Page 1

AN2002

APPLICATION NOTE

Usin g the Demoboard for the TD350 Advanc ed IGBT Driver

1 Introduction

TD350 is an advanced I GBT/MOSFE T driver with integrated cont rol and protection functi ons. Principles

of operation and application examples for the TD350 are described extensively in application note

AN1944. The presen t application note con cerns the characteristics a nd use of the dem oboard available

for testing the TD350.

Figure 1: TD350 pinout

1

VREF

IN

2

14

13

DESAT

VH

NC

COFF

NC

LVOFF

3FAULT

4

5

6

7

date code

TD350I

12

11

10

9

8

OUT

OUTL

VL

CLAMP

GND

Bevelled edg e

indicates pin 1

location

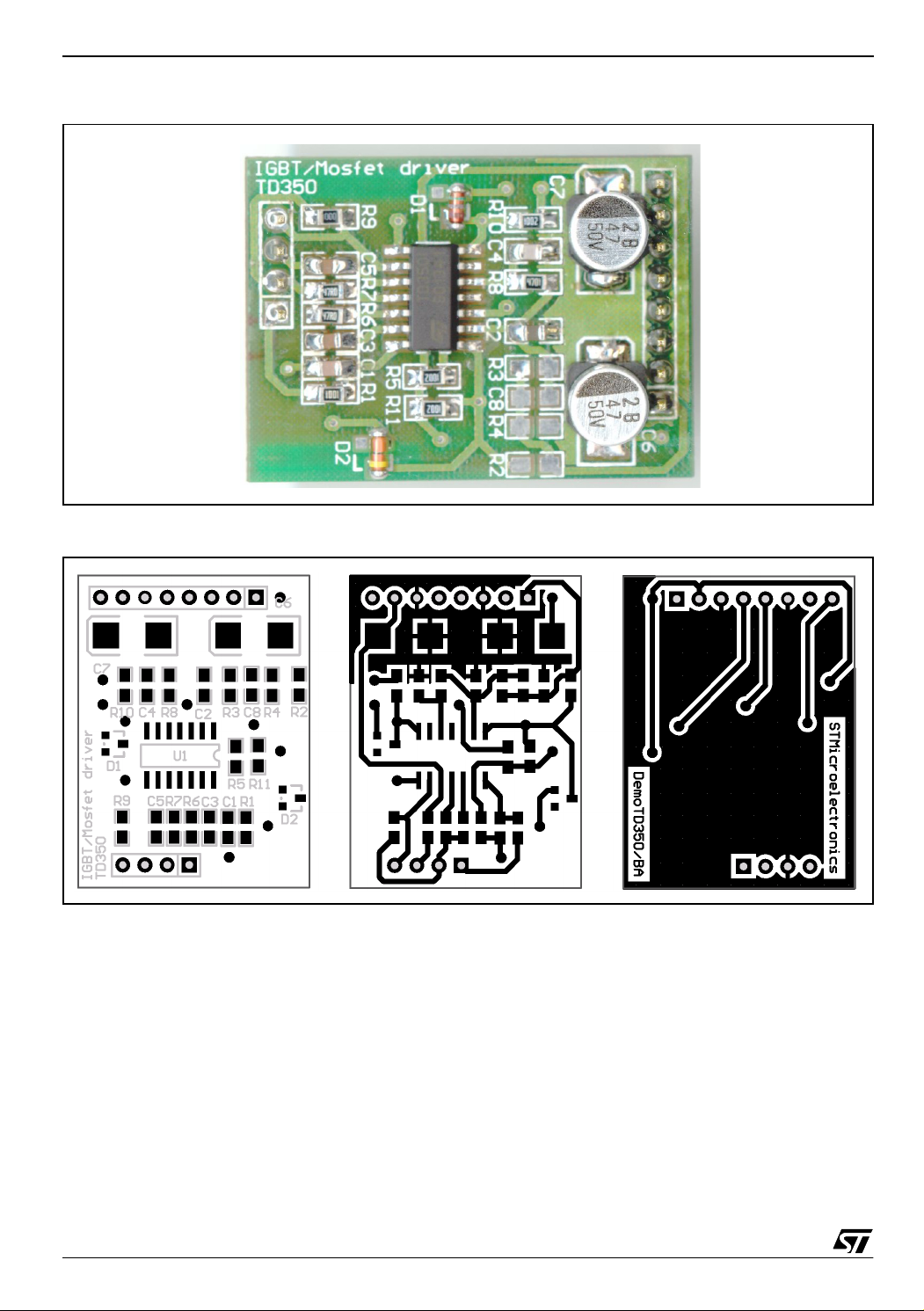

2 Printed circuit board presentation

The demoboard is a 26x35mm double-sided PCB with the TD350 and its peripheral components

