Page 1

AN2009

APPLICATION NOTE

PWM MANAGEMENT FOR

3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

INTRODUCTION

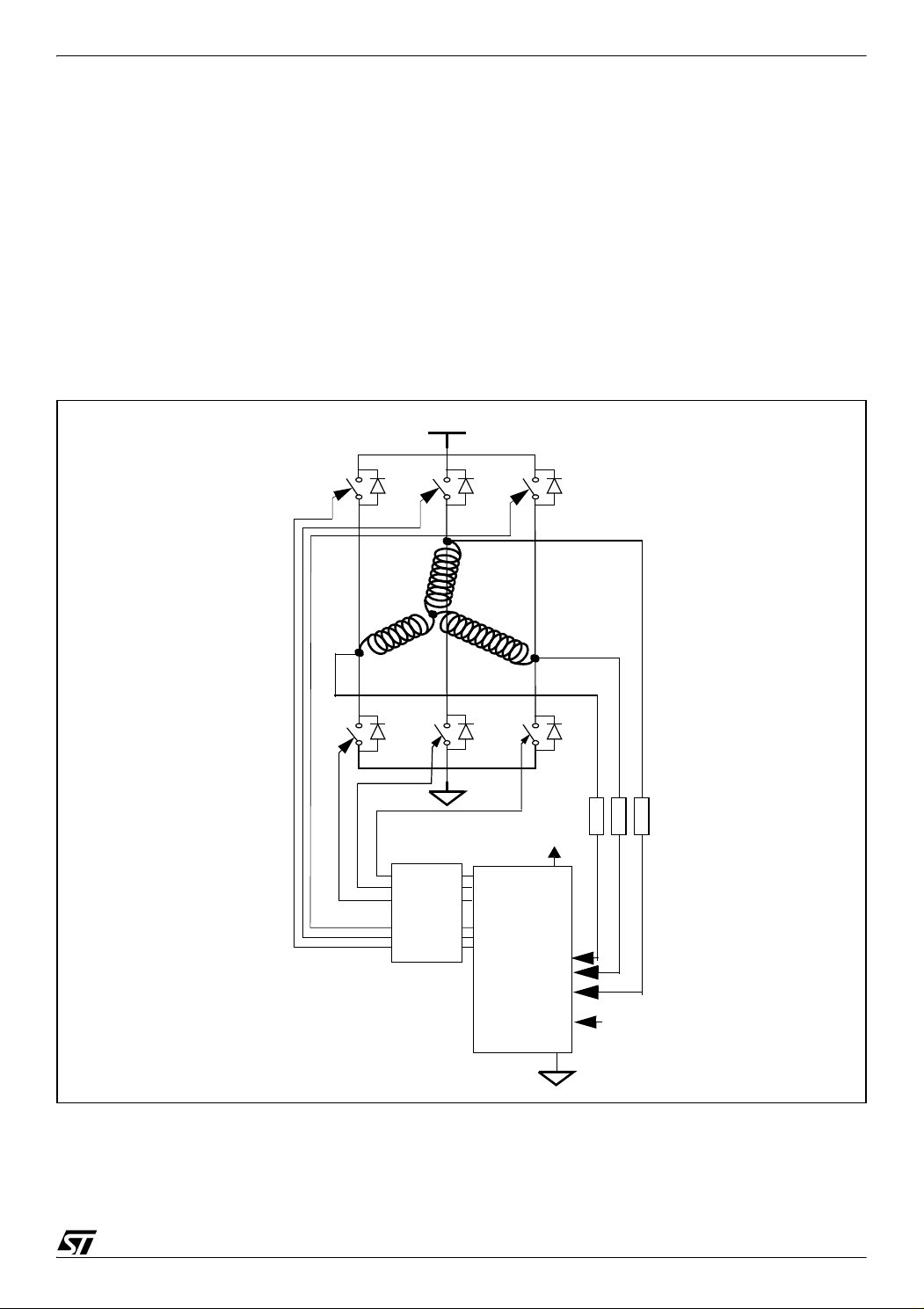

The ST7MC microcontroller family is the second generation of the 8-bit microcontroller family

dedicated to the driving of 3-phase brushless motors. Permanent Magnet Brushless DC mo

tors are replacing DC brush motors more and more in many applications due to advantages

such as higher efficiency, quieter operation and better reliability. These motors require the

control of an inverter stage. In most cases the switching devices are MOSFET transistors or

IGBTs and are organized in a three-phase bridge with free-wheeling diodes as shown in

Figure 1. There are two methods of controlling the motor and reading information back from

the rotor. These are called the sensor and the sensorless methods. The sensor method uses

Hall sensors whereas the sensorless method reads the Back Electromotive Force (BEMF)

signal back to determine the position of the rotor and so is less expensive.

The ST7MC microcontroller features a dedicated peripheral to drive this type of motor with the

best efficiency in order to maintain the advantages of these types of motor. Besides the high

flexibility of this dedicated peripheral, its high hardware integration allows cost savings for the

application by reducing external components. It is suitable for both sensor and sensorless

methods of PM BLDC motor control.

-

Although using the sensorless mode has big advantages in terms of cost and size, it makes

the motor drive a little more complicated. The purpose of this application note is to explain in

which cases the ST7MC motor control unit can directly read the BEMF voltage and how to

quickly set up its control registers in order to use all the advanced features of this product. We

will detail and explain the PWM management inside the ST7MC in order to help the developer

use all the advantages of this flexibility to optimize the design and the efficiency of the appli

cation.

AN2009 Rev 2 1/39

-

1

Page 2

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1 MOTOR CONTROL MACROCELL INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 SIX-STEP, 120° DRIVE AND PWM POWER CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 SENSORLESS CONTROL METHODS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 CLASSIC METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 ST METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 PWM MANAGER IN VOLTAGE MODE AND CURRENT MODE . . . . . . . . . . . . . . . . . . 10

4.1 PWM MANAGER IN VOLTAGE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.2 PWM signal register setting in Voltage mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2 PWM MANAGER IN CURRENT MODE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2.2 PWM signal register setting in Current mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 SUMMARY VOLTAGE/CURRENT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 MANAGEMENT OF PWM AND READING OF BEMF . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 PWM ON THE HIGH SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 PWM ON THE LOW SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 EXAMPLE OF CONFIGURATION OF THE ST7MC REGISTERS . . . . . . . . . . . . . 22

6 SYNCHRONOUS RECTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 SYNCHRONOUS RECTIFICATION PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 SYNCHRONOUS RECTIFICATION CONFIGURATION . . . . . . . . . . . . . . . . . . . . . 27

7 WINDING DEMAGNETIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.1 ACCELERATION OF DEMAGNETIZATION WHEN PWM IS APPLIED ON THE LOW

SIDE SWITCH 29

7.2 ACCELERATION OF DEMAGNETIZATION WHEN PWM IS APPLIED ON THE HIGH

SIDE SWITCH 31

7.3 REGISTERS CONFIGURATION TO ACCELERATE THE DEMAGNETIZATION. . 34

8 CONFIGURATION EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 CONCLUSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

39

10 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2/39

Page 3

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 1. ST7FMC Microcontroller with a three-phase bridge

