Page 1

AN1957

APPLICATION NOTE

Microprocessor Supervisor Functions

Designers of microproce ssor systems have to achieve high r eliability, in the face of a large number of

threats to stabilit y or e ven c orr ec t f u nc tio ning (s uch as , v ol tage d ro ps , g li tch es , long ramp-up times, p ro grams stuck in endless loops, etc.).

Supervisor circuits, fro m STMicroelectronics, provide highly effective solutions for minimizing the risks of

system failure, and for ensuring the safe running of the system, at a low cost. The m embers of the ST

Supervisor family offer various combinations of functions.

This Application N ote describes the main Sup ervisor functions and fea tures, to help the user to understand their principl es and the advantages of us ing them, through the desc ription of waveforms, rec ommended values, and hardware hookup diagrams.

Overview of ST Supervisors

– Microprocesso r Sup ervi s ors

STM705, STM706, STM706T/S/R, STM707, STM708, STM708T/S/R, STM813L, STM706P,

STM6321L/M, STM6321T/S/R, STM6821L/M, STM6821T/S/R, STM6823L/M, STM6823T/S/R,

STM6824L/M, STM6824T/S/R, STM6825L/M, STM6825T/S/R

– Microprocessor Supervisors with Switchover

M40SZ100W, M40Z111, M40Z300W, STM690A, STM692A, STM690T/S/R, STM802L/M, STM802T/

S/R, STM703, STM704, STM704T/S/R, STM806T/S/R, STM805L, STM805T/S/R, STM804T/S/R,

STM817L/M, STM818L/M, STM819L/M, STM795T/S/R

– TIMEKEEPER™ Sup er vis or s

M41ST95W, M41ST87W, M41ST87Y, M41ST85W, M41ST85Y, M41T315V, M48T201V, M48T201Y,

M48T212V

This Application Note is dedicated to the Microprocessor Supervisor and Microprocessor Supervisor with

Switchover families.

1/22March 2005

Page 2

AN1957 - APPLICATION NOTE

TABLE OF CONTENTS

Overview of ST Supervisors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 1. Supervisor Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

POWER-ON RESET AND LOW VOLTAGE DETECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Block Diagram Showing the Supervisor Reset Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 1. Supervisor Reset Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Reset Waveforms for the Microprocessor Supervisor Devices . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Power-On Reset and Low Voltage Detect Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Reset Timings for the STM703/704 Supervisor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. Reset Thresholds (V

Hardware Hookup for the STM703/704 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Hardware Hookup for the STM703/704 Supervisor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

POWER-FAIL COMPARATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Block Diagram of a Power-Fail Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Block Diagram of a Power-Fail Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hardware Hookup for the STM692A Supervisor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Example calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Recommended Resistances for some V

Figure 5. Hardware Hookup for the STM692A Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Example of Power-Fail Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Voltage Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 5. Power-Fail Values for all Microprocessor Supervisors (except

for the devices mentioned in Table 6.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 6. Power-Fail Values for 3V Microproces sor Superv isor s

with Battery Switchover (STM690/704/802/804/805/806) . . . . . . . . . . . . . . . . . . . . . . . . 10

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RST

Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TRIP

WATCHDOG TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Logic Diagram of a Watchdog Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8. Watchdog Timer Input and Output Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 7. Watchdog Timer Time-out Value for the STM705 Supervisor. . . . . . . . . . . . . . . . . . . . . 11

Hardware Hookup for the STM705 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. Hardware Hookup for the STM705 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

BATTERY SWITCHOVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 10.Block Diagram of a Battery switchover Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Switchover Waveforms for the STM806R Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11.Battery Switchover Waveforms for the STM806R Supervisor. . . . . . . . . . . . . . . . . . . . . 14

Figure 12.Switchover Waveforms with Hysteresis Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 8. Switchover Values for the STM806R Supervisor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hardware Hookup for the STM806R Supervisor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 13.Hardware Hookup for the STM806R Supervisor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hardware Hookup for the STM795 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 14.Hardware Hookup for the STM795 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2/22

Page 3

AN1957 - APPLICATION NOTE

CHIP ENABLE GATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 15.Chip Enable Gating Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Typical Waveforms for the STM818 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 16.Typical Waveforms for the STM818 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 9. Typical values for the STM818 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hardware Hookup for the STM818 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 17.Hardware Hookup for the STM818 Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

BATTERY FRESHNESS SEAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 18.Typical Waveforms for the STM817/818/819 Supervisors . . . . . . . . . . . . . . . . . . . . . . . 20

CONCLUSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 10. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3/22

