Page 1

AN1948

Obsolete Product(s) - Obsolete Product(s)

®

- APPLICATION NOTE

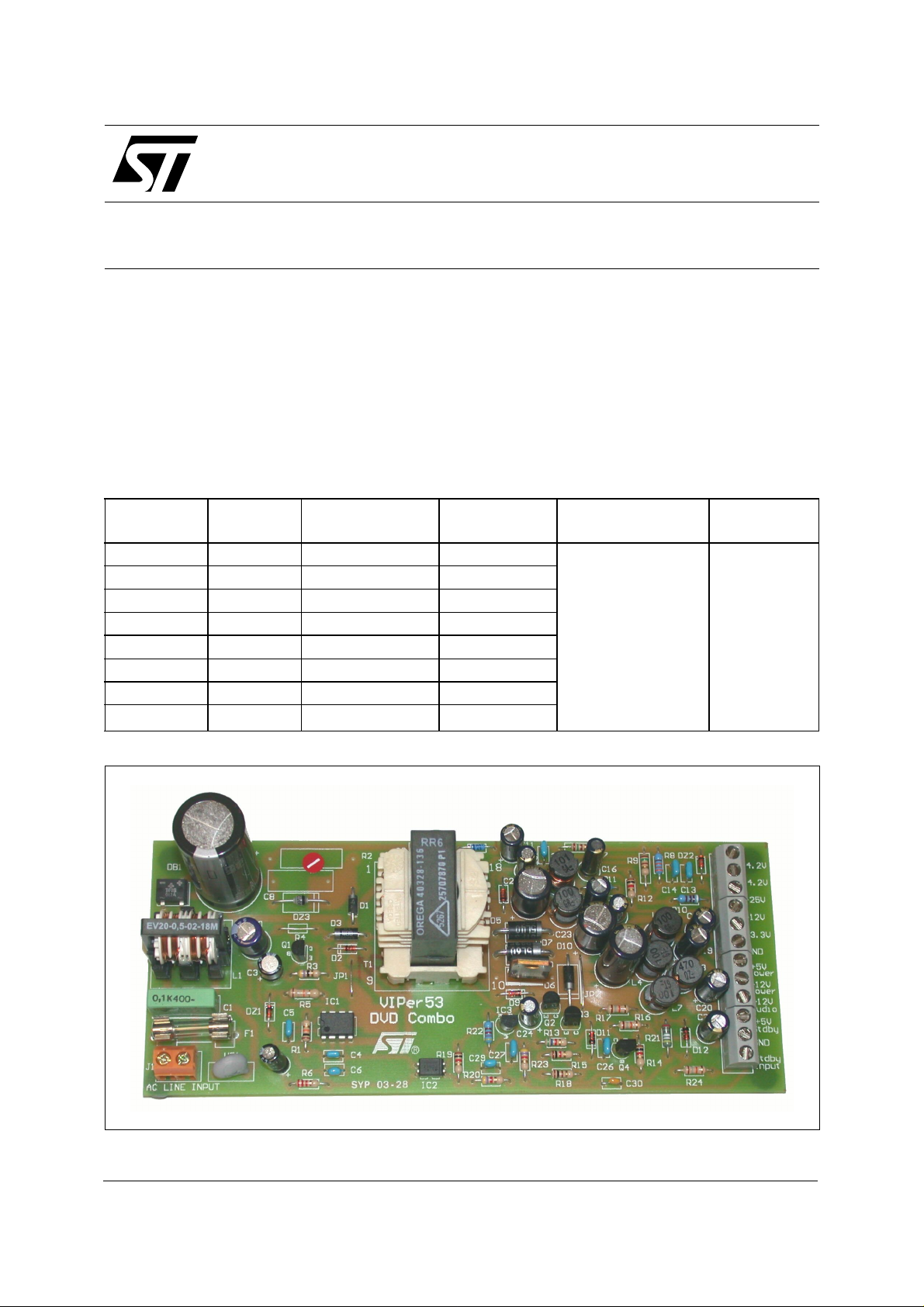

DVD Combo Power Supply with VIPer53

A. Bailly - S. Luciano

Despite the s trong growth of t he DVD readers, the VCR ones are still present o n the marke t. A lot of

equipment now includes both types of media in the same case. This paper proposes a typical solution to

efficiently supply such applications and other equipment where logic, DC motor drive and LCD display

are to be implemented together in the 35W power range and suite any input voltage standard (85Vac to

265Vac).

Key features for this application are high efficiency, low st andby consumption and cost effective solutions

to fit the high volume consumer market needs.

The specification can be summarized as shown in the following table:

Voltage

+/-5%

Output 1 3.3V 1.5A 4.95W

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

Output 8

5V Stand-by 100mA 500mW

5V Power 1.5A 7.5W

12V Power 1.5A 18W

12V Audio 200mA 2.4W

-12V Power 15mA 180mW

-25V 25mA 625mW

4.2V Display 50mA 210mW

Maximum Curr ent Outp ut Po wer MaximumPower Board S i ze

L x W x H

Normal Operation:

35W max output

power

Stand-by Operation:

750mW max input

power

With 40mA on the

5VStandby output

170x 70 x 40

(mm)

