the discharge is driven through a known and controlled path on

the silicon die. Specific design rules and techniques can be used by designers to better

protect against ESDs, such as Faraday shields, perimeter ground lines or ground planes.

In a production line, the part handling until the assembly line has to be carefully ESDprotected.

Table 2. ESD generation

ESD generation means Static voltage levels

Walking across a carpet 1 500 V to 35 000 V

Worker on a bench 100 V to 6 000 V

Chair with Urethane Foam 1 500 V to 18 000 V

1. The charge unbalance depends on many factors such as the contact area, separation speed and relative

humidity.

(1)

3.1.3 ST EEPROM ESD protection

ST EEPROM devices offer a specific protection circuit against Human Body Model ESDs of

up to at least 3000 V in non-operating mode (in accordance with AEC-Q100-002).

During write operations, the EEPROM is much more sensitive to ESDs because of the

architecture of its internal high voltage generator. Applications exposed to ESD should avoid

writing data in the EEPROM when an ESD is more likely to occur.

Doc ID 10701 Rev 8 19/69

Page 20

Recommendations to improve EEPROM reliability AN2014

3.2 Electrical overstress and latchup

Electrical overstress (EOS) and latchup are also damaging stresses that are either

immediately destructive, or may create latent defects leading to premature failure.

3.2.1 What are EOS and latchup?

In comparison with ESDs, EOS and latchup are lower-intensity events that last much longer

(sometimes more than a few seconds). That is why the energy induced by an EOS is higher

than the ESD energy. EOS and latchup induce current injections inside the EEPROM when

an overvoltage stress is applied on one or more package pins. Latchup occurs when a

charge injection triggers the I/O parasitic thyristors (also called SCR) thus generating a very

high current between V

turned off.

3.2.2 How to prevent EOS and latchup events

Typically power supply cycling leads to EOS situations. During the power-up and powerdown phases, the EEPROM I/Os interfaced with other ICs may temporary see voltages

greater than V

biasing conditions may lead to positive and negative current injections, respectively. This

kind of stress cannot always be completely prevented but it can be minimized. The switching

sequence of the different interfaced ICs must be carefully determined, and if necessary

protection resistor (<1K

(<50

Ω) to limit eventual latchup current. Please refer to Section 4: Hardware considerations

for more details.

or lower than VSS. When outside Absolute Maximum Ratings, these

CC

and VSS. This phenomenon lasts until the VCC power supply is

DD

Ω) can be placed on critical pins or sometimes directly on V

CC

pin

Overshoots and undershoots may occur on external device pins when the application is

running. They can be generated by radiations, power supply disturbances or even some ICs.

The very first protection is provided by the semiconductor manufacturer (ST) which offers

the best possible robustness against EOS and latchup. If extra protection is needed, the

application designer can add small value resistors (<1kΩ) in series on all interfaced lines

and (<50Ohm) in series on VCC line so that it can be compatible with the communication speed

constraints and power supply range. Please refer to the Hardware considerations section for

more details.

Manufacturing and handling devices are also sources of EOS: all voltage levels applied to

the device must be checked accurately and regularly. In addition all equipment should be

constantly calibrated.

During write operations, an EEPROM device is more sensitive to overvoltages on its power

supply pin because the internal high voltage generator is directly fed by the voltage applied

to the power supply pin.

20/69 Doc ID 10701 Rev 8

Page 21

AN2014 Recommendations to improve EEPROM reliability

Ai11084b

SCR is switched on by an external

stress coming from an I/O pin.

5V

V

CC

V

SS

Latch up risk minimized

R

P

<50Ω

RP<1KΩ

SRC

5V

V

SS

V

CC

I/O

EEPROM

I or V stress

SRC

I/O

High current(often destructive)