Page 4

AN1957 - APPLICATION NOTE

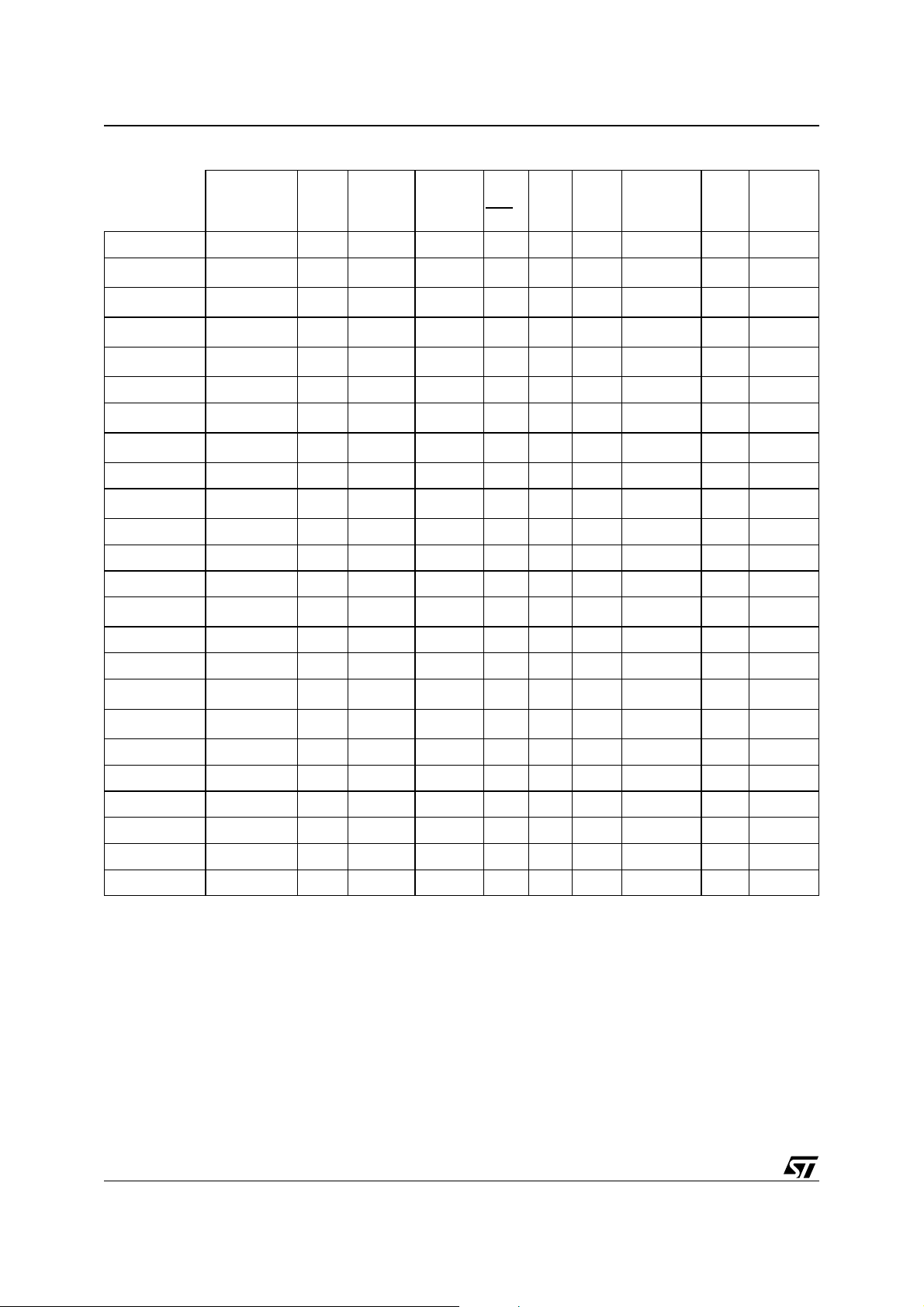

Table 1. Supervisor Options

Active

3V or 5V

Supervisor

Battery

Switch

over

Watchdog

Input

Watchdog

output

Active

Low

(1)

ST

R

STM690T/S/R 3V !! ! !

STM690A

STM692A

STM703

STM704

(3)

(3)

(4)

(4)

5V !! ! !

5V !! ! !

5V !!!!

5V !!!!

STM704T/S/R 3V !!!!

STM705

STM706

(5)

(5)

5V !!! !!

5V !!! !!

STM706T/S/R 3V !!! !!

STM706P

(6)

3V !! !!!

STM707 5V !! ! !

STM708 5V !! ! !

STM708T/S/R 3V !! ! !

STM795T/S/R 3V !

(2)

!

STM802L/M 5V !! ! !

STM802T/S/R 3V !! ! !

STM804T/S/R

STM805T/S/T

(7)

(7)

3V !!

3V !!

STM805L 5V !! ! !

STM806T/S/R 3V !!!!

STM813L 5V !! !!!

STM817L/M 5V !! ! ! !

STM818L/M 5V !! ! !!

STM819L/M 5V !!!!!

Note: 1. Push-Pull Output (unless otherwise specified).

2. Open drain output.

3. STM690A has a typical Reset Threshold of 4.65V and STM692A has a typical Reset Threshold of 4.40V.

4. STM703 has a typical Reset Threshold of 4.65V an d ST M704 has a typical Reset Threshold of 4.40 V.

5. STM705 has a typical Reset Threshold of 4.63V an d ST M706 has a typical Reset Threshold of 4.38 V.

6. The STM706P is identical to the STM706R, except for i ts Re set output which is active High.

7. STM804T/S/R and STM805T/S/R have different minimum and maximum Reset Thresholds with V

datasheet).

High

RST

!

!

(1)

(2)

(2)

Manual

Reset

Input

Power-fail

Comparator

!

!

falling and VCC rising (see

CC

ChipEnable

Gating

!

Battery

Freshness

Seal

4/22

Page 5

AN1957 - APPLICATION NOTE

POWER-ON RESET AND LOW VOLTAGE DET ECT

After system start-up, a certain period of time is required for the power supply voltage to stabilize. For this

reason, ST Supervisor devices generate a Reset pulse after power-up (the minimum pulse width is

t

= 140ms, see Table 2.). Over the t

rec

the registers are set to their default values. This function is called Power-On Reset (POR).

Some designers attempt to use RC circuits, instead of a Reset implementation, because it is cheaper. But

it is also unsafe and u nreliable. RC circu its are not suitable fo r use as professional devi ces in industr ial

environments (see REFERENCES section, AN1772).

Another major function is Low Voltage Detect (LVD), which detects power supply brownouts and glitches.

Whenever V

after VCC increases above the V

falls below the Reset thres hold (V

CC

rst

is guaranteed. Also, if the triggering event is a narrow glitch, an RC circuit will only generate a poor Reset,

which may lead to malfunct ioning of the mi croprocess or (failing t o load registers correctly, ex ecuting invalid instructions, processing incorrect data, etc.).

