Page 1

AN1904

Application note

ST7MC three-phase AC induction motor control

software library

Introduction

This Application Note describes a 3-phase induction motor control software library

developed for the ST7MC. This 8-bit microcontroller contains a peripheral dedicated to 3phase brushless motor control, making it suitable for AC induction motors and permanent

magnet DC/AC motors (PMDC/PMAC also called BLDC).

The library described here is made of several C modules that contain a set of convenient

functions for the scalar control of AC induction motors and is compatible with COSMIC

(www.cosmic-software.com) and METROWERKS (www.metrowerks.com) compilers. The

control of a Permanent magnet motor in Six-step mode is detailed in application note

AN1905. The control of a PMAC motor in Sine wave mode with sensors is detailed in

application note AN1947.

This software allows users to quickly evaluate both the MCU and the available tools, and to

have a motor running in a very short time when used together with the ST7MC starter kit

(ST7MC-KIT/BLDC) and the demonstration AC motor (ST7MC-MOT/IND). It also eliminates

the need for time consuming development of sine wave generation and speed regulation

algorithms by providing ready-to-use functions that let the user concentrate on his

application layer.

The prerequisite for using this library is the basic knowledge of C programming, AC motor

drives and power inverter hardware. In-depth know-how of ST7MC functions is only required

for customizing existing modules and when adding new ones (grey modules in Figure 1) for

a complete application development.

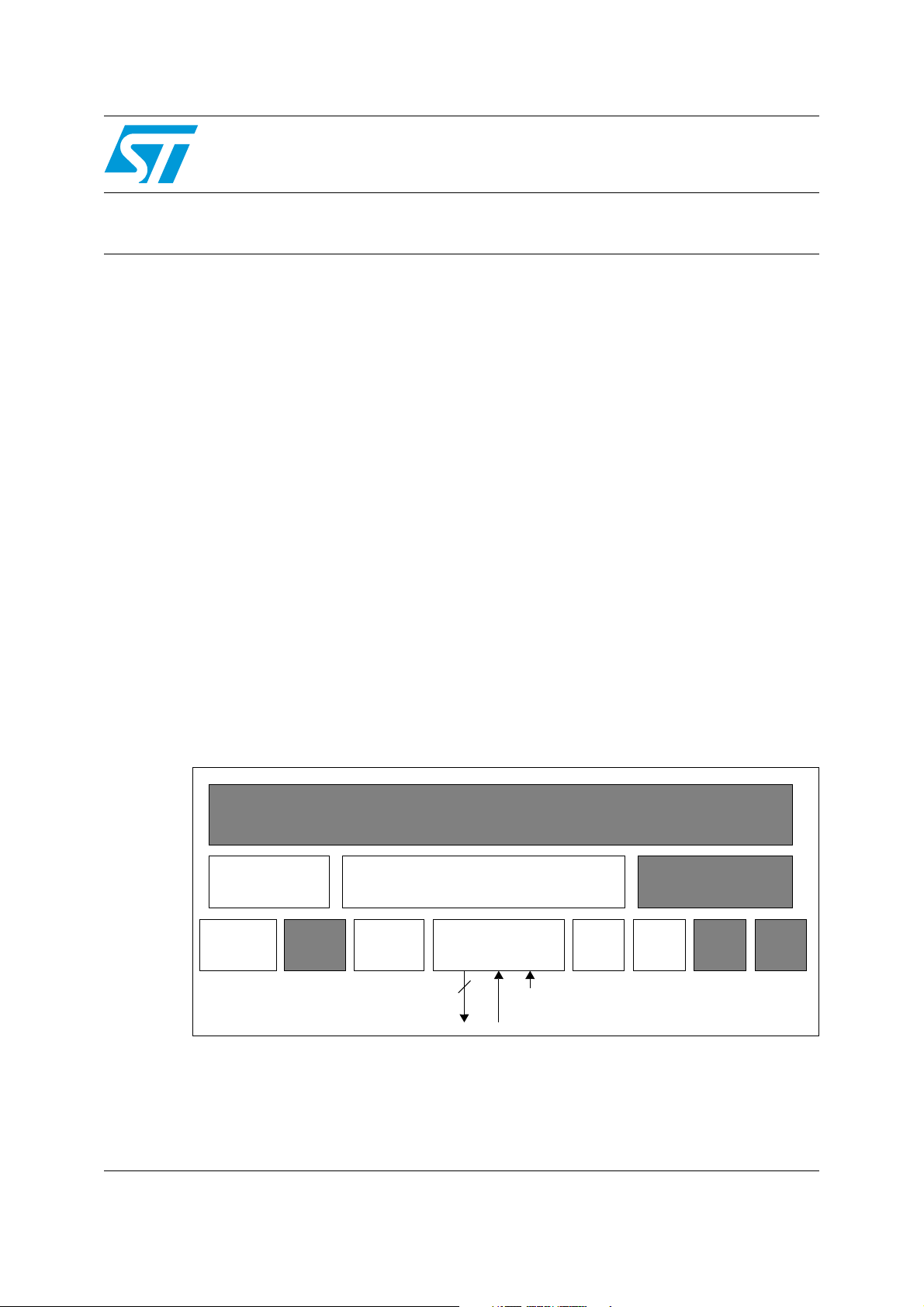

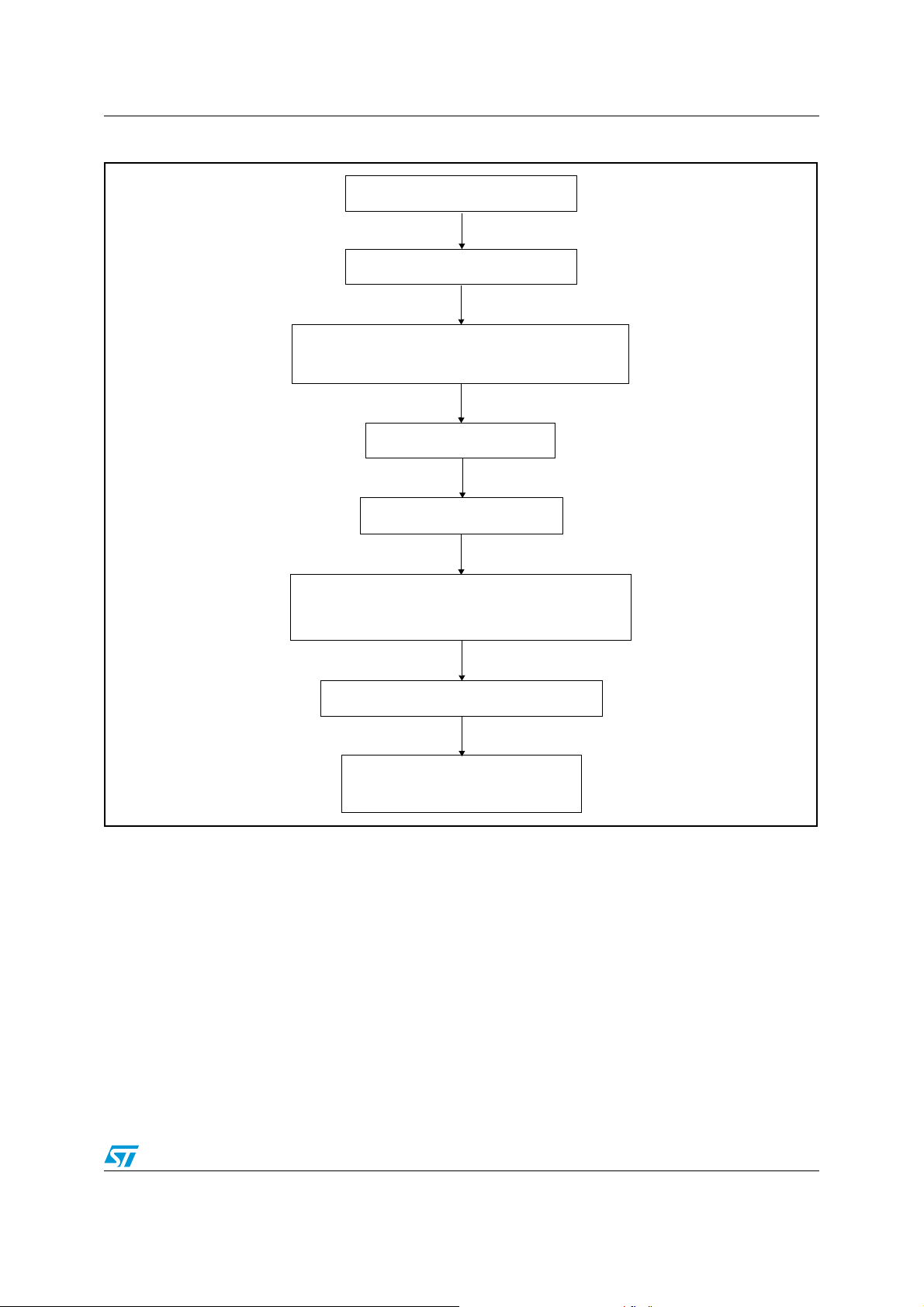

Figure 1. Overall software architecture

APPLICATION LAYER

SLIP

REGULATION

PWMART PORTS

WWDG

3-PHASE SINE WAVE GENERATION

MCO[0..5]

PWM outputs

AC MOTOR DRIVE

MTC SPI

Speed feedback

ADC

Emergency Stop input

COMMUNICATION

PROTOCOL

SCI

16-bit

Timer

July 2007 Rev 3 1/102

www.st.com

Page 2

Contents AN1904

Contents

1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Working environment set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Development tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Integrated Development Environments (IDE) . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Emulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3 Programmers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.4 Starter kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Library source code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.2 File structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.1 lib.h file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.2 Sine wave look-up table spreadsheet . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.3 HyperTerminal file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Technical literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Getting started with the library using the ST7MC-KIT/BLDC . . . . . . . 10

3.1 Running the motor with the ST7MC control panel . . . . . . . . . . . . . . . . . . 10

3.2 Library configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Customizing the files for your ST7MC derivative . . . . . . . . . . . . . . . . . . . 13

3.3.1 Memory mapping with COSMIC toolchain . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.2 Memory mapping with METROWERKS toolchain . . . . . . . . . . . . . . . . . 14

3.3.3 Hardware registers description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 How to define and add a C module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.1 Using STVD7 release 2.5.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.2 Using STVD7 release 3.x.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Library functions per software module . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Function description conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Sine wave generation and speed feedback (MTC) . . . . . . . . . . . . . . . . . . 18

4.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.2 List of available functions and interrupt service routines . . . . . . . . . . . . 19

2/102

Page 3

AN1904 Contents

4.2.3 Detailed explanations and customization of MTCparam.h . . . . . . . . . . . 38

4.3 Induction motor scalar control (ACMOTOR) . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.2 List of available functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.3 Detailed explanations and customization of ACMparam.h . . . . . . . . . . 58

4.4 Analog to digital converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.4.1 Module description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.4.2 Synopsis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.4.3 Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.4.4 Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.4.5 Customizing the ADC module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.5 I/O ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.5.1 Push button reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.5.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.6 PWM auto reload timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.6.1 Software timebases working principle . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.6.2 Timebase use for the AC motor control library and demo program . . . . 75

4.7 Serial communication interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.7.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.7.2 Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.7.3 Changes vs ST7 library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.7.4 Customization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.7.5 Important notice for hardware implementation . . . . . . . . . . . . . . . . . . . 78

4.8 Nested interrupt controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5 Running the demo programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.1 Open loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.2 Closed loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.3 Using the serial communication interface . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.4 Mainparam.h file description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.4.1 Start-up parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.4.2 Brake parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.4.3 Closed-loop slip control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6 Designing your application with the library . . . . . . . . . . . . . . . . . . . . . 85

6.1 Library maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3/102

Page 4

Contents AN1904

6.2 Incremental system build . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.2.1 Preliminary notice on debugging tools . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.2.2 Build step1: open loop, low voltage, no motor connected . . . . . . . . . . . 87

6.2.3 Build step2: open loop, rated voltage/power, motor connected . . . . . . . 88

6.2.4 Build step3: open loop, rated power, motor connected with speed

feedback 88

6.2.5 Build step4: closed loop operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.3 Motor control related CPU load in the application . . . . . . . . . . . . . . . . . . 89

6.3.1 Estimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.3.2 Adjustment guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix A Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