Fail

ai10858

Fail

Current Injection

100mA

−100mA

Good = Class A

Good = Class A

−0.5 x V

CC

max

1.5 x V

CC

max

Overvoltage

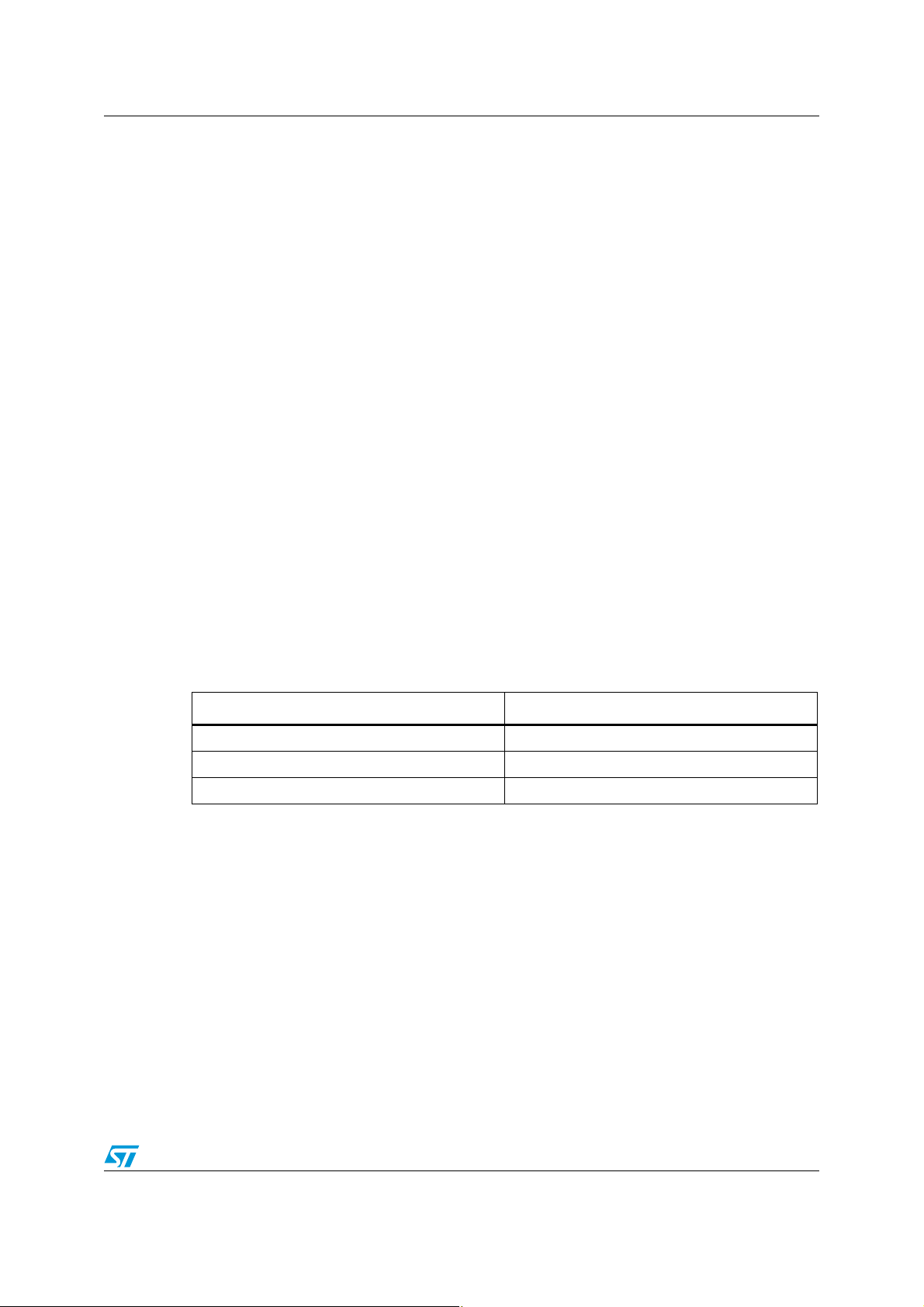

Figure 12. Latchup mechanism and protection

1. Protection is only recommended if latchup risk is identified.

3.2.3 ST EEPROM latchup protection

During the qualification process, samples from three different lots are tested for voltage

overshoots (positive and negative injections). Figure 13 shows the levels of stress applied to

the tested devices.

Figure 13. Latchup test conditions

1. The device does not latch up within the gray areas.

Doc ID 10701 Rev 8 21/69

Page 22

Recommendations to improve EEPROM reliability AN2014

V

POR

VCCmin

V

CC

max

Monotonous rising slope

slower than 1 V/µs

Part locked

by POR

Standby

mode

Operation allowed

time

ai10859b

Voltage

3.3 Power supply considerations

The power supply also has a major impact on the operating reliability of the EEPROM

device.

3.3.1 Power-up and power-on-reset sequence

During power-up, in order for the internal EEPROM reset to be performed correctly, the

application designer has to make sure that the V

monotonously, with a maximum slew rate of 1 V/µs, from V

supply value.

In ST EEPROM devices, the POR (power-on-reset) circuit is activated first as it locks the

part before the internal logic is able to run: at power-up, the device does not respond to any

instruction until V

passes the V

POR

has reached the power-on-reset threshold voltage, V

CC

threshold, the device is reset, in Standby Power mode, but the application

designer should make sure that no instruction is issued to the EEPROM until the power

supply has reached a stabilized value of V

CC

Before a controlled power-down sequence (continuous decrease in V

be placed in the Standby Power mode.

If, for some uncontrolled reason, the power supply drops, it is recommended to carry out a

safe power-down sequence by pulling V

to 0 V, and then to perform a safe power-up

CC

sequence, as described previously. This will secure the device re-initialization.

supply voltage waveform rises

CC

to the final stabilized V

SS

. When VCC

POR

max > VCC > VCCmin (see Figure 14).