Some Supervi sor devi ces in clude a Manua l Reset i nput (M

device, to generate a Reset. T ypically, a low-c ost push-button s witch is conne cted to the Manual Res et

input, which allows the user to restart the pr ocessor witho ut turning off the power. No add itional co mponents are needed becaus e Sup er viso r de vi ce s al ready inc lu de a deb oun ce circ uit that fil ter s the nois e of

contact closure. This fun ction c an be us ed to de bug , to pe rf orm the final test of a process or, or to r est art

a processor that is locked. The Reset button is also useful in systems where the processor is never turned

off, even when the system is in Off mode. Some processor s inclu de an interna l Reset that operates cor rectly under stable power supply conditions, but usually has difficulties in handling voltage drops and transients as well as looser tolerances for V

period, during which reset is asserted, the clock is stabilized and

rec

), the Reset output is ass erted and remains so t

RST

rec

threshold. In the case of an RC circuit, no minimum Reset pulse width

R) that can be used by the user, or the external

. The use of an external Reset is therefore recommended.

rst

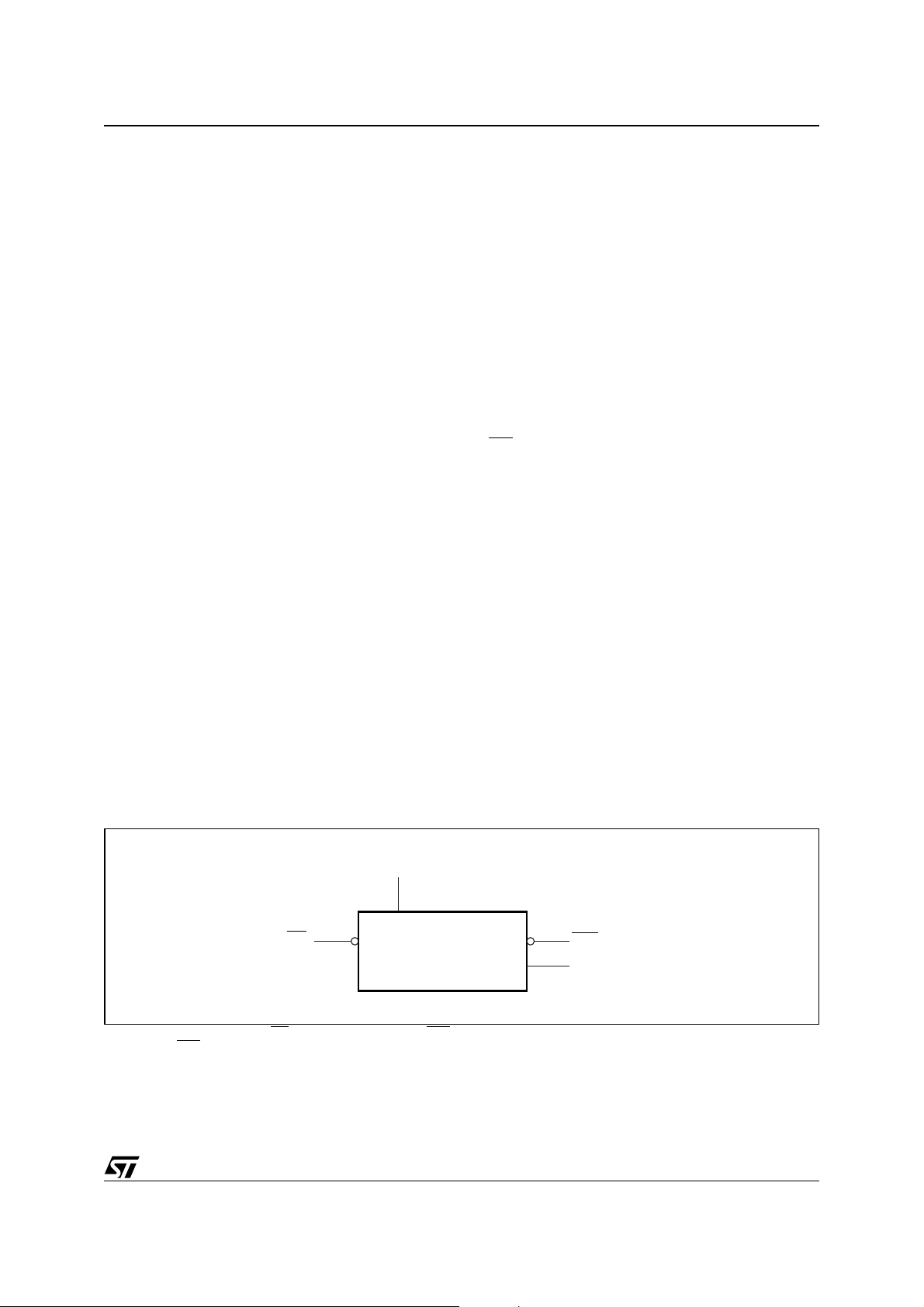

Block Diagram Showing the Supervisor Reset Feature

Figure 1 . illustrates the Power-On Reset, Low Vol tage Detect and Manu al Reset features. The Reset is

asserted if one of the following events occurs:

■ system start-up;

■ Brownout, voltage drop, significant transient or glitch, negative voltage spike etc. on the power supply

line;

■ Manual Reset.

Figure 1. Supervisor Reset Features

V

CC

RESET

Power-On Reset

Low V oltage Detect

RST

ai10104

Note: V

MR RST

is the supply voltage, MR i s the Manu al Reset input . RST and RST are Reset outputs. Supervi sor dev ices can have an ac tive-Lo w

CC

output (R

ST), an active-High output (RST) or both.

