Page 1

AN1897

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

®

- APPLICATION NOTE

VIPower: LOW COST UNIVERSAL INPUT

DVD SUPPLY WITH VIPer22A

Jun-fen g Zhang

INTRODU CTI ON

In the past few years, many consumer products have been provid ed to the end user, such as DVD or

VCD players. Generally their power supply require multiple outputs to supply a variety of control circuits:

MCU, Motor, Amplifier, VFD.

ST VIPer series of off-line switch mode power supply regulators c ombines an optimized, high voltage,

avalanche rugged Vertical Power MOSFET with current mode c ontrol PWM circuitry. The result is truly

innovative AC to DC conversion that is simpler, quicker and - with component count halved - less

expensive.

The VIPer family al so represents th e ea sies t s olution to com ply with the "Blue Angel" and "Energy Star"

Eco norms, with extremely low total power consumption at stand-by mode, thanks to the burst operation.

This document would present the ap plication on DVD player pow er supply with VI Per22A satisfying the

specification See table 1 below.

Table 1: Output Specification

INPUT OUTPUT 1 OUTPUT 2 OUTPUT 3 OUTPUT 4 OUTPUT 5 OUTPUT 6

Universal

mains lin e

Min: 85Vac

Max:

265Vac

Note 1: The accuracy of + /- 5% is reached only for a cer tain range of loads combination. See paragraph 3. 2 for cross regulation results.

5 V +/- 5%

(See note 1)

Imin: 20mA

Imax: 1.5 A

+12 V +/- 5%

(See note 1)

Imax: 30 mA Imax: 30 mA Imax: 50mA Imax: 150mA Imax: 100mA

-12 V +/- 5%

(See note 1)

-26 V + /- 5%

(See note 1)

3.3 V +/- 5%

(See note 1)

+/- 5%

5V

stb

(See note 1)

