Page 1

AN1894

®

- APPLICATION NOTE

VIPower: VI Per 12A NON ISOLATED BUCK AND

BUCK-BOOST CONVERTER REFERENCE BOARD

P. LIDAK - R. HAUSER

ABSTRACT

Presented circuit can be used to produce a single, non isolated positive or negative voltage. It is

dedicated for bu ildi ng an au xiliary pow er sup ply ba sed on the VIPer12A S mo nolithic d evice wi th rath er

low output power required.

1. INTRODUCTION

There are some appli cat io ns, wher e an off- line pow e r supp l y wit hout is o lati on be tween i n put an d out put

can be tolerated a nd rather l ow output current is required. I n this case the converter s hould be sim ple

and low cost. These requirements can be satisfied by a step-down converter based on monolithic device

VIPer12AS that inco rporates the PWM contro ller together w ith the Vertical power MOSFET switch in a

SO8 package. Th e presen ted pow er supply has two var iants. The f irst is a bu ck (ste p-down) co nvert er

with a positive output voltage refer enced to the common grou nd. The second one with negati ve output

voltage is a buck-boost converter. The presented reference board incorporates both variants by different

assembly options.

2. CIRCUIT DESCRIPT ION

2.1 Buck Converter +15V/100mA, +5V/60mA or 20mA (Variant 1)

2.1.1 Operating Cond itio ns

Input Voltage range

Input Voltage Freq uency rang e

Main Output

Second O utput (thr ough linear r egulator)

Total Maximum Output Powe r

2.1.2 Circuit Operation

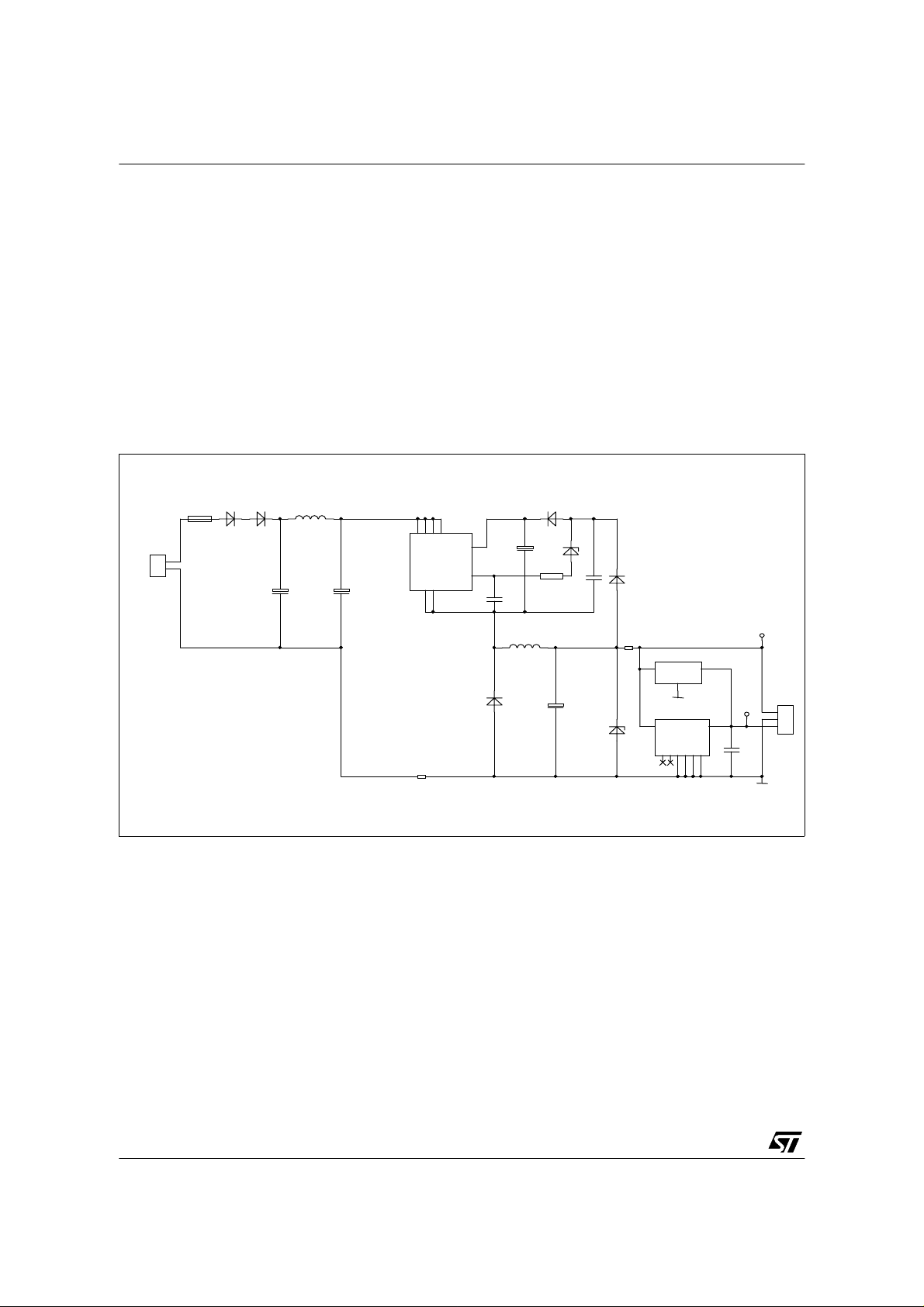

The total schema tic of the power supply can be seen in Figure 1. The output of the conver ter is not

isolated from inpu t. F or t hi s re ason the r efer enc e grou nd is c omm on f or a n inp ut and output conne ct ion

terminal. The inp ut capacitor C1 is charg ed from line via one w ay rectifier co nsisting of diodes D1 and

D2. Two diodes in series are used for EMI reasons to sustain bur st pulses of 2kV. The capacitor C1

together with capacitor C2 and ind uctor L1 for ms an EMI filter. The DC voltage at C2 is then app lied to

the VIPer12 that works as a high side switch . It means the IC and correspon ding supply and feedback

loop circuitry is floating. The IC supply circuit consists of the high voltage diode D4, ceramic capacitor C7

low voltage D7 and capacitor C4. T he voltage feedback loop is provided via z ener diode D3 , resistor R 3

and capacitor C6.

The diode D7 between capacito r C7 and C 4 ensure s the prop er s tart-u p of the conve rter. Thanks to this

diode the feedback loop circu it is separated fr om supply ci rcuit. The internal start-u p current sourc e of

the VIPer12 charges the IC supply capacitor C4 to a specified start-up threshold voltage of about 16V.

March 20 04 1/14

90-264 VAC

50/60 Hz

15V / 100mA

5V / 60 or 20mA

1.6W

Page 2

AN1894 - APPLICATION NOTE

As soon as C4 voltage rea ches th e start- up t hreshold the inter nal 6 0 kHz o scillator se ts the inte rnal flipflop and th rough output driver tur ns-on the inter nal high vo ltage power M OSFET. Th e power M OSFET

applies the bulk capacitor C1 and C2 high voltage to the cathode of the power diode and to one terminal

of the inductor. Since the voltage at the out put capac itor C3 co nnecte d to the induc tor’s second terminal

is much lower than input bulk capacitor voltage the inductor current will ramp-up. As soon as the inductor

current ra mp reache s the VIPer ’s inter nal set -point defi ned b y feedback loop, t he int ernal pow er swi tch

turns off. The inductor keeps the direct ion of the curren t flowing and it reverses th e voltage at C3. The

inductor current then flows through the forward biased D5 diode and charges the output capacitor C3. In

this switch -off phase the sou rce termi nal of the V IPer1 2 sees a negat ive lev el of the forwa rd biase d D5

(when refere nced to ground) so i t can be considered a s grounded. This all ows the inductor cur rent to

flow also through D4 and supply the VIPer12 and give the feedback information about output voltage.

Figur e 1: Schematic diagram of non isolated buck converter with positive output voltage

D1

90...264V~

L

N

clamp

CON1

D2

L1

1.5mH 100mA

C1

+

4.7uF

400V

KMG

BC

8

U1

C4

10uF

4

VDD

Drain15Drain26Drain37Drain4

C2

+

4.7uF

400V

KMG

2

Source11Source2

VIPer12AS

50V

KME

3

FB

R1

10R

GL1M

1000V

1A

GL1M

1000V

1A

3W

L

1

2

N

VDD

C6

22nF

D7

LL4148

+

D3

ZMM13

R3

1k

C7

100nF

D4

RGL34J

600V

0.5A

+15V

CON2

3

+5V

2

C8

100nF

1

clamp

1

Layout Hints: C4, C6 have

to be close to VIPer12A

Assembly options:

(1a): +5V/60mA, +15V/100mA

(1b): +5V/20mA, +15V/100mA

note: all voltages refer to neutral

note: sum of currents is 100mA max.

R6

D6

ZMM18

0R

U3 L78M05CDT (1a)

VIN VOUT

GND

(1b)

U2 L78L05CD

VIN8VOUT

GND36GND47GND23GND12NC25NC1

4

L2

1mH

200mA

D5

RGL34J

600V

0.5A

R5

0R

LBC

C3

+

56uF

35V

LXY

The output voltage of the convert er at the 1 5V term inal is de termin ed by the vo ltage dro p across zener

diode D3 togeth er with voltage dr op across the re sistor R3 and FB pin voltage. Resistor R3 limits the

feedback current to a safe value lower than the maximum rating specified in the data sheet. Capacitor C6

protects the FB input against EMI. One has to take into account the slight variation of the output voltage

with the load. It is because the feedback current reacts to the output load change to adopt switching duty

cycle. The variable feedback current creates different FB voltage, different voltage drop across the

resistor R3 and D3 zener voltage. The feedback current c an change from 0mA (ful l output power) to

about 0.9mA a t no outpu t load. The R3 voltage vari atio n i s 0.9 V a nd F B pi n voltage about 1.2V. The D3

voltage variation depends on the diode V-I characteristics. Diode D6 limits the output voltage at light load

condition and it also protects the U2 voltage re gulator. Regulator U2 a ccommodated in DPAK or SO-8

package is optional and can be assembled if the power supply for a microcontroller or logic part is

required. The DPAK package version of U2 is dedicated for 60mA output current option while U3 in SO-8

can provide max. 20mA.

2/14

Page 3

AN1894 - APPLICATION NOTE

2.1.3 Bill of Materials

The bill of material that corresponds to the Figure 1 can be seen in Table 1.

Table 1: Bill of Material for Non Iso lated Buck Converter with Positive Output Voltage

Ref. Q.ty Value Description

CON1 1 WECO 10.877.002 - clamp, 2 pole, horizontal, type 94 380V 15A

CON2 1 WECO 10.877.003 - clamp, 3 pole, horizontal, type 94 380V 15A

C1, C2 2 4.7uF Nippon Chemi-Con K M G 400 VB 4R7 M Electrolytic capacitor KMG 400V 20%

C3 1 56uF Nippon Chemi-Con LXY 35 VB 56 M F11 Electrolytic capacitor LXY 35V 273mA

0.35R 20 % -

C4 1 10uF Nippon Chemi-Con KM E 50 VB 10 M Electrolytic capacitor KME 50V 20%

C6 1 22nF Ceramic capacitor X7R 50V 10%

C7 1 100nF Ceramic capacitor X7R 50V 10%

C8 1 100nF Ceramic capacitor X7R 50V 10%

D1, D2 2 GL1 M Diotec GL1M d iode, trr=1.5us 1000V 1A

D3 1 ZMM13 Zener diode 13V 0.5W 5%

D4, D5 2 RGL34J Diotec RGL34J Fast recovery diode trr=250ns 600V 0.5A

D6 1 ZMM18 Zener diode 18V 0.5W 5%

D7 1 LL414 8 L L4148 diode 75V 200mA

L1 1 1.5mH EPCOS B78108-S1155-J inductor, bobbin core BC 100mA 23R 10%

L2 1 1mH EPCOS B82144-A2105-J in ductor, large bobbin core LBC 200mA 3.8R 10%

R1 1 10R Yageo 254-0 10R 5% 1J resistor, wirewound, fusible, TK120 CRF 254-4 3W 5%

R3 1 1k resistor, metal film 100V 0.125W 1%

R5 1 0R resistor, metal film

R6 1 0R resistor, metal film

U1 1 VIPer12AS STMicr oelectroni cs VIPer12AS Off-line SMPS Primary IC 730V 0.4A 27R

U2 1 L78L05CD STMicroelectronics L78L05CD positive voltage regulator 5V 100mA 10%, for

variant 1b

U3 1 L78M05CDT STMicr oelectroni cs L78M05CDT positive voltage regulator 5V 0.5A 5%, for

variant 1a

3/14

Page 4

AN1894 - APPLICATION NOTE

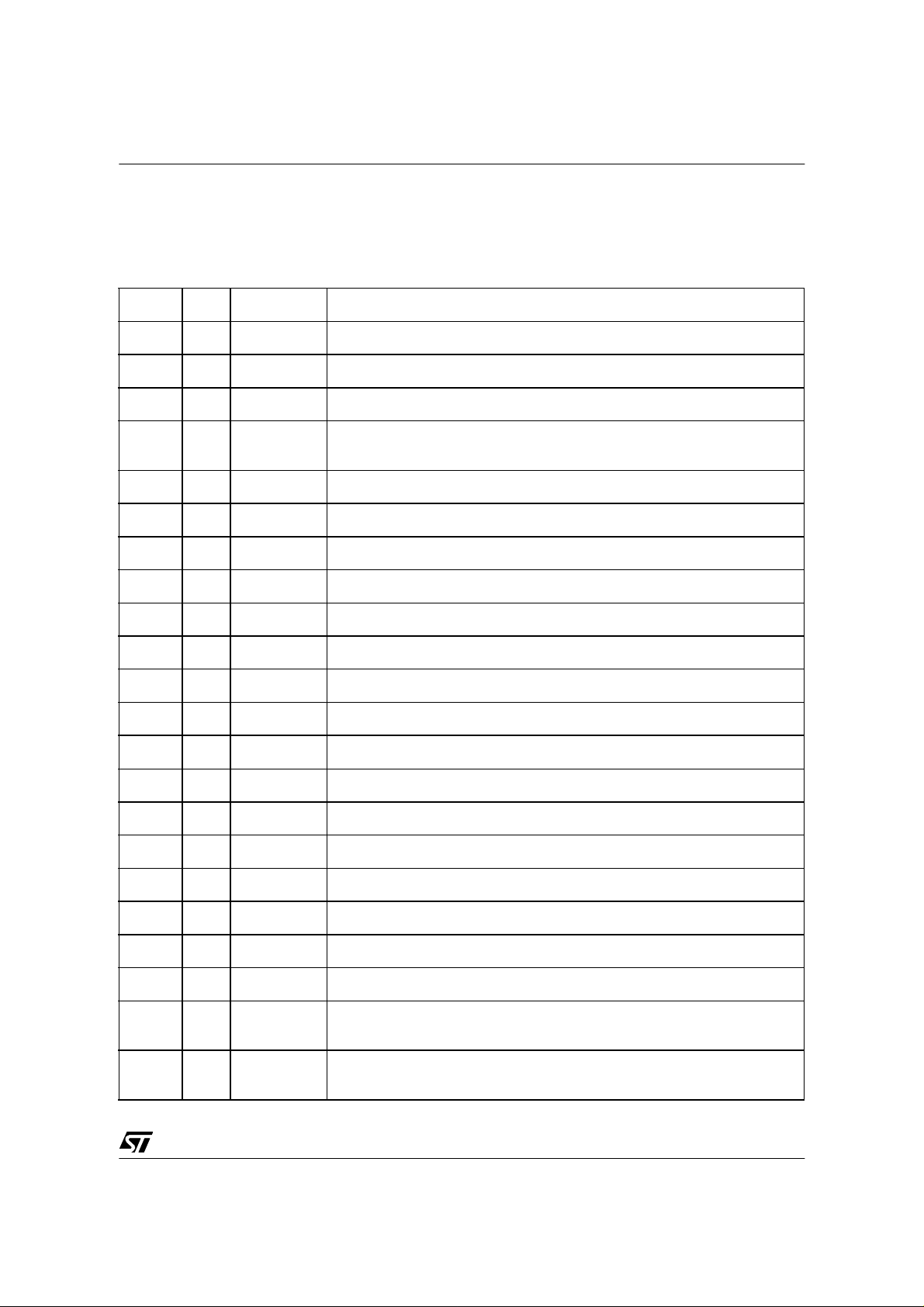

2.1.4 PCB Layout

The PCB is designed as single sided board made of FR-4 material with 35mm copper plating with solder

and silk screen mask. The assembled board co ntains both SMD and through h ole components. The

board incor porates both a buck and buck-boost variant of the converter. The outline dimensions are

38x29mm. Assem bly top side (trough-hole components ) and solder botto m (S MD compon ents) sid e can

be seen in Figure 2 and Figure 3.

Figur e 2: Assembly T op