5/22

Page 6

AN1957 - APPLICATION NOTE

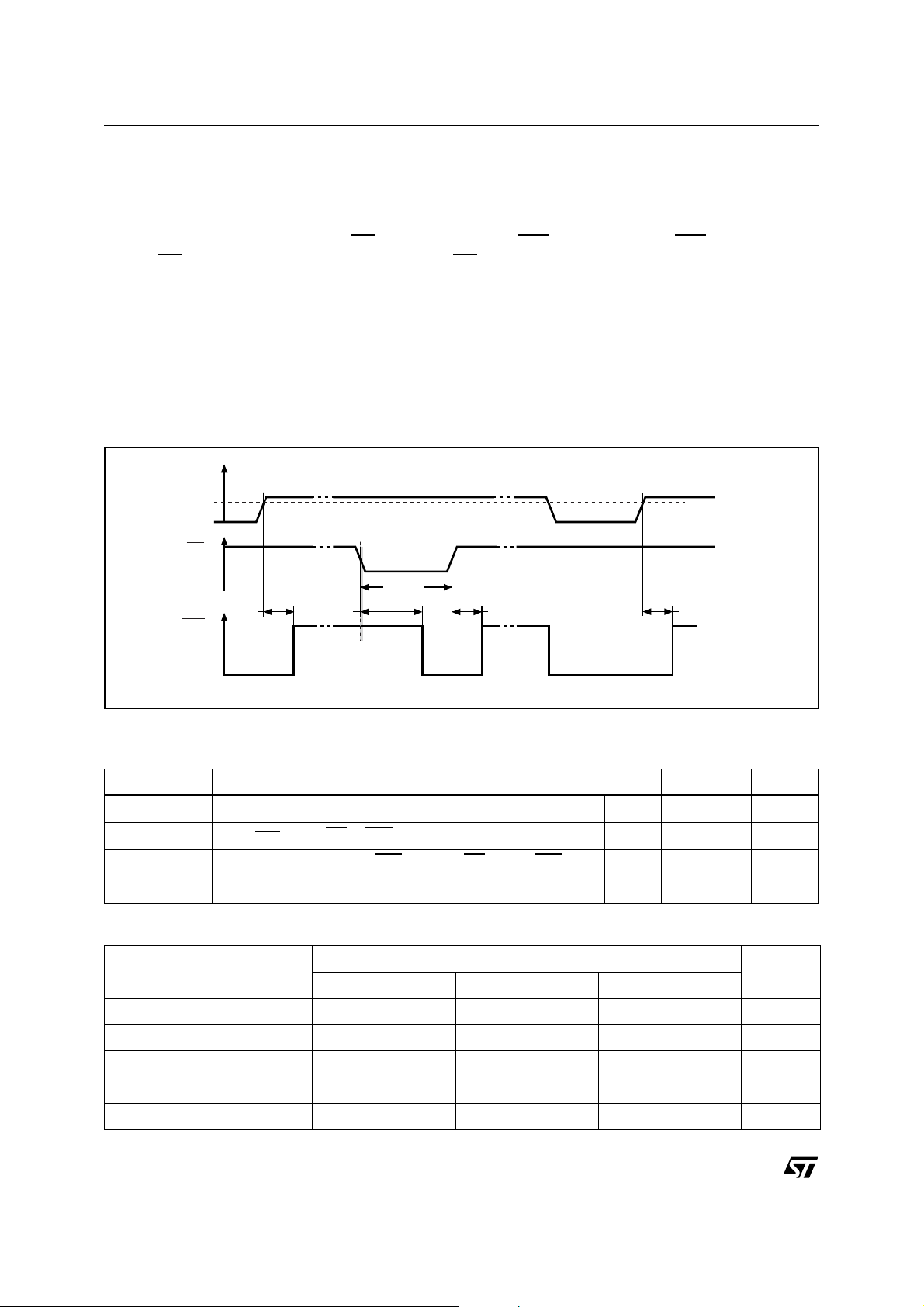

Reset Waveforms for the Microprocessor Supervisor Devices

When the input vol tage l evel re aches th e Re set th reshold (V

holds the Reset output signal (RST

) Low for a minimum time of t

2.).

Switching the Manual Reset signal (M

long as MR

is kept Low, and returns High t

R) to Low, causes the RST signal to go Low. RST remains Low as

after MR has been released.

rec

All Microprocesso r Supervisor device s have glitch immunit y. That is, the minimum MR

quired to Reset the output is fixed. All shorter pulses are ignored.

The Supervisor also r eacts to vol tage drops, brow nouts a nd signific ant glitc hes. If the inpu t voltage fa lls

below V

, the Reset output is asserted.

RST

Note that some Supervisor devices have a Reset output that is active High (RST). They therefore have a

waveform that is the inversion of the one that is shown in Figure 2.

Figure 2. Power-On Reset and Low Voltage Detect Waveforms

) after system power-up, the Super visor

RST

before driving it High again (see Figure

rec

pulse width re-

CC

Power-up

t

rec

Manual Reset

t

MLRL

Manual Reset

Glitch Immunity

t

MLMH

t

rec

Voltage drop

t

rec

Note: V

V

V

RST

MR

RST

is the Reset threshold, see Table 3. for values.

RST

Table 2. Reset Timings for the STM703/704 Supervisor

Symbol Alt Parameter Value Unit

t

MLMH

t

MLRL

t

rec

t

MR

t

MRD

MR Pulse Width Min. 150 ns

MR to RST Output Delay Max. 250 ns

V

to RST High and MR High to RS T High

RST

Min. 140 ms

Manual Reset Glitch Immunity Typ. 100 ns

AI10105

Table 3. Reset Thresholds (V

Supervisor

RST

)

Reset threshold (V

RST

)

Min. Typ. Max.

