Page 1

AN1934

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

®

- APPLICATION NOTE

VIPower: VIPer12A NON ISOLATED FLYBACK

CONV ERTE R RE FE R EN CE BO AR D

P. LIDAK - R. HAUSER

ABSTRACT

Presented circuit can be used to produce multiple outputs, non isolated pos itive or negat ive voltage. It is

dedicated for building an auxiliary power supply based on the VIPer12AS monolithic device.

1. INTRODUCTION

The aim of the presented reference boards is to propose a solution of the power supply based on an offline discontinuous current mode flyback converter without isolation between input and output. The

flyback topology allows to fully exploit current capability of the incorporated monolithic device VIPer12AS

when compared with buck converter based power s uppl y. To ensure low cost of the whole power supply

the isolation between input and output is not provided. This greatly simplifies the transformer design and

production. The VIPer12AS incorporates the PWM controller with 60 kHz internal oscillator and

altogether with the vertical power MO SF ET sw itch in a S O-8 package. T he presented power supply has

four variants. All these variants have been incorporated in presented reference board by different

assembly options.

2. CIRCUIT DESCRIPTION

2.1 NON ISOLATED FLYBACK +5V/500MA, +15V/200MA (VARIANT 1)

2.1.1 Operating Conditions

Input Voltage range

Input Voltage Frequency range

Main Output (regulated)

Second Output

Total Maximum Output Power

2.1.2 Circuit Operation

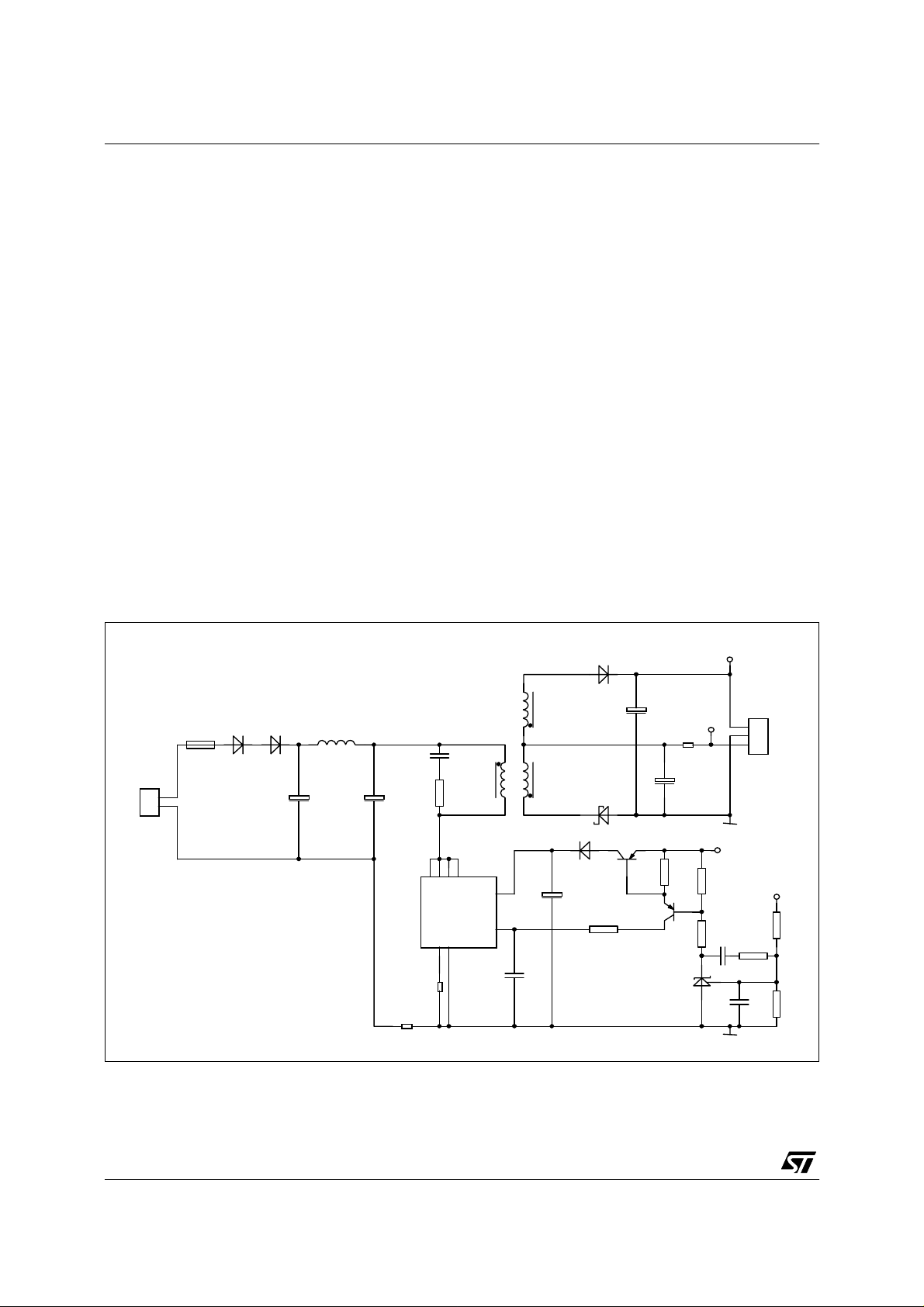

The total schematic of the power supply (Variant 1) can be seen in figure 1. The output of the converter is

not isolated from input. For this reason the reference ground is common for an input and output

connection terminal. The input capacitor C1 is charged from the mains by single rectification consisting

of diodes D1 and D2. Two diodes in series are used for EMI reasons to sustain burst pulses of 2kV. The

capacitor C1 together with capacitor C2 and inductor L1 form an EMI filter.

The DC voltage at C2 is then applied to the primary winding of the transformer through the internal

MOSFET switch of VIPer12 d uring ON time of the switching period. The s nubber circuit consisting of

resistor R3 and capacitor C6 red uces the voltage spike across the primary winding of the transformer

due to the parasitic leakage inductance. It al so slows down dV/dt of the primary winding’s voltage a little

bit and thus improves EMI.

The power supply provides two out puts from two transformers‘ windings through rectifiers D4, D5 and

smoothing capacitors C3 and C4. The VIPer12AS is supplied by 15V output voltage through transistor

90-264 VAC

50/60 Hz

5V / 500mA

15V 200mA

5.5W

April 2004 1/24

Page 2

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Q2 and diode D7. The diode D7 ensures the proper start-up of the converter by separating the 15V

output from the internal start-up current source of the VIPer12AS which will charge the IC supply

capacitor C5 to a specified start-up threshold voltage of about 16V. As soon as C5 voltage reaches the

start-up thr eshold t he interna l 60 kHz o scillator se ts the int ernal flip- flop and tu rns on the i nternal h igh

voltage power MOSFET through the output driver. The power MOSFET applies the bul k capacitor C1

and C2 high voltage to the transformer’s primary winding a nd primary current will ramp-up. As soon as

the primary current ramp reaches the VIPer’s internal set-point defined by feedback loop, the internal

power switch turns off. The output capacitor C3 or C4 is charged by energy stored in the transformer

through rectifier diode D4 or D5. The current loop which charges the 5V output flows through diode D5

only. Because of the D5 location, the 15V output is charged via both diodes D4 and D5. Beside the slight

decrease of the conv erter power efficiency, it significantly im proves the cross-regulation of th e outputs

which was the main purpose of this arrangement.

