Page 1

AN1941

APPLICATION NOTE

LOW VOLTAGE LED DRIVER USI N G

L6920D, L4971 AND L6902D

1 INTRODUCTION

High brightness LE Ds are becoming a pr ominent sou rce of li ght and often have be tter eff iciency and reliability when compared to that of conventional light sources. While LEDs can operate from an energy source as simple as a battery and resistor, most applications require an

efficient e nergy sour ce not onl y for t he red uction of l osses, bu t als o for the l umen mainten ance

of the LED itself. STMicroelectronics has developed the following non-isolated DC-DC constant current LED driver to aid designers in developin g a low cost and efficient pl atform for dri ving high brightnes s LEDs.

This application note will cover 3 DC-DC power supplies to drive high intensity LEDs.

1 The L6920D boost converter to drive 1 LED for a flash lig ht application

2 The L4971 buck converter to dr ive 1 to 9 LEDs

3 The L6902D buck converter to dr ive 1 to 6 LEDs

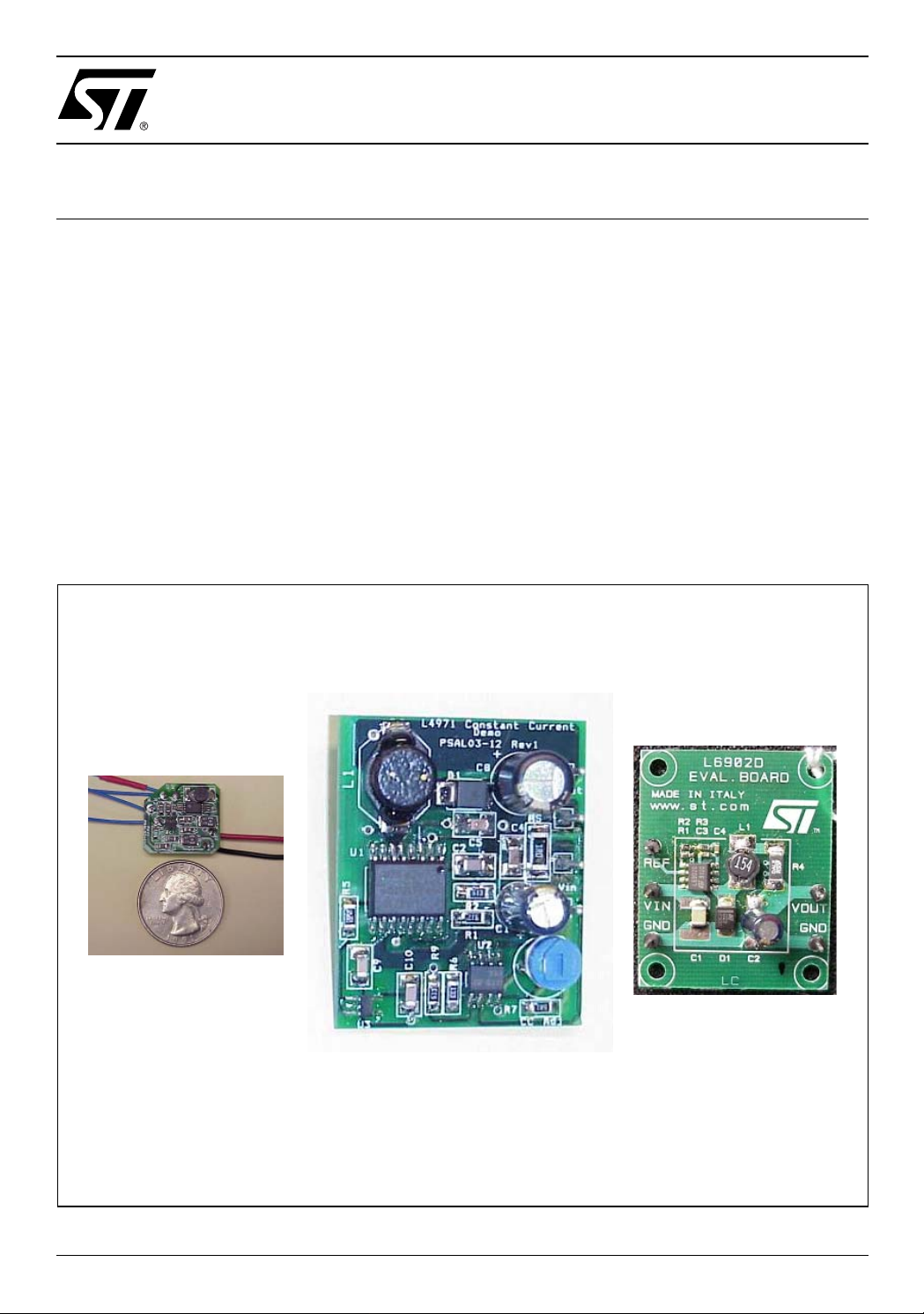

Figure 1. Reference Design Boards:

AN1941/0604

L6920D L4971 L6902D

1/15

Page 2

AN1941 APPLICATION NOTE

2 L6920D LED DRIVER

White LEDs are gaining popularity as sources of illumination because of their high efficiency

and reliabili ty. Typical forwar d volt age dr op of a wh ite LED i s appr oximat el y 3.5V. When these

LEDs are power ed fr om a singl e or two cell batt erie s, a boos t convert er i s needed t o boost the

voltage to drive the LEDs.