STM706P/70xR 2.55 2.63 2.70 V

STM70xS 2.85 2.93 3.00 V

STM70xT 3.00 3.08 3.15 V

STM692A/704/706/708, 8xxM 4.25 4.40 4.50 V

STM690A/703/705/707, 8xxL 4.50 4.65 4.75 V

6/22

Unit

Page 7

AN1957 - APPLICATION NOTE

Hardware Hookup for the STM703/704 Supervisor

In the example of Figure 3., the Reset output is asserted in three cases:

■ during system power-up, until V

■ after a V

■ by pressing the Manual Reset push-button (the Reset button should be held for at least for t

drop (VCC falls below V

CC

The Manual Reset input is not necessarily connected to a physical push button switch, it can also be connected to a peripheral, provided that a minimum MR

If the Res et cir cuit i s plac ed in a noi sy envi ronme nt, or if MR

to use an external 0.1µF capacitor, as shown in Figure 3.

The MR

input includes an internal pull-up resistor. So in applications where the MR input is not used, the

pin can be left unco nnected. The MR

drain output.

It is always appropria te to conne ct a deco upling c apacitor in parall el with the power su pply. Th e recommended value is 1µF.

Figure 3. Hardware Hookup for the STM703/704 Supervisor

is stabilized (VCC is greater than V

CC

)

RST

) for a duration of t

RST

rec

MLMH

pulse width of 150ns is ensured.

is driven from long cables, it is recommended

input can be driven with a T TL ou tpu t, a CMOS output, or an open

).

Microprocessor

V

GND

RST

CC

V

CC

C

1

1µF

STM703/704

1

OUT

V

2

CC

V

3

SS

PFI PF0

45

SO8/TSSOP8

V

BAT

RST

MR

8V

7

6

Reset

Button

C

2

0.1µF

AI10106

7/22

Page 8

AN1957 - APPLICATION NOTE

–

----

–

POWER-FAIL COMPARATOR

Inadvertent or unexpected power loss can cause a number of malfunctions in a system (data loss, uncontrolled program status, indeterminate processor state, etc.).

For a reliable design, sys tems should rece ive early power fail ure warning, to leave enough time for the

microprocessor to start a safeguard routine, for backing up crucial data, registers, etc.

Power-fail comparato rs are used to monitor unregulated powe r supplies. The ir reaction to power los s is

very fast, and can provide enough time to execute all the necessary safeguard processes that precede an

expected power failure (see REFERENCES section, AN1336).

Block Diagram of a Power-Fail Comparator

The power-fail comparator works like an ordinary comparator with hysteresis (see Figure 4.). The PowerFail Input (PFI) is compared to an internal reference voltage, the power-fail threshold, V

on PFI is less than V

, the Power-Fail Output (PFO) is assert ed.

PFI

Figure 4. Block Diagram of a Power-Fail Comparator

PFI

PFO

. If the voltage

PFI

V

PFI

ai10107

Hardware Hookup for the STM692A Supervisor

The Power-fail compa rator can be used i n many different ways . It is most comm only used as an Early

Power-Fail Warning (see Figure 5.) to monitor an unregulated supply voltage.

Two external resistors R

and R2 form a voltage divider to set the voltage level (V

1

) below which PFO

TRIP

is asserted (see the waveforms shown in Figure 6.).

Usually, a value is selected for R

V

R

×=

2

TRIPVPFI

--------------------------

V

PFI

R

1

, Where V

, then R1 is derived using the following formula:

2

= 1.25V.

PFI

The sum of the resista nces sh ould be ab out 1MΩ t o minimize power co nsumption , and the to lerance of

the resistor should not exceed 1%, to ensure that there are not large variations in the sensed voltage.

Example calculation.

We have: V

Let us put: R

R

is calculated as follows:

1

Thus R

= 820kΩ.

1

= 11.5V and V

TRIP

= 100kΩ

2

R

PFI

1

= 1.25V.

V

R

TRIPVPFI

----------------------------- -× 100 10

2

V

PFI

11.5 1.25–

3

--------------------------×⋅ 820kΩ== =

1.25

8/22

Page 9

AN1957 - APPLICATION NOTE

Table 4. Recommended Resistances for some V

V

(V) R1 (kΩ)R

TRIP

TRIP

Voltages

8.5 750 130

10.0 910 130

11.5 820 100

12.5 820 91

15.0 1100 100

Figure 5. Hardware Hookup for the STM692A Supervisor

~220V

~120V

Power

Supply

V

UNREG

R

V

PFI

Regulator

1

R

2

V

CC

STM692A

1

OUT

V

2

CC

V

3

SS

PFI PF0

45

SO8/TSSOP8

V

BAT

RST

WDI

(kΩ)

2

Microprocessor

V

C

1µF

8V

7

6

CC

NMI

GND

ai10108

9/22

Page 10

AN1957 - APPLICATION NOTE

Example of Power-Fail Waveforms

Figure 6 . shows the cas e of a voltage drop . The unregulated powe r supply voltage (V

decrease. As it falls below V

, at t0 in Figure 6., PFO is asserted, invoking a non-maskable interrupt in

TRIP

the microprocessor, and causing the execution of the safeguard routine. The mic roprocessor continue s

operating until Reset is asserted. From t

, the power supply volt age (VCC) starts to fall. At t2 Reset is as-

1

serted and Write Protect occurs. This means that the safeguard routine cannot last more than t

Figure 6. Voltage Drop

UNREG

) begins to

− t0.

2

V

UNREG, VCC

V

V

V

Note: At t0 the voltage drop is detected; at t1 VCC begins to fall; at t2 Reset is asserted and/or Write Protect occurs.

TRIP

RST

PFO

V

UNREG

V

CC

Voltage Drop

t

0t1t2

+12V

+11.5V

+5V

+4.4V

t

t

Table 5. Power-Fail Values for all Microprocessor Supervisors (except

for the devices mentioned in Table 6.)