The voltage feedback loop senses the 5V ou tput by resistor divider R5, R7. The c ontrol IC U2 compares

the resistor divider output voltage with internal reference voltage of 2.5V and changes the cathode

voltage accordingly to keep 5V output stable. If the 5V output voltage rises above it’s nominal value, the

cathode voltage of U2 g oes down and ca thode current will increase. The cathode current w ill cause a

voltage drop across R9 and opens transistor Q1 which will inject the current from Vcc line to FB pin 3 of

the VIPer12AS. The FB pin current will decrease the peak primary current to reduce the power delivered

to the outputs. Resistor R10 limits the U2 cathode current . Resistor R9 has two roles: it works as pull up

for Q1 and ensures bias current of at least 1mA for U2 proper operation.

Figure 1: Schematic diagram of non isolated flyback converter (variant 1)

R14

0R

C4

220uF

35V

LXY

R10

U2

+15V

CON2

3

+5V

2

1

clamp

+15V

R9

470R

1k

C9

100nF

C10

1nF

+5V

R5

4.7k

R8

4.7k

R7

4.7k

90...264V~

CON1

clamp

D1

R1

10R

GL1M

3W

1000V

L

1

2

N

1A

Layout Hints: C5, C8 have

to be close to VIPer12A

Assembly options:

(1): +5V/500mA, +15V/200mA

note: all voltages refer to

neutral

D2

GL1M

1000V

1A

C1

22uF

400V

KMG

L1

BC

330uH 190mA

+

C2

10uF

400V

KMG

D4

U1

15

56

4 3

VDDVDDVDDVDDVDDVDD

C5

10uF

4

50V

KME

3

FB

C8

22nF

EF16/4.7

AL = 120nH

Gap = 0.22mm

C6

100pF

500V

R16

0R

100R

R17

R3

0R

+

8

2

T1A

3.1mH

160 turns

0.18 CuLL

VDD

Drain15Drain26Drain37Drain4

Sour ce11Source2

VIPer12AS

T1B

33uH

16.5 turns

0.315 CuLL

T1C

10uH

9 turns

0.315 CuLL

D7

+

STPR120A

200V 1A

D5

STPS1L40A

40V 1A

LL4148

R11

4.7k

Q2

BC856B

BC856B

C3

+

120uF

35V

LXY

Q1

TS2431ILT

+

R2

4.7k

Resistor R11 limits the feedback current to a safe value, which is lower than specified by the maximum

rating table in the data sheet. Capacitor C8 improves noise immunity of the FB input against noise.

2/24

Page 3

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

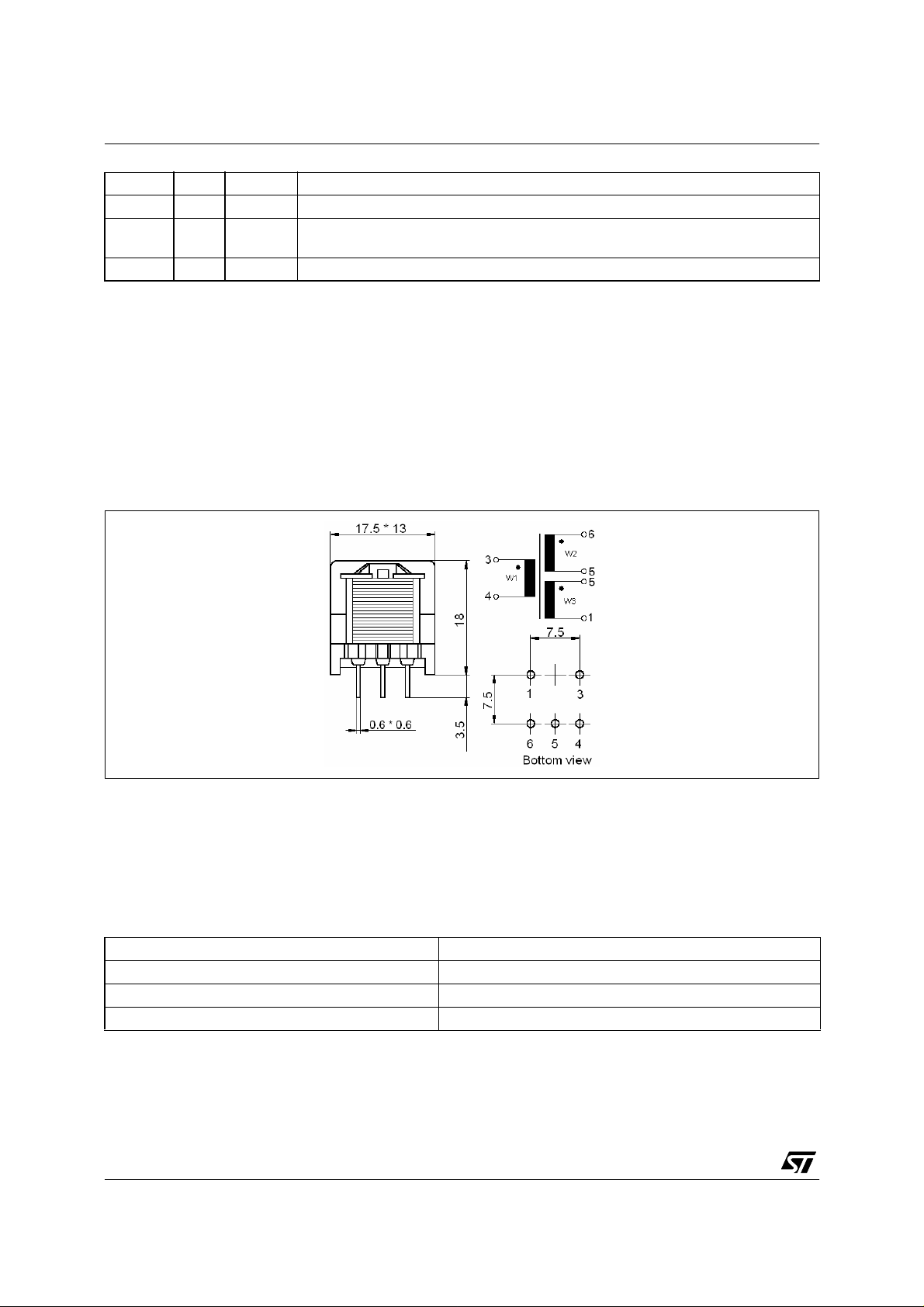

2.1.3 Bill of materials

The bill of material presented in Table 1 covers all power supply variants. The components which are

specific for a particular variant can be recognized by column named "V ariant". Peak clamp D6 connected

across the primary winding is optional and it is not assem bled on the board. In case a precise voltage

regulation of the 15V output is required, resistor R6 connected from the 15V output to the control input of

U2 can be assembled instead of R5.