2.1 L6920D Descripti on

L6920D is a hig h efficiency step-up converter requiring very few ext e rnal components to realize the conversio n from the batt ery voltag e to the selected output volt age or curren t. The startup is guaranteed at 1V and the device i s operating down to 0.6 V. The device has very low qui escent current, only 10µA. Internal synchronous rectifier is implemented with a 120mΩ Pchannel MOSFET, replaci ng the convent ional boos t diode, to impro ve the effi ciency. This al so

implies a reduced cost in the application since no external diode required.

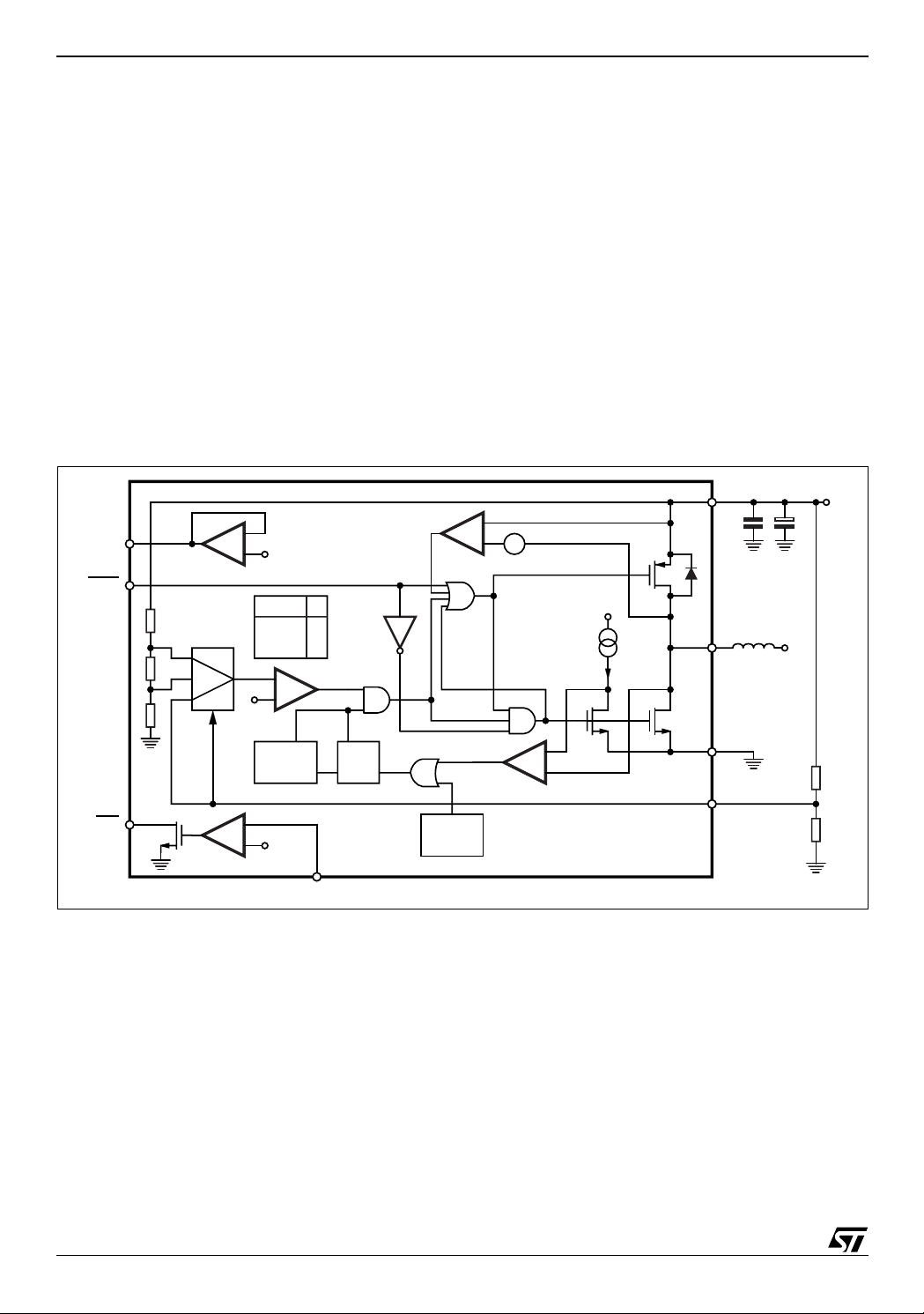

Following is the block diagr am of L6920D.

Figure 2. Block diagram of L6920D

V

OUT

V

IN

V

REF

SHDN

LBO

OUT

ZERO CROSSING

+

VBG

FB Y

V

OUT

A

GND

B

R

C

+

Y

VBG

1,R2

-

+

Toff min

1µsec

VBG

OPAMP

(CR)

LBI

RQS

A

B

C

Ton max

5µsec

+

- +

CURRENT LIMIT

VOUT

LX

+

GND

FB

D99IN1041

In L6920D, the control is based on the comparator that continuously checks the status of the

feedback signal. If the feedback voltage is lower than reference value, the control function of

the L6920D directs the energy stored in the inductor to be transferred to the load. This is accomplished by alternating between two basic steps:

– Ton phase: the botto m MOFSET Q1 is t urn ed on, an d the i nduc tor is c harg ed. The s wit ch

is turned off if the current reaches 1A or after a maximum on-time set to 5s.