HV

T0

T3

D0 D2 D4

T2

M

A

D3

T5

Level

shifter

B

D5

Low

Side

outputs

High

Side

outputs

T4

T1

C

5V

Rotor

position

inputs

D1

Feedback

ST7FMC

1 MOTOR CONTROL MACROCELL INTRODUCTION

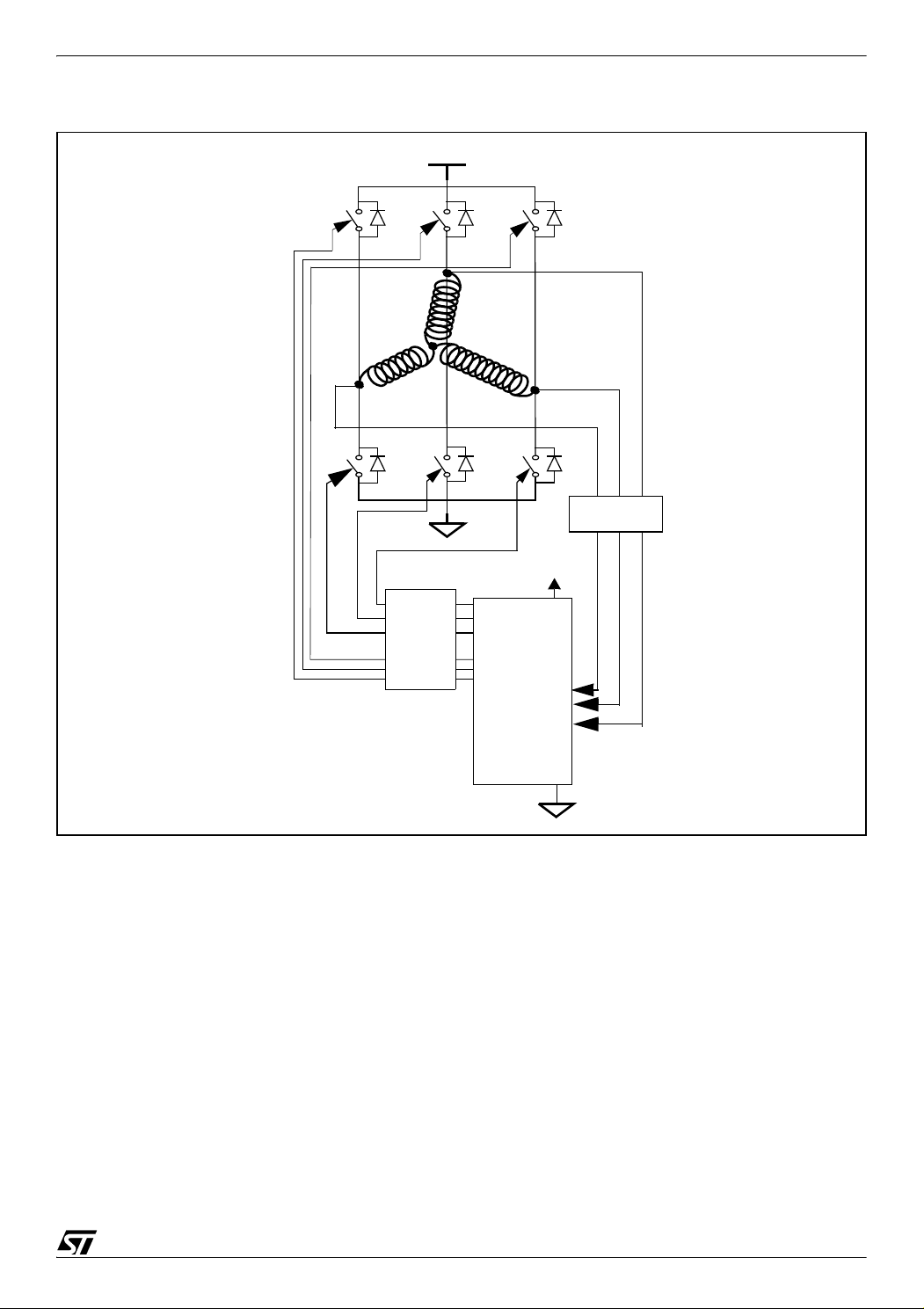

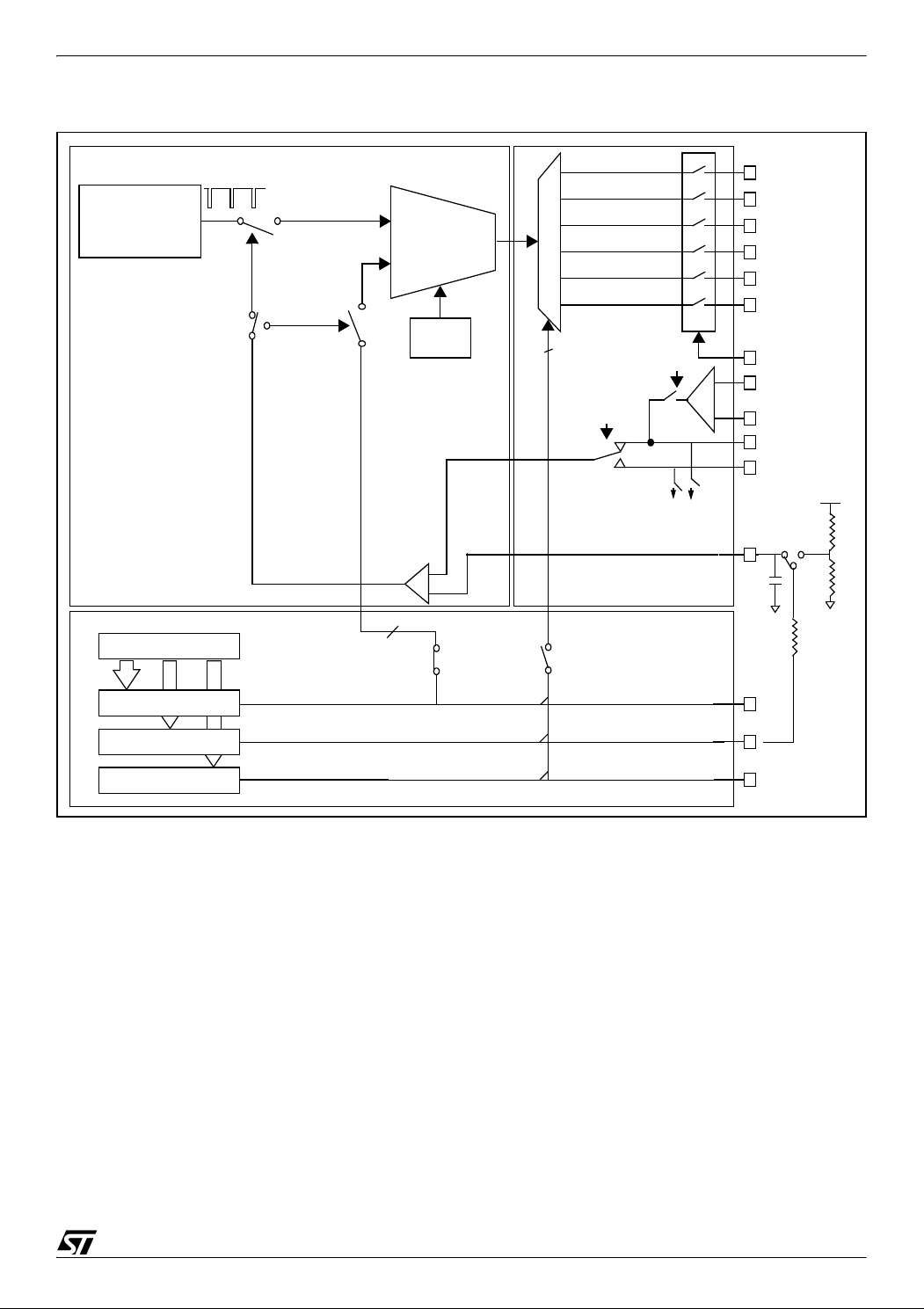

Figure 2 below gives a detailed view of the motor control macrocell included in the ST7MC mi-

crocontroller. In bold are the parts of the macrocell that are going to be described in this application note and that have a role in the PWM management. The purpose of this document is to

ease the understanding of the PWM management with the ST7MC to control a brushless 3phase DC motor and to make this explanation easier, the schematic on the figure below can

be taken as a reference of a global view of the mechanism. Besides the drawings of the func

tionalities, the names of the registers involved and often even the bits are written in this schematic. Anyhow, each time a register is discussed in this document, either a reference or an

exact description will be made for that register.

3/39

-

Page 4

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 2. Detailed view of the MTC for PM BLDC motor control

DD

Board + Motor

MCPWMU/V/W

HV

C

B

A

drivers

MCIC

MCIA

MCIB

MCVREF

MPWME Reg

MCPWMU

MCPWMV

MCPWMW

MCO0

MCO2

MCO4

MCO1

MCO3

MCO5

NMCES

MOE bit

1

6

MPOL Reg

x6 x6

V

A

OAN

OAP

OCV bit

CLI bit

CLIM bit

-

+

OAON

1ext

2ext

R

R

(I)

(V)

ext

C

MCCFI0

MCCREF

OAZ(MCCFI1)

CFAV bit

bit

IS

Reg

MREF

bits

n

n

12-bit PWM generator

OS

3

Time

Dead

Ch0

Ch2

Ch1

Time

Dead

Ch3Ch4

MPHSTn Reg

High Frequency Chopper

Time

Dead

Ch5

6

2

8

6

PCN bit =0

MDTG register

MPAR Reg

-

+

CFW[2:0] bit

CFF[2:0] bit

VR2-0

REF

V

S,H

-

+

S,H

D

C

V

2

I

1

D/Z Window filter

DQ

CP

S,H

C

S,H

D

2

SPLG

1

1 /20

1 / 4

F

PRESCALER

mtc

1 / 2

+

R

MTIM

= FFh?

+1

periph

F

Z event generation

D event generation

H

Z

XT16:XT8 bit

H

D

Microcontroller

Compare U

1/128

➘

1

Ratio

1 / 2

4

ST3-0 bits

SR bit

MZREG

Z

SWA bit

SA3-0 &

OT1-0 bits

-

< 55h?

-1

S,H

D

SQ

V

R

CLI

I

]

n

H

C

1

0

H

MDREG Reg [D

D

bit

n

SDM

Compare

S

D

Filter / C

DWF[3:0]

CL

MIMR Reg

MISR Reg

S,H

-/+

R

S,H

S,H

C

D

Z

E

clr

n

bit

SZ

8

Compare

ck

nn-1

MTIM [8-bit Up Counter]

R

]

n

MZREG Reg [Z

H

Z

]

n-1

MZPRV Reg [Z

S,H

Z

DCB bit

Filter / D

ZWF[3:0]

S

Z

S,H

C

8

]

n+1

8

MWGHT Reg [a

8

A x B / 256

SWA bit

Compare

]

n+1

MCOMP Reg [C

4/39

Page 5

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

2 SIX-STEP, 120° DRIVE AND PWM POWER CONTROL

To control a BLDC motor with the best efficiency, we have to know the rotor position at all

times. To achieve this there are two modes. One is called the sensor mode, where the infor

mation read back from the motor is the one coming from Hall Effect sensors (1 per phase).

The other one is the sensorless mode, where the Back Electromotive Force (BEMF) signal in

formation is the one read back from the motor. The strength of the ST7FMC is that it is compatible with all the modes to control a BLDC motor, whether it is sensorless or not and it is

even suitable with different variations within the sensorless or sensor modes which will be de

tailed later on in this application note.

In sensorless mode, in order to be able to read the BEMF information, the phase switching has

to include a dead time during which no current flows in one of the motor windings.

As shown in Figure 4, in six-step, 120° drive, power is removed from each winding every three

steps. During this dead-time phase, it is possible to detect the BEMF zero-crossing event on

this non powered winding (see

In order to control the speed, the torque or the power applied to the motor, a PWM signal is

usually logically ANDed with the switch control signals. This control is implemented by modi

fying the duty cycle of this logically ANDed PWM signal.

Figure 3 for an example).

-

-

-

-

With this method, the BEMF voltage is referred to point M of the motor and not to ground. Because this point is at high voltage, the microcontroller cannot read its value directly.

Note: In sensor mode the six-step drive or the sinusoidal drive can be implemented as the

feedback signal comes independently from the Hall Effect sensor in the dedicated input of the

microcontroller. However, in six-step drive, the method will be exactly the same as the one de

tailed for the sensorless mode. For the sensor sinusoidal mode, the PWM management is the

same as for the AC induction motor drive.

-

5/39

Page 6

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 3. Reading the BEMF (Step Σ4)

HV

T0

D0 D2 D4

T2

T4

B

Read BEMF

on phase C

T3

M

B

E

A

D3

T5

M

F

D5

T1

C

D1

Figure 4. Six-step, 120° drive: control signal on the transistor gate

Σ

Step

Switch

T0

T1

1Σ2Σ3Σ4Σ5Σ6Σ1Σ2Σ3

ON

OFF

ON

OFF

ON

T2

OFF

ON

T3

OFF

ON

T4

OFF

ON

T5

OFF

Node

HV

A

0

HV

B

0

HV

C

0

BEMF Voltage

Note: voltages are represented without any PWM or demagnetization effect.