April 2004 1/17

Page 2

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

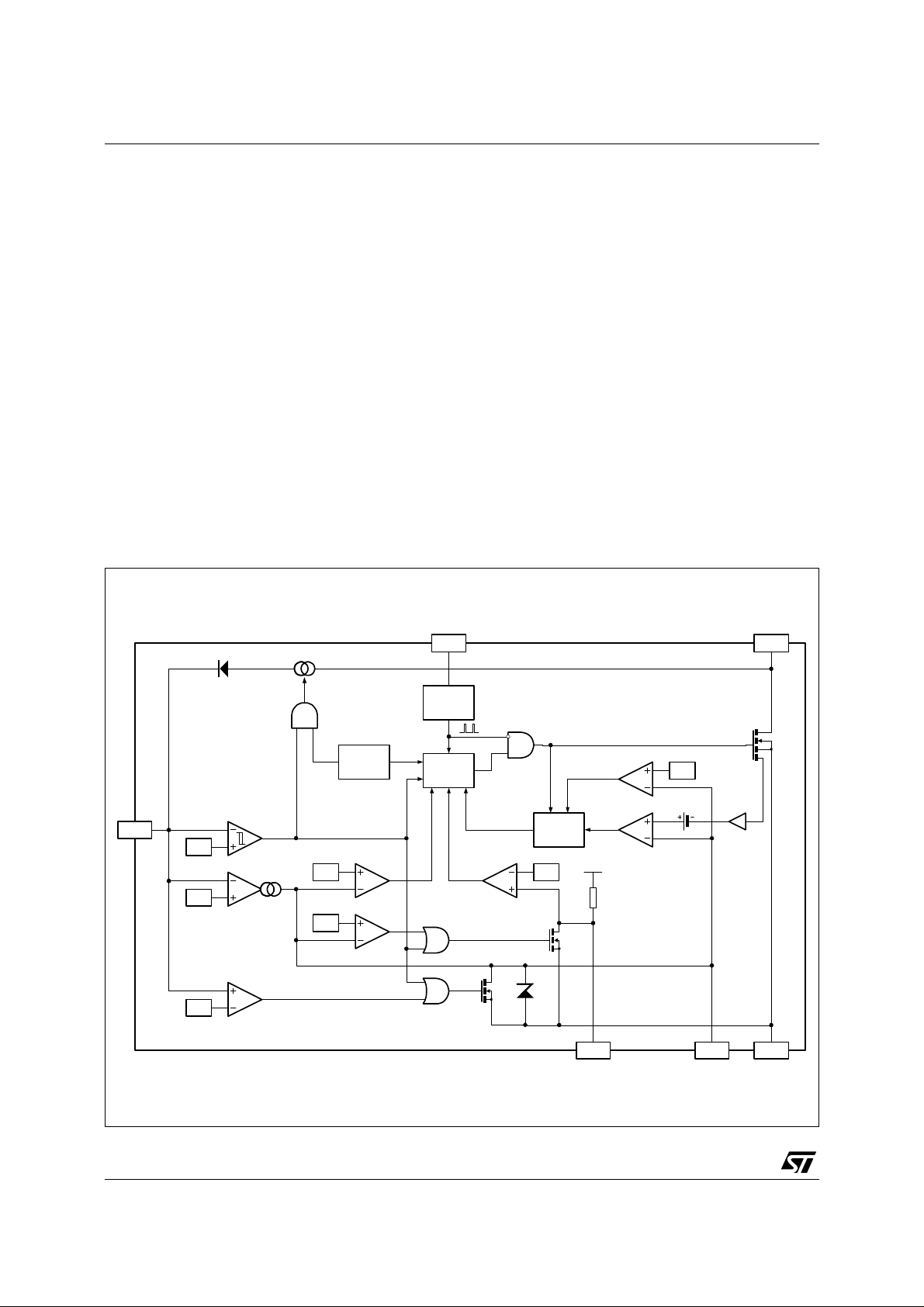

1. VIPer53 D ESCR IPTION

VIPer53, the first multichip device of the VIPer family has been chosen to fulfill the requirements. It

features very low Rdson of 1Ω allowing to deliver up to 35W in wide range in a standard DIP -8 pack age

without a heatsink, answering the need f or high er efficiency and reduced space thanks to a lower power

dissipation.

1.1 General features

The block diagram is given in figure 1. An adjustable oscillator drives a current controlled PWM at a fixed

switching frequency. The peak drain current is set for each cycle by the voltage present on the COMP

pin. The useful range of the COMP pi n extends from 0.5V to 4.5V, with a corres ponding drain current

range from 0A to 2A.

This COMP pin can be either used as an in put wh en working i n sec ondary f eedback conf iguration, or as

an output when the internal error amplifier co nnected on the VDD pin operates in primary feedba ck to

regulate the VDD voltage to 15V.

The VDD undervoltage comparator drives a high vol tage startup current source, which is switched off

during the norm al o pera tion of the devic e. Th is fe ature toge ther wi th th e burs t mod e c apabilit y allo ws t o

reach very low level of input power in standby mode, when the converter is lightly loaded.

Figure 1: VIPer53 block diagram

OSC DRAIN

ON/OFF

OSCILLATOR

PWM

LATCH

S

R1

FF

R2

R3 R4 R5

Q

4.5V

VDD

8.4/

11.5V

15V

18V

UVLO

COMPARATOR

ERROR

AMPLIFIER

OVERVOLTAGE

COMPARATOR

0.5V

4.35V

OVERTEMP.

DETECTOR

STANDBY

COMPARATOR

OVERLOAD

COMPARATOR

BLANKING TIME

SELECTION

150/400ns

BLANKING

4V

PWM

COMPARATOR

8V

125k

TOVL COMP SOURCE

1V

0.5V

H

COMP

CURRENT

AMPLIFIER

2/17

Page 3

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

1.2 Overload protection

A threshold of 4.35V typical has been i mplem ente d on t he CO MP pin . This ov erload thresho ld is 150 mV

below the clamping voltage of 4.5V which corresponds to the current limitation of the device. In case of a

COMP voltage exceeding the overload threshold, the pull up resistor on the TOVL pin is released and the

external capacitor connected on this pin begins to charge. When a valu e of 4V typical is reac hed, the

device stops switching and remains in this state until the VDD voltage reaches VDDoff, or resumes

normal operation if the COMP voltage returns to a value below the overload threshol d. The drain current

that the device is a ble to deliver wit hout triggering the overl oad threshold is c alled "current capabilit y",

specified as IDmax in the datasheet. This value must be used to correc tly size the converter versus its

maximum output power.