), the device must

CC

CC

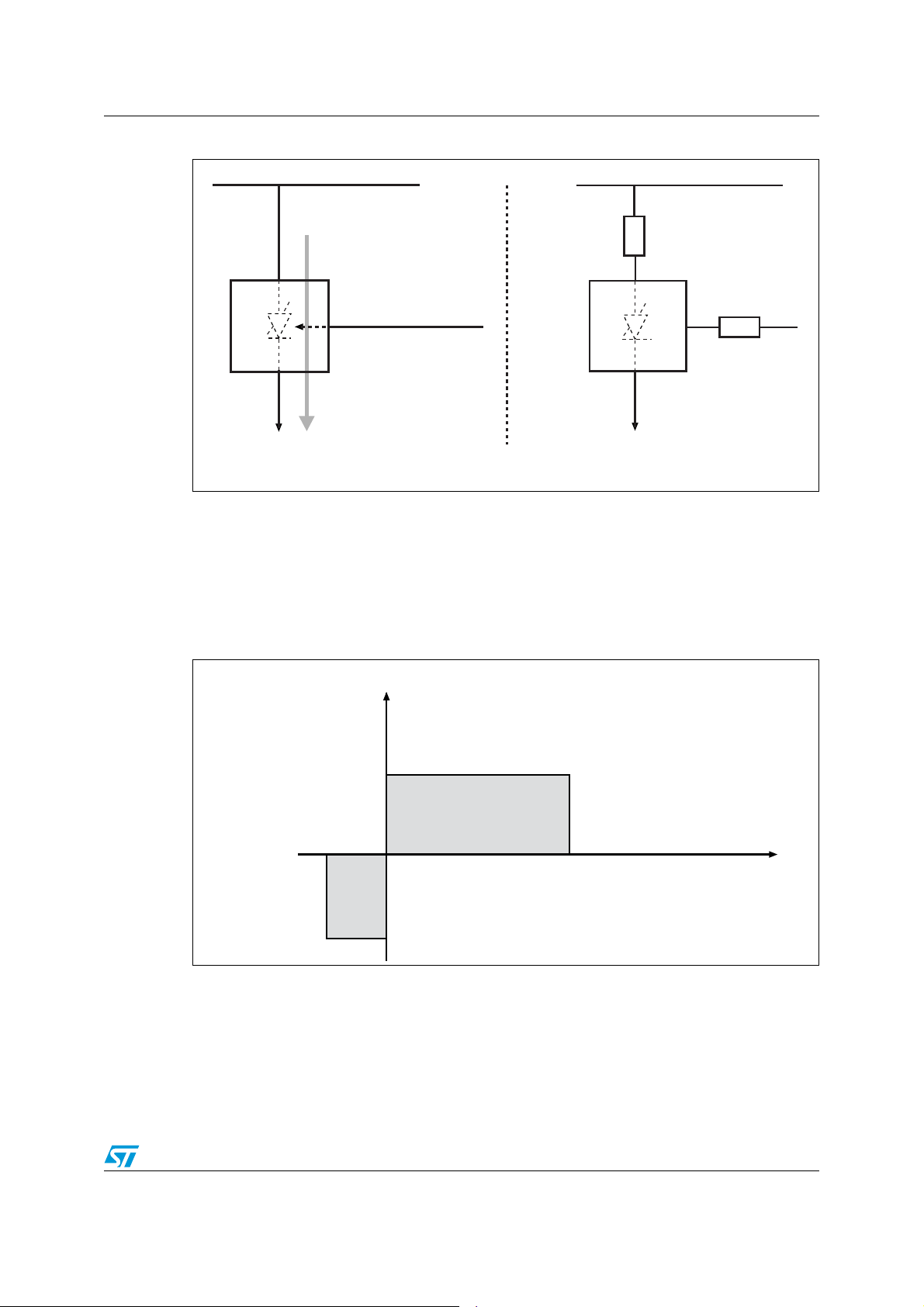

Figure 14. Power-up

1. Power-up is safe with a monotonous rising slope slower than 1V/µs.

Table 3. Typical POR threshold values

Bus protocol I²C SPI MICROWIRE

Device voltage range All 5 V

POR threshold limits

over the whole

temperature range

22/69 Doc ID 10701 Rev 8

1V ± 0.5V 3V ± 0.5V 1V ± 0.5V 3 V ± 0.5 V 1V ± 0.5V

Other Device

Ranges

5 V

Other Device

Ranges

Page 23

AN2014 Recommendations to improve EEPROM reliability

Voltage supply

EEPROM device

Ai11064b

VCC

V

SS

10 nF < C < 100 nF

50 Ω

3.3.2 Stabilized power supply voltage

The value of the stabilized power supply voltage, including potential variations, must always

