Page 1

AN1905

APPLICATION NOTE

ST7MC THREE-PHASE BLDC MOTOR CONTROL

SOFTWARE LIBRARY

INTRODUCTION

This application note describes one of the software libraries available for the ST7MC MCU.

The ST7MC microcontroller comes with a dedicated motor control cell (MTC) and can drive

both permanent magnet DC/AC motors (PMDC/PMAC also called BLDC) and induction AC

motors. This application note describes the ST7MC software library required to control a

BLDC motor with a trapezoidal 6-step drive in sensor or sensorless mode, open or closed

loop, and in current or voltage mode. The control of a PMAC motor in Sinewave mode with

sensors is detailed in application note AN1947. The control of an AC induction motor in Sinewave mode is detailed in application note AN1904.

The library is made of different C modules, compatible with both COSMIC

(www.cosmic-software.com) and METROWERKS (www.metrowerks.com) toolchains. The

functions are grouped into several families, making this library an easy way to go through any

BLDC project development. Used in conjunction with the ST7MC starter kit

(ST7MC-BLDC-KIT), evaluation can be achieved in a very short time, as the library eliminates

the need to study the MCU in detail.

A basic knowledge of C Language, PMDC motor drives and power inverter hardware is required.

AN1905 Rev 2 1/77

1

Page 2

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

OVERALL SOFTWARE ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 GETTING STARTED WITH TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 WORKING ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 SOFTWARE TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 PROGRAMMERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Emulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 LIBRARY SOURCE CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 File structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 UTILITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.1 lib.h file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 CUSTOMIZING THE WORKSPACE FOR YOUR ST7MC DERIVATIVE . . . . . . . . . 11

2.1 USING STVD7 RELEASE 2.5.X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Memory mapping with the COSMIC toolchain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 Memory mapping with the METROWERKS toolchain . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 USING STVD7 RELEASE 3.X.X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 "VERSION.H" FILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 ADDITIONAL OR UP-TO-DATE TECHNICAL LITERATURE . . . . . . . . . . . . . . 15

3 GETTING STARTED WITH THE LIBRARY USING THE ST7MC-KIT/BLDC . . . . . . 16

3.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 RUNNING THE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 STANDALONE MODE AND CLOSED LOOP OPERATION . . . . . . . . . . . . . . . 18

3.4 NOTE ON DEBUGGING TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4.1 Low voltage applications (below 30V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4.2 Medium-high voltage application (above 30V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 USING YOUR OWN POWER STAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6 CHECKING THE CURRENT SENSOR RESISTOR VALUE . . . . . . . . . . . . . . . 21

3.6.1 Maximum current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6.2 Interpreting the current feedback/settings in the GUI . . . . . . . . . . . . . . . . . . . . . . . 23

2/77

1

77

Page 3

Table of Contents

4 MODULES PRESENTATION, LIBRARY ROUTINES . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 LIBRARY REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 MTC SOFTWARE LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.1 List of available routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.2 List of MTC interrupt routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3 APPLICATION LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.3.1 regul.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.3.2 adc.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.3.3 it_ST7MC.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.3.4 ports.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.4.1 Push button reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.4.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.5 spi.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.6 LinSCI.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5 HOW TO DEFINE AND ADD A MODULE (STVD7 2.5.X) . . . . . . . . . . . . . . . . . . . . . 49

5.1 COSMIC TOOLCHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2 METROWERKS TOOLCHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6 CODE EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7 PMDC (PMAC) MOTOR CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1 PHYSICAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1.1 Checking the number of pair poles of the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1.2 Connecting the sensor outputs to the board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.2 CONTROL STRATEGY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.1 Voltage versus current mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.2 Choosing a demagnetization type (Sensorless mode only) . . . . . . . . . . . . . . . . . . . 56

7.2.3 The 4 Z event sampling methods (Sensorless) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.2.3.1 At the end of the PWM low state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.2.3.2 At PWM On, with delay once . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.2.3.3 At PWM On, with delay, at fSCF frequency . . . . . . . . . . . . . . . . . . . . . . . 58

7.2.3.4 At fSCF frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.2.3.5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.2.4 Setting the PWM distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.3 SOFTWARE SETTING CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.3.1 PI regulator implementation and tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.3.2 Adjusting falling/rising Bemf settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.3.3 Completion of Fine Tuning and Other Software Considerations . . . . . . . . . . . . . . . 75

3/77

Page 4

Table of Contents

8 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4/77

1

Page 5

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

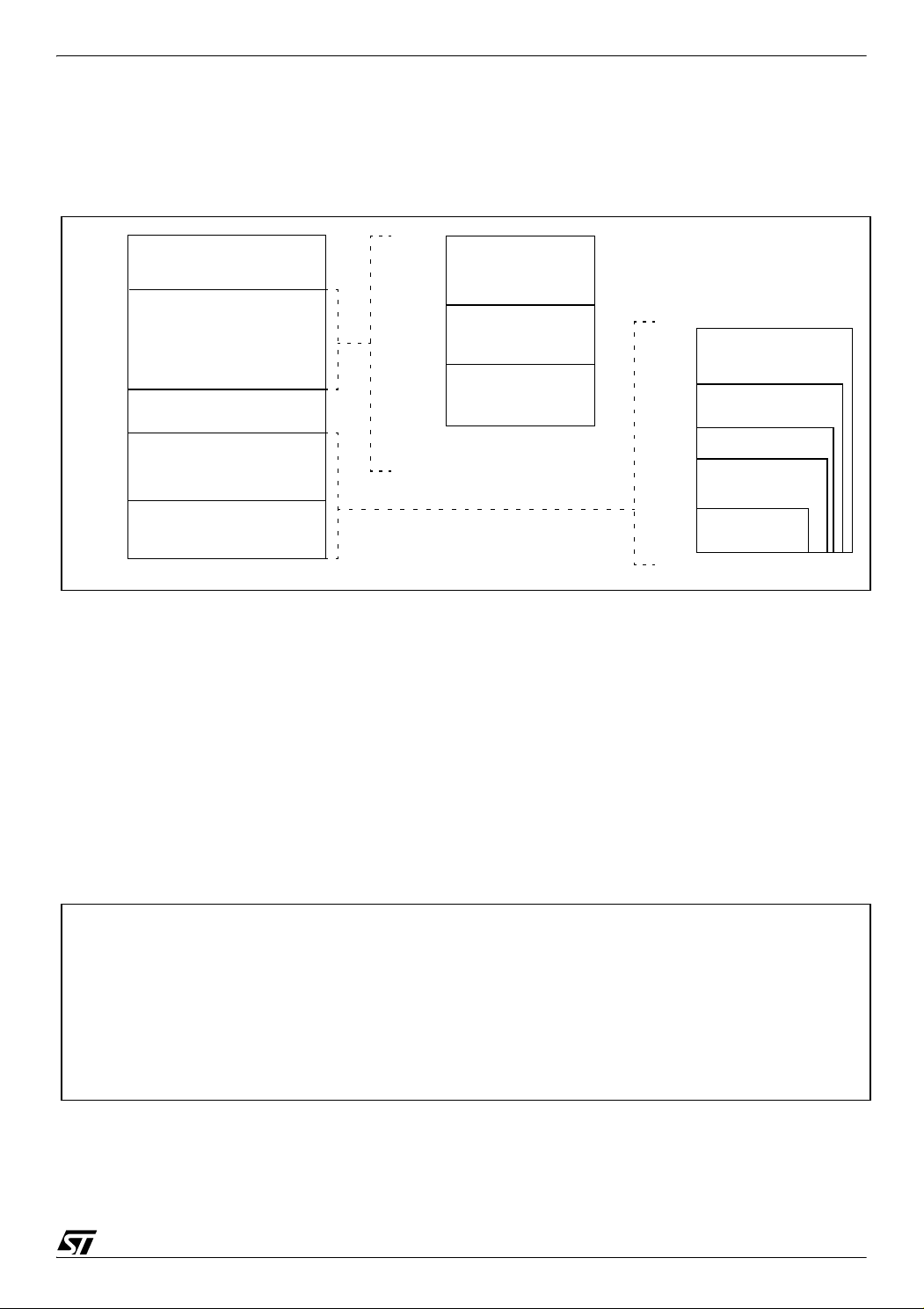

OVERALL SOFTWARE ARCHITECTURE

APPLICATION LAYER

PI

REGULATION

WDG

PMDC MOTOR DRIVE

I/Os

PWM outputs

MCO[0..5]

MTC

MCES

MCIx (Optional hall effect sensors)

ADC

COMMUNICATION

PROTOCOL

LIN

SCI

SPI

16-bit

Timer

ST7MC Library Version 1.0 Characteristics (CPU running at 16 MHz)

- BLDC (trapezoidal 6 step method) modes available:

1.Sensorless : Back EMF voltage on the non-energized phase is monitored and used to

trigger the commutation events

Sensor : Hall effect sensors trigger the commutation events.

2.Voltage : PWM duty cycle is set directly via 12-Bit PWM Generator.

Current : Internal current loop and external voltage reference are used conjointly to set

the maximum current in motor windings. PWM duty is automatically set according to current feedback loop output.

3.Open loop operation.

Closed loop operation : PI regulation, 1 to 255 ms sampling time.

- 12-bit PWM generation frequencies:

Current mode, Voltage mode: fixed 390Hz, 625Hz, 961Hz, 1.25Khz, 1.56Khz, 3.13Khz,

6.25Khz, 10Khz, 12.5Khz, 15.4Khz, 18.1Khz, 20Khz, 25Khz, 33.33Khz, 40Khz, 50Khz.

(Voltage mode PWM frequency can be manually adjusted up to 50Khz in the library)

5/77

Page 6

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

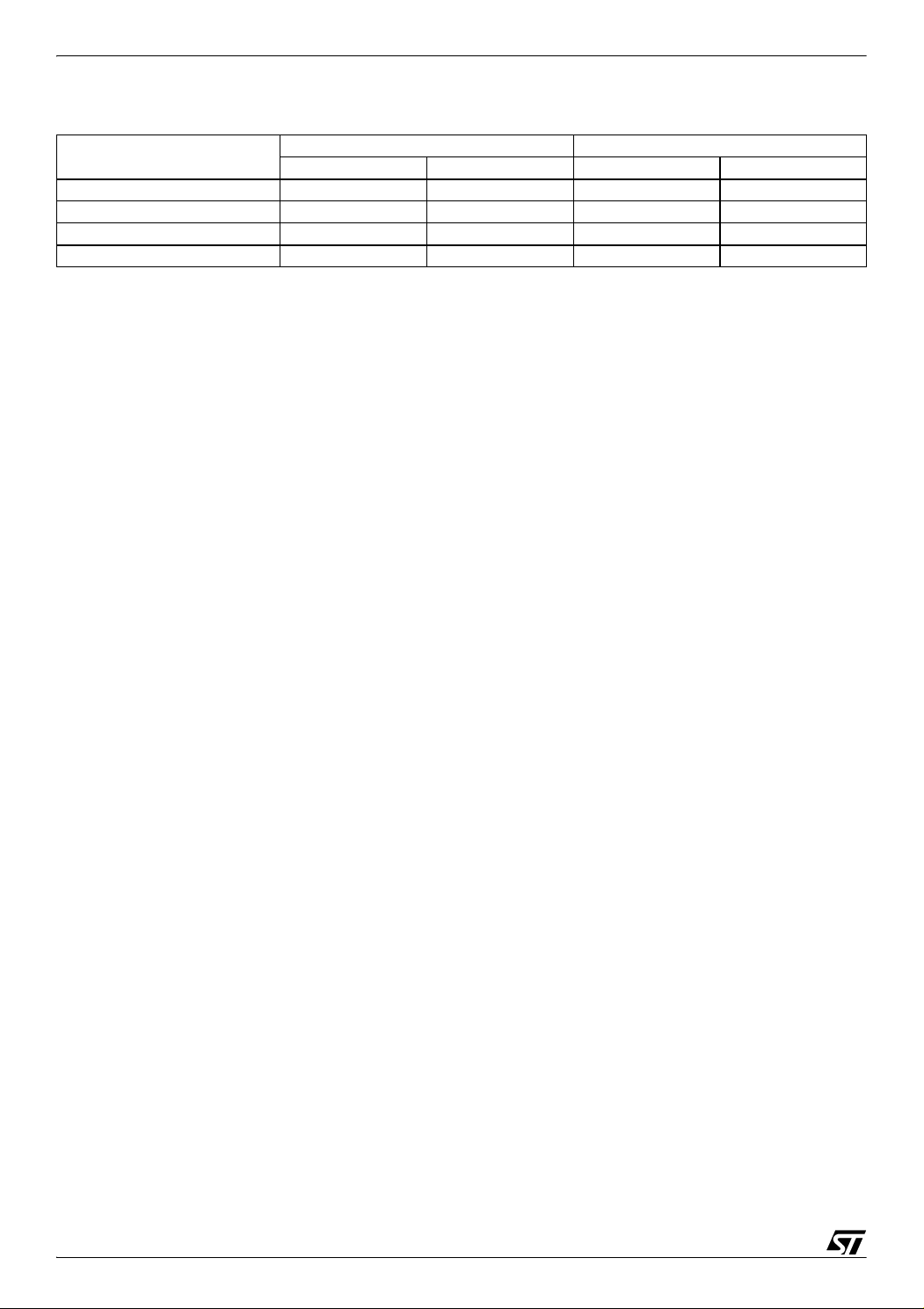

- Required ROM/RAM:

ROM (bytes) RAM (bytes)

Cosmic 4.5A Metrowerks 1.1 Cosmic 4.5A Metrowerks 1.1

Sensorless open loop 3400 4500 100 115

Sensorless closed loop 4700 6000 130 150

Sensor open loop 2370 3200 85 90

Sensor closed loop 3500 4600 120 125

These metrics include non motor control related code, implemented for demo purposes (such

as ADC management, software time bases, etc.). Depending on the chosen memory model,

the code size produced can be smaller or larger. This must therefore be considered only as indicative figures.

6/77

Page 7

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

1 GETTING STARTED WITH TOOLS

1.1 WORKING ENVIRONMENT

The present software library was fully validated using the main hardware board (a complete inverter and control board) included in ST7MC-KIT/BLDC starter kit. The ST7MC-KIT/BLDC

starter kit also includes a low-cost INDART hardware debugger, making this tool an ideal set

for starting a project and evaluating/using the library.

Therefore, for rapid implementation and evaluation of the software discussed in this application note, it is recommended to acquire the ST7MC-KIT/BLDC starter kit and one of the two

compatible C-toolchains.

1.2 SOFTWARE TOOLS

This library has been compiled using COSMIC and Metrowerks C-toolchains, running under

STVD7 release 2.5.4 (ST Visual Debugger) and STVD7 release 3.x.x. Free IDE and demo

versions of third party toolchains can be found at http://www.st.com/mcu/ (then select Downloads). A complete software package consists of:

- An IDE interface: STVD7 (free download available on internet), or third party IDE (e.g.

SOFTEC Indart STX for ST7).

- A third party C-compiler: either Cosmic or Metrowerks (if needed, time-limited evaluation versions can be obtained upon request. A free 4K COSMIC version can compile all stand alone

firmware configurations).

The choice of the C Toolchain is left to the appreciation of the user. Both COSMIC and

METROWERKS are fully supported, and the dedicated workspace (compatible with ‘STVD7’

and ‘STVD7 for Indart’) can be directly opened in the root of the library installation folder

(BLDC_Sensorless_Metrowerks_STVD2_5_4.wsp,BLDC_Sensorless_Cosmic_STVD2_5_4.

wsp,BLDC_Sensor_Metrowerks_STVD3_x.wsp, BLDC_Sensor_Cosmic_STVD3_x.wsp).

In addition, the GUI included in the ST7MC-KIT/BLDC starter-kit allows customization of these

libraries with variables prepared for your own motor. This makes the first implementation of

this library significantly easier. See Section 3 of this document.

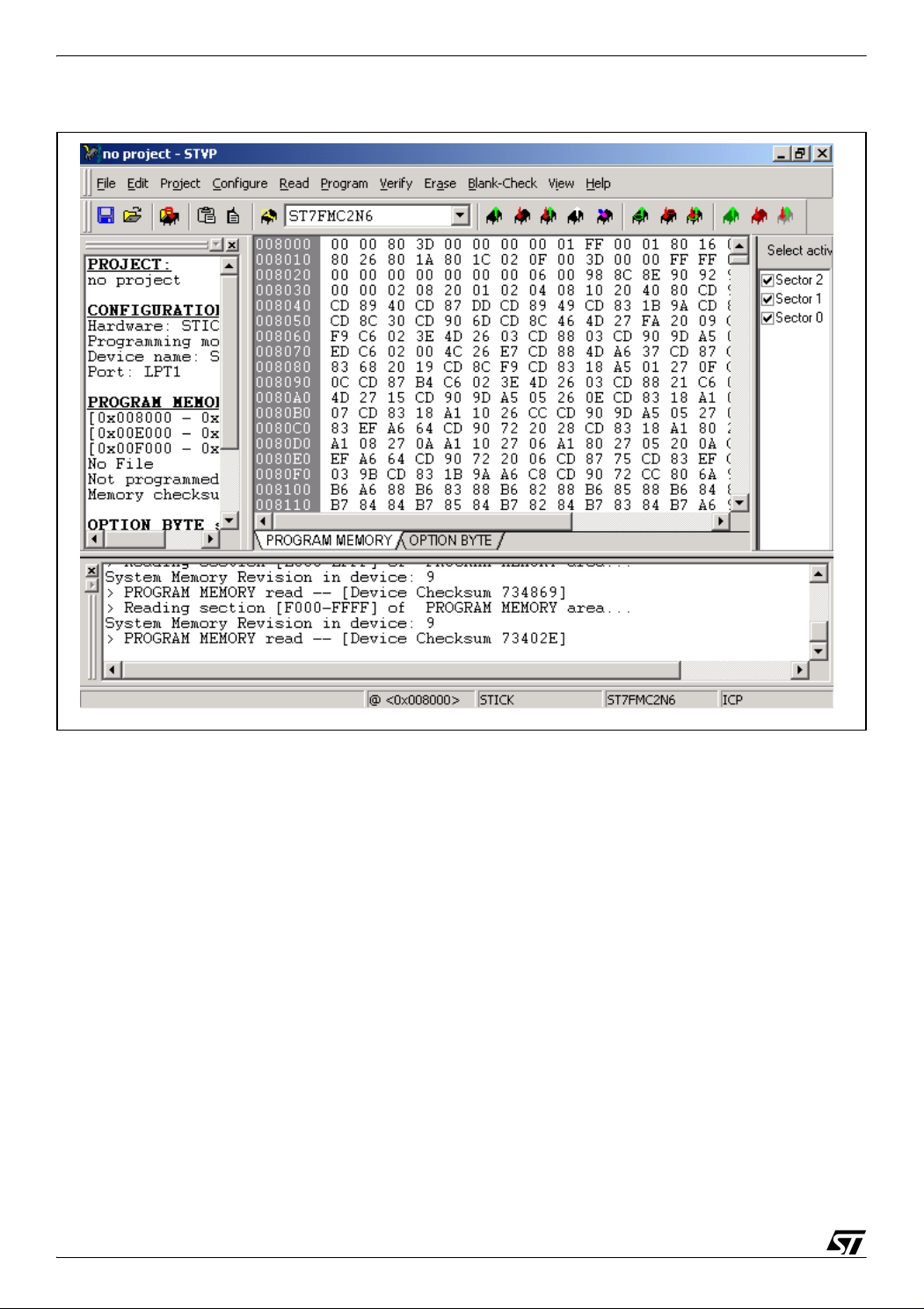

1.2.1 PROGRAMMERS

In order to program an MCU with the generated S19 file, you should also install the ST Visual

Programmer software (please visit our internet web-site) and use a programming interface

(STICK programmer for example for In-Circuit-Programming). The Visual Programmer tool

provides an easy way to erase, program and verify the MCU content.

Please note that the INDART STX kit from SOFTEC (see next chapter) is also a programming

tool (installation of DataBlaze Programmer is required).

7/77

Page 8

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 1. STVisual Programmer software

1.2.2 Emulators

Two types of real-time development tools are available for debugging applications using

ST7MC:

- In-circuit debugger from Softec (salestype : STXF-INDART/USB)

The INDART from SOFTEC features an emulation and a programming tool. This is achieved

using the In-circuit debug module embedded on the MCU. The real-time features of the Indart

include access to real-time registers and 2 break-point settings. However, trace is not available.

- ST7MDT50-EMU3 emulator

Fully-featured emulator: real-time with trace capability, performance analysis, advanced

breakpoints, light logical analyser capabilities, etc. It can also function as a programming tool

when used with the delivered ICC ADDON module (select STMC-ICC as hardware target in

STVP7). This ICC-ADDON module allows In-Circuit-Debugging with STVD7.

8/77

Page 9

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

1.3 LIBRARY SOURCE CODE

1.3.1 Download

The complete source files are available for free on the ST website (http://www.st.com/mcu), in

the Downloads section, as a zip file. This library is also copied by default on the hard-disk

when installing the ST7MC Control Panel from Softec micro systems, or available in the

Downloads section of www.softecmicro.com, software part (AK-ST7FMC System Software).

Important Note: It is highly recommended to check for the latest releases of the library

before starting any new development, and then verify from time to time

all release notes to be aware of any new features that might be of

interest for the project. Registration mechanisms are also available on

the web sites of ST and Softec Microsystems to automatically obtain

update information.

1.3.2 File structure

Once the files are unzipped, the following library structure appears, depending on the toolchain.

■ Library release 1.0

This library contains the workspace for both the STVD7 2.5.4 and STVD7 3.x IDEs. Four separate folders are provided (see Figure 2).

9/77

Page 10

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 2. Library structure for release 1.0

BLDCmotor_1.0 \ BLDC sensor \ config

\ object

\ source

\ debug

\ release

\ BLDC sensorless

\ config

\ object

\ source

\ debug

\ release

\ Pair poles chk

\ config

\ object

\ source

\ debug

\ release

\ cosmic

\ metrowerks

\ cosmic

\ metrowerks

\ cosmic

\ metrowerks

\ cosmic

\ metrowerks

\ cosmic

\ metrowerks

\ cosmic

\ metrowerks

\ sci

1.4 UTILITIES

1.4.1 lib.h file

The purpose of this header file is to provide useful macros and type re-definitions which will be

used throughout the entire library:

– Re-definition of data types using the following convention: a first letter indicating if a variable

is signed (s) or unsigned (u), plus a number indicating the number of available bits (for instance: u8, s16, etc.),

– Defines for assembly mnemonics used in C source code: Nop(), Trap(), etc.

– Common macros used for bit-level access (SetBit, ClrBit, etc.), to get the dimension of an

array (DIM[x]), etc.

10/77

Page 11

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

2 CUSTOMIZING THE WORKSPACE FOR YOUR ST7MC DERIVATIVE

2.1 USING STVD7 RELEASE 2.5.X

Figure 3. Memory Map

0000h

007Fh

0080h

067Fh

0680h

0FFFh

1000h

FFDFh

FFE0h

FFFFh

HW Registers

RAM

(1536/1024

768/384 Bytes)

Reserved

Program Memory

(60K, 48K, 32K, 24K, 8K)

Interrupt & Reset Vectors

0080h

00FFh

0100h

01FFh

0200h

01FFh

or 037Fh

or 047Fh

or 067Fh

Short Addressing

RAM (zero page)

256 Bytes Stack

16-bit Addressing

RAM

1000h

4000h

8000h

A000h

E000h

FFFFh

60 KBytes

48 KBytes

32 KBytes

24 KBytes

8 KBytes

The ST7MC memory is shown on Figure 3. The memory arrangement may vary depending on

the type of the MCU. Please refer to the datasheet in order to get more information.