March 2004 1/11

Page 2

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1897 - APPLICATION NOTE

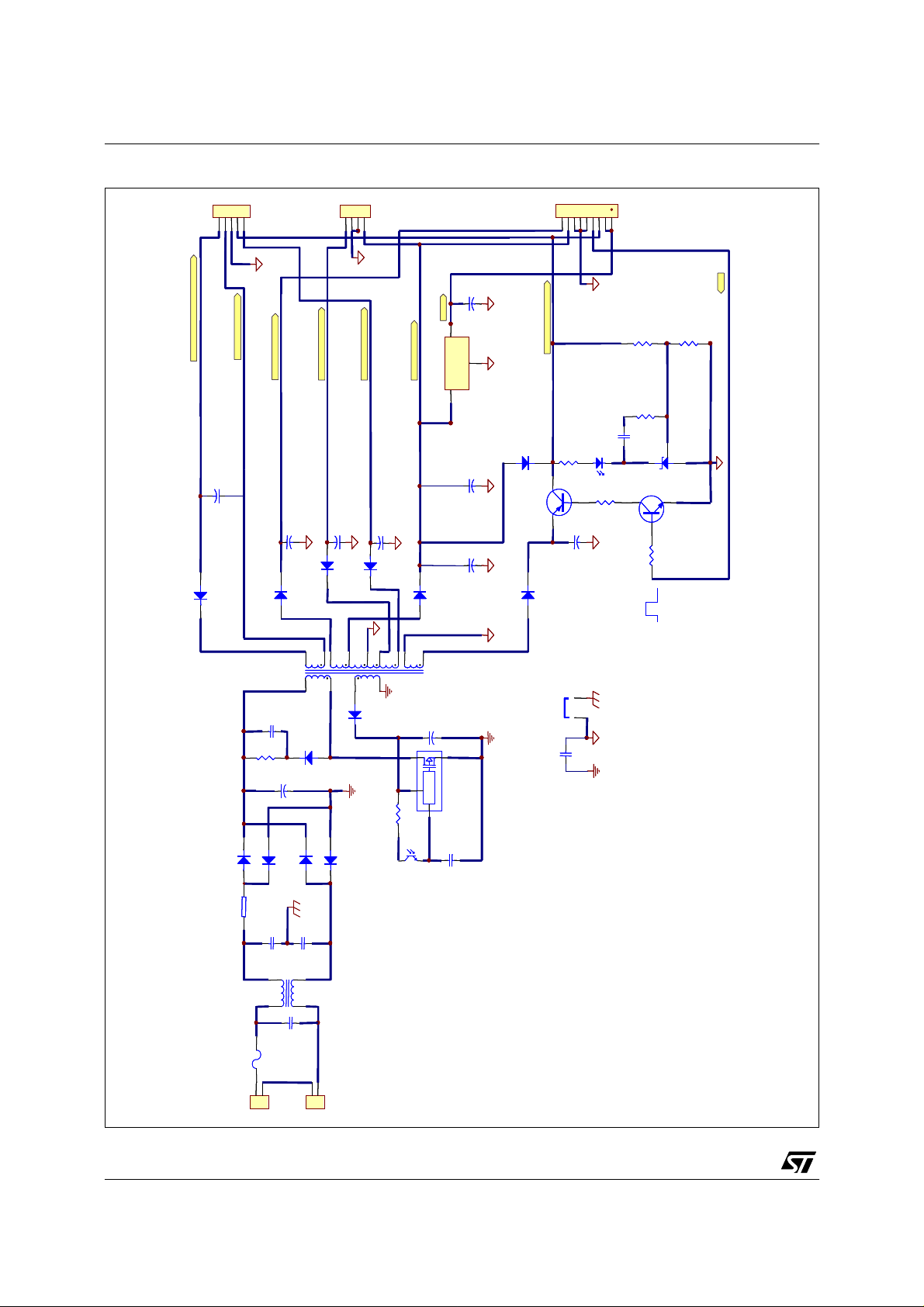

1. APPLICATION DESCRIPTION AND DESIGN

1.1 Schematics

The overall schematic is shown in figure 2.

1.1.1 Start-up Phase

As any member of the VIPer family, VIPer22A has an integrated high voltage current source linked to

Drain pin . At the startup converter, it will charge the V

(14.5V), and then the VIPer22A starts switching.

1.1.2 Auxiliary Supply

VIPer22A has a wide operating voltage range from 8V to 42V, respectively minimum and maximum

values for under-voltage and over-voltage protections.

This function is very useful for achievin g low stand-by total power consum ption. During norma l working,

the feedback loop is connected to 5V output by D12 to regulate 5V output. At the mean time, +5Vstb

output is blocked by Q3, so +5Vstb regulation is neglected. When the stand-by signal is present, the Vce

of Q3 can not provide enough voltage to maintain D12 conducted, so the 5V output is blocked, and the

+5Vstb output is connected to the feedback loop. In this condition the +5 Vstb is regulated. Thanks to the

transformer structure, all the other secondary outputs and the auxiliary voltages are pulled down to a very

low level, also pulling down the total power consumption.

All these contents can be summarized by the following list:

• in normal full load, the V

• in short circuit, the V

to the well known hiccup mode in practice;

• in no load condition, the V

voltage of the device must be lower than the over-voltage protection;

DD

voltage must be lower than the shutdown vol tage. Actually, this condition leads

DD

voltage must be higher than the shutdown voltage.

DD

capacitor until it reaches VIPer startup level

DD

1.1.3 Burst Mode

The Viper22A integrates a current mode PWM with a Power MOSFET and includes the leading edge

blanking function. The burst mode is a feature which allows VIPer22A to skip some switching cycles

when the energy drained by the output load goes be low E =(T

input voltage, f

It has the consequence to redu ce the switching losses when working in low load cond ition by reducing

the switching frequency.