A.1 Flowcharts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

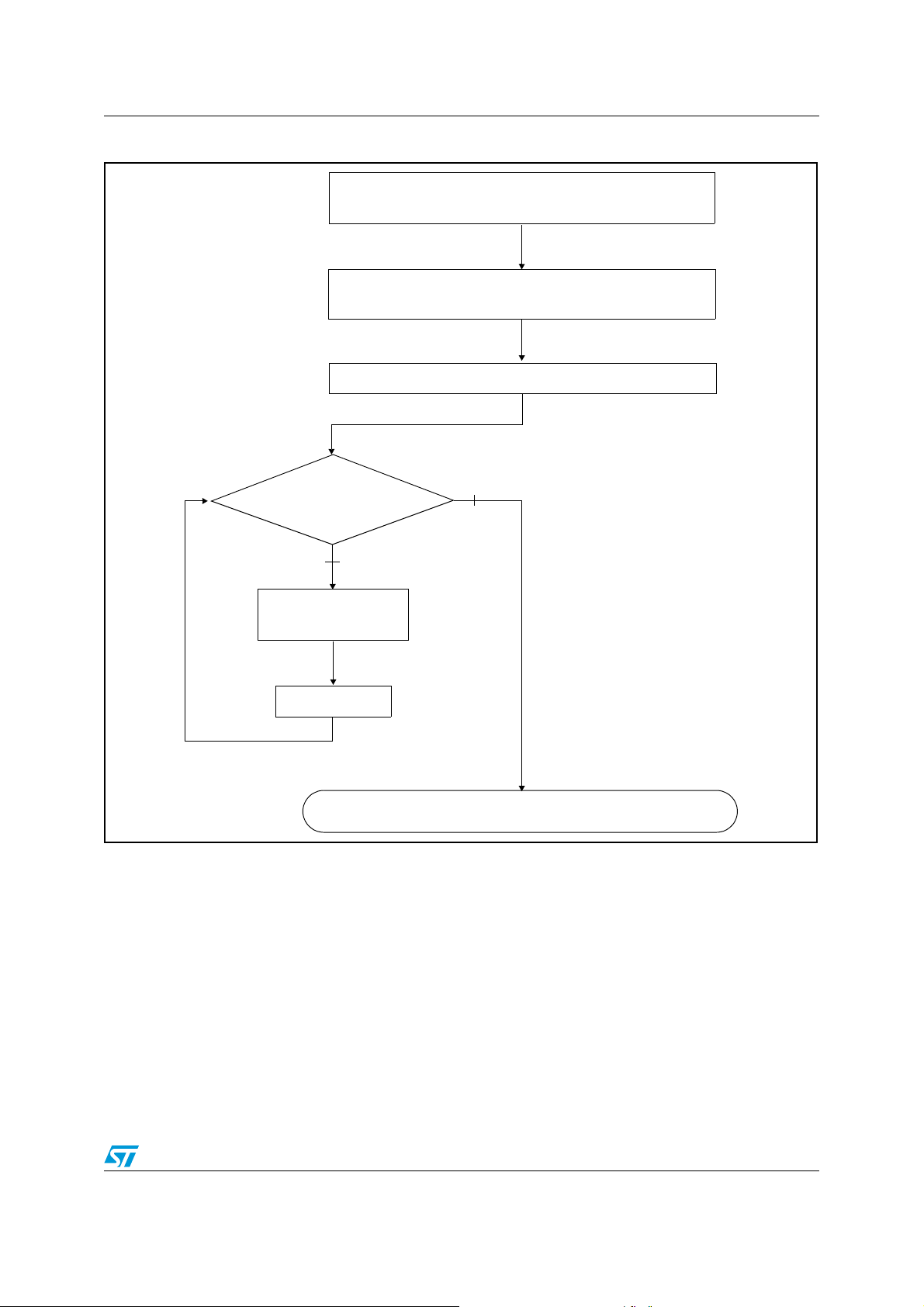

A.1.1 MTC_U_CL_SO_IT interrupt routine . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

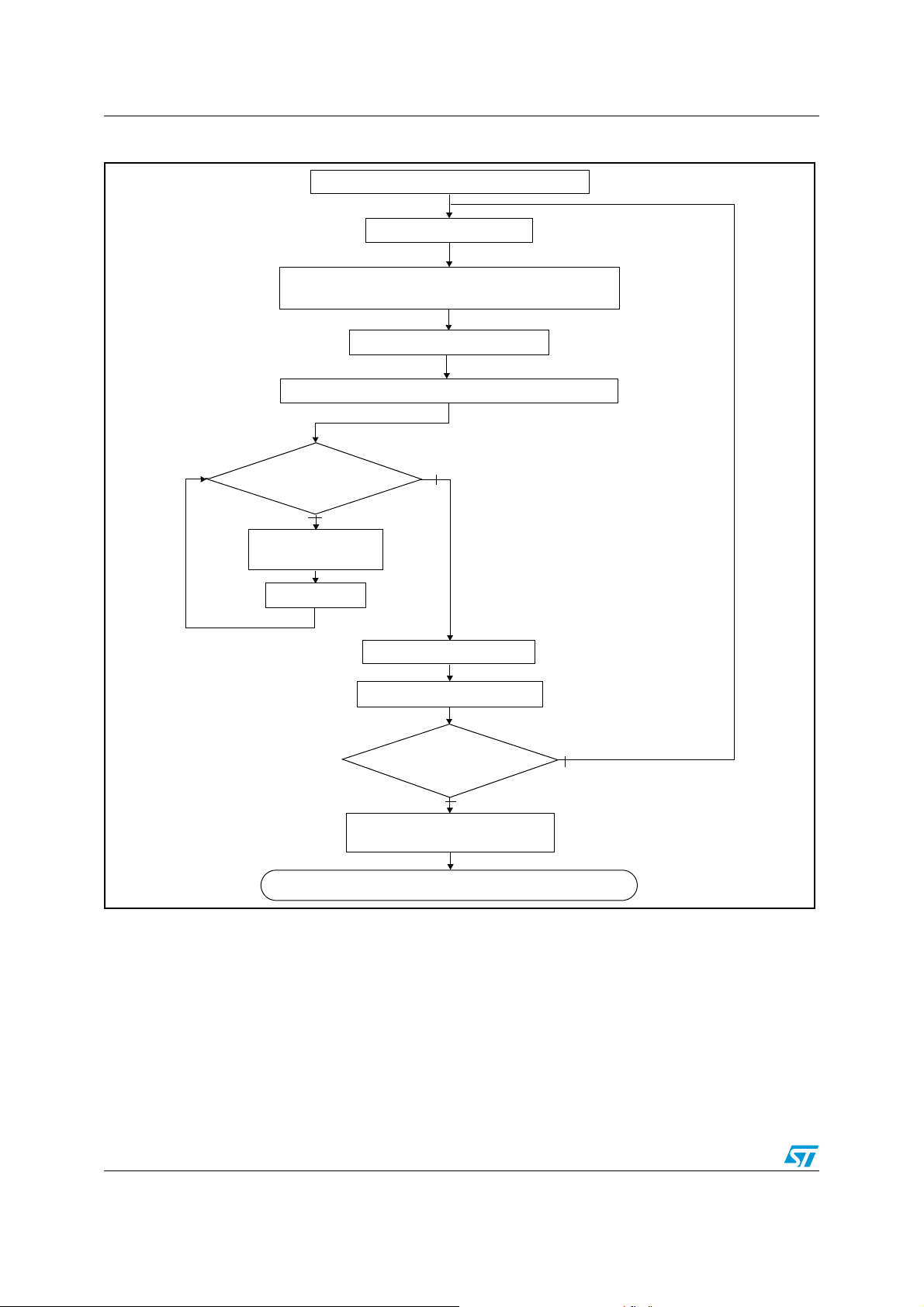

A.1.2 MTC_C_D_IT interrupt routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A.1.3 MTC_GetRotorFreq function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

A.1.4 GetLastTachoPeriod function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

A.1.5 GetAvrgTachoPeriod function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

A.1.6 MTC_StartBraking function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

A.1.7 MTC_Brake function state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

A.1.8 MTC_StopBraking function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

A.1.9 ACM_InitSoftStart function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

A.1.10 ACM_SoftStart function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

A.1.11 Open Loop motor control demo program . . . . . . . . . . . . . . . . . . . . . . . . 99

A.2 Selni motor characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4/102

Page 5

AN1904 Features

1 Features

ST7MC Library Version 1.0.1 Overview (CPU running at 8 MHz):

● Stator Frequency Range: From 0.2 Hz up to 680.0 Hz (see Section on page 44) with

resolution depending on PWM frequency (typically ~0.1Hz)

● Voltage Resolution: 8-bit modulation index

● 9 to 10-bit PWM generation for sine wave (typical resolution in inaudible PWM range)

● PWM Frequency: can be set by default to 1.95, 3.9, 7.8, 12.5 and 15.66 kHz, with

centred pattern PWM generation

● Brake capabilities (DC current injection)

● Speed reversal

● Tacho generator Speed acquisition

● Speed regulation and control routines for speed profile management

● CPU Load (sine wave generation only) around 20%, adjustable (see Section ). Total

CPU load (including closed loop control) is typically around 30% for a standard

application (see Section 6.3)

● Free C source code and spreadsheet for look-up tables

The 12.5 kHz switching frequency is proposed by default, providing a PWM resolution close

to 10-bit with a 16-MHz CPU clock. In addition, this frequency is a good compromise

between the reduction of switching losses and acoustic noise (rejected in the inaudible

range due to centred mode PWM patterns).

Note: These figures are for information only; this software library may be subject to changes

depending on the use of the final application and peripheral resources. It must be noted that

it was built using robustness-oriented structures, therefore preventing the speed or code

size from being fully optimized.

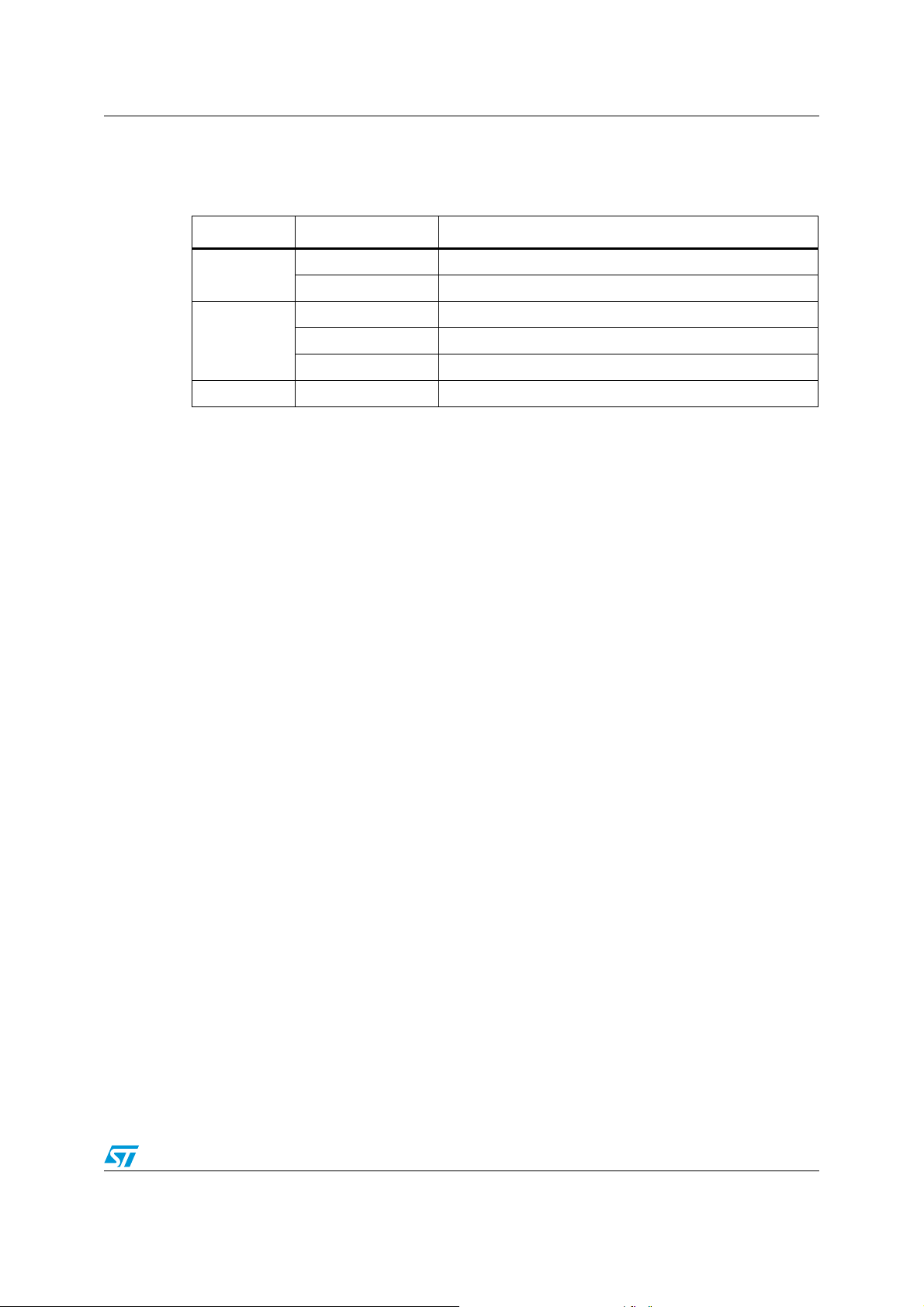

Ta bl e 1 below summarizes the memory required by the software library, as it is delivered.

