Page 1

AN1947

APPLICATION NOTE

ST7MC PMAC SINE WAVE MOTOR CONTROL

SOFTWARE LIBRARY

INTRODUCTION

This application note describes a 3-phase synchronous permanent magnet motor control software library developed for the ST7MC drive with sinusoidal waveform. The ST7MC microcontroller contains a peripheral dedicated to 3-phase brushless motor control, making it suitable

for AC induction motors and permanent magnet DC/AC motors (PMDC/PMAC, also called

BLDC).

The library described here is made of several C modules that contain a set of convenient functions for the generation of the sinusoidal waveform, the synchronization mechanism and

closed loop control of PMAC induction motors and is compatible with both COSMIC

(www.cosmic-software.com) and METROWERKS (www.metrowerks.com) compilers.

The control of a Permanent magnet motor in six-step mode is detailed in application note

AN1905. The control of an AC induction motor is detailed in application note AN1904.

This software allows users to quickly evaluate both the MCU and the available tools, and to

have a motor running in a very short time when used together with the ST7MC starter kit

(ST7MC-KIT/BLDC) and the demonstration AMETEK BLDC motor. It also eliminates the need

for time-consuming development of sine wave generation and speed regulation algorithms by

providing ready to use functions that let the user concentrate on his application layer.

The prerequisite for using this library is the basic knowledge of C programming, AC motor

drives and power inverter hardware. In-depth know-how of ST7MC functions is only required

for customizing existing modules and when adding new ones for complete application devel

opment.

-

AN1947 Rev. 2 1/36

1

Page 2

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 WORKING ENVIRONMENT SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.1 Integrated Development Environments (IDE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.2 Emulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.3 Programmers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.4 Starter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 LIBRARY SOURCE CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 File structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 UTILITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 lib.h file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 TECHNICAL LITERATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 PMAC BASIC PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 HOW A PM MOTOR CAN BE RUN IN SYNCHRONOUS SINE-WAVE MODE 10

2.2 VARIOUS CONFIGURATIONS OF HALL SENSORS . . . . . . . . . . . . . . . . . . . . 11

2.3 PHASE ANGLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 GETTING STARTED WITH PMAC LIBRARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 HARDWARE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Connect the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 HOW TO RUN A PM MOTOR FOR THE FIRST TIME WITH THE LIBRARY AND

HOW TO CONFIGURE THE PHASE ANGLE 14

3.3 COMPILING THE LIBRARY AND LOADING THE SOFTWARE . . . . . . . . . . . 16

4 CONFIGURATION FILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 CONFIGURATION PARAMETERS FOR LIBRARY USE . . . . . . . . . . . . . . . . . 19

4.2 CONFIGURATION EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.1 Three hall sensors 60° or 120° settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.2 Two hall sensors 90° settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.3 One hall sensor settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.4 Open loop settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.5 Closed loop settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

36

2/36

1

Page 3

Table of Contents

5 LIBRARY FUNCTIONALITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 CAPTURE INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 START UP PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3 DIRECTION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 REGULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5 BRAKING STRATEGY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 RESULTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 OSCILLOSCOPE ACQUISITION OF PHASE CURRENT WAVEFORM . . . . . 31

6.2 MOTOR CONTROL RELATED CPU LOAD IN THE APPLICATION . . . . . . . . 34

6.2.1 Estimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3/36

Page 4

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Why use PMAC?

Standard induction motors, normally designed to run at base speeds between 850 to 3500

rpm, are not particularly well suited for low-speed operation, as their efficiency drops with the

reduction in speed. They may also be unable to deliver sufficient smooth torque at low speeds.

The use of a gearbox is the traditional mechanical solution to this problem. However, the

gearbox is a complicated piece of machinery that takes up space, reduces efficiency, and

needs both maintenance and significant quantities of oil. Replacing the gearbox with perma

nent magnet motors/drive configurations saves space and installation costs, energy and maintenance, and provides more flexibility in production and facility design. These motors use

magnets to produce the magnetic rotor field rather than the magnetizing component of the

stator current like in the induction motor.

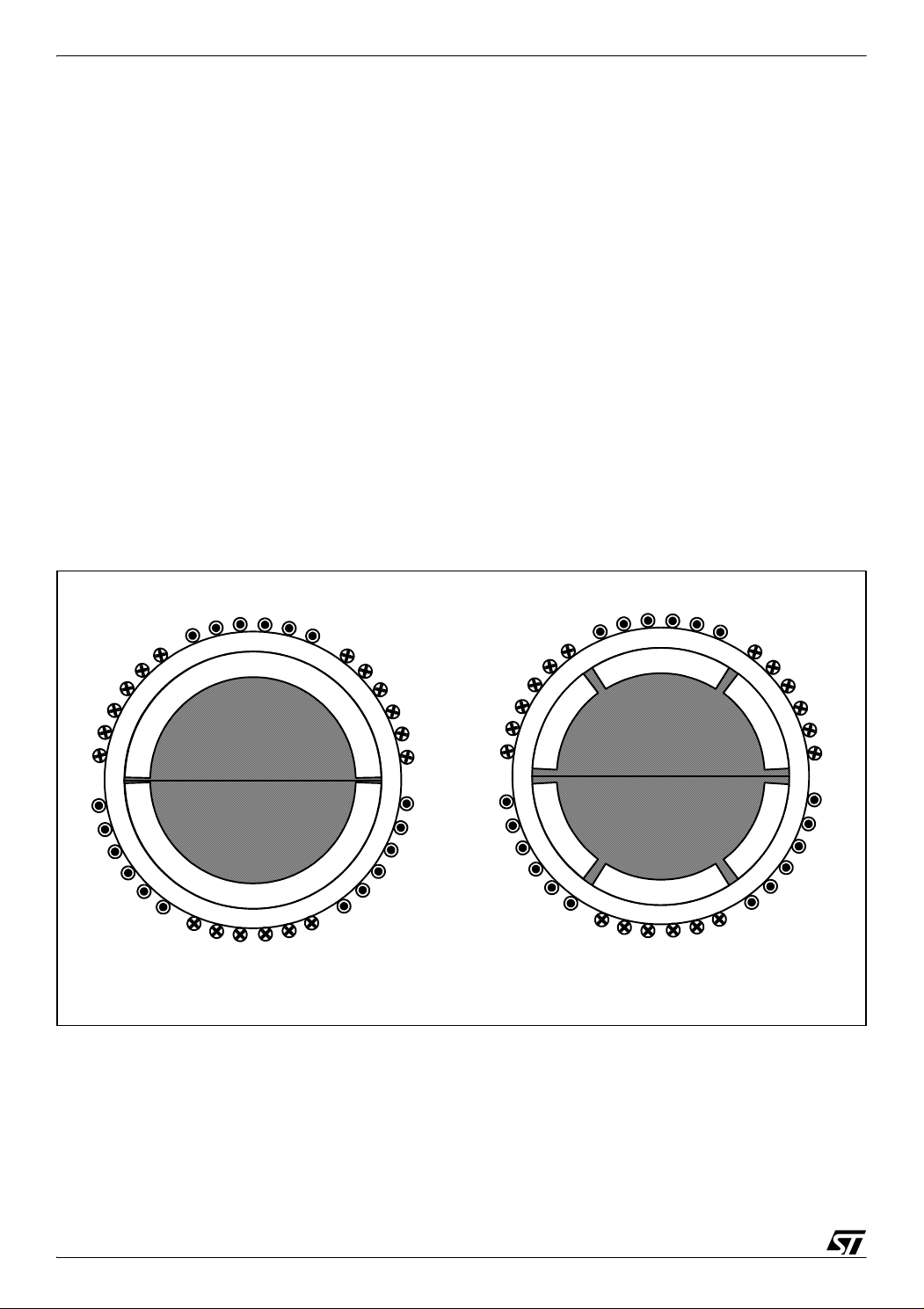

Figure 1 shows a cross section of a typical PM motor. The rotor has an iron core in the surface

of which is mounted a thin permanent magnet. An alternating magnet of opposing magnetization produces radially directed flux density across the air gap. This flux then reacts with currents in the stator windings to produce torque.

-

Figure 1. Cross Section of PM Motor

a

N

-b

a

N

-c

-b

S S

N

c

S

b

-a

1 Poles Pairs 3 Poles Pairs

The two most common types of brushless PM motors are classified as:

c

S

-a

-c

N

b

– synchronous, with a uniformly rotating stator field as an induction motor. This is also referred

to as PMAC,

– switched or trapezoidal, with stator fields that are switched in discrete steps. This is also re-

ferred to as PMDC.