Symbol Parameter Value Unit

V

PFI

Power-fail threshold Typ. 1.25 V

ai10109

Table 6. Power-Fail Values for 3V Microprocessor Supervisors

with Battery Switchover (STM690/704/802/804/805/806)

Symbol Parameter Value Unit

10/22

V

PFI

Power-fail threshold Typ. 1.237 V

Page 11

AN1957 - APPLICATION NOTE

WATCHDOG TIMER

The role of a Watchdog timer is to prevent system failures that are ca used by certain typ es of hardwar e

errors (non-responding peripherals, bus contention etc.) or software errors (bad code jump, code stuck in

loop etc.).

The watchdog timer has an input, WDI, and an output, WDO

timer periodically wi thin the specifi ed time-out pe riod, t

correctly, it periodically toggles the Watchdog Input, WDI (see Figure 8.). If the system fails, the watchdog

timer is not reset, a nd a system alert is generated: the W atchdog output, W DO

asserted (see Figure 8.).

Some microprocessors have an integrated watchdog timer, with a time-out period that is software-adjustable. The great disadvantage of this solution, though, is that the integrated watchdog timer uses the same

power supply, and clock signal, as the microprocessor. So, a system malfunction may also lead to a failure

of the watchdog timer.

Figure 7. Logic Diagram of a Watchdog Timer

(see Figure 7.). The input is use d to clea r the

(see Table 7.). While the system i s operating

WD

, or the Reset output, is

WDI WDO

Note: 1. WDI is the Watchdog Input, WDO is the Watchdog Output.

Watchdog

timer

Figure 8. Watchdog Timer Input and Output Waveforms

Correct operation

of the system

WDI

WDO

Note: 1. WDI signal frequencies greater then 50MHz (20ns period) will be filtered.

2. t

is the Watchdog time-out period. See Table 7. for value.

WD

System

failure

t

WD

System

restart

Correct operation

of the system

Table 7. Watchdog Timer Time-out Value for the STM705 Supervisor

Symbol Description Value Unit

t

WD

Note: This tWD value is valid for all Microprocessor Supervisors.

Watchdog time-out period Typ. 1.6 s

ai10110

t

t

ai10111

11/22

Page 12

AN1957 - APPLICATION NOTE

Hardware Hookup for the STM705 Super viso r

WDI is usually connected to the output pin of the mi cr op ro ce ssor as sh own in Fi gure 5 . and WDO

to the microprocessor Non-Maskable Interrupt (N

MI) or Reset input.

The code should take care of clearing the watchdog timer within the time-out period by toggling the microprocessor’s I/O pin.

Figure 9. Hardware Hookup for the STM705 Supervisor

is tied

STM705

1

MR

2

V

V

3

PFI PF0

45

WDO

8

RST

CC

SS

SO8

RST

7

WDI

6

), WDO goes Low even if the w atchdo g time r

ai10112

In any case, if V

Microprocessor

V

CC

I/O

NMI

drops below the Res et threshol d (V

CC

C

1µF

has not timed out. The ti mer remains cleared and do es not count fo r as long as Re set is asserted . The

counter automatically restarts after t

expires.

rec

In 5V supply devices, the watchdog function may be disabled by floating WDI or tri-stating the driver that

is connected to WDI.

12/22

Page 13

AN1957 - APPLICATION NOTE

BATTERY SWITCHOVER

A common task of battery switchover devices is to provide an uninterrupted power supply to external devices in the event of voltage drops and brownouts.

Battery switchover devices can also be useful in portable devices. When the external power supply (such

as the AC power supply adapte r) is disconn ected, the bat tery switcho ver devic e switches to the internal

supply (such as a battery).

The use of a battery switchover has the following advantages:

■ providing continuous and reliable service, even if the external supply fails

■ extending the battery lifetime

■ debouncing the power spikes occurring while connecting and disconnecting the AC adapter.

Battery switchover devices can be used as a main power supply backup for MCUs, memories and other

peripherals, and to prevent system failures (see Figure 10.).

Diode-OR connections are often use d as an equiv alent soluti on. However th e diode vol tage drop rep resents a large percentage of the battery voltage, and power supply spikes are not filtered. With an ST Supervisor, the device is supplied from the main powe r supp ly as long as the vo ltage is high en ough, ev en

if the battery voltage is greater than the power supply voltage, which sa ves the battery and extends its

lifetime.

Instead of a backup battery it is also possible to use a backup capacitor. Recommended capacitor values

start from 0.1F.

The battery switch over device monitor s the power supp ly voltage , V

ence voltage, V

voltage, V

BAT

, as shown in Figure 11. If VCC drops too low, the V

SO

. The comparator includes hysteresis for noise immunity purposes.

, which is compared t o the refer-

CC

output is switched to the battery

OUT

Figure 10. Block Diagram of a Battery switchover Device

V

CC

V

BAT

V

SO

V

OUT

ai10113

13/22

Page 14

AN1957 - APPLICATION NOTE

Switchover Waveforms for the STM806R Supervisor

The Battery Backup Switchover Voltage (V

ver Threshold, V

V

, VSO is equal to V

BAT

Whenever V

CC

(see Figure 11.). If VSW is lower than V

SW

.

BAT

falls below VSO, the V

OUT

Figure 11. Battery Switchover Waveforms for the STM806R Supervisor

V

V

CC

,

BAT

) depends on the Battery Voltage (V

SO

, VSO is equal to VSW. If VSW is greater than

BAT

output is connected to the battery, V

) and on the Switcho-

BAT

(see Figure 11.).

BAT

V

V

BAT

then V

V

BAT

V

SW

V

SO

Voltage

V

OUT

V

SW

Note: The red line represents the switchover voltage (VSO). The blue line represents the battery switchover circuit output voltage (V

which is switched to V

Drop

, or to V

CC

,

>

SW

= V

SO

SW

depending on the voltage magnitude.