Table 1: Bill of material for all variants of non isolated flyback converter

Ref. Q.ty Variant Description

CON1 1

CON2 1

C1 1 22µF Electrolytic capacitor, Nippon Chemi-Con, KMG 400V, 20%

C2 1 10µF Electrolytic capacitor, Nippon Chemi-Con, KMG 400V, 20%

C3 1 120µF Electrolytic capacitor, Nippon Chemi-Con, LXY 35V 20%

C4 1 (1, 2, 4) 220µF Electrolytic capacitor, Nippon Chemi-Con, LXY 35V 20%

C5 1 10µF Electrolytic capacitor, Nippon Chemi-Con, KME 50V 20%

C6 1 100pF Ceramic capacitor, X7R, 500V C1206 10%

C8 1 22nF Ceramic capacitor, X7R, 50V C0805 10%

C9 1 (1, 4) 100nF Ceramic capacitor, X7R, 50V C0805 10%

C10 1 (1, 4) 1nF Ceramic capacitor, X7R, 50V C0805 10%

C11 1 (2)

(3)

D1, D2 2 GL1M Diode, Diotec, trr=1.5µs 1000V 1A, MiniMELF

D4 1 STMicroelectronics STPR120A Diode, fast recovery trr=25ns 200V 1A SMA

D5 1 (1, 2, 4)

(3)

D6 1 optional STMicroelectronics PKC-136 Diode, Peak clamp, Vbr=160V, 700V, 1.5W DO-15

D7 1 LL4148 Diode 75V 200mA

D8 1 (2, 3) ZMM13 Zener diode, 13V 0.5W 5%

L1 1 330µH Inductor, EPCOS, bobbin core, B78108-S1334-J, 190mA 6.4R 10%

Q1, Q2 2 (1, 4) BC856B Bipolar transistor, PNP, 65V 100mA 330mW

R1 1 10R resistor, Yageo, wirewound, fusible, TK120 CRF 254-4 3W 5%

R2, R5,

R7, R8

R3 1 100R resistor, metal film, 200V 0.25W R1206 1%

R4 1 (2, 3) 0R resistor, metal film, R1206

R6 1 optional 24K resistor, metal film, R0805, 100V 0.125W 1%

R9 1 (1, 4) 470R resistor, metal film, R0805, 100V 0.125W 1%

R10 1 (1, 4) 1K resistor, metal film, R0805, 100V 0.125W 1%

R17 1 0R resistor, metal film, R1206

T1 1 (1, 3, 4)

4 (1, 4) 4.7K resistor, metal film, 100V 0.125W R0805 1%

(2)

Clamp, WECO, 2 pole, horizontal, 1.5mm

Clamp, WECO, 3 pole, horizontal, 1.5mm

2.2µF Tantalum capacitor, Size A, B45196E, 10V 7.0R 20%

100nF Ceramic capacitor, X7R, 50V C1206 10%

STMicroelectronics STPS1L40A Diode, Schottky, 40V 1A, SMA

0R Resistor, metal film, R1206

Ns=16/9 turns transformer, Vogt, ferrite Fi324, EF16/4.7, ord. num. 545 23 249 00

Ns=14/11 turns transformer, Vogt, ferrite Fi324, EF16/4.7, ord. num. 545 23 249 00

2

, 380V, 15A

2

, 380V, 15A

3/24

Page 4

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

U1 1 STMicroelec tronics VIPer12AS, 730V 0.4A, 27R, f=60kHz, SO-8

U2 1 (1, 4) STMicroelectronics TS2431ILT shunt ref. IC, 2.5V 1mA to 100mA 360mW 2%

U3 1 (2)

(3b)

U4 1 (3a) STMicroelectronics L78M05CDT positive voltage reg., 5V, 0.5A 5%

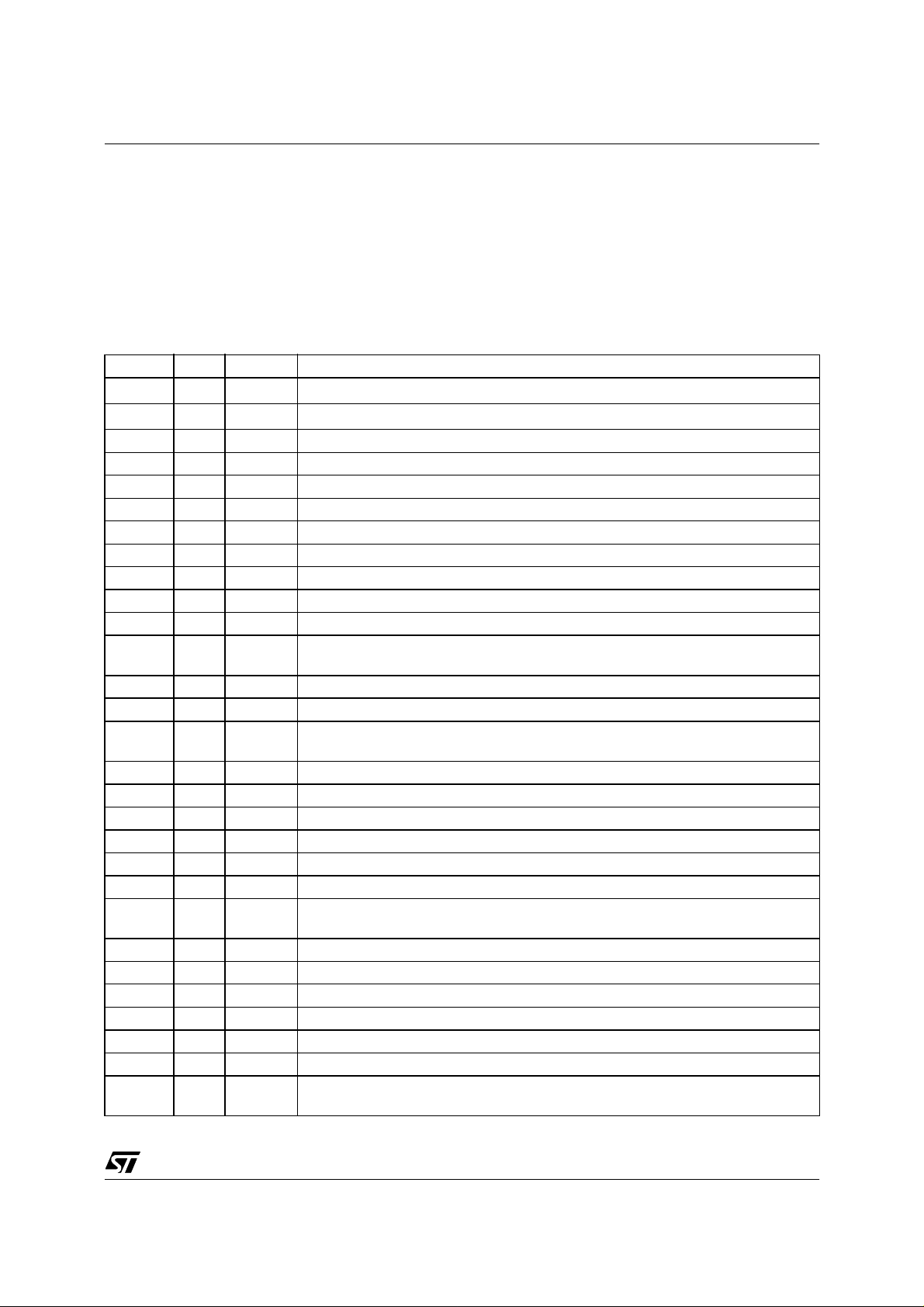

2.1.4 Transformer Design

Since there is no requirement regarding isolation bet ween primary and sec ondary s ide, the t ransformer

construction is easier compared to the isolated version. There is only a single layer of Mylar tape

between the primary winding an d secondary windings. Its purpose is n ot to make transformer passing

safety regulations but to ensure proper operation of the power s uppl y. Also creepage distances between

windings are not that crit ical. T he physical appearance, dimensions and windin gs and pins arrangement

can be seen in figure 2.