6/39

Page 7

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

3 SENSORLESS CONTROL METHODS

In order to make the BEMF signal readable by the microcontroller and to detect the zerocrossing voltage of this signal, there are two main methods which we will call the classic

method for the first one and the ST method for the second. The ST7FMC microcontroller is

suitable for both methods. Each method is declinable in sub-method and the ST7MC allows

complete flexibility on which sub-method to use. Please refer to the Application Note AN1946

for a complete view and details on all the methods as this document briefly covers only the 2

main methods.

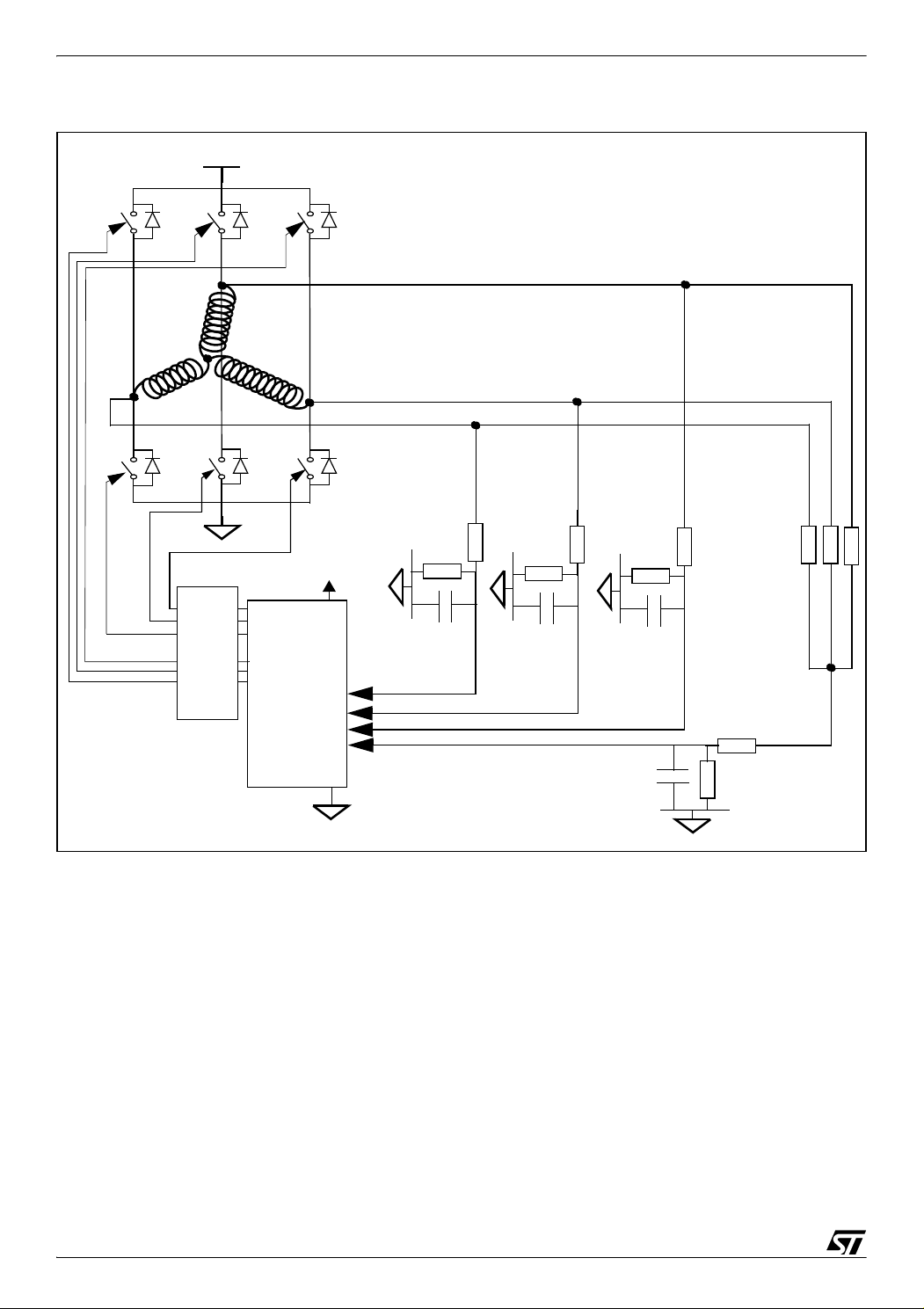

3.1 CLASSIC METHOD

The classic method involves dividing and filtering the signal coming from the non-powered

phase to make it readable by the 5V microcontroller as shown in

built and is used as the voltage reference to detect the zero-crossing event of the BEMF

signal. With this method, the PWM signal which is logically ANDed with the switch control

signal can be applied either on the high or on the low side switches as explained in the next

section. The ST7MC is able to detect the BEMF zero-crossing signal during either the PWM

signal ON time or OFF time.

Figure 5. A virtual ground is

7/39

Page 8

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 5. Classic sensorless control method

HV

T0

T3

D0 D2 D4

T2

M

A

D3

T5

Level

shifter

B

D5

Low

Side

outputs

High

Side

outputs

ST7FMC

T4

T1

C

5V

Rotor

position

inputs

internal

Vref

D1

External

Vref

Virtual

ground

Note: The digital filter of ST7MC allows use of the classical method wiring without an analog

filter. In that case we can remove the virtual neutral network and replace this by just a voltage

divider on the High VOLTAGE BUS. In this situation, sampling at PWM "OFF" is possible only

for PWM applied on the high side switch. Please refer to Application Note AN1946 for more

details on this method.

8/39

Page 9

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

3.2 ST METHOD

With the ST Method, by using the free-wheeling diodes during the OFF time of the PWM

signal, the M potential is put to ground and the ST7MC microcontroller samples the BEMF

signal voltage during the OFF time of the PWM signal. This involves the fact that the PWM has

to be applied on the high side and that an OFF time is needed as explained in the next section

of this application note. However, fewer external components are required as it is no longer

necessary to divide and filter the signal coming from the non-powered winding. As shown in

Figure 6, only 3 external resistors are needed to limit the current input in the microcontroller

pins.

Figure 6. ST sensorless control Method

HV

T0

T3

D0 D2 D4

T2

M

A

D3

T5

Level

Shifter

B

D5

Low

Side

outputs

High

Side

outputs

ST7FMC

T4

T1

C

5V

Rotor

position

inputs

internal

Vref

D1

External

Vref

9/39

Page 10

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

4 PWM MANAGER IN VOLTAGE MODE AND CURRENT MODE

The PWM signal logically ANDed with the switch control signal is used to control the power applied to the motor. It can either control the voltage on the motor with a fixed PWM duty cycle

or the current by means of an integrated current control circuitry.

When the PWM signal controls the voltage, the motor is driven in voltage mode. When it is

controlling the current, the motor is driven in current mode.

Voltage mode allows you to control the speed easily by changing the motor reference voltage.

It does not give you fine control of the current but you can limit the current and consequently

the torque to a maximum value. The voltage control is done by the PWM duty cycle.

Current mode allows you to permanently control the torque by changing the motor reference

current, because torque is proportional to current. The current in the windings is regulated in

real time and there is a true DC current flowing through the DC Bus. Current mode also allows

the current for each of the 6 steps to be finely controlled as the current control is done during

the PWM cycle.

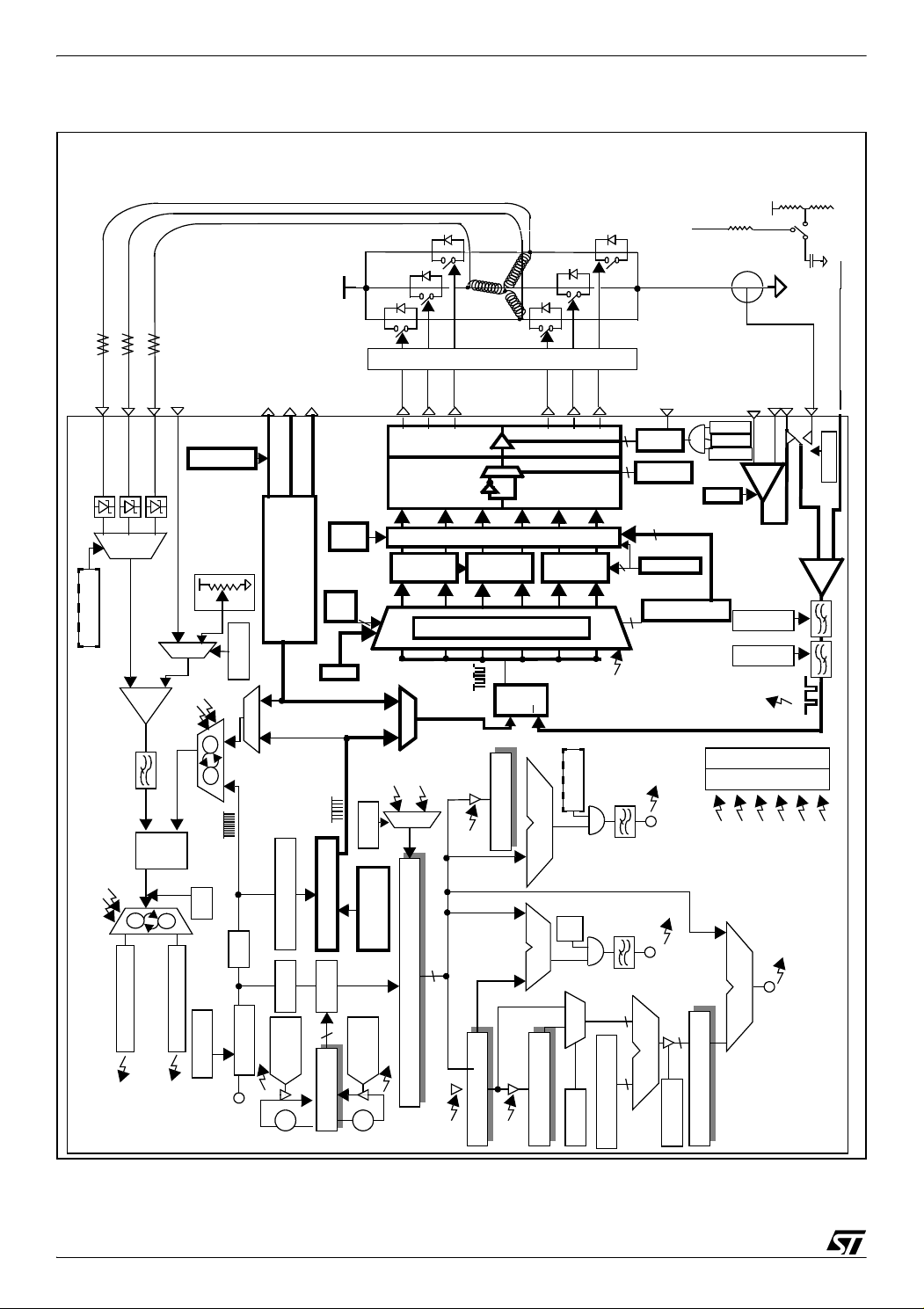

Depending on whether the motor is driven in current or voltage mode, the PWM signal does

not have the same origin as shown in

Figure 7.