stay within the operating V

reliable and guaranteed. Application designers deal mostly with transient peak currents and

voltages. Transient peak current generated by EEPROM during read, write and output buffer

transitions induces transient voltage disturb on power supply lines. Therefore, the use of

high-frequency, low-inductance capacitors located as close as possible to the device V

and V

pins are also recommended. Some applications with a limited power supply driving

SS

capability may require a small value resistor (<50 Ω) connected to the EEPROM V

that the peaks of current sunk by the EEPROM during the write cycle (10 mA typical during

a few nanoseconds, with a duty cycle of less than 1/100) are mostly supplied by the

decoupling capacitor and so, induce less disturbance on the voltage supply line of the

application. See Figure 15.

Figure 15. Local EEPROM supply filtering

range specified in the datasheet, where device operation is

CC

pin, so

CC

CC

1. Capacitor should be placed as close as possible to VCCand VSS pins to avoid parasitic inductive effects.

2. Resistor must never be placed between the decoupling capacitor and the V

3.3.3 Absolute maximum ratings

Absolute maximum ratings are not operating values for the device. They provide an

additional security margin for temporary operating deviations. Temporary operation within

this margin will not cause the device to be damaged. However, the normal operation of the

EEPROM is neither guaranteed nor reliable under absolute maximum rating conditions that

are above or below normal operating conditions.

Doc ID 10701 Rev 8 23/69

pin of the EEPROM.

CC

Page 24

Hardware considerations AN2014

4

4

2

0$

)TYP!

AT6##6

6

##

%3$%/30ROTECTION

%IPIN

AID

4 Hardware considerations

EEPROM connections are essential for an application’s robustness. During Power up,

Power down and Application Reset, input signals must be fully controlled to avoid hazardous

behavior or random operation. For each product family a good hard-wiring design can

protect the parts from uncontrolled behavior.

4.1 I2C family (M24xxx devices)

4.1.1 Chip enable (E0, E1, E2)

The Chip Enable (E0, E1, E2) inputs have an internal pull-down resistor. It is thus possible to

have the three Chip Enable inputs unconnected (Chip Enable address is then decoded as

‘000’). However, this configuration should be avoided since inputs are still prone to antennalike pick-up or other cross coupling effects.

To achieve a robust design, Ei inputs must not be driven dynamically but must be directly

tied to V

The input leakage current on Ei pins depends on the input voltage value (see Ta bl e 4 ).

or VSS.

CC

Figure 16. Chip Enable inputs E0, E1, E2

Table 4. Connecting the Ei inputs of I²C products

I²C products 1 Kbits to 16 Kbits

Typical internal E0, E1, E2 pulldown resistance (RPD)

Input leakage I

of Ei pins

li

Recommended connection of Ei

pins

30 kΩ 100 kΩ 50 kΩ

Ili = 0 for VEi > V

Ili = VEi/RPD for 0 < V

Direct connection to V

32 Kbits to 128

Kbits

CC

256 Kbits to 512

IH

< V

Ei

IH

or V

SS

Kbits

24/69 Doc ID 10701 Rev 8

Page 25

AN2014 Hardware considerations

Ai11088

SDA pad

ESD/EOS Protection

RC Filter

Schmitt trigger

Open-drain Resistor

INPUT

OUTPUT

4.1.2 Serial data (SDA)

The Serial Data (SDA) input/output is a bidirectional signal. The SDA pin is internally

connected to a CMOS Schmitt trigger input buffer and an open drain output transistor (see

Figure 17.). The SDA line must be pulled to the V

(R

). The value of the pull-up resistor depends on capacitive load of SDA line, Master and

PU

EEPROM I/O buffer characteristics. See Ta bl e 5 for calculation rules.

The input pin leakage is negligible (typically a few nA). The input schematic (including

protection circuit) does not offer any open path to the V

can be set before the EEPROM power up and remain high even after Power Down with no

risk of leakage or EOS.

Figure 17. Serial Data input/output SDA

of the device with a pull-up resistor

CC

or VCC therefore the SDA level

SS

Table 5. Calculation rules for pull-up resistor on SDA

Maximum R

Minimum R

1. The smaller RPU, the faster the clock frequency. The higher RPU, the lower the operating current, the

slower the transitions and the lower the electromagnetic interference.