– Toff phase: the bottom MOSFET Q1 is turned off, a nd top MOSFET Q2 is turned on. The

energy stored in the inductor is transferred to the load for at least a minimum off time of

1s. After this, the synchronous switch is turned off as soon as the feedback signal goes

lower than reference or the current flowing in the inductor goes down to zero.

2/15

Page 3

AN1941 APPLICATION NOTE

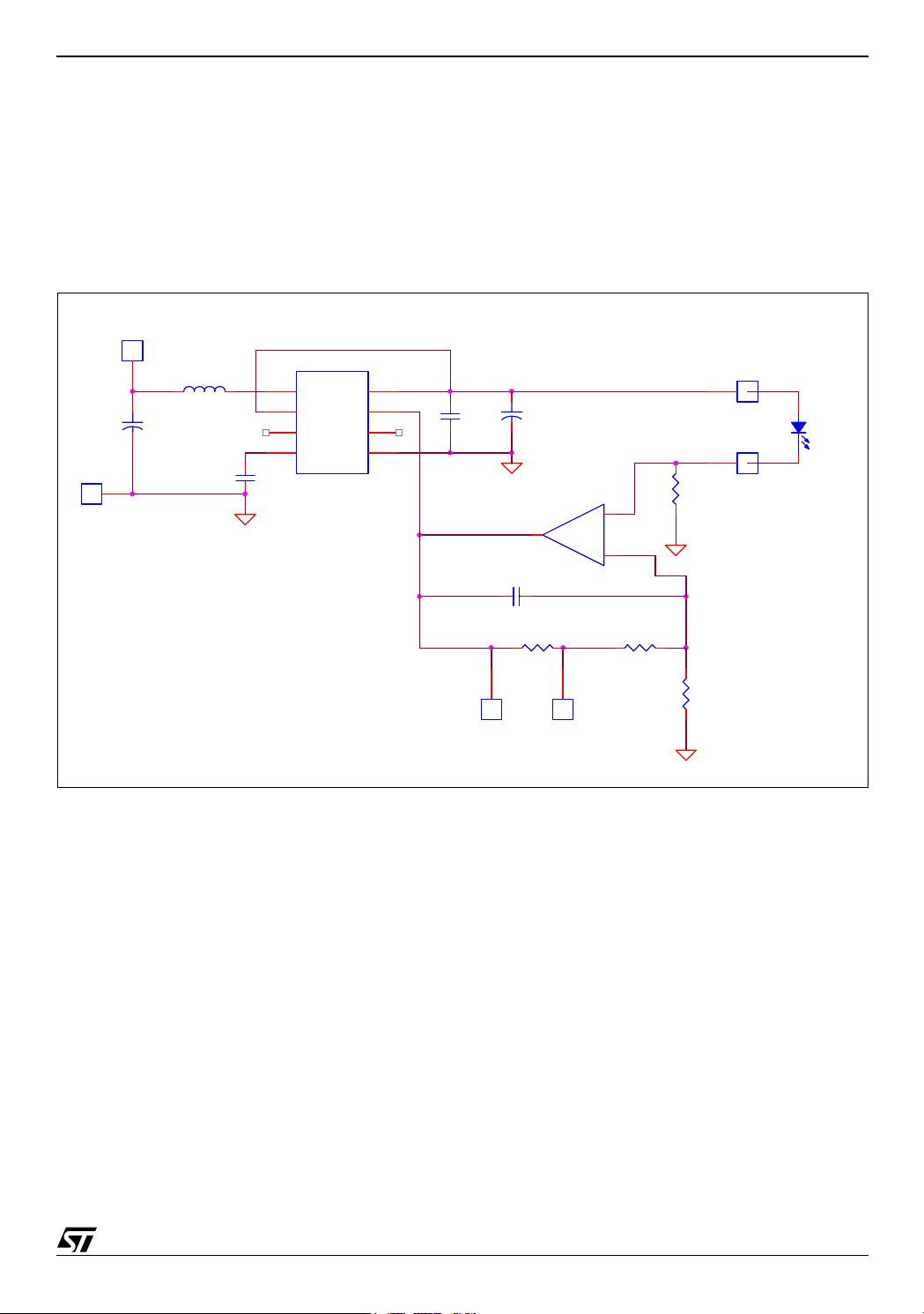

2.2 Circuit Description

The circuit shown in fi gure 3 is a constant current control to provide constant luminosity from

the LED. A current sensing res istor is in series with the white LED is used to provi de the current

feedback. Th e feedback r eference voltage for the controller i s 1.23V. If this voltage level is directly feedback from the current sensing resistor, the loss in the resistor will be too high. The

circuit uses a low value se nse re sist or, R1 to reduce t he dissi pati on and an op-amp to ampl ify

the current sense vol tage back up to the required 1.23V level.