10/39

Page 11

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 7. The PWM manager

MEASUREMENT

WINDOW

GENERATOR

PWM MANAGER

12-bit counter

(I)

(V)

Phase U

(I)

CURRENT

VOLTAGE

(V)

MODE

1

(V)

PCN bit

PHASE

U, V, W

Phases

CFAV bit

OAON bit

+

-

ADC

CHANNEL

MANAGER

12-bit THREE-PHASE

PWM GENERATOR

MCO5

MCO4

MCO3

MCO2

MCO1

MCO0

NMCES

OAP

OAN

OAZ(MCCFI1)

MCCFI0

MCCREF

C

(V)

(I)

V

DD

R

1

R

2

R

3

Phase U

Phase V

Phase W

MCPWMU

MCPWMV

MCPWMW

The PWM manager manages two different integral parts of the way the ST7MC drives the

motor:

– Current regulation or limitation

– Generation of the PWM signal applied on the switches

The PWM manager has two distinct motor driving modes: voltage mode and current mode. In

both cases, the motor control 12-bit timer peripheral has an essential role.

In Figure 7, the PWM manager uses the paths indicated by the (I) symbol for current mode

and by the (V) symbol for voltage mode.

11/39

Page 12

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

4.1 PWM MANAGER IN VOLTAGE MODE

4.1.1 Description

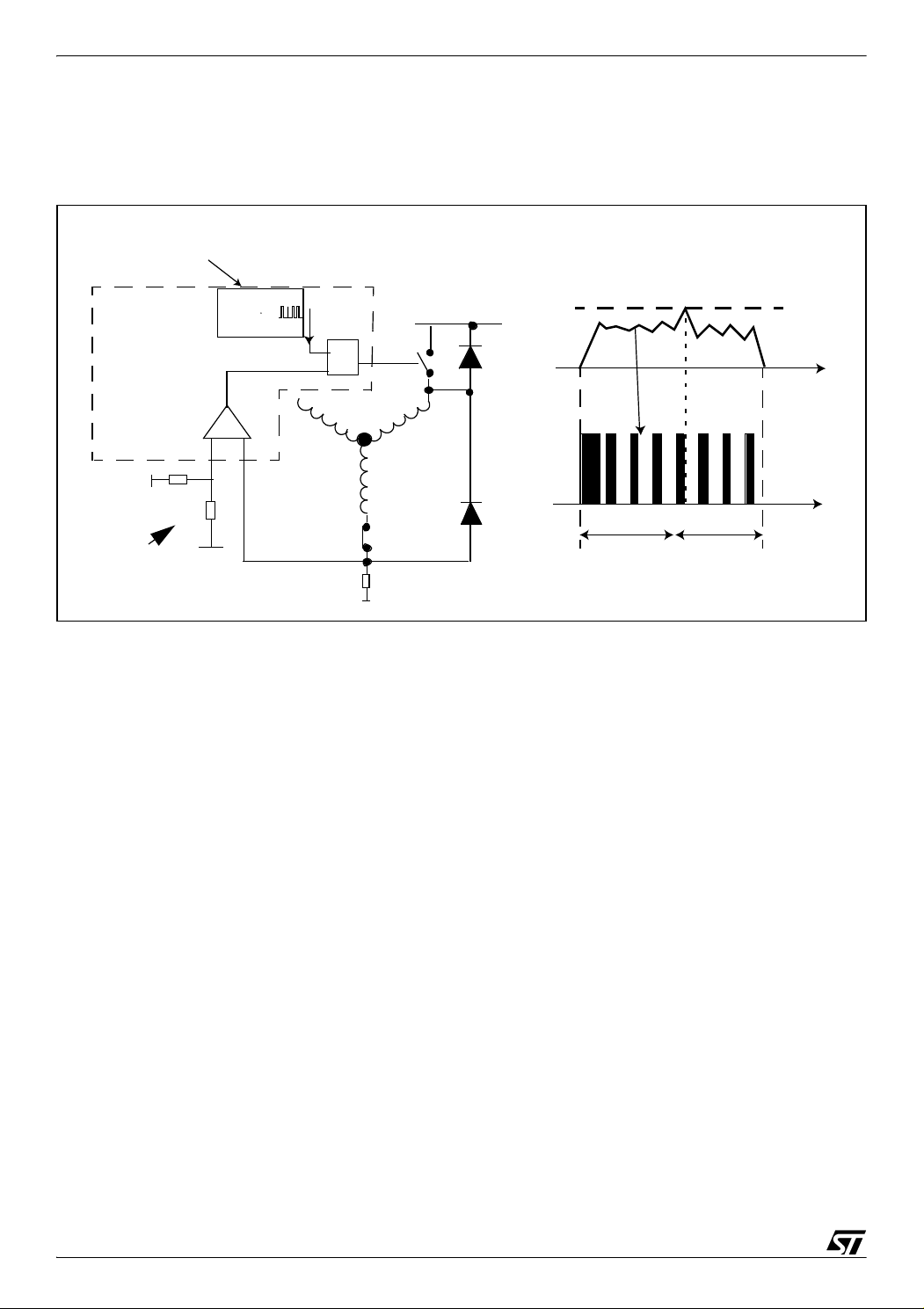

Figure 8. Current limitation in voltage mode control

ST7MC

PWM U output

Max current

ST7MC

Microcontroller

TIMER

set

R

HV

T1

reference

I

t

A

Motor

Voltage

step time step time

T1-T4

T1-T6

VR02139M

t

Vdd

Rext

Rext

Max current

reference

-

+

T4

In voltage mode, the PWM of the 12-bit timer (through the compare U register) gives the

voltage which is supplied to the motor, it is the voltage control of the motor. This PWM signal

is the one logically ANDed with the control switches signal in order to be able to detect the

zero-crossing and demagnetization events.

In voltage control mode, we can set a limitation to the current. The current limitation can be set

by the user with an external resistor divider as shown in

Figure 7 (R1 and R2) and Figure 8

(Rext). Usually this current limitation is the one given by the motor manufacturer. When the

current feedback reaches the maximum reference current at the comparator input, the tran

sistor to which the PWM is applied is put in off state until the current feedback becomes less

than the maximum current limit. So, one of the inputs of the internal comparator is the max

imum current limitation, the other input is the current feedback from the motor (MCCFI0 pin or

the output of the internal operational amplifier if used as shown in

Figure 7).

-

-

This current limitation is for protection and should normally never be reached when running

the motor correctly.

Figure 9 is a capture made with an oscilloscope of the different signals in Voltage mode:

We can see that the current feedback from the motor never reaches the current limitation and

the increase and decrease of the current in the motor corresponds to the PWM signal on the

waveform 2.

12/39

Page 13

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 9. Oscilloscope waveforms: Voltage Mode

1. Current in Phase A

2. Signal on High Side

Switch of Phase A on

Triple Half Bridge

Configuration

3. Current Limitation

3. Current Limitation

4. Current Feedback

Note: In speed regulation, the PWM duty cycle value only needs to be correct when starting

the motor. Once the target speed is reached, the PWM duty cycle will be adjusted automati

cally by the ST7MC.

-

4.1.2 PWM signal register setting in Voltage mode

In voltage mode, the 12-bit timer is used to set the PWM signal.

Compare 0 registers:

The compare 0 high and low registers are for setting the frequency of the PWM.

COMPARE 0 PRELOAD REGISTER HIGH (MCP0H)

Read/Write (except bits 7:4)

Reset Value: 0000 1111 (0Fh)

7 0

- - - - CP0H3 CP0H2 CP0H1 CP0H0

Bits 7:4 = Reserved.

Bits 3:0 = CP0H[3:0] Most Significant Bits of Compare 0 preload value.

COMPARE 0 PRELOAD REGISTER LOW (MCP0L)

Read/Write

Reset Value: 1111 1111 (FFh)

7 0

CP0L7 CP0L6 CP0L5 CP0L4 CP0L3 CP0L2 CP0L1 CP0L0

Bits 7:0 = CP0L[7:0] Low byte of Compare 0 preload value.

13/39

Page 14

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Compare U registers:

The compare U high and low registers are for setting the duty cycle of the PWM signal in

voltage mode.

COMPARE PHASE U PRELOAD REGISTER HIGH (MCPUH)

Read/Write

Reset Value: 0000 0000 (00h)

7 0

CPUH7 CPUH6 CPUH5 CPUH4 CPUH3 CPUH2 CPUH1 CPUH0

Bits 7:0 = CPUH[7:0] Most Significant Byte of phase U preload value

COMPARE PHASE U PRELOAD REGISTER LOW (MCPUL)

Read/Write Read/Write (except bits 2:0)

Reset Value: 0000 0000 (00h)

7 0

CPUL7 CPUL6 CPUL5 CPUL4 CPUL3 - - -

Bits 7:5 = CPUL[7:3] Low bits of phase U preload value.