mounted in a typical configuration (pictured in Figure 2). To aid in the understanding and easy

modification of the board, the PCB top-side and bottom-side layers, as well as the silk-screen previews

are shown i n Figure 3.

The demoboard electrical schematic is presented on Figure 4, and the associate d bi ll o f material can be

found on Table 1 on page 5.

Let’s study step by step the demoboard original configuration, and the way it can be modified to be

adapted to the application.

July 2004

Revision A 1/8

Page 2

AN2002 Using the Demoboard for the TD350 Advanced IGBT Driver

Figure 2: Demoboard layout

Figure 3: Demoboard PCB: Silk-screen, top-layer an d bottom -layer previews

2.1 Input stage

The TD350 can be drive n by either a pulse transformer or an optocoupler. The dem oboard is set up to

use an optoc oupler. The T D350 IN pin i s clamped t o 5V by a zener diode D2 and its bleeding resistor

R11=10K (see demoboa rd schematic on Fi gure 4). To interface the demoboard with the system, the IN1

pin of the input connector can simply be connected to a low-side optocoupler, as show on Figure 5. An

optional filtering capacitor can be added (for instance 47pF) in the event of a highly noisy environment,

although the TD350 already includes a filtering o n input signals and reject s signals smaller than 1 00ns

specification).

(t

onmin

The demoboard can be modified to be driven by a pulse transformer by implementing the optional

components R2, R3, R4 and C8. The principle of operation with a pulse transformer is explained in

AN1944.

2/8

Page 3

Using the Demoboard for the TD350 Advanced IGBT Driver AN2002

VH

GNDVLOUTL

2.2 Output stage

The TD350 uses separate sink and source outputs (OUTL/OUTH ) for easy gate driving. The integrated

circuit output stage is able to sink/source about 2A/1.5A typical at 25°C, but the IGBT turn-on and turn-off

current can be limited independently by the g ate resistors R6 and R7 includ ed on the demoboard. The

original value for these resistors are R6=R7=47R.

Output current capability can be increased by using an external buffer with two low-cost bipolar

transistors. This configuration is described in Section 4 on page 7.

2.3 Active Miller Clamp

The TD350 offers an alternative solution to the problem of the Miller current in IGBT switching

applications. Instead of driving the IGBT gate to a negative voltage to increase the safety margin, the

TD350 uses a dedicated CLAMP pin to control the Miller current. When the IGBT is off, a low impedance

path is established between IGBT gate and em itter to carry the Miller current, and the voltage spike on

the IGBT gate is greatly reduced. The CLAMP switch is opened when the input is activated and is closed

when the actua l gate voltage goes close to the ground level. In th is way, the CLAMP funct ion doesn’t

affect the turn-off characteristic, but only keeps the gate to the low level throughout the off time.

On the demoboard, the CLAMP pin is connected to the IGBT gate by strap R9. This strap can be

removed when the clamp feature is not needed, or when an external buffer is used (see reference

schematic on Figure 6).

Figure 4: Demoboard PCB: Electrical Schematic

VH

R6

R7

C1

C3

C5 C7

R1

VH

C6

R9

VL

1

2

3

4

Desat

Out

Gnd

Clamp

Gnd

Fault

Gnd

Lvoff

In2

VH

In1

R2*

1

2

3

4

5

6

7

VL

VL

8

C8*

VH

R3*

C2VH

R4*

R5

VREF

R8

C4

R10

D1

(*): optional parts not m ounted on demoboard original configurati on

R11

D2

TD350

IN

1

VREF

2

FAULT

3

NC

4

COFF

5

NC

6

LVOFF

7

DESAT

OUTH

CLAMP

14

13

12

11

10

9

8

2.4 2-level turn-off

In the event of a short-circuit or overcurrent in the load, a large voltage overshoot can occur across the