When an overload occurs on secondary side of the converter, the output power is first limited by the

current limitation of the device. If this overload lasts for more than a time constant defined by a c apacitor

connected on the TOVL pi n, the dev ice is reset , a nd a new res tarting s equence is initiated by turning on

the startup current source. The capacitors on the VDD pin and on the TOVL pin will be defined together

in order to insure a correct startup and a low restart duty cycle in overload or short circuit operation. Here

are the typical corresponding formulas:

–

C

C

C

OVL

VDD

VDD

12.5 10

⋅⋅ ⋅>

810

I

DD1

---------------------------

>

V

DDhyst

Where tss and DRST are respect ively the time needed for the output voltages to pass from 0V to their

nominal values at startup, and the restart duty cycle in overload or short circuit condition. A ty pical value

of 10% is generally set for this last parameter, as it insures that the output diodes and the transformer

don’t overheat. The other parameters can be found in the datasheet of the device.

As the VDD capacitor has to respect two conditions, the m aximum value will be retained to define its

value.

1.3 Stand-by operation

On the opposite load configuration, the converter is lightly loaded and the COMP voltage decreases until

it reaches the shutdown threshold typically at 0.5V. At this point, the switching is disabled and no more

energy is passed on secondary side. So, t he output voltage decreases and t he regulation loop rises

again above the shutdown threshold, thus resuming the norm al switching operation. A burst mode with

pulse skipping takes plac e, as lo ng as the output power i s below the one correspond ing to the minimum

turn on of the device. As the COMP voltage works around 0.5V, the peak drain current is very low (it is

actually defined by the minimum turn on time of the device, and by the primary inductance of the

transformer) and no audible noise is generated.

In addition, the minimum turn on time depends on the COMP voltage. Below 1V (VCOMPbl), the blanking

time increases to 400ns, whereas it is 150ns for higher voltages. The minimum turn on times resulting

from these values are respectively 600ns and 350ns, when taking into account the internal propagation

time. This feature brings the following benefits:

- this brutal change induces an hyste resis between normal operation and burst mode which i s reached

sooner when the output power is decreased.

- a short value in normal operation insures a good drain current control in case of short circuit on

secondary side.

- long value in standby operation reinforces the burst mode by skipping more switching cycles, thus

decreasing switching losses.

More details regarding the standby operation can be found in the datasheet.

6

tss⋅⋅>

–

4

1

-----------------

–

D

tss⋅

1

RST

C

⋅

OVLIDDch2

------------------------------------------- -

V

DDhyst

3/17

Page 4

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

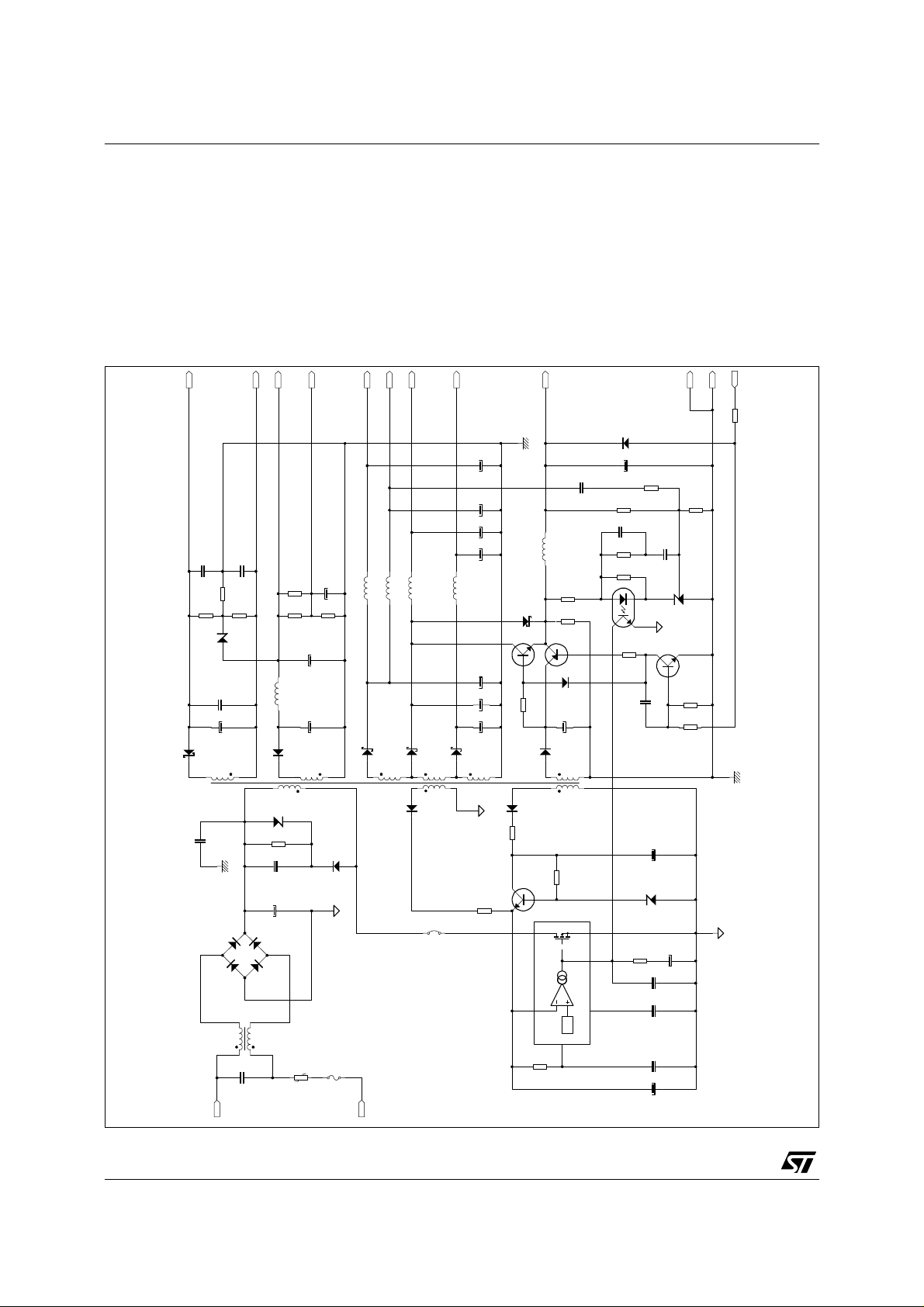

2.0 DVD COMBO POWER SUPPLY

2.1 Schematics

The power topology is an off line flyback work ing at a fixed switching frequency of 70kHz. The board

offers two operating modes. The normal one delivers 8 different output voltages and t he st andby one only

provides a 5V outpu t. This is achieved by a s mart standby management feature, based on a specific

transformer design which allows to dropout most of the output voltages, providing a low power

consumption in standby mode. The overall schematics is presented in figure 2.