4/36

2

Page 5

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

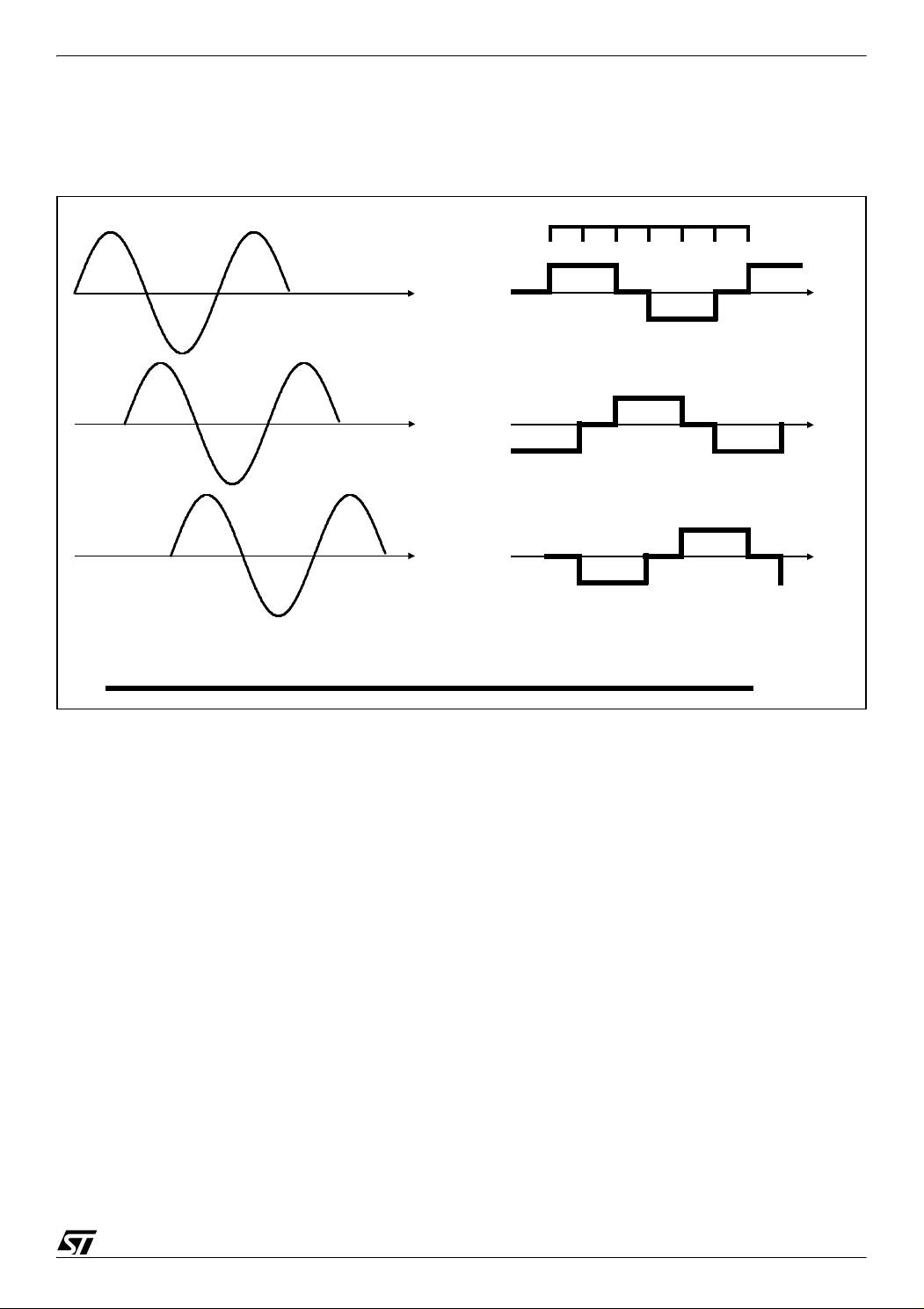

Figure 2 provides a direct comparison of ideal current excitation waveforms for typical three-

phase sinusoidal and trapezoidal PM machines.

Figure 2. Sinusoidal (PMAC) and Trapezoidal (PMDC or 6-step) Current Excitation

120°

240°

(a) Sinusoidal

Phase A

Phase B

Phase C

1

120°

2

240°

3

(b) Trapezoidal

456

2

The trapezoidal PM machine (also called PMDC or BLDC) is specifically designed to develop

nearly constant output torque when excited with a six-step switched current waveform. The

stator windings of the trapezoidal PM machine are concentrated into narrow phase belts. The

resulting back-EMF voltage induced in each stator phase winding during rotation can be mod

elled quite accurately as a trapezoidal waveform.

The sinusoidal PM machine also called PMAC or synchronous PM is specifically designed to

be excited with a sinusoidal current waveform. The stator windings of the sinusoidal PM ma

chine are instead typically distributed over multiple slots in order to approximate a sinusoidal

distribution. The resulting back-EMF waveforms generated by sinusoidal PM machine are, in

fact, sinusoidally shaped.

Except for the intrinsic characteristics of stator windings, a PM machine can be excited with

both drive methods without a great loss of efficiency, instead the main difference between the

two types of excitation is the acoustic noise generated. The abrupt variation of the trapezoidal

phase current generally introduces a great amount of acoustic and electronic noise in compar

ison to the sinusoidal phase current. Frequently the reduction of noise when a PM motor is excited with sinusoidal current in comparison to trapezoidal is appreciable even audibly and the

5/36

-

-

-

Page 6

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

efficiency loss cause by an incorrect type of waveform excitation is negligible. The drawback

of using the PMAC method is that the PMAC software library requires at least one sensor to

detect the rotor position. The elimination of the position sensor in sinusoidal PMAC machines

is more challenging since all three phases are continuously excited. This differs in the 6-step

PMDC method where one of the three phases is unexcited during each 60° electrical interval,

making it possible to get information about bemf zerocrossing. ST7MC is not designed to con

trol PMAC machines without sensors.

ST7MC Library Version 1.0.0 overview (CPU running at 8 MHz):

– Stator Frequency Range: From 0.2 Hz up to 680.0 Hz with the resolution dependent on the

PWM frequency (typically ~0.1Hz)

– Voltage Resolution: 8-bit modulation index

– 9 to 10-bit PWM generation for sine wave (typical resolution in the inaudible PWM range)

– PWM Frequency: can be set by default to 1.95, 3.9, 7.8, 12.5 and 15.66 kHz, with centered

pattern PWM generation

-

– Brake capabilities

– Speed reversal

– Speed acquisition from Hall sensors signal

– Speed regulation and control routines

– Free C source code

The 12.5 kHz switching frequency is proposed by default, providing a PWM resolution close to

10 bit with a 16-MHz CPU clock. In addition, this frequency is a good compromise between the

reduction of switching losses and acoustic noise (rejected in the inaudible range due to cen

tred mode PWM patterns).

Note: These figures are for information only; data provided in this software library may be dependent on the use of the final application and peripheral resources. It must also be noted that

it was built using robust oriented structures, therefore preventing the speed or code size from

being fully optimized.

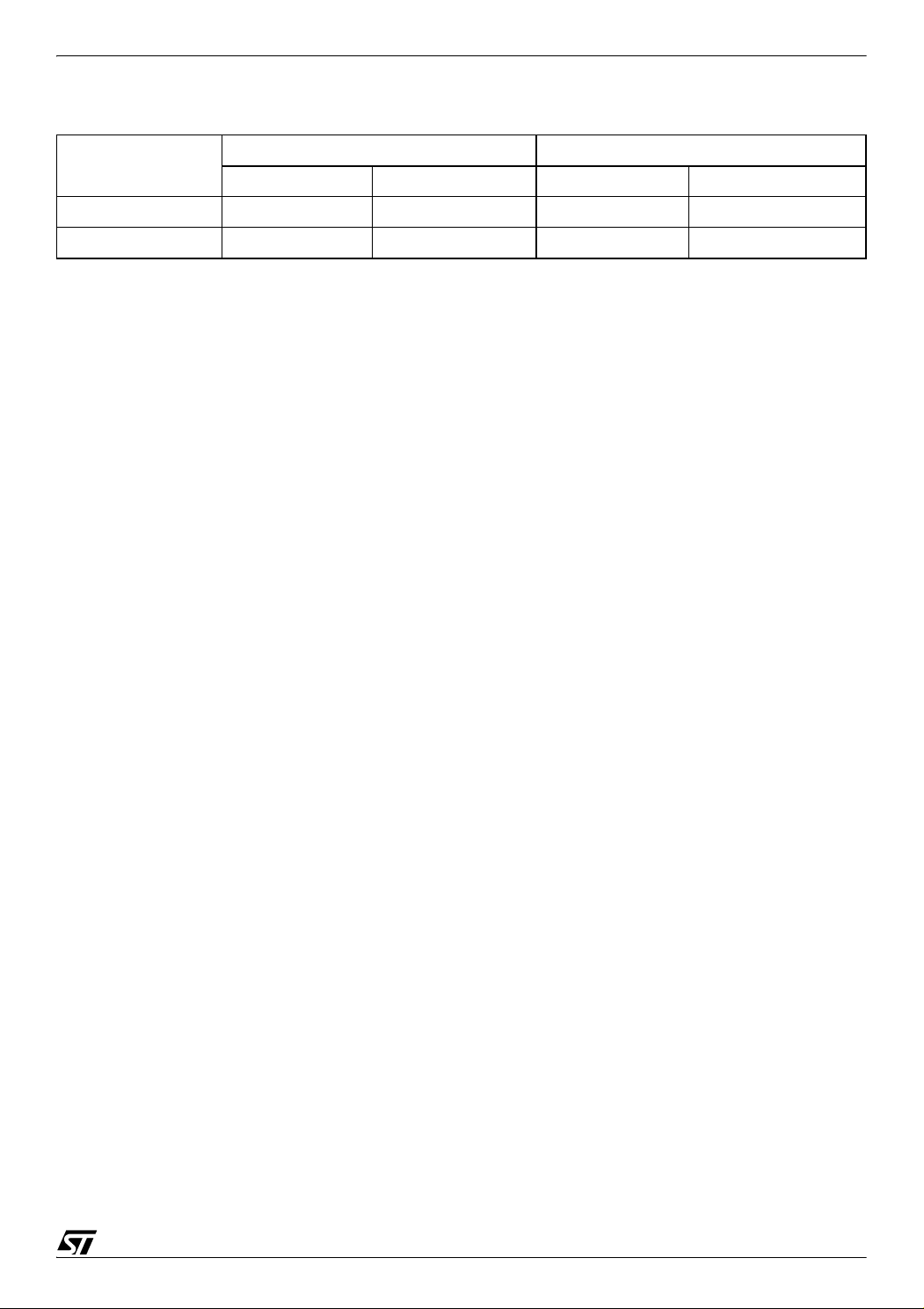

Table 1 below summarizes the memory required by the software library, as it is delivered.