Figure 3. Schematic of L6920D LED driver

J2

J6

CON1

CON1

L1

1

C2

10 uH

+

47uF

6.3V

1

U1

7

LX

5

SHDN

2

LBI

4 6

REF GND

L6 920

C4

.1u F

OUT

LBO

J4

R1

.33 O hm

1 2

1/4W

1

1

CON1

J5

CON1

D1

LED

8

.47uF

+

C5

C1

47uF

6.3V

OPAMP

U2 TS95 1ILT

+

OUT

-

1

FB

3

C3

.01uF

From the circuit, the control rule is: I

where I

is the current through the LED; R1 is the current sensing resistor, K is the gain of

LED

·R1·K = Vref

LED

1

J7

CON1

R2

1 2

100K

1/8W

1

J8

CON1

R3

1 2

12K

1/8W

R4

1K

1/8W

1 2

the OP AMP, and Vref is the reference voltage.

V

REF

Therefore, the LED current will be

I

LED

----------------=

R1 K⋅

In the reference ci rcuit, there are two gains. When J7 and J8 ar e shorted, K1= 1+R3/R4. When

J7 and J8 are open, K2=1+(R3+R2) /R4.

In the circuit, R1 = 0.33Ω; R2 = 100 kΩ; R3 = 12 kΩ; R4 = 1 kΩ. the current level of the LED

can be I

= 280mA or I

LED1

LED2

= 32 mA.

Following are some typical waveforms at Vin=2.5 V.