Figure 2: schematics

J2-7

J2-8

J2-3

100nF

DZ2

J2-2

C14

100nF

R8

33k

R9

150

BZX79C5.1

C12

100nF

C11

10V

180µF

D5

J2-4

-25V / 25mA

+4.2V / 50mA

910

R11

910

R10

C16

39µF

L2

100µH

C15

39µF

BAV21

J2-1

-4.2V / 50mA

C13

R7

150

D4

BAT43

J2-9

-12V / 15mA

+12V audio / 0.2A

+12V power / 1. 5A

C17

35V

39µF

L3

47µHL410µH

1k

R12

35V

35V

D6

D8

STPS5L60

STPS8H100D

J2-5

+5V / 1.5A

+3.3V / 1.5A

C20

25V

120µF

25V

C19

120µF

C25

10V

180µF

C22

10V

180µF

L6

L5

10µH

10µH

25V

C18

820µF

C23

6.3V

1200µF

C21

6.3V

1200µF

D7

STPS5L40

J2-10

D12

+5V standby / 100mA

L7

10µH

100

R18

D10

1N5818

1K

R14

Q2

MPS2907A

D11

Q3

1N4148

PN2222A

R13

5.6k

35V

C24

39µF

D9

BAV21

1N4148

10V

C28

180µF

C30

6.8nF

1%

R21

4.99k

C29

10nF

R20

4.7k

1k

R19

IC2

1k

R15

C26

100nF

J2-6

J2-11

J2-12

GND

Standby

18k

R24

R23

4.7k

1%

R22

4.7k

C27

100nF

IC3

PC817

TL431LP

Q4

PN2222A

18k

R17

18k

R16

T1

OREGA

25707870P1

C9

1kV

2.2nF

DB1

DF08M

C1

J1-1

100nF

200

DZ3

BZT03C

R2

C8

C2

L1

0.5A

18mH

400V

D1

Not

Not

68µF

AC

1N4947GP

fitted

fitted

450V

33

F1

1A

VR1

250V

CT<0

IN

J1-2

D2

1N4148

JP1

D3

BYT01-400

0

R4

C10

250V

R5

Q1

18k

0.66W

2N5551

47

R3

DRAIN

VDD

IC1

VIPer53

R1

SOURCECOMPTOVL

15V

OSC

10k

4.7µF

10

DZ1

BZX79C

C7

R6

1µF

63V

2.2k

C6

10nF

C5

100nF

C4

2.2nF

C3

16V

47µF

4/17

Page 5

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

2.1.1 Normal operation mode

In this mode, the Standby input is dri ven low, Q4 and Q2 are blocked and Q3 c onductis. All the ou tput

voltages are delivered to the loads and both 5V and 5VStandby outputs are provided.

The transformer turn ratio leads to a voltage of about 30V across C24. This voltage is blocked by Q2, and

the 5VStandby output is derived from the main 5V output through Q3. In the case where no load is

connected on the 5VStandby output, R14 allows to absorb the Q3 base current delivered by R13.

The same applies at primary side for the auxiliary supply of IC1. In normal operation, the VDD pin energy

is delivered by the stan dard auxiliary winding t hough D2. The c orresponding voltage is higher than the

one developed by the ze ner diode DZ1 on the base of Q1, and this transistor is blocked. In the m ean

time, the second auxiliary winding delivers five times more voltage than the one needed in standby mode

(see section 2.1.2), and values as high as 130V can be o bserved across C10. As a consequen ce, C10,

D3 and Q1 are high voltage type, and R5 may dissipate up to 1W.

2.1.2 Stand-by mode

All the output voltages are dropped down, except the 5VStandby one which is typically used to supply an

infrared receiver and its decoding circuit, and also to maintain the Standby input in the high state, which

makes Q4 and Q2 conducting, and disables Q3 thanks to D11.

As Q2 is conducting, the 5VStandby output is supplied through D9 and the corresponding winding o f the

main transformer. This winding therefore reduces its voltage by a ratio of about 5, because the regulation

loop still maintains the value of 5V on this output. Since all the outputs are coupled together on the same

transformer core, they are all divided by a ratio of about 5. This is sufficient to insure a reduced

consumption mode, as the loads are now supplied with a much lower voltage.

D11 is needed in this mode to efficiently turn off Q3. Otherwise, its base remains high as it is supplied by

R13 connected to a voltage of about 5V, and some reverse current flows from the 5V Standby output to

the main 5V one.

On primary side, the standard auxiliary winding doesn’t provide a sufficient voltage, and Q1 acts as a

serial regulator with the voltage delivered b y the second auxiliary winding, maintaining the VDD pin of

IC1 at higher level than the disabling threshold VDDoff. R14 on the 5VStandby output provides a

minimum consumption in this mode to insure a suitable voltage for Q1.

The transition between the normal mode and the standby mode has been slowed down by C26. Th is is

mandatory to avoid any under- or overvoltage on the out puts during this event. See also th e following

sect ion.

2.1.3 Regulation

The regulation sets the DC operating point from the 5VStandby output through R21 and R22. Note that it

would be difficult to implement a split regulation, as the other outputs operate with a different value when

in standby mode.

Some AC signals are also introdu ced int o t he r egu lat ion lo op t o ins ure stabilit y. The conventional pat h is

done through R18 connected to the 5VStandby output, but another AC component has been added

thanks to C30 and R23 conne cted on the 12V power output . This is needed to prevent any instability in

situations where the 5VStandby output is lightly loaded versus the 12V one. In order to transmit this

signal, a resistance R20 has also been added in series with the conventional capacitive feedback C27 at

the level of IC3.

The bandwidth of this regulation loop has been set at a few kHz in order to insure a good dynamic

response when submitted to load variations, or during the transitions between the normal mode and the

standby mode.

C29 on secondary side and C6 on primary side cancel any switching noise which may produce

subharmonic operation.