These metrics include non motor control related code, implemented for demo purposes (such

as ADC management, software time bases, etc.). These must therefore be considered only as

indicative figures, which will be lower in the final application.

-

6/36

Page 7

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Table 1. Memory size metrics

ROM (bytes) RAM (bytes)

Cosmic 4.4d Metrowerks 1.1 Cosmic 4.4d Metrowerks 1.1

Closed Loop 5528 5965 164 189

Open Loop 4557 4747 164 166

1 WORKING ENVIRONMENT SET-UP

This section presents the available material needed to start working with the ST7MC and the

library discussed in this document.

1.1 DEVELOPMENT TOOLS

1.1.1 Integrated Development Environments (IDE)

This library has been compiled using Cosmic & Metrowerks C compilers, launched with

STVD7 release 2.5.4 (ST Visual Debugger) and STVD7 release 3.x.x.

A complete software package consists of:

– An IDE interface: ST's proprietary STVD7 (free download available on internet: www.stm-

cu.com), or third party IDE (e.g. Softec Microsystems' STVD7 for InDART-STX).

– A third party C-compiler: either Cosmic or Metrowerks (if needed, time limited evaluation ver-

sions can be obtained upon request).

The choice of the C Toolchain is left to the appreciation of the user. Both COSMIC and

METROWERKS are fully supported, and the dedicated workspace (compatible with 'STVD7'

& 'STVD7 for Indart') can be directly opened in the root of the library installation folder

(PMAC_Metrowerks.wsp, PMAC_Cosmic.wsp, pmacmotor.stw).

Note: You can use the 4K limited free version of Cosmic compiler to compile the software library. To do this you must disable the RS232 communication in the config.h as follows:

//#define ENABLE_RS232

In this case, to read the Phase Angle value you can run the program in Debugger mode, stop

it and use the Watch features.

1.1.2 Emulators

Two types of real-time development tools are available for debugging applications using

ST7MC:

– In-circuit debugger from Softec (sales type: STXF-INDART/USB).

The inDART-STX from Softec Microsystems is both an emulator and a programming tool. This

is achieved using the In-circuit debug module embedded on the MCU. The real-time features

7/36

Page 8

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

of the Indart include access to working registers and 2 breakpoint settings. However trace is

not available.

– ST7MDT50-EMU3 emulator

Full-featured emulator: real-time with trace capability, performance analysis, advanced breakpoints, light logical analyser capabilities, etc. It can also be a programming tool when used

with the delivered ICC ADDON module (where STMC-ICC is selected as the hardware target

in STVP7). This ICC-ADDON module allows In-Circuit-Debugging with STVD7.

1.1.3 Programmers

In order to program a MCU with the generated S19 file, you should also install the ST Visual

Programmer software (please visit our internet web-site) and use a dedicated programming

interface (stick programmer for example for In-Circuit-Programming). The Visual Program

ming tool provides an easy way to erase, program and verify the MCU content.

Please note that the inDART-STX from Softec Microsystems is also a programming tool (installation of DataBlaze Programmer software is required).

-

1.1.4 Starter Kit

The present software library was fully validated using the main hardware board (a complete inverter and control board) included in ST7MC-KIT/BLDC starter kit, and the demonstration PM

motor from AMETEK. The ST7MC-KIT/BLDC starter kit also includes a low-cost inDART hard

ware emulator, making this tool an ideal set for starting a project and evaluating/using the library.

Therefore, for rapid implementation and evaluation of the software discussed in this application note, it is recommended to acquire the ST7MC-KIT/BLDC starter kit and one of the two

compatible C-toolchain (or at least time limited evaluation versions).

1.2 LIBRARY SOURCE CODE

1.2.1 Download

The complete source files are available for free on the ST website (www.stmcu.com), as a zip

file in the Technical Literature and Support Files section. A Graphical User Interface (ver. 2.0)

which supports this type of motor is to be released soon by Softec. Check

www.softecmicro.com for updates.

Important Note: It is highly recommended to check for the latest releases of the library before

starting a new development, and then verify from time to time release notes to be aware of

8/36

Page 9

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

new features that might be of interest for the project. Registration mechanisms are also available on the web sites of ST and Softec Microsystems to automatically get update information.

1.2.2 File structure

Once the files are unzipped, the following library structure appears.

– Library release 1.0.0

This library contains the workspace for both the STVD7 2.5.x and STVD7 3.x IDEs. Two separate folders are provided, with different file structure based on the same set of source files.

This is to ensure the compatibility with STVD7 for inDART-STX, based on STVD7 2.5.4.

All build information is provided in makefiles and linker command files, in dedicated folders:

config\Cosmic and config\Metrowerks. Object files are also provided in dedicated folders.

Figure 3. Library Structure for release 1.0.0

PMAC

\config

\cosmic

\metrowerks

\object

\cosmic

\metrowerks

\source

\debug

\release

1.3 UTILITIES

1.3.1 lib.h file

The purpose of this header file is to provide useful macros and type re-definitions which will be

used throughout the entire library:

– Re-definition of data types using the following convention: a first letter indicating if a variable

is signed (s) or unsigned (u), plus a number indicating the number of available bits (for in

-

stance: u8, s16, etc.),

– Defines for assembly mnemonics used in C source code: Nop(), Trap(),...

– Common macros used for bit-level access (SetBit, ClrBit,...), to get the dimension of an array

(DIM[x]), etc.

1.4 TECHNICAL LITERATURE

More information can be found on the ST website (www.st.com/mcu).

9/36

Page 10

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

More specifically, latest documents and software can be found at:

http://mcu.st.com/devicedocs-ST7MC2N6-15.html

In addition, a Knowledge base (FAQ) and Forum are available at:

http://www.st.com/stonline/products/support/micro/st7/st7mc.htm.

2 PMAC BASIC PRINCIPLE

2.1 HOW A PM MOTOR CAN BE RUN IN SYNCHRONOUS SINE-WAVE MODE

PMAC machines are synchronous so the average torque can be produced only when the excitation is synchronized with the rotor frequency and instantaneous position. The most direct

and powerful means of ensuring that this requirement is always met is to continuously

measure the rotor's absolute angular position and rotational speed, so that the excitation can

be switched among the PMAC motor phases in exact synchronism with the rotor's motion.

This concept, known commonly as self-synchronization uses direct feedback of the rotor an

gular position to ensure that the PMAC machine never loss synchronization. Commonly Hall

sensors are used to get information about the angular position of rotor, finding the magnetic

flow direction caused by the permanent magnet running with the rotor.