IGBT at turn-off and can ex ceed t he IGB T breakdown voltage. By reducing the ga te voltag e bef ore turnoff, the IGBT current i s limited a nd the pote ntial overvoltage is redu ced. Thi s technique is called 2-level

turn-off. Both the level and duration of the intermediate off level are adjustable. Duration is set by the

external resistor R8 and capacitor C4 i n conjunction with the integrated voltage reference for accurat e

3/8

Page 4

AN2002 Using the Demoboard for the TD350 Advanced IGBT Driver

timing. The level can be easily set by an ext ernal Zener diode D1, and its v alue is chos en depending on

the IGBT characteristics. This 2-level turn-off sequence takes place at each cycle, it has no effect if the

current doesn’t exceed the normal m aximum rated value, but protects the IGBT in case of overcurrent

(with a slight increase of conduction losses).

In the demoboard original configuration, Ta (duration of the intermediate level) is set to approximately

1.5µs by R8 =4K7 and C4=470pF. The i ntermediate level is set by 1 0V Zener diode D1 and b leeding

resistor R11=10K.

Tip: How can you inhibit 2-level turn-off?

Connect LVOFF to VH b y replacing R10 by a short-circuit, remove C 4 capacitor and keep

COFF pin connected to Vref by R8=4K7.

2.5 Desaturation protection feature

The desaturation function provide s a protection against overcurrent events. Voltage ac ross the IGBT is

monitored, and the IGBT is turned off if the vo ltage th reshold is reached. A blanking time, t

an internal 250mA c urrent source a nd an ex ternal capacitor C1. The DES AT pin is con nected t o output

demoboard connector by R1 resistor. In order to implement the desaturation feat ure, an external high

voltage diode (1kV or more) should be connected between the IGBT collector and the demoboard output

connector pin 1 (see Figure 6 for reference schematic).

, is set using

b

The high voltage diode blocks the high voltage during IGBT off state. This diode doesn’t need to be fast,

a standard 1kV (or more) diode is acceptable.

During operation, the DESAT capacitor is discharged when TD350 out put is low (IGBT off). When the

IGBT is turned on, the DE SAT capac itor starts c harging and desat uration protec t ion is effective after the

blanking time, t

With the capacitor used in the demoboard (C1=100pF), the blanking time value will be close to 3ms.

Tip: What should one do with the DESAT pin when it isn’t used?

, has elapsed:

b

C

1

t

7.2V

b

Connect DESAT to GND by shorting together pin 1 and pin 3 on the demoboard output

connector (see Figure 5).

----------------- -Þ=

250µA

4/8

Page 5

Using the Demoboard for the TD350 Advanced IGBT Driver AN2002

Table 1: Bill of materials f or demoboard

Designator Description Value Package

R1 desaturation resistor 1K-1% 0805

C1 desaturation filtering capacitor 100pF-X7R 0805

C3 positive supply ceramic decoupling capacitor 100nF-X7R 0805

C5 negative supply ceramic decoupling capacitor 100nF-X7R 0805

C6 positive supply electrolytic capacitor 47

C7 negative supply electrolytic capacitor 47

R6 turn-on gate drive resistor 47R-1% 0805

R7 turn-off gate drive resistor 47R-1% 0805

R9 strap (optional) 0R 0805

R11 bleeding resistor for Zener diode D2 10K-1% 0805

C2 Vref decoupling capacitor 10nF-X7R 0805

R5 FAULT pin pull-up resistor 10K-1% 0805

R8 2-level turn-off timing resistor 4K7-1% 0805

C4 2-level turn-off timing capacitor 470pF-X7R 0805

R10 bleeding resistor for Zener diode D1 10K-1% 0805

D1 Zener diode for 2-level turn-off intermediate level programming 10V Melf

D2 Zener diode for IN pin level 5V1 Melf

U1 IGBT/MOSFET driver TD350 SO-14

µF-50V d6.3 x h7.7

µF-50V d6.3 x h7.7

J1 Input connector 8-lead

J2 Output connector 4-lead

C8 Vref/2 filtering capacitor not mounted 0805

R4 Vref/2 divider bridge lower resistor (only with pulse transformer) not mounted 0805