5/17

Page 6

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

2.1.4 Drain voltage clamping

The board comes with a zener (DZ3) clamp type on the drain of the VIPer53 device. Provision is made to

also use an R-C type clamping network to replace this zener. The corresponding components R2 and C8

are to be populated according to the bill of material. See par. 2.3.1.

2.1.5 Short circuit protection

This paragraph only deals with the main outputs (i.e. all the 5V, 12V and 3.3V outputs). The following

section deals with the plasma ones.

When in normal mode, al l these out puts are protecte d agai ns t a perman ent short circuit. When the sho rt

circuit is applied on the 5V Standby, the short circuit current flows in to D10 which bypas ses Q3, thus

avoiding its destruction. The protection is done through the overload feature of the VIPer53 device, which

leads to hiccup mode when the COM P voltage remai ns high for a too long time. This time i s adjust ed by

the capacitor on the TOVL pin, and is needed at startup for authorizing a temporary overload during the

charge of the output capacitors.

In standby mode, only the 5VStandby output is protected thanks to D12 which forces the standby signal

in the low state, and the converter returns to the normal mode where Q2 is off. This is mandatory to avoid

the destruction of Q2 and D9 in this condition. The other out puts are not protected against a permanent

short circuit, because the converter can still regulate correctly the 5VStandby output even if one of the

others is short circuited. This is d ue to the high turn ratio existing between t he 5VStandby winding and

the other ones, and to the low consumption on this output . Nevertheless, the user will adopt one of the

following options:

- these outputs can withstand a short circuit for a few seconds. If this time is too long, the corresponding

rectifying diode may blow up, and the converter will enter into hiccup mode because of the short circuit

presented by the blown diode on secondary side of the transformer.

- addi tional diodes similar to D12 can be implemented on the other outputs to force the converter to the

normal mode, where it can withstand permanent short circuit on the main outputs.

2.1.6 Plasma display outputs

A whole set of outputs are dedicated to the driving of a plasma display in front of t he equipment: Negative

25V and 12V outputs, togethe r with a symmetrical +/-4.2V centered 5V high er than the -25V output

voltage.

Please note that these outputs are not protected against short circuits or overloads. For instance, the

short circuit of the 4.2V outputs to ground leads to the destruction of R7 or R9. Also, the rectifying diodes

chosen for these outputs don’t withstand a permanent short circuit.

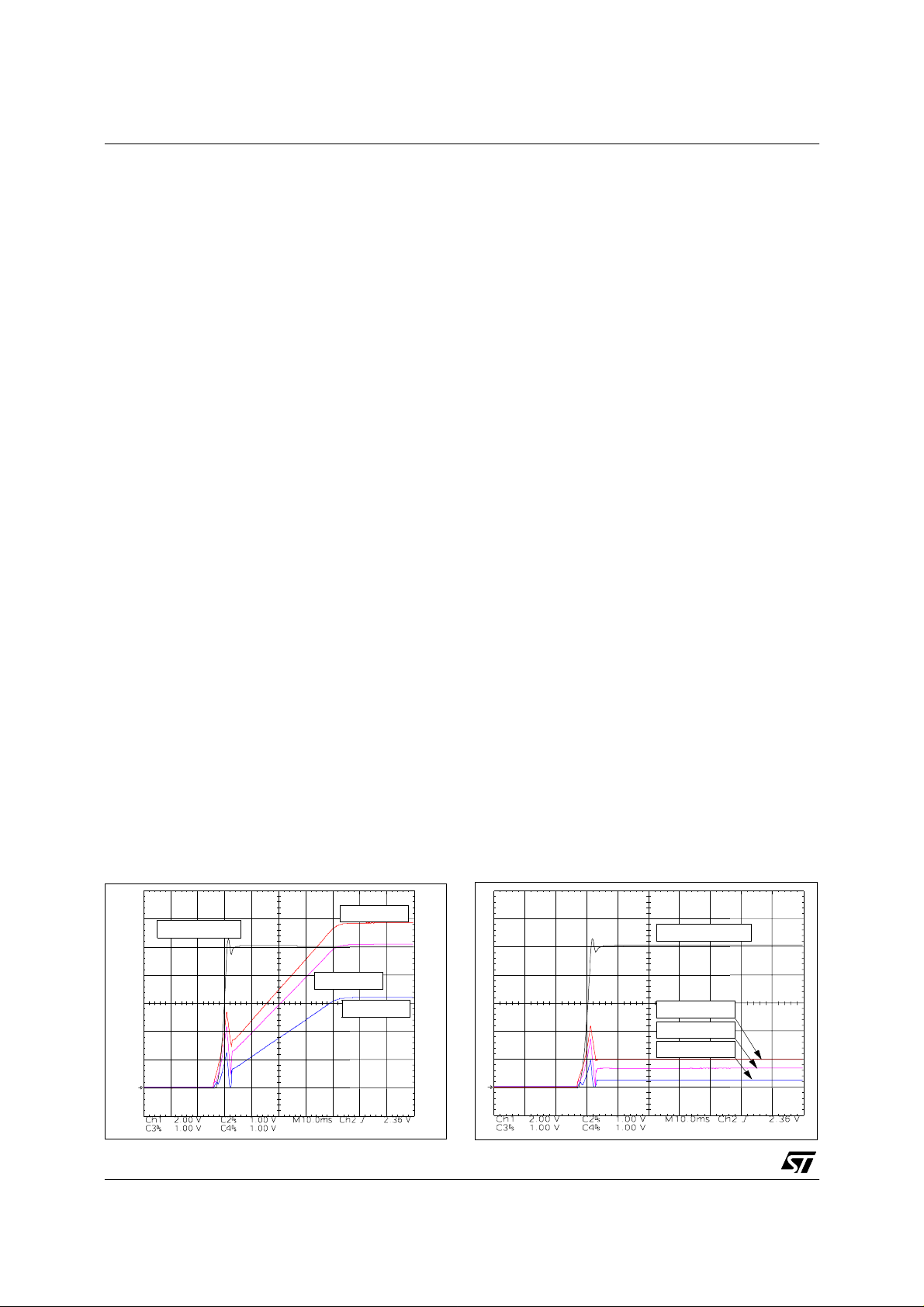

Figure 3: startup in normal mode Figure 4: startup in standby mode

Ch1 : 12V out

Ch2 : 5Vstby out

Ch3 : 5V out

Ch4 : 3.3V out

1

2

3

4

6/17

1

1

2

2

3

3

4

4

Ch2 : 5Vstby out

Ch1 : 12V out

Ch3 : 5V out

Ch4 : 3.3V out

Page 7

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

2.2 Results

Unless otherwise specified, all the tests are made at 300VDC input voltage and full load.