The library is dedicated by default to the ST7FMC2N6B6 MCU (SDIP56, 32KB Flash, 1K

RAM). In order to target another ST7MC MCU, you may need to modify the C-toolchain configuration files. Here’s a basic example of what has to be done prior to any other modifications.

This example is based onto the ST7FMC2S4 MCU (TQFP 44, 16K Flash, 768 Bytes RAM)

2.1.1 Memory mapping with the COSMIC toolchain

Go into the ..\BLDC sensorless\config\Cosmic\ folder ( ..\BLDC sensor\config\Cosmic\ for

sensor driving mode).

Edit the "BLDC_Cosmic.lkf" file and check the following lines, in ‘SEGMENT DEFINITION’:

# SEGMENT DEFINITION (.text, .const, .data, .bss, .bsct, .ubsct, .eeprom are c compiler

predefined sections)

+seg .text -b0x8000 -m0x7f00 -nCODE -sROM # executable code

+seg .const -aCODE -it -sROM # constants and strings

+seg .bsct -b0x0080 -m0x007F -nZPAGE -sRAM # initialized variables in SHORT range

+seg .ubsct -aZPAGE -nUZPAGE -sRAM # uninitialized variables in SHORT range

+seg .share -aUZPAGE -is -sRAM #

+seg .bss -b0x0200 -m0x0280 -nUDATA -sRAM # uninitialized variables

+seg .data -aUDATA -nIDATA -sRAM # initialized variables

This section contains the memory placement for the object files, listed just after this declaration.

In order to target the memory size of the ST7MC2S4, the sizes of ROM and RAM memory have to be

changed (32K -> 16K Flash, 1K RAM -> 768 Bytes RAM)

shared segment

11/77

Page 12

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

+seg .text -b0xc000 -m0x3f00 -nCODE -sROM # executable code

where 0xc000 is the new starting address of the program memory and 0x3fe0 the size in

bytes.

+seg .bss -b0x0200 -m0x0180 -nUDATA -sRAM # uninitialized variables

where 0x0180 is the new 16-bit addressing RAM memory in bytes.

2.1.2 Memory mapping with the METROWERKS toolchain

Go into ..\BLDC sensorless\config\Metrowerks ( ..\BLDC sensor\config\Metrowerks\ for sensor driving

mode).

Edit the "BLDC_Metrowerks.prm" file

SECTIONS

ZRAM = READ_WRITE 0x0080 TO 0x00FF; // zeropage

RAM = READ_WRITE 0x0200 TO 0x047F; // 16 bit adressing RAM

ROM_SEC_2 = READ_ONLY 0x8000 TO 0xDFFF; // sector 2

ROM_SEC_1 = READ_ONLY 0xE000 TO 0xEFFF; // sector 1

ROM_SEC_0 = READ_ONLY 0xF000 TO 0xFEFF; // sector 0 - 0xFF00 to 0xFFDF reserved for

ICC

This Section contains the memory locations of pages declared at the end of this file.

To target the memory size of the ST7MC2S4, ROM and RAM memory settings have to be changed (32K

-> 16K Flash, 1K RAM -> 768 Bytes RAM).

ROM_SEC_2 = READ_ONLY 0xC000 TO 0xDFFF; // sector 2

where 0xc000 is the new starting address of the program memory

RAM = READ_WRITE 0x0200 TO 0x027F; // 16-bit addressing RAM

where 0x027F is the ending address of the 16-bit addressing RAM memory

Important Note: The application layer has been written for the STMFC2NB6. Using a

different ST7MC sales type can imply the need for some modifications

to the library, according to the available features (some of the I/O ports

are not present on low-pin count packages). Please refer to the data

sheet for details.

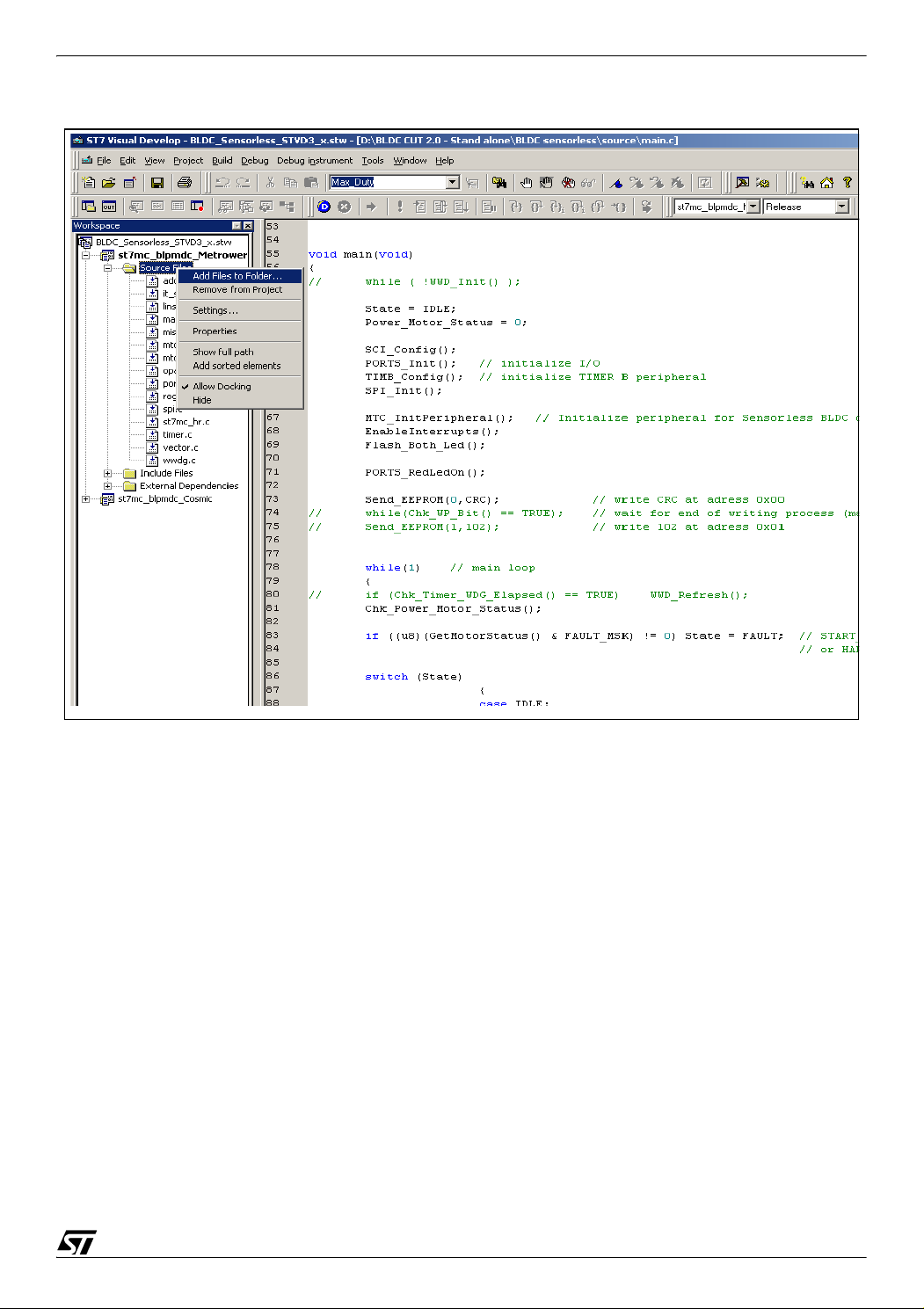

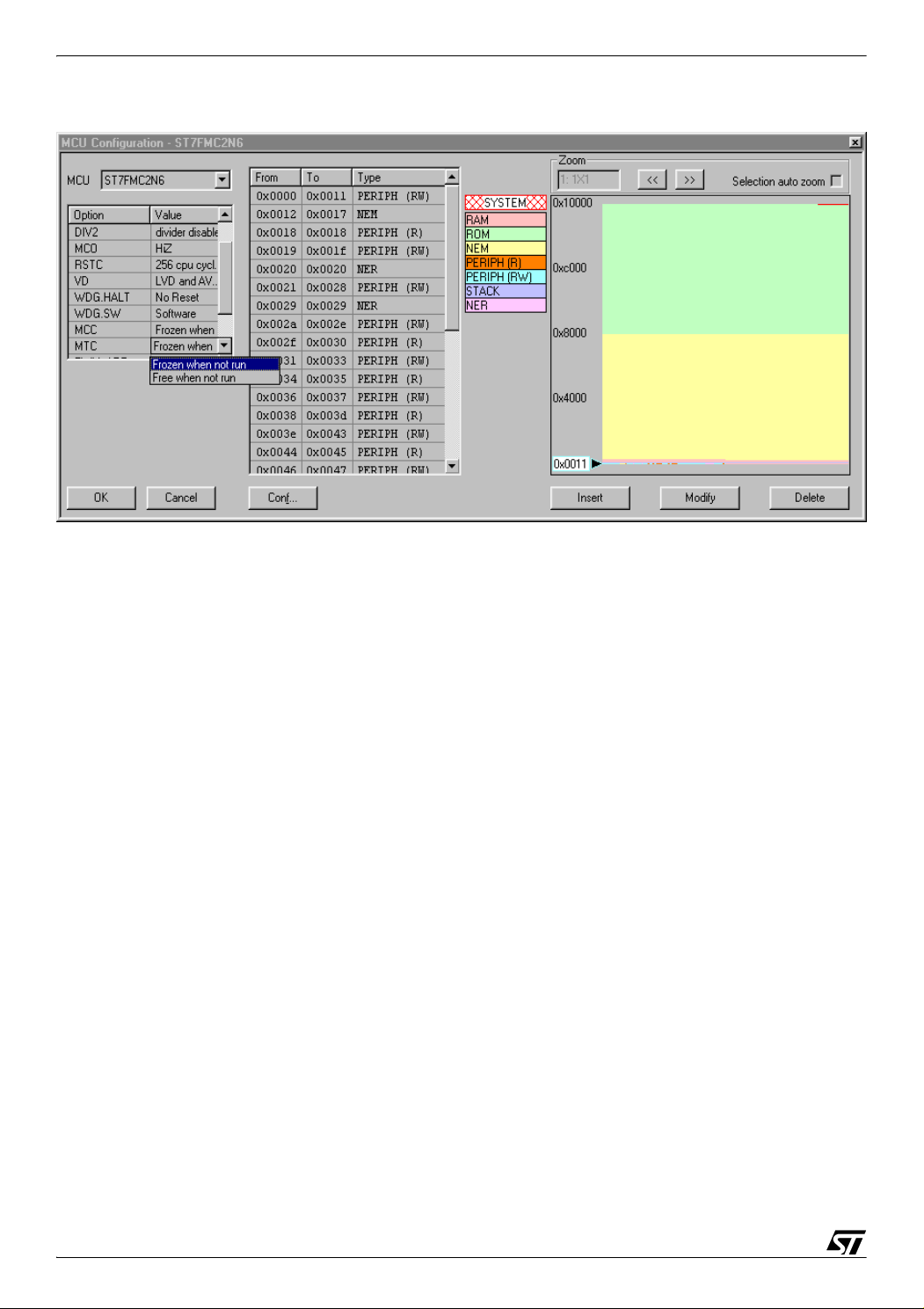

2.2 USING STVD7 RELEASE 3.X.X

The procedure is far easier with STVD7 3.x.x, as the makefile and linking command files are

automatically generated.

In the workspace window, just right click on the selected project (either cosmic or metrowerks)

and select “Add Files to Project”. You’ll be asked to select the source file.

