AN1902

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

®

- APPLICATION NOTE

VIPower: HF CO NVERTER BASED ON VK 06TL

DEVICES TO DRIVE 58W TL TUBES

N. AIELLO - S. MESSINA

This document des cribes a re ference desi gn for Lightin g Ballast dedicate d to drive 58 W T8 tubes. The

board accepts DC in put vo l tage (u p to 430V ) reali zing the c athod es pr ehea ti ng, t he E oL prot ecti on a nd

the maximum current limitation. It is based on the new VK06 device that integrates the controller and the

Power stage on the same chip. It is housed in SO-16 and SIP-9 packages.

INTRODUCTION

The European Comm unity has agreed on a new direct ive for banning electro magnetic control gea r for

fluorescent lamps. The aim is to improve the system efficiency (EEI-Energy Efficiency Index) reducing

the environmen tal impact. This new di recti ve div ide s the b all ast in different classe s fr om A1 to D . A1 is

the most efficient system, D the least efficient.

■ A1 → Dimmable electronic

■ A2 → Low-loss electronic

■ A3 → Standard electronic

■ B1 → Extra low-loss magnetic

■ B2 → Low-loss magnetic

■ C → Normal-loss magnetic

■ D → High-loss magnetic

Since 1998, the energy classi fication has be come compulsory and it has be en inserted in a Cenelec

standard. It means:

- since April 2002, all ballasts with an EEI of D are banned;

- starting from October 2005, all ballasts with an EEI of C will be banned.

Thus the market is aski ng for cost effectivene ss, good per formance, l ow noise and com pact ballasts to

feed this kind of applications. The VK06 is a very suitable device, satisfying all the requirements with few

external components.

The proposed reference design can supply 58W T8 FL tube with preheating function and EoL

protection. Being the design reference focused on the converter realization (we don ’t co ver the PFC

stage) it has been set to give out the right output power when 400V dc voltage is applied.

1. VK06 DESCRIPTION

The VK06 is a monolithic device made by using the VIPower® M3-3 STMicroelectronics proprietary

technology that integrates in the same chip a vertical flow Power stage and a BCD based control circuit.

The Power stage is made by a high v oltage Bipolar transistor together with a low voltage n-channel

MOS transistor in emitter switching configuration Its performances are a good trade-off betwee n the

Bipolar transisto r low drop/hig h breakdow n voltages and the MOS transi stor hi gh switching s peed. The

block diagram is shown in figure 1.

March 20 04 1/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

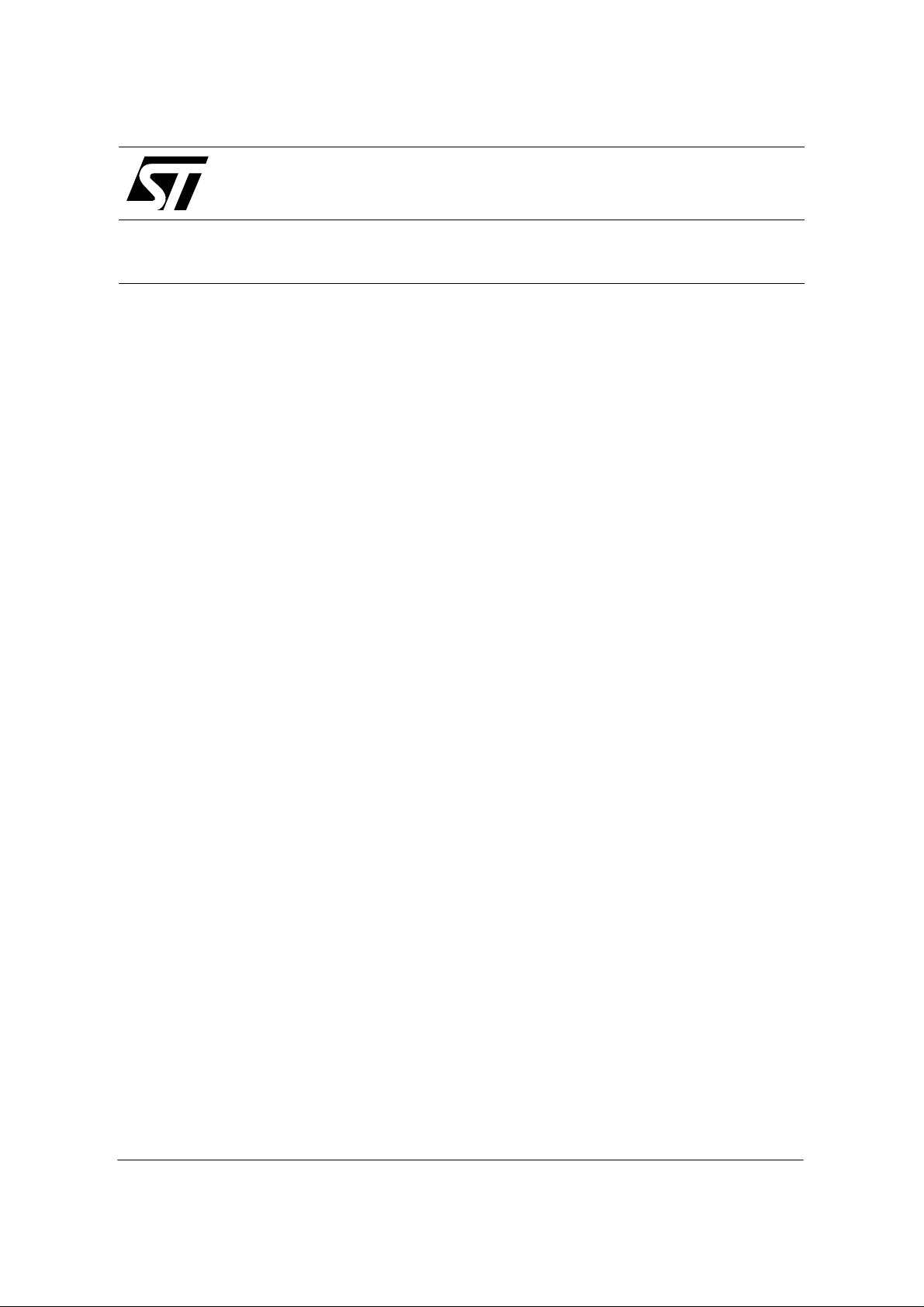

In the control part the following sections can be analyzed:

1) Supply

2) Oscillator/Trigg er

3) Diac

4) Protections

Figur e 1: VK06 Internal Block diagram

VCC

SEC

DIAC

CapPREH

Vdd

CLAMP

Vref1

DIAC

Reset

Preheating

Vcc

diac on/off

COLL

sec on/off

protection

Vref3

Vcc

Vcc

Reset

CAP1

Vdd

Vref2

Vdd

Supply

Vref4

CAP2 CAP1 GND

Delay on

protection

Gate Driver

latch

Vcc

Vcc charge

VddVcc

Vref6

CapEOL

Bipolar Driver

Over Curr ent

Detector

Over Temperature

Detector

Vcc

Vcc

Vref5

COLL

sense

R

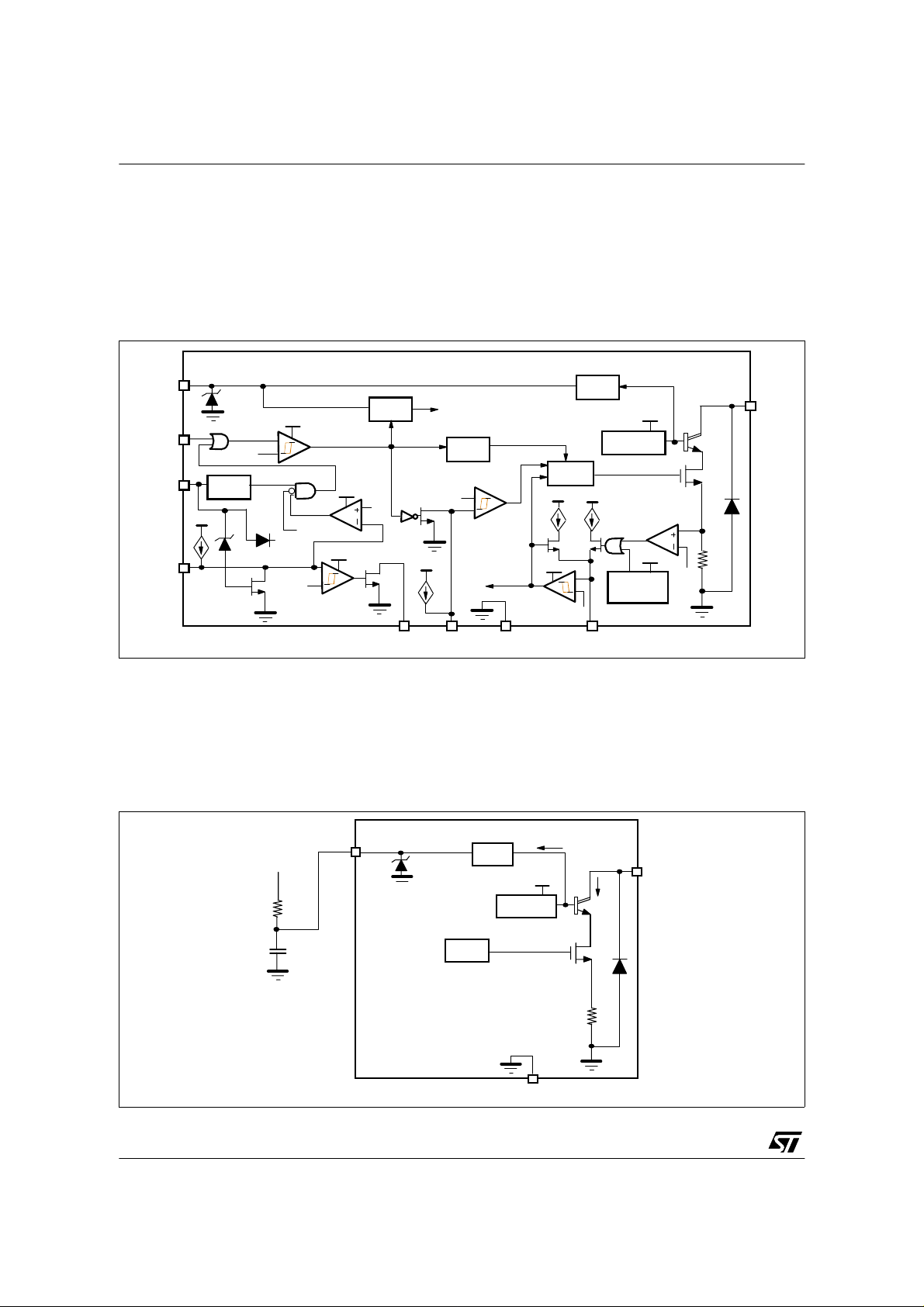

1.1 SUPPLY (Figure 2)

The device is supplied from the VCC pin connected to an R-C network. From VCC both the control and the

power stage are supplied. A t start up the supply capacitor is charged through a resistor and only few

hundreds µ A are ne eded. Duri ng the opera ti on the devic e is s elf-supplied recovering o n VCC the charge

taken from the Power Bipolar base at turn-off. The voltage on VCC is internally clamped at ~6.8V.

Figur e 2: Internal Supply Block

Bipolar Driver

Ic

Vcc

R

COLL

Ic

sense

DC BUS

VCC

CLAMP

Vcc charge

Gate Driver

GND

2/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

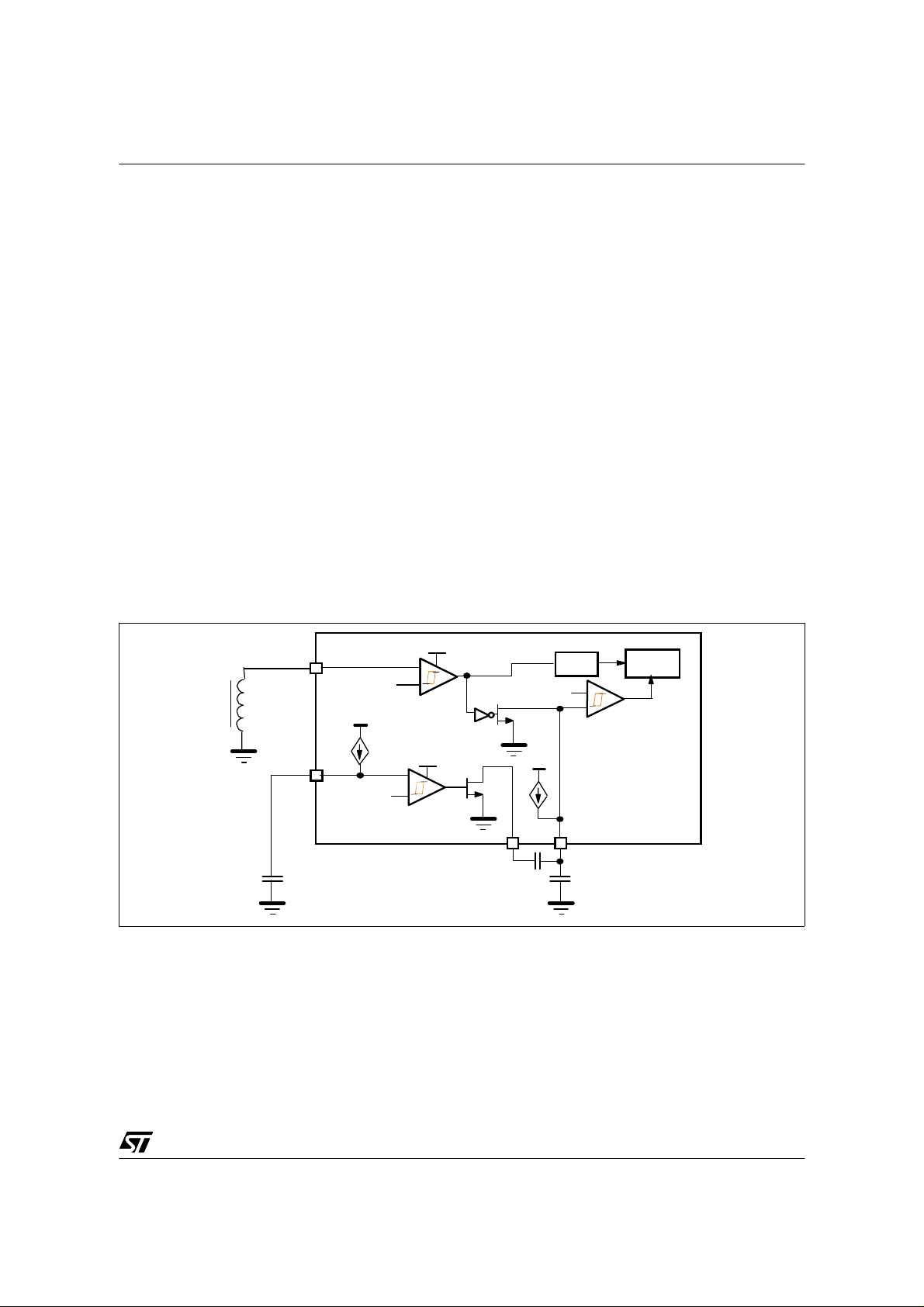

1.2 OSCILLATOR/TRIGGER (Figure 3)

It fixes the conver ter working frequenci es (preheating, ign ition, and steady-state ). The tON (conducti on

time) is set using S EC, CAP1, CAP2 and C apPREH pins. T he device is tri ggered ON when the voltage

on SEC reache s ~2.2V. When this condition is detected the Pow er stage is switched ON and internal

current gene rators start to give co nstant currents to C AP1 and CapPREH. T he device will be switched

OFF when one of the two following conditions is present: the voltage across CAP1 is equal to the internal

voltage referenc e (~2.3V), the voltage on S EC is lower than 0.9V. Using a capacitor on CapPREH and

the two frequency capacitors on CAP1 and CAP2 it is possible to have both preheating and steady state

frequencies. Until the voltage on CapPR EH is lower than 4.2V only the Cfpreh (capaci tor connected to

CAP1) will be cha rged setting the prehea ting frequency. When 4.2V on CapPRE H pin is overcome, an

internal switch puts in parallel Cfpreh with the Cfst capacitors (connected between CAP1 and CA P2)

lowering th e fre quency to the steady-state one. The value of CapPREH fixes t he pr ehea ting dur ati on. In

all the operative conditions the frequency capacitors will be discharged when the voltage on SEC

becomes lower than 0.9V.

During the la mp igni tion the frequency cont rol is realized throug h the secondary wi ndin gs wou nd o n the

primary choke and connected to the SEC pins. In this phase the voltage on SEC reaches 0.9V before the

tON is set by the f requency capacitors. The system oscillate at its resonance freq uency (higher than

steady state one ) allowing the tube igniti on. After the tube ignition the tON will be set by the frequenc y

capacitors.

An internal delay at Power turn-on avoids the hard switching condition.