Bits 2:0 = Reserved.

4.2 PWM MANAGER IN CURRENT MODE CONTROL

4.2.1 Description

Figure 10. Current regulation in current mode control

ST7MC

Microcontroller

TIMER

12-bit internal timer

PWM output

clock

- +

set

R

T4

A

T1

HV

current

reference

clock

Motor

Voltage

I

step time

T1-T4

t

t

t

step time

T1-T6

VR02139N

14/39

Page 15

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

In current mode, the PWM output by the 12-bit timer (either MCPWMU, V or W) represents the

reference current to be applied to the motor. The PWM duty cycle is the current level at which

we want to polarise the motor. At 100% duty cycle, the signal output is at 5V, this corresponds

to the maximum current to be applied to the motor for maximum torque. The PWM duty cycle

is obtained by dividing the reference current we want in the motor (depending on the torque

needed) by the maximum current. For example, if the maximum current is 1A and if the refer

ence current has to be 0.2A, the PWM duty cycle will be 20%.

An external resistor and capacitor are added as shown in Figure 7 (R3) and Figure 10 in order

to generate the reference current based on a digital to analog converter (DAC) of the PWM

signal.

So, for the internal comparator, one of the inputs is the current feedback of the motor (MCCFI0

pin or the output of the internal operational amplifier if used), the other input is the reference

current given by the filtered PWM signal from the 12-bit timer.

We see in Figure 7 and Figure 10 that the internal clock is used in current mode control. The

internal clock outputs a PWM signal as well. The frequency of this signal is user-selectable

from several values from 390Hz to 50KHz through 4 bits and the off-time of this signal is also

user-selectable (from 2.5µs to 40µs) with a minimum value of 2.5µs needed to allow the sta

bilization of the system if the ST method is used to allow the sampling of the back-EMF signal

during off-time. The PWM signal frequency output by the clock represents the current fre

quency used to supply the motor. The off-time of this PWM signal is variable, with a lower limit

of 2.5µs in the sensorless mode ST method. The PWM signal output by the internal clock is

applied to the designated switch. This mechanism has the following procedure as shown in

Figure 10:

-

-

-

When the current feedback from the motor reaches the reference current given by the 12-bit

timer PWM signal at the comparator input, the internal clock signal is reset. The switch where

the PWM is applied is put in an OFF state until the current feedback is lower than the refer

ence current as shown in Figure 10. That’s why the duty cycle of the internal clock is variable.

A minimum off-time has to be defined by the software programmer in sensorless ST method

but the duty cycle is modified depending on the motor behaviour.

Figure 11 is a capture done with an oscilloscope of the different signals in Current mode.

We can see that as soon as the current back from the motor reaches the level of the current

limitation, the PWM signal on waveform 2, meaning the PWM signal on the high side switch of

the corresponding phase is put off.

15/39

-

Page 16

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 11. Oscilloscope waveforms: Current Mode

1. Current in Phase A

2. Signal on High Side

Switch of Phase A on

Triple Half Bridge

Configuration

3. Current Regulation

Signal through PWM

Compare U filtered

4. Current Feedback

Note: In speed regulation, the 12-bit timer PWM duty cycle only has to have the right value to

start the motor. Once the target speed is reached, the PWM duty cycle will be adjusted auto

matically by the ST7MC.

4.2.2 PWM signal register setting in Current mode

In current mode, a combination of an internal clock and the output of the current comparator is

used to set the PWM signal, the registers described below are the ones used to set the fre

quency and the minimum OFF time if needed from the PWM signal for the internal clock.

PRESCALER & SAMPLING REGISTER (MPRSR)

Read/Write

Reset Value: 0000 0000 (00h)

7 6 5 4 3 2 1 0

SA3 SA2 SA1 SA0 X X X X

Bits 7:4 = SA[3:0]: Sampling Ratio.

These bits contain the sampling ratio value for current mode. This sets the frequency of the

PWM according to the following table

-

-

16/39

Page 17

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Table 1. Frequency selection

SA3 SA2 SA1 SA0 Sampling Frequency

0 0 0 0 50.0 KHz

0 0 0 1 40.0 KHz

0 0 1 0 33.33 KHz

0 0 1 1 25.0 KHz

0 1 0 0 20.0 KHz

0 1 0 1 18.1 KHz

0 1 1 0 15.4 KHz

0 1 1 1 12.5 KHz

1 0 0 0 10 KHz

1 0 0 1 6.25 KHz

1 0 1 0 3.13 KHz

1 0 1 1 1.56 KHz

1 1 0 0 1.25 KHz

1 1 0 1 961 Hz

1 1 1 0 625 Hz

1 1 1 1 390 Hz

PWM REGISTER (MPWME)

Read/Write

Reset Value: 0000 0000 (00h)

7 6 5 4 3 2 1 0

X PWMW PWMV PWMU OT3 OT2 OT1 OT0

The current reference is provided to the comparator by Phase U, V or W of the PWM Generator (up to 12-bit accuracy) and the signal from the three compare registers U, V or W can be

output by setting the PWMU, PWMV or PWMW bits.

Bits 3:0 = OT[3:0]: Off Time selection

These bits are used to select the OFF time in sensorless current mode as shown in the following table

17/39

Page 18

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Table 2. off time table

Off Time sensorless

OT3 OT2 OT1 OT0

0 0 0 0 2.5 µs

0 0 0 1 5 µs

0 0 1 0 7.5 µs

0 0 1 1 10 µs

0 1 0 0 12.5 µs

0 1 0 1 15 µs

0 1 1 0 17.5 µs

0 1 1 1 20 µs

1 0 0 0 22.5 µs

1 0 0 1 25 µs

1 0 1 0 27.5 µs

1 0 1 1 30 µs

1 1 0 0 32.5 µs

1 1 0 1 35 µs

1 1 1 0 37.5 µs

1 1 1 1 40 µs

mode (SR=0)

(DS[3:0]=0)

Sensor Mode (SR=1) or sampling

during ON time in sensorless

(SPLG =1 and/or DS[3:0] bits)

No minimum off time

4.3 SUMMARY VOLTAGE/CURRENT MODE

In voltage mode, the 12-bit timer PWM signal (compare U register) gives the voltage to be applied to the motor. This PWM signal is applied to the switches. The internal clock is not used

in this mode.

A current limitation is implemented in voltage mode. The current limitation can be set by an external divider resistor or by an other PWM signal filtered.

In current mode, the 12-bit timer PWM signal gives the reference current to be applied to the

motor. This signal has to be filtered by an external RC. The internal clock is used and the

PWM signal from the internal clock is applied to the switches.

In current mode, the current is regulated by comparing the reference current and the feedback

current from the motor.

18/39

Page 19

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

5 MANAGEMENT OF PWM AND READING OF BEMF

Depending on the control method used to drive the motor, the PWM signal to detect the BEMF

zero voltage crossing signal can be applied in 2 ways:

– On the high side: During the step, the PWM is applied only on the high side switch, the low

side is ON during the complete step.

– On the low side: During the step, the PWM is applied only on the low side switch, the high

side is ON during the complete step.

In the ST7MC device, OE [5:0] bits in the MPAR register are used to define whether the corresponding outputs are in high or low side switch position. Then OO [5:0] bits in MPHST register define if the channel is active or not and finally OS [2:0] bits in MCRB register distribute

the PWM on the active channels high or low side. Please refer to the product datasheet for the

motor control device in the channel manager section for more details or to

complete configuration.

Figure 12. Current during PWM ON time

HV

Section 6 to see a

T0

T3

The 2 switches T2 and T3 are ON

D0 D2 D4

T2

HV

A

2

D3

T5

T4

B

M

C

D5

T1

D1

5.1 PWM ON THE HIGH SIDE

When the related switches are ON, the current passes through the two switches and two

motor windings (these are switches T2 and T3 in the example in

Figure 12).

The potential at point M is HV/2. If nothing is done, the BEMF can not be read by the ST7MC

because the voltage is too high to be read by the microcontroller.

Using the classic method, the BEMF is divided and filtered as is the rebuilt virtual ground and

so the BEMF zero-crossing event can be read when the PWM is ON on the high side switch.

19/39

Page 20

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

When the PWM signal is ON when using the Classic method, the voltage at the virtual ground

will be HV/2 divided and filtered and the voltage at point C will be (HV/2 + BEMF) divided and

filtered so the comparison can be done by the comparator in the microcontroller as it will stay

within the microcontroller supply voltage range (0 - Vdd) after division and filtering.

When the high side switch PWM is OFF, the current inside the motor continues to flow in the

same direction (

Figure 13). While the switch is off, the current can only use the diode (D5 in

our example).

In this case the potential in A is the Von of the T3 switch, the potential in B is -Vf of D5 and the

potential at M is (Von-Vf)/2. It is close to zero because in most cases Von = Vf.

In this case the microcontroller can read the complete BEMF voltage referred to the ground

terminal on the phase C.

This is the configuration used for the ST method where the sampling of the BEMF signal is

only done during the Off time of the PWM signal. No dividers nor filters are needed externally

as we are looking at a signal that is close to the MCU ground level.

Note: This sampling method of the BEMF signal is also appropriate for the classic method. In

fact the sampling of the BEMF can be done either during ON or OFF time of the PWM for the

classic method.

Figure 13. PWM on high side: Current during OFF time

HV

B

D5

Free-wheeling

diode: D5

T4

C

T1

T0

T3

PWM on T2

T2

D0 D2 D4

PWM

M

A

0V

D3

T5

current during OFF TIME

D1

20/39

Page 21

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

5.2 PWM ON THE LOW SIDE

When the related switches are ON (example of Figure 12) the current passes through the two

switches and two motor windings.

When the low side is switched OFF, the current inside the motor continues to flow in the same

direction (

Figure 14). While the switch is OFF, the current can only use the diode (D0 in our ex-

ample).

In this case the potential at A is (HV+Vf), the potential at B is (HV-Von) and the potential at M

is (2xHV+Von-Vf)/2. We can consider it to be HV (because in most cases Von = Vf).