12/77

Page 13

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

When rebuilding the library, the configuration files will be updated accordingly.

13/77

Page 14

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

2.3 "VERSION.H" FILE

The purpose of this file is to declare the compiler options which will be used throughout the entire library compilation process.

– Define the PMDC driving mode: voltage/current, open/closed loop

– In sensorless mode, 3 more options are added for the demagnetization type: hardware, hard-

ware with software backup, software.

Special care has to be taken for the demagnetization type, since the value range is 1, 2 and 3,

corresponding respectively to hardware, hardware with software backup, software demagnetization type (HW, HSW, SW).

Other compiler options can be disabled/enabled by writing 0 or 1 in front of each declaration (0

for disable, 1 for enable). Figure 4 gives an example when setting the current/closed loop/alternate hard soft demagnetization in sensorless mode.

Figure 4. Settings for current/closed loop/alternate hard soft demagnetization

(sensorless)

.....

/* Demagnetization type parameters */

#define HW 1 // 1 -> Hard demag only

#define HSW 2 // 2 -> Hard with soft backup

#define SW 3 // 3 -> Soft Demag only

/* Driving mode parameters */

#define CURRENT_MODE 0 // 0 -> Current mode

#define VOLTAGE_MODE 1 // 1 -> Voltage mode

/* Regulation type parameters */

#define OPEN_LOOP 0 // 0 -> Open loop

#define CLOSED_LOOP 1 // 1 -> Closed loop

....

/******************************************************************************/

/* Option settings used throughout the compilation process */

#define SENSOR_TYPE 0 // no use in sensorless

#define DEMAG_TYPE 2// no use in sensor mode

#define DRIVING_MODE 1

#define FEEDBACK_TYPE 1

mode

After choosing the desired compiler options, the whole library has to be rebuilt. To launch the

compilation, click on the ’rebuild all’ icon.

14/77

Page 15

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

2.4 ADDITIONAL OR UP-TO-DATE TECHNICAL LITERATURE

More information can be found on the ST website (http://www.st.com/mcu).

More specifically, the latest documents and software can be found directly at:

http://www.st.com/mcu in the Downloads section

In addition, FAQ and Forums can be found directly at :

http://www.st.com/stonline/products/support/micro/st7/st7mc.htm

15/77

Page 16

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

3 GETTING STARTED WITH THE LIBRARY USING THE ST7MC-KIT/BLDC

3.1 INTRODUCTION

There are two ways to get started with this software library.

The first way is to edit (with your motor specific features), compile and assemble the modules

described in Section 5 and Section 6 of this application note. Then, program ST7MC and run

your motor on hardware like the one provided in the ST7MC-KIT/BLDC Starter-kit.

The second way is to use the ST7MC-KIT/BLDC Starter-kit and follow this process:

- run and fine-tune the motor parameters with the GUI

- generate the *.H files and manually select/save the key parameters

- edit mtc.h file with key parameters

- compile, link, program ST7MC

- run the motor

If you are new to the BLDC environment or to the ST7MC product, the second method is

highly recommended and is described below.

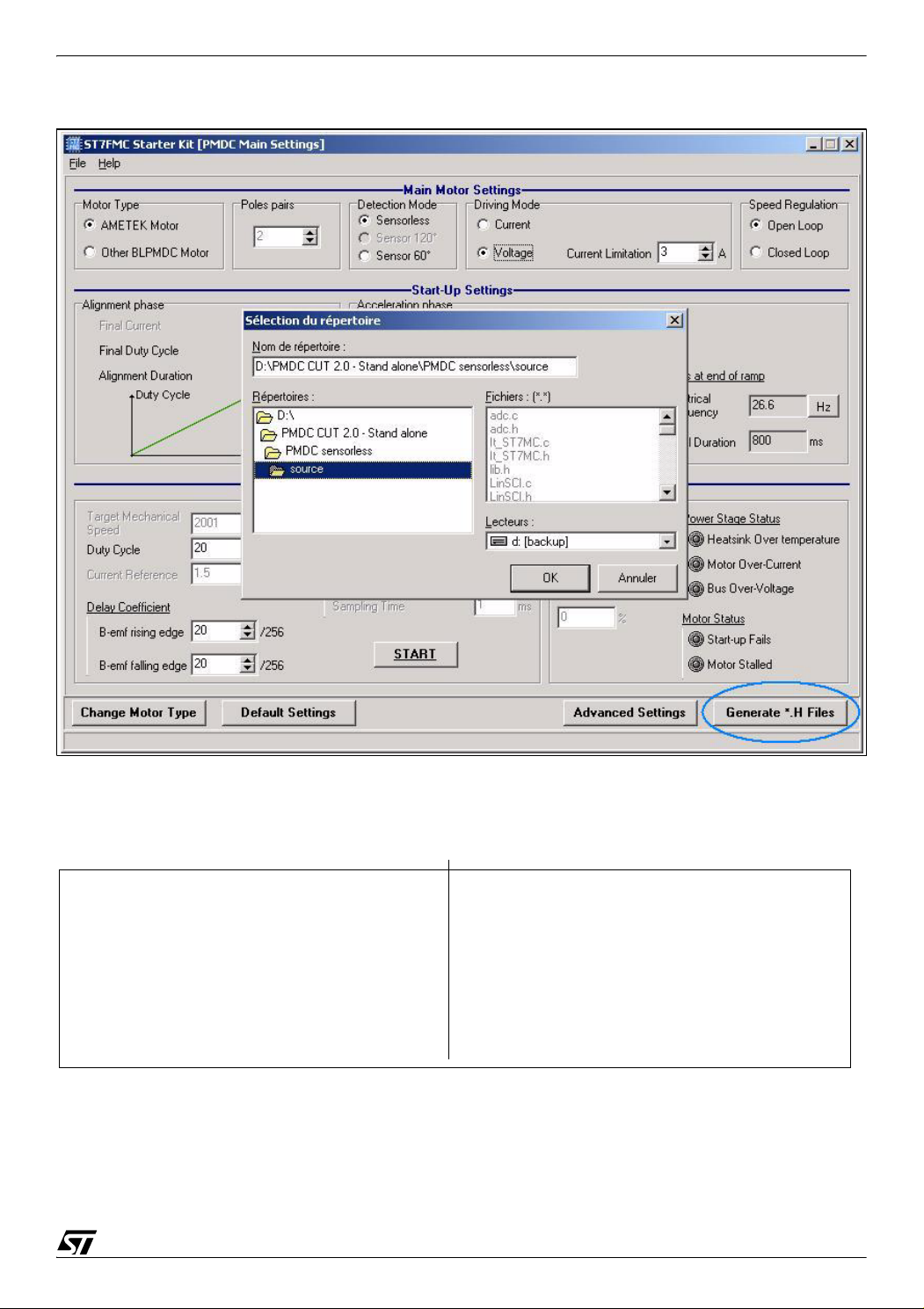

3.2 RUNNING THE MOTOR

As a starting point, the open loop mode shall be used for the first trials. Low-duty cycle values

should be used also (alignment, ramp and real time settings) and then increased smoothly

step by step.

Once the motor settings have been finely adjusted (whatever the driving mode, sensor/sensorless), the parameters have to be ‘injected’ into the stand-alone library. Simply click on

‘Generate *.h Files’ and select the source directory of the stand-alone library.

16/77

Page 17

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

The GUI will generate 1 dedicated header file containing the settings of the motor (mainly the

MTC peripheral settings) and another one containing the compiler options (see Figure 5).

Figure 5. Files generated in sensorless and sensor mode

SENSORLESS MODE

“MTC_Settings_Sensorless.h”

“Version.h”

Once previous files have been generated, launch a new compilation. Firmware will then be

compiled according to the new settings/compiler options automatically.

SENSOR MODE

“MTC_Settings_Sensor.h”

“Version.h”

17/77

Page 18

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

3.3 STANDALONE MODE AND CLOSED LOOP OPERATION

To run a BLDC motor in standalone closed loop, the approach should be, for a given target

mechanical speed, to fine tune all the realtime parameters most adequate for this speed. For

each target speed, these values should be recorded in the form of a table, which will be used

by the ST7MC standalone firmware. You should collect data for 4 speeds: the min and max

speeds specified in the GUI advanced screen, and 2 intermediate speeds of your choice. The

ST7MC standalone firmware will then make a linear extrapolation of realtime parameters in

between the 4 specified speeds to ensure smooth operation.

Once the data is collected, edit the ‘mtc.h’ file and fill in the field dedicated to the Rising/Falling

Bemf, Ki, Kp coefficient calculation (see Figure 6).

Figure 6. ‘mtc.h’ field for coefficient computation

// See 'Mtc_Settings_Sensorless.h' for Freq_Min & Freq_Max values

//Fmin

#define Rising_Fmin 20 // Frequency min coefficient settings

#define Falling_Fmin 30

#define Ki_Fmin 10

#define Kp_Fmin 30

//F_1

#define F_1 1000 // 100 Hz

#define Rising_F_1 50 // Intermediate frequency 1 coefficient settings

#define Falling_F_1 40

#define Ki_F_1 20

#define Kp_F_1 10

//F_2

#define F_2 2000 //

#define Rising_F_2 30 // Intermediate frequency 2 coefficient settings

#define Falling_F_2 10

#define Ki_F_2 50

#define Kp_F_2 40

//Fmax

#define Rising_Fmax 10 // Frequency max coefficient settings

#define Falling_Fmax 16

#define Ki_Fmax 13

#define Kp_Fmax 18

200 Hz

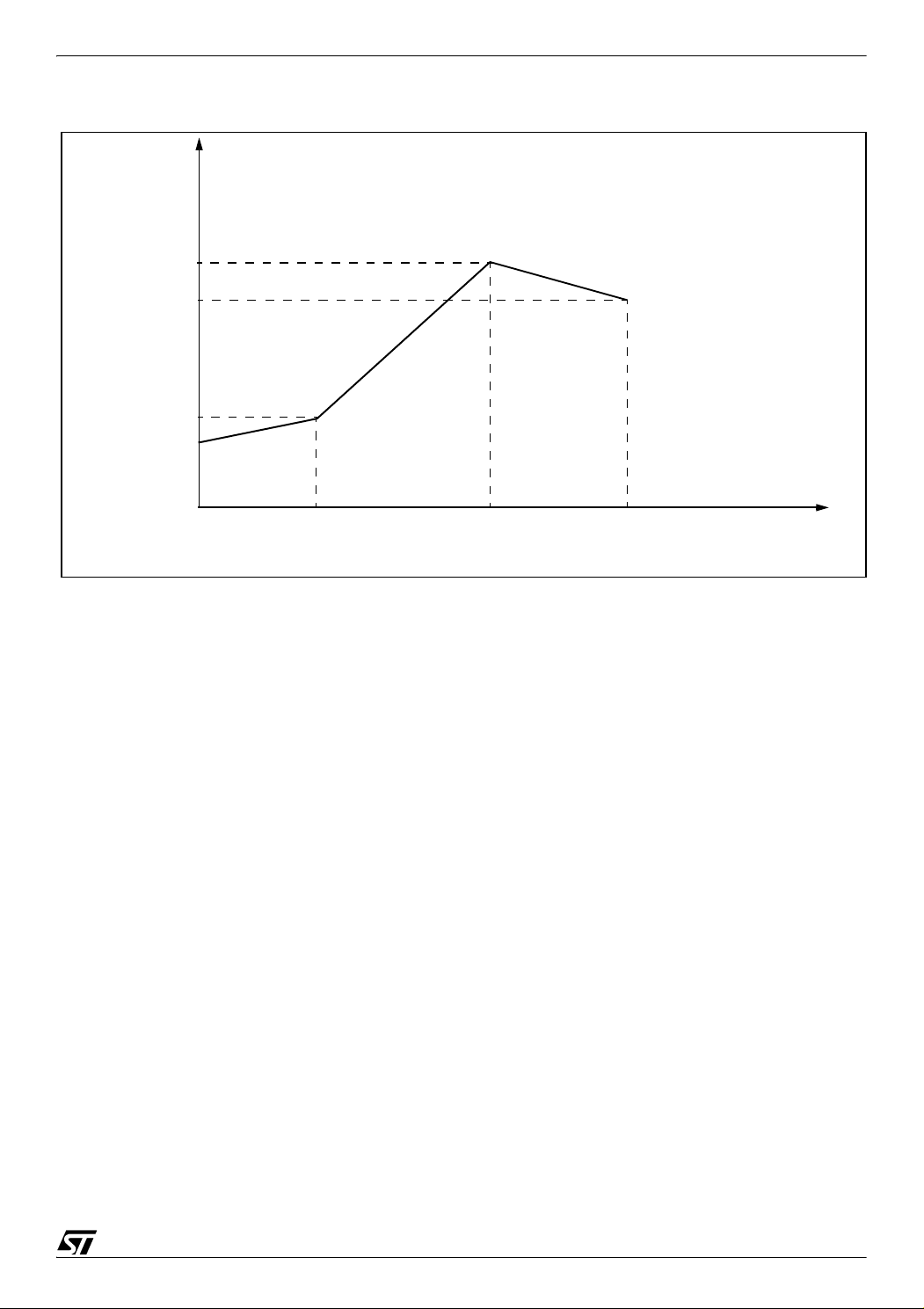

Once the motor runs, rising/falling Back-EMF and proportional/integer coefficients are computed following a linear curve between F_min and F_1, F_1 and F_2, F_2 and F_max (see