These metrics include non motor control related code, implemented for demo purposes

(such as ADC management, software timebases, etc.). These must therefore be considered

only as indicative figures, which will be lower in the final application.

Table 1. Memory size metrics

ROM (bytes) RAM (bytes)

Cosmic 5.2b Metrowerks 1.1 Cosmic 5.2b Metrowerks 1.1

Closed Loop 4943 5729 136 161

Open loop 3840 4361 108 130

5/102

Page 6

Working environment set-up AN1904

2 Working environment set-up

This section presents the available material that is needed to start working with the ST7MC

and the library discussed in this document.

2.1 Development tools

2.1.1 Integrated Development Environments (IDE)

This library has been compiled using Cosmic & Metrowerks C compilers, launched with

STVD7 release 2.5.4 (ST Visual Debugger) and STVD7 release 3.x.x.

A complete software package consists of:

● An IDE interface: ST’s proprietary STVD7 (free download available on internet:

www.stmcu.com), or third party IDE (e.g. Softec Microsystems’ STVD7 for InDARTSTX).

● A third party C-compiler: either Cosmic or Metrowerks (if needed, time limited

evaluation versions can be get upon request).

The choice of the C Toolchain is left to the appreciation of the user. Both COSMIC and

METROWERKS are fully supported, and the dedicated workspace (compatible with

‘STVD7’ & ‘STVD7 for Indart’) can be directly opened in the root of the library installation

folder (AC_Metrowerks.wsp, AC_Cosmic.wsp, acmotor.stw).

2.1.2 Emulators

Two types of real-time development tools are available for debugging applications using

ST7MC:

● In-circuit debugger from Softec (sales type: STXF-INDART/USB).

The inDART-STX from Softec Microsystems is both an emulator and a programming

tool. This is achieved using the In-circuit debug module embedded on the MCU. The

real-time features of the Indart include access to the working registers and 2 breakpoint

settings. However trace is not available.

● ST7MDT50-EMU3 emulator

Full-featured emulator: real-time with trace capability, performance analysis, advanced

breakpoints, light logical analyser capabilities, etc. It can also be a programming tool

when used with the delivered ICC ADDON module (select STMC-ICC as hardware

target in STVP7). This ICC-ADDON module allows In-Circuit-Debugging with STVD7.

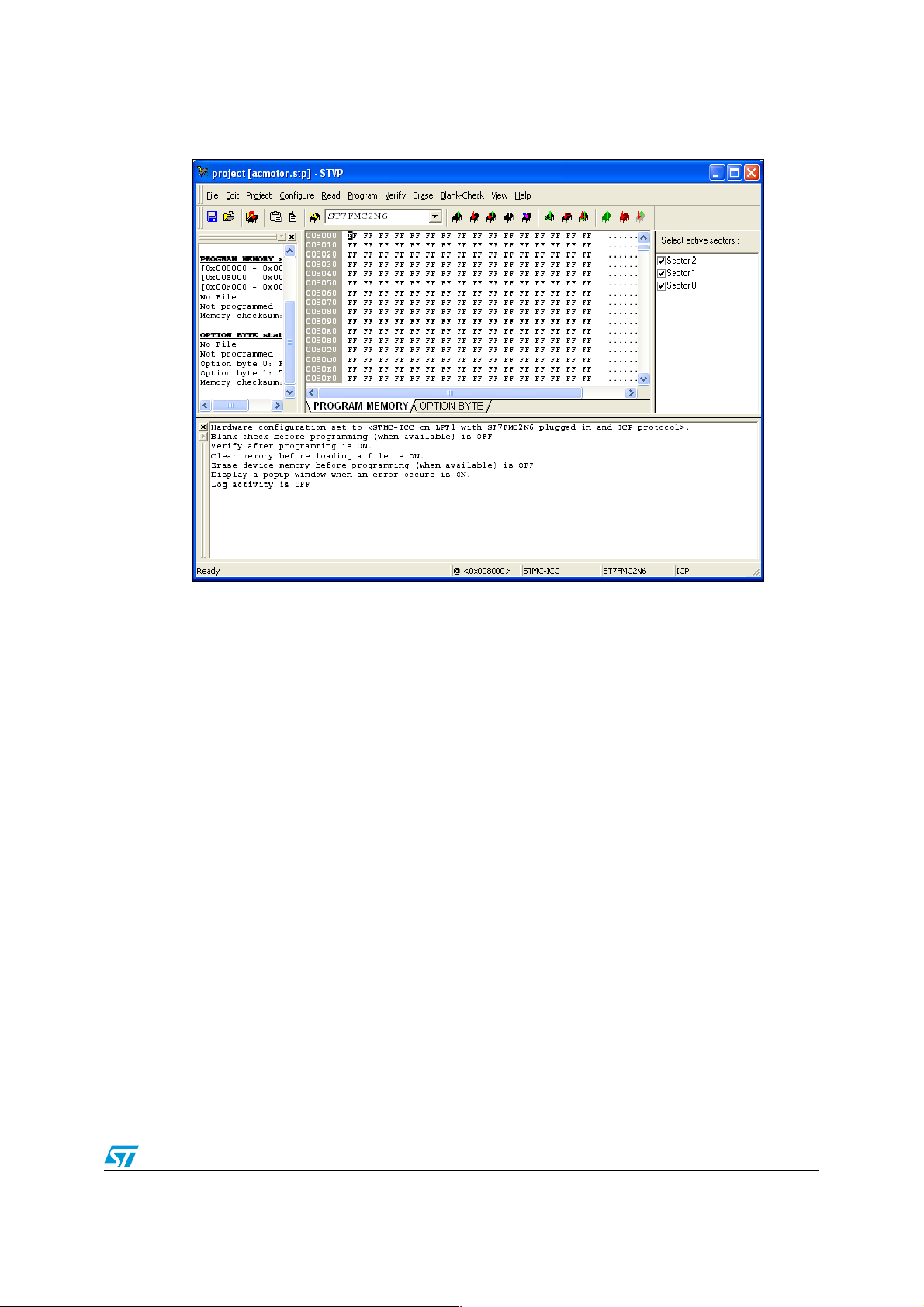

2.1.3 Programmers

In order to program an MCU with the generated S19 file, you should also install the ST

Visual Programmer software (please visit our internet web-site) and use a dedicated

programming interface (stick programmer for example for In-Circuit-Programming). The

Visual Programming tool provides an easy way to erase, program and verify the MCU

content.

Please note that the inDART-STX from Softec Microsystems is also a programming tool

(installation of DataBlaze Programmer software is required).

6/102

Page 7

AN1904 Working environment set-up

Figure 2. STVisual Programmer software (STVP7)

2.1.4 Starter kit

The present software library was fully validated using the main hardware board (a complete

inverter and control board) included in ST7MC-KIT/BLDC starter kit, and the demonstration

AC motor from SELNI (Sales type ST7MC-MOT/IND). See Section A.2 on page 100 for

electrical specifications of this motor. The ST7MC-KIT/BLDC starter kit also includes a lowcost inDART hardware emulator, making this tool an ideal set for starting a project and

evaluating/using the library. Finally, the graphical user interface included in the starter kit

(ST7MC Control Panel) is primarily intended to run motors from a PC for testing and demo

purposes, and is also able to generate library configuration files, with defines corresponding

to your own motor. This makes the first implementation of this library significantly easier.

See Section 4 of this document for details.

Therefore, for rapid implementation and evaluation of the software discussed in this

application note, it is recommended to acquire the ST7MC-KIT/BLDC starter kit and one of

the two compatible C-toolchain (or at least time limited evaluation versions).

2.2 Library source code

2.2.1 Download

The complete source files are available for free on ST website (www.stmcu.com), in the

Technical Literature and Support Files section, as a zip file. This library is also copied by

default on the hard-disk when installing the ST7MC Control Panel from Softec micro

systems, or available on www.softecmicro.com, in the Downloads section, software part

(AK-ST7FMC System Software).

7/102

Page 8

Working environment set-up AN1904

Caution: It is highly recommended to check for the latest releases of the library before starting a new

development, and then verify the release notes from time to time to be aware of new

features that might be of interest for the project. Registration mechanisms are also available

on the web sites of ST and Softec Microsystems to get automatically update information.

2.2.2 File structure

Once the files are unzipped, the following library structure appears, depending on the

toolchain.

● Library release 1.0.0

This release only supports STVD7 2.5.x workspace; this IDE does not provide C

builder capabilities. All build information is provided in makefiles and linker command

files, in dedicated folders: config\Cosmic and config\Metrowerks (see Figure 3). Object

files are also provided in dedicated folders.

Figure 3. Library structure for release 1.0.0

ACmotor \ config

\ object

\ source

● Library release 1.0.1

\ cosmic

\ metrowerks

\ cosmic

\ metrowerks

This library contains the workspace for both the STVD7 2.5.x and STVD7 3.x IDEs.

Two separate sets of folders are provided to differentiate object and configuration files,

with a common set of source files (see Figure 4).

This is to ensure the compatibility with STVD7 for inDART-STX, based on STVD7 2.5.3.

Figure 4. Library structure for release 1.0.1

ACmotor_1.0.1

\ config

\ object

\ Debug

\ Release

\ Source

\ Utilities

\ cosmic

\ metrowerks

\ cosmic

\ metrowerks

For STVD7_3.x

For STVD7_2.5.x

8/102

Page 9

AN1904 Working environment set-up

2.3 Utilities

2.3.1 lib.h file

The purpose of this header file is to provide useful macros and type re-definitions which will

be used throughout the entire library:

● Re-definition of data types using the following convention: a first letter indicating if a

variable is signed (s) or unsigned (u), plus a number indicating the number of available

bits (for instance: u8, s16, etc.),

● Defines for assembly mnemonics used in C source code: Nop(), Trap(),...

● Common macros used for bit-level access (SetBit, ClrBit,...), to get the dimension of an

array (DIM[x]), etc.

2.3.2 Sine wave look-up table spreadsheet

A sine3.xls Excel file is provided with the library, in the \utilities folder. It contains the data

and calculations necessary to re-generate the sine wave reference look-up table. This lookup table includes 3rd harmonics and is therefore not suitable as it is for bi-phase motor

control. PWM frequency set-up on page 39.