Figur e 3: Internal oscillator/trigger block

Vcc

Vcc

Reset

CAP1

CAP2 CAP1

Cfst

Vdd

2.3V

Delay o n

Cfpreh

Gate Driver

SEC

2.2V

Vdd

CapPREH

4.2V

Cappreh

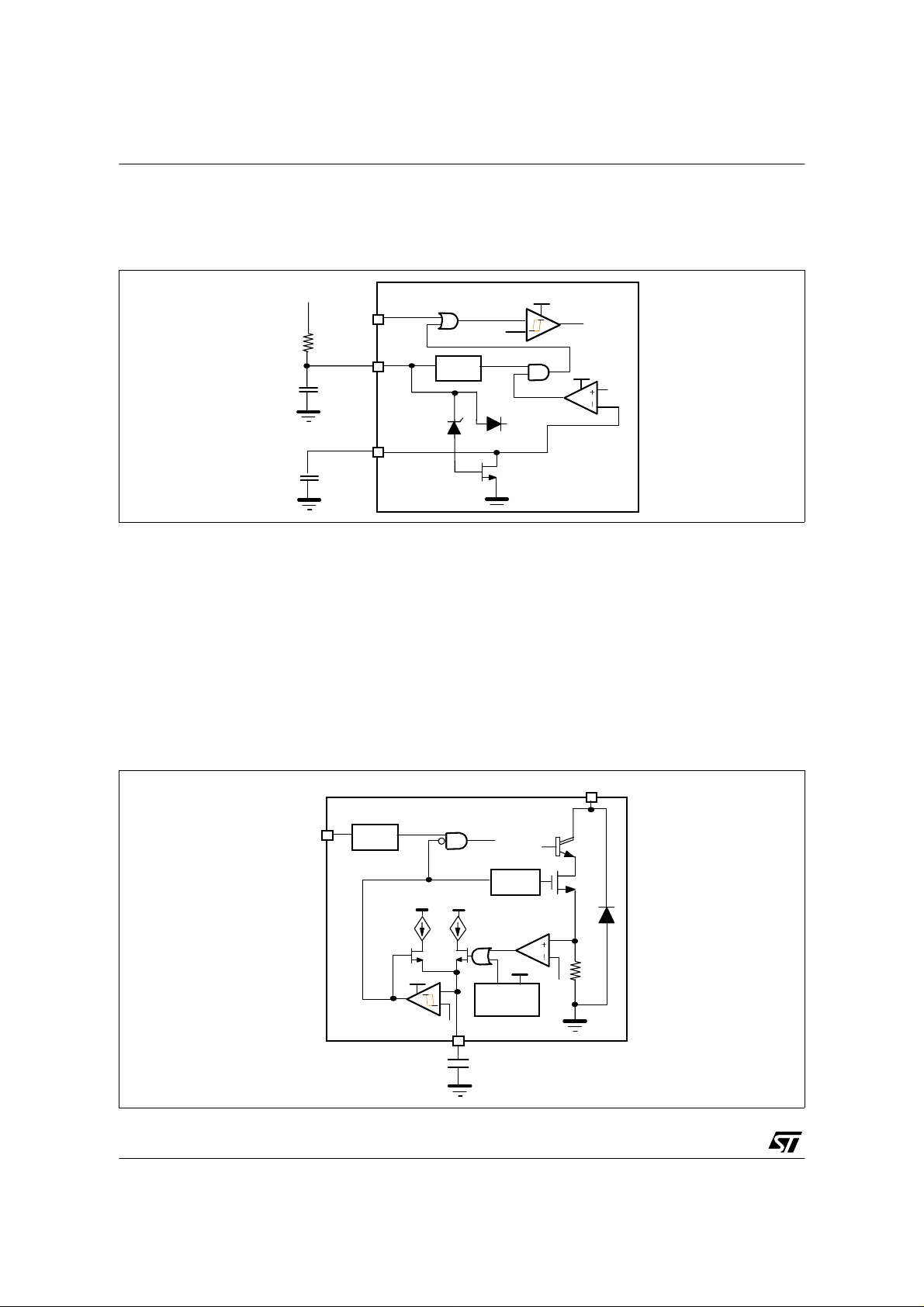

1.3 DIAC (Figure 4)

Through the DIAC pin two functions are achieved: start of oscillations and reset of the preheating

capacitor CapPREH.

1) St art of oscillation: in OFF condition (voltage on the SEC pin lower than 2.2V) the device can be turned

ON when t he voltage across DIAC ov erco mes ~ 28V. An HV diode keeps the DIAC low when the Po wer

stage is ON.

2) Reset of preheating capacitor: in order to guarantee the right preheating timing the preheating

capacitor must be discharg ed before starti ng oscilla tions. To realize this function a switch on CapPREH

3/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

pin is activated when the voltage across DIAC pin overcomes ~12V. On the other side the diac can

activate the circuit only when the voltage on CapPREH becomes lower than ~0.6V.

Figur e 4: Internal diac block

DC BUS

DIAC

CapPREH

Cappreh

SEC

DIAC

Reset

Preheating

Vref1

diac on/off

COLL

Vcc

sec on/of f

Vcc

0.6V

1.4 PROTECTIONS (see figure 5)

The device is protected against over-current and over-temperature. Both protections are activated

connecting on the CapEOL p in a capacitor that fixes the timing. T he over-curren t protection works as

follows: an internal Rsense checks the cur rent through the Power stage and if it exceeds ~1.5A, an

internal generator gives current to CapEOL pin. When the voltage across CapEOL pin reaches ~4.3V the

Power stage is kep t OFF, the diac is deactivated and the current consum ption from VCC is lowered. At

the same time another current generator is activated latching the device in OFF state.

The thermal prote ction is activated when the junction temperatu re exceeds ~150°C. This block, wh en

activated, acts on the same EoL circuit latching the device.

Figur e 5:. Internal protections block

COLL

Vcc

Vcc

Capeol

diac on/off

Vdd

4.3V

Gate Driver

Over Current

Detector

Vcc

Over Temperature

Detector

CapEOL

Rsense

Vref

DIAC

DIAC

latch

protection

4/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

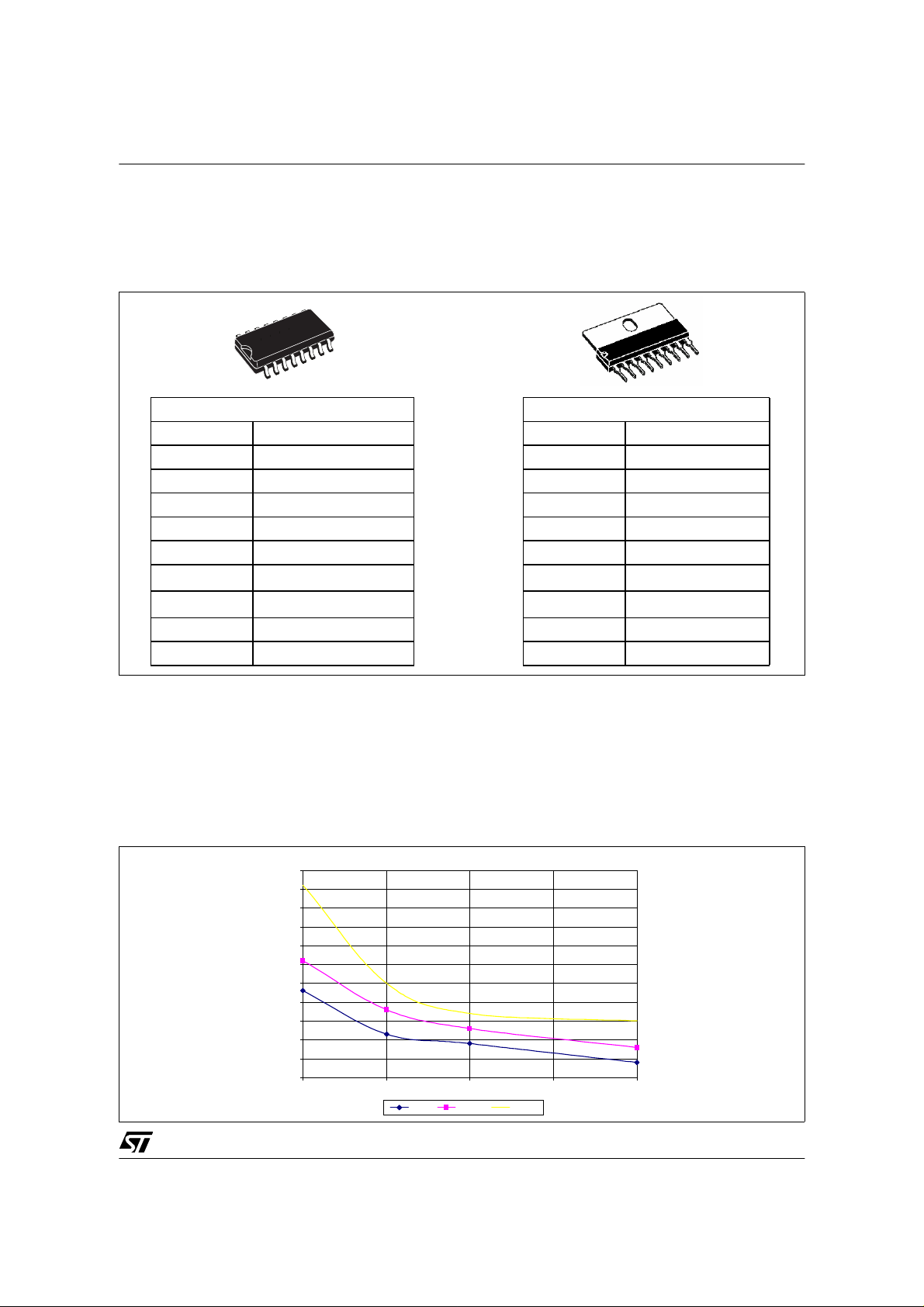

2. PACKAGES

The VK06 is ass embled in two different packages in order to cover both the s urface mounting and the

through-hole PCB. The packages are the SO-16 narrow and the SIP-9 (see figure 6).