Figure 7). Note that F_min, F_1, F_2, F_max are electrical frequencies, with 0.1 Hz resolution

(for example F_1 = 1234 means F_1 = 123.4Hz).

18/77

Page 19

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 7. Linear curve for coefficient computation

Rising/Falling Bemf

Ki, Kp

Rising_F_2, Falling_F_2

Ki_F_2, Kp_F_2

Rising_Fmax, Falling_Fmax

Ki_Fmax, Kp_Fmax

Rising_F_1, Falling_F_1

Ki_F_1, Kp_F_1

Rising_Fmin, Falling_Fmin

Ki_Fmin, Kp_Fmin

F_min

F_1

F_2

F_max

Target rotor

electrical

frequency

3.4 NOTE ON DEBUGGING TOOLS

3.4.1 Low voltage applications (below 30V)

For these voltage levels, the real-time emulator can be connected to the application, taking

care to connect the protective boards provided with the MDT50 emulator (refer to the emulator

datasheet for details). It offers trace and advanced breakpoint capabilities, as well as the possibility to automatically disable the PWM outputs on a breakpoint to avoid any DC current injection in the motor (see Figure 8).

This emulator is delivered with a set of three boards to protect some of the motor control dedicated I/Os from voltages greater than 5V. It is highly recommended to have them connected

during the development. A neutral board is also provided in case the protection networks impedance (1K series resistor plus 5V3 zener diode) is an issue for the application. Refer to the

ST7MDT50-EMU3 Probe user guide Section 3.1 for details.

An In-Circuit Debugging tool can also be directly connected, as long as an ICC connector is

available on the application.

Important Note: When using ICD, during a breakpoint, the clock circuitry is not disabled:

a permanent DC current may flow in the motor as the PWM outputs are

enabled. It is thus recommended to use a power supply with fast

current limitation capabilities or if possible to disable the PWM outputs

(by inserting MTC_DisableMCOutputs function) before the breakpoint.

19/77

Page 20

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 8. Configuring the Motor Controller clock state on breakpoint with MDT50

3.4.2 Medium-high voltage application (above 30V)

Here the real-time emulator use is not recommended, even if protective boards are inserted.

Important Note: In the event of high voltage applications connected to the mains, the

application ground may be at a dangerous voltage; so too then would

be the MDT50 emulator (the protective boards do not provide

galvanic isolation).

For voltages above 30V, it is highly recommended to use only programmed devices. ICD debugging can be used in conjunction with an ICC isolation board, as the one provided with the

ST7MC-KIT/BLDC starter kit, but the limitations mentioned in Section 3.4.1 nevertheless

apply, and are even emphasized by the high voltage levels.

Good practice for real-time application debugging is to use “diagnostic tools” such as:

– RS232 communication which can be easily isolated,

– Standalone DAC (serial SPI-based model for instance) to be able to monitor signals on an

oscilloscope,

– Debug outputs of the ST7MC itself (MCDEM and MCZEM pins), to monitor the D, Z and C

events (refer to datasheet for details).

Refer to the application note AN438 (Safety Precautions for Development Tool Triac + Microcontroller) for further details when working with the mains supply.

20/77

Page 21

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

3.5 USING YOUR OWN POWER STAGE

In order to configure the standalone library to match any kind of power stage, care should be

taken to observe the logic input diagrams of the drivers. The starter kit uses three L6386 highvoltage high and low side drivers; other devices may require adjustments, depending on

whether their logical inputs are active low or high. The ‘MPOL’ register has then to be set manually in the firmware. Modifications can be done in the ‘MTC_InitPeripheral’ routine (see

Figure 9). It has to be noted also that the option byte has to be updated accordingly (MCO

output states during reset).

Figure 9. MPOL register configuration

void MTC_InitPeripheral(void)

{

MTC_ResetPeripheral();

// Initialize registers in page 1 first

SET_MTC_PAGE(1);

MCONF = mem_MCONF;

MPWME = (u8)(mem_MPWME | DG_MSK); //Force output of debug signal

MPOL = ALL_ACTIVE_HIGH; // (L6386D) <-- to be updated according to your own

device characteristics

// ZVD bit=0; Z and D have opposite edge

The starter kit can also be connected directly to an external power stage using the socket J6

(26 pins).

3.6 CHECKING THE CURRENT SENSOR RESISTOR VALUE

The starter kit comes with a current sensor resistor of 0.047 Ohm (R21 on the schematic, see

Figure 10). The current limiter of the MTC cell relies on a comparator that turns off the PWM

when the voltage on this resistor has reached a limit (see Section 7.2.1 Voltage versus current

mode for more details). This voltage is amplified by a factor of 11 by the internal OPAMP con-

figured as a non-inverter amplifier (see R66 and R67 values).

21/77

Page 22

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 10. Starter kit: zoom on the power stage

‘R21’ 47 milli-ohm

resistor acting as

a current sensor

3.6.1 Maximum current

The saturation voltage of the internal comparator is 5 Volts. Figure 11 summarizes the hardware configurations when the winding current is set to maximum.

22/77

Page 23

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 11. Configuration at max. current

MCCREF

5 Volts

OAZ/MCCFI1

clock

PWM freq.

comparator

HV

Set

-

R

+

T1

A

Uout

OPAMP

X11

Usense

T4

47 milli-Ohm

Therefore, the maximum current can be calculated:

Imax = Vsaturation / (OPAMPgain x Rsense)

Previous formula applied to the starter kit leads to:

Imax = 5 / (11 x 0.047) = 9.67 amperes

The current sense resistor value has to be adjusted when a different working range is needed.

It is then necessary to decrease it when the current requirement is higher, or to increase it

when the current requirement is lower. It is also possible to adjust the OPAMP gain, but it has

to be remembered that:

– A High-gain OPAMP configuration may decrease EMC performance.

– A low-gain OPAMP combined with a high current sense resistor value will induce higher pow-

er loss (into the resistor).

– The power stage of the starter kit has been designed to handle power up to 1KW. For higher

power, a bigger heat sink and current capability IGBTs or MOSFETs may be required.

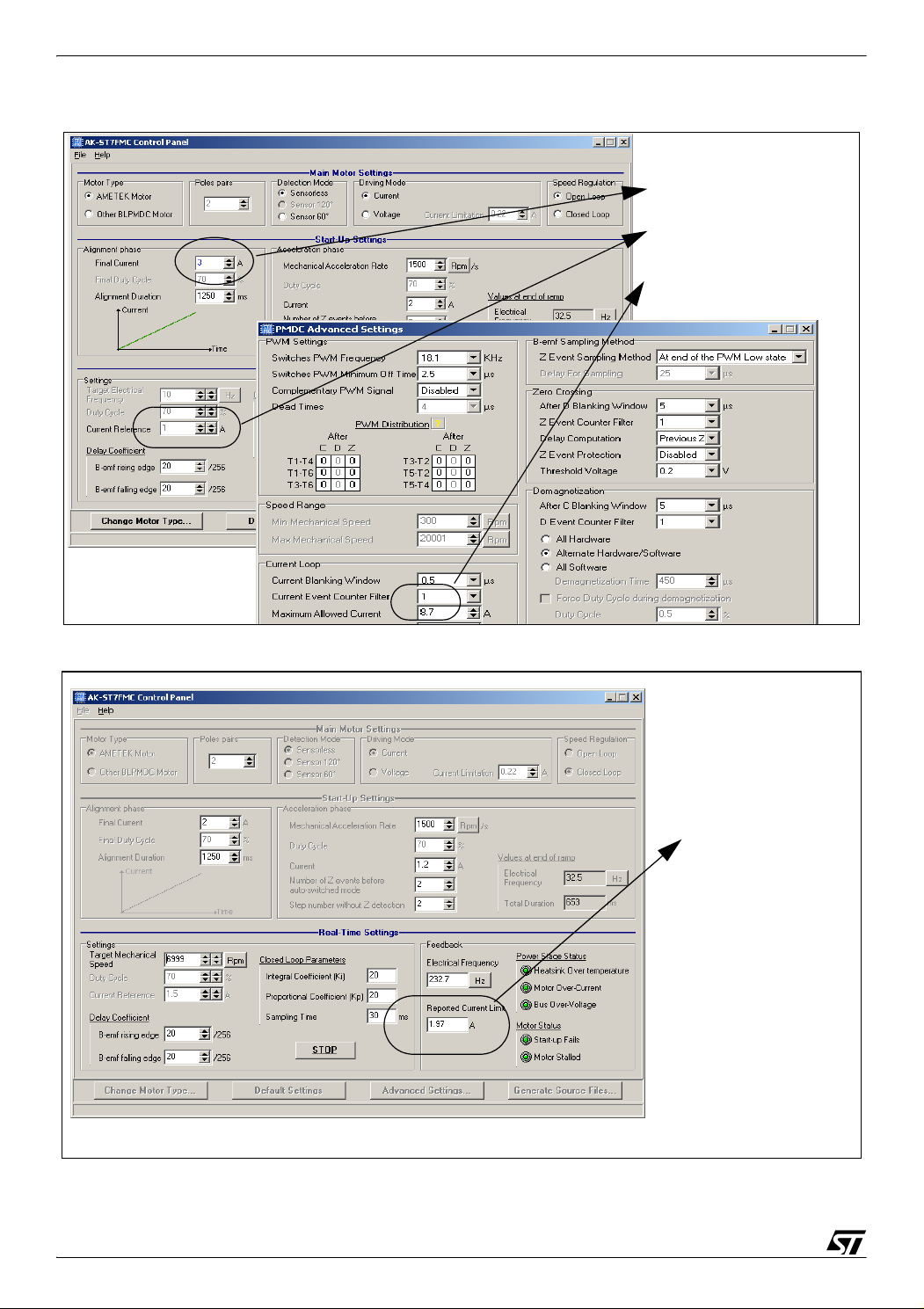

3.6.2 Interpreting the current feedback/settings in the GUI

Settings related to current values on the GUI are treated as if the current sensor value were a

47 milli-Ohm type (with OPAMP gain equal to 11). When using a different resistor value, settings concerning current can’t be read/written directly but have to be calculated manually

using a proportional coefficient equal to:

K = 47 milli-Ohm / new value

The actual current information is the one shown on the GUI multiplied by the proportional coefficient ‘K’ (See Figure 12 & Figure 13).