3/15

Page 4

AN1941 APPLICATION NOTE

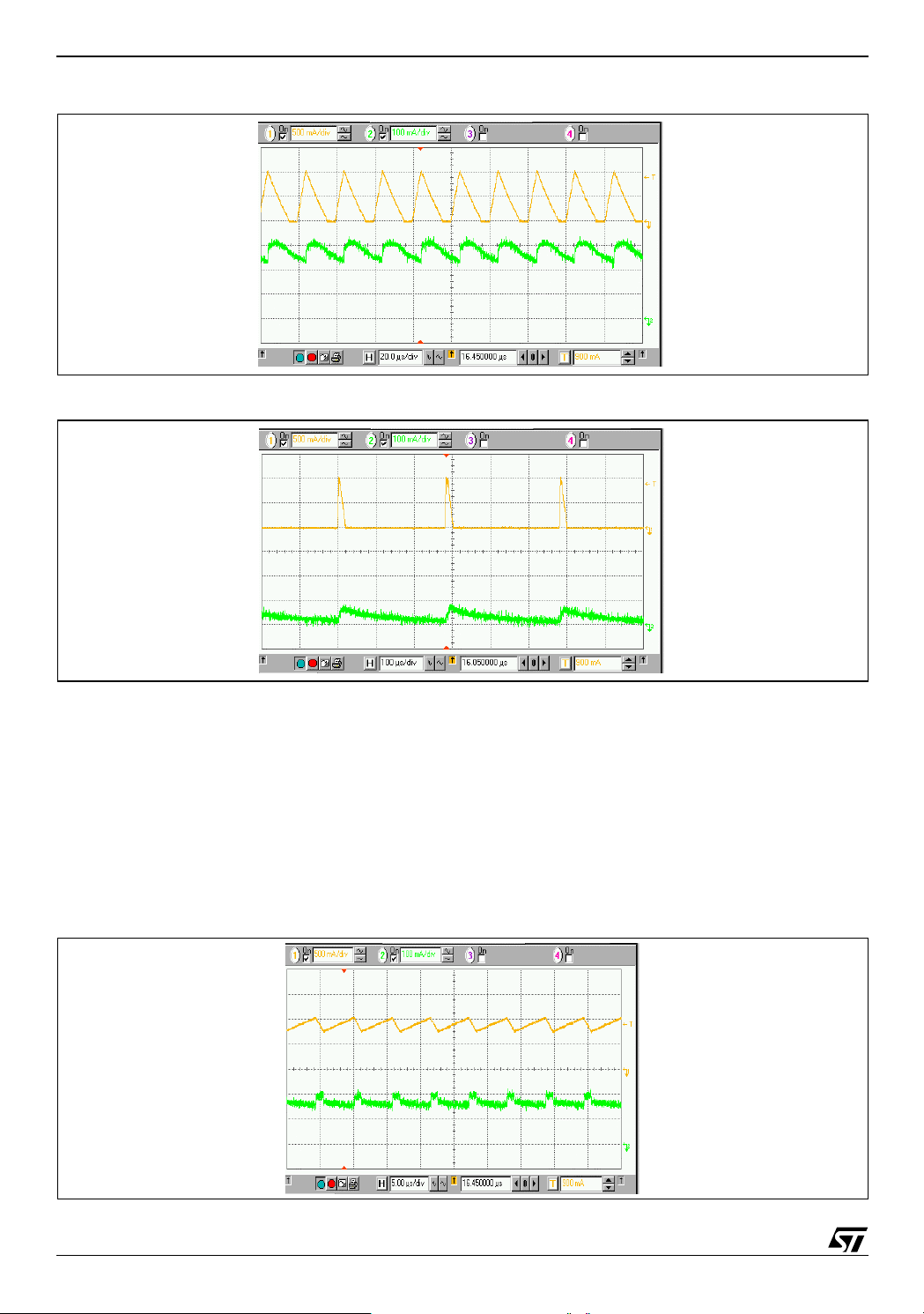

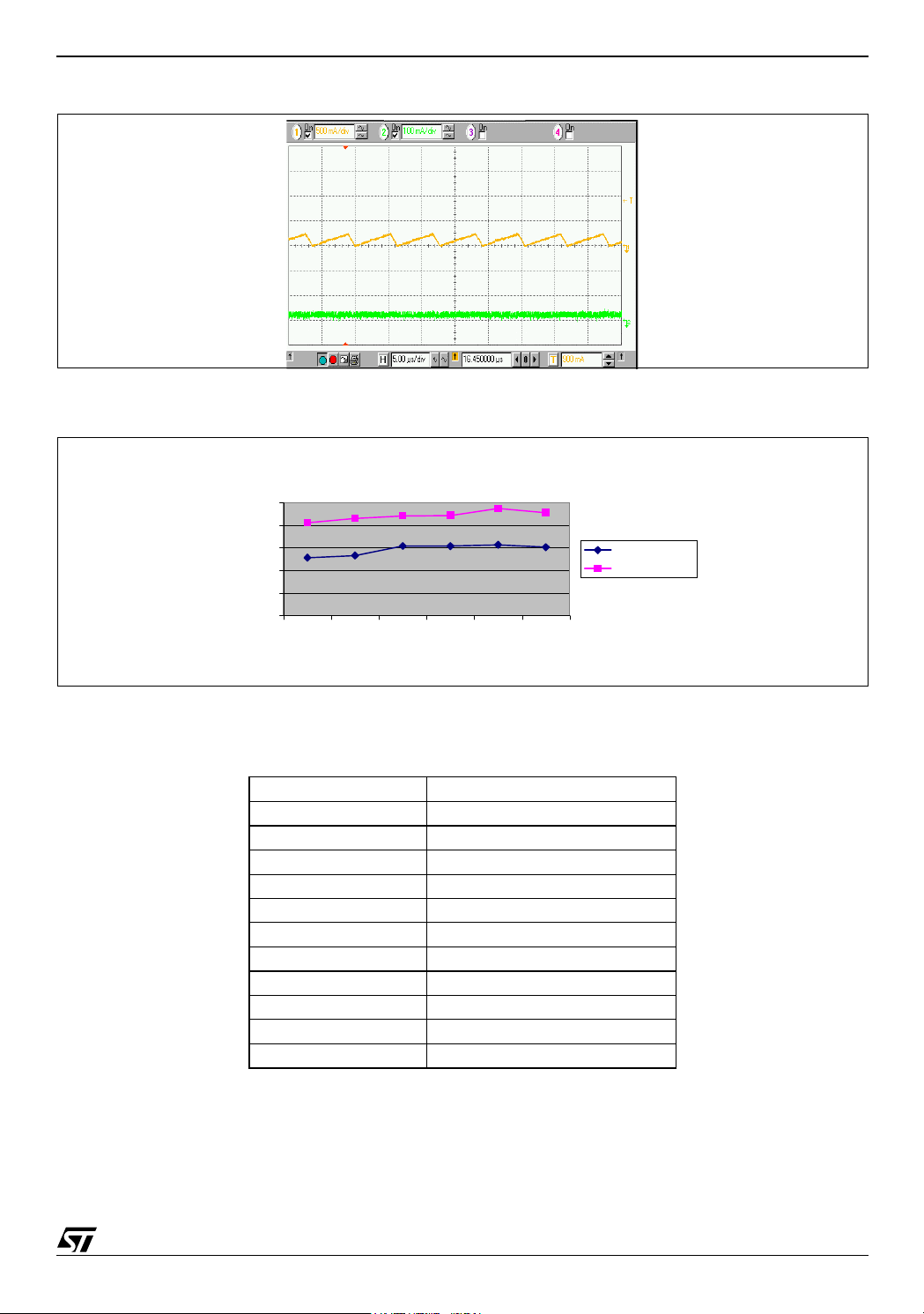

Figure 4. Upper trace: inductor current; lower track: LED current

500mA/div

I

L

100mA/div

I

LED

Figure 5. Upper trace: inductor current; lower track: LED current

500mA/div

I

L

100mA/div

I

LED

from the waveforms, the inductor peak current is limited at 1A. the maximum load current is

defined by following relationship:

I

load_lim

where η is the efficiency, I

=1A, and T

lim

When the load is heavier than I

Vin

-------------

Vout

load_lim

I

T

lim

offmin

off min

=1µs.

, the regulation will be lost, an d the inductor current will

Vout Vin–

-----------------------------

⋅

2L⋅

η⋅–⋅=

go to continuous mode. Fig. 6 and Fig. 7 show that the circui t loses th e regulatio n, but the circuit is running at its maximum duty cycle.