Figur e 6: Package outline and pin configuration

9

16

8

1

1

9

SO16 PACKAGE SIP9 PACKAGE

N° pin Name N° pin Name

1 CAP1 1 CAP1

2 CapPREH 2 CapPREH

3 GND 3 GND

4DIAC 4DIAC

5 SEC 5 COLL.

6V

CC

7CAP2 7V

6SEC

CC

8 CapEOL 8 CAP2

9÷16 COLL 9 CapEOL

In figure 7 the SO-16 thermal characterization is reported. In this package eight pins are connected to the

tab to reduce the junction-pin thermal resistance whereas the case-ambient thermal resistance is related

to the copper a rea on the P CB (device h eat-s ink). The devi ce has bee n charac terized at th ree differe nt

copper ar eas: 0.5, 1 and 2 cm2; at three different po wer dissipatio ns: 0.25, 0.5 and 1W an d measur ing

the devices case temperatures.

Figur e 7: SO-16 R

th case-ambient

°C/W

Vs. PCB Copper Area

160

150

140

130

120

110

100

90

80

70

60

50

0 0.5 1 1.5 2

Rth case-ambient

1W 0.5W 0.25W

Cm

2

5/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

In Figure 8 the SIP-9 thermal characterization (no heat-sink) is reported.

Figur e 8: SIP-9 R

th case-ambient

[°C/W]

(no heat-sink)

46

45

44

43

42

41

40

39

0 0.25 0.5 0.75 1 1.25 1.5 1.75 2

Rth case-ambient

[W]

3. CONVERTER DESCRIPTION

In figure 9 th e elec t ric al sc hem e, re ali zing a v oltage-fe ed c on verte r based on VK06 is repo rted. The two

windings Ls connected to the S EC p ins are wou nd on th e chok e Lp. Four different o perative phases can

be described:

- start-up

- preheat

- steady state

- ignition

Figur e 9: Typical application circuit

R14

C12

R1

C3

C15

C16

C10

C6

VCC

CAP2

CAP1

CapPREH

VCC

CAP2

CAP1

CapPREH

C9

CapEOL

CapEOL

COLL

DIAC

SEC

GND

Ls

COLL

DIAC

SEC

GND

C8 C7

Ls

R15

C11

Dz2

R3

C4

C14

R10

Lp

Tube

C2

DC BUS

C1

Cbulk

D1 Dz1 R6

6/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

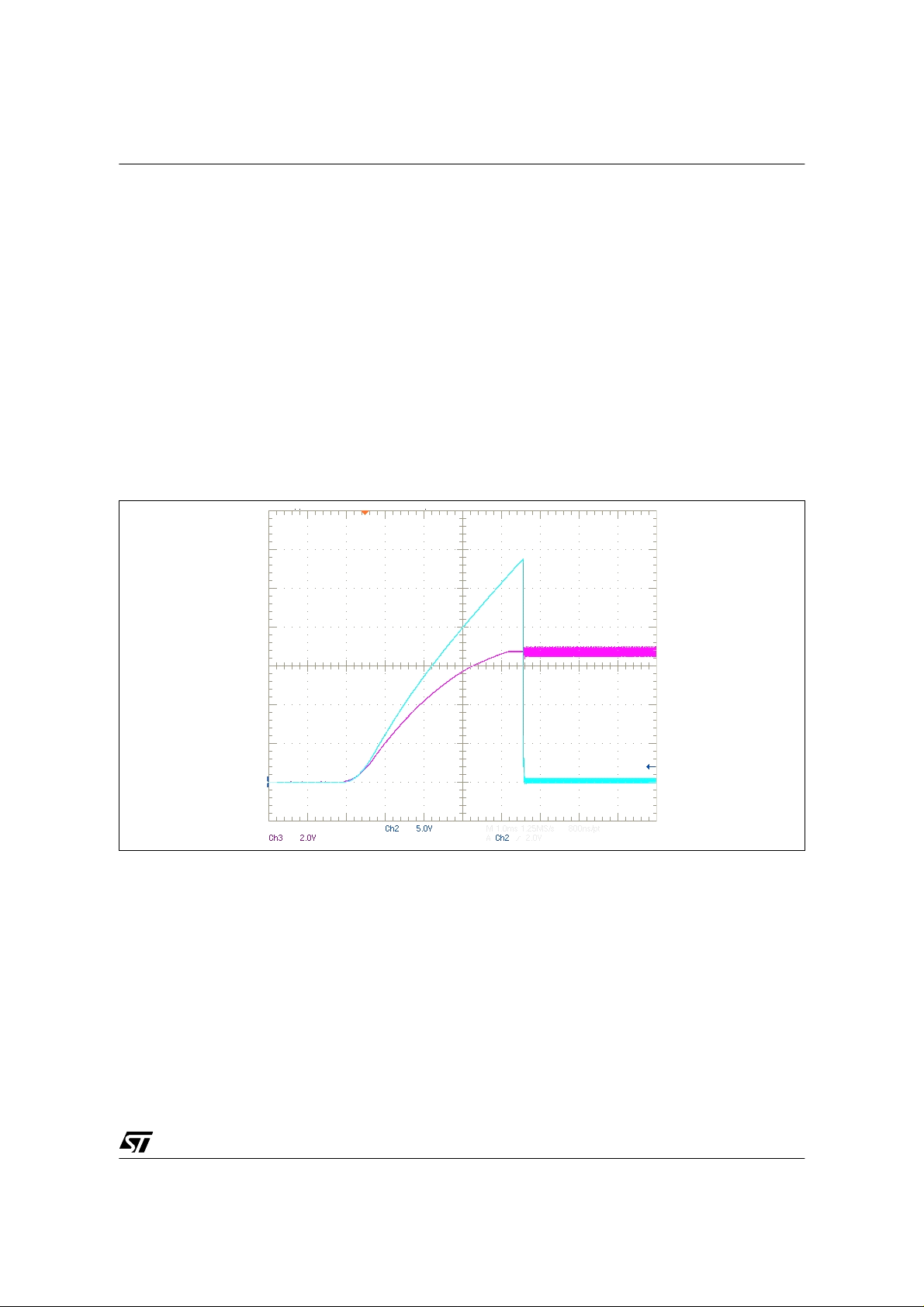

3.1 START-UP

As soon as the system is supplied, the VCC capacitors C3 and C1 2 start to be ch arged from the DC bus

respectively by means of the resistors R1 and R14-R10. At the same time, the low side diac capacitor C4

starts to be charged by the resistor R3. The network R15-C11 biases the high side DIAC.

In normal ope rations the l ow side device is the one to go o n the fir st time, wh ile in the h igh side d evice

the DIAC pin, clamped by Dz2, is used only to reset the preheating capacitor C9.

As soon as the voltage on C4 reaches about 28.5V the diac block switch ON the device. At that time both

devices must b e biased with the minim um requested VCC voltage (~ 5V) in order to make the system

oscillate properly.

In figure 10 low side (LS) diac and VCC typical wave forms are shown. In the picture the VCC voltage

reaches 6.8V after 4.2 m sec rema ini ng constant at th is value (it is internally clampe d) until the converter

starts to oscillate. At that time the storage charge recovery will be responsible f or the device supply,

charging the VCC capacitor at the final voltage value (~6.8V).

Figure 10: Typical start-up operation

LS DIAC pin voltage

For the diac and VCC biasing networks the following choices can be done:

R14=R10; R14+R10=R1; C3=C

R15>>R

With this setting the converter midpoint will stay at V

the same for any DC bus voltage.

For a proper start up phase the following condition has to be satisfied:

14

dcbus/2

LS V

pin voltage

CC

12

and the voltages across C3 and C12 will be

VC3=V

≥ 5V when V

C12

=28.5V

C4

7/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Where:

τ

Vc3=R1

The networ k R15-C11 must be chosen to have the co mplete discha rge of C9 when th e low side diac

strikes the converter. The zener diode Dz2 (~18V) clamps the DIAC pin below the diac activation

threshold.