Figure 2: Transformer dimensions, windings and bottom view pin arrangement

STMicroelectronics L4931CD50 voltage reg., low drop, with inhibit, 5V, 250mA 4%

STMicroelectronics L78L05CD positive voltage reg., 5V, 100mA 10%

The basic parameters of the ferrite core selected from Vogt’s ferrite materials and shapes can be seen in

table 2. The gap size was optimised to ensure appropriate current capability and inductance to fully

exploit switching frequency and to switch peak current limit of the VIPer12AS to achieve maximum output

power.

Table 2: Transformer’s core parameters

Shape

Material

Gap size [mm]

Inductance Factor AL [nH]

EF16/4.7

Vogt Fi 324

0.24

120

An overview of the most important parameters for each winding can be found in table 3. This table is valid

for all variants. The only differentiation between the variants is the num ber of turns for the secondary

windings. The difference is indicated in the "number of turns" column.

4/24

Page 5

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Table 3: Transformer’s windings parameters

AN1934 - APPLICATION NOTE

Order Start Pin End Pin No. of turns Wire

diameter [mm]

13 4

26 5

35 1

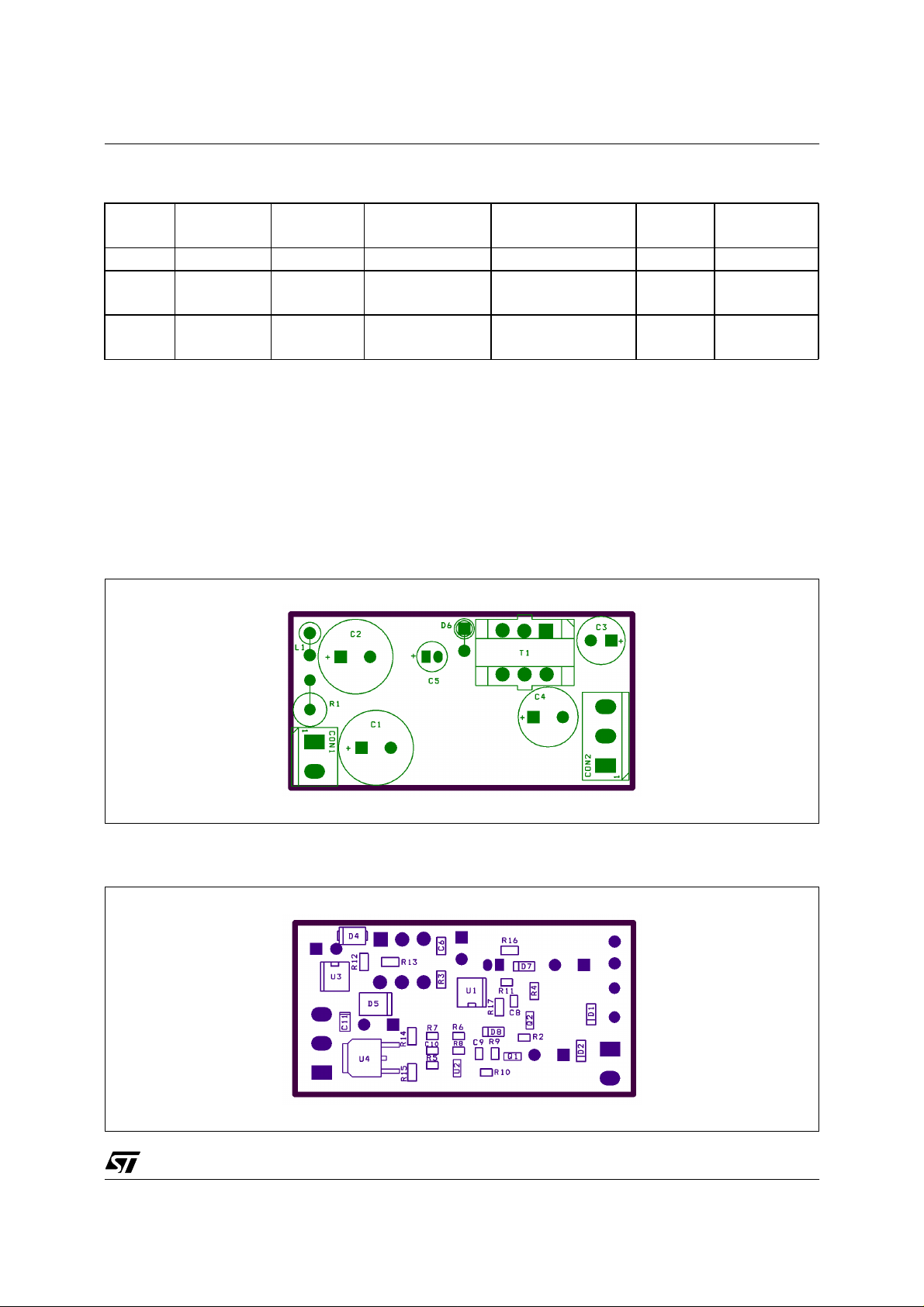

2.1.5 PCB Layout

The PCB is designed as a single sided board made of FR-4 material with 35µm copper plating with

solder and silk screen mask. The assembled board contains both SMD and through hole components.

The board includes all variants of the converter. The o utline dimensions are 59x30mm. Ass embly top

side (trough-hole components) and solder bottom (SMD com ponents) side can be s een in figure 3 and

fi gure 4.

Figure 3: Assembly Top (not in scale)

160

9 (1, 3, 4)

11 (2)

16.5 (1, 3, 4)

14.5 (2)

0.18 CuLL 3.1mH

0.315 CuLL 10µH

0.315 CuLL 33µH

Wire

material

Inductance

15µH

25µH

Figure 4: Assembly Solder Side (not in scale)