R3 Vref/2 divider bridge upper resistor (only with pulse transformer) not mounted 0805

R2 adjustment resistor (only with pulse transformer) not mounted 0805

5/8

Page 6

AN2002 Using the Demoboard for the TD350 Advanced IGBT Driver

3 Application example no. 1

This first application example demonstrates the typical configuration in which TD350 can be used in low

and medium power applications. In this configuration, the TD350 is able to drive IGBTs with current

ratings up to about 50A. The schematic showing how to connect the demoboard to the optocoupler,

power supply and IGBT module is presented on Figure 5. The demoboard doesn’t require any

modification in order to be used in this configuration. However, it should be noted that C5 and C7

(decoupling capacitors for negative supply) are not needed in this example and they could be removed to

optimize application cost and PCB space.

The main characteristics of this example are:

l

Single S upply: w ith the benefit of the Active Miller Clamp feature, n egative supply isn’t need ed to

avoid mistriggering of the IGBT at turn-off

l

Active Miller Clamp: the feature is implem ented on the demoboard by conne cting TD350 CLAMP

pin to the IGBT gate with R9=0R resistor

l

2-Step Turn-Off: at turn-off the gate-to-source voltage will be lowered to 10V during approximately

1.5µs to reduce over-voltage stress on the IGBT in case of over-current event

l

DESAT not used: to simplify the design DESAT pin is connected to GND to inhibit the function. To

implement the desaturation protection, see Section 2.5.

Figure 5: TD350 demoboard used in basic application

6/8

47pF*

16V

In2

1

VH

2

Gnd

3

In1

4

Fault

5

Gnd

6

VL

7

8

Lvoff

(*): opt i on al part s

TD350 de m o bo a rd

Desat

Out

Gnd

Clamp

1

2

3

4

Page 7

Using the Demoboard for the TD350 Advanced IGBT Driver AN2002

Desat

Clamp

4 Application example no.2

This second application example shows the typical configuration in which the TD350 can be used in high

power applications. With the use of an additional buffer, the TD350 can drive IGBTs with a current rating

above 100A. The schematic in Figure 6 shows how to connect the demoboard with the optocoupl er and

the power supplies o n t he i nput side, and with the IGBT module and the gate buffer circuit on th e output

side.

The demoboard n eeds a few m odif ications wi th respec t to its original conf iguration to be us ed as s ho wn

in this example:

1)The R9 strap should be removed.

2)The resistors R6 and R7 should be replaced by short-circuits.

The main characteristics of this example are:

l

A dual supply +16V/-10V is used as often needed in high power applications,

l

Output buffer stage: considering the high val ue of the IGBT gate c apacitanc e, t he TD350 output is

connected to a discrete buffer stage made of two complementary bipolar transistors,

l

CLAMP used as secondary gate discharge: the CLAMP pin is connected to a external buffer to

feature a secondary gate discharge,

l

DESAT feature is implemented.

Figure 6: TD350 demoboard used in high power applications

In2

47pF*

16V

10V

1

2

3

4

5

6

7

8

TD350 demoboard

VH

Gnd

In1

Fault

Gnd

VL

Lvoff

(*): opti onal part s

Out

Gnd

1

2

3

4

1kV

diode

VH

T1

T2

VL

T3

VL

7/8

Page 8

AN2002 Using the Demoboard for the TD350 Advanced IGBT Driver

Information furnished is believed to be accurate and reliable. However, STMicroelectronics a ssumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from

its use. No license i s granted by implication or ot herwise under any patent or patent rights of STMi croe lectr onics. S pecifications

mentioned in this publication are subject to change without notice. This publicatio n supersedes and replaces all information

previously supplied. STMicroe lectronics products are not aut horized for use as cr itical components in life su pport devices or

systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

All other n ames are the property of the ir respective owners

© 2004 STMicroelectronics - All Rights Reserved

Australi a - Belgium - Brazil - Canad a - China - Czech Repubic - Fi nl and - France - Germany - Hong Kong - India - Israel - Italy - Japan

Malaysia - M al ta - Morocco - Singapore - Sp ai n - Sweden - Switzerland - United Kingdom - United S tates

STMicroelectronics GROUP OF COMPANIES

www.st.com

8/8

Loading...

Loading...