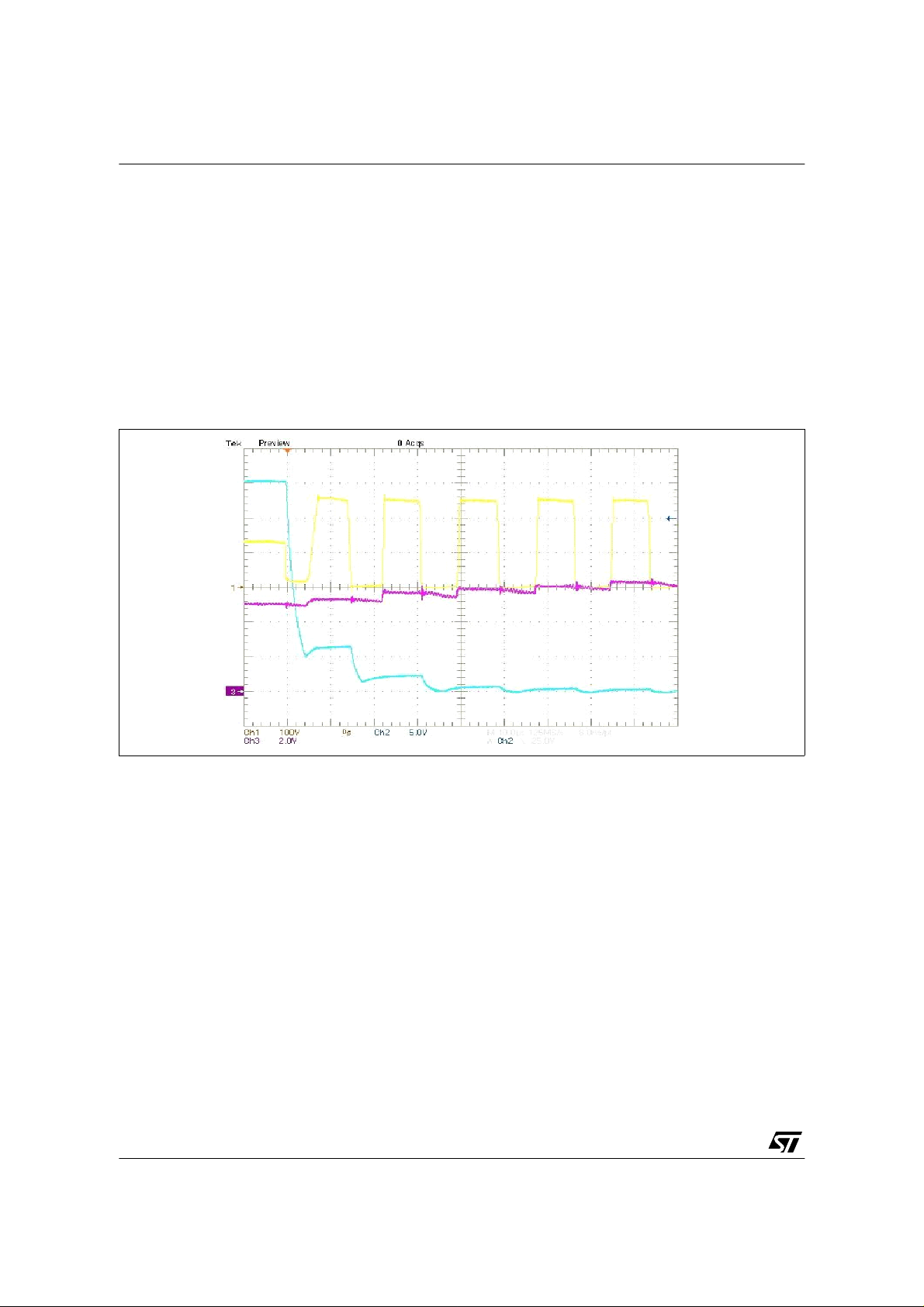

During oscillations the diac capacitors C4 and C11 will be discharged b y the in ternal diod es connect ed

between DIAC and Power collector while the VCC capacitor will be charged by the charge recovered from

the Power stage (see figure 11).

Figur e 11: Typical waveforms after the diac strike

Mid point voltage

• C

τ

Vc4=R3

3

= (R

• C

14 + R10

(low side)

4

) • C

12

LS VCC pin voltage

LS DIAC pin voltage

3.2 PRE-HEAT

Still referring to the figure 9, the capacitors C7-C9 (with C7=C9) fix the cathodes preheating time

duration. The preheating frequency is set by the capacitors C10-C6 (with C10=C6).

3.2.1 PRE-HEATING TIME

CapPREH pin supplies a constant current I

capPREH

~

55µA. This current is supplied only during the t

ON

.

The preheating ends when 4.2V is reached on CapPREH.

Assu ming that

V

∆ 4.2V=

CapPREH

I

CapPREH

the preheating time t

55µA≅

will be:

preh

V

∆

CapPREH

t

preh

-------------------------- -

C7

• 0.15s==

I

CapPREH

---------------------

2

/µF

8/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

3.2.2 PRE-HEATING FREQUENCY

For the pre-heating frequency calculation the following considerations can be done:

1

--

f

=

1

-- -T t

2

ON

++=

t

storage

t

dVdt

T

t

storage

const 300n≈= sec

(storage duration of the device Power stage)

tdV/dt is the duration of the snubber capacitor (C14) charge during the half-bridge mid-point commutation

between ground and VDC bus.

It can be calculated using the following relationship:

t

dV/dt

= C

snubber

x

∆V/i

peak

where:

■ ∆V (DC bus voltage);

■ i

(peak current);

peak

■ C

(snubber capacitance).

snubber

tON is the conduction time fixed by the preheating frequency capacitor (C6) and device characteristics.

It can be calculated according to the following formula:

tON=K • C6

Where K=6.7µsec/nF (fixed by the VK06)

3.3 STEADY STATE

The steady stat e fre quen cy is se t by the par all el of the capac itors C 6- C16 for the l ow si de a nd C10- C 15

for the high side, where C16=C15. The same formulae of the preheat can be applied:

1

--

f

=

1

-- -T t

2

t

storage

ON

++=

const 300n≈=

t

storage

t

dVdt

sec

t

ON

KC6C16+()=

T

3.4 IGNITION

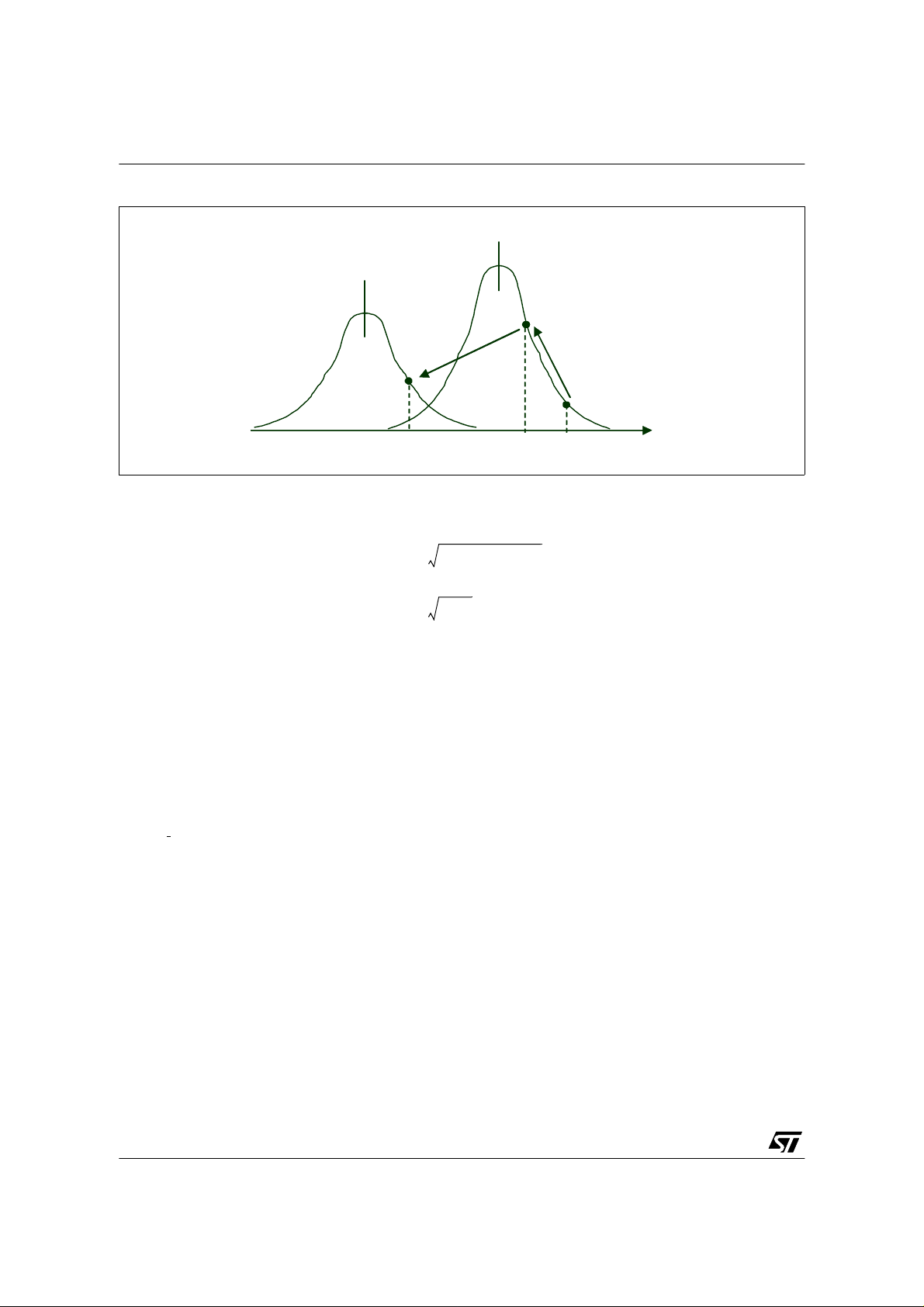

The converter of figur e 9 has two different resonan ce frequencies, the firs t one before the tube igni tion

the second o ne after the tube ignition . Th e con verte r operation from preh eat to st e ady state is shown in

figure 12.