-

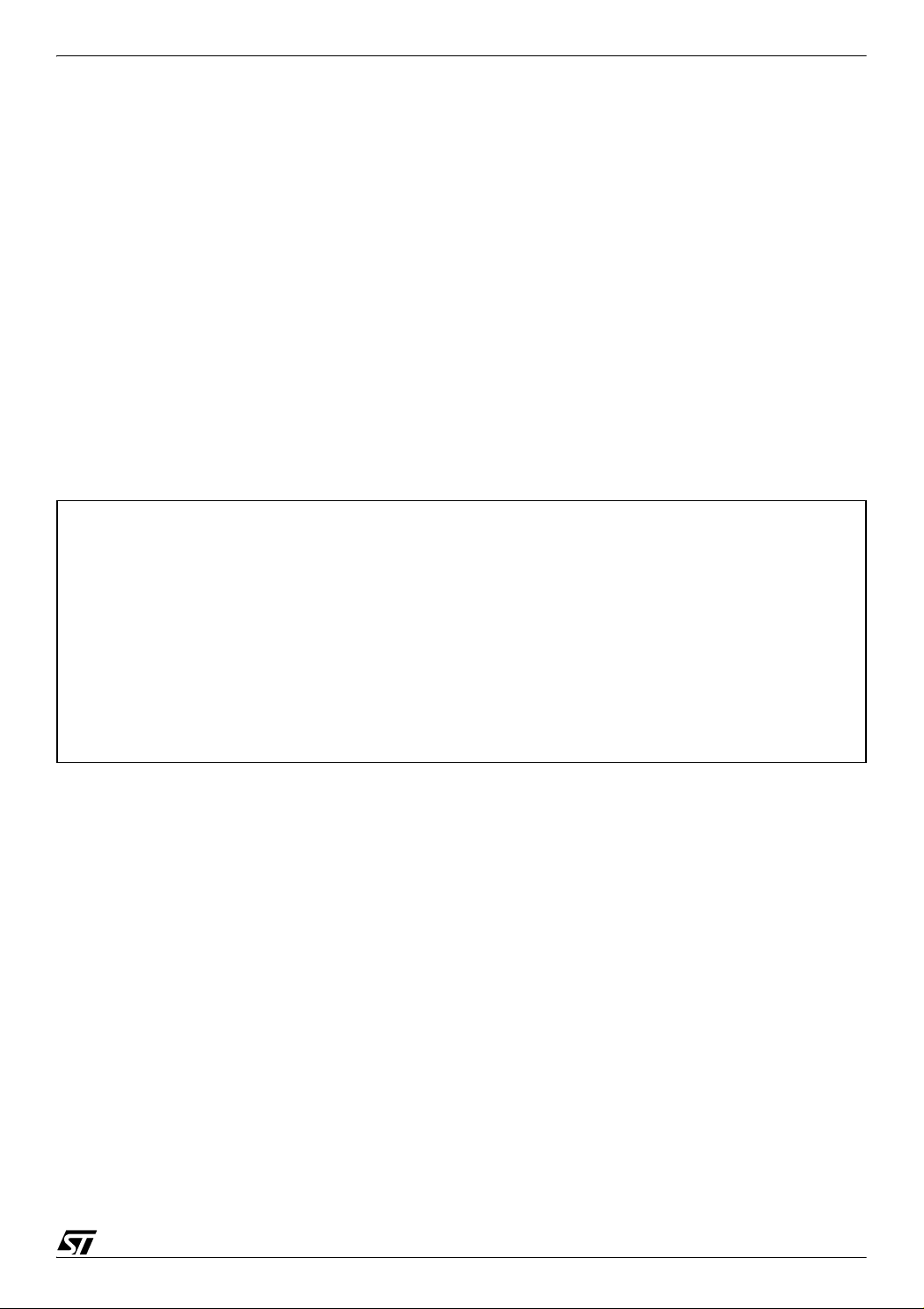

In Figure 4 is showed the block diagram of the PMAC self-synchronization algorithm implemented in the software library.

Figure 4. SELF-SYNCHRONIZATION ALGORITHMS FOR PMAC

Φ

A* sin(2πf+Φ)

A

The motor is supplied by a sinusoidal voltage waveform with amplitude A*, frequency f, and

phase Φ. The motor supplied by this signal is forced to run with frequency f*. For each con

troller cycle, to maintain the synchronism the new frequency of the rotor is measured and sup-

V/F

Limitation

A*

f

Phase

Synch.

f=f*

Motor

f*

-

10/36

Page 11

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

plied to the motor by the controller. Together with the frequency synchronization the phase Φ

must be synchronized according the position of the rotor read by the Hall sensors.

To avoid giving a high voltage value based on the current frequency, a V/F limitation curve is

used to fix the maximum voltage value supplied for that stator frequency.

2.2 VARIOUS CONFIGURATIONS OF HALL SENSORS

In commerce there are motors with different numbers of Hall sensors and various Hall sensor

configurations. The most common PM motors have three, two or one hall sensors. Motors with

three hall sensors can be arranged in two configuration types: 120° spatial distribution or 60°

spatial distribution. Motors with 2 hall sensors have spatial distribution of 90°.

Figure 5 sum-

marizes the most common Hall sensor configurations and the relative waveforms of the signals that are observed from the Hall sensors during an electrical cycle of the rotor.

2.3 PHASE ANGLE

We refer as “Phase Angle” the angle between the H1 edge transition and the 90° of A winding

sinus phase. This value must be set to get the synchronism between rotor and stator and to

optimize the efficiency of the motor. This value can be different for different speed and/or load

condition. See

Figure 6.

11/36

Page 12

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Figure 5. Hall sensors configuration

3 Sensor 120°

H1

120°

H2 H3

H1

H2

H3

2 Sensor 90°

H1

90°

H2

H1

H2

3 Sensor 60°

H1

H2

H1

H2

H3

1 Sensor 180°

H1

H1

H3

60°

12/36

Page 13

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Figure 6. Phase Angle is the angle between edge of H1 and 90° of A winding Sinus

Phase

Stator Voltage – Phase A

H1

Rotor

Flux

Stator

Flux

Rotor

Flux

Stator

Flux

C

H1

A

N

S

Phase_Angle

A

S

N

B

H1

Stator Voltage – Phase A

Phase_Angle

B C

H1

3 GETTING STARTED WITH PMAC LIBRARY

3.1 HARDWARE CONFIGURATION

3.1.1 Tools Required

– STMC Starter Kit

– Power Supply (Low or High voltage according to the motor needs)

– Oscilloscope, one current probe, three voltage probes

– Null modem cable for RS232 communications

3.1.2 Connect the hardware

– Connect the ST7MC starter kit board with the ICC isolator board through an ISP cable and

connect the ICC isolator board with the inDART board through an ISP cable.

13/36

Page 14

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

– Connect the inDART board to the PC through USB cable.

– Connect the motor phases to the J12 connector of ST7MC starter kit board and the hall sen-

sor signal to the J19 connector in any order.

– Set w14, w15, w16 to the unmarked jumper positions (hall sensor position). Open w13 jump-

er. Set w1 according to the power supply (Low voltage or High voltage)

– Connect the power supply to J3 connector of ST7MC starter kit board.

Note: To run the motor in High Voltage (>50 Vac) you must connect all the J8 jumpers (1-2, 3-

4. 5-6, 7-8) to filter the noise on the Hall sensor signals.

3.2 HOW TO RUN A PM MOTOR FOR THE FIRST TIME WITH THE LIBRARY AND HOW TO CONFIGURE THE PHASE ANGLE

To make the software run the motor correctly it's necessary to properly connect the phases

and hall sensor signals to the board. When we use one or two sensors there isn't a particular

correct setting as in both cases we can connect the wires in any order.

In case of three hall sensors (each 60 and 120 degree) we must perform the following procedure.

Set the software to run with only one sensor, open loop control method. Set the option to read

the phase angle through RV3 and set the RS232 communication. To do this you can open the

configuration file MTCParam.h and modify the following parameter:

#define Pole_Pair_Num "with the number of poles pairs of the motor"

#define Hall_Sensor_Num 1

Then we must ensure that the following line is uncommented in PMACparam.h.

#define Phase_Angle_RV3

This allows the Phase Angle to be set with the RV3 potentiometer.

And we must ensure that in Config.h the control mode is set to open loop with the following

line.

#define CONTROL 0

Another step that must be performed is to activate the RS232 communication by uncommenting the following line in Config.h.

#define ENABLE_RS232

14/36

Page 15

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Then, compile the library using STVD7 for Indart STx and the Cosmic or Metrowerk compiler

and load the executable file into ST7MC microcontroller memory.

Before running the motor it's better to check if w14, w15, w16 are in the unmarked jumper positions (hall sensor position).

Set RV1 to ¼ of the full CW position to limit the stator voltage. Push the SW1 button (On/Off).

Rotate the RV3 from CCW to CW until the motor starts to run.

If the motor doesn't start, rotate RV1 CW a little to increase the stator voltage and retry to find

a position of RV3 that allows the motor to run.

If the motor runs in the opposite to the desired direction, swap phase B and phase C connection J12 and restart.

When the motor runs in the correct direction with one hall sensor you can stop the motor and

recompile the software with the three hall sensor settings.

#define Hall_Sensor_Num 3

Load the software and run the motor. Leave RV1 in the current position. Push SW1. Rotate

the RV3 from CCW to CW until the motor start to run.

Monitor the phase A current with the oscilloscope. If the motor runs but the phase current is

completely different from the sinusoidal waveform you must swap H2 with H3 connection in

the J19 connector.

To see if the connections are correct, you can view the hall sensors signals and the debug pin

signal from the microcontroller (MCDEM pin 43) to see if the sequence is right or wrong. You

can compare the signal you get with the

Figure 7.

Figure 7. Wrong and correct hall sensor sequence and debug pin

Wrong sensor sequence

Correct sensor sequence

15/36

Page 16

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

You can see in the Figure 7 that in the correct sequence there is a toggle of the debug pin for

each toggle of any one of hall sensors signal.

The position of RV3 can be rotated until the optimum Phase Angle is reached the optimum

value. Commonly we have two important Phase Angle values: one that minimizes the current

absorption and one that maximizes the speed. It is recommended to use the first as the op

timum Phase Angle.

Once the motor runs and the optimum Phase Angle is set, this value can be read by connecting the ST7MC starter kit board to the PC through a Null Modem cable and using Hyper

Terminal with the following parameters

– Bits per second: 38400

– Data bit: 8

– Parity: None

– Stop bit: 1

– Flow control: None

-

Then, we can set the phase angle as a fixed value by adding the optimum Phase Angle value

obtained from previous step to the two following lines from PMACparam.h. The same value

must be used in both defines if you want to keep the Phase Angle value constant for any stator

frequency.

#define Phi_min(u8) xx

#define Phi_max(u8) xx

And the following line must be commented

//#define PHASE_ANGLE_RV3

At this point, the software library has now been configured to run the motor and we have set

the right phase angle value.

3.3 COMPILING THE LIBRARY AND LOADING THE SOFTWARE

The steps below must be followed to generate the correct firmware to use the Starter Kit in

stand alone mode.