BAT

V

BAT

then V

<

V

SW

= V

SO

Voltage

Drop

,

BAT

V

CC

V

SO

V

OUT

V

V

CC

BAT

ai10114

OUT

),

14/22

Page 15

AN1957 - APPLICATION NOTE

STM806R has a voltage hysteresis of 40mV, which gives it good noise immunity. The hysteresis depends

on V

■ If V

■ If V

Figure 12. Switchover Waveforms with Hysteresis Details

and VSW as illustrated in Figure 12.:

BAT

> VSW and VCC falls, the battery switchover detects the switchover threshold VSW and switches

BAT

V

to the backup battery supply. When VCC rises, the voltage level VSW + 40mV is detected and

OUT

V

is switched back to the main power supply (VCC).

OUT

< VSW and VCC falls, the battery switchover detects the voltage level V

BAT

switches V

detected and V

V

CC, VBAT

V

SW

V

OUT

to the backup battery supply. When VCC rises, the voltage level V

OUT

is switched back to the main power supply (VCC).

OUT

V

> V

BAT

SO

SW

= V

then V

V

BAT

V

SO

Voltage

Drop

− 75mV and

BAT

− 35mV is

BAT

,

SW

V

BAT

then V

< V

SO

SW

= V

,

BAT

Voltage

Drop

V

CC

V

SO

V

V

SW

V

CC

V

CC

V

BAT

V

SW

V

CC

V

OUT

V

SW

+ 40mV

V

BAT

V

CC

V

SW

V

BAT

− 75mV

OUT

V

CC

V

BAT

Table 8. Switchover Values for the STM806R Supervisor

Symbol Description Condition Typical Value Unit

V

SW

V

hys

V

SO

Threshold 2.4 V

Hysteresis 40 mV

V

Battery Backup Switch ov er Voltage

< V

BAT

SW

V

> V

BAT

SW

VSO = V

VSO = V

BAT

SW

V

OUT

V

− 35mV

BAT

ai10115

V

V

15/22

Page 16

AN1957 - APPLICATION NOTE

Hardware Hookup for the STM806R Supervisor

Figure 13. shows one pa rticular hardw are hookup, usin g the STM806R Supe rvisor to s witch the power

supply source, with good efficiency and without introducing any switching noise.

In this case, the battery switchover backups the main power supply of MCU, memories and other periph-

erals. If sufficient p ower is avail able fro m the bac kup sup ply, t he sy stem can contin ue w orking normall y.

However it is also possible to run a safeguard routine, and to force the system to the low-power mode, so

that the backup power supply can last longer, until the main power supply is restored.

Figure 13. Hardware Hookup for the STM806R Supervisor

V

CC

SRAM

V

CC

GND

C

1µF

STM806R

1

OUT

2

V

CC

3

V

SS

45

PFI PF0

SO8/TSSOP8

V

BAT

RST

MR

8V

7

6

3V Battery

AI10263

Hardware Hookup for the STM795 Supervisor

The V

possible to use the Vccsw

output is able to s witch 75mA (m aximum). If the peripheral s have greate r current needs , it is

OUT

output of the STM795 device, and to drive the gate of the external PMOS tran-

sistor (as shown in Figure 14.).

When V

switches to the battery, the Vccsw goes High. When V

OUT

switches back to VCC, Vccsw goes

OUT

Low again, and the transistor provides current directly from the power supply.

Figure 14. Hardware Hookup for the STM795 Supervisor

V

CC

Microprocessor

V

CC

GND

SRAM

V

CC

GND

C

1µF

STM795R

1

OUT

2

V

CC

3

V

CCSW

45

V

SS

SO8/TSSOP8

E

V

BAT

RST

CON

E

8V

7

6

3V Battery

16/22

AI10264

Page 17

AN1957 - APPLICATION NOTE

CHIP ENABLE GATING

Internal gating of the chip ena ble sign al preven ts erroneo us data fro m corrupti ng the exter nal SRA M, in

the event of an under-voltage condition. The chip enable signal, which normally goes directly from

the microcontr ol le r to the S RAM , i s rou t ed ins tea d th ro ugh the Sup er vis or dev ic e. The s ho rt p ropag ati on

delay enables the chip enable gating to be used with most microcontrollers.

During normal operati on ( when Re se t i s no t as s erted ), the Ch ip Enable signal is tr an sm itt ed thr ou gh the

Supervisor device unaltered. When Reset is asserted, the SRAM is placed in its low power mode and the

memory is inaccessible. In this way, the SRAM contents are protected from data corruption.

Chip enable gating uses a series transmission gate from E

ation (with Reset not asser ted), the E

time, the impedance of E

appears as a resistor, typically about 40Ω, in series with the load at E

transmission gate is enabled , and passes all E transition s. At that

to E

When Reset is asserted, the transmission path becomes disabled. In the disabled mode, E

impedance, the tran smis sion gate is tu rned off, a nd an act ive pull-up con nects E

up turns off again, when the transmission gate is enabled.

Figure 15. Chip Enable Gating Block Diagram

V

V

CC

RST

Comparator

t

rec

Generator

(see Figure 15.). During normal oper-

CON

becomes high

CON

to V

. This pull-

OUT

CON

RST

V

OUT

.

E

Note: Connect E to VSS if unused.

E

CON

Output

Control

E

CON

AI10265

17/22

Page 18

AN1957 - APPLICATION NOTE

Typical Waveforms for the STM818 Supervisor

After power-up, the E

the E

input signal on.

output stays High for a period of t

CON

While Reset is asserted, the chip-enable transmission gate is disabled, E

pull-up connects E

quence (when V

mediately becomes hi gh impedance. I f E

to V

CON

passes the Reset threshold), the chip-enable transmission gate is disabled, and E im-

CC

(disabled mode). If the voltage at E is High during a Power-down se -

OUT

is Low when Reset is asserted, the ch ip-enable transmission

gate will be disabled 15µs after Reset is asserted. This permits the current write cycle to complete during

power-down.