23/77

Page 24

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 12. Using a 20 milli-Ohm resistor, K = 2.35 (47/20)

Actual value:

3x2.35 = 7.05 A

1x2.35 = 2.35 A

8.7x2.35 = 20.45 A

Figure 13. Using a 100 milli-Ohm resistor, K = 0.47 (47/100)

Actual value:

1.97x0.47 = 0.93 A

24/77

Page 25

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

4 MODULES PRESENTATION, LIBRARY ROUTINES

4.1 LIBRARY REFERENCES

Functions are described in the format given below:

Synopsis This section lists the referenced include files and prototype declarations.

Description The functions are specifically described with a brief explanation of how

they are executed.

Input This section gives the format and units.

Returns Gives the value returned by the function, including when an input value

is out of range or an error code is returned.

Caution Indicates the limits of the function or specific requirements that must be

taken into account before implementation.

Warning Indicates important points that must be taken into account to prevent

hardware failures.

Functions called Used to prevent conflicts due to the simultaneous use of resources.

Code example Indicates the proper way to use the function if there are certain prereq-

uisites (interrupt enabled, etc.).

Some of these sections may not be included if not applicable (no parameters, obvious use,

etc.).

4.2 MTC SOFTWARE LAYER

The software related to the MTC peripheral is part of a module which is call ‘mtc.c’. This

module refers to all the routines needed to initiate and run the peripheral properly. The dedicated MTC hardware registers declaration are also grouped into a module named ‘mtc_hr.c’.

This module provides:

- Basic setup

- Control routines

- Related interrupt handling routines

- Speed acquisition for closed loop operation

Routine prototypes can be found in the ‘mtc.h’ header file.

25/77

Page 26

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

4.2.1 List of available routines

The following is a list of available functions as listed in the mtc.h header file.

MTC_InitPeripheral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 27

MTC_StartMotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 28

MTC_StopMotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 29

Set_Duty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

Set_Target_Electrical_Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 31

active_brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

Get_Motor_Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 33

Set_Motor_Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

Chk_Motor_Stalled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

MTC interrupt handling routines are described in the next chapter.

26/77

Page 27

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

MTC_InitPeripheral

Synopsis #include "mtc.h"

void MTC_InitPeripheral(void)

Description The purpose of this function is to (re-)initialize the MTC cell. A reset of

this peripheral is done first, and the hardware registers are then set with

appropriate values.

Caution It must be noted that part of MPOL and MDTG registers are written

once, meaning they cannot be modified any further once the

MTC_InitPeripheral() function has been executed

Functions called MTC_ResetPeripheral()

See also ST7MC Datasheet: MTC chapter.

27/77

Page 28

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

MTC_StartMotor

Synopsis #include "mtc.h"

void MTC_StartMotor(void)

Description This function Initializes HW registers and SW variables needed in real

time for the motor drive. To ensure a proper start-up, the bootstrap capacitors of the high side switch drivers are refreshed. Finally, this function performs the alignment of the rotor in a known position, and sets the

flags of expected MTC interrupt events.

Functions called Init_PI (closed loop only), MTC_EnableDirectAccess,

MTC_DisableDirectAccess, MTC_EnableOutputs, RefreshBootstrap,

MTC_EnableClock, MTC_DisableClock, AlignRotor

See also ST7MC Datasheet: MTC chapter.

28/77

Page 29

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

MTC_StopMotor

Synopsis #include "mtc.h"

void MTC_StopMotor(void)

Description This function disables all motor control related interrupts and switches

off all transistors. This puts the windings in floating state once they are

completely demagnetized.

Functions called MTC_EnableDirectAccess, MTC_DisableDirectAccess

29/77

Page 30

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Set_Duty

Synopsis #include "mtc.h"

void Set_Duty(u16 duty)

Description This function is used to refresh the MCPUH/L register contents

(MCPVH/L in current mode).

Input The ‘duty’ is a u16 variable, and has to be set according to the PWM fre-

quency (MCPOH/L registers) for both voltage or current mode.

The desired duty cycle is set using this formula:

Duty = desired duty (0 to 100%) x MCPOH/L (voltage mode’)

Duty = desired current limitation (Amp) x MCPOH/L / 9.7(current mode)

Caution In voltage mode, the ‘duty’ variable is directly linked to the PWM duty

cycle while in current mode, the ‘duty’ variable sets the voltage reference (MCPVH/L, actually the current limitation) at the input of the MTC

cell comparator (MCCREF pin, via a RC filter on the board).

See also ST7MC Datasheet: MTC chapter.

Code example Voltage mode:

20 Khz PWM frequency (ratio between 12-bit PWM clock and PWM frequency, MCPOHL = 16 MHz/20kHz = 800), desired duty = 40%:

duty = 40 x MCPOHL/100 = 320

-> Update_Duty(320);

Current mode:

*Fixed 10 Khz PWM frequency (MCPOHL = 1600), desired current limitation = 4 Amp:

duty = 4 x MCPOHL/9.7 = 4 x 1600/9.7 =

-> Update_Duty(660);

* hardware dependant. For other PWM frequencies, please check the

RC filter value at the input of the MTC comparator cell (MCCREF pin).

30/77

Page 31

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Set_Target_Electrical_Frequency

Synopsis #include "mtc.h"

void Set_Target_Electrical_Frequency(u16 target_freq)

Description This function is used to refresh the MCPUH/L register contents

(MCPVH/L in current mode). The output of the PI regulation loop routine

is used to do so.

Input The ‘target_freq’ is a u16 variable, and has to be set according to the de-

sired target frequency (0.1Hz resolution).

The target electrical frequency is given by:

target_freq = desired electrical frequency x 10 (0.1 Hz resolution)

Caution Frequency is given with 0.1Hz resolution.

Functions called regul_PI

See also ST7MC Datasheet: MTC chapter.

Code example desired electrical frequency : 100 Hz:

target_freq = 100 Hz x 10 = 1000;

-> Set_Target_Electrical_Frequency(1000)

Reminder:

Electrical frequency = number of pair poles x mechanical frequency

RPM speed = 60 x Mechanical frequency (RPM: revolutions per minute)

example: electrical frequency = 100 Hz, motor with 8 pair poles:

100Hz electrical <-> 100/8 =12.5Hz mechanical <-> 12.5 x 60=750 RPM

31/77

Page 32

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

active_brake

Synopsis #include "mtc.h"

BOOL active_brake(u16 duty, u16 time)

Description The purpose of this function is to switch the active brake of the motor, by

sinking a DC current in 1 phase, another one being grounded.

Input Duty cycle applied during active brake phase, with the Time given in

milli-seconds

Returns TRUE if brake time elapsed or duty sets to 0.

Caution In voltage mode, the ‘Duty’ variable is directly linked to the PWM duty

cycle while in current mode, the ‘Duty’ variable sets the voltage reference at the input of the MTC cell comparator (MCCREF pin, via a RC

filter on the board).

Functions called MTC_EnableDirectAccess, MTC_DisableDirectAccess

See also ST7MC Datasheet: MTC chapter.

Code example The ‘duty’ is a u16 variable, and has to be set according to the PWM fre-

quency (MCPOH/L registers).

Example:

PWM frequency set at 10 Khz, MCPOH/L = 1600 (ratio between 12-bit

PWM clock and PWM frequency 16 MHz/10kHz = 1600)

Desired duty = 40% = 40 x MCPOHL/100 = 40 x 1600/100 = 640

Desired braking time : 2 sec = 2000 ms

-> if (active_brake(640,2000) == TRUE) State = STOP; // stop motor

32/77

Page 33

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

GetMotorStatus

Synopsis #include "mtc.h"

u8 GetMotorStatus(void)

Description This function returns the ‘MotorStatus’ byte.

Bit description:

MotorStatus

Sensorless

EMERGENCY_STOP

START_UP_FAILED

HARD_FAILURE

MOTOR_STALLED

LAST_FORCED_SWITCH

FIRST_AUTO_SWITCH

AUTO_SWITCH

MotorStatus

Sensor

EMERGENCY_STOP

HARD_FAILURE

6

5

7

6

7

4

54

3

3

21

2

0

0

1

MOTOR_STALLED

Returns unsigned char

33/77

Page 34

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

SetMotorStatus

Synopsis #include "mtc.h"

void SetMotorStatus(u8 status)

Description This function updates the ‘MotorStatus’ byte according to the ‘status’

byte parameter. Please see ‘GetMotorStatus’ routine description for

status byte definition.

Input unsigned char

34/77

Page 35

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Chk_Motor_Stalled

Synopsis #include "mtc.h"

void Chk_Motor_Stalled(void)

Description The purpose of this function is to check the ratio of the MTC cell set in

the MPCR register. If the ratio is equal to the maximum ratio (15), then

the bit ‘MotorStalled’ of ‘Power_Motor_Status’ is set.

See also ST7MC Datasheet: MTC chapter.

35/77

Page 36

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

4.2.2 List of MTC interrupt routines

The following is a list of the MTC interrupt handling routines. These functions are all included

in the ‘mtc.c’ module.

MTC_U_CL_SO_IT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 37

MTC_C_D_IT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 38

MTC_R_Z_IT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 42

36/77

Page 37

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

MTC_U_CL_SO_IT

Synopsis #include "mtc.h"

void MTC_U_CL_SO_IT(void)

Description This interrupt routine is entered once there is a current limitation, PWM

update or Sampling Out event. Only the current limitation event is processed in the library: status flag is reset, and the bit ‘OverCurrent’ of

‘Power_Motor_Status’ is set.

See also ST7MC Datasheet: MTC chapter.

Figure 14. CLI event processing (sensorless/sensor)

CLI interrupt request

Set overcurrent flag in Power_Motor_Status

Disable CLI interrupt for 300 ms

Return from interrupt

37/77

Page 38

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

MTC_C_D_IT

Synopsis #include "mtc.h"

void MTC_C_D_IT(void)

Description This function is dedicated to the Commutation and Demagnetization in-

terrupt service routine. Figures 15,16,17,18 & 19 show the routine flow-

charts.

See also ST7MC Datasheet: MTC chapter.

Figure 15. Commutation event processing (Sensor mode only)

C interrupt request?

Preload active phase on next C event: MPHST with phase,

MCRB with comparator edge, PWM orientation

Voltage mode

: save MCPUHL and force duty cycle during demag if enabled

MWGHT = RISING/FALLING delay

Return from interrupt

38/77

Page 39

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 16. Commutation event processing (Sensorless mode only)

Reset RPICounter

Preload active phase on next C event: MPHST with phase,

MCRB with comparator edge, demagnetisation mode and PWM orientation

Voltage mode: save MCPUHL and force duty cycle during demag

StepIndex = StepIndex + 1

if enabled

C interrupt request?

SW DEMAG

Adjust soft demagtime according

to RPICounter

yes

Preset soft demag time + MCOMP > 0xff

MotorStatus?

no

HSW DEMAG

HW DEMAG

FORCED_SWITCH

C_IT_ForcedSW

LAST_FORCED_SWITCH FIRST_AUTO_SWITCH

MDREG = MCOMP/(SWITCHED_SW_DEMAG)

Wait for Z event (MCOMP=255)

MWGHT = TRANSITION_DELAY

Enable autoswitchand relevant interrupts

MotorStatus= FIRST_AUTO_SWITCH

Return from interrupt

MWGHT = AUTO_DELAY

Init PI buffer (Step_Z[ ])

Reset delay_counter

MotorStatus= AUTO_SWITCH

C_IT_AutoSW

AUTO_SWITCH

39/77

Page 40

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 17. Commutation event processing (Sensorless mode only) continued

SW DEMAG

HW DEMAG

Update MCOMP& MPRSR with step

time and ratio stored in RAMP[ ]

Enable D event if RampIndex= 2

MDREG = MCOMP/(SWITCHED_SW_DEMAG)

Ramp finished

without success?

no

Bemf blanking over?