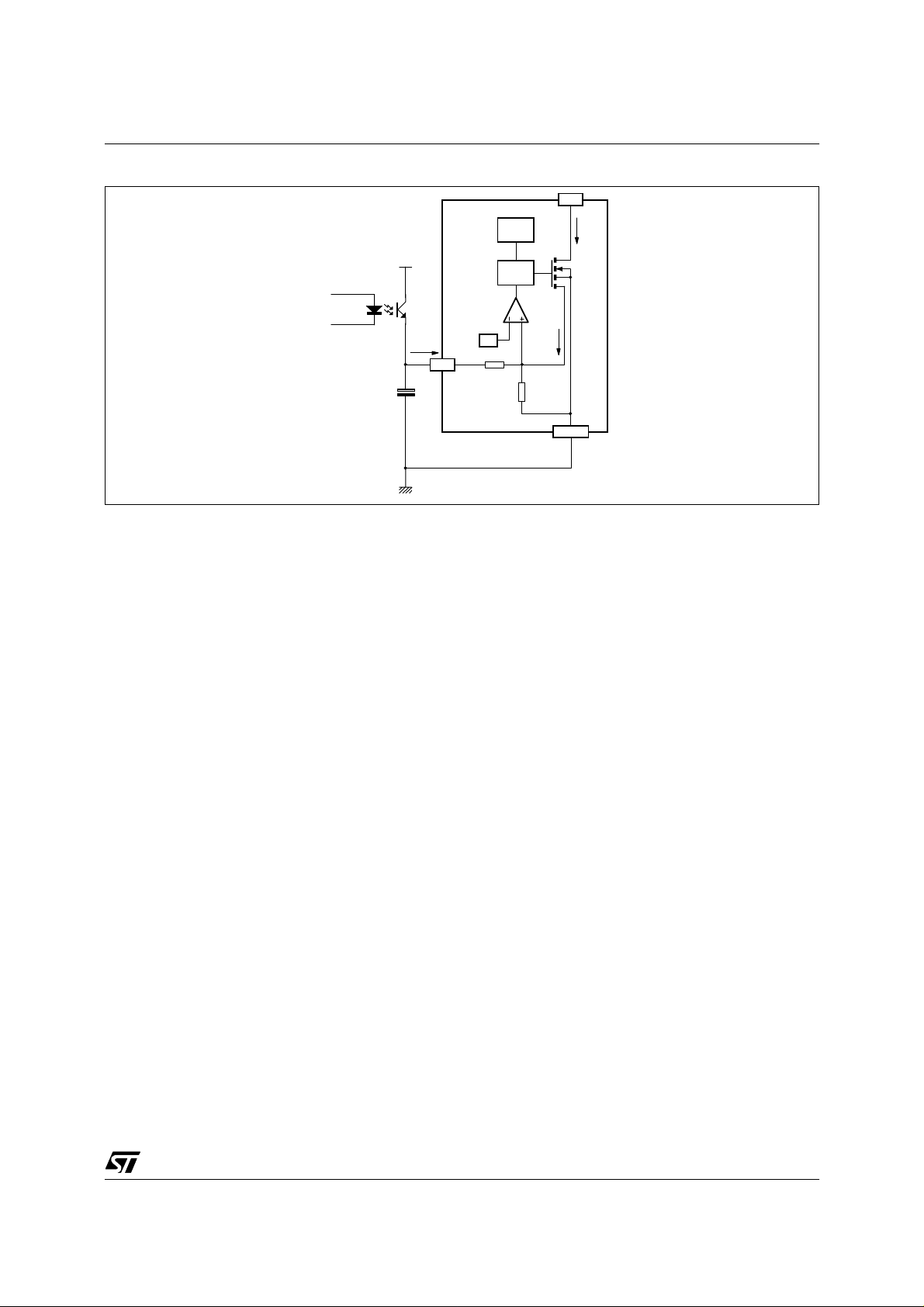

1.1.4 Feedback Loop

The 5V output voltage is regulated with a TL-431 (U3) via an optocoupler (U2) to the feedback pin. If the

output voltage is high, the TL-431 will draw more current through its cat hode to t he anode and the current

increases in the optocoupler diode. The current in optocoupler NPN increases accordingly and the

current into the VIPer22A FB pin increases. When the FB current increases, the VIPer22A will skip some

cycles to decrease turn on time and lower the output voltage to the proper level (see figure 1).

The 5V output voltage is regulated thanks to the reference voltage of TL-431 and the resistive divider R8

and R9.