2.2.1 Startup

When starting, C26 is discharged, an d t he conv erter operates in standby mode. S o, the 5V Standby voltage appears first, and the other out puts rise slowl y, just like a transition from a standby mo de to t he normal one. Of course, if the Standby signal is asserted hig h (active level), the converter remains in this

mode and only the 5VStandby output is delivered. This is illust rate d in figures 3 and 4.

The input voltage doesn’t impact on the dynamic behavior of the converter. The rising slope of the output

voltage at startup is mainly governed by the charge of C26 with the current defined by the base to emitter

voltage of Q4 together with R16 and R17.

2.2.2 Switch off

Figure 5 presents the output voltages at switch off of the conv erter. All the voltages drop down a t the

same time, because the converter doesn’t deliver any more energy. So, the slopes are individually driven

by the output capacitors and the output current.

Figure 5: switch off Figure 6: normal to stand-by mode transition

Ch1 : 12V out

Ch3 : 5V out

Ch2 : 5Vstby out

Ch4 : 3.3V out

1

2

3

4

1

2

3

4

Ch1 : 12V out

Ch3 : 5V out

Ch4 : 3.3V out

Figure 7: stand-by to normal mode transition Figure 8: load regulation

Ch1 : 12V out

Ch2 : 5Vstby out

Ch3 : 5V out

Ch4 : 3.3V out

5.5

5

4.5

4

V5V, V3.3V (V)

3.5

Ch2 : 5Vstby out

16

15

14

13

V12VPower (V)

12

V5VStandby

V5VPower

V3.3V

V12VPower

1

2

3

4

3

0 20 40 60 80 100 120

load (% full l oad)

11

7/17

Page 8

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

2.2.3 Transitions between normal and stand-by modes

The standby input is quickly driven from low state to high state, and inversely. The corresponding

evolution of the output voltages are shown in figures 6 and 7. Note the very low disturbance on the

5VStandby output.

2.2.4 Load and cross regulation in norm al mo de

For these tests, the 12V audio output has always been let open. As it is connected almost in parallel with

the 12V power output (only a n L-C filter), it is assumed to follow the same vol tage variation than this

output, and its current is summed to the power one.

Also, load variation are only made on the main power outputs, that is to say the 5Vstandby, the 5V power,

the 3.3V and the 12V p ower ones. The -2 5Vand +/-4.2V s econdary outputs are either not loaded (load

regulation test) or fully loaded (cross regulation test).

The load regulation is c hecked by changing th e l oads on all the outputs simul taneously. This test is also

used for measuring the efficiency of the converter over a large range of output power. Figure 8 shows the

corresponding results for the four main outputs and figure9 the ones for the two secondary ones.

When not loaded, the converter operates correctly, except for the 12V and 3.3V outputs which do not

have any load. So, the corresponding voltages rise up respectively to 15.3V and 4.1V. If this is not

acceptable, the user has to foresee an adequate minimum load or a clamper.

Figure 9: cross regulation for secondary outputs Figure 10: 5VPowe r cross regulation

5

4.5

4

V4.2V (V)

3.5

3

0 20 40 60 80 100 120

Load (% full load )

27

26

25

24

V4.2V

23

V25V

V25V (V)

22

21

20

19

5.5

5

4.5

4

V5V, V3.3V (V)

3.5

3

0.001 0.01 0.1 1 10

I5VPower (A)

12

11.8

11.6

11.4

11.2

11

V12VPower (V)

V5VStandby

V5VPower

V3.3V

V12VPower

As the load on the secondary outputs is zero during this test, figure 9 shows the cross regulation between

the main outputs and the secondary ones. Note that the secondary output voltages don’t change

significantly versus their own load current, because these currents are low values, and these outputs are

already significantly loaded on the board itself. So, no load regulation is presented for the secondary

outputs.

The cross regulation between the main outputs has been measured. For this purpose, all the output are

loaded at intermediate level (half the maximum rated load), except one output which varies between zero

and maximum load. This test i s repeated for t he four ma in outputs and i s presented i n figures 1 0 to 13.

The result is also used for computing the relative efficiency for each main output.

8/17

Page 9

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

Figure 11: 5VStandby cross regulat ion Figure 12: 3.3V cross regulation

5.5

5

4.5

4

V5V, V3.3V (V)

3.5

3

0 0.02 0.04 0.06 0.08 0.1 0.12

I5VStandby (A)

12

11.8

11.6

11.4

11.2

11

V12VPower (V)

V5VStandby

V5VPower

V3.3V

V12VPower

5.5

5

4.5

4

V5V, V3.3V (V)

3.5

3

0.001 0.01 0.1 1 10

I3.3V (A)

Figure 13: 12VPower cross regulation Figure 14: Global efficiency

5.5

5

4.5

4

V5V, V3.3V (V)

3.5

3

0.001 0.01 0.1 1 10

I12VPower (A)

15

14

V12VPower (V)

V5VStandby

V5VPower

V3.3V

V12VPower

13

12

11

10

85

80

75

70

65

60

Efficiency (%)

55

50

45

0 20 40 60 80 100 120

Load (% full load)

11.75

11.74

11.73

11.72

11.71

11.7

V12VPower (V)

V5VStandby

V5VPower

V3.3V

V12VPower

2.2.5 Efficiency in normal mode

The global efficiency is measured by varying all the outputs load simultaneously, except for the

secondary ones (-25V and +/-4.2V) which are n ot loaded in order to get the lowest values. Figure 14

presents the result.