2. Refer to the "Maximum R

PU

PU

value Vs. Bus capacitance" figure in I2C datasheet

L

RPU x C

- V

(V

CC

< SDA rise time (I

load

Maximum value of:

IL EEPROM/IOL Master

(1)

2

C specification is 300ns)

, V

- V

CC

IL Master/IOL EEPROM

(2)

)

Doc ID 10701 Rev 8 25/69

Page 26

Hardware considerations AN2014

4

2

05

6

##

3$!,INE

%%02/-$EVICE

,OWIMPEDANCEPATH2PU

DOESNOTLIMITTHECURRENT

!IB

-ASTERPUSHPULL

OUTPUTBUFFER

2

3

./42%#/--%.$%$3$!"53#/..%#4)/.

Figure 18. SDA bus conflict with push-pull buffers (NOT RECOMMENDED)

1. RS > VCC/IO with IO = min(Master IOH, EE IOL). Without the RS resistor the current is limited by the Master

buffer and transistor T2 producing overstress at both Master and EEPROM side.

On the Master side, the SDA line should be connected to an open drain output. The Master

SDA output must not be a push-pull buffer as this would lead to a conflict when the Master

drives high SDA line and when the EEPROM drives low the SDA line (this induces a high

current between the power supply of the Master and the ground of the EEPROM device).

This event occurs each time when the I

2

C device acknowledges an instruction from the

Master (see Figure 18).

4.1.3 Serial clock (SCL)

The Serial Clock (SCL) input is connected to a CMOS Schmitt trigger input buffer. In

applications with a multiple master configuration, the master must have an open drain output

with an external pull-up resistor. In applications using a single master configuration, SCL

line can be connected to a push-pull buffer. For a safe design, the SCL line must never be

left floating (Hi-Z) and must be driven low when SDA transitions are not under control to

avoid undesired START and STOP conditions. As a consequence, Power up, Power down

phases as well as Reset states, can be secured using a pull-down resistor on the SCL line.

This will minimize the chances of a parasitic STOP/START condition, when the controller

releases the I

The input pin leakage is negligible (typically a few nA). Input schematic (including a

protection circuit) does not offer any open path to V

set before the EEPROM power up and can remain high even after power down with no risk

of high leakage or EOS.

2

C bus.

or VCC. Therefore SCL level can be

SS

26/69 Doc ID 10701 Rev 8

Page 27

AN2014 Hardware considerations

Ai11725

SCL pad

ESD/EOS Protection

Glitch Filter

Schmitt trigger

100ns

WC pin

ai10916b

T

1

T

2

R

PD

I typ = 2.5µA

at VCC = 5V

V

CC

ESD/EOS Protection

Figure 19. Serial Clock input SCL

4.1.4 Write control (WC)

The Write Control (WC) input includes an internal pull-down resistor, in case the application

designer leaves it floating (See Figure 20). If no write protection is necessary, it should be

directly tied to the V

input to a Master output and a pull-up resistor to V

write protection also during the critical Power-up, Power Down and Application Reset phase.

Prior to issuing any Write instruction the WC

maintained Low during the whole operation.

Input pin leakage current depends on input pin voltage. See Tab le 6 .

. The best write protection is obtained by connecting the Write Control

SS

(see Figure 22), thus allowing a default

CC

pin should be driven Low and it should be

Figure 20. Write Control input (WC

)

Doc ID 10701 Rev 8 27/69

Page 28

Hardware considerations AN2014

R

PD

R

PURPD

+

---------------------------- - 0.7≥

R

PU

3R

PD

×

7

-------------------- -<

Table 6. Connecting WC inputs in I2C products

I²C 1 Kbit to 16 Kbits 32 Kbits and more

WC

internal pull-down resistance

(RPD)

(1)

Condition:

15 kΩ 30 kΩ

External pull-up (R

inputs not connected (left

WC

floating)

PU

)

Therefore:

is read as “0”

WC

Ili = 0 for Vi = 0V

Input leakage I

1. These pull-down values can change within the range authorized in the datasheet without previous notice.

li

Ili = Vi/RPD for 0<Vi<V

lli < 5µA for Vi > V

IH

IH

28/69 Doc ID 10701 Rev 8

Page 29

AN2014 Hardware considerations

6

##

%

%

%

6

33

)#%%02/-

6

##

7#

3#,

3$!

'.$

2

,

2

,

N&

6

33

6

##

-36

-ASTER

)#BUS

6

##

)#%%02/-

'.$

K٪

22

,

2

,

%

%

%

6

33

6

##

7#

3#,

3$!

N&

6

33

6

##

-36

-ASTER

)#BUS

4.1.5 Recommended I2C EEPROM connections

Recommended I²C EEPROM connections are shown in Figure 21 and Figure 22. Note that

for both circuits:

1. The decoupling capacitor (10 nF min) must be placed as close as possible to the

package pins V

2. A pull-up resistor should be used only when the WC

unused, the WC

3. The I

2

C specification recommends to connect 220-Ohm serial resistors on SCL and

SDA. They are not useful unless identified overstress is liable to occur on these pins or

electromagnetic disturbances must be reduced.