5/24

Page 6

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

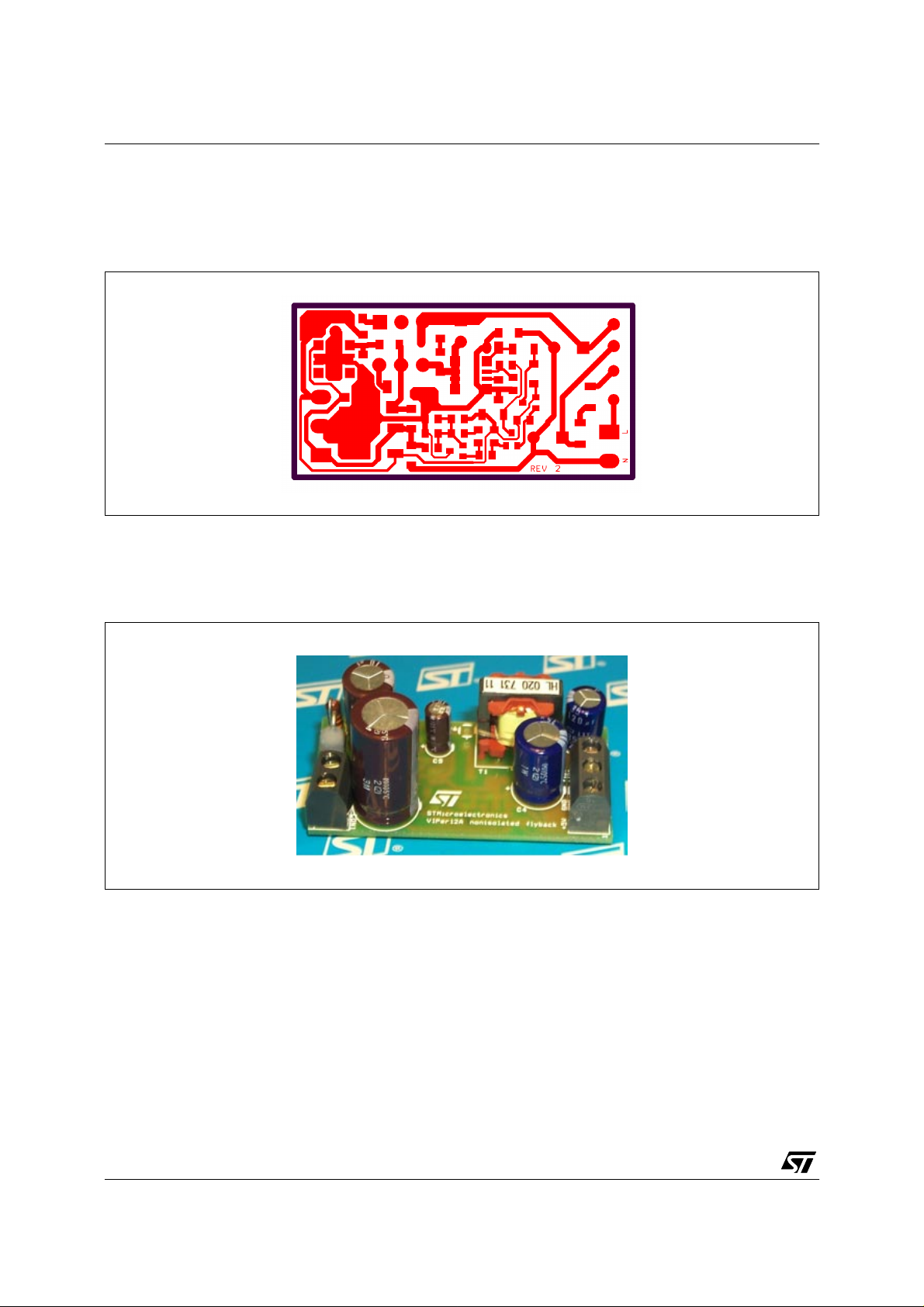

The PCB layout of the copper connections is depicted in figure 5. The holes for through-hole components

are not seen in the picture.

Figure 5: PCB Layout (not in scale)

The physical appearance of the converter can be observed in figure 6.

Figure 6: Picture of the Converter

2.1.6 Evaluation and Measurements

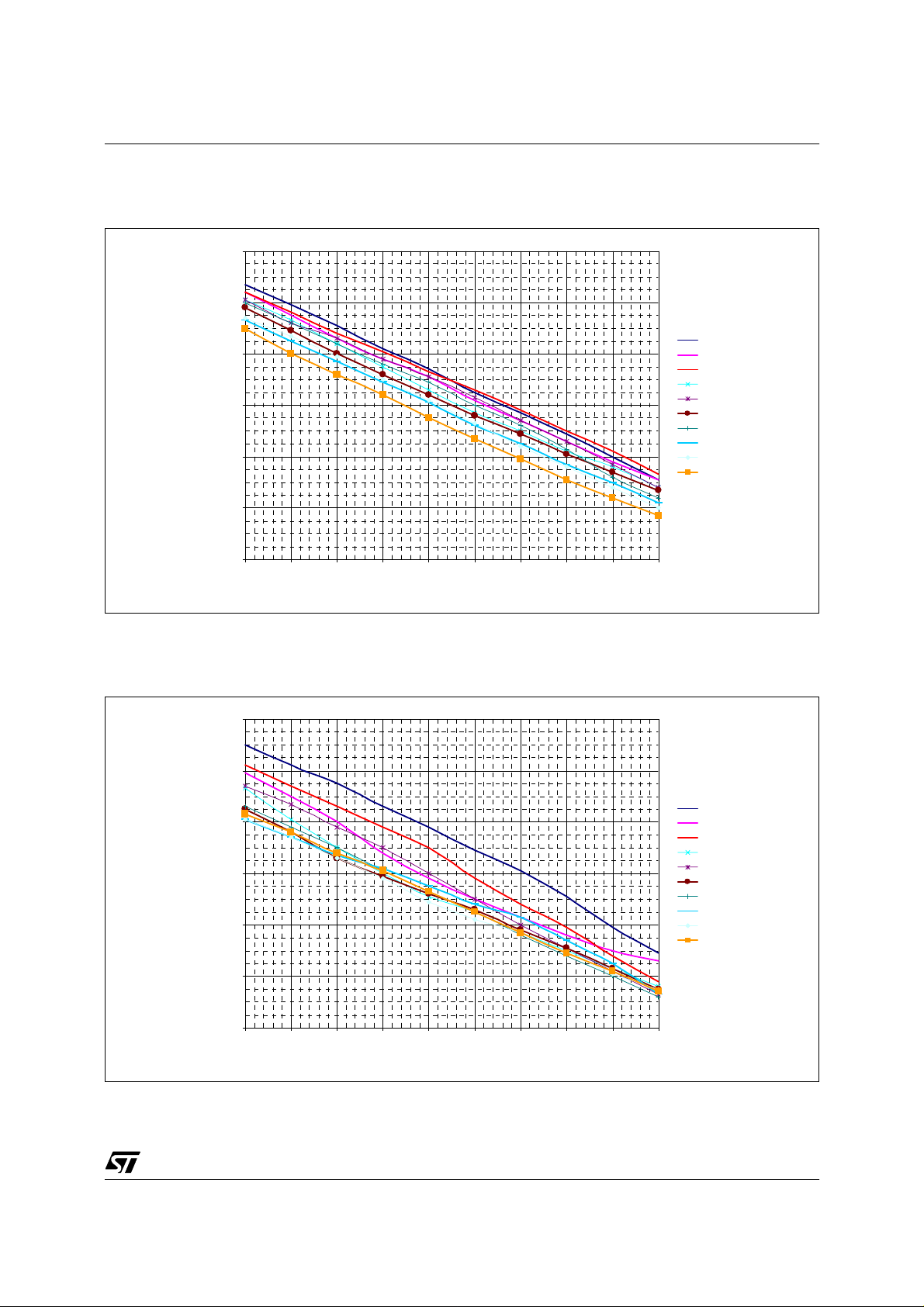

The output regulation characteristics measured on 5V output can be seen in figure 7. It shows the

voltage variation of the 5V output when different load is applied to 15V ou tput. Fi gure 8 s hows t he sam e

characteristic as figure 7 but measured at 375VDC input voltage.

6/24

Page 7

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 7: Output Regulation Cha racteristics of 5V output at 12 5VDC Input Voltage (Parameter is load

current on 15V output)

5.009

5.007

5.005

5.003

Output Voltage [V]

5.001

4.999

4.997

50 100 150 200 250 300 350 400 450 500

Out p ut Cu r r ent [A ]

20mA

40mA

60mA

80mA

100mA

120mA

140mA

160mA

180mA

200mA

Figure 8: Output Regulation Cha racteristics of 5V output at 37 5VDC Input Voltage (Parameter is load

current on 15V output)

5.009

5.007

5.005

5.003

Output Voltage [V]

5.001

4.999

4.997

50 100 150 200 250 300 350 400 450 500

Out p ut Cu r r ent [A ]

20mA

40mA

60mA

80mA

100mA

120mA

140mA

160mA

180mA

200mA

Similarly figure 9 shows the output regul ation characteristics measured on 15V output when different

7/24

Page 8

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

load current applied to 5 V output . Figure 10 shows the s ame cha racteristic as figu re 9 but measured at

375VDC input voltage.