Each cross regulation measurement is used for computing the relative efficiency Er on the corresponding

output by using the following formula:

P

outmaxPoutmin

--------------------------------------------------------=

E

R

P

The results are shown in the following table:

Er 77% 73% 80% 85%

–

–

inmaxPinmin

3.3V 5VStandby 5VPower 12VPower

9/17

Page 10

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

The lower the output v oltage, the lower the relative efficiency bec ause of the fixed vo ltage drop in the

output rectifying diodes. The relative efficiency for the 5VStandby output is low when compared to the

other ones, because of two reasons:

1) it is derived from the 5VPower output, with a voltage drop in Q2 of about 100mV which leads to a loss

of 2% in efficiency.

2) when the output current on the 5VStandby increases, its output voltage remains fixed by the regulation

loop, and all the other outputs increase by 2%. So, the onboard dummy loads for the secondary

outputs (R7 to R12) increase by 5% (related to the 500mW of full load on the 5VStandby output), and

the relative efficiency is decreased by this figure.

Overall, the total efficiency is decrease by 7%, which corresponds to the difference between the

5VPower and the 5VSt andby outputs.

The efficiency has also been measured at full load and for an input voltage varying between 120Vdc and

400Vdc. The results are shown in figure 15.

Figure 15: efficiency Vs. input voltage Figure 16: load regulation and input power in

standby mode

85

80

75

70

Efficiency (V)

65

60

100 150 200 250 300 350 400 450

Vin (V)

5.2

5.15

5.1

V5V (V)

5.05

5

0 0.02 0.04 0.06 0.08 0.1 0.12

I5VStandby (A)

1600

1200

800

400

0

Pin (mW)

V5VStandby

Pin

2.2.6 Load regulation and input power in standby mode

As there is only one active output in standby mode, th ere is no cros s regulation m easurement . Instead,

the input power is measured to check its compliance versus specific energy saving standards like Energy

Star or Blue Angel. Both output voltage value and input power are shown in figure 16.

All the other outputs are not loaded. The user will pay attention to its real load, which may consume some

power in this condition: Even if the voltages are reduced by a ratio of five or more, they are still able to

deliver the rated current!

At 300Vdc input voltage, the converter always works in burst mode in standby condition. This mode is

characterized by the fact that the device skips some switching cycles, as shown in figure 17. The

magnification in figure 18 presents a conduction time of 700ns, which correspond s to the long blanking

time of the VIPer53 device, as the COMP voltage operates around the shutdown value (0.5V typical),

well below the blanking value threshold (1V typical). Also note the reduced reflected value versus the

normal full load switching cycle in figure19.

10/17

Page 11

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

Figure 17: burst mode in standby condition Figure 18: Magnification of a switching cycle in

standby condition

Ch1 : Vds

Ch1 : Vds

1

1

2.2.7 Line regulation

The output voltage has been measured at full load for an input voltage varying between 120Vdc and

400Vdc for both power (figure 20) and secondary (figure 21) outputs.

4

Ch4 : Ids

Figure 19: normal full load switching cycle Figure 20: Line regulation for the main outputs

5.5

5

Ch1 : Vds

1

4

Ch4 : Ids

4.5

4

V5V, V3.3V (V)

3.5

3

100 150 200 250 300 350 400 450

Vin (V DC)

12

11.9

11.8

11.7

11.6

11.5

V12VPower (V)

V5VStandby

V5VPower

V3.3V

V12VPower

2.2.8 Dynamic load variation

Each main output h as been submitted to fast load variation between 10% and 100% of their rated full

load. All the others are loaded with a fixed current corresponding to half load . Results are presented in

figures 22 to 25.

11/17

Page 12

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

Figure 21: line regulation for secondary outputs Figure 22: 5VPowe r dynamic load regulation

4.45

4.4

4.35

V5V, V3.3V (V)

4.3

4.25

100 150 200 250 300 350 400 450

Vin (V DC)

26

25.75

25.5

25.25

25

Ch2 : V5VPower

V25V

V4.2V

V12VPower (V)

Ch4 : I5VPower

4

Figure 23: 5VStandby dynamic load regulation Figure 24: 3.3V dynamic load regulation

Ch2 : V3.3V

Ch2 : V5VStandby

Ch4 : I3.3V

Ch4 : I5VStandby

4

4

2.2.9 Stability

An example of stability measurement is presented in figure 26 at full load. The phase margin is about 50°

with a gain margin of about 10dB.

12/17

Page 13

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

Figure 25: 12V dynamic load regula tion Figure 26: gain and phase plot at full load

100

80

Ch2 : V12VPower

Ch4 : I12VPower

4

60

40

Gain (dB)

20

0

-20

1 10 100 1000 10000 100000

150

100

50

0

-50

-100

-150

Gain

Phase

Phase (°)

2.2.10 Short circuit operation

Refer to paragraph2.1.4 and 2.1.5 for the effectiveness of the short circuit protections.

A short circuit has been made on the 12VPower output in the normal mo de. The conv erter protects itself

by entering an en dless restarting sequence, dri ven by the VIP er53 VDD v oltage colla psing down to the

VDDoff threshold periodically.

Note that the VDD voltage doesn’t decrease sufficiently during the switching operation, and that the

overload feature of the device is the real protection. This is visible in figure27, where the TOVL voltage

rises up as soon as the COMP pin is stuck to its maximum value of about 4.5V. When it reaches the

overload threshold (about 4V), the converter halts switching, and the V DD voltage decreases a little bit

and remains at 9.6V for 30ms. This is due to the additional auxiliary winding and associated components

which discharge the energy stored in C10, and act as a serial regulator. Then, the VDD voltage definitely

decreases until it triggers the reset voltage VDDoff (8.4V typical), and the device ac tivates its internal

high voltage startup current source to recharge the VDD capacitor C3.

The full restarting cycle can be observed in figure28. The restarting duty cycle defined as the ratio of the

active phase wh e re th e VIPer5 3 d e vi ce switches, over the tota l restarting cycle, i s ke p t to about 8%. This

low value prevents any overheating of the output diode and of the transformer. The short circuit can be

indefinitely applied without any stress for the converter.