Figure 21. Recommended I²C connections – safe design

and VSS.

CC

pin is driven by a Master I/O. If

pin must be connected to ground or left floating.

1. The pull-up resistor RL value must be large enough for the I²C master bus to pull WC low (current sink

capability of the I²C master bus I/O).

2. E0/E1/E2 must be connected either to V

or to GND.

CC

Figure 22. Recommended I²C connections – robust design

1. E0/E1/E2 must be connected either to VCC or to GND.

2. The use of external pull-up and pull-down resistors is strongly recommended even if the Master I/Os for the

2

C bus are already providing them. Please refer to Section 6.1.1 for more details.

I

Doc ID 10701 Rev 8 29/69

Page 30

Hardware considerations AN2014

-36

(OLD3#$

%3$%/30ROTECTION

3CHMITT4RIGGER

4.2 SPI family (M95xxx devices)

4.2.1 Chip Select (S)

Chip Select (S) is a CMOS Schmitt trigger input buffer.

For safe design, Chip Select (S

V

outside the communication slots. It is strongly recommended to add a pull-up resistor to

CC

) must never be left floating, and must be constantly held at

ensure a high level on the Chip Select pin at any time and in particular during power-up,

power-down and during the reset phase of the master, since, during these phases, the

master usually leaves its I/Os in high impedance. The pull-up resistance should be

calculated as a function of the bus capacitive load so that the voltage on the S

remains above V

= 0.7VCC during power-up.

IH

pin always

The input pin leakage is negligible, typically a few nA. The input schematics, including the

protection circuit, does not offer any open path to the V

or VCC.

SS

Note: To filter out wrong selections, the M95xxx devices are internally selected only when the

following two conditions are met: S

falling edge and S remains low.

Figure 23. Chip Select, Clock, Data, Hold input pins

4.2.2 Write Protect (W)

The Write Protect (W) signal is a CMOS input used to enable or disable Write protection. To

ensure write protection at Power-up and Power-down, its default state should be low. It is

therefore recommended to add a pull-down resistor (which value must be smaller than the

pull-up resistor on S

the SPI bus in high impedance (power-up, power-down and Master reset phases). In this

case the Write Protect (W

time constant of the W

resistor, see Section 4.2.6: Recommended SPI EEPROM connections), thus preventing the

potential execution of an ongoing write command (Write to memory for 1 Kbit to 4 Kbit SPI

devices and Write Status Register for SPI devices of density above 8 Kbits).

The input pin leakage is negligible, typically a few nA. The input schematic, including the

protection circuit, does not offer any open path to V

30/69 Doc ID 10701 Rev 8

line), to optimize write protection in cases where the controller releases

) line goes low before the Chip select (S) line goes high (since the

pull-down resistor is smaller than the time constant of the S pull-up

or VCC.

SS

Page 31

AN2014 Hardware considerations

Ai11066

W pin

ESD/EOS Protection

Figure 24. Write Protect input W

4.2.3 Serial Data input (D) and Serial Clock (C)

The Serial Data Input (D) and Serial Clock (C) signals are connected to a CMOS Schmitt

trigger input buffer and should be controlled by push-pull buffers (from the SPI master bus).

An external pull-down resistor on Serial Clock (C) signal will prevent “out-of-specification”

configurations like simultaneous rising edges on S

bus (violation of the t

SHCH

and t

timings). An external pull-down resistor on the Serial

CHSH

Data Input (D) (see Figure 27: Recommended SPI connections - robust design) will optimize

the signal control and the device standby current.

and C when the Master releases the SPI

The pull-down resistor value on C is optimized if its value is larger than the pull-up resistor

value on the Chip Select (S

) line. In this case, if the SPI bus is released, the Chip Select (S)

line goes high faster than the Clock (C) line goes low and so deselects the device before the

Clock signal crosses the input buffer trigger point (around V

CC

/2).

The input pin leakage is negligible, typically a few nA. The input schematic, including the

protection circuit, does not offer any open path to the V

or VCC.

SS

Note: If the Clock (C) line cannot be pulled down (and must be pulled up due to other system

constraints), it is recommended to choose a weaker pull-up resistor value (at least three

times weaker) than the pull-up resistor value on the Chip Select (S

of-specification" configuration can also be minimized by connecting the Hold (HOLD

) line. Moreover, the "out-

) pin to

the reset signal (active low) of the Master: if the Master leaves the SPI bus in high

impedance, the Hold (HOLD

) line goes low, locking the Clock to a low level (if already low),

thus preventing the occurrence of a rising edge on both the Clock and Chip Select lines (this

prevents the violation of the t

CHSH

and t

SHCH

timings).