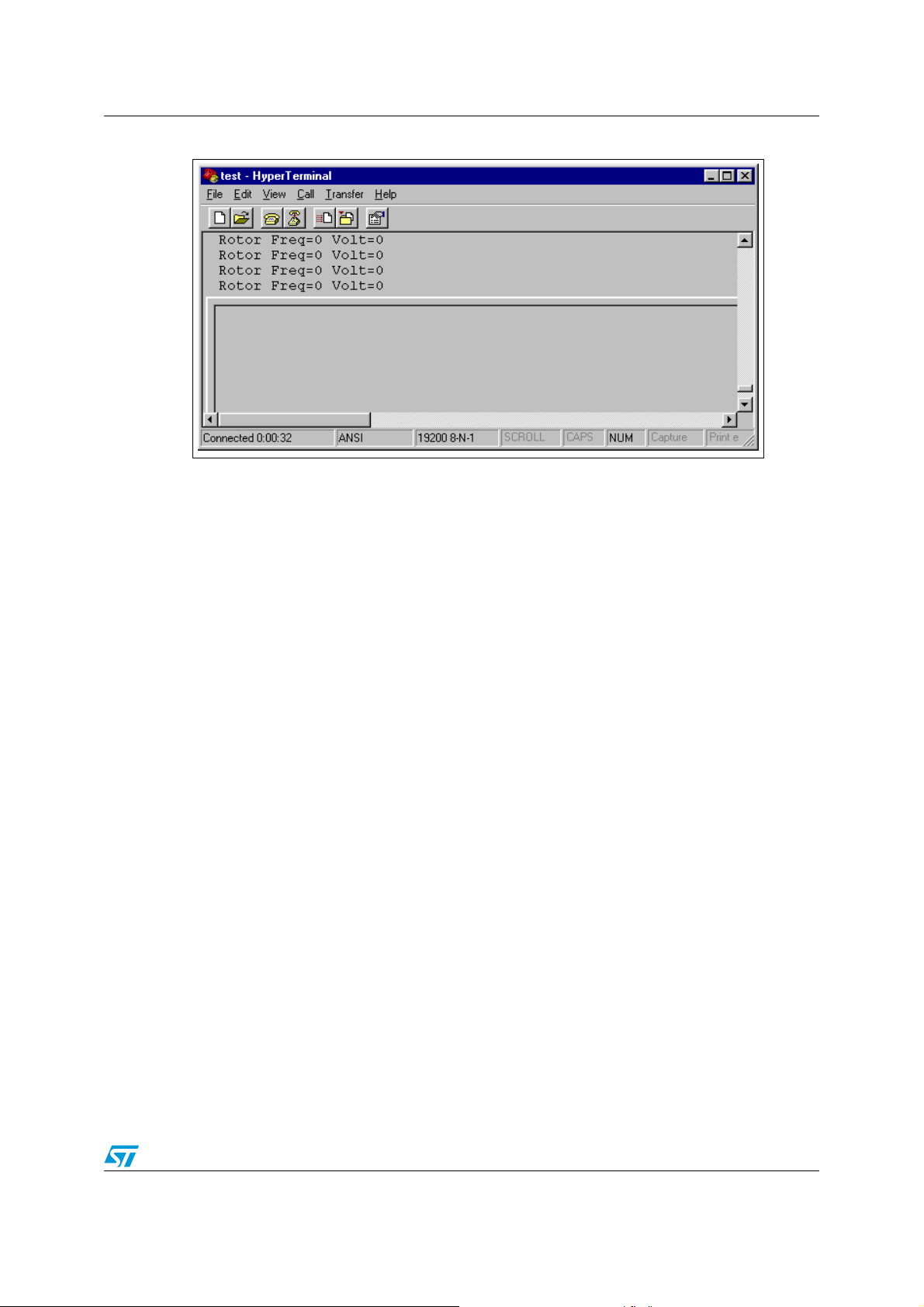

2.3.3 HyperTerminal file

An AC Library.ht file is also provided in the \utilities folder to set-up the HyperTerminal

software when the RS232 communication is enabled. Serial communication interface on

page 76.

2.4 Technical literature

More information can be found on the ST website (www.st.com).

9/102

Page 10

Getting started with the library using the ST7MC-KIT/BLDC AN1904

3 Getting started with the library using the ST7MC-

KIT/BLDC

There a two ways to get started with this software library.

■ The first method is to edit (with your motor specific features) and compile the modules

described in Section 4 of this application note. Then program ST7MC and run your motor

using the ST7MC-KIT/BLDC Starter-kit hardware or your own design.

■ The second method is to use the ST7MC-KIT/BLDC Starter-kit and follow this process:

– run and fine tune motor parameters with the ST7MC Control Panel,

– generate *.h files and select/save manually key parameters,

– edit some of the .h files with run-time parameters collected with the GUI (see

Section 4.2.3 and Section 4.3.3 for details),

– compile, link and program the ST7MC,

– run the motor.

This second method is highly recommended and is described below.

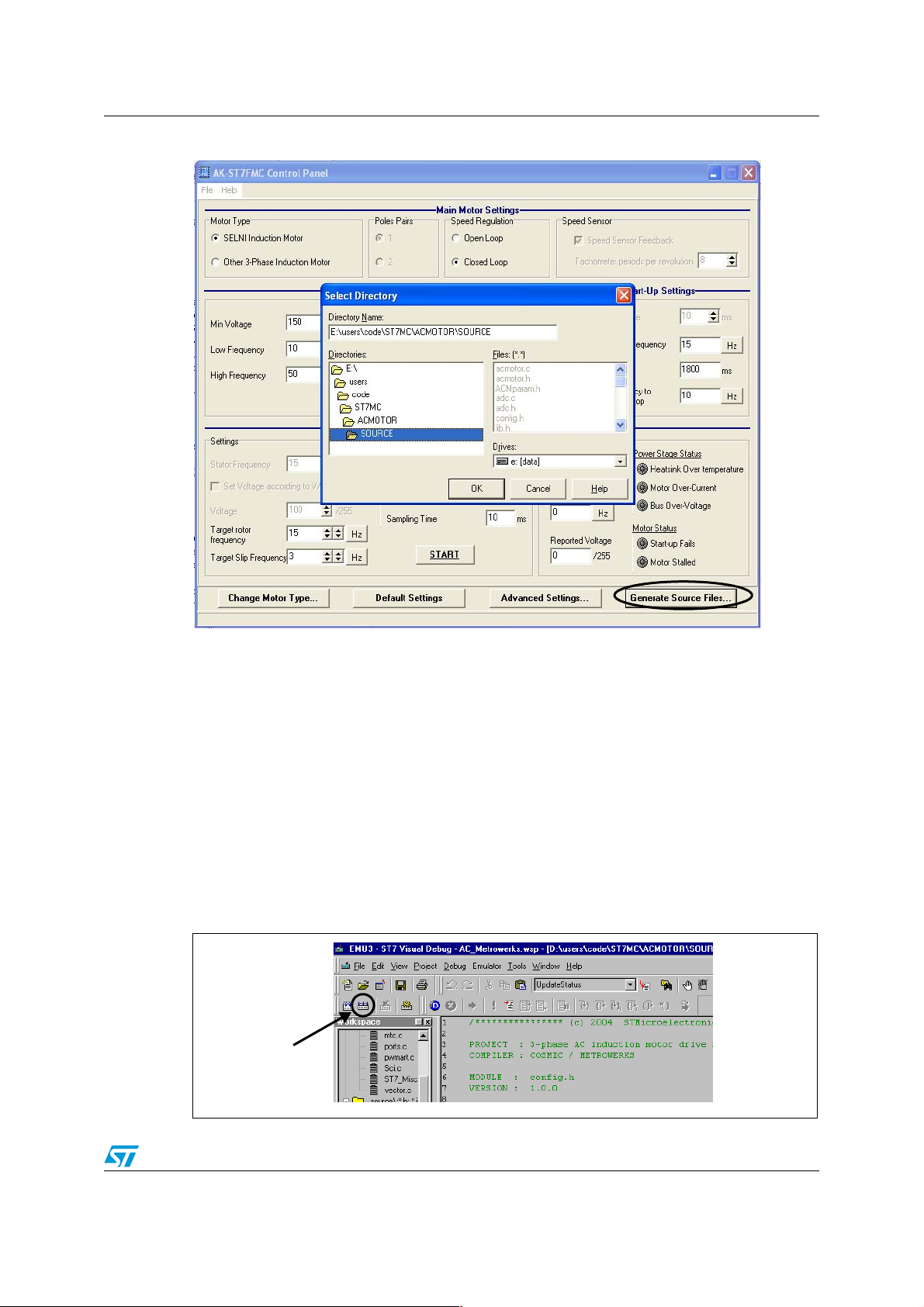

3.1 Running the motor with the ST7MC control panel

As a starting point, the open loop mode can be used for the first trials. Low voltage values

can be used for safety and then increased smoothly step by step. Incremental system build

on page 86 for details.

Once the motor settings have been finely adjusted (whatever the driving mode, open or

closed loop), the parameters have to be imported into the stand-alone library. Simply click

on ‘Generate *.h Files’ and select the source directory of the stand-alone library: see

Figure 5

10/102

Page 11

AN1904 Getting started with the library using the ST7MC-KIT/BLDC

Figure 5. . ST7MC Control Panel: library header files generation

This interface generates 3 header files containing the motor and application parameters plus

a file with conditional compilation keys for library re-build (see Section 3.2):

● MTCparam.h contains parameters of routines directly related to the motor controller

peripheral, mainly PWM, sine wave generation and speed feedback processing (see

Section 4.2.3 on page 38),

● ACMparam.h contains parameters related to the motor and the load, such as V/f curve

and speed regulation (see Section 4.3.3 on page 58),

● Mainparam.h contains some application/demo specific features (see Section 5.4 on

page 84).

Once the above files have been generated, the whole library must be re-built. The library

and its demo program will then include the new settings automatically.

To launch the compilation, click on the ’rebuild all’ icon of STVD7: see Figure 6

Figure 6. Rebuilding the whole application with STVD7

Rebuild

11/102

Page 12

Getting started with the library using the ST7MC-KIT/BLDC AN1904

3.2 Library configuration file

The purpose of this file is to declare the compiler conditional compilation keys which will be

used throughout the entire library compilation process, to:

● define the AC motor driving mode: open / closed loop (see Section 5 and Section 5.3),

● define the PWM resolution (needed to define the PWM frequency range, see Section ),

● enable or disable the RS232 communication (see Using the serial communication

interface on page 83),

● enable or disable the PI parameters tuning (see Regulation tuning procedure on

page 62).

Below are the compilation key definitions in config.h:

// Define here the desired control type

// 0 -> Open loop

// 1 -> Closed loop

#define CONTROL1

//-------------------------------------------------------------------------

// Define here the chosen PWM resolution (linked to PWM switching frequency)

// 0 -> 9-bit: 1.95kHz, 3.9kHz, 7.8kHz, 15.66kHz: cf. "MTCparam.h"

// 1 -> 10-bit: 12.5 kHz

#define PWM_RESOLUTION 1

//-------------------------------------------------------------------------

// Define here the way the closed loop parameters (Kp, Ki) are set

// if this label is commented, Kp and Ki are set according to a look-up table

// defined in ACMparam.h.