In this case the microcontroller can read the BEMF voltage only if the Classic method is used

during ON time of the PWM signal because the signal in C is divided and filtered before the mi

crocontroller input pin. Considering the ST method, the sampling of the BEMF is done only

during the OFF time of the PWM and as with the ST method, the signal is not divided and fil

tered in C before the microcontroller pin, this method can not be used as the voltage in C is

close to HV during the PWM off time.

– Von is the voltage of the switch when it is turned ON

-

-

– Vf is the forward voltage of a diode

Figure 14. PWM on low side: Current during OFF time

HV

T0

T3

PWM

PWM on T3; Free-wheeling diode D0

D0 D2 D4

T2

HV

A

D3

T5

T4

B

M

D5

T1

C

D1

21/39

Page 22

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

5.3 EXAMPLE OF CONFIGURATION OF THE ST7MC REGISTERS

As explained in section 2 “Sensorless control methods”, we have described 2 main sensorless

control methods which the ST7MC is compatible with. Please refer to AN1946 for more de

tails. The steps to correctly configure the ST7MC registers depending on the sensorless control method used are as follows:

– Generate a Pulse Width Modulation signal. If the ST sensorless control method is used, then

a 2.5µs minimum off time is needed to read the BEMF voltage during the off time (useless in

Classic method detection).

In Voltage mode (the VOC1 bit is reset in the MCRA register), when driving a PM BLDC motor

(the PCN bit is reset in the MDTG register) in six-step drive, a single PWM signal is used to

supply the input stage. This PWM signal which is applied to the switches is generated using

the 12-bit PWM counter for frequency and the 13 bit compare U register for duty cycle

(MCPUL:MCPUH registers).

In Current mode (VOC1 bit is set in the MCRA register), the PWM output signal is generated

by a combination of the output of the measurement window generator and the output of the

current comparator and is directed to the output channel manager as well. This can be done

by setting the PWM frequency through SA[3:0] bits in the MPRSR register and the minimum

off time using the OT[3:0] bits in the MPWME register. The off time is also dependent on the

output of the current comparator as explained in

Section 4 of this document.

-

– Apply this PWM on the high side or low side switches depending on the sensorless control

method used. To do so, you have to configure the microcontroller with the right configuration.

In order to configure correctly the registers, this sequence has to be followed.

– Split the switches in two parts by means of the high side/low side configuration. This is done

using the OE [5:0] bits in the MPAR register.

PARITY REGISTER (MPAR)

Read/Write

Reset Value: 0000 0000 (00h)

7 6 5 4 3 2 1 0

X X OE5 OE4 OE3 OE2 OE1 OE0

Bits 5:0 = OE[5:0]: Output Parity Mode.

0: Output channel is High

1: Output channel Low

For example: T1, T3, T5 low side and T0, T2, T4 high side.

22/39

Page 23

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

– Select the group you want to read the BEMF from by programming the REO bit in the MPOL

register. The group the BEMF is read from depends on the sensorless control method used.

If the ST method is used, the high side group has to be selected because the PWM has to

be applied on the high side as seen in the previous chapter, therefore, the BEMF can be read

only from the high side group, REO bit is reset. If the classic method is used, the BEMF can

be read either from the high side group or from the low side group, it depends on where the

PWM signal will be applied as described below. So in this configuration, the REO bit can be

set or reset. Select also the polarity of the output channel through the MPOL register.

POLARITY REGISTER (MPOL)

Read/Write (some bits write-once)

Reset Value: 0011 1111 (3Fh)

7 6 5 4 3 2 1 0

ZVD REO OP5 OP4 OP3 OP2 OP1 OP0

Bit 7 = ZVD: Z vs D edge polarity.

0: Zero-crossing and End of Demagnetization have opposite edges

1: Zero-crossing and End of Demagnetization have same edge

Bit 6 = REO: Read on High or Low channel bit

0: Read the BEMF signal on High channels

1: Read on Low channels

Note: This bit always has to be configured whatever the sampling method.

Bits 5:0 = OP[5:0]: Output channel polarity.

These bits are used together with the OO[5:0] bits in the MPHST register to control the output

channels.

0: Output channel is Active Low

1: Output channel is Active High.

– Select the PWM direction after Demagnetization (D) event just before the Zero-crossing (Z)

event. The demagnetization event and the corresponding PWM configuration will be ex

plained in Section 5. So the PWM direction can be selected using the OS1 bit in MCRB register. The same is true for the group to read the BEMF from, the PWM can be applied

differently depending on the sensorless control method used. If the ST method is used, then

the PWM signal has to be applied on the high side, which means that the OS1 bit is reset in

MCRB register. If the classic sensorless control method is used, then the PWM signal can

be applied either on the high side or on the low side. In both cases, the microcontroller is able

23/39

Page 24

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

to detect the BEMF. So, in that case OS1 bit can be set or reset. It depends mainly on the

application and on the user.

MPHST register bits OO[5:0] are used to put the corresponding output channel active or not.

This has to be configured each step over the repetition of the six steps.

PHASE STATE REGISTER (MPHST)

Read/Write

Reset Value: 0000 0000 (00h)

7 6 5 4 3 2 1 0

X X OO5* OO4* OO3* OO2* OO1* OO0*

Bits 5:0 =OO[5:0]*: Channel On/Off bits

These bits are used to switch channels on/off at the next commutation

0: Channel Off, the relevant switch is OFF, no PWM possible

1: Channel On the relevant switch is ON, PWM is possible

OO[5:0] Bit Meaning

OO[5:0] Output Channel State

0 Inactive

1 Active

* = Preload bits, new value taken into account at next C event

In addition to the PWM configuration flexibility, the ST7MC microcontroller features a dead

time generator embedded in the motor control peripheral. This is used mainly for the genera

tion of the 3 sinewave 120° shifts for the drive of an AC induction 3-phase motor but it can be

used to perform “synchronous rectification” as explained in the next chapter when driving a

PM BLDC motor.

-

24/39

Page 25

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

6 SYNCHRONOUS RECTIFICATION

6.1 SYNCHRONOUS RECTIFICATION PRINCIPLE

Whatever method is used, the classic method or the ST method, as soon as a PWM signal is

logically ANDed with the switch control signal, the free wheeling diodes of the triple half bridge

configuration are used during the off time off the PWM signal and the current continues to flow

in the same direction in the motor. The ST7MC features a dead time generator that allows ap

plication of complementary PWM on the switch adjacent to the one where PWM is applied.

With this feature, the conduction losses can be reduced. This is called the “synchronous rec

tification”.

Precautions must be taken to avoid short circuits in half bridges. This is ensured by driving

high and low side switches with complementary signals and by managing the time between

the switching-off and the switching-on instants of the adjacent switches. This time is the dead

time and has to be adjusted depending on the devices connected to the PWM outputs and

their characteristics (intrinsic delays of level-shifters, delays due to power switches,...).

-

-

-

In the ST7MC, the dead time is set on six dedicated bits in a register allowing a range of dead

times from 125ns to 16µs. When Fmtc is 16MHz. Dead time can be set with steps of 125, 250

or 500ns.

As an example on Figure 14, if the dead time generator is activated, then during the off time of

the PWM on T3, T0 will be switched-on so the current will flow through the switch and not

through the free-wheeling diode D0.

Figure 15 shows the relationship between the output signals of the deadtime register on the

adjacent switches and its inputs.

Once activated, the dead time generator generates two output signals on the adjacent

switches: A and B.

The A output signal is the same as the input phase signal except for the rising edge, which is

delayed relative to the input signal rising edge.

The B output signal is the opposite of the input phase signal except the rising edge which is

delayed relative to the input signal falling edge.

25/39

Page 26

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 15. Dead times waveform

Reference

Input signal

Output A

Delay

Output B

Delay

5V

0V

5V

0V

5V

0V

Figure 16 and Figure 17 show waveforms of the signal on 2 adjacent switches during synchro-

nous rectification. Figure 17 is a zoom of Figure 16

The dead time has been set in this example to 0.75µs.

Figure 16. Oscilloscope waveform: synchronous rectification 1

1. Current Waveform in Phase A

26/39

2. signal on the high side switch

of phase A

3. signal on the adjacent switch,

the low side switch of phase A

when the synchronous

rectification is enabled and a

dead time is set

Page 27

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 17. Oscilloscope waveform: synchronous rectification 2

1. Current Waveform in Phase A

2. signal on the high side switch

of phase A

3. signal on the adjacent switch,

the low side switch of phase A

when the synchronous

rectification is enabled and a

dead time is set

6.2 SYNCHRONOUS RECTIFICATION CONFIGURATION

When driving a PM BLDC motor (PCN bit is reset in MDTG register), the PWM applied to the

output channel depends if the motor is driven in voltage or current mode but the dead times

are applied in the same way regardless of the source of the PWM signal.

As soon as the dead time generator is activated (DTE bit is set in MDTG register), a complementary PWM is applied to the adjacent switch. The dead time value is set-up through the bits

DTG [5:0] in MDTG register. The range can go from 125ns to 16µs with steps of 125ns, 250ns

and 500ns when Fmtc is 16MHz.

Note: It is also possible to add a chopper on the PWM signal output using bits HFE[1:0] and

HFRQ[2:0] in the MREF register.

DEAD TIME GENERATOR REGISTER (MDTG)

Read/Write (except bits 5:0 write once-only)

Reset Value: 1111 1111 (FFh)

7 0

PCN DTE DTG5 DTG4 DTG3 DTG2 DTG1 DTG0

Bit 7 = PCN: Number of PWM Channels.

0: Only PWM U signal is output to the PWM manager for six-step mode motor control (e.g. PM

BLDC motors)

1: The three PWM signals U, V and W are output to the channel manager (e.g. for three-phase

sinewave generation)

27/39

Page 28

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Bit 6 = DTE*: Dead Time Generator Enable

0: Disable the Dead Time generator

1: Enable the Dead Time generator and apply complementary PWM signal to the adjacent

switch

Bits 5:0 = DTG[5:0]*: Dead time generator set-up.

These bits set-up the deadtime duration and resolution

* = write once-only bit if PCN bit is set, read/write if PCN bit is reset. To clear the DTE bit if

PCN=1, it is mandatory to clear the PCN bit first.