Figure 6. Vin = 1V; upper trace: inductor current; lower trace: LED current

500mA/div

500mA/div

I

I

L

L

100mA/div

100mA/div

I

I

LED

LED

4/15

Page 5

AN1941 APPLICATION NOTE

Figure 7. Vin = 0.6V; upper trace: inductor current; lower trace: LED current

500mA/div

I

L

100mA/div

I

LED

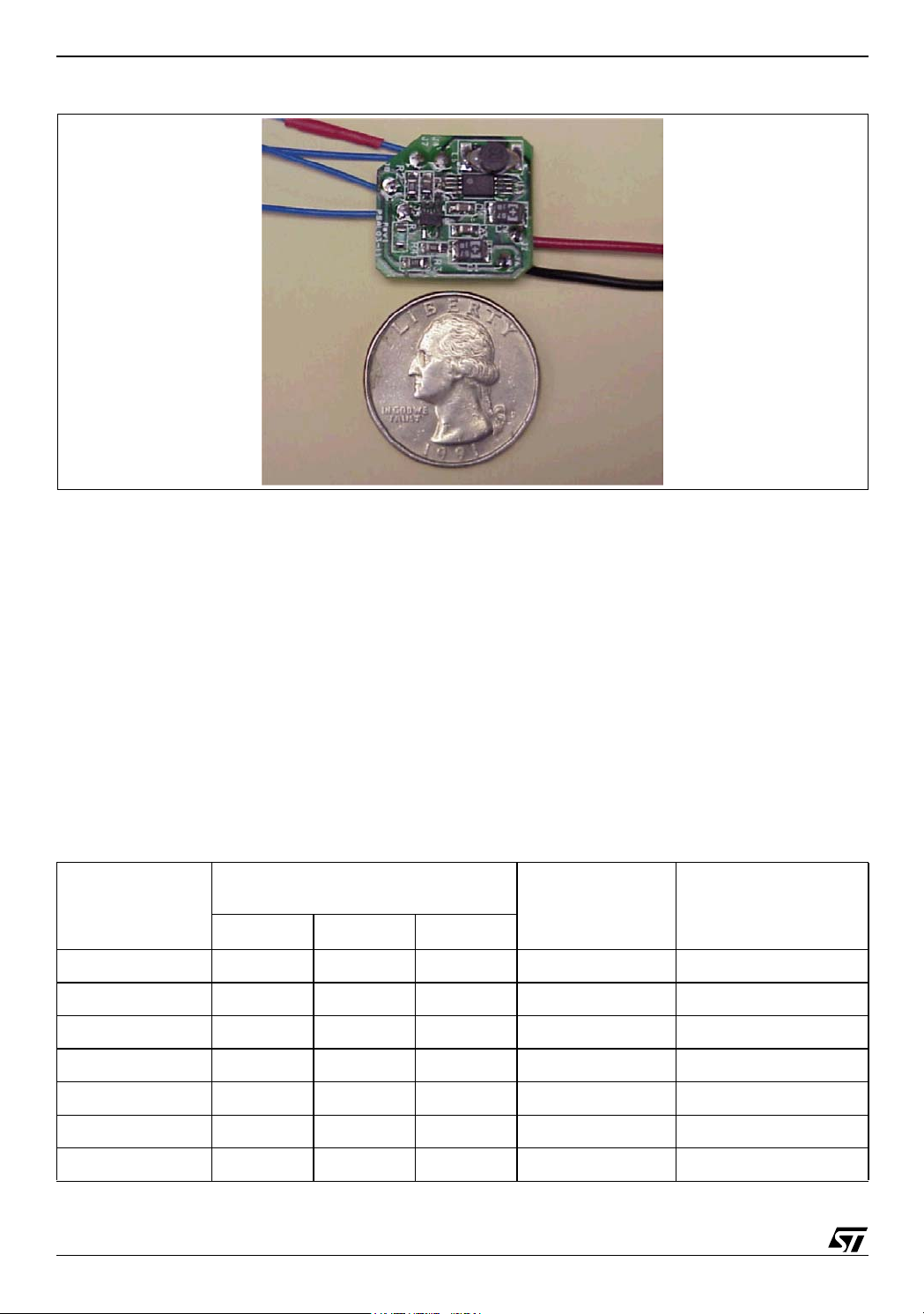

Fig. 8 shows the efficiency of the driver at dif ferent load and input voltages.

Figure 8. Efficiency curve

Efficiency

1

0.9

0.8

0.7

0.6

Efficiency (%)

0.5

1.92.12.32.52.7 3

Input Voltage (V)

275mA Output

30mA Output

Table 1. Bill of Material :

C2,C1 47uF 6.3V Electro sm

C3 .47uF 0805

C4 .1uF 0805

C5 .01uF 0805

L1 10uH sm inductor

R1 .33 Ohm 1% 1/4W 0805

R2 100K 5% 0805

R3 12K 5% 0805

R4 1K 5% 0805

U1 L6920D Tssop8

U2 TS951ILT sot23

Ref Value

5/15

Page 6

AN1941 APPLICATION NOTE

Figure 9. Size of the demo board

3 L4971 BUCK LED DRIVER:

For applicati ons that use multiple LEDs it is better to drive LEDs in series rather than parallel.

3.1 LED parameters;

As shown below, the LED volta ge drop tolerance varies by ±16.6% for the whit e LED. Different

colors will have dif ferent typical voltage drop. For t his reason, it is recommended that the LEDs

be connected in series rather than parallel. If connected in parallel, the current would not be

shared equally b etwe en the mul tipl e LEDs due to the di ffer ences i n forwar d v oltage dro p. Different brightn ess would resul t depending on individua l voltage drop of the string of LEDs. With

the LEDs connect ed in ser ies t he same curren t fl ows thro ugh ea ch LED and t he out put wi ll be

better matched.

Below is the forward voltage drop spec sheet from Luxeon Star Technical Data Sheet DS23

Table 2.

Forward Voltage

(V)

V

Color

Min. Typ. Max.