//#define PI_PARAM_TUNING

//-------------------------------------------------------------------------

// Define here if you want to use the SCI interface to monitor some internal

// variables during run time

// IMPORTANT NOTE: As communication is done by polling, this will decrease

// the sampling rate of the PI Speed controller

#define ENABLE_RS232

12/102

Page 13

AN1904 Getting started with the library using the ST7MC-KIT/BLDC

3.3 Customizing the files for your ST7MC derivative

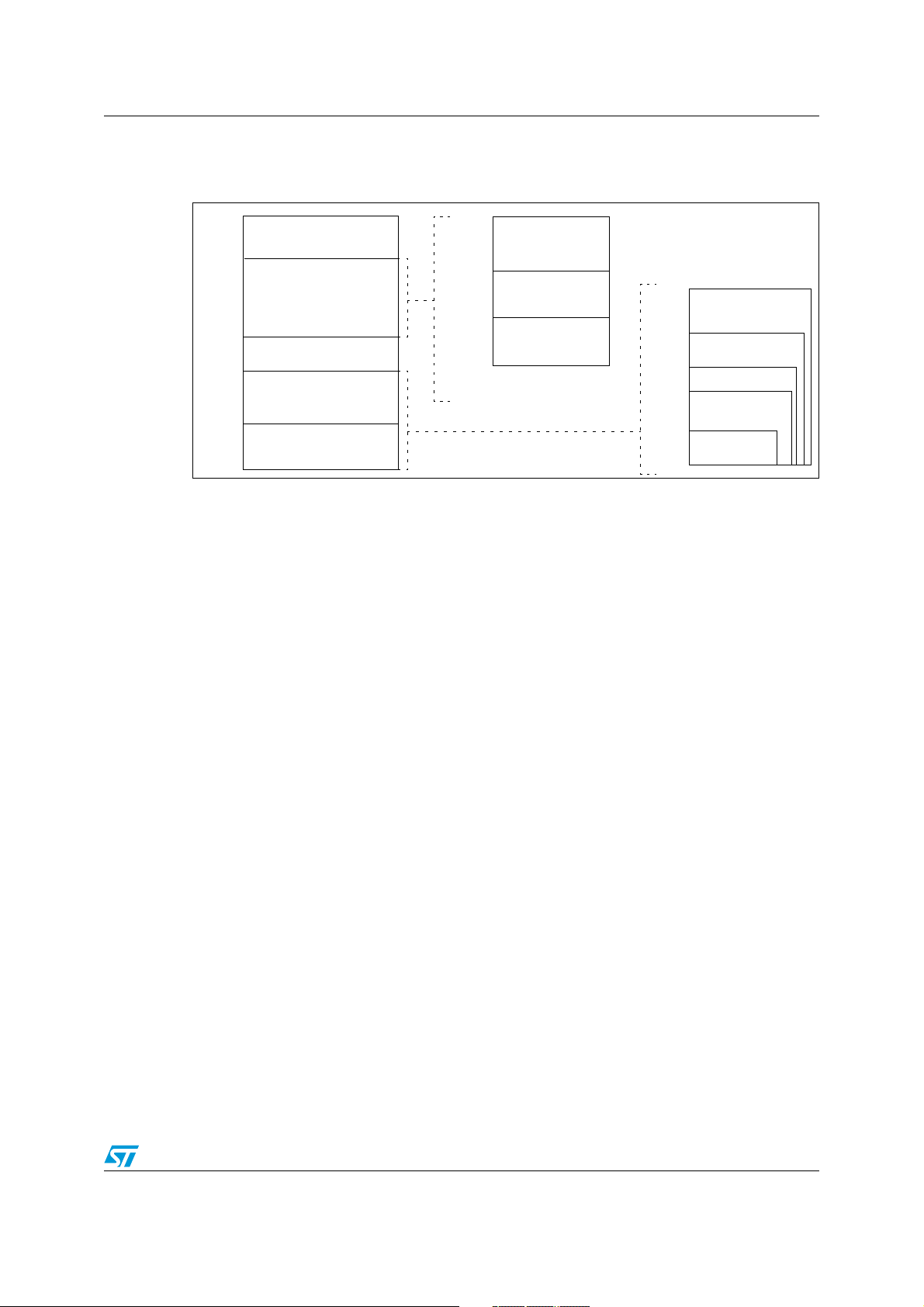

Figure 7. Memory map

0000h

007Fh

0080h

067Fh

0680h

0FFFh

1000h

FFDFh

FFE0h

FFFFh

HW Registers

768/384 Bytes)

Program Memory

(60K, 48K, 32K, 24K, 8K)

Interrupt & Reset Vectors

RAM

(1536/1024

Reserved

0080h

00FFh

0100h

01FFh

0200h

01FFh

or 037Fh

or 047Fh

or 067Fh

Short Addressing

RAM (zero page)

256 Bytes Stack

16-bit Addressing

RAM

1000h

4000h

8000h

A000h

E000h

FFFFh

60 KBytes

48 KBytes

32 KBytes

24 KBytes

8 KBytes

The ST7MC memory is shown on Figure 7. The memory arrangement may vary depending

on the type of the MCU. Please refer to the ST7MC datasheet for more information.

The library is dedicated by default to the ST7FMC2N6B6 MCU (SDIP56, 32KB Flash, 1K

RAM). In order to target another ST7MC MCU, you may need to modify the C-toolchain

configuration files. Here’s a basic example of what has to be done prior to any other

modifications.

The above example is based on the ST7FMC2S4 MCU (TQFP 44, 16K Flash, 768 Bytes

RAM).

3.3.1 Memory mapping with COSMIC toolchain

Go to \config\Cosmic, edit 32K.lkf and check the following lines, in ‘SEGMENT

DEFINITION’:

# SEGMENT DEFINITION (.text, .const,.data,.bss,.bsct,.ubsct are c compiler

predefined sections)

+seg .text -b0x8000 -m0x8000 -nCODE -sROM # executable code

+seg .const -aCODE -it -sROM # constants and strings

+seg .bsct -b0x0080 -m0x007F -nZPAGE -sRAM #initialized variables in SHORT range

+seg .ubsct -aZPAGE -nUZPAGE -sRAM # uninitialized variables in SHORT range

+seg .share -aUZPAGE -is -sRAM # shared segment (defined when using compact or

memory models only)

+seg .data -b0x0200 -m0x27F -nIDATA -sRAM # NO initialized variables

+seg .bss -aIDATA -nUDATA -sRAM # uninitialized variables

This section contains the memory placement for the object files, listed just after this

declaration.

In order to enter the memory mapping of the ST7FMC2S4, the size of ROM and RAM

memory have to be changed (32K -> 16K Flash, 1K RAM -> 768 Bytes RAM). For ROM:

13/102

Page 14

Getting started with the library using the ST7MC-KIT/BLDC AN1904

+seg .text -b0xc000 -m0x3fe0 -nCODE -sROM # executable code

(where 0xc000 is the new starting address of the program memory and 0x3fe0 the size in

bytes). For RAM:

+seg .bss -b0x0200 -m0x0180 -nUDATA -sRAM # uninitialized variables

(where 0x0180 is the new size of the 16 bit addressing RAM memory).

3.3.2 Memory mapping with METROWERKS toolchain

Go to \config\Metrowerks, edit acmotor.prm and check the following lines:

SECTIONS

ZRAM = READ_WRITE 0x0080 TO 0x00FF;

RAM = READ_WRITE 0x0200 TO 0x047F;

ROM = READ_ONLY 0x8000 TO 0xFFDF;

This part of the prm file contains the memory locations of pages declared at the end of the

file.

To modify the memory size for the ST7FMC2S4, ROM and RAM memory settings have to

be changed (32K -> 16K Flash, 1K RAM -> 768 Bytes RAM):

ROM = READ_ONLY 0xC000 TO 0xDFFF;

(where 0xc000 is the new starting address of the program memory),

RAM = READ_WRITE 0x0200 TO 0x027F; // 16 bit addressing RAM

(where 0x027F is the end address of the 16 bit addressing RAM memory).

Caution: The application layer has been written for the STMFC2NB6. Using a different ST7MC sales

type can imply the need to do some modifications to the library, according to the available

features (some of the I/O ports are not present on low-pin count packages). Please refer to

the datasheet for details.

3.3.3 Hardware registers description

The library is based on the ST7FMC2N6.h file, which contains the hardware registers

declarations and memory mapping for the ST7FMC2N6. It also contains most of the bit

masks for the peripherals, at the exception of some Motor Controller bits and bitfields

described in mtc_bits.h.

The ST7FMC2N6.h is provided by default with the STVD7 release 3.x.x toolchain, usually

in:

C:\Program Files\STMicroelectronics\st7toolset\include

All other ST7MC derivative descriptions can be found in this folder, from the ST7FMC1K2 to

the ST7FMC2M9. The name of the corresponding header file will have to be changed in the

config.h file.

14/102

Page 15

AN1904 Getting started with the library using the ST7MC-KIT/BLDC

3.4 How to define and add a C module

This chapter describes how to define and declare a new module in a project based on the

library. The example is based on the addition of 2 files: ‘my_file.c’ and the corresponding

header file ‘my_file.h’.

The first step is the creation of these files. Existing files can be copied, pasted and renamed,

or created by clicking on the ‘new files’ icon and then saving them with the right extension

(*.c or *.h).

Three files (two source and one object) have to be declared in the toolchain configuration

files.

3.4.1 Using STVD7 release 2.5.x

COSMIC compiler

COSMIC compiler is launched using a makefile (acmotor.mak) and the linker gets

information from the linker command file 32K.lkf file. These two files need to be modified.

In 32.lkf, the new object file has to be added in the common object file list, or apart from this

object list with correct settings (for instance for interrupt vectors or constants that need to be

at fixed location, see documentation of C compiler for details).

# OBJECT FILES

..\..\object\cosmic\main.o

...

..\..\object\cosmic\my_file.o

...

# OBJECT FILES END

In acmotor.mak, ‘my_file.c’ has to be added in the C source file list:

C_SRC = \

main.c \

acmotor.c \

... \

my_file.c \

... \

vector.c

and the list of dependencies has to be updated accordingly:

# RULES FOR MAKING THE OBJECT FILES:

main.o: main.c lib.h ports.h adc.h pwmart.h Sci.h mtc.h acmotor.h

config.h Mainparam.h ST7FMC2N6.h

$(CC) ..\..\source\main.c

15/102

Page 16

Getting started with the library using the ST7MC-KIT/BLDC AN1904

...

my_file.o: my_file.c my_file.h lib.h ST7FMC2N6.h ...

$(CC) ..\..\source\my_file.c

METROWERKS compiler

For METROWERKS users, modifications have to be done in acmotor.prm and acmotor.mak

files. In the makefile, the new object file my_file.o has to be added in the ‘Object file list’

section and the corresponding dependencies have to be set in the ‘Application files’ section:

# ----------------------------- OBJECT FILES LIST -----------------------------

OBJ_LIST = main.o mtc.o ... my_file.o

...

# --------------------------- APPLICATION FILES ------------------------------

main.o : $(ENV) main.c lib.h ports.h adc.h pwmart.h sci.h mtc.h acmotor.h \

config.h MainParam.h ST7FMC2N6.h

$(CC) main.c

my_file.o : $(ENV) my_file.c my_file.h lib.h ST7FMC2N6.h ...

$(CC) my_file.c

In acmotor.prm the new object file has to be added in the ‘Project module list’ section:

/*** PROJECT MODULE LIST ***/

NAMES

main.o

mtc.o

...

my_file.o

...

start07.o

ansi.lib

END

3.4.2 Using STVD7 release 3.x.x

The procedure is far easier with STVD7 3.x.x, as the makefile and linking command files are

automatically generated.

In the workspace window, just right click on the selected project (either cosmic or

metrowerks) and select “Add Files to Project”. You’ll be asked to select source file.

When rebuilding the library, the configuration files will be updated accordingly.

16/102

Page 17

AN1904 Getting started with the library using the ST7MC-KIT/BLDC

Figure 8. Adding a source file using STVD7 3.x.x

17/102

Page 18

Library functions per software module AN1904

4 Library functions per software module

4.1 Function description conventions

The functions are described in the format given below:

Synopsis This section lists the required include files and prototype declarations.

Description The functions are described with a brief explanation on how they are

executed.

Input In few lines, the format and units are given.

Returns Gives the value or error code returned by the function.

Caution Indicates the limits of the function or specific requirements that must be

taken into account during library integration.

Warning Indicates important points that must be taken into account to prevent

hardware failures.

Functions called Allows to prevent conflicts due to the simultaneous use of resources.

Duration The approximate duration of the routine. This is performed using the

maximum CPU clock frequency (8 MHz) without interrupts if not notified.

Slight variations may be expected when changing compiler, options,

memory models,...

Code example Indicates the proper way to use the function if there are certain

prerequisites (interrupt enabled, etc.).

Some of these sections may not be included if not applicable (no parameters, obvious use,

etc.).

4.2 Sine wave generation and speed feedback (MTC)

4.2.1 Overview

The “mtc.c” module is intended to handle all motor control functionalities directly linked to

the motor control peripheral hardware (initialization or run-time accessed registers, interrupt

service routine).

It can be seen as an interface between the AC motor control specific module and the low

level control routines having direct influence on the hardware (PWM outputs, speed sensor,

Emergency Shutdown pin).

It contains, among other functions:

● basic setup / control functions for the Motor Controller Peripheral (MTC),

● Sine wave generation (through PWM interrupt processing),

● DC current braking,

● Direction reversal,

● speed acquisition related interrupts and functions.

The prototype functions are located in the “mtc.h” header file.

18/102

Page 19

AN1904 Library functions per software module

4.2.2 List of available functions and interrupt service routines

The following is a list of available functions as listed in the mtc.h header file.