(RampIndex

Bemf are present and consecutive?

(same number of C & Z event?)

= bemf_blank?)

no

C_IT_ForcedSW

HSW DEMAG

yes

Stop motor

yes

Enable Z event

yes

CeventCounter++

no

Reset CeventCounter

& BemfCounter

Return from interrupt

40/77

Page 41

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 18. Commutation event processing (Sensorless mode only) continued

HSW DEMAG SW DEMAG HW DEMAG

SDM bit set? (hard + soft demag ongoing?)

yes

yes

RM event?

no

no

MDREG = SoftDemagTime + MCOMP

delay_counter <= MAX_DELAY_COUNTER?

MWGHT = RISING/FALLING delay

SoftDemagTime

MCOMP+SoftDemagTime / 2^(RP_counter) > 0xff ?

Adjust SoftDemagTime& RPICounter

no

= SoftDemagTime*2

yes

for correct MTIM timer overflow

yes

delay_counter = AUTO_DELAY_STEP?

C_IT_AutoSW

no

Increase delay_counter

no

Update MDREG with user settings

MDREG = preset demag

Return from interrupt

C_IT_AutoSW C_IT_AutoSW

time

yes

MWGHT = MEDIUM_DELAY

Figure 19. Demagnetisation event processing (Sensorless mode only)

SENSORLESS

SoftDemagTime

Autoswitchmode?

= 1.25 x (MDREG-MCOMP)

Return from interrupt

Voltage mode?

yes

Restore MCPUHL values if duty

no

cycle has been forced during demag

HSW DEMAG SW DEMAG

noyes

SoftDemagTime = 1.25 x MDREG

D interrupt request?

HW DEMAG

41/77

Page 42

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

MTC_R_Z_IT

Synopsis #include "mtc.h"

void MTC_R_Z_IT(void)

Description This function is dedicated to the Zero-Crossing and Ratio Increment/

Decrement interrupt service routines. Figures 20, 21, 22, 23, 24 & 25

show the routine flowcharts.

See also ST7MC Datasheet: MTC chapter.

Figure 20. Z event processing (sensorless mode only)

Z interrupt request?

yes no

Save MZREG value and

prescaler ratio into Step_Z buffer

(save step time between two

zero crossing events)

Autoswitchmode?

no

Return from interrupt

BemfCounter++

Correct number of

Successive Bemf detected?

MotorStatus = LAST_FORCED_SWITCH

yes

Center last zerocrossing in the middle

of 2 C events (

MCOMP = MZREG x 2

)

42/77

Page 43

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 21. Z event processing (Sensor mode only)

Save MZREG value

and prescaler ratio into Step_Z buffer

(save step time between two

zero crossing events)

Z interrupt request?

Return from interrupt

Figure 22. RP event processing (Sensorless mode only)

HW DEMAG

yes no

RPICounter = 0?

RPICounter = RPICounter-1

RPICounter = 0?

no

Return from interrupt

RP interrupt request?

HSW DEMAG

SW DEMAG

yes

MDREG = SoftDemagTime

43/77

Page 44

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 23. RP event processing (Sensor mode only)

RP interrupt request?

Return from interrupt

Figure 24. RM event processing (Sensorless mode only)

RM interrupt request?

Set RM_EVT Flag

Return from interrupt

Figure 25. RM event processing (Sensor mode only)

RM interrupt request?

44/77

Return from interrupt

Page 45

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

4.3 APPLICATION LAYER

The application layer is split into modules; each module comes with a set of routines dedicated

to a peripheral, event (interrupt routines), or are grouped by functionality. The following information summarizes the most important routines in the different modules.

regul.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

adc.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

it_ST7MC.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 46

ports.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 47

LinSCI.c. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48

4.3.1 regul.c

This module contains the code of the PI regulation loop, which is used for closed loop operation.

The ‘u16 Period_To_Frequency(void)’ routine converts the Step_Z buffer information into

frequency (the Step_Z buffer contains the time elapsed between 7 zero-crossing events ->

corresponds to the time of six (6) steps period of the electrical frequency).

The ‘u16 regul_PI(u16 Target_Freq)’ routine computes the PI output according to Ki, Kp,

sampling time, and target electrical frequency. The returned value is a 10-bit long integer (0 to

1024).

4.3.2 adc.c

This module starts and initializes the analog to digital converter, and launches upon request a

conversion on a channel. It is able to provide ready-to-use values to the upper software layer.

It was basically written to monitor signals that vary slowly, such as trimmers, since the returned results are averaged values of 8 successive conversions.

The ‘u16 ADC_Get_10bits(u8 Channel)’ and ‘u8 ADC_Get_8bits(u8 Channel)’ functions

return the ADC result on the selected channel.

The ‘u8 Get_RV1(void)’, ‘u8 Get_RV2(void)’ and ‘u8 Get_RV3(void)’ routines return the

value read on the potentiometers connected to the MCU (RV1, RV2, RV3).

The ‘BOOL Get_Temperature(void)’ returns a boolean. This function returns ‘TRUE’ if the

voltage on the thermal resistor connected to channel AIN0 has reached the threshold level or

if the voltage has not yet reached back the threshold level minus the hysteresis value after an

overheat detection.

In order to set the temperature and hysteresis threshold, the ‘NTC_THRESHOLD’ and

‘NTC_HYSTERIS’ values can be adjusted in the adc.c file.

45/77

Page 46

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

The ‘BOOL Get_HVBus(void)’ returns a boolean. This function returns ‘TRUE’ if the voltage

of the HVBUS connected to channel AIN1 has reached the threshold level or if the voltage has

not yet returned to the threshold level minus the hysteresis value after an over-voltage detection.

In order to set the voltage and hysteresis threshold, the ‘HVBUS_THRESHOLD’ and

‘HVBUS_HYSTERIS’ values can be adjusted in the adc.c file.

4.3.3 it_ST7MC.c

This module contains all non-MTC related interrupt service routines. In the stand alone

firmware, the timer B resource is the only one to be used. The output compare capability is

used in order to decrease 2 different time bases, 10ms and 1ms (see ‘Timer.c’ file for the timer

B registers configuration).

Basically, unless equal to 0, variables are decreased by one each timer B output compare interrupt event (every 10ms or 1ms for output compare 1 and 2 respectively). Therefore, a variable ‘VAR’ is loaded with ‘50’ in the main code and decreased by one every 10 ms, and will

reach ‘0’ after 500ms (490 to 500 ms if the initialization of ‘VAR’ is done outside of the interrupt

routine).

Figure 26. Time base Principle: Timer B output compare 1 interrupt every 10ms

Main routine:

VAR = 50 VAR = 49 VAR = 48

int

10 ms

int

int

int

int

Clear Status flag, refresh timer B output compare registers,

and update variables used for timing purpose

VAR = 47

For more information regarding the configuration of this peripheral, please refer to the data

sheet of the MCU, ‘16-bit timer’ section.

46/77

Page 47

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

4.3.4 ports.c

The purpose of the ports.c module is to centralize all information regarding the I/O ports (including the alternate functions) within the same file.

It is intended to clarify the sharing of I/Os between the peripherals and the functions requiring

standard input/outputs, such as LEDs and push button reading.

I/Os are initialized at the beginning of the main program, using the ‘void PORTS_Init(void)’

function. Two functions are handled by this module, needed when running the software library

with the ST7MC starter kit hardware.

4.3.4.1 Push button reading

The function ‘BOOL key_scan(void)’ returns a boolean, TRUE if the push button (connected

to PC0) has been pushed during a minimum duration. This duration can be programmed in

ms, to debounce the button reading. This timing is verified using ‘it_ST7MC.c’ module resources, in ‘void TIMB_Interrupt(void)’ interrupt routine.

The location of the push button (port and bit location) must be specified at the beginning of the

ports.c file. The push button must be connected between ground and a pull-up resistor to get

a low level on the input pin when it is pushed (refer to ST7MC starter kit schematics for details).

4.3.4.2 LEDs

A set of functions can be called to switch ON, OFF or toggle the two LEDs present on the

starter kit: PORTS_RedLedOn, PORTS_RedLedOff, PORTS_RedLedToggle, etc. It must

be remembered that these two LEDs are powered using a single I/O (see schematics for details). Consequently:

– they cannot be turned ON simultaneously

– the I/O port state can be configured either as an output or as a floating input to switch OFF

the LEDs.

4.3.5 spi.c

This module contains the code related to the SPI peripheral. The initialization of this peripheral

is made within the ‘void SPI_Init(void)’ function. Care should be taken when configuring the

SPI interface in accordance with the system (particularly operating frequency and polarity).

Communication with a serial EEPROM can be done using the ‘Send_EEPROM(u8 address,

u8 data)’ and ‘Read_EEPROM(u8 address)’ routines.

47/77

Page 48

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

4.3.6 LinSCI.c

This module contains the code related to the LINSCI serial communication interface and gives

an example of configuration and usage (with the ‘void SCI_Config(void)’ and ‘void

SCI_Send_Data(u8 data)’ routines) and the ‘TTY_7.exe’ executable file. You can find the executable in the ‘SCI’ folder of the stand alone firmware. Working TTY Settings with the stand

alone firmware are as follow:

- Baud Rate 38.4K, Data Bits 8, Parity none, Stop Bits 1, RTS/CTS enable, other options disabled.

When running the code in:

- Closed loop : the MCU feeds back respectively the rising, falling Bemf delay coefficients, integral, proportional coefficients, motor frequency (LSB then MSB), then ‘0’ (decimal values).

- Open loop : the MCU feeds back respectively the rising, falling Bemf delay coefficients, the

motor frequency (LSB then MSB), then ‘0’, ‘0’, ‘0’ (decimal values).

Those settings can be changed in the ‘main.c’ file, by modifying the values entered in the

‘Lin_Tx_Buffer[0...7]’.

Figure 27. Running TTY_7.exe on a PC (open loop firmware)

48/77

Page 49

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

5 HOW TO DEFINE AND ADD A MODULE (STVD7 2.5.X)

This chapter describes how to define and declare a new module within the library. The example is based on the addition of 2 files: ‘my_file.c’ and the corresponding header file

‘my_file.h’. Users of STVD7 3.x can refer to Section 2.3.

The first step is the creation of two new files. You can either copy and paste existing files and

rename them, or click on the ‘new files’ icon and save it in the right format (*.c or *.h extension).

The new files containing the user code will generate a new ‘my_file.o’ object file that has to be

declared in the toolchain configuration files.

5.1 COSMIC TOOLCHAIN

For COSMIC users, modifications have to be done in BLDC_Cosmic.lkf and

BLDC_Cosmic.mak files.

In BLDC_COSMIC.lkf, the new object file has to be added to the main object file list (see

Figure 28). However, if special options are required (for example, no optimization, or the

forced placement of variables in memory), then it has to be declared in another section (e.g.

after the main list) with the correct settings. See your C toolchain documentation for further details.

Figure 28. BLDC_COSMIC.lkf

# OBJECT FILES

..\..\object\cosmic\main.o

..\..\object\cosmic\LinSCI.o

.....

..\..\object\cosmic\my_file.o

In BLDC_Cosmic.mak, ‘my_file.c’ has to be added in the C source file list (see Figure 29) and

the list of dependencies has to be updated accordingly (see Figure 30).

Figure 29. BLDC_Cosmic.mak, C source list

C_SRC = main.c \

mtc.c \

vector.c \

opamp.c \

.....

my_file.c \

49/77

Page 50

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 30. BLDC_Cosmic.mak, dependencies

# RULES FOR MAKING THE OBJECT FILES:

main.o: main.c version.h lib.h RAM_Sensorless.h

$(CC) ..\..\source\main.c

.....

my_file.o: my_file.c my_file.h

$(CC) ..\..\source\my_file.c

5.2 METROWERKS TOOLCHAIN

For METROWERKS users, modifications have to be done in BLDC_Metrowerks.prm and

BLDC_Metrowerks.mak files; in BLDC_Metrowerks.prm the new object file has to be added

in the ‘Project module list’ section (see Figure 31). In BLDC_Metrowerks.mak, the new source

file and the corresponding dependencies have to be set in the ‘Application Files’ section (see

Figure 32).