2/11

=Switching frequency, Lp=Primary Inductance).

sw

)2 * fsw/2Lp (Tb=blanking time, Vin=DC

b*Vin

Page 3

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 1: VIPer22A FB pin internal structure

60kHz

OSCILLATOR

AN1897 - APPLICATION NOTE

DRAIN

Id

Secondary

feedback

+Vdd

I

FB

FB

C

0.23V

1 kΩ

S

PWM

Q

LATCH

R

Is

R1

230 Ω

R2

SOURCE

1.1.5 Primary Driver

In a fly-back power supply, the transformer is used as an energy tank fuelled during the ON time of the

MOSFET. When the MOSFET turns off, its drain voltage rises from a low value to the input voltage plus

the reflected voltage while the secondary diode conducts, transferring on the secondary side the

magnetic energy stored in the transformer. Because primary and secondary windin gs are not perfectly

magnetically coupled, there is a serial leakage inductance that behaves like an open inductor charged at

that causes the voltage spikes on the MOSFET drain. These voltage spikes must be clamped to keep

I

pk

the VIPer22A Drain voltage below the BVds s (730Vmin) rating. If the peak voltage is higher than this

value, the device will be destroyed. The most used solution is the RCD clamp (see figure 3). This is a

very simple and chea p solution, but it impacts on the efficiency and even on the power dissipation in

stand-by condition. Also the clamping voltage varies with load current. RCD clamp circuits may allow the

drain voltage to exceed the data sheet breakdown rating of VIPer22A during overload operation or during

turn on with high line AC input voltage. So, a zener clamp is recommended (see figure 4). However such

a solution gives higher power dissipation at full load, even if the clamp voltage is exactly defined.

1.2 Transformer Consideration

On the electrical specification of a multiple output transformer (cross regulation, leakage inductance), the

main efforts focused on the proper coupling between the windings. A lower leakage inductance

transformer will allow a lower power clamp to reduce the input power. It will lead to lower power

dissipation on the primary side.

Auxiliary and secondary windings are swapped in order to decrease the coupling to the primary one. The

secondary windings act as a shielding layer to reduce the capacitive coupling. Fewer spikes are

generated on the auxiliary windings, the primary and secondary windings have better coupling.

Designing transformers for low leakage inductance involves several considerations:

•Minimize number of turns

•Keep winding build (ratio of winding height to width) small

•Increase width of windings

•Minimize insulation between windings

•Increase coupling between windings

3/11

Page 4

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1897 - APPLICATION NOTE

Figure 2: Application schematic

J4

J4

J4

CON4

CON4

CON4

--12V / 0.03A

--12V / 0.03A

--12V / 0.03A

470uF/25V

470uF/25V

470uF/25V

C19

C19

C19

D13

D13

D13

BYW 100/ 2 00

BYW 100/ 2 00

BYW 100/ 2 00

CON5

CON5

CON5

F- (3.3Vac) / 0.15A

F- (3.3Vac) / 0.15A

F- (3.3Vac) / 0.15A

J3

J3

J3

12345

12345

12345

C25

C25

C25

100uF/10V

100uF/10V

100uF/10V

D11

D11

D11

1N5818

1N5818

1N5818

F+ (3.3Vac)

F+ (3.3Vac)

F+ (3.3Vac)