White 2.79 3.42 3.99 1.0 -2.0

Green 2.79 3.42 3.99 1.0 -2.0

Cyan 2.79 3.42 3.99 1.0 -2.0

Blue 2.79 3.42 3.99 1.0 -2.0

Royal Blue 2.79 3.42 3.99 1.0 -2.0

F

Dynamic

Resistance

(Ω) R

D

T emperature Coefficient

of Forward Voltage

(mV/°C)

∆V

/∆T

F

J

6/15

Red 2.31 2.85 3.27 2.4 -2.0

Amber 2.31 2.85 3.27 2.4 -2.0

Page 7

AN1941 APPLICATION NOTE

The brightness is directly proportional to the current driving the LED. A test was conducted i n

a closed box with a white LED mounted 12 inches away from the light meter. The results

showed a linear relationship between current and light output. The graph in figure 2.3 also

shows the relation between current and forward drop of the LED.

When driving LEDs from a DC-DC buck topology the minimum voltage input that the power

supply will operate, the maximum voltage i nput and the maximum power capability of the unit

must be taken int o account. Tab le 2.2 shows t he capability o f the L4971 and L 6902D reference

designs for minimum input vo ltage and the maximum input voltage.

Table 3.

Control V in # LEDs Current

L6902D 8 1 350mA

L6902D 25 6 350mA

L4971 20 5 220-400mA

L4971 55 9 220-400mA

Figure 10.

3.2 L4971 LED Driver

The L4971 is a step down monolithic power switching regulator able to deliver 1.5A. Its construction i s BCD mixed technol ogy using an internal D-MOS t ransistor with low Rdson t o obtain

high efficiency and high switching speeds. Features of this DC-DC converter are pulse by

pulse curr ent l imit ; hi cc up mode fo r sho rt cir cuit p rotect ion, vol tage f eed for ward, sof t star t and

thermal shutdown. Typically it is used for regulating an output voltage. An output current can

also be regulated by sensing the voltage drop across a sense resistor, Rs as shown on the

following schematic.

7/15

Page 8

AN1941 APPLICATION NOTE

Figure 11.

3.3 Circuit description:

The input ranges from 20 vol ts to 55 volts. The switching frequency is set by

1

6

-- -

5

100 C

⋅+ln⋅

osc

where R

osc

and C

F

SW

represent R2 and C2.

osc

-------------------------------------------------------------------------------=

R

oscCosc

The minimum volta ge for the L4 971 is 8 volts but the regu lator-ref erence U3 needs a minimum

of 20 volts to stay in regulation. A higher breakdown voltage regulator can be used to achieve

a wider range of input. U3 provides power to the LM393 and a reference for the comparator

input. This vo ltage is compared t o the voltag e drop across Rs to mai ntain it at t he same voltage

set by the poten tiomet er R8. Th e v oltage drop acr oss t he res isto r is propor tio nal t o the cur rent

following through it by:

Iout = V(U2Apin3)/Rs.

The output of the LM 393 turns on and off to adjust the voltage at the slow start pin. The slow

start voltage is directly related to the output regulation thus achieving a constant current output. The L4971 regulates by adjusting the duty cycle to maintain a constant output. R9 set s

the gain o f the loop by c ontroll ing the discharg e rate. L1 and C8 form the o utput fil ter to smooth

out the current. The inductor required is calculated at the worse case which is max input line

and minimum LEDS. This gives the minimum duty cycle and maximum time that the i nductor

has to suppl y current to the load.

D

max

VoVf+

-----------------------------

V

+

in minVf

D

min

VoVf+

-----------------------------

V

+

in minVf

L

VoVf+()

o

1D

–()

min

---------------------------

⋅===

I

⋅∆

ofsw

is the current ripple set by the application, usually 10% of the max current.

∆I

o

8/15

Page 9

AN1941 APPLICATION NOTE

R3 and R4 set the maximum voltage to 30 volts. R8 will adjust the constant curren t output from

220 mA to 400 mA.

I

Table 4. Part List

tem Qty Ref Part Tolerance Description

1 1 C1 39u 63V P10339-ND

2 1 C2 1nF 50V sm ce ramic

3 1 C4 22nF 50V sm ceramic

4 1 C5 1u 25V sm PCC1893CT

5 1 C6 0.1u 50V sm ceramic PCC1893CT

6 1 C7 220nF 50V sm ceramic

7 1 C8 100u 35V P10294

8 2 C9,C10 0.1u sm ceramic

9 1 D1 STPS160U ST

10 1 D3 1N5242A 12V zener

11 1 L1 470uH Coilcraft DO3316P-474

12 1 RS 1 1/2W sm 2510

13 1 R1 9.1k

14 2 R9,R2 51k

15 1 R3 8.2k

16 1 R4 1k

17 1 R5 15k

18 1 R6 13k

19 1 R7 560

20 1 R8 500 36G52-ND

21 1 U1 L4971 ST

22 1 U2 LM393D ST

23 1 U3 LD2979_sot23-5 ST

The output voltage can be changed by readjusting the resistor divider R3 and R4 to allow a

higher output voltage to drive as many as 15 LEDs of typical forward volta ge drop.

3.4 Results:

With a minimum in put vol tage of 20 V, u p to 5 LEDs can be d riven and wi th 33 V to 55 V i nput,

9 LEDs can be driven limited by the output voltage set at 30 volts.

9/15

Page 10

AN1941 APPLICATION NOTE

Figure 12. Current regulation:

The current regulation is ± 1% for the range of 1 to 9 LEDs or a voltage range of 3.3 volts to

29 volts output.