28/39

Page 29

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

7 WINDING DEMAGNETIZATION

When the microcontroller switches from one step to the next, the non-powered winding needs

a certain demagnetization time. During this time, the current in the winding continues in the

same direction but decreases to zero. It is not possible to see the BEMF voltage as long as

this current is still present, because during this time the voltage on the winding is tied to 0V or

HV by the free-wheeling diode.

Due to the winding self-induction, the demagnetization time decreases if the reverse voltage

on the winding increases. We want to decrease the demagnetization time of the winding so

that the window to detect the BEMF zero voltage crossing event is wider. So the goal to de

crease this time and to accelerate the end of demagnetization event is to apply the maximum

reverse voltage on the winding that needs to be demagnetized. To do so, depending on the

previous step configuration as we are going to describe in this section, we can apply either the

PWM on the low side switch or on the high side switch to accelerate the demagnetization.

Let’s look at two examples to illustrate the two possible cases:

-

7.1 ACCELERATION OF DEMAGNETIZATION WHEN PWM IS APPLIED ON THE LOW SIDE SWITCH

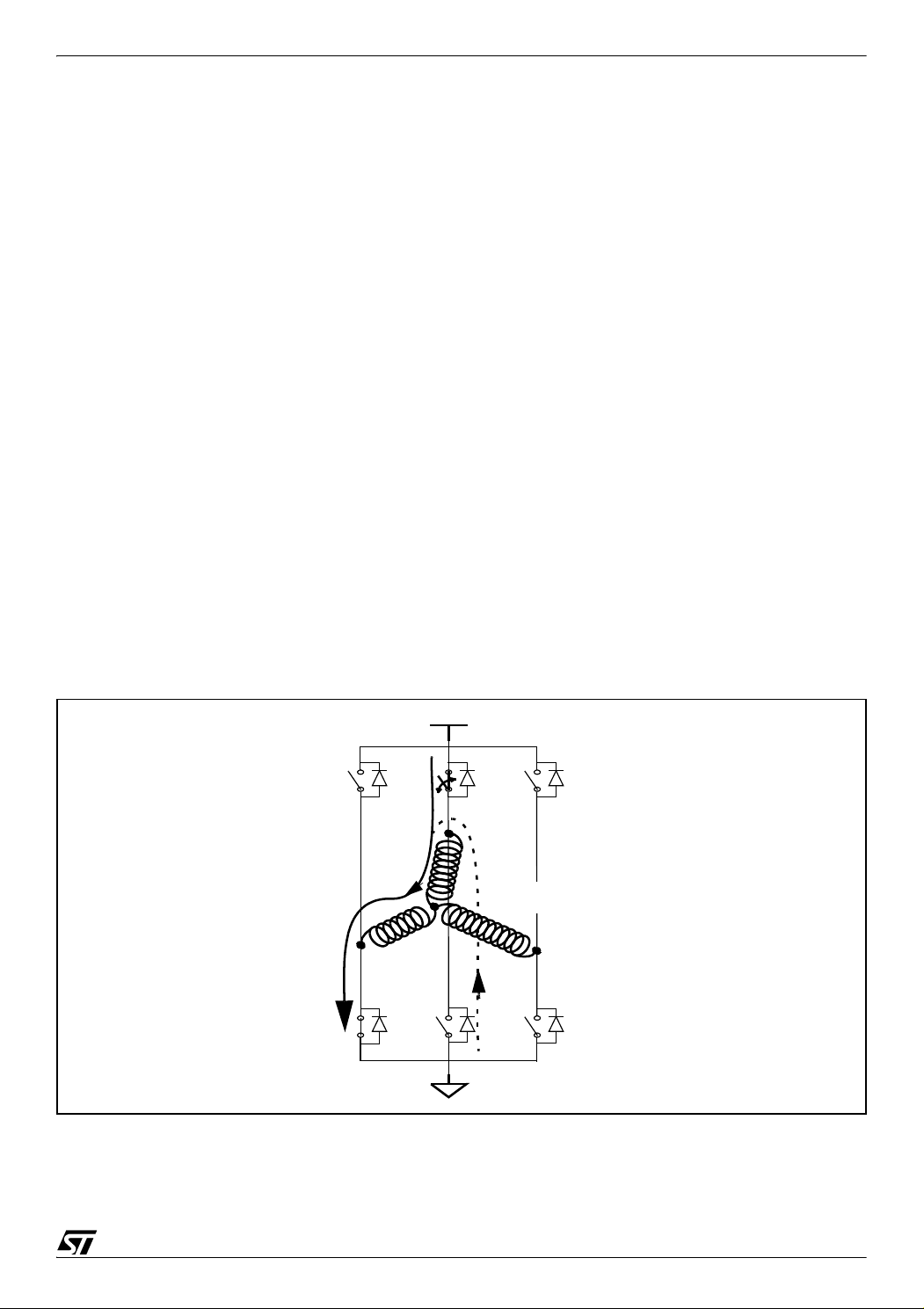

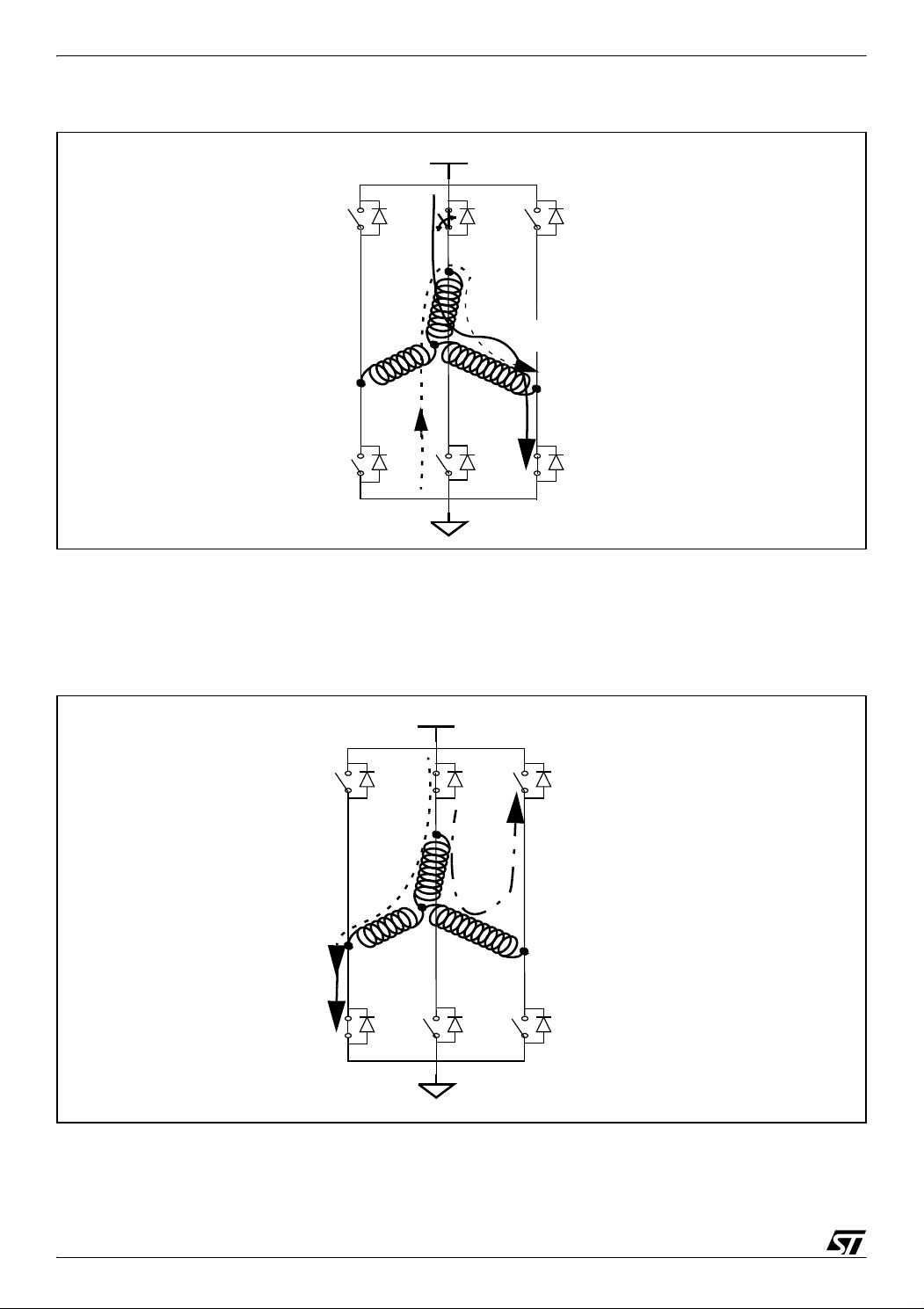

Figure 18 shows step Σ4 (switches T2-T3 are ON) with the normal current and the free-

wheeling current (dotted line) during the PWM OFF time of the high side switch T2.

Figure 18. Step Σ4 (switches T2-T3 are ON)

HV

T0

T3

D0 D2 D4

T2

Normal

current

M

A

D3

T5

T4

B

free-wheeling current

for BEMF reading (ST method)

C

D5

T1

D1

29/39

Page 30

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

When switching from step Σ4 (switches T2-T3 are ON) to step Σ5 (switches T4-T3 are ON), a

free-wheeling, decreasing demagnetization current is still present through the B terminal

(dashed line) and an increasing magnetization current appears through the C terminal (dotted

Figure 19 shows these two currents during the PWM ON time.

line).

Figure 19. Step Σ5 (switches T4-T3 are ON) during the demagnetization PWM ON time

HV

T0

A

T3

PWM on T2

T2

D0 D2 D4

B

M

D3

T5

T4

Normal mode

magnetization

current

C

D5

T1

free wheeling

demagnetization

current

D1

F

This means, during the PWM ON time:

– The potential of B is zero

– The potential of M is close to HV/3

Now depending on the switch we are going to apply the PWM signal, the demagnetization

time of winding B will be decreased and the end of demagnetization event will be accelerated

during this PWM signal OFF time. The numerous dedicated registers in the ST7MC peripheral

allow the flexibility to choose where to apply the PWM signal between the different events. The

maximum reverse voltage to decrease the demagnetization time is achieved during the OFF

time of the PWM signal.