+12V / 0.03A

+12V / 0.03A

+12V / 0.03A

C17

C17

C17

D9

D9

D9

BYW 100/ 200

BYW 100/ 200

BYW 100/ 200

470uF/25V

470uF/25V

470uF/25V

123

123

123

4

4

4

--26V / 0.05A

--26V / 0.05A

--26V / 0.05A

C20

220uF/50V

C20

220uF/50V

C20

220uF/50V

D10

D10

D10

BYW 100/ 200

BYW 100/ 200

BYW 100/ 200

+5V / 1.5A

+5V / 1.5A

+5V / 1.5A

D8

D8

D8

STPS5L60

STPS5L60

STPS5L60

3.3V

3.3V

3.3V

GND

GND

GND

Vout

Vout

Vout

3

3

3

Vin

Vin

Vin

1

1

1

C15

C15

C15

100uF/10V

100uF/10V

100uF/10V

2

2

2

U4

LD33V

U4

LD33V

U4

LD33V

C13

C13

C13

470uF16V

470uF16V

470uF16V

C12

C12

C12

1000uF/16V

1000uF/16V

1000uF/16V

D12

D12

1N5818

1N5818

J5

J5

J5

123456789

1234567

123456789

CON9

CON9

CON9

+5Vstb / 0.1A

+5Vstb / 0.1A

+5Vstb / 0.1A

R11

R11

680 ohm

680 ohm

C9

C9

C9

220uF/50V

220uF/50V

220uF/50V

D7

D7

D7

BYW 100/ 200

BYW 100/ 200

BYW 100/ 200

Q3

Q3

Q3

8550

8550

8550

8

9

STB

STB

STB

R9

R8

R9

R8

R9

R8

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

R6

R6

1K

1K

C10

C10

C10

47pF

47pF

47pF

U1A

U1A

U3

817

817

R5

R5

R5

1K

1K

1K

U3

TL431

TL431

R4

R4

R4

1K

1K

1K

Q1

Q1

Q1

9014

9014

9014

151411131298

151411131298

1

2

1

2

1

2

C5

C5

47pF/1KV

47pF/1KV

D5

D5

FR157

FR157

R3

R3

C4

C4

100k/1W

100k/1W

47uF/400V

47uF/400V

1N4007D21N4007D11N4007

1N4007D21N4007D11N4007

1N4007D21N4007D11N4007

1N4007

1N4007

1N4007

D4

D3

D4

D3

D4

D3

RT1

RT1

RT1

NTC5D-9

NTC5D-9

NTC5D-9

2200pF Y1C12200pF Y1

2200pF Y1C12200pF Y1

C2

C2

34

34

CH1

CH1

2.2mH

2.2mH

1 2

1 2

C3

C3

0.1uF X2

2

2

2

1

1

1

CON2

CON2

CON2

0.1uF X2

1

2

1

2

1

2

CON2

CON2

CON2

J2

J2

J2

F1

250V 1A

F1

250V 1A

J1

J1

J1

10

7

10

7

D6

D6

D6

1N4937

1N4937

1N4937

R3

R3

R3

9.1K

9.1K

9.1K

DRAIN

DRAIN

DRAIN

VDD

VDD

VDD

U1B

U1B

817

817

TX1

TX1

TFO EC28---VER3

TFO EC28---VER3

C7

C7

47uF/50V

47uF/50V

U2

U2

U2

SOURCE

SOURCE

SOURCE

CONTROL

CONTROL

CONTROL

VIPER22A

VIPER22A

VIPER22A

C6

C6

C6

47nF

47nF

47nF

2JP1

2JP1

2JP1

1

1

1

JUMPER

JUMPER

JUMPER

C8

C8

C8

1nF / 1KV

1nF / 1KV

1nF / 1KV

Auxilia ry Volt 10 Vmin

Auxilia ry Volt 10 Vmin

+ 5V 1.5A

+ 5V 1.5A

+ 5V 1.5A

Auxilia ry Volt 10 Vmin

+ 5Vstb 0.1A

- 12V 0.03A

+ 12V 0.03A

- 26V 0.05A

3.3Vac 0.15A

+ 5Vstb 0.1A

- 12V 0.03A

+ 12V 0.03A

- 26V 0.05A

3.3Vac 0.15A

+ 5Vstb 0.1A

- 12V 0.03A

+ 12V 0.03A

- 26V 0.05A

3.3Vac 0.15A

4/11

Page 5

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1897 - APPLICATION NOTE

Figure 3: RCD clamp topology Figure 4: Zener clamp topology

For a transformer m eeting international insul ation a nd s afet y requi reme nts, a practical value for leak age

inductance is about 1-3% of the open circuit primary inductance.

A high efficiency transformer should have low inter-winding capacitance to decrease the switching

losses. Energy stored in the parasitic capacitance of the transformer is absorbed by VIPer cycle by cycle

during the turn-on transition. Excess capacitance will also ring with stray inductance during switch

transitions, causing noise prob lems. Capacitance effects are usually the m ost important in the primary

winding, where the operating voltage (and consequent energy storage) is high. The primary winding

should be the first winding on the transformer. This allows the primary winding to have a low mean length

per turn, reducing the internal capacitance. The d riven end of the primary winding (the e nd c onne cted to

the Drain pin) should be the beginning of the winding rather than the end.

This takes advantage of the shielding effect of the second half of the primary winding and reduces

capacitive coupling to adjacent windings. A layer of insulation between adjacent primary windings can cut

the internal capacitance of the primary winding by as much as a factor of four, with consequent reduction

of losses. A common technique for winding multiple secondaries with the same polarity sharing a

common return, is to stack the secondaries (see figure 5). This arrangement will improve the load

regulation, and reduce the total number of secondary turns.