Figure 13. Efficiency at 55V input:

The efficiency differences shown in figure 13 are primarily related to differences in the output

power. As the numbe r of LEDs increa ses, the output power also i ncrease s. However, the los ses in the system remain r elati vely co nstant over the r ange so the effici ency in cre ases with the

number of LEDs.

Figure 14. Ripple current

10/15

Page 11

AN1941 APPLICATION NOTE

4 L6902D BUCK LED DRIVER:

Another buck topology reference design that is much simpler, less expensive and requires

fewer external compon ents is the L6902D LED driver. The f eatures of the L6902D are:

4.1 L6902D Descripti on

– Up to 1A of output current

– Input voltage from 8V to 36V

– Built in 5% output current accura cy

– 250KHz internall y fixed frequency

– Adjustable current limit

– Thermal shut down

The L6902D is a complete and simple step down switching regulator with adjustable constant

voltage and constant current. By means of a current sense resistor set to give a 0.1V drop

across it, the current ca be set to any desired value up to 1 amp. Iout=0.1V/Rsen se.

Figure 15. Internal Block Diagram:

The L6902D contai ns a vol tage a nd a c urr ent er ror ampl ifi er wi th an i nt ernal r efer ence of 3.3V

and 1.235 with a tolerance of ±2%. Most of the external circuits of the previous design are incorporated inside this battery charger chip. This 8 pin chip mini mizes pin count by fixing the

switching fr equency and allowing 2 pins for current sensing, 1 for sensing the output voltage .

11/15

Page 12

AN1941 APPLICATION NOTE

Figure 16. Schematic

R4a

6.2

1W

R4

.30

1W

I=350 mA up to 23.2V

1

R1

4.7K

R2

240

Vout

+

C2

47uF

25V

GND out

1

Vin=8 to 25V

1

GND in

1

C1

10uF

25V

C3

220pF

C4

22nF

R3

5.1K

U1

L6902D

8

Vcc

6

Vref

4

Comp

1

Out

2

CS+

3

CS-

5

FB

Gnd

7

0

L1

150uH

D1

STPS340U

4.2 Circuit description:

The IC can operate up to 36 volts. The 25 volt input capacitor was the restr icting factor for the

input and o utput voltage. More LEDs can be driven i f a 35 volt cap is used for C1 and C2. C3,

C4, and R3 stabilize the feedback loop. R1 and R2 set the output voltage limit to 23.2 volts,

below the rating of the output capacitor. D1 recirculates the current when the internal 250mΩ

P-channel DMOS transistor is turned off. R4, 0.3 ohms 1% standard resistor, sets the current

to 330mA. R4a, 6.2 ohms tweaks it to 350mA for the precise industry standard. L1 is det ermined as shown in the Table 4.

Table 5. BOM:

Qty Ref Part Voltage Cat #

1 C1 10uF 25V PCC2243CT

1 C2 47uF 25V P10267

1 C3 220pF PCC221BVCT

1 C4 22nF PCC2283CT

1 D1 STPS340U ST STPS340U

1 L1 150uH 350ma MOS-6020-154MXB

1 R1 4.7K P3.9KGCT

1 R2 240 P240GCT

1 R3 5.1K P5.1KGCT

1 R4 .30 1W 71-WSL2010-0.332

1 R4a 6.2 1W 71-WSL2010-0.332

1 U1 L6902D ST L6902D

12/15

Page 13

AN1941 APPLICATION NOTE

4.3 Results:

With a minimum of 8 volt s, 1LED can be dri ven and with the maxi mum of 25 volts, up t o 6 LEDs

can be driven.

Figure 17. Current regulation

The current regulat ion from 1 to 6 LEDs or 3.3V to 19.5V is ± 1.5%.

Figure 18. Efficiency at 25V input:

The efficiency ranges from 80% to 90% for 2 LEDs or more.

Figure 19. Ripple current

Peak to peak output rippl e current is less than 7% of the output current.

13/15

Page 14

AN1941 APPLICATION NOTE

5 CONCLUSION :

This application note has shown three reference designs to drive LEDs in constant current

mode. One is a boost, to drive a flashli ght at a higher voltage than the input. The others are

two buck topology to drive string in series for a various number of LEDs.

Table 6. Revision History

Date Revision Description of Changes

June 2004 1 First Issue

14/15

Page 15

AN1941 APPLICATION NOTE

The present note which is for guidance only, aims at providing customers with infor mation regarding their products in

order for them to save time. As a result, STMicroelectronics shall not be held liable for any direct, indirect or

consequential damages with respect to any claims arising from the content of such a note and/or the use made by

customers of the information contained herein in connection with their products.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such inf orma tio n nor for any i nfr inge ment of pa tent s or oth er ri ght s of thi rd pa rti es wh ich m ay re sul t fr om it s use . No li cense is granted

by implica tio n o r ot he rw is e un d er a ny pa te nt o r pa te nt righ ts of S TM ic ro el ec tro nic s. Sp ec ific at io ns m e nt ion ed in this pu bl ica tion are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singa pore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicr oe le ct ron ic s GR O U P OF CO MP A NI ES

www.st.com

15/15

Loading...

Loading...