9/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Figure 12: Load typical resonance curves

Resonance frequency

after the tube ignition (f2).

Where the two frequencies are:

f

1

f

2

3

------------------------------------------------

=

2

π L

-----------------------

=

2

π L

1

seriesC

()

PC1

1

PC2

Resonance frequency

before the tub e ignition(f1).

2

1

fpreh

fign fsteady

(before the tube ignition)

2

(after the tube ignition)

f

In good b allast design the cathode prehe ating is requeste d in order to increase the tub e lifetime. I t is

obtained making high curren t flow through the cathodes for a fixed time. A simple rule for the prehea ting

efficiency check is reported:

1) measure the cathode resistance at the beginning of the preheating;

2) measure this resistance at the end of the preheating;

3) if its value is increased 3-4 times, the cathodes will work at the right temperature during ignition.

During the preheating the current level has to be able to heat the cathodes without generating the ignition

voltage on the start-up capacitor C1. Still referring to figure 12, the converter will operate as follows: it will

start working at the pre heat in g frequ ency (do t 1) that mu st be higher than the re sonance freque nc y f1. It

will remain in this condition for the time fixe d by the preheating capacitor. After the preheating the device

frequency control is taken by the two secondar y windings mov ing the working fre quency up to the dot 2

where the tube is supposed to ignite. Once the tube is ignited the converter resonance frequency is

lowered to f2 and the conver ter can work at the steady state frequency (dot 3) fixed by the o scillato r

capacitors.

In figure 13 the complete start-up sequence is shown.

10/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 13: T ypical converter operation from start-up to steady state

AN1902 - APPLICATION NOTE

Preheating

Ignition

3.5. PROTECTIONS

The converter is protected against:

- End of Life (EoL)

- Overtemperature

- Overcurrent

3.5.1 End of Life

If the tube is in EoL conditi on it w ill not ignite any mo re for cing the c onve rter to work at its reson ance (f1 )

with very high current levels. This condition must be checked, stopping the oscillation, before the system

destruction for high power dissipation. In the suggested converter (figure 9) the EoL condition is detected

in the low side VK06 using the capacitor C 8 connected to C apEOL pin. Th is pin is shorted (di sabled) i n

the high side device.

The protection is activated as follows: an internal Rsense checks the current through the Power stage. If

this current exceeds ~1.5A an internal generator supplies current (i

soon as the voltage acros s CapEOL p in reaches ~4.3V (∆v

diac is deacti vated and the curr ent consu mption from VCC is lowered. At the same time another c urrent

generator is activated latching the device. This condition is maintained until the DC bus voltage is

present. Th e duration of EoL co ndition before latch ing is establishe d by C8 according to the f ollowing

considera tions.

I

t

×

EOL

C

8

M

---------------------

=

∆

v

EOL

Steady-state

about 350µA) to CapEOL pin. As

EOL

) the Pow er stage is switched OFF, the

EOL

11/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

where:

IM = average current flowing into C8 during the period of oscillation. Referring to the figure 14, IM can be

i

×

EOLtch earg

-------------------------------

I

M

f is the frequency during EoL condition (~ resonance frequency)

Combining the equations we obtain:

C

Figure 14: Device current during the EoL condition

T

i

× f t

EOLtch earg

--------------------------------------------------------

=

8

∆

× f×==

i

EOLtch earg

v

EOL

××

EOL

1.5A

t

Figure 15 sh ows the operation during the EoL condition. The ca pacitor C8 is maintained d ischarged

during the preheating phase and the oscillation are stopped as soon as it is charged to 4.3V

LS Collector current

charge

12/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 15: Operation during the EoL phase

AN1902 - APPLICATION NOTE

Choke Curre nt

LS CapEOL pin Voltage

3.5.2 OVERTEMPERATURE

A thermal protection is activated when the junction temperature exceeds ~150°C. Its effect i s the same of

the EoL detection. For the timing definitio n it must be considered t hat the current gener ator on CapEOL

pin is activated during the tON of the device.

The duration of the over-temperature condition before latching (tTH) can be calculated as follows

v

∆

EOL

t

th

where:

i

= 350µA;

EOL

∆v

=4.3V.

EOL

3.5.3 OVERCURRENT

The network D1, Dz1 and R6 connected between SEC and CAP1 pins realizes the overcurrent

protection l imiting the maximu m accepted peak curr ent. This function is v ery useful during the ign ition

and the EoL, where the converter, working v ery close t o the resonanc e frequen cy (f1), can re ach very

high current levels (possibility of saturation of the transformer). This circuit is applied only on the low side

VK06. It works anticipating the device switch OFF when a defined current level is reached, in other words

the working frequency is incre ased. The modality is the following: an increasing in the current value

causes an i ncrease of t he seconda ry wind ing voltage (we are work ing at the reso nance frequen cy). As

soon as this voltage exceeds the zener Dz1 + diode D1 brea kdown, an amount o f current will flow into

-------------- -

C

×=

8

I

EOL

----------

2

13/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

the frequency capacitor anticipating the device switch-OFF. The resistance R6 limits injected current

realizing a d elay in the capacitor ch arge. The diode D1 d ecoup les SEC and CAP1 pins d uring t he OFF

state (negativ e voltage on SEC pin). In figu re 15 the EoL inte rventio n with th e current limited at 2,4A i s

shown.

3.6 MORE ABOUT THE TRIGGER

With high resist ive tubes the voltage on the secondary w indings could decrease very rapidly, reaching

the SEC pin switch-OFF threshold (0.9V), before than the internal oscillator switch OFF the device. This

cause an increase of the working frequency.

The phenome non can be explained as foll ows: the voltage drop on the chok e Lp is equal to V

minus the drop on the impedance made by the tube and C1 that is proportional to the current.

The voltage on the secondary windings is a fixed portion of the primary one. If the voltage on Lp becomes

zero no voltage will be transferred on SEC pin and the device will be switched-OFF.

The higher is the tube impedance the lower is the current level at which the situation can occur.

In this case to guar antee the r ight fre quency contro l, an R-C or R -C-D filter h as to be ins erted betwe en

the secondary winding and SEC (see figure 16).

The values of R 1f and C1f have to be c hosen in order to maintain the v oltage on SEC pin high er than

~0.9V during the fixed tON even if the voltage on the secondary winding becomes zero or negative.

On the other side it is important to have the SEC pin voltage higher than 2.2V before the end of the free-

wheeling diod e conduction to avoid delay at Power switch-ON. Therefor e the filter dimensioning is a

trade-off between the charge and the discharge time constant.

The circuit reported in figure 16b can be used if different and independent time constants are necessary.

DCbus

/2

Figure 16: External trigger circuits

C1f

SEC

SEC

VK06

VK06

a)

b)

R1f

C1f

R2f

R1f

Df

3.7 CONVERTER FOR COLD IGNITION APPLICATIONS (NO PRE-HEAT)

For applicati ons where the pre- heating of t he cathod es is no t reque sted, it is po ssib le to use a sim plifi ed

converter as reported in figure 17.

14/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 17: Application circuit without preheat

AN1902 - APPLICATION NOTE

R14

C12

R1

C3

C10

C6

VCC

CAP2

CAP1

CapPREH

VCC

CAP2

CAP1

CapPREH

CapEOL

CapEOL

C8

COLL

COLL

DIAC

GND

DIAC

SEC

GND

SEC

DC BUS

Ls

Ls

R3

C4

C14

R10

Lp

C1

Tube

Cbulk

C2

4. VK06 Design Reference

This design reference has been developed to help the VK06 users in the application board development.

To point out the m aximum VK06 performa nces we decided to drive a 5 8W T8 FL tube. Two different

PCBs have been realized, the first on e using only su rface mounting com ponents and the seco nd one

using only through hole components. In the figure 18a, 18b, 18c their photos are shown.

15/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Figure 18: VK06 demoboard: SMD components, top (a) and bottom (b) view; through-hole top view (c)

a)

b)

c)

4.1 Electrical scheme

In figures 19 and 20 th e electri cal sche mes for both tro ugh hole and s urface mou nting de moboards ar e

shown.