Commonly a clamper based on an RCD network or a diode with a zene r to clamp the rise of the dr ain

voltage is used.

Figure 5: Multiple output winding

5/11

Page 6

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1897 - APPLICATION NOTE

+12V/30mA, -12V/30mA, -26V/50mA,

2. LAYOUT RECOMMENDATION

Since EMI issues are strongly related to layout, a basic rule has to be taken into account in high current

path routing, i.e. the current loop area has to be minimized. If a heat-sink is used it has to be connected

to ground too, in order to reduce common mode emissions, since it is close to the floating drain tab.

One more consideration has to be made regarding the control ground connection: in fact in order to avoid

any noise interference on VIPer logic pin the control ground has to be separated from power ground.

3. EXPERIMENTAL RESULT

3.1 Efficiency

Figure 6: Efficiency at 230Vac (Load on 5V) Figure 7: Efficiency at 260Vac (Load on 5V)

80.00%

70.00%

60.00%

50.00%

40.00%

30.00%

Efficiency

20.00%

10.00%

0.00%

+12V/30mA, -12V/30mA, -26V/50mA,

3.3V/0.15A

0.1A 0.5A 1A 1.5A 2A

Efficiency at 230Vac Mains Input

80.00%

70.00%

60.00%

50.00%

40.00%

30.00%

Efficiency

20.00%

10.00%

0.00%

0.1A 0.5A 1A 1.5A 2A

Efficiency at 260Vac Input

3.3V/0.15A

Figure 8: Efficiency at 85Vac (Load on 5V) Figure 9: Load Regulation (load on +5V)

Voltage

5.20

5.15

5.10

5.05

5.00

4.95

4.90

4.85

4.80

0A 0.1A 0.5A 1A 1.5A 2A

Load (A)

+5V Load Regualtion

76.00%

74.00%

72.00%

70.00%

68.00%

66.00%

Efficiency

64.00%

62.00%

60.00%

+12V/30mA, -12V/30mA, -26V/50mA,

3.3V/0.15A

0.1A 0.5A 1.0A 1.5A 2.0A

Efficiency at 85Vac Input

3.2 Re gulati on

Table 2: Line regulation

Output 85Vac 230Vac 260Vac

5V/ 0.1A 5.15V 5.15V 5.15V

5Vstb/ 0A 5.15V 5.15V 5.15V

12V/ 0A 12.08V 12.11V 12.12V

-12V/ 0A -11.98V -11.99V -12.00V

-26V/ 0A -25.82V -25.85V -25.86V

3.3V/ 0A 3.87V 3.87V 3.88V

6/11

Page 7

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

Figure 10: Cross regulation

15.00

10.00

5.00

0.00

-5.00

-10.00

Voltage

-15.00

-20.00

-25.00

-30.00

AN1897 - APPLICATION NOTE

+5V/0.5A

0m A 10mA 30mA 50mA 100m A 150mA

Load (mA)

+12V -12V -26V 3.3V

Table 3: Stand by model

Output 85Vac 230Vac 260Vac

5V

5Vstb (100mA)

12V

-12V

-26V

3.3V

Pdis

2.05V 2.05V 2.07V

5.08V 5.11V 5.14V

4.00V 3.99V 3.98V

3.99V 3.99V 3.98V

9.12V 9.10V 9.08V

1.70V 1.50V 1.51V

0.8W 1W 1.1W

Table 4: Full Load Regulation

Output 85Vac 230Vac 260Vac

5V/ 1.5A

5Vstb/ 0A

12V/30mA

-12V/30mA

-26V/50mA

3.3V/0.15A

VIPer Temp

5.02V 5.09V 5.08V

5.02V 5.09V 5.08V

12.03V 12.06V 12.05V

-12.01V -12.05V -12.05V

-26.06V -26.16V -26.15V

3.77V 3.80V 3.78V

53°C 47°C 45°C

7/11

Page 8

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1897 - APPLICATION NOTE

4. TRANSFORMER SPECIFICATION

Figure 11: Transformer Structure

Primary inductance: Lp = 2.8 mH 1KHz, 0.3V

Leakage inductance: Lk < 28uH at Seconda ry

and auxiliary winding short (1KHz, 0.3V)