MTC_ResetPeripheral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 20

MTC_InitPeripheral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 20

MTC_InitSineGen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 20

MTC_EnableMCOutputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 21

MTC_DisableMCOutputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 21

MTC_CheckEmergencyStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 22

MTC_ClearEmergencyStop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 22

MTC_StartBraking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 23

MTC_Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 24

MTC_StopBraking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 25

MTC_Toggle_Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 26

MTC_Set_ClockWise_Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 26

MTC_Set_CounterClockWise_Direction . . . . . . . . . . . . . . . . . . . . . . . . . . on page 26

MTC_GetRotationDirection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 26

MTC_GetVoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 27

MTC_GetStatorFreq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 27

MTC_GetSlip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 27

MTC_InitTachoMeasure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 28

MTC_StartTachoFiltering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 28

MTC_ValidSpeedInfo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 29

MTC_GetRotorFreq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 30

MTC_UpdateSine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 31

GetLastTachoPeriod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 32

GetAvrgTachoPeriod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 32

MTC_U_CL_SO_IT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 33

MTC_C_D_IT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 34

MTC_R_Z_IT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 35

MCES_SE_IT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 36

SET_MTC_PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 37

ToCMPxL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 37

ToCMPxH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 37

MTC_EnableClock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 37

MTC_DisableClock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on page 37

19/102

Page 20

Library functions per software module AN1904

MTC_ResetPeripheral

MTC_InitPeripheral

MTC_InitSineGen

Synopsis #include "mtc.h"

void MTC_ResetPeripheral(void);

void MTC_InitPeripheral(void);

void MTC_InitSineGen(void);

Description The purpose of these three functions is to set-up the Motor Controller

peripheral and to initialize the software variables needed for sine wave

generation.

MTC_ResetPeripheral

Resets the whole circuitry of the Motor Controller peripheral of the ST7MC,

as it is found after a microcontroller RESET, with the sole exception of the

MDTG and MPOL write-once registers (see datasheet for details).

MTC_InitPeripheral

Performs the initialization of the Motor Controller peripheral hardware

registers, for the sine wave general parameters (such as PWM frequency,

output polarity, deadtime, interrupts,...) and speed feedback processing

(tacho input selection, edge sensitivity,...). It also starts the 12-bit PWM

timer and the tacho dedicated timer (MTIM:MTIML). All required motor

control related interrupts are unmasked upon completion of this routine.

MTC_InitSineGen

Initialization of software variables needed for sine wave generation and

used in the PWM update interrupt routine. Ensures that once the PWM

update interrupts will have been enabled, the sine wave generated will

have a null voltage and that stator frequency change will be taken into

account.

Duration 2.75µs for MTC_ResetPeripheral, 26µs for MTC_InitPeripheral and 392µs

for MTC_InitSineGen.

Note: These three functions do not need to be called by the user application, as they are managed

by the ACM_Init function.

20/102

Page 21

AN1904 Library functions per software module

MTC_EnableMCOutputs

MTC_DisableMCOutputs

Synopsis #include "mtc.h"

void MTC_EnableMCOutputs(void);

void MTC_DisableMCOutputs (void);

Description The purpose of these two functions is to configure the MCOx outputs of the

ST7MC.

MTC_EnableMCOutputs

Enables the MCOx pins to output the PWM signals of the Motor Controller

Peripheral. This function must be called to re-start PWM generation after

an emergency shutdown (low state on MCES pin).

MTC_DisableMCOutputs

This function immediately disconnects the MCOx PWM outputs pins from

the Motor Controller peripheral. It resets the MOE bit in the MCRA register,

thus causing the MCOx pins to be in their reset configuration, as defined in

the options bytes (high impedance or low impedance high/low state).

Duration 2.15 µs

See also ST7MC Datasheet: MTC chapter.

21/102

Page 22

Library functions per software module AN1904

MTC_CheckEmergencyStop

MTC_ClearEmergencyStop

Synopsis #include "mtc.h"

BOOL MTC_CheckEmergencyStop(void);

void MTC_ClearEmergencyStop(void);

Description The purpose of these two functions is to provide to the higher level control

modules information regarding an Emergency Stop of the PWM operation.

This information is returned by a function call once the related interrupt

routine has been serviced. For users requiring immediate action taken as

soon as the NMCES event occurs, the interrupt routine needs to be used

directly (see MCES_SE_IT on page 36).

MTC_CheckEmergencyStop

Indicates if PWM outputs are enabled or not, and therefore if MOE bit

(Main Output Enable) has been cleared by hardware, upon Emergency

Stop event.

MTC_ClearEmergencyStop

Resets the boolean where the emergency Stop interrupt routine execution

was recorded, regardless of the MOE bit state.

Returns MTC_CheckEmergencyStop returns a boolean parameter, TRUE if an

emergency Stop interrupt has been serviced, causing the PWM outputs to

be disabled.

Duration 2.5 µs

See also ST7MC Datasheet: Motor Controller section, Emergency feature section.

MCES_SE_IT on page 36.

22/102

Page 23

AN1904 Library functions per software module

MTC_StartBraking

Synopsis #include "mtc.h"

void MTC_StartBraking(u16 DutyCycle);

Description The purpose of this function is to start the braking sequence by initializing

the brake related flags, stopping the PWM interrupts generation, disabling

the PWM outputs and starting the timebase needed for stator

demagnetization. It also set the sine wave voltage to zero in case the

braking sequence is interrupted and sine wave generation is re-started.

Braking is obtained by sinking DC current in one motor winding. The

braking torque is also defined in this function, in direct relation with the duty

cycle applied to one of the motor winding, the other two phases being

grounded (low side switches continuously ON).

Input Duty cycle value is entered as a u16 variable without unit: to get the

applied duty cycle, the value has to be compared to the CMP0 register

value, defining the PWM frequency.

For instance, for a PWM frequency of 12.5kHz, CMP0 = 639 (refer to the

Section for details). If the DutyCycle variable is set to 32, this will lead to

an applied duty cycle of 32/(639+1) = 10% (with center-aligned patterns).

As the AC motor is driven in voltage mode, there’s no way to define a

relationship between this duty cycle, the braking torque and the current

feed in the motor. This duty cycle will therefore have to be defined

empirically.

Functions called MTC_UpdateSine, MTC_DisableMCOutputs, ART_SetSequenceDuration.

Duration 70 µs

See also MTC_Brake, MTC_StopBraking, flowchart on A.1.6 on page 95,

Section 5.4 on page 84 and Section on page 45 for timings set-up.

23/102

Page 24

Library functions per software module AN1904

MTC_Brake

Synopsis #include "mtc.h"

void MTC_Brake(void);

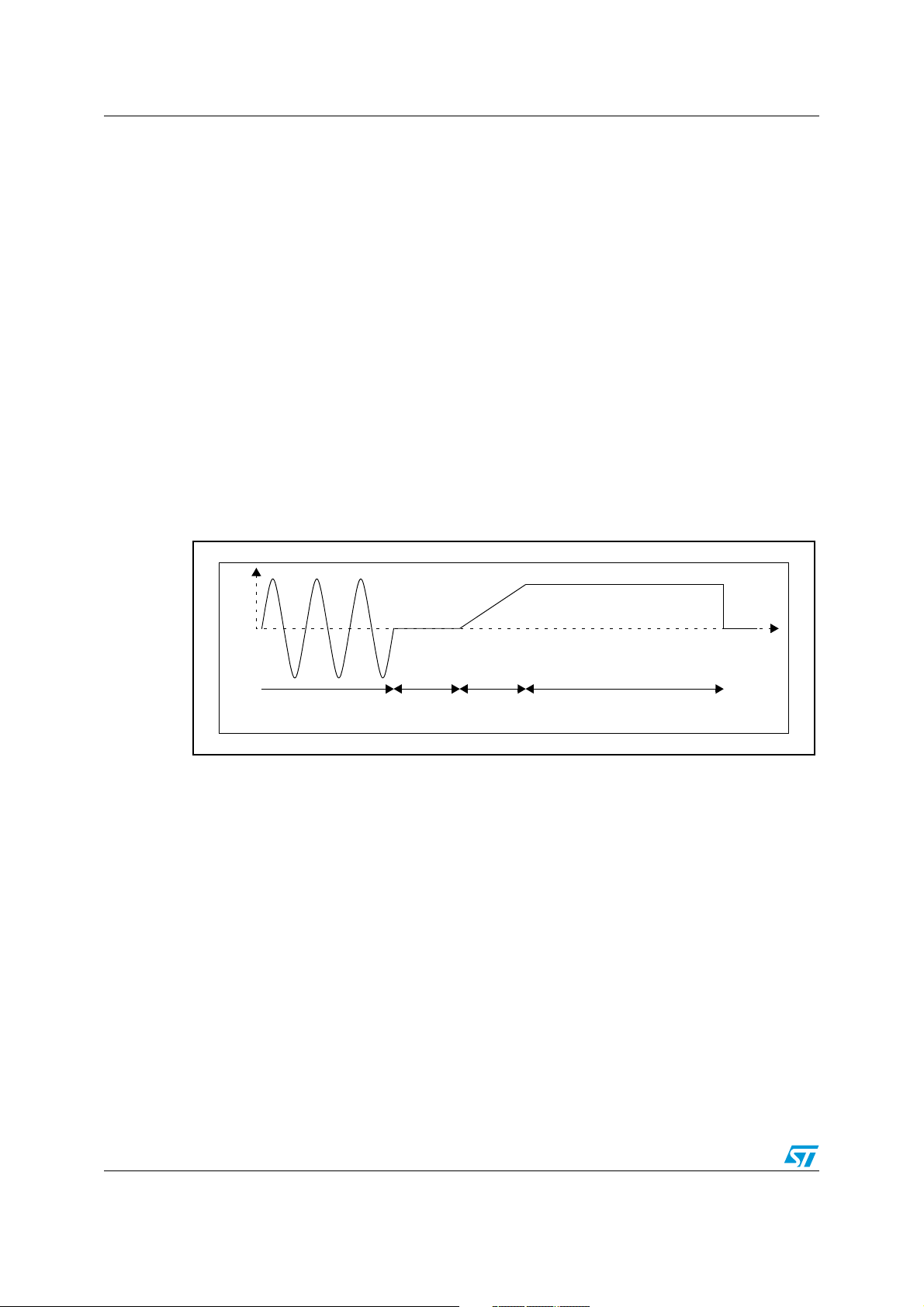

Description The purpose of this function is to handle the three phases of the braking

sequence, as represented below in Figure 9

1. A waiting time for the Stator current to decrease down to zero

(demagnetization), all PWM being OFF.

2. A smooth DC current increase up to expected value to avoid inrush

current in the stator.

3. The sustaining of this current permanently up to the MTC_StopBraking

function call.

Figure 9. . Current waveform during brake sequence

Current

Motor running

Rotor

demag.

Current

settle

Active brake

This function must be called as often as possible (typically from the main

loop) to respect the required timings. Once the steady state current is

attained, the brake continues permanently, until the MTC_StopBraking

function is called.

Caution 1 Independently from software timebase jitter (+/-1ms), the programmed

duration may vary depending on the interval between two MTC_Brake

function call (the lower the interval, the better the resolution).

Caution 2 If the user stops calling this function, the current will be maintained to its

last value (either null during rotor demagnetization or below the final

expected value).

Duration 14 µs average

Functions called ART_IsSequenceCompleted, ART_SetSequenceDuration,

MTC_EnableMCOutputs, MTC_DisableMCOutputs

See also MTC_StartBraking, MTC_StopBraking, Section 5.4 on page 84 and Brake

on page 45 for timings set-up, flowchart on A.1.7 on page 96.

24/102

Page 25

AN1904 Library functions per software module

MTC_StopBraking

Synopsis #include "mtc.h"

void MTC_StopBraking(void);

Description This function stops the active braking, whatever the current sequence

(stator demagnetization, current settle, steady state).

It disables the PWM outputs and re-starts the PWM Update interrupts

generation.

Duration 41.5 µs

Functions called MTC_DisableMCOutputs

Caution: The PWM outputs are disabled when exiting this function. In order to resume motor

operations, it is mandatory to call a start function (ACM_InitSoftStart,

ACM_InitSoftStart_OL) or MTC_EnableMCOutputs.

See also MTC_StartBraking, MTC_Brake, flowchart on A.1.8 on page 96

25/102

Page 26

Library functions per software module AN1904

MTC_Toggle_Direction

MTC_Set_ClockWise_Direction

MTC_Set_CounterClockWise_Direction

MTC_GetRotationDirection

Synopsis #include "mtc.h"

void MTC_Toggle_Direction(void)

void MTC_Set_ClockWise_Direction(void)

void MTC_Set_CounterClockWise_Direction(void)

Direction_t MTC_GetRotationDirection(void)

Description These functions are used to set, modify or get indication of the rotating

direction. Rotation direction change is achieved by modifying the sign of

the variable holding the phase shift between the three phases (either 120°

or -120°).