Notes:

1.The following steps require that the inDart - STX for ST7 System Software be installed.

16/36

Page 17

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

2. In order to compile a project linked to the STMicrocoelectronics Motor Control library, it is

possible to use :

– Full version of either the Metrowerks or Cosmic C compiler.

– Limited version of the Cosmic compiler (downloadable directly from www.cosmic-soft-

ware.com ).

Cosmic tools for STMicro ST7 family, free version limited to 4k.

Requires registration.

In this case it necessary to modify the following lines in in 32K.lkf file inside the folder config\cosmic as follows:

# STARTUP FILE

#C:\COSMIC\ST7\LIB\crts.st7

C:\COSMIC\CXST7_4K\LIB\crts.st7

# INTEGER LIBRARY FOR SMALL MEMORY MODEL

#C:\COSMIC\ST7\LIB\libims.st7

C:\COSMIC\CXST7_4K\LIB\libims.st7

# MACHINE LIBRARY FOR ALL MEMORY MODELS

#C:\COSMIC\ST7\LIB\libm.st7

C:\COSMIC\CXST7_4K\LIB\libm.st7

And set the correct path in the Project->Toolchains Path. Cosmic Builder Path:

C:\COSMIC\CXST7_4K

Run the STDV7 IDE. From the main menu, choose File > Open Workspace. Select the

"PMACMOTOR_COSMIC.wsp" if you use Cosmic compiler or

"PMACMOTOR_METROWERKS.wsp" if you use the Metrowerks compiler.

Select the "Build" command from the "Project" menu. The project will be compiled and built,

and an executable file will be generated.

Connect the InDart board with the ICC isolation board and supply the starter kit.

Press the debug button and then the MCU configuration button. Select the Device Code:

ST7FMC2N6B.

The option bytes must be configured by pressing the “Set option bytes” button and then by following the setup as displayed in Figure 8.

17/36

Page 18

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Figure 8. Editing the Option Bytes

Then the software is ready to be loaded in the Flash of the ST7MC microcontroller by clicking

on the "Program” button. Then program window then appears and you must configure the set

tings as shown in Figure 9.

Figure 9. Loading software to Flash

-

Once the program has been loaded in to the micro, disconnect the cable between the Starter

Kit board and the ICC isolator board.

4 CONFIGURATION FILE

The PMAC software library can be easily configured using the following configuration files:

– Config.h: for setting general configuration parameters such as the control method, PWM res-

olution and for Kp & Ki tuning and RS232 communication

– MTCParam.h: for setting motor-specific parameters like the number of pole pairs, number of

hall sensors and dead time duration

18/36

Page 19

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

– PMACParam.h: for setting more specific parameters regarding PMAC control like startup pa-

rameters, frequency range, target frequency for closed loop operation, phase angle setting

and V/F curve

– MainParam.h: for setting the brake parameters.

4.1 CONFIGURATION PARAMETERS FOR LIBRARY USE

Config.h file

– CONTROL: This define sets the desired control method.

0 = Open Loop, 1 = Closed Loop

#define CONTROL0

– PWM_RESOLUTION: This define sets the resolution of PWM.

0 = 9-bit resolution (15.66 kHz, 7.9kHz, 3.9kHz, 1.95kHz of PWM), 1 = 10-bit resolution (12.5

kHz of PWM).

#define PWM_RESOLUTION1

– PI_PARAM_TUNING: This define sets up Ki & Kp to be read by RV2 RV3.

#define PI_PARAM_TUNING

– ENABLE_RS232: This define enables communication between the board and PC through a

serial cable.

#define ENABLE_RS232

MTCParam.h file

– POLE_PAIR_NUM: This define sets the number of the motor’s pole pairs.

#define POLE_PAIR_NUM ((u8)1) /* Number of motor's pole pairs */

– HALL_SENSOR_NUM: This define sets the Number of Hall sensors (3, 2 or 1)

#define HALL_SENSOR_NUM 1 /* Number of Hall Sensors */

– DEAD_TIME: This define sets the Dead time duration. The defined value is loaded into the

MDTG register value so that you can use the following formula.

MDTG

PCN DTE DTG

5

DTG

4

DTG

3

DTG

2

DTG

1

DTG

0

19/36

Page 20

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

DTG5 DTG4 Tdtg Dead time expression Dead time value Tdtg* Range*

0 X 2xTmtc (DTG[4..0]+1) x Tdtg From 1 to 32 Tdtg 125ns 0.125us to 4us

1 0 4xTmtc

(DTG[3..0]+17) x Tdtg From 17 to 32 Tdtg

1 1 8xTmtc 500ns 8.5us to 16us

#define DEADTIME((u8)4) // Define a Dead time of 625ns

250ns 4.25us to 8us

PMACParam.h file (start-up phase)

– VOLT_SLEW_RATE: This define sets the time in ms for each increment by one unit of stator

voltage during the startup phase in both open and closed loop.

#define VOLT_SLEWRATE ((u8)15) /* Slope of startup voltage */

– STARTUP_STATOR_FREQ: This define sets the stator frequency during asynchronous

startup

#define STARTUP_STATOR_FREQ ((u16) 50) /* Frequency of the Asynchronous

phase of startup must be major or equal than LOWEST_FREQ*/

– START_TIMEOUT: This define sets the timeout of the start-up phase.

#define START_TIMEOUT((u16)5000) /* Resolution: 1ms */

– HIGHEST_FREQ: This sets the Max stator frequency with a resolution of 0.1 Hz

– LOWES_FREQ: this sets the minimum stator frequency with a resolution of 0.1 Hz

#define HIGHEST_FREQ((u16)5000)/* Sine wave Max Frequency 500 Hz*/

#define LOWEST_FREQ((u16)5) /* Sine wave Min Frequency 0.5 Hz*/

– TARGET_FREQ_CL: This define sets the target rotor frequency with the closed loop control