30/39

Page 31

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 20. Acceleration of demagnetization during low side switch PWM OFF time

HV

T0

T3

PWM

D0 D2 D4

T2

A

D3

T5

T4

B

M

C

D5

T1

Demagnetization

current

Normal

current

D1

In our example, during step Σ4 (switches T2-T3 are ON), the VMB voltage on the MB winding

was positive. At the beginning of step Σ5 (switches T4-T3 are ON), the voltage on terminal B

will be tied to 0V and the shortest demagnetization configuration is the one that provides the

highest voltage at point M to apply the maximum reverse voltage and decrease the demagnet

ization time.

It is easy to verify that the highest voltage (2HV/3) is obtained when the PWM is applied only

on the low side switch T3. During the OFF time of this PWM signal (configuration shown in

Figure 20), the voltage at point M is 2HV/3. Otherwise if the PWM signal is applied on the high

side switch T4, then during the OFF time of the PWM signal, the voltage at point M is 0V. So,

in this configuration, the PWM signal has to be applied on the low side switch T3 after the com

mutation event in order to accelerate the demagnetization time during the OFF time of this

PWM signal.

-

-

7.2 ACCELERATION OF DEMAGNETIZATION WHEN PWM IS APPLIED ON THE HIGH SIDE SWITCH

Figure 21 shows step Σ3 (switches T2-T1 are ON) with the normal current and the free-

wheeling current (dotted line) during the PWM OFF time of the high side switch T2.

31/39

Page 32

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Figure 21. Step Σ3 (switches T2-T1 are ON)

HV

T0

T3

D0 D2 D4

T2

Normal

current

M

A

D3

T5

T4

B

free-wheeling current

for BEMF reading (ST method)

C

D5

T1

D1

When switching from step Σ3 (switches T2-T1 are ON) to step Σ4 (switches T2-T3 are ON), a

free-wheeling, decreasing demagnetization current is still present through the C terminal

(dashed line in

Figure 22) and an increasing magnetization current appears through the B ter-

minal (dotted line). Figure 22 shows these two currents during the PWM ON time.

Figure 22. Step Σ4 (switches T2-T3 are ON) during the demagnetization PWM ON time

HV

T0

Normal mode

magnetization

current

T3

D0 D2 D4

A

D3

PWM on T2

This means, during the PWM ON time:

– The potential of B is HV

32/39

T2

T5

T4

B

M

D5

free wheeling

demagnetization

current

C

T1

D1

Page 33

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

– The potential of M is close to 2HV/3

Now depending on the switch we are going to apply the PWM signal ON, the demagnetization

time of winding C will be decreased and the end of demagnetization event will be accelerated

during this PWM signal OFF time. The goal is to apply the maximum reverse voltage on

winding C.

Figure 23. Acceleration of demagnetization during high side switch PWM off time

HV

T0

Normal mode

magnetization

current

T3

D0 D2 D4

A

D3

PWM on T2

T2

B

M

T5

T4

D5

T1

Normal

current

demagnetization

current

C

D1

In our example, during step Σ3 (switches T2-T1 are ON), the VMC voltage on the MC winding

was negative. At the beginning of step Σ4 (switches T2-T3 are ON), the voltage on terminal C

will be tied to HV and the shortest demagnetization configuration is the one that provides the

lowest voltage at point M to apply the maximum reverse voltage and decrease the demagnet

ization time.

It is easy to verify that the lowest voltage HV/3 is obtained when the PWM is applied only on

the high side switch T2. During the OFF time of this PWM signal, the voltage at point M is HV/

3 (configuration shown in

Figure 23). Otherwise if the PWM signal is applied on the low side

switch T3, then during the OFF time of the PWM, the voltage at point M is HV. So, in this configuration, the PWM signal has to be applied on the high side switch T2 after the commutation

event in order to accelerate the demagnetization time.

-

33/39

Page 34

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

7.3 REGISTERS CONFIGURATION TO ACCELERATE THE DEMAGNETIZATION.

The ST7MC allows you to program different PWM configurations in sensorless mode. In

sensor mode, the demagnetization event is useless as the feedback information is not read

from the windings.

In order to minimize the demagnetization time in sensorless mode, the ST7MC allows you to

modify the PWM direction between the step commutation and the end of demagnetization.

In sensorless mode the OS2 bit in register MCRB enables the PWM on the high side or low

side channels between the commutation and the demagnetization event.

Table 3. OS bits in MCRB register

OS2 bit

0 On High Channels

1 On Low Channels

PWM after C and

before D

OS1 bit

0 On High Channels

1 On Low Channels

0 On High Channels

1 On Low Channels

PWM after D and

D event: Demagnetization

C event: Commutation

Z event: BEMF zero voltage crossing event

before Z

OS0

0

1

0

1

0

1

0

1

PWM after Z and

before next C

On high

channels

On low

channels

On high

channels

On low

channels

On high

channels

On low

channels

On high

channels

On low

channels

34/39

Page 35

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

8 CONFIGURATION EXAMPLE

This section gives a configuration example for a six-step 120° motor drive for a PM BLDC

motor in sensorless, current and autoswitched mode. The sensorless control method used

would be the ST method.

The configuration registers can be divided in two parts: Table 4 lists the configuration bits that

only need to be written once, Table 5 gives the step-dependent configuration bits. The registers in Table 2 must be updated within each commutation interrupt routine in order to select

the configuration for the next step.

Table 4. General Configuration Registers

Register

MPAR

MCRA

MCRB

MCRC OI HZ SZ SC SPLG VR2 VR1 VR0

MDTG PCN DTE DTG5 DTG4 DTG3 DTG2 DTG1 DTG0 Only PWM U is output to the PWM

MPHST

Notes:

- Bits marked with X depend on the motor and / or the application:

PZ depends on the noise present in the application,

DCB depends on the motor symmetry;

VR[2:0] bits depend on the noise level on the BEMF input pins.

- Bits marked with S have to be modified after each commutation (step dependent configuration). These

bits are summarized in

7 6 5 4 3 2 1 0

TES1 TES0 OE5 OE4 OE3 OE2 OE1 OE0

0 0 1 0 1 0 1 0

MOE CKE SR DAC V0C1 SWA PZ DCB The motor runs in autoswitched

1 1 0 0 1 1 X X

Res CPB HDM SDM OCV OS2 OS1 OS0

0 S S S S S 0 1

0 1 0 0 0 X X X

0 0 0 0 0 0 0 0

IS1 IS0 OO5 OO4 OO3 OO2 OO1 OO0

S S S S S S S S

Table 4. Those bits are taken in account only at the next commutation event.

Val ue

Comments

Outputs 0, 2, 4 are HIGH channels

Outputs 1, 3, 5 are LOW channels

mode,

current mode, sensorless mode.

PWM after end of demagnetization:

on HIGH channels.

Hardware Z event

Sampling at the end of PWM off time

manager

No Dead time generator

Input selection and output data

change at each step.

35/39

Page 36

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Table 5. Step Configuration Registers

Step

Σ

1

Σ

2

Σ

3

Σ

4

Σ

5

Current direction A to B A to C B to C B to A C to A C to B

High side T0 T0 T2 T2 T4 T4

Low side T5 T1 T1 T3 T3 T5

OO<5-0> output bits 100001 000011 000110 001100 011000 110000

Measure done on terminal:

Connected to pin

IS<1:0> selection bits value

MPHST

Back EMF shape

CPB value for BEMF detection

C B A C B A

MCIC MCIB MCIA MCIC MCIB MCIA

10 01 00 10 01 00

10100001 01000011 00000110 10001100 01011000 00110000

Falling Rising Falling Rising Falling Rising

0 1 0 1 0 1

(ZVD=0)

Voltage on measured point at the

0V HV 0V HV 0V HV

start of demagnetization

Transition at end of

demagnetization

Hardware demagnetization

HDM-HDM bit value

0V->BEMF

(rising)

always

possible

10 11 10 11 10 11

HV-

>BEMF

(falling)

not always

possible

0V->BEMF

(rising)

always

possible

HV>BEMF

(falling)

not always

possible

0V->BEMF

(rising)

always

possible

(Hard - Soft Demagnetization

Mask bits)

PWM side selection for acceler-

Low Side High Side Low Side High Side Low Side High Side

ating demagnetization

Driver selection for accelerating

T5 T0 T1 T2 T3 T4

demagnetization

OS2 bit 0 1 0 1 0 1

MCRB xx010001 xx111101 xx010001 xx111101 xx010001 xx111101

Σ

6

HV->BEMF

(falling)

not always

possible

36/39

Page 37

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

9 CONCLUSION

As seen in this document, the ST7MC with the features of its dedicated peripheral offers a lot

of combinations for the PWM management when driving a BLDC motor. Thanks to a high

hardware integration (both digital and analog) and a high flexibility of configuration through

dedicated registers, the PWM management can be fine-tuned and optimized to reach and

maintain the best efficiency of the motor whatever the control method.

This flexibility combined with the fact that the ST7MC family comes with the 8-bit ST7 core, a

very well known and stable core, and is offered in a wide range of packages (8Kbytes to

60Kbytes memory size Flash/ROM and from 32 pins to 80 pins) allow this part to be suitable

for all the motor control applications requiring a scalar motor control.

The associated development kit, ST7MC-KIT/BLDC, that is provided with full C libraries software and reference hardware design allows you to get his application up and running in a minimum amount of time for a better “time to market”.

In conclusion, a good time to market, high performances and cost savings are the keys of a

successful design done with the ST7MC.

37/39

Page 38

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

10 REVISION HISTORY

Table 6. Document revision history

Date Revision Changes

06-Jan-2005 1 Initial release

12-Jul-2007 2 Removed references to obsolete products

38/39

Page 39

PWM MANAGEMENT FOR 3-PHASE BLDC MOTOR DRIVES USING THE ST7MC

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE

SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN

PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT

SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

39/39

Loading...

Loading...