The clockwise direction is defined randomly. The real direction will only

depend on the physical connection of the motor.

Duration 2.25 µs for MTC_Set_ClockWise_Direction and

MTC_Set_CounterClockWise_Direction, 3.5µs for the other two functions.

Returns The Direction_t type is a public enumerated typedef defined in the mtc.h

file: {CLOCKWISE, COUNTERCLOCKWISE}.

Caution: No tests are performed on motor status (running or stopped) inside these functions.

You must therefore be sure that motor is stopped before calling any of the three routines

able to modify the rotation direction. On the contrary, if direction is changed while motor is

running, it can immediately become generator, thus injecting reactive energy in the high

voltage DC bus capacitor, causing the voltage to go above capacitor’s maximum voltage

rating.

26/102

Page 27

AN1904 Library functions per software module

MTC_GetVoltage

MTC_GetStatorFreq

MTC_GetSlip

Synopsis #include "mtc.h"

u8 MTC_GetVoltage(void);

u16 MTC_GetStatorFreq(void);

u16 MTC_GetSlip(void);

Description MTC_GetVoltage

This function returns the current modulation index, corresponding to the

voltage applied on the motor winding.

MTC_GetStatorFreq

This function returns the current Stator frequency; if a stator frequency

update (done in PWM Update interrupt) is on-going after a call to the

MTC_UpdateSine function and it has not been completed, the previous

value is returned.

MTC_GetSlip

This function returns the difference between the stator and rotor

frequencies. This value will always be positive (unsigned variable)

assuming that this software library is not designed to handle negative slip

operations (i.e. motor used as a generator). However, if the slip is negative,

the returned value will be zero.

Returns Stator and slip frequencies are given in [0.1Hz] unit using 16-bit format: a

returned value of 357 corresponds to 35.7Hz.

The voltage is an 8-bit value; 0 to 100% modulation index is described

within the 0 to 255 range; 255 corresponds to full voltage.

Duration MTC_GetVoltage: 1.85 µs

MTC_GetStatorFreq: 3.5 µs

MTC_GetSlip: 620 µs (including ~20% of CPU time spent in interrupt for

sine wave generation)

See also MTC_GetRotorFreq, MTC_UpdateSine.

Note: MTC_GetSlip duration mainly comes from the Rotor speed calculation, done in

MTC_GetRotorFreq; if MTC_GetRotorFreq and MTC_GetSlip have to be used in the same

function of your own, it may be interesting to compute the slip directly from the Stator and

rotor speed information to spare CPU processing time.

27/102

Page 28

Library functions per software module AN1904

MTC_InitTachoMeasure

MTC_StartTachoFiltering

Synopsis #include "mtc.h"

void MTC_InitTachoMeasure(void);

void MTC_StartTachoFiltering(void);

Description MTC_InitTachoMeasure

The purpose of this function is to initialize the flags and variables

associated with speed acquisition: the software FIFO stack where the last

4 speed acquisitions are stored, the tacho timer clock prescaler and the

flag disabling rolling average. Upon completion of this routine,

MTC_GetRotorFreq function call will return a speed calculated from the

very last tacho capture only.

MTC_StartTachoFiltering

Once called, this function enables the MTC_GetRotorFreq to return a

speed corresponding to the average of the last four captured values. On

the tacho event following this function call, the whole software FIFO stack

is filled with the latest captured value to start the rolling average with

values up to date.

Duration MTC_InitTachoMeasure: 26 µs

MTC_StartTachoFiltering: 2.75 µs

Code example

...

...

IMC_InitTachoMeasure();/*Must be called before motor start*/

...

/* Start routine */

if (MTC_ValidSpeedInfo(MinRotorFreq))

{

MTC_StartTachoFiltering (); /* Must be called once we

} are sure that we have reliable speed information */

See also MTC_GetRotorFreq, MTC_ValidSpeedInfo.

28/102

Page 29

AN1904 Library functions per software module

MTC_ValidSpeedInfo

Synopsis #include "mtc.h"

BOOL MTC_ValidSpeedInfo (u16 MinRotorFreq);

Description The purpose of this function is to determine if the motor has actually

started and if the rotor speed exceeds a given threshold above which the

tachometer can be considered has providing reliable information.

Two conditions are evaluated:

- If the actual speed is higher than the defined threshold,

- If the acceleration is positive: the very last speed captured is higher than

the average of the four previous values. This is necessary to discard the

parasitic information appearing at the beginning of motor rotation. This

spurious tacho events are usually due to the tachogenerator technology,

made of winding and magnet; at very low speed, the tacho output signal is

in the range of hundreds of mV, with relatively low signal vs noise ratio.

Input The input parameter is the minimum rotor speed at which the motor is

considered as really being started, in tenth of Hz. For instance,

MinRotorFreq=105 corresponds to 10.5Hz. The minimum Rotor speed has

to be set inside the intrinsically stable tile of the motor’s torque versus

frequency characteristic (typically 10-20Hz), keeping in mind that it must

not be too high: the higher this value, the bigger will be the stator

voltage/current inrush current at start-up.

Furthermore it is recommended to set a value as close as possible to the

target speed to be reached when exiting the start-up routine to ease the

transition to the closed loop speed regulation. If the target frequency is too

high, then a ramp function has to be implemented.

Returns Boolean parameter, TRUE if both the above conditions are verified, FALSE

otherwise. The function will also return FALSE if called with the

MinRotorPeriod parameter set to 0 (incorrect value).

Duration 88 µs maximum

Caution: There is no way to differentiate rotation directions using a tachogenerator. Take note that

this routine may return TRUE in certain conditions, even if the motor is not started in the

right direction. In this case, you should manage a minimum amount of time before restarting (for instance with high inertia load). Obviously, this function may be ineffective if the

start-up duration is far shorter than time needed to have at least few consecutive speed

values.

Functions called MTC_GetRotorFreq, GetAvrgTachoPeriod, GetLastTachoPeriod.

29/102

Page 30

Library functions per software module AN1904

MTC_GetRotorFreq

Synopsis #include "mtc.h"

u16 MTC_GetRotorFreq (void);

Description The purpose of this function is to provide the rotor rotational frequency. The

frequency is calculated using the period between two edges of the sensor

signal (typically a tachometer), the [MTIM:MTIML] counter and the MPRSR

prescaler.

If the MTC_StartTachoFiltering function has been called previously to this

function, the rotor frequency is computed as the average of the last four

values and the speed value is up-to date whatever the motor speed and

the tacho information rate (rolling average). On the contrary, the very last

tacho period is used to do the computation; this is of interest during the

start-up phase of the motor, when the tachogenerator signal is very weak.

Returns Rotor frequency with [0.1Hz] unit; for instance a returned value of 357

corresponds to rotor mechanical frequency of 35.7Hz

If the calculated speed is less than a minimum speed the returned value

will be 0. This minimum speed is checked using the MPRSR prescaler

value, which is automatically updated (refer to the ST7FMC datasheet for

details): if its value is >= MAX_RATIO constant, the returned speed is zero.

MAX_RATIO is defined in MTCparam.h; it is set by default to 7: if no tacho

edges are detected within a period of 500 ms to 1 second, the motor is

considered to be stopped. This time out period depends on the previous

value of the MPRSR prescaler: see the equations below.

Figure 10. Time Out duration before having Freq=0, depending on MPRSR value

Timeout

Timeout

0xFFFF 2

---------------------------------- -

×

16M Hz

0xFFFF 27×

---------------------------------- - 524ms==

16M Hz

5

0xFFFF 26×

---------------------------------- -

16M Hz

0xFFFF 27×

---------------------------------- -++ 917 ms==

16M Hz

MPRSR=7

MPRSR=5

Note on accuracyWith the 16-bit timer range and its automatically updated prescaler, the

accuracy is better than 0.1Hz up to tacho input frequency of 1265Hz. This

limit is lowered when having Fmtc below 16MHz.

Duration 560 µs (inc. ~20% CPU time spent in U interrupt for sine generation)

Functions called GetAvrgTachoPeriod, GetLastTachoPeriod.

See also MTC_StartTachoFiltering on page 28, MTC_C_D_IT on page 34,

Customization hints in Rotor frequency computation on page 38, flowchart

on A.1.3 on page 92

30/102

Page 31

AN1904 Library functions per software module

MTC_UpdateSine

Synopsis #include "mtc.h"

BOOL MTC_UpdateSine (u8 NewVoltage, u16 NewFrequency);

Description The aim of this function is to update the 3-phase sine wave parameters: the

amplitude (voltage) and the frequency. This routine will limit the frequency

within a range defined in the constants section of the MTCparam.h file

(between LOWEST_FREQ and HIGHEST_FREQ limits). The new

parameters are taken into account in the PWM Update interrupt following

this function completion, thus with a maximum delay of two PWM periods,

due to the PWM preload registers mechanism.

Inputs NewStatorFrequency is given with [0.1Hz] unit. This unit does not

correspond to the real frequency resolution, which varies with the PWM

switching frequency (refer to Stator frequency resolution on page 43 for

details). With the default PWM frequency of 12.5kHz, the resolution is

around 0.1Hz.

NewVoltage is the value of the modulation index, in 8-bit format. The 0 to

100% modulation index corresponds to the 0 to 255 range. 255

corresponds to full voltage.

Returns Boolean type variable. FALSE if the previous call to MTC_UpdateSine has

not yet been taken into account in U interrupt.

Duration 630 µs (inc. ~20% CPU time spent in U interrupt sine generation).

Warning No tests are performed in this function on the input parameters, except for

the frequency range. You must therefore verify the following conditions

before calling the function:

– voltage and frequencies must be compliant with the characteristics of the

motor: over-voltage can cause motor flux saturation, excessive frequency

is incompatible with motor mechanics (ball bearings or rotor may explode

for instance).

– voltage and frequencies values should not vary too suddenly when the

motor is running, to avoid over current conditions. This is usually handled

by the AC motor control software layer, by means of smoothing functions

and/or regulation loops.

– Stator frequency must not be set below the rotor frequency value: this

would cause the motor to become a generator, thus injecting reactive

energy in the high voltage DC bus capacitor, causing the voltage to go

above the capacitor’s maximum voltage rating. If this situation is foreseen

in the final application, a dissipative brake has to be implemented on the

three-phase power inverter. By correctly managing a PWM signal applied

to a brake dedicated transistor, regenerative power can be dissipated in a

power resistor.

Note: MCOx outputs state (enabled/disabled) is not tested in this routine.

31/102

Page 32

Library functions per software module AN1904

GetLastTachoPeriod

GetAvrgTachoPeriod

Synopsis None (mtc.c module private functions).

Description These functions provide the raw results of the tacho speed measurement,

as a period between two capture events. Their result is converted by the

MTC_GetRotorFreq function to get the speed of the motor in Hz.

Returns The function returns a 32 bit variable corresponding to the time interval

(averaged or not) between two tacho capture events. The unit is Tmtc, set

by default to 62.5ns (1/16MHz).

GetLastTachoPeriod returns the very last captured period,

GetAvrgTachoPeriod returns the average of the four last captured values.

Duration GetLastTachoPeriod: 32.6 µs

GetAvrgTachoPeriod: 115 µs

Caution: The GetAvrgTachoPeriod function disables the tacho capture interrupts for 5.5µs

(Fcpu=8MHz) to avoid the software FIFO stack being written in the capture interrupt while it

is being read from the main program.

Note: By default, these functions are defined as private to the module, assuming they are only

used by MTC_GetRotorFreq function.

See also Flowcharts, on A.1.4 on page 93 and A.1.5 on page 94.

32/102

Page 33

AN1904 Library functions per software module

MTC_U_CL_SO_IT

Synopsis Not relevant (interrupt service routine).

Description In this interrupt are the PWM duty cycles updated for the sine wave

generation. This is done by loading the appropriate values in the MCPUx,

MCPVx and MCPWx registers. This algorithm is extensively described in a

dedicated application note.

The Update (U) interrupt is triggered when the repetition counter is at zero

value, corresponding to the loading of the values stored in the compare

preload registers into the active registers. Using preload registers (with

automatic hardware loading) decreases real time constraints, but as a

consequence, introduces a delay: the values loaded in the current U

interrupt will be used when the next one occurs.