Any time a Reset is ge ner at ed, the c hi p- en abl e tran sm is si on gat e r ema in s d is abl ed , and E

impedance (regardless of any activity on E

the chip-enable transmi ssion gate depe nds on V

and the loading on E

. For the minimum propagation delay, minimize the capacitive load on E

CON

) for the Reset time-out period. The propagation delay through

, the source impedanc e of the drive c onnected to E,

CC

use a low-output impedance driver.

Figure 16. Typical Waveforms for the STM818 Supervisor

V

V

CC

RST

(see Figure 16.). After this it starts to pass

rec

is high impedance, and an active

remains high

CON

and

E

CON

V

BAT

RST

E

Note: The chip enable gating function is also implemented on the STM795 device. Nevertheless there are two differences, in comparison to

the STM818. Firstly the E

disabled only 10µs after Reset is asserted if the E

t

rec

signal is held High only for half of the t

CON

input is Low.

V

BAT

15µs

t

rec

AI10266

period, and secondly the chip-enable transmission gate is

REC

Table 9. Typical values for the STM818 Supervisor

Description Typical Value Unit

E

-to-E

Reset-to-E

-to-E

E

E

CON

Resistance

CON

High Delay (Power-down)

CON

Propagation Delay

CON

Short Circuit Current

40 Ω

15 µ s

2ns

0.75 mA

18/22

Page 19

AN1957 - APPLICATION NOTE

Hardware Hookup for the STM818 Supervisor

Figure 17. illustrates the hookup of the STM818 Supervisor circuit connected to a microprocessor and an

SRAM memory . All th e functi ons of the STM8 18 are u sed (bat tery sw itch over, w atchd og, ch ip enabl e gating, Power-On Reset, Low Voltage Detect).

The Chip Enable signal is de coded by the Ad dress De coder and i t goes to the E

circuit. The E

output is connected to the CS (Chip Select input) of the SRAM memory.

CON

Figure 17. Hardware Hookup for the STM818 Supervisor

V

Microprocessor

V

CC

A0-A15

I/O

RST

GND

Address

Decoder

CC

C

1µF

STM818

1

OUT

2

V

CC

3

V

SS

45

EE

SO8/TSSOP8

V

BAT

RST

WDI

CON

8V

7

6

input of the Superviso r

3V Battery

SRAM

A0-Axx

V

CC

CS

GND

AI10267

19/22

Page 20

AN1957 - APPLICATION NOTE

BATTERY FRESHNESS SEAL

The battery Freshness Seal is a feature that is available on the STM817/818/819. It disconnects the backup battery from the internal circuitry and V

Manufacturer) to ensure that the backup battery connected to V

is put to use.

To enable the Freshness Seal on the STM817 and STM819:

1. Connect a battery to V

BAT

2. Ground PFO

3. Bring VCC above the Reset threshold voltage, and hold it there until Reset is deasserted, following the

Reset timeout period

4. Bring V

Low again (see Figure 18.).

CC

For the STM818, use the same procedure, but ground E

Once the battery Fre shness Seal has e nabled (disconnec ting the backup batte ry from internal circuitry

and anything that is connected to V

OUT

Figure 18. Typical Waveforms for the STM817/818/819 Supervisors

V

V

CC

RST

until it is needed. This allows an OEM (Original Equipment

OUT

will still be fresh when the final product

BAT

instead of PFO.

CON

), it remains enabled until VCC is next brought above V

RST

.

t

rec

RST

AI10268

Note: 1. For the STM818, E

function is enabled.

2. For the STM817 and STM819, PFO

Freshness Seal function is enabled.

is held Low, externally. The E

CON

is held Low, externally. The PFO state is latched half way through the t

state is latched half way thr ough the t

CON

period, and the Freshness Seal

REC

period, and the

REC

CONCLUSION

ST Microprocessor Supervisors have a large range of features adapted to the user’s needs:

■ Centralised function for managing a system Reset.

■ Early warning of power failure, in time to initiate any safeguard routines.

■ Watchdog timer, monitoring for cessation of normal processor activity.

■ Battery switchover, either to allow continued operation, or to maintain minimum functionality. Also

useful for the regulation of noisy power supplies.

■ Battery Freshness Seal, for maintaining the battery life on the production line, for the end user.

ST Microprocessor Supervisors are the ideal choice for adding protection to applications that are used in

noisy environments and require power supply monitoring for proper operation.

20/22

Page 21

REFERENCES

■

AN1772

: How to Control Power-up/Reset and Monitor the Voltage in Microprocessor Systems using

ST Reset Circuits.

■

AN1336

: Power-Fail Comparator for NVRAM Supervisory Devices.

REVISION HISTORY

Table 10. Document Revision History

Date Version Revision Details

15-Mar-2005 1 First issue

AN1957 - APPLICATION NOTE

21/22

Page 22

AN1957 - APPLICATION NOTE

If

this d

MPG

you have any questions or suggestions concerning the matters raised in

ocument, please refer to the

request support web page:

http://www.st.com/askmemory

Information furnished is be lieved to be a ccur ate and reli able. Howe ver, STMicroele ctronic s assu mes no r esponsib ilit y for th e consequences

of use of such information nor for any infrin gement of patent s or other rights of third parties which ma y result from it s use. No license is granted

by implication or otherwi se under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without not ice. This pub licat ion su persed es and repl aces all in format ion previou sly su pplie d. STMicroele c tronic s prod ucts ar e no t

authorized for use as critical compone nts in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2005 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - It aly - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

22/22

Loading...

Loading...