method with a resolution of 0.1 Hz

#define TARGET_FREQ_CL 500 /* Target frequency 50 Hz */

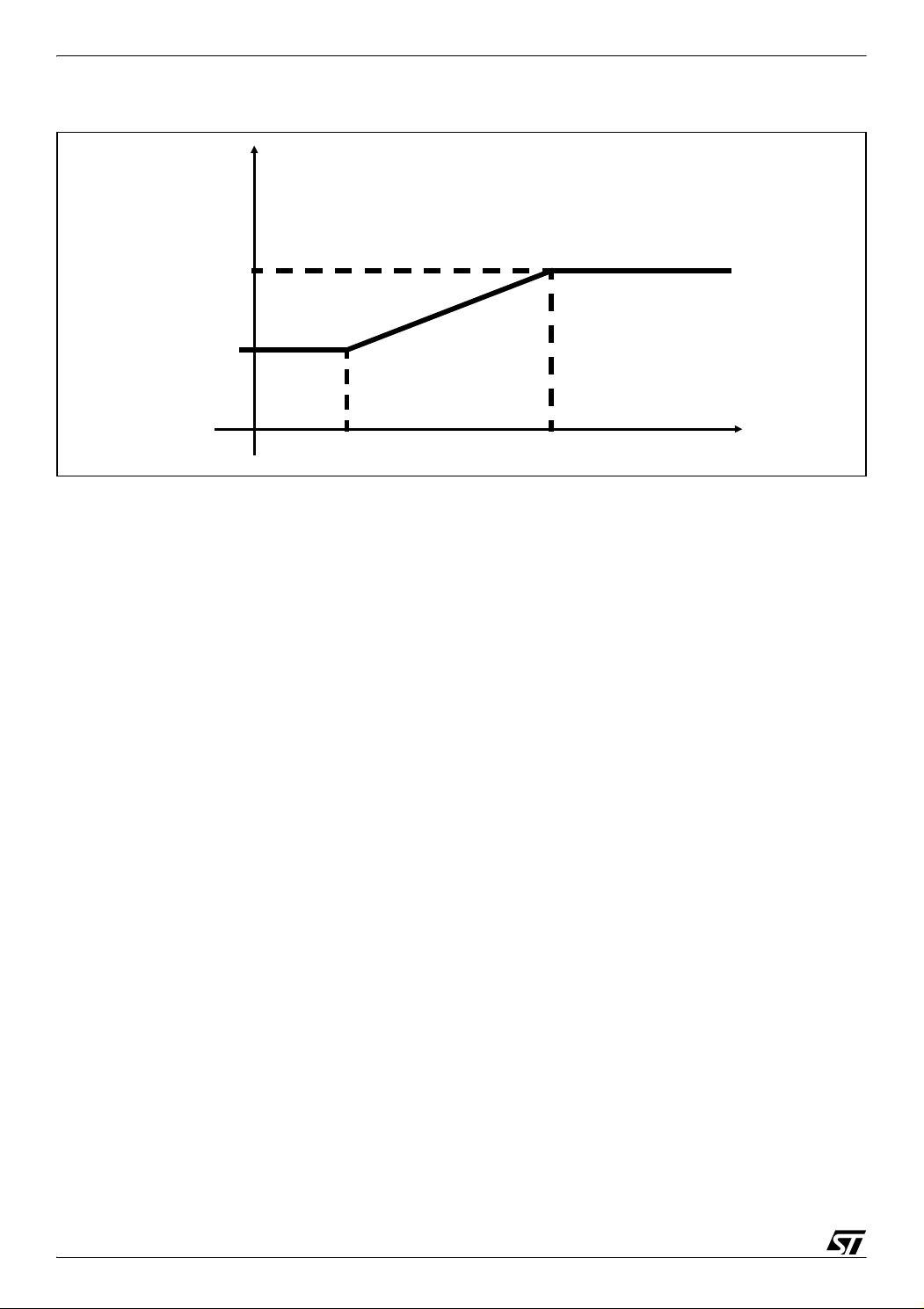

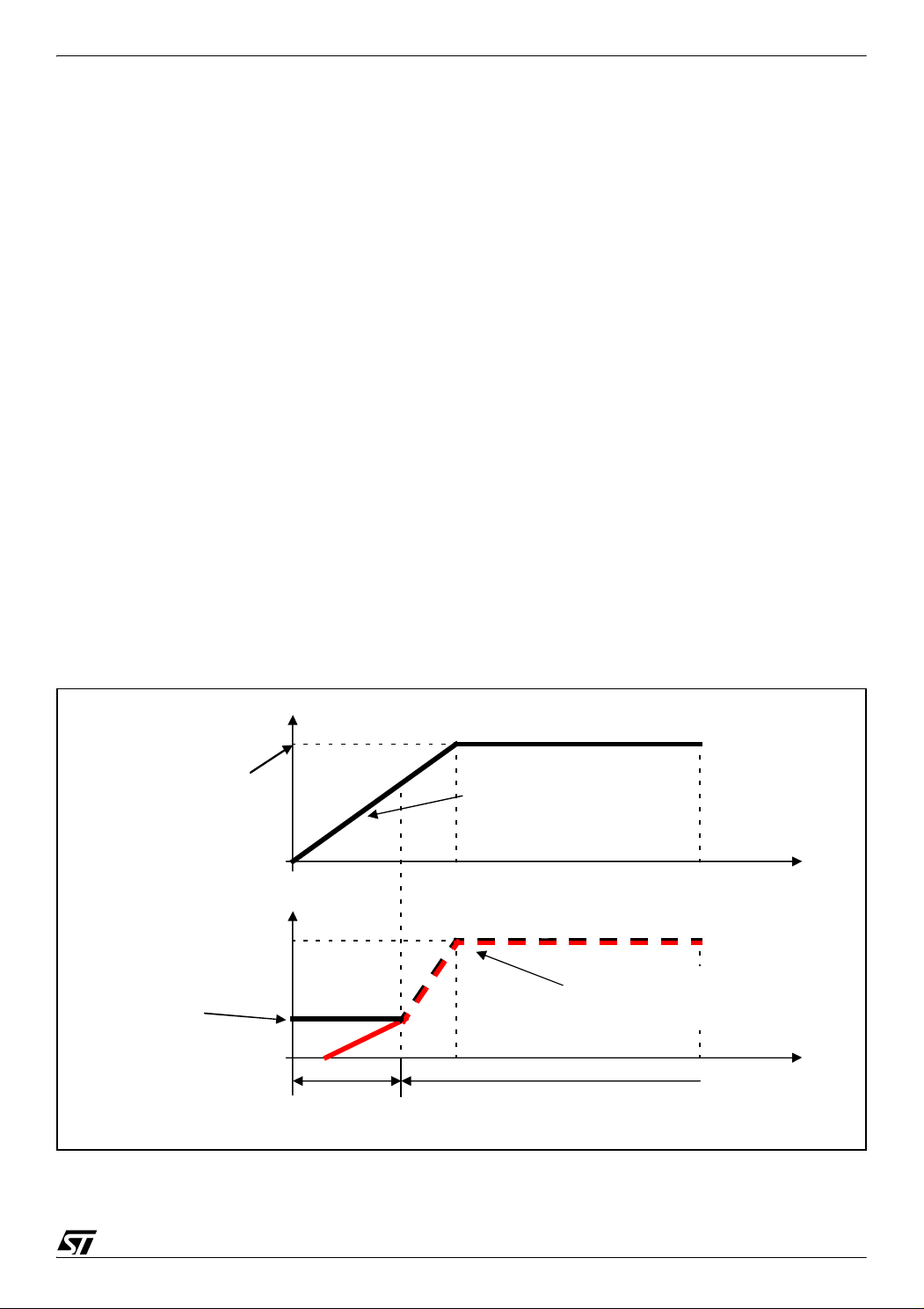

– PHI_MIN, PHI_MAX, PHI_LOWFREQ, PHI_HIGHFREQ: Phase angle definition. See Figure

6 and Figure 10.

20/36

Page 21

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

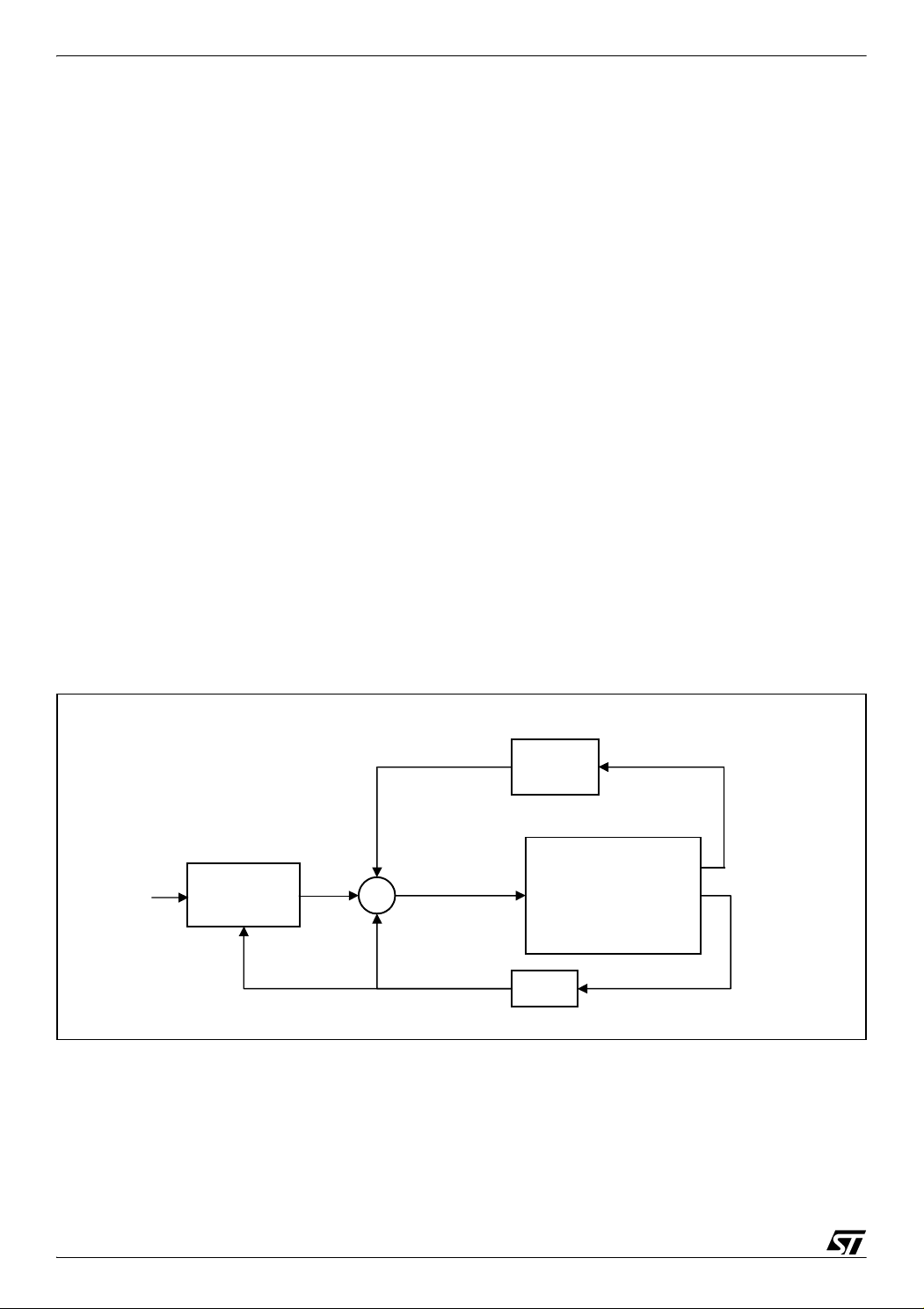

Figure 10. Phase Angle versus frequency curve

Phase Angle

PHI_MAX

PHI_MIN

PHI_LOWFREQ PHI_HIGHFREQ

#define PHI_MIN (u8) 140

#define PHI_MAX (u8) 160

#define PHI_LOWFREQ (u16) 500// 50 Hz

#define PHI_HIGHFREQ (u16) 2500// 250 Hz

Frequency

– PHASE_ANGLE_RV3: This define configures the Phase angle to be set using RV3 potenti-

ometer.

#define PHASE_ANGLE_RV3 /* If defined the Phase angle is read by RV3 */

– V_MAX, V_MIN, VF_LOWFREQ_LIMIT, VF_HIGHFREQ_LIMIT: These defines set the V/F

curve. See

Figure 11. V/F curve definition. The V/F curve is used to limit the maximum stator

voltage applied to the value below that curve. This curve fixes a maximum stator voltage value in relation to the actual stator frequency.