Figure 9: Output Regul ation Characteristics of 15V Ou tput at 125VDC Input Voltage (Parameter is load

current on 5V output)

15.2

15

14.8

14.6

Output Voltage [V]

14.4

14.2

14

20 40 60 80 100 120 140 160 180 200

Output Current [A]

50mA

100mA

150mA

200mA

250mA

300mA

350mA

400mA

450mA

500mA

Figure 10: Output Regulation Characteristics of 15V Output at 375VDC Input Voltage (Parameter is load

current on 5V output)

15.2

15

14.8

14.6

Output Voltage [V]

14.4

14.2

50mA

100mA

150mA

200mA

250mA

300mA

350mA

400mA

450mA

500mA

14

20 40 60 80 100 120 140 160 180 200

Output Current [A]

8/24

Page 9

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

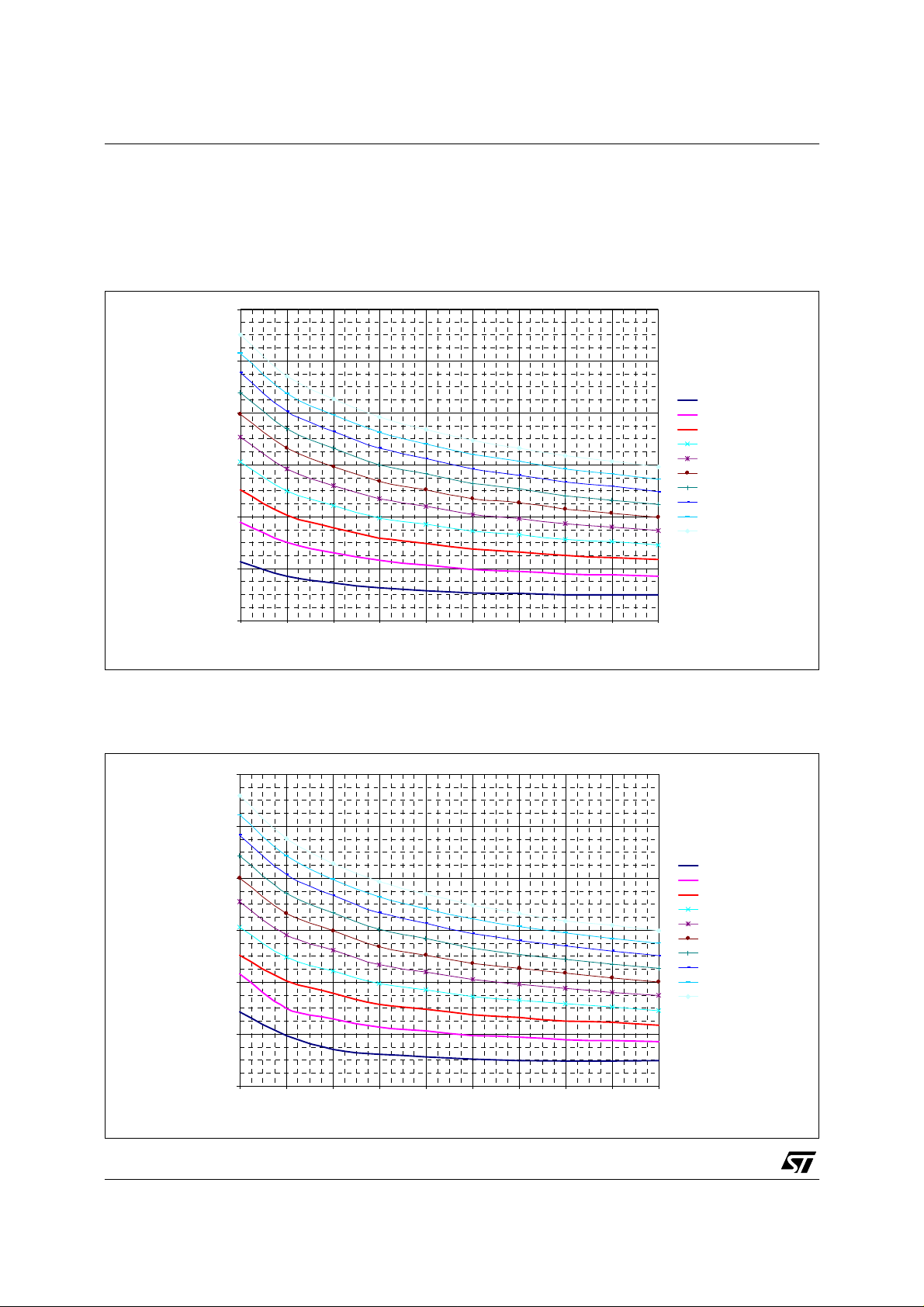

One of the most observed parameters when judging the converter performance is power efficiency.

Figure 11 depicts the dependency of the efficiency on load ap plied to the 5V output (parameter is l oad

current on 15V output). Similarly figure 12 shows the dependency on the 15V output current (parameter

is load current on 5V output). Figures 12 and 13 show t he same characteristics as figures 10, 11a and

11b, but measured at input voltage of 375 VDC.

Figure 11a: Efficiency vari ation with 5V Output Curren t at 125VDC Input Voltage (Parameter is loaded

current on 15V output)

80

75

20mA

40mA

60mA

70

Efficiency [%]

65

80mA

100mA

120mA

140mA

160mA

180mA

200mA

60

50 100 150 200 250 300 350 400 450 500

Output Current [mA]

Figure 11b: Efficiency variation wi th 15V O ut put Current at 125VDC Input Voltage (Parameter is loaded

current on 5V output)

80

75

50mA

100mA

150mA

70

Efficiency [%]

65

200mA

250mA

300mA

350mA

400mA

450mA

500mA

60

20 40 60 80 100 120 140 160 180 200

Output Curre nt [mA]

9/24

Page 10

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 12: Efficiency variation with 5V Output Current at 375VDC Input Voltage (Parameter is loaded

current on 15V output)

80

75

70

20mA

65

60

Efficiency [%]

55

50

45

50 100 150 200 250 300 350 400 450 500

Output Curre nt [mA]

40mA

60mA

80mA

100mA

120mA

140mA

160mA

180mA

200mA

Figure 13: Efficiency variation with 15V O utput Current at 375VDC Input Voltage (Parameter is loaded

current on 5V output)

80

75

70

50mA

65

60

Efficiency [%]

55

50

45

20 40 60 80 100 120 140 160 180 20 0

Figure 14 to figure 23 show the most important voltage or current waveforms at different input and output

conditions. Channel 1 (pi nk) is the power MO SFET Source te rminal voltage of the VIPer12. Ch annel 4

Output Current [mA]

100mA

150mA

200mA

250mA

300mA

350mA

400mA

450mA

500mA

(blue) shows the drain current of the VIPer12. The purpose of those pictures is to demonstrate the

skipping cycle function at light or no-load condition and cycle-by-cycle primary current limitation at output

shorted condition

10/24

Page 11

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 14: Vin=127VDC, no-load Figure 15: Vin=373VDC, no-load

Figure 16: Vin=127VDC, nominal load Figure 17: Vin= 373VDC, nominal load

Figure 18: V

=127VDC, 50% load on both outputs Figure 19: Vin=373VDC, 50% load on both outputs

in

11/24

Page 12

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 20: Vin=127VDC, 5V output shorted, 15V

output no-load

Figure 22: Vin=373VDC, 5V output shorted, 15V

output no-load

Figure 21: Vin=127VDC, 15V output shorted, 5V

output no-load

Figure 23: Vin=373VDC, 15V output shorted, 5V

output no-load

The feedback loop stability and reaction to the load change are demonstrated from figures 24 to 27.