Core: EER28L

Bobbin: ER28 (6 + 9 Pin)

Vendor: YuanDongDa electronics Co., Ltd

Table 5: Winding Parameters

Layers description Symbol Start Pin End Pin Number of Layer Turns Wire Size

(mm)

Primary

Out1 (5V/1.5A)

Out2 (12V/0.03A)

Out3 (-12V/0.03A)

Out4 (-26V/0.05A)

Out5 (5Vstb/0.1A)

Out6 (3.3V/0.15A)

Auxiliary

B

O

B

B

I

N

Wp

2 1

Wp Pin2 Pin1 2 65 0.3

W5 Pin7 Pin12 1 4 2*0.6

W12 Pin11 Pin7 1 5 0.3

W-12 Pin12 Pin10 1 9 0.45

W-26 Pin10 Pin13 1 10 0.3

Wstb Pin9 Pin8 1 12 0.3

W3v3 Pin14 Pin15 1 3 0.3

Waux Pin6 Pin5 1 24 0.3

Barrier (3mm)

12

W5

7

7

W12

11

10

W-12

12

Barrier (3mm)

13

W-26

10

15

W3v3

14

8

Wstb

9

5

Waux

6

8/11

Page 9

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

5. PCB LAYOUT

Figure 12: Bottom v iew of the demo board (not in scale)

AN1897 - APPLICATION NOTE

Figure 13: PCB Art Work (not in scale)

9/11

Page 10

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1897 - APPLICATION NOTE

5. BILL OF MATERIALS

Ref. Description Note

U1

U2

U3

U4

Q1

Q3

D1, D2, D3, D4

D5

D6, D7, D9, D10, D13

D8

D11, D12

C1, C2

C3

C4

C5, C8

C6

C7

C9

C10

C12

C13

C15

C17

C19

C20

C25

RT1

R2

R3

R4, R5, R6

R8, R9

R11

CH1

TX1

F1

J1, J2

J3

J4

J5

Photocoupler PC81 7 SHA RP

VIPer22A DIP STMicroelectronics

TL431 ACZ STMicroelectronics

L4931 ABV33 STMicroelectronics

SS9014

SS8550

1N4007

FR157

STTH102 STMicroelectronics

STPS5L60 STMicroelectronics

1N5818 STMicroelectronics

Y1 Capacitor 2200pF

X2 Capacitor 0.1uF

Electrolytic Capacitor 100uF/400V

1nF/1KV

Ceramic Capacitor 47nF/ 50V

Electrolytic Capacitor 47uF/50V

Electrolytic Capacitor 220uF/50V

Ceramic Capacitor 47pF/ 50V

Electrolytic Capacitor 1000uF/16V

Electrolytic Capacitor 470uF/16V

Electrolytic Capacitor 100uF/10V

Electrolytic Capacitor 470uF/25V

Electrolytic Capacitor 470uF/25V

Electrolytic Capacitor 220uF/50V

Electrolytic Capacitor 220uF/16V

Not fit

9.1KΩ ¼ W

100KΩ 1W

1KΩ ¼ W

5.1KΩ ¼ W

680Ω ¼ W

2.2mH Common choke

EER28 transformer

Fuse 1A

2pin connector

5pin connector

4pin connector

9pin connector

10/11

Page 11

Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)

AN1897 - APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such i nformat ion nor f or any infr ingement of patents or other rig hts of third par ties w hich may res ults from i ts use. No license is

granted by i m pl i cation or ot herwise under any pate nt or patent ri ghts of STMicroelectr oni cs. Specifications mentioned i n this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical compone nts in lif e support de vi ces or syste m s without express writt en approval of STMicr oelectronics.

The ST logo is a trademark of STMicroelectronics.

All other names are the property of their re spective ow ners

2004 STMicroelectronics - Printed in ITALY- All Rights Reserved.

Austra lia - Belgium - Brazil - C anada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysi a - M al ta - Morocco - Singapo re - Spain - Sweden - Switzerl and - Unit ed Kingdom - Uni ted States

11/11

STMicroele ctronics GROUP OF C OM PANIES

http:// www.st.co m

Loading...

Loading...