21/36

Page 22

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Figure 11. V/F curve definition

Stator Voltage

V_MAX

V_MIN

VF_LOWFREQ_LIM VF_HIGHFREQ_LIM

#define V_MAX ((u8)255)

#define V_MIN ((u8)100)

#define VF_LOWFREQ_LIMIT ((u16)200)// 20 Hz

#define VF_HIGHFREQ_LIMIT ((u16)1000)// 100 Hz

Frequency

– V_F_LIM: This define represents the V/F limitation and can be excluded by commenting.

//#define V_F_LIM // Exclude V/F limitation if commented

Caution: Disabling the V/F limitation can be dangerous.

– SLEW_LIMIT: This define sets the voltage variation rate during run time, expressed in milli-

seconds. The stator voltage can increment or decrement by one unit each SLEW_LIMIT millisecond.

#define SLEW_LIMIT((u8)10)// 10 milliseconds

– REG_LOOP_TIME: This define sets the sampling frequency of the PI regulator, expressed

in milliseconds.

#define REG_LOOP_TIME((u8)10)

MainParam.h

– BRAKE_VOLTAGE: This is the voltage modulation index of the sinusoidal waveform applied

during the brake. The greater this value, the stronger the brake is but also the higher the cur

rent that flows into the motor during the brake.

22/36

-

Page 23

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

– BRAKE_MIN_SPEED: This is the minimum rotor speed to be reached before to end the

brake phase express in 0.1 Hz. See

Section 5.5 Braking Strategy

4.2 CONFIGURATION EXAMPLE

4.2.1 Three hall sensors 60° or 120° settings

In MTCparam.h

#define HALL_SENSOR_NUM3

4.2.2 Two hall sensors 90° settings

In MTCparam.h

#define HALL_SENSOR_NUM 2

4.2.3 One hall sensor settings

In MTCparam.h

#define HALL_SENSOR_NUM 1

4.2.4 Open loop settings

In Config.h

#define CONTROL 0

4.2.5 Closed loop settings

In Config.h

#define CONTROL 1

In PMACparam.h

#define TARGET_FREQ_CL 500 // 50Hz of target frequency

5 LIBRARY FUNCTIONALITIES

5.1 CAPTURE INTERRUPT

The flowchart of the Capture Event is shown in Figure 12.

23/36

Page 24

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Figure 12. Capture event interrupt Flowchart

MTC_C_D_IT

MPHST_prev = MPHST

Yes

MPHST = MCIB

Yes

MPHST = MCIC

Yes

MPHST = MCIA

Yes

MPHST_prev

= MCIA

MPHST_prev

= MCIB

MPHST_prev

= MCIC

Direction = CW

Yes

MPHST = MCIC

Yes

MPHST = MCIA

Yes

MPHST = MCIB

Yes

MPHST_prev

= MCIA

MPHST_prev

= MCIB

MPHST_prev

= MCIC

Yes

Hall Sensor

Num = 3

MPHST_prev

= MCIA

Yes

MPHST = B

Hall Sensor

Num = 2

Yes

MPHST_prev

= MCIA

MPHST = A

Yes

Step_Index = 0

24/36

Yes

PBDR & 0x02

Direction = CW

Step_Index =

HALL_SENSOR_NUM

Phase = Pase Angle + PhaseVal [Step_Index]

Yes

Step_Index =

HALL_SENSOR_NUM

Rotor Speed

Measurement

Return

PBDR & 0x02

Step_Index = 0 Step_Index ++

Page 25

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

The capture event occurs when the selected MCIx input receives one edge transition from the

sensors from low to high or from high to low. This lets the software know the rotor position and

sets the correct phase value to be provided by the sine wave generation routine.

The software distinguishes between 3 cases:

– 3 Hall sensors

– 2 Hall sensors

– 1 Hall sensor

The software must set the port MCIx from where the next expected transition occurs. So the

software must discern between the hall sensors sequence.

If you have set three sensors and the sequence is H1-H2-H3 then:

– If MCIA transition occurs, the next expected will be MCIB

– If MCIB transition occurs, the next expected will be MCIC

– If MCIC transition occurs, the next expected will be MCIA

Otherwise if we have set the sequence H3-H2-H1 then:

– If MCIA transition occurs, the next expected will be MCIC

– If MCIB transition occurs, the next expected will be MCIA

– If MCIC transition occurs, the next expected will be MCIB

This is the same for each 60° and 120° hall sensor. The software should be written keeping in

mind that a clockwise direction of the rotor generates the sequence H3-H2-H1.

If you have set two sensors, regardless the hall sensor sequence, the software follows the

rule:

– If MCIA transition occurs, the next expected will be MCIB

– If MCIB transition occurs, the next expected will be MCIA

If you have set one sensor, the transition expected is only in the port MCIA.

Then, after each capture event, the software must calculate the correct phase to be applied to

the stator voltage sine wave. The main synchronization is between winding A and hall sensor

H1 so the software checks if the actual transition is on the MCIA input. If the transition on

MCIA occurs the sine wave generated relative to windings A is forced to phase 0° if MCIA

switches from low to high or to phase 180° if MCIA switches from high to low. This is per

formed checking the state of PB2 connected with MCIA.

-

PhaseVal is a vector that contains the phase value to be supplied on each sensor transition,

expressed in u16 value so we have:

25/36

Page 26

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

PhaseVal: 6 values for 3 sensors

0° 60° 120° 180° 240° 300°

0 10923 21845 32768 43691 54613

PhaseVal: 4 values for 2 sensor

0° 90° 180° 270°

0 16384 32768 49152

PhaseVal: 2 values for 1 sensor

0° 180°

0 32768

Step_Index is a variable which points into the PhaseVal to the last phase used for resynchronization so when the software receives one capture event that isn't in the MCIA input the

Step_Index is incremented and the resynchronization will be performed.

Finally, the software performs the rotor speed measurement with the information of two consecutive hall sensor edge events. The rotor speed measurement is performed to force the

synchronism between stator and rotor frequency.

5.2 START UP PROCEDURE

The startup procedures are defined in ACMotor.c module:

– ACM_InitSoftStart()

– ACM_SoftStart()

– ACM_SoftStartOL(TargetVoltage)

Open loop strategy

Provide a ramp of stator voltage with fixed slewrate set in VOLT_SLEW_RATE. Initially the

stator frequency is fixed to the value set up in STARTUP_STATOR_FREQ. When the rotor

frequency reaches STARTUP_STATOR_FREQ the synchronous mode starts and stator fre

quency is fixed to be equal to the reported rotor frequency. The startup phase finishes when

the stator voltage reaches TargetVoltage. This value is actually the reference stator voltage

fixed by RV1. See

Figure 13.

-

26/36

Page 27

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Closed loop strategy

Provide a ramp of stator voltage with fixed slewrate set in VOLT_SLEW_RATE. Initially the

stator frequency is fixed to the value set up in STARTUP_STATOR_FREQ. When the rotor

frequency reaches STARTUP_STATOR_FREQ the synchronous mode starts and the stator

frequency is fixed to be equal to the reported rotor frequency and the startup phase finishes.

Figure 14.

See

ACM_InitSoftStart: this procedure is common to open and closed loop control methods and

must be called before ACM_SoftStart or ACM_SoftStartOL. It is used to perform the fol

lowing tasks:

– Initialize the Hall sensor acquisition.

– Set the initial value of stator voltage and frequency (stator voltage equal to zero and stator

frequency to LOWEST_FREQ).

– Set the time interval in ART (Automatic Reload Timer) equal to VOLT_SLEWRATE (succes-

sively for each ART interrupt the SoftStart or SoftStartOL procedures increase the stator voltage by one).

-

– Set the timeout if in a closed loop.

Figure 13. Open loop startup strategy

Stator Voltage*

Fixed by RV1, that is the

reference stator voltage for

open loop mode*

Stator Frequency

Rotor Frequency

Startup_Stator_Freq

Asynchronous mode

*

For Stator Voltage is intend the voltage modulation index [0,255]

Voltage_SlewRate

between the increasing by one of

stator voltage

Synchronous mode

: The time

Time Out

During Synchronous mode the

Frequency

rotor frequency.

is imposed to be equal to the

Time

Stator

Time Time Out

27/36

Page 28

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Figure 14. Closed loop startup strategy

Stator Frequency

Rotor Frequency

Target Rotor Freq

Startup_Stator_Freq

* For Stator Voltage is intend the voltage modulation index [0,255]

Stator Voltage*

imposed by RV1

Startup phase

Asynchronous mode

Regulation Phase

Voltage_SlewRate

increasing by one of stator voltage

Synchronous mode

: The time between the

Time Out

During Syncronous mode the

Frequency

rotor frequency.

is imposed to be equal to the

If Time_out is reach during the Startup

phase fails to start.

Time

Stator

Time Time Out

ACM_SoftStartOL(TargetVoltage): this is used to perform the open loop startup strategy.

The function has one parameter called TargetVoltage that set the maximum stator voltage

modulation index (from 0 to 255) that can be reached during the startup phase. The function

performs the following task:

– Each VOLT_SLEW_RATE millisecond increases the stator voltage by one unit until the Tar-

getVoltage is reached.