Figure 27: short circuit protection Figure 28: Restarting cycl es

Ch4 : Vtovl

Ch2 : Vdd

Ch3 : Vcomp

3

4

2

1

Ch2 : Vdd

Ch1 : Vds

2

Ch1 : Vds

1

13/17

Page 14

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

2.3 Board description

2.3.1 Bill of material

Q.ty Reference Description Note

1 D1 1N4947GP Diode

3 D2, D11, D12 1N4148 Diode

1D3 STMicroelectronics BYT01-400 Diode

1D4 STMicroelectronics BAT43 Schottky Diode

2 D5, D9 BAV21 Schottky Diode

1D6 STMicroelectronics STPS8H100D Schottky Diode

1D7 STMicroelectronics STPS5L40 Schottky Diode

1D8 STMicroelectronics STPS5L60 Schottky Diode

1D10 STMicroelectronics 1N5818 Schottky Diode

1 DZ1 BZX79C10 Zener Diode

1 DZ2 BZX79C5.1 Zene r Diode

1 DZ3 BZT03C200 Zener Diode

1 DB1 DF08M Diode bridge

1 Q1 2N5551 transistor

1Q2 STMicroelectronics PN2907A transistor

2 Q3, Q4 STMicroelectronics PN2222A transistor

1IC1 STMicroelectronics VIPer53 SMPS controller

1 IC2 PC817 Optocoupler

1IC3 STMicroelectronics TL431ILP Voltage reference

1 C1 100nF 20% 400V Ceramic capacitor

1C2 68

1C3 47

1 C4 2.2nF 10% 100V Ceramic capacit or

6 C5, C12, C13, C14, C26, C27 100nF 10% 100V Ceramic capacitor

2 C6, C29 10nF 10% 100V Ceramic capacitor

1C7 1

0 C8 6.8nF 10% 400V Ceramic capacitor Option - not fitted

1 C9 2.2nF 10% 1KV Ceramic capacitor

1 C10 4.7

4 C11, C22, C25, C28 180

4 C15, C16, C17, C24 39

1 C18 820

2 C19, C20 120

2 C21, C23 1200

1 C30 6 .8nF 10% 100V Ceram ic capacit or

1R1 10K

0R2 22K

1R3 47

1 R4 0 Resistor

1R5 18K

1 R6 2.2K

2 R7, R9 150

1R8 33K

2 R10, R11 910

µF 20% 450V Electrolitic capacitor

µF 20% 16V Electrolitic capacitor

µF 20% 63V Electrolitic capacitor

µF 20% 250V Electrolitic capacitor

µF 20% 10V Electrolitic capacitor

µF 20% 35V Electrolitic capacitor

µF 20% 25V Electrolitic capacitor

µF 20% 25V Electrolitic capacitor

µF 20% 6.3V Electrolitic capac itor

Ω 1/4W 5% Resistor

Ω 3W 5% Resistor Option - not mounted

Ω 1/4W 5% Resistor

Ω 1/2W 5% Resistor

Ω 1/4W 5% Resistor

Ω 1/4W 5% Resistor

Ω 1/4W 5% Resistor

Ω 1/4W 5% Resistor

14/17

Page 15

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

Bill Of Material (Continued)

Q.ty Reference Description Note

4 R12, R14, R15, R19 1K

1 R13 5.6K

3 R16, R17, R24 18K

1 R18 100

2 R20, R23 4.7K

1 R21 4.99K

1 R22 4.7K

1 L1 18mH 0.5A Common mode filter

1 L2 100

1L3 47

4 L4, L5, L6, L7 10

1 T1 Thomson Multimedia - Orega 25707870P1 Transformer

1 F1 250V 1V Fuse

2 F1 Fuse clip

0 No Ref. 18ºC/W Dissipator Option - not fitted

1 J1 2 Points connector

4 J2 3 Points connector

4 No Ref. Adhesive base 1 per board angle

Ω 1/4W 5% Resistor

Ω 1/4W 5% Resistor

Ω 1/4W 5% Resistor

Ω 1/4W 5% Resistor

Ω 1/4W 5% Resistor

Ω 1/4W 1% Resistor

Ω 1/4W 1% Resistor

µH 10% 0.75A Inductor

µH 10% 1.4A Inductor

µH 20% 4.3A Inductor

2.3.2 Board layout

Conventional cares have been observed when designing this board:

- the ground pin of IC1 (VIPer53 device) is a star point for two connections: The first one is dedicated to

the power ground line issued f rom C2 and the transformer T 1, and the second one i s reserved for all

low signal components associated with this circuit. This rule should be respected in order to avoid any

spurious noise to be injected on the signal pins.

- a sufficient copper area is foreseen at the level of the drain pin of IC1 and for all main secondary

rectifying diodes (D6 to D8) in order to provide a heatsink capability for these devices.

15/17

Page 16

Obsolete Product(s) - Obsolete Product(s)

2.3.3 Transformer specification

AN1948 - APPLICATION NOTE

Number of turns:

Primary 67 turns

Auxiliary 66 turns

Add. auxiliary 66 turns

3.3V 4 turns

5VPower 6 turns

12V 13 turns

- 25V 27 turns

- 4.2V / 4.2V 5 turns

5VStandby 28 turns

16/17

Page 17

Obsolete Product(s) - Obsolete Product(s)

AN1948 - APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such i nformat ion nor f or any infr ingement of patents or other rig hts of third par ties w hich may res ults from i ts use. No license is

granted by i m pl i cation or otherwise und er any patent or patent rights o f ST M i croelectroni cs. Specifi cations ment i oned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical com ponents in life support devices or systems without express written approval of STM i croelectronics.

Austra lia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - Ind i a - Israel - Italy - Japan - Malaysi a -

Malta - Morocco - Singapore - Spain - Sweden - Switzerl and - United K in gdom - U.S.A.

The ST logo is a trademark of STMicroele ct ronics

2003 STMicroelectronics - Printed in ITALY- All Rights Reserved.

STMicroelectronics GROUP OF COMPANIES

http:// www.st.com

17/17

Loading...

Loading...