16/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 19: Thro ugh hol e compone nts demoboar d electr ica l scheme

AN1902 - APPLICATION NOTE

M1

F1

R1

58W

C1

R4

C2

T1

R12

C13

R14

C12

R15

C11

C10

Dz2

4

7

VK06TLS

1

6

7

VK06TLS

4

1

6

C16

5

C15

5

C9

3

9

2

8

+

3

2

8

C14

R10

R8

C7

C8

+

R5

D1

Dz1

C4 C3

C5

R6

C6

17/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 20: SMD demoboard electrical scheme

F1

AN1902 - APPLICATION NOTE

R1

M2

58W

C1

R2

C2

R3 R4

T1

R12

C13

R5

R14

R13

C12

C11

R15

R16

Dz2

6

4

5

6

4

5

9÷16

VK06TL

1 2

7

C15

C10

R18

9÷16

VK06TL

1

7

C16

R17

3

8

C9

3

8

2

C8

C14

R10

R9

R8

D1

Dz1

R6

C3

C4

C5

C7

C6

4.2. COMPONENTS LIST

The material lists for both PCB are reported in tables 1 and 2.

18/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Table 1: Components list of the VK06 demoboard with trough hole components

Reference Value Description

R1

R4

R5, R12

R6

R8

R10, R14

R15

C1

C2

C3, C12, C8

C4

C5, C13

C6, C10, C15, C16

C7, C9

C11

C14

D1

Dz1

Dz2

T1

IC1, IC2

330kΩ 1/2W 5% 400V Resistor

1MΩ 1/2W 5% 400V Resistor

15kΩ 1/4W 5% Resistor

68kΩ 1/4W 5% Resistor

1MΩ 1/4W 5% Resistor

180kΩ 1/2W 5% 400V Resistor

2.2MΩ 1/2W 5% 400V Resis tor

8.2nF 2000V 5% Resonan t capacitor

100nF 400 V Capaci tor

330nF 16V 10% Capaci tor

47nF 50V 10 % Capacitor

100 pF 100 V 10% Capacitor

1nF 2% Capacitor

4.7µF 16V 20% Electrolytic capacitor

10nF 50V Capaci tor

1nF 630V Snubber capacitor

If=0.15A Vrrm=75V Rectifier diode

36V Zener diode

18V Zener diode

1.8 mH 10% Resonant Inductor Pulse Eld or 60010019

STMicroelectronics VK06TLS

THROUGH HOLE COMPONE NTS DEMOBOARD INDUCTOR SPECIFICATION

MECHANICAL DRAWING (Bottom view) MECHANICAL DRAWING

ELECTRICAL CONNECTION ELECTRICAL CHARACTERISTI CS

Nominal Inductance (W 1=1-8) L=1.8m H ± 10%

Core EC 28

Turn ratio = W1/W2=W1/W3=10

2 = Lamp;

3 = Ground;

4 = Low Side SEC pin;

5 = Not connected;

8 = High Side SEC pin;

9 = Not connected;

11 = Mid Point

19/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Table 2: Components list of the VK06 demoboard with SMD components

Reference Value Description

R17,R18 R19,R20 0 Ω Zero ohm Resistor

R15,R16 1MΩ 200V 5% 200V Resistor 1206

R8 1MΩ 5% Resistor

R3,R4 470kΩ 5% 200V Resistor 1206

R1,R2 220kΩ 5% 0.25W 200V Resistor 1206

R9,R10 R13,R14 100kΩ 5% 0.25W 200V Resistor 1206

R5,R12 15kΩ 5% Resistor

R6 68kΩ 5% Resistor

C5,C13 100pF 10 0V 10% Capacitor

C6,C10 , C15,C16 1nF 2% 16V Capacitor

C7,C9 4.7uF 10% 16V Capacitor

C3,C8,C12 330nF10% 16V Capacitor

C11 10n F 50 V Capac itor

C4 4 7n F 50 V 10% Capac itor

C1 8. 2n F 5% 20 00 V Resonant capa ci t or

C2 100nF 40 0V Capacitor

C14 1nF 630V Snubber capacitor

D1 If=0.15A Vrrm=75V Rectifier diode

Dz1 36V Zener di od e

Dz2 18V Zener di od e

T1 1.8 mH 5%

IC1, IC2 STMicroelectronics VK06TL

Resona nt Inductor VO G T: LL 010 205 31

TDK: SRW2 5EVD4-E01H003.

SMD COMPONENTS DEMOBOARD INDUCTOR SPECIFICATION

MECHANICAL DRAWING (Bottom view) MECHANICAL DRAWING

ELECTRICAL CONNECTION ELECTRICAL CHARACTERISTI CS

Nominal Inductance (W 1=1-8) L=1.8m H ± 5%

Core EVD 25

Turn ratio = W1/W2=W1/W3=10

1 = Lamp;

2 = Ground

3 = Low Side SEC pin;

5 = High Side SEC pin;

8 = Mid point

20/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

4.3. PCB DEFINITION

In figures 21 and 22 the proposed PCB for both SMD and trough hole demoboards are shown.

Figure 21: SMD PCB Bottom view (not in scale)

Figure 22: Through hole PCB Bottom view (not in scale)

The componen ts placement on the PCB is important and few simple ru les have to be followed for its

realization.

1) Frequency capacitor placement:

These components must be connected as close as possible to the CAP1 pin.

2) Ground path:

The ground paths (signal and power) must be separate in order to reduce interference on the logic part.

In figure 23 an example of this rule is shown.

21/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Figure 23: PCB Ground path

Signal Ground

Power Ground

4.4. EXPERIMENTAL RESULTS

For the board testing it is i mportant to connect on the input termina ls an electrolyti c capacitor (10µF,

450V), in order to bypass the parasitic inductance present in the connection wires between the DC

supply voltage and the board (see figure 24).

Figure 24: Connection between the DC supply voltage and the board

DC Power Supply VK06 Demoboard

All the measurements have been done supplying the converter with 400V DC.

4.4.1 START-UP PHASE

In figure 25 the start-up phase is shown. The voltages on the low side (LS) VCC and diac pins are

reported.

It is possible to notice that th e VCC voltage reaches its cl amp value (~6.8V) before the dia c strike. In

figure 26 the first oscillation cycles after the diac strike are shown.

22/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 25: Start-up phase

AN1902 - APPLICATION NOTE

LS DIAC pin voltage

LS VCC pin voltage

Figure 26: First oscillation cycles after the diac strike

LS colle ctor current

Mid point voltage

LS DIAC pin voltage

4.4.2 PRE-HEATING PHASE

The preheati ng frequen cy has to be fi xed in order to reach a cur rent le vel enough to h eat the catho des

without tube ignition. Figure 27 shows the main waveforms of the LS device.

LS VCC pin voltage

23/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 27: Operation during the pre-heat

LS CAP1 pin voltage

AN1902 - APPLICATION NOTE

LS SEC pin voltage

The preheating frequency is ~59KHz with a peak current of ~800mA.

Being the reson ance capacitor C1= 8.2nF, d uring the preheat its voltage is lower th an the preheating

specification of a 58W T8 tube (350V peak).

Figure 28 shows the preheating timing. The choke current and the voltage on the CapPREH pin are

reported. The preheating duration is ~0.84s (C7=4.7uF)

Figure 28: Pre-heating phase timing

Choke current

Choke cu rrent

Mid point voltage

LS CapPREH pin voltage

24/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

4.4.3 IGNITION PHASE

Figure 29 shows the main waveform during the ignition phase. The peak current is limited to ~2A thanks

to the o vercur rent pr otec tion ne tw ork made by D1, Dz1 and R6 ( see figure s 19 and 20 ). In fact as soon

as the voltage on the sec pi n overcomes ~40V the frequen cy capacitors charge becomes faster (see

CAP1 waveform) anticipating the device switch-off.

Figure 29: Igni tion phase

LS CAP1 pin voltage

LS SEC pin voltage

Choke current

Mid point voltage

4.4.4 STEADY STATE

Figure 30 shows the steady state phase main waveforms. The working frequency is ~34KHz with a peak

current of ~700mA.

Figure 30: Steady state phase

LS CAP1 pin voltage

LS SEC pin voltage

Choke current

Mid point voltage

25/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

4.5 PROTECTIONS

4.5.1 End of Life

In figure 31 the timing of the EoL protection is shown.

Figure 31: End Of Life timing

Choke cur ren t

AN1902 - APPLICATION NOTE

The system oper ates as follows: after the start-up, the prehe ating phase starts an d l asts ~0.84 s ec as in

the normal opera tion. After the prehe ating phase the system could perma nently work in free oscilla tion

condition due to the EoL state. The protection stops the oscillation after ~50msec.

Figure 32: EoL: device turn-off

Choke current

LS CapPREH pin voltage

Mid point voltage

26/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Figure 32 shows the particular of the LS device turn-off when the voltage on the LS CapPREH pin

reaches the internal threshold.

4.6 THERMAL EVALUATION

The thermal analysis has been performed measuring the devices temperatures in the SMD version

demoboard. The heat sink copper area copper area is ~100mm2 for each device.

The temperature has been measured with K type thermocouples put on the top of the SO-16 packages.

The measurements have been performed at two different ambient temperatures: room temperature

(about 25°C) and 50°C. The results are summarized in table 3.