– If the rotor frequency is below LOWEST_FREQ then the stator frequency is set to the mini-

mum admissible value (LOWEST_FREQ).

– If the rotor frequency is above LOWEST_FREQ the synchronism is imposed setting Stator

frequency equal to rotor frequency.

This function is called from the main loop by the function StartMotor. StartMotor sets the TargetVoltage to a value obtained from RV1. In open loop, RV1 sets the stator voltage modulation

index so the startup phase finishes when this value is reached.

ACM_SoftStartOL returns a value of type SystStatus_t that can be:

– START if the startup phase is ongoing,

– RUN if the startup phase is finished.

StartMotor returns this value in the main loop to change the actual status if needed.

28/36

Page 29

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Note: StartMotor is a function that is compiled differently depending on whether closed loop or

open loop is defined.

ACM_SoftStart(): this is used to perform the closed loop startup strategy. The function performs the following tasks:

– Soft start by increasing the voltage from zero to a predefined value.

– Initialization of the Hall sensor acquisition for closed loop mode.

– Monitoring of the Hall sensor feedback to limit the starting voltage (and therefore limit the

starting torque).

– At the end of the Soft start initialize the regulation procedure.

This function is called from the main loop by the function StartMotor (the version compiled

with closed loop define).

ACM_SoftStart returns a value of type StartStatus_t that can be:

– START_ONGOING if the startup phase is ongoing,

– START_OK if the startup phase is successfully finished,

– START_FAIL if time out is reached and the rotor frequency if below the minimum value.

The startMotor (Closed Loop) returns a value of type SystStatus_t that can be:

– START if the startup phase is ongoing,

– RUN if the startup phase is successfully finished,

– FAULT if the startup phase fails.

The value returned is used in the main loop to change the actual status.

5.3 DIRECTION PROCEDURES

The direction procedures are defined in the MTC.c module:

– MTC_Toggle_Direction()

– MTC_Set_ClockWise_Direction()

– MTC_Set_CounterClockWise_Direction()

– MTC_GetRotationDirection()

These functions are used to set, modify or get an indication of the actual rotating direction. Rotation direction change is achieved by modifying the sign of the variable holding the phase

shift between the three phases (either 120° or -120°).

Note: The clockwise direction is defined randomly. The real direction will only depend on the

physical connection of the motor.

29/36

Page 30

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

The return value of MTC_GetRotationDirection() is of type Direction_t and can be CLOCKWISE or COUNTERCLOCKWISE.

Warning: No tests are performed on the motor status (running or stopped) inside these func-

tions.

You must therefore be sure that the motor is stopped before calling any of the three routines

able to modify the rotation direction. On the contrary, if the direction is changed while the

motor is running, it can immediately become a generator, thus injecting reactive energy in the

high voltage DC bus capacitor, causing the voltage to go above the capacitor’s maximum

voltage rating.

5.4 REGULATION

The functions that perform the regulation are defined in the ACMotor.c module:

– ACM_InitSpeedReg()

– ACM_SpeedRegulation()

The ACM_InitSpeedReg function must be called before calling the regulation routine

ACM_Speedregulation (typically after completing the ACM_SoftStart function). It guarantees

a smooth transition from open loop to closed loop operations.

It performs the initialization of the integral term of the PI regulator (VoltageIntegralTerm) formula shown below and resets the PI regulator clamping flags.

The VoltageIntegralTerm is set using the formula:

Voltage = Integral + Proportional > Integral = Current Voltage - Proportional

ACM_SpeedRegulation performs a closed loop rotor speed control (in terms of the rotor frequency) to obtain the voltage to be supplied on the stator winding. This function uses a PI

(Proportional and Integral) regulation algorithm to determine the most appropriate voltage

value to get the expected rotor frequency. The function returns the modulation index voltage

(u8).

Caution 1 This function is executed regardless of the regulator sampling time; this period

must be managed by the calling function actually DoMotorControl().

Caution 2 The sine wave parameters are not modified in this routine; the MTC_UpdateSine

function has to be called after this function using the voltage value returned.

Note: For more information about all other routines in the library see the application note 1904

“ST7MC THREE-PHASE AC INDUCTION MOTOR CONTROL SOFTWARE LIBRARY”. The

PMAC software library, indeed, contains the same functions and configuration files as the AC

Induction motor software library with the exception of the above explained in this AN.

30/36

Page 31

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

5.5 BRAKING STRATEGY

During the braking process, a sinusoidal waveform is provided to the motor to generate a statoric field 90° in advance with respect to the rotoric field. The sinusoidal waveform supplied for

the brake has a ramp of voltage modulation index that reaches a user defined value. This

braking is active until the motor slows down to the minimum rotor frequency fixed by the user.

During the braking process, the self synchronization mechanism is maintained.

6 RESULTS

6.1 OSCILLOSCOPE ACQUISITION OF PHASE CURRENT WAVEFORM

PMAC motor with three 120° Hall sensors

Figure 15 (a) shows the oscilloscope acquisition during the startup phase.

Channel description:

– CH1: Hall sensor H1

– CH2: Hall sensor H2

– CH3: Hall sensor H3

– CH4: Current probe on phase A

Figure 15. PMAC motor with three 120° Hall sensors

(a) Startup Phase (b) Run phase

Figure 15 (b) shows the oscilloscope acquisition during the run phase.

Channel description:

– CH1: Hall sensor H1

31/36

Page 32

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

– CH2: Hall sensor H2

– CH3: Hall sensor H3

– CH4: Current probe on phase A

AMETEK motor with three 60° Hall sensors and with only one sensor setting

Figure 16 (a) shows the oscilloscope acquisition during the run phase using three hall sen-

sors.

Channel description:

– CH1: MC01 HiRes (stator voltage of phase A)

– CH2: MC03 HiRes (stator voltage of phase B)

– CH3: MC05 HiRes (stator voltage of phase C)

– CH4: Current probe on phase A

Figure 16. AMETEK motor three 60° Hall sensors or one sensor mode.

(a) three 60° Hall sensors (b) one sensor mode

In Figure 16 (b) shows the oscilloscope acquisition during the run phase using only one sensor

mode.

Channel description:

– CH1: MC01 HiRes (stator voltage of phase A)

– CH2: MC03 HiRes (stator voltage of phase B)

– CH3: MC05 HiRes (stator voltage of phase C)

– CH4: Current probe on phase A

32/36

Page 33

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Dynamic performance of a PI controller

In the Figures below are showed two graphs of the speed measured of the Ametek motor run

in PMAC mode with 3 Hall sensors. The graphs show the rotor speed variation (express in 0,1

Hz) that follow an abrupt rise of target frequency from 0 Hz to 150 Hz (a value of 1500 in the

graph).

The first graph is performed using Kp = 50 and Ki = 10 and sampling time of 10 ms.

The second is performed using Kp=200 and Ki = 10.

Figure 17. Dynamic performance (Kp = 50 and Ki = 10)

1800

1600

1400

1200

1000

800

600

400

Frequency (x10 Hz)

200

0

1 30 59 88 117 146 175 204 233 262 291 320 349 378 407 436 465 494 523 552 581 610 639 668 697 726 755 784 813 842 871 900

Time ( x ~0.3ms )

Figure 18. Dynamic performance (Kp=200 and Ki = 10)

1600

1400

1200

1000

800

600

400

Frequency (x10 Hz)

200

0

1 24 47 70 93 116 139 162 185 208 231 254 277 300 323 346 369 392 415 438 461 484 507 530 553 576 599 622 645 668 691 714 737 760 783

Time ( x ~0.3ms )

33/36

Page 34

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

6.2 MOTOR CONTROL RELATED CPU LOAD IN THE APPLICATION

6.2.1 Estimation

The CPU load consumption induced by the motor control mainly comes from three tasks

which are listed below.

Sine wave generation

This is the main source of work for the CPU and it is done in interrupts (MTC_U_CL_SO_IT)

at a fixed rate: the related value is thus constant whatever the sine wave frequency or voltage;

with the default setting MREP = 3 the CPU load measured is 25%

Speed feedback processing

This is also done in interrupt (MTC_C_D_IT), at a rate proportional to the motor speed. For instance, running at 5000RPM, this gives:

5000RPM / 30 = 166.6Hz rotational frequency

CPU load for 1 sensor setting: 0.4% (23µs duration time)

CPU load for 3 sensors setting: 3% (30µs duration time)

PI regulator

This term includes the MTC_GetRotorFreq,

ACM_SpeedRegulation and the MTC_UpdateSine functions (totally 1.7ms).

This contribution is inversely proportional to the sampling time of the PI regulator.

For instance, if Tsampling = 20ms, this will lead to:

(1.7) / 20 =8.5%.

Total CPU load

Here below is an example for a Ametek motor running at 5000RPM:

Total CPU load = 8.5% (PI) + 25% (sine) + 3% (speed feedback) = 36.5%.

Note: for open loop applications, speed feedback, synchronization and sine wave generation are the only

parameters to be taken into account.

34/36

Page 35

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

7 REVISION HISTORY

Table 2. Document revision history

Date Revision Changes

14-Dec-2004 1 Initial release

16-Jul-2007 2 Removed references to obsolete products

35/36

Page 36

ST7MC PMAC SINE WAVE MOTOR CONTROL SOFTWARE LIBRARY

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE

SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN

PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT

SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

36/36

Loading...

Loading...