12/24

Page 13

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 24: Load transient response, 50mA to

0.5A on 5V output, 15V output

unloaded, Vin=127VDC

Figure 26: Load transient response, 50mA to

0.5A on 5V output, 15V output

unloaded, Vin=373VDC

Figure 25: Load transie nt response, 50mA to

0.5A on 5V output, 15V output nominal

load, Vin=127VDC

Figure 27: Load transie nt response, 50mA to

0.5A on 5V output, 15V output nominal

load, Vin=373VDC

Furthermore, conducted emissions were measured in neutral and line wire using a peak or average

detector. The measurements were performed at 230VAC input voltage and both outputs were fully

loaded. The results can be seen from figures 28 to 31.

13/24

Page 14

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 28: Phase L, average detector Figure 29: Phase L, peak detector

Figure 30: Phase N, average detector Fi gure 31: Phase N, peak detector

2.2 NON ISOLATED FLY BACK +5V/250m A, +15V/ 200mA (VARIANT 2)

2.2.1 Operating Conditions

Input Voltage range

Input Voltage Frequency range

Main Output (regulated)

Second Output

Total Maximum Out pu t Power

14/24

90-264 VAC

50/60 Hz

15V / 200mA

5V / 250mA

4.25W

Page 15

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

2.2.2 Circuit Operation

The total schematic of the power supply can be seen in figure 32. Compared to variant 1, this variant has

some differences. The major difference is the feedback loop. Instead of 5V output the 15V output is

regulated by a simp le circuit consisting of zener diode D8 a res istor R11. Since 5V output is not well

stabilized by the feedback loop a linear regulator U3 is used. The linear regulator requires some input-tooutput voltage difference to assure a minimum dropout voltage. For this reason the number of turns of

secondary windings is slightly different compared to variant 1 (see table 3).

Figure 32: Schematic diagram of non isolated flyback converter (Variant 2)

D4

90...264V~

CON1

L

N

clamp

D1

GL1M

1000V

1A

D2

GL1M

1000V

1A

C1

22uF

400V

KMG

R1

10R

3W

L

1

2

N

Layout Hints: C5, C8 hav e

to be close to VIPer12A

Assembly options:

(2): +5V/250 mA, +15V/200mA

note: all voltages refer to neutral

L1

330uH 190mA

+

BC

C2

10uF

400V

KMG

T1A

VDD

15

56

4 3

U1

FB

VDD

C5

4

10uF

50V

KME

3

C8

22nF

EF16/4.7

AL = 120nH

Gap = 0.22mm

C6

100pF

500V

+

R16

0R

100R

R3

R17

0R

3.1mH

160 turns

0.18 CuLL

8

Drain15Drain26Drain37Drain4

Source 11Source 2

VIPer12AS

2

T1B

25uH

14.5 turns

0.315 CuLL

T1C

15uH

11 turns

0.315 CuLL

LL4148

+

D7

STPR120A

200V 1A

D5

STPS1L40A

40V 1A

R4

0R

R11

1k

2.3 NON ISOLATED FLYBACK +15V/200mA, +5V/60mA (VARIANT 3)

2.3.1 Operating Conditions

Input Voltage range

Input Voltage Frequency range

Main Output (regulated)

Second Output

Total Maximum Out pu t Power

C3

+

120uF

35V

LXY

+15V

D8

ZMM1 3

+

R13

0R

C4

220uF

35V

LXY

U3 L4931CD50

VIN8VOUT

4

90-264 VAC

50/60 Hz

15V / 200mA

5V / 20mA or 60mA

4.25W

+15V

CON2

3

+5V

1

GND36GND47GND23GND12NC25NC1

2

1

clamp

C11

+

2.2uF

10V

Ta

2.3.2 Circuit Operation

The schematic diagram is depicted in figure 33 and is very similar to the schematic of variant 2. It has

only one output rectifier diode and one o utput electrolytic capacitor. The 5V linear regulator is directly

supplied from 15V output . There are t wo sub-varia nts. Depending on the output current requiremen t for

5V output, U3 or U4 can be mounted.

15/24

Page 16

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 33: Schematic Diagram of Non Isolated Flyback Converter (Variant 3)

+5V

+15V

CON2

3

2

1

GND36GND47GND23GND12NC25NC1

1

clamp

C11

100nF

90...264V~

CON1

L

N

cl amp

D1

GL1M

1000V

1A

D2

GL1M

1000V

1A

C1

22uF

400V

KMG

R1

10R

3W

L

1

2

N

Layout Hints: C5, C8 have

to be close to VIPer12A

Assembly options:

(3a): +5V/60mA, +15V/200mA

(3b): +5V/20mA, +15V/200mA

note: all voltages refer to neutral

L1

330uH 190mA

+

BC

C2

10uF

400V

KMG

+15V

D4

15

STPR120A

T1B

56

VDD

C8

22nF

200V 1A

33uH

16.5 turns

0.315 CuLL

T1C

10uH

9 turns

0.315 CuLL

D7

LL414 8

C5

+

10uF

50V

KME

R11

C3

+

120uF

35V

D5

0R

1k

LXY

R4

+15V

0R

D8

ZMM13

EF16/4.7

AL = 120nH

Gap = 0.22mm

C6

100pF

500V

100R

+

R17

0R

R16

0R

T1A

3.1mH

160 tur ns

R3

0.18 CuLL

8

2

VDD

Drain15Drain26Drain37Drain4

Source11Source2

VIPer12AS

4 3

U1

4

3

FB

R12

(3b)

0R

U4 L78M05CDT

(3a)

VIN VOUT

GND

U3 L78L05CD (3 b )

VIN8VOUT

4

2.3.3 Evaluation and Measurements

The output regulation characteristics measured on 5V output can be seen in figure 34. It shows the

voltage variation of the 5V ou tput when a different load is applied to 15V output . Figure 35 shows the

same characteristic as figure 34 but measured at 375VDC input voltage.

Figure 34: Output Regulation Characteristics of 5V output at 125VDC Input Voltage (Parameter is

loaded current on 15V output)

5.013

5.011

5.009

5.007

5.005

5.003

5.001

4.999

4.997

Output Voltage [V]

4.995

4.993

4.991

4.989

4.987

6 1626364656

Output Current [A]

20mA

40mA

60mA

80mA

100mA

120mA

140mA

160mA

180mA

200mA

16/24

Page 17

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 35: Output Regulation Characteristics of 5V output at 375VDC Input Voltage (Parameter is

loaded current on 15V output)

5.012

5.010

5.008

5.006

5.004

5.002

5.000

4.998

4.996

Output V oltag e [ V ]

4.994

4.992

4.990

4.988

4.986

4.984

6 1626364656

Output Current [A]

20mA

40mA

60mA

80mA

100mA

120mA

140mA

160mA

180mA

200mA

Similarly, figure 36 shows the output regulation characteristics measured on 15V output when different

load current applied to 5V output. Figure 3 7 s hows the same characteristic as figure 36 but measured at

375VDC input voltage.