Table 3: Devices temperature

T

ambient

25ºC 90ºC

50ºC 115ºC

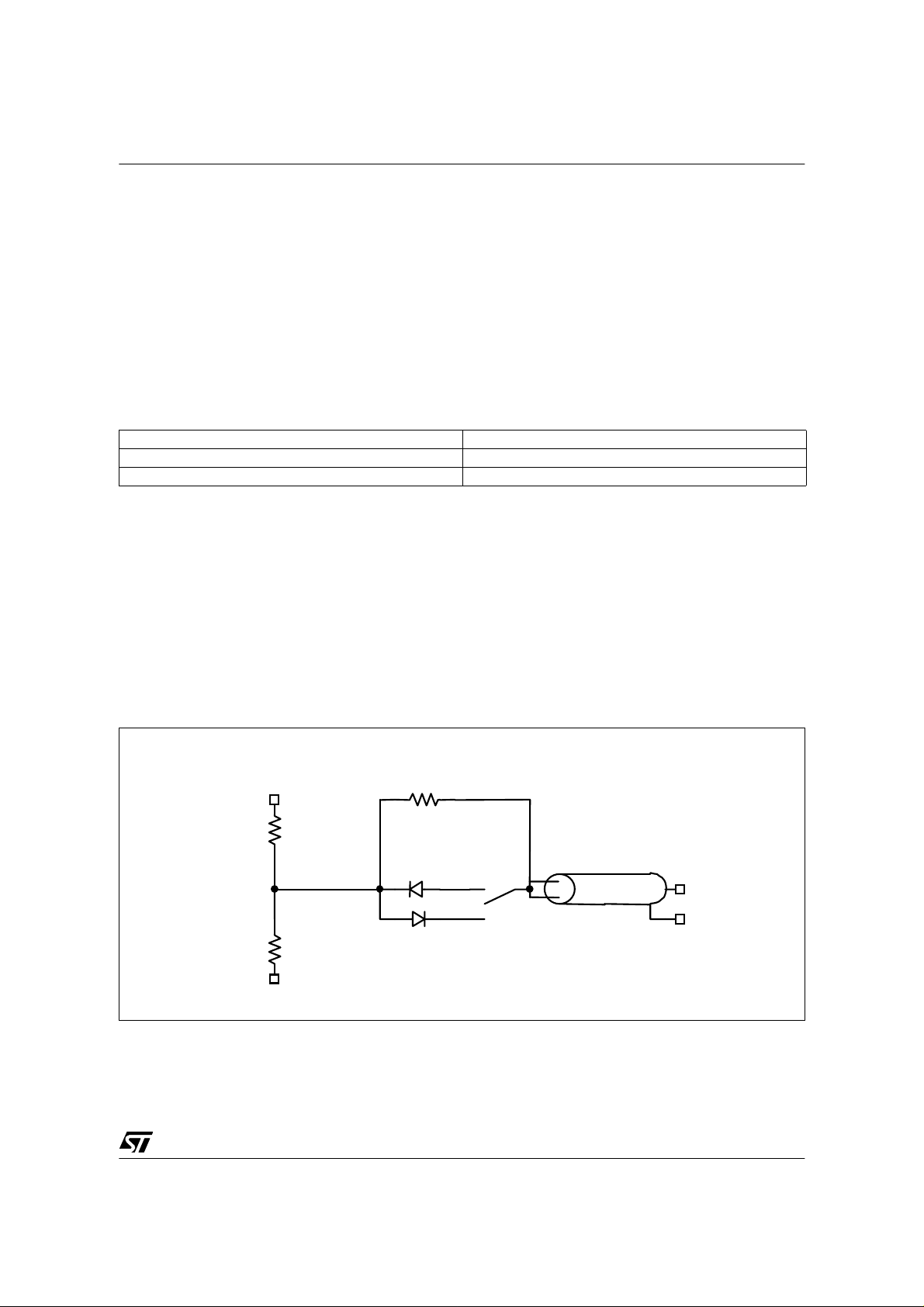

5. TUBE RECTIFICATION (not included in the reference demoboards)

Below, a network for the r ectification detec tion is described. Th e dimensioning is related to a 58W T 8

tube. This is an anomalous condition happening during the steady state phase causing lamp overvoltage

and not overcurrent, for this reasons it is not possible to detect it by the EoL protection.

The propos ed network realizes a lam p voltage sense. The timing and the device l atch is realiz ed using

the same internal EoL circuit.

The circuit used to simulate the rectification condition has been realized according to E DIN IEC 61347-23/A1 2002-02 standard (see figure 33).

T

case

Figure 33: Circuit for simulating the rectifying effects

C

R1

5.6

5W

5.6

R2

5W

E

The points C,D,E,F must be connect to the VK06 converter output terminals.

R1

100 10W

D2

2 x BYV228

D1

2 x BYV228

Tube T8 58W

D

F

In figure 34 the circuit used for the tube rectification detection is shown.

27/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 34: Proposed circuit for detecting the rectifying effects

AN1902 - APPLICATION NOTE

EOL Pin

Mid Point

27k

C

E

T1

1.8mH

R

DZ

33V

D

0.2A, 75V

470 pF 630V

C

560k

R

R 180k

C2

100 nF

C1

8.2nF

D

DC Bus = 400V

F

The terminals C-E and D-F must be connected to the circuit of figure 33.

The rectification condition is detected monitoring the voltage across the 180kΩ resistor.

When the rectifying effects occur, the increase of the voltage across the lamp causes the increase of the

voltage across the resistor R= 180kΩ over the threshold fixed by the network D-Dz-R. At that moment the

EoL protection is activated.

During the preheating phase the voltage across the resistor R=180kΩ is higher than the steady state and

the protect ion can be activ ated. For this reason a further circuit is n eeded for disa bling the prote ction

during the preheat.

6. CONVERTER FREQUENCY TOLERANCE VS. FREQUENCY CAPACITOR TOLERANCE

Following a practical example showing the variation of converter frequency versus the frequency

capacitor tolerance.

The analysis has been performed in steady state condition but it is also applicable to the pre-heat.

A VK06TL based prototype board with the following setting has been used:

VDC bus= 350V

C

freqLS

= C

=C=1.22 nF (measured)

freqHS

Figure 35 shows the related steady state waveforms.

28/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Figure 35: Test condition: C

LS collector current

Following the measured parameters:

f=52.2KHz

duty cycle ≈ 50%

P=45.5W

With:

t

= t

ONLS

t

storageLS

dv/dt=920ns

ONHS

= t

storageHS

= 8.36µs

=320ns

= C

freqLS

Mid point voltage

freqHS

HS colle c tor current

LS CAP1 pin vol tage

According to the theoretical relationship:

tON=K*C with K=6.7µs/nF (5% internal guaranteed) (1)

The expected tON is:

tON= 6.7*1.22=8.2µs (inside 5% device tolerance)

- Experiment 1

Only the frequency capacitors have been changed:

C

=C+6%

freqLS

C

Figure 2 shows the related waveforms.

freqHS

=C-6%

29/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 36: Test condition: 6% opposite variation on Cfreq

AN1902 - APPLICATION NOTE

LS collector current

Mid point voltage

Following the measured parameters:

frequency f=52.12KHz

duty cycle ≈ 47.4%

P=45.5W

With:

t

=8.8µs (+6%)

ONLS

t

=7.72µs (-6%)

ONHS

t

storageLS

dv/dt=920ns

= t

storageHS

= 320ns

HS colle c tor current

LS CAP1 pin vol tage

It means tha t the opp osite va riation of the tON causes a distortion of the duty cycle without var iation on

the frequency and power.

- Experiment 2

C

=C+6%

freqLS

C

Figure 37 shows the related waveforms.

freqHS

=C+6%

30/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 37: Test condition: +6% variation on Cfreq

AN1902 - APPLICATION NOTE

LS colle ctor current

Mid point voltage

Following the measured parameters:

f=49.8KHz

duty cycle ≈ 50%

P= 46.2W

With:

T

= T

onLS

T

storageLS

dv/dt=920ns

=8.8µs (+6%)

onHS

= t

storageHS

=320ns

HS colle ct or current

LS CAP1 pin voltage

The frequency variation respect to the initial condition (C

than the capacitor tolerance (6%). The power variation is instead ~1.6%.

According to the rel atio nshi p ( 1), the sa me results can be ob tained i f the tON variation is c au sed on l y by

VK06TL internal tolerance. The worst case frequency variation will be anyway less than 5%.

freqLS

= C

= 1.22 nF) is 4.6% and it is less

freqHS

31/32

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1902 - APPLICATION NOTE

Information furnished is believed to be accurate and r eliable. However, STMicroelect r onics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may results from its use. No license is

granted by implication or otherwi s e under any patent or patent rights of STMicroel ec tronics. Specificat ions mentioned in this publication are

subject to c hange without notic e. This publicatio n s upersedes and rep lac es all information previously supplied. STMicroelec tronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a tr ademark of STMicroelectronics.

All other names are the property of their r es pective owners

2004 STMicroelectronics - Prin ted in ITALY- All Rights Reserved.

Australia - B elgium - Brazil - Canada - China - Czech Republic - Finland - France - German y - Ho ng K ong - India - Israel - Ital y - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

32/32

Loading...

Loading...