Duration 34.1 µs, including average interrupt latency of 13 cycles and IRET

execution.

Caution A software preload mechanism is implemented in the U interrupt to avoid

potential problems if the interrupt is triggered during the 16-bit frequency

variable update (SineFreq) in the MTC_UpdateSine function.

Consequently, any change of stator frequency done by calling

MTC_UpdateSine will be inactive as long as U interrupts are masked, and

MTC_UpdateSine will return a boolean equal to FALSE.

Note: No SO (Sampling Out) event is generated when running an induction motor. CL (Current

Limit) interrupt can be used but is not handled in the software library as of today.

See also Section Nested interrupt controller on page 78, flowchart on A.1.1 on page

90.

33/102

Page 34

Library functions per software module AN1904

MTC_C_D_IT

Synopsis Not relevant (interrupt service routine).

Description This interrupt is triggered after every active edge on the MCIx input pin.

The time interval since the last event is captured in the [MZREG:MZPRV]

registers and the [MTIM:MTIML] counter registers are cleared (by

hardware). The purpose of this interrupt is to store this period, which will

be used later to compute speed feedback by converting it into the

frequency domain with the correct unit (0.1Hz).

The last four acquired values are stored in a software FIFO stack which is

useful to average the raw results and thus reduce errors due to noise,

tachogenerator dissymmetry, etc.

In this routine the FIFO stack is also initialized in a synchronous manner, if

the MTC_StartTachoFiltering function has been called.

Duration 22 µs, including average interrupt latency of 13 cycles and IRET execution

(CPU running at 8 MHz)

Note: No D event is generated when running an induction motor

See also MTC_GetRotorFreq on page 30, flowchart on A.1.2 on page 91, section

Nested interrupt controller on page 78.

34/102

Page 35

AN1904 Library functions per software module

MTC_R_Z_IT

Synopsis Not relevant (interrupt service routine).

Description This interrupt occurs as soon as the prescaler of the MTIM timer is

modified (this automatically updated prescaler allows to optimize the speed

measurement resolution). Two flags are set in the MTCStatus byte to

indicate that the prescaling ratio was increased or decreased (R+ or Revents). This information is mandatory when computing the period

between two speed information in the MTC_C_D_IT interrupt service

routine.

Duration 14 µs, including average interrupt latency of 13 cycles and IRET execution.

Note: No Z event is generated when running an induction motor.

See also MTC_C_D_IT on page 34, section Nested interrupt controller on page 78,

ST7MC datasheet, section 9.6.7.5 “Speed Measurement Mode”.

35/102

Page 36

Library functions per software module AN1904

MCES_SE_IT

Synopsis Not relevant (interrupt service routine).

Description This routine is executed with top priority as soon as a low level is applied

on the MCES input pin. It allows the passing of information that the MCOx

PWM outputs have been disabled (this is done automatically by hardware)

and stores the information in the MCES_Status variable.

It also gives the possibility to add some application specific code to be

processed immediately after a MCES event.

Duration 13.5 µs, including average interrupt latency of 13 cycles and IRET

execution.

Note: This routine is also intended to handle Speed Error interrupts. No specific processing of this

event is done in the current version of the library. Nevertheless, the corresponding SEI flag

of the MCRC register is reset.

See also MTC_CheckEmergencyStop on page 22, section Nested interrupt

controller on page 78.

36/102

Page 37

AN1904 Library functions per software module

SET_MTC_PAGE

ToCMP xH

ToCMP xL

MTC_EnableClock

MTC_DisableClock

Synopsis #include "mtc_bits.h"

SET_MTC_PAGE(x); (x = 0 or 1)

ToCMPxL(MCPxL, 16-bit compare value);

ToCMPxH(MCPxH, 16-bit compare value);

MTC_EnableClock();

MTC_DisableClock();

Description These macros are intended to ease the handling of motor control

peripheral bits and specific registers.

SET_MTC_PAGE selects the active peripheral register page. It must be set

to page 0 once the peripheral initialization is done.

ToCMPxL and ToCMPxH allow the two 8-bit PWM compare registers to be

loaded without taking care of their left-alignment (bits 0..2 are not

significant).

MTC_EnableClock and MTC_DisableClock act directly on the motor

control peripheral clock: it is not recommended to disable the clock while

the motor is running, as this will freeze the PWM output state and may

result in excessive current in the motor.

37/102

Page 38

Library functions per software module AN1904

4.2.3 Detailed explanations and customization of MTCparam.h

Rotor frequency computation

In order to process speed feedback with minimal CPU overhead, the MTC peripheral

contains a dedicated timer. The method used to determine the rotor frequency is shown in

Figure 11 (Tacho refers to the tachogenerator, a common low-cost speed sensor).

Figure 11. Tacho Signal for rotor frequency calculation

Tacho pin input signal

(after amplification)

T

TACHO

T''

The basic principle is to have a clear on capture counter triggered by tacho signal edges.

For this, a small conditioning stage may be needed to get a clean square wave signal from

the sine wave generated by the tachogenerator, particularly at low speed. It is possible to

have both edges sensitivity but this is not recommended to avoid problems that may arise

due to a dissymmetry of the tacho magnets/coils. For the same reasons, it is also

recommended to average the information over several periods, when possible (usually every

time, at the exception of the starting phase where tacho information is not yet reliable

enough): this is done by calling the MTC_StartTachoFiltering function.

T'''

Note: Note: when using one or several Hall sensor(s) for speed feedback, signal conditioning is

not necessary and the signal can be directly input on the MCIx pins.

In order to minimize the CPU consumption, the only information stored during the capture

interrupt routine are the register contents (MTC_C_D_IT on page 34). The conversion of the

raw register’s content into a convenient variable is then only done when needed, for instance

every time the speed regulation task is executed (See flowchart on A.1.3 on page 92).

Several parameters must be taken into account to compute the rotor frequency with a

convenient unit (see Figure 12 for formula):

● The number of pulses per rotor revolution (TachoPulsePerRev): this depends on the

sensor (either position sensor: hall, etc. or velocity sensor: tacho generator with n

number of poles, etc.),

● Input clock of the timer (F

): the higher, the better the resolution, usually set to

mtc

16MHz,

● Number of motor poles pairs (PolesPairs).

To obtain the required accuracy (0.1 Hz) throughout the entire speed range, the dynamic

range of a 16-bit capture registers (MZREG and MZPRV) is not enough. The tacho counter

input clock is automatically prescaled according to the rotor frequency that is to be

measured (see ST7MC datasheet for details on this mechanism); this is reported as a factor

ST[3:0]

2

, where ST[3:0] are the prescaler bits from the MPRSR register.

Figure 12. Equations giving rotor frequency with 0.1Hz unit

F

rotor 0.1Hz[]

PolesPairs F

-------------------------------------------------------------- -

TachoPulsePerRev

mtc

10××

------------------------------------------------- -

×=

Capture 2

1

×

ST 3.0[]

Capture 256 MZREG× MZPRV+=

38/102

Page 39

AN1904 Library functions per software module

■ Customizing Rotor Frequency Acquisition

This parameter can be automatically modified by the ST7MC Control Panel. Depending on

the system parameters (sensor characteristics, etc.), you can edit the following defines:

#define POLE_PAIR_NUM ((u8)1) /* Number of motor's pole pairs */

#define TACHO_PULSE_PER_REV ((u8)8) /* Number of pulses per revolution */

TACHO_PULSE_PER_REV

is the number of logical pulses issued (directly or after amplification) by

the speed sensor after each mechanical revolution of the rotor.

POLE_PAIR_NUM is necessary to compute a rotor frequency that ease slip frequency

evaluation. Using P Pole Motors on page 71. For instance 4 pole motors (two pairs) will be

coded as

■

POLE_PAIR_NUM=2.

Zero speed detection

This parameter is not modified by the ST7MC Control Panel but can be edited.

MTC_GetRotorFreq on page 30 for details.

#define MAX_RATIO ((u8)7) /* Max MTIM prescaler ratio defining the lowest

expected speed feedback */

■

Acquisition FIFO size

The depth of the software FIFO stack where tacho information is stored can be modified in a

define (this parameter is not modified by the ST7MC Control Panel):

#define SPEED_FIFO_SIZE ((u8)4)

Increasing this size will result in additional computing time to get the rotor frequency value.

MTC_StartTachoFiltering on page 28 for details of use. Furthermore attention must be paid

to the size of the FIFO, located in memory page 0 for speed optimization: each level of the

stack uses 3 bytes.

PWM frequency set-up

This parameter can be automatically modified by the ST7MC Control Panel. Five values are

proposed: 15.66kHz, 12.5kHz, 7.8kHz, 3.9 kHz and 1.95kHz.

These five values are actually resulting from two base frequencies: 12.5kHz and 15.66kHz.

The other values are derived by modifying the PWM timer prescaler (7.8kHz is 15.66kHz/2,

3.9kHz is 15.66KHz/4, etc.).

For each of these two base frequencies, several parameters have to be modified:

● PWM_PRSC is the value loaded in the PWM counter prescaler

● PWM_MCP0 is the value loaded in the Compare 0 register, which directly sets the

PWM frequency; it is set to 639 for 12.5kHz (and thus linked to the PWM_10BIT key

defined in config.h), while it is set to 511 for all the other frequencies (compiled with the

PWM_9BIT key).

● OFFSET: this value is coding for the neutral point of the sine wave, where the PWM

duty cycle is 50%; this value corresponds to the most significant byte only and has to

be modified according to the MCP0 value.

● const u8 SINE3RDHARM[256]: this is the sine wave reference look-up table stored in

Flash memory. As the maximum value of this table is also linked to the MCP0 value, it

must be changed with the PWM switching frequency. This table can be easily recomputed with the Excel file provided with the library (sine3.xls).

39/102

Page 40

Library functions per software module AN1904

According to the above listed values, the preprocessor recomputes at compile time the

conversion factors used to get the expected stator frequency with 0.1Hz unit (PWM_FREQ

and STATOR_FREQ_RESOL, see Adjusting the CPU load related to sine wave generation on

page 42 for details).

Note: 1 The provided look-up tables contain 3

rd

harmonics by default, which allows around 15%

more voltage to be obtained on a motor, out of a given DC bus, compared to pure sine, see

Third harmonics modulation on page 40 for explanations.

2 The sine wave generation method will be described in details in a dedicated Application

note. Refer to it for implementation details.

To summarize, PWM frequency can be manually modified by editing a conditional

compilation key in config.h:

// Define here the chosen PWM resolution (linked to PWM switching

frequency)

// 0 -> 9-bit: 1.95kHz, 3.9kHz, 7.8kHz, 15.66kHz: cf. "MTCparam.h"

// 1 -> 10-bit: 12.5 kHz

#define PWM_RESOLUTION 1

and the PWM counter prescaler in MTCparam.h:

// Prescaler ratio defines PWM frequency in a rough way:

// 0 -> 15.66kHz, 12.5 kHz (depending on CMP0 value)

// 1 -> 7.8kHz

// 3 -> 3.9kHz

// 7 -> 1.95kHz

#define PWM_PRSC ((u8)0)

Third harmonics modulation

To fulfil the basic AC induction motor voltage needs, the reference PWM modulating signal

can be a pure sine wave (Figure 13 left), but this kind of modulation has the drawback that it

makes poor usage of the DC bus voltage.

Let’s consider Vbus as the bus voltage after mains rectification. One can easily find that the

maximum available voltage on a motor using a standard three-phase power inverter is

around 86% of Vbus.

V

bus

------------

V

phase neutral–

V

phase phase–

2

3Vpk⋅

with V

-------

neutral

3

⋅==

2

Adding a third harmonic modulation to the reference sine wave fundamental decreases the

overall amplitude of the resulting PWM modulation (PWM duty cycle never reaches either

0% or 100%, Figure 13 right). This is due to the fact that the minimum of the 3rd harmonic

corresponds to the maximum of the fundamental and vice versa.

V

bus

----------- -==

2

V

bus

40/102

Page 41

AN1904 Library functions per software module

Figure 13. Pure sine wave modulation and equivalent with third harmonic added

Sinewave modulation

120

100

80

60

40

20

0

PWM duty cycle (full modulation)

-20

PWM Modulation

As a consequence, this allows the fundamental + 3

Sinewave modulation with 3rd harmonic injection

equivalent to pure sinewave modulation

120

100

80

60

40

20

PWM duty cycle (full modulation)

0