Figure 36: Output Regulation Characteristics of 15V Output at 125VDC Input Voltage (Parameter is

loaded current on 5V output)

15

14.8

14.6

Output Vo l tage [V ]

14.4

6mA

12mA

18mA

24mA

30mA

36mA

42mA

48mA

54mA

60mA

14.2

20 40 60 80 100 120 140 160 180 200

Output Current [A]

17/24

Page 18

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 37: Output Regulation Characteristics of 15V Output at 375VDC Input Voltage (Parameter is

loaded current on 5V output)

15.2

15

Output Voltag e [V]

14.8

14.6

20 40 60 80 100 120 140 160 180 200

Output Current [A]

6mA

12mA

18mA

24mA

30mA

36mA

42mA

48mA

54mA

60mA

Figure 38 depicts the dependen cy of the efficiency on load applied to the 5V output (parameter is l oad

current on 15V output). Similarly, figure 39 shows the dependency on t he 15V output current (parameter

is load current on 5V output). Figures 40 a nd 41 s how the same characteristics as figures 38 and 39 but

measured at input voltage of 375 VDC.

Figure 38: Efficiency variation with 5V Output Current at 125VDC Input Voltage (Parameter is loaded

current on 15V output)

80

75

70

65

60

55

Efficiency [%]

50

45

40

35

20mA

40mA

60mA

80mA

100mA

120mA

140mA

160mA

180mA

200mA

30

61626364656

Output Cu rr ent [m A]

18/24

Page 19

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 39: Efficiency variation with 15V O utput Current at 125VDC Input Voltage (Parameter is loaded

current on 5V output)

80

75

70

65

60

55

Efficiency [%]

50

45

40

35

6mA

12mA

18mA

24mA

30mA

36mA

42mA

48mA

54mA

60mA

30

20 40 60 80 100 120 140 160 180 200

Output Cur rent [mA]

Figure 40: Efficiency variation with 5V Output Current at 375VDC Input Voltage (Parameter is loaded

current on 15V output)

65

60

55

50

45

Efficiency [%]

40

35

30

20mA

40mA

60mA

80mA

100mA

120mA

140mA

160mA

180mA

200mA

25

6 1626364656

Output Current [m A]

19/24

Page 20

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 41: Efficiency variation with 15V O utput Current at 375VDC Input Voltage (Parameter is loaded

current on 5V output)

65

60

55

50

45

Efficiency [%]

40

35

30

25

20 40 60 80 100 120 140 160 180 200

Output Current [mA]

50mA

100mA

150mA

200mA

250mA

300mA

350mA

400mA

450mA

500mA

The feedback loop stability and response to load transients are demonstrated from figures 42 to 45.

Figure 42: Load transient response, 20mA to

0.2A on 15V output, 5V output

unloaded, Vin= 127VDC

Figure 43: Load transie nt response, 20mA to

0.2A on 15V output, 5V output loaded

by 60mA, Vin= 127VDC

20/24

Page 21

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 44: Load transient response, 20mA to

0.2A on 15V output, 5V output

unloaded, Vin= 373VDC

Conducted emissions were measured in neutral and line wire using a peak or average detector. The

measurements were performed at 230VAC input voltage and both out puts were fully loa ded. Th e res ults

can be seen from figures 46 to 48.

Figure 46: Phase L, peak detector

Figure 45: Load transie nt response, 20mA to

0.2A on 15V output, 5V output loaded

by 60mA, Vin= 373VDC

21/24

Page 22

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 47: Phase N, average detector Fi gure 48: Phase N, peak detector

2.4 NON ISOLATED FLYBACK -5V/500mA, +10V/200mA (VARIANT 4)

2.4.1 Operating Conditions

Input Voltage range

Input Voltage Frequency range

Main Output (regulated)

Second Output

Total Maximum Out pu t Power

2.4.2 Circuit Operation

Variant 1 can be switched to variant 4 by removing short R16 and placement of R15. This reconfiguration

will make previous +5V output terminal from variant 1 as a common ground. Previous output ground from

variant 1 is disconnected from input ground and is referenced as -5V terminal. The total schematic of the

power supply can be seen in figure 49.

90-264 VAC

50/60 Hz

-5V / 500mA

10V / 200mA

5.5W

22/24

Page 23

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Figure 49: Schematic Diagram of Non Isolated Flyback Converter (Variant 4)

90...264V ~

CON1

L

N

clamp

D4

EF16/4.7

AL = 120nH

Gap = 0.22mm

D1

GL1M

1000V

1A

D2

GL1M

1000V

1A

C1

22uF

400V

KMG

R1

10R

3W

L

1

2

N

Layout Hints: C5, C8 have

to be close to VIPer12A

Assembly options:

(4): -5V/500mA, +15V/200mA

note: all voltages refer to

neutral

L1

330uH 190mA

+

BC

C2

10uF

400V

KMG

C6

100pF

500V

+

R15

0R

100R

R17

0R

R3

8

2

T1A

3.1mH

160 turns

0.18 CuLL

VDD

Drain15Drain26Drain37Drain4

Sou rce11Sou rce2

VIPer12AS

15

56

4 3

U1

4

3

FB

C8

22nF

T1B

33uH

16.5 turns

0.315 CuLL

T1 C

10uH

9 turns

0.315 CuLL

C5

+

10uF

50V

KME

STPR120A

200V 1A

D5

STPS1L40A

40V 1A

D7

LL4148

R11

4.7k

BC856B

Q2

BC856B

C3

+

120uF

35V

LXY

R2

4.7k

Q1

TS2431ILT

R14

0R

C4

+

220uF

35V

LXY

+10V

R9

470R

R10

1k

C9

100nF

U2

-5V

C10

1nF

R8

4.7k

+10V

CO N2

3

2

1

cla mp

-5V

R5

4.7k

R7

4.7k

3. CONCLUSION

Several variants of the reference board based on a non isolated flyback conve rter built with monolithic

switcher VIPer12AS were presented. It was demonstrated, how the reference board can be easily

switched between variants or options. Depicted output regulation, waveforms, overall converter efficiency

characteristics and transient responses measured at different working conditions show good

performance of the reference boards. Also, thanks to the presented PCB layout and EMI input filter,

boards are EMI compliant with regards to the emissions as it was validated by presented EMI

measurements. All boards also passed EMI surge and burst tests for power supply immunity agai nst

incoming noise from mains.

23/24

Page 24

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1934 - APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such i nformat ion nor f or any infr ingement of patents or other rig hts of third par ties w hich may res ults from i ts use. No license is

granted by i m pl i cation or ot herwise under any patent or patent rights of STM i croelectr oni cs. Specifications mentioned i n this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical compone nts in lif e support de vices or syste m s without ex press written approval of STMicroelectronics.

Austra lia - Brazil - Canada - Chin a - F i nl and - Franc e - Germany - Hong Kong - Ind i a - Israel - Italy - Japan - Malays i a -

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

The ST logo is a trademark of STMicroelectronic s

2004 STMicroelectronics - Printed in ITALY- All Rights Reserved.

STMicroele ctronics GROUP OF C OM PANIES

http://www.st.com

24/24

Loading...

Loading...