Figure 31. BLDC_Metrowerks.prm

/*** PROJECT MODULE LIST ***/

NAMES

main.o

ST7MC_hr.o+

mtc_hr.o+

....

my_file.o

ansi.lib

END

Figure 32. BLDC_Metrowerks.mak

# --------------------------- APPLICATION FILES ------------------------------main.o : $(ENV) main.c version.h lib.h RAM_Sensorless.h

$(CC) main.c

ST7MC_hr.o : $(ENV) ST7MC_hr.c ST7MC_hr.h mtc_hr.h version.h lib.h

$(CC) ST7MC_hr.c

.....

my_file.o : $(ENV) my_file.c my_file.h

$(CC) my_file.c

50/77

Page 51

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

6 CODE EXAMPLE

This section gives a very simple code example. Once an action on the start button is detected,

the motor starts and runs in open loop voltage sensorless mode with a duty cycle of 25%; once

an action on the stop button is detected, an active brake procedure is engaged for 2 seconds

with a duty cycle of 17%, then the power stage is switched off.

Warning: This code example assumes that correct settings have been entered

for the alignment phase and ramp data. Modifications may be done

using the Graphical User Interface provided with the demokit (by

clicking on the ‘generate *.h files’ icon).

51/77

Page 52

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

Figure 33. Code example

While(1) // main loop

// if (Chk_Timer_WDG_Elapsed() == TRUE)WWD_Refresh();

Chk_Power_Motor_Status();

{

if ((u8)(GetMotorStatus() & FAULT_MSK) != 0) State = FAULT; // START_UP_FAILED

switch (State)

// overvoltage, overtemperature

if (GetMotorStatus() & AUTO_SWITCH)

{

}

Chk_Motor_Stalled();

if (timer_10ms == 0) PORTS_GreenLedOn();

break;

{

case IDLE:

if (timer_10ms == 0) PORTS_RedLedOn(); // red LED back to normal after

if (key_scan() == TRUE) State = START;

break;

case START:

if (MTC_StartMotor() == TRUE) State = RUN;

break;

case RUN:

if (ValBit(Flag_MTC,SAMP_EVT)) // update PWM?

{

Falling_bemf = (u8)(Get_RV3()); // read RV3 & set falling

Rising_bemf = (u8)(Get_RV2()); // read RV2 & set rising Bemf

Set_Duty((u16)(PWM_FREQUENCY*25/100)); // 25% duty cycle

}

if (key_scan() == TRUE) State = BRAKE;

// or MOTOR_STALLED

// or HARD_FAILURE

// or EMERGENCY_STOP?

detection

// Bemf coefficient accordingly

// coefficient accordingly

if (active_brake((PWM_FREQUENCY*17/100),2000) == TRUE) State = STOP;

MTC_StopMotor();

PORTS_RedLedOn();

PORTS_RedLedOn();

}

52/77

case BRAKE:

// Brake_Duty = 17%

break;

case STOP:

State = IDLE;

break;

case FAULT:

default:

MTC_StopMotor();

if ((u8)(GetMotorStatus() & FAULT_MSK) == 0) State = IDLE;

break;

}

Page 53

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

7 PMDC (PMAC) MOTOR CONSIDERATIONS

7.1 PHYSICAL CONSIDERATIONS

7.1.1 Checking the number of pair poles of the motor

In most cases, there is an easy way to check how many pair poles are present with the motor

you are working with. This applies only to motors from which you can observe any mechanical

effect (by looking at the axis for example).

The trapezoidal driving method is based on 6 steps, and each step involves a particular low /

high side driver configuration. 1 electrical cycle is then accomplished within 6 steps. The

number of pair poles gives the link between electrical frequency and mechanical frequency:

mechanical frequency (hertz) = electrical frequency (hertz) / number of pair poles

Thus, by switching from one step to another at a very low frequency (e.g. 1Hz) and simply by

controlling the mechanical effect by sight, we can determine the number of pole pairs by

counting the number of steps within 1 mechanical cycle. It is given by:

number of pole pairs = total number of steps / 6

Example: assuming that 24 steps are needed to describe 1 mechanical cycle (e.g. 360 degrees on the axis of the motor), then the number of pole pairs is 24/6 = 4.

The software package includes a workspace containing a firmware example in order to drive

the motor step by step at a frequency of 1Hz. You can open it in the ‘Pair poles chk’ folder

and open the dedicated workspace to your toolchain. This folder contains also a s19 file (in

‘S19 file for EEPROMER’) so that you can program a MCU directly and avoid the use of an

emulator. RV1 potentiometer is used to set the PWM duty cycle. The Start/Stop push button

launches/stops the procedure.

Warning: Operations are made in voltage mode with a PWM frequency of 10Khz

and duty cycle is set via RV1 potentiometer. Make sure that the duty

cycle is not too high as the winding currents can increase very quickly

in this particular mode of operation.

53/77

Page 54

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

7.1.2 Connecting the sensor outputs to the board

Two configurations are commonly used: sensor 60 / sensor 120 degrees.

The easiest and most time-efficient solution is to connect the motor cables into the demokit by

trying all the connection style combinations.

First you need to check which sensor distribution is used by connecting the sensor outputs to

a scope and running the motor smoothly (by hand, for example). The consecutive events (in

the time domain) have to be monitored (with a scope/multimeter): 3 successive rising/falling

edges means a sensor 60 configuration, while an alternate rising/falling edge means a sensor

120 configuration.

Now that the sensor distribution is known, you have to randomly connect the sensor outputs to

the demokit (select the right sensor configuration in the GUI). As there are 3 phases (let’s say

P1,P2 and P3), that simply means we have 6 possibilities of connection: P1P2P3, P1P3P2,

P2P1P3, P2P3P1, P3P1P2 and P3P2P1.

For each connection, you may try to start the motor (with the GUI for example) and find out

which 1 of the 6 cable connections is able to run the motor properly. If none of them is able to

do so (wrong motor direction), then 2 sensor cables have to be swapped and the same procedure repeated.

Warning: Make sure that the duty cycle is not set too high as the winding currents

can increase very quickly, especially if the motor is stalled.

54/77

Page 55

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

7.2 CONTROL STRATEGY CONSIDERATIONS

7.2.1 Voltage versus current mode

The motor control peripheral of the ST7MC allows voltage and current control modes. Both

modes set the PWM duty cycle according to:

- Voltage mode: the values of the MCPUH/L registers allow direct configuration of the duty

cycle in accordance to the maximum allowed current thanks to the comparator cell (see Figure

34).

- Current mode: the current threshold that will turn the PWM into off-state (see Figure 35).

Figure 34. PWM duty cycle behaviour in voltage mode

MTC peripheral

PWM

ST7MC

Microcontroller

Max current

reference

channel U

Max current

HV

set

-

R

+

T1

reference

I

A

Channel V

100nF

MTC peripheral

PWM

33K

W12

MCCREF

Pot 1

OAZ/MCCFI1

Vdd

T4

OPAMP

Motor

Voltage

Figure 35. PWM duty cycle behaviour in current mode

ST7MC

Microcontroller

current

reference

Channel V

MTC peripheral

PWM

33K

clock

PWM freq.

MCCREF

100nF

-

+

OAZ/MCCFI1

OPAMP

Set

R

HV

T1

A

T4

current

reference

clock

Motor

Voltage

step time

T1-T4

I

step time step time

T1-T4

t

t

step time

T1-T6

t

t

t

T1-T6

55/77

Page 56

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

M

Basically, the current sense circuit acts as a PWM duty cycle manager in current mode while

it acts as a maximum current limiter in voltage mode. The current loop allows a fine control of

the torque by imposing the current in the windings.

Voltage mode can be used when there is a high torque variation.

7.2.2 Choosing a demagnetization type (Sensorless mode only)

There are 3 methods in sensorless mode to detect the end of demagnetization: software,

hardware with software backup and hardware demagnetization (no demagnetization event in

sensor mode).

A. Hardware

Detection of the end of demagnetization is entirely done by hardware and no safety precaution

is taken in order to manage a wrong event detection. Hardware demagnetization can be

chosen for system running at low speed. Generally, this method doesn’t have any advantage

compared to the ‘Hardware with software backup’, and therefore shouldn’t be used.

B. Hardware with software backup

This method gives the advantage of an hardware detection combined with a software demagnetization used as a backup method when the system fails to detect the end of a demagnetization event. This allows the most accurate demagnetization time to be achieved and therefore permits the window timing to be opened for the Bemf detection as early as possible.

If there is a problem with the end of demagnetization event detection (which could occur on a

falling Bemf event detection while running at high speed), then a software demagnetization

occurs after a pre-programmed amount of time.

In the stand-alone library, the time is set to 125% of the last hardware demagnetization time

(see ‘mtc.c’ file, ‘MTC_C_D_IT’ routine).

Figure 36. Software backup demagnetization time update routine

{

if (MotorStatus == AUTO_SWITCH) temp_D = (u8)(MDREG - MCOMP); // Demag.time = MDREG - MCO

else temp_D = MDREG; // synchronous mode

SoftDemagTime = (temp_D >> 2); // div/4

SoftDemagTime += temp_D; // next MDREG value = 1.25*(hard demag.time)

RP_counter=0;//reset counter of RP event coming between Dhard and next C

ClrBit(Flag_it,RM_EVT);

}

56/77

Page 57

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

C.Software demagnetization

All demagnetization events are simulated and the end of the demagnetization occurs after a

pre-programmed amount of time (see ‘MTC_Settings_Sensorless.h’ file, ‘Setting of demagnetization time in running mode’ section). The demagnetization time is an arbitrary value that

has to adjusted according to the motor specifications; it has to be kept in mind that very inductive motors will require longer demagnetization time, and therefore will require longer step

times. This solution might be preferred when the ‘Hardware with software backup’ demagnetization solution can’t provide reliable motor operation.

7.2.3 The 4 Z event sampling methods (Sensorless)

Below is the description of the 4 sampling types that can be used for Z event detection while

running motors in sensorless mode (for further information on these methods, refer to the application note AN1946).

Figure 37. Z event sampling methods as shown in the GUI

7.2.3.1 At the end of the PWM low state

This is the ST patented method; it provides very good sensitivity on the full speed range,

without the usage of any external components. This solution requires an OFF time during

each PWM period in order to detect the zero-crossing event (PWM low state). Samples are

taken after a time window configured with ZWF[3:0] bits in MZFR register. Therefore the dutycycle can’t be set to its maximum. The maximum duty cycle will depend of the minimum PWM

off time needed by the system in order to detect the Z event.

Figure 38. Sampling during OFF time, at PWM frequency

sample

Current

sample

New

PWM signal

T

Sampling

PWM OFF

time

ZWF[3:0]

ZWF[3:0]

57/77

Page 58

ST7MC THREE-PHASE BLDC MOTOR CONTROL SOFTWARE LIBRARY

7.2.3.2 At PWM On, with delay once

This method requires additional external components (resistor dividers, with/without RC filtering). Samples are taken once, each PWM ON time, after a delay programmed by DS[3:0]

bits in MCONF register. Duty cycle variation induces jitter on the sampling clock; if the system

f

stability is affected, sampling should then be done at

frequency (see next section). True

SCF

100% duty cycle can be set.

Figure 39. Sampling during ON time, at PWM frequency

T

Sampling

PWM signal

7.2.3.3 At PWM On, with delay, at

DS[3:0]

PWM OFF

time

f

frequency

SCF

DS[3:0]

Current

sample

New

sample

This method requires additional external components (resistor dividers, with/without RC fil-

f