4.2.4 Hold (HOLD)

The Hold (HOLD) is a CMOS Schmitt trigger input buffer used to pause communication. It

should be driven by a push-pull buffer (SPI master bus) for a better timing control, or tied

directly to V

before the EEPROM power up and can remain high after power down. The Hold

not sink a current even if a voltage higher than V

The input pin leakage is negligible, typically a few nA. The input schematic, including the

protection circuit, does not offer any open path to the V

Select, Clock, Data, Hold input pins).

if unused. The hold pin cannot be left floating. The Hold input can be set

CC

input will

is applied to it.

CC

or VCC (see Figure 23: Chip

SS

Doc ID 10701 Rev 8 31/69

Page 32

Hardware considerations AN2014

Ai11067

Q pin

ESD/EOS Protection

1

0

4.2.5 Serial Data output (Q)

The Serial Data Output (Q) is a push-pull tri-state output buffer. The Serial Data Output

being often in the high impedance state and connected to a master input pin, it may be

useful to connect it to a pull-up (or pull-down) resistor to set a default value on the bus and

thus prevent the master input from toggling (see Figure 23: Chip Select, Clock, Data, Hold

input pins). Application designers must be aware that connecting several devices on the

Serial Data Output (Q) increases capacitive load of the line. The access time of the device is

tested with a 100 pF or 30 pF capacitive load, depending on the clock frequency (refer to the

M95xxx device datasheet for the values of the capacitive load and clock frequency).

Figure 25. Output pin tri-state buffer

32/69 Doc ID 10701 Rev 8

Page 33

AN2014 Hardware considerations

6

##

3

1

7

6

33

30)%%02/6

##

(/,$

#

$

'.$

N&

6

##

2

05

6

33

-36

2

0$

-ASTER

30)BUS

6

##

3

1

7

6

33

30)%%02/6

##

(/,$

#

$

'.$

2

0$

KΩ

2

0$

KΩ)

2

05

2

0$

205KΩ

N&

6

33

6

##

-36

-ASTER

30)BUS

2

0$

KΩ)

4.2.6 Recommended SPI EEPROM connections

Recommended SPI EEPROM connections are shown in Figure 26 and Figure 27. Note that

for both circuits:

1. The decoupling capacitor (10 nF min) must be placed as close as possible to the

package pins V

2. S

input is pulled high with RPU and C input is pulled low with RPD. In doing so, if the SPI

master bus leaves S

ensured that clock C remains low or falls low (unlike a case where S and C could rise

together, that is t

3. If unused, the Hold

must never be left floating.

Figure 26. Recommended SPI connections - safe design

and VSS.

CC

and C in high impedance, the SPI EEPROM is deselected and it is

=0, out of a specification event).

CHSH

and W pins must be directly connected to VCC, as a CMOS input

Figure 27. Recommended SPI connections - robust design

1. Q must be connected either to RPD or RPU.

Doc ID 10701 Rev 8 33/69

Page 34

Hardware considerations AN2014

Table 7. Calculation for external pull-up and pull-down resistors in SPI products

EEPROM input pins (S, W, HOLD, C, D) EEPROM output pin Q

R

PD

R

PU

RPD > VIH EEPROM / IOH master RPD > VIH master / IOH EEPROM

RPU > (VCC − VIL EEPROM) / IOL master RPU > (VCC − VIL master) / IOL EEPROM

34/69 Doc ID 10701 Rev 8

Page 35

AN2014 Hardware considerations

Ai11727

S, C, D

ESD/EOS Protection

Glitch Filter

Schmitt trigger

Typical 50ns

4.3 MICROWIRE® family (M93Cxxx and M93Sxxx devices)

Only devices designed for 4.5 V/5.5 V range offer both TTL and CMOS input/output level

compatibility. 2.5 V/5.5 V range products are only CMOS compatible.

4.3.1 Chip Select (S)

The Chip Select (S) input pin is connected to a CMOS Schmitt trigger input buffer (see

Figure 28: Chip Select, Clock, Data input pins). It is recommended that the master bus

controls the Chip select (S) with a push-pull buffer.

S must never be left floating. It is therefore strongly recommended to add a pull-down

resistor to ensure a low level on the Chip Select input at any time, including during periods

when the S line is in high impedance, such as power-up, power-down and the reset phase of

the Master.

It is therefore strongly recommended to add a pull-down resistor to ensure a low level on the

Chip Select pin at any time and in particular during power-up, power-down and the reset

phase of the Master.

The input pin leakage is negligible, typically a few nA. The input schematic, including the

protection circuit, does not offer any open path to the V

Figure 28. Chip Select, Clock, Data input pins

or VCC.

SS

4.3.2 Serial Data (D) and Serial Clock (C)

Serial Data (D) and Serial Clock (C) input pins are connected to a CMOS Schmitt trigger

input buffer (see Figure 28).It is recommended the Master bus controls them with a pushpull buffer. An external pull-down resistor (R

an “out-of-specification” configuration such as a clock rising edge while Chip Select goes

low when the Master releases the bus (Hi-Z state, violation of the t

pull-down resistor on Serial Data Input (D) will optimize signal control and standby current.

Pull-down resistor values on Serial Clock (C) and Serial Data (D) are optimized if they are at

least three times bigger than the pull-down value on the Chip Select (S) line. In this case, if

the SPI bus is released, the Chip Select (S) line goes Low faster than the Clock (C) line

goes low, and so, deselects the device before the Clock signal crosses the input buffer

trigger point (area around V

/2 is always sensitive).

CC

Doc ID 10701 Rev 8 35/69

) on a Serial Clock (C) signal will prevent from

PD

timing)). An external

SLCH

Page 36

Hardware considerations AN2014

Ai11089

ORG pin

ESD/EOS Protection

(1)

If the Clock (C) line cannot be pulled down and must be pulled up due to other system

constraints, it is recommended to choose a weaker pull-up value (at least three times

weaker) than the pull-down value on Chip Select (S).

The input pin leakage is typically a few nA. The input schematic, including the protection

circuit, does not offer any open path to the V

or VCC.

SS

4.3.3 Organization Select (ORG)

ORG is not a CMOS input. If left floating, it is interpreted internally as being High. It is

strongly recommended to connect it directly to the V

dynamically implies that application software can handle specific MICROWIRE dual

organization and switch from Single data byte management to word data management.

or VSS pin of the device. Driving it

CC

The input pin leakage is negligible,

including the protection circuit, does not offer any open path to the V

in standby mode, typically a few nA. The input schematic,

or VCC. (See

SS

Figure 29)

Figure 29. Organization input ORG

1. The Pull up is switched off in standby mode. Pull up is only active for a short time at chip select to ensure 1

level is latched when ORG is floating.

4.3.4 Serial Data output (Q)

It is a push-pull tri-state output buffer. As the Serial Data Output is often in the Highimpedance state and connected to a Master input pin, it may be useful to connect a pull-up

resistor to set a default value (corresponding to the Ready state) on the bus and thus

prevent the Master input from toggling. Application designers must be aware that connecting

several devices on Serial Data Output (Q) increases the capacitive load of the line. Access

time of M93C ST EEPROM is tested with 100pF load (see Figure 25: Output pin tri-state

buffer)

4.3.5 Don’t use (DU)

Pin does not contribute to the normal operation of the device. It is reserved for use by

STMicroelectronics during test sequences. The pin may be left unconnected or may be

36/69 Doc ID 10701 Rev 8

Page 37

AN2014 Hardware considerations

6

##

3

#

$

1

-)#2/7)2%%%02/-

6

##

$5

/2'

6

33

'.$

2

0$

2

05

N&

6

##

6

33

-36

-ASTER

BUS

6

##

3

#

$

1

-)#2/7)2%%%02/-

'.$

205K٪

6

##

$5

/2'

6

33

N&

6

##

6

33

-36

20$KΩ

2

0$

KΩ

2

0$

KΩ

-ASTER

BUS

connected to VCC or VSS. No other connection is allowed. Direct connection of DU to VSS is

recommended for the lowest standby power consumption mode.

4.3.6 Recommended MICROWIRE EEPROM connections

Recommended MICROWIRE EEPROM connections are shown in Figure 30 and Figure 31.

Note that for both circuits:

1. A decoupling capacitor (10 nF min) must be placed as close as possible to the package

pins V

2. A 50 Ohm resistor can be connected to V

identified latchup risk is to be minimized.

Figure 30. Recommended MICROWIRE connections - safe design

and VSS.

CC

if extra filtering on VCC is needed or if an

CC

Figure 31. Recommended MICROWIRE connections - robust design

Table 8. Calculating external pull-up and pull-down resistors in MICROWIRE products

Recommended

connection

EEPROM input pins (S, C, D, W

R

PD

R

PU

RPD > VIH EE / IOH master RPD > VIH master / IOH EE

RPU > (VCC − VIL EE) / IOL master RPU > (VCC − VIL master) / IOL EE

Doc ID 10701 Rev 8 37/69

, ORG) EEPROM output pin Q

Page 38

Hardware considerations AN2014

V

CC

V

SS

+

-

Other ICs

EEPROM

1 µF < C2 < 100 µF

10 nF < C1 < 100 nF

GND

V

CC

Ai11079b

4.4 PCB Layout considerations

The full system layout becomes ever more critical because of space constraints, high

communication speed, noise due to interference and all EMC constraints.

4.4.1 Cross coupling

The cross coupling effect increases with the frequency and fine PCB technology. All floating

signals or pins, weak pull-up or pull-down connections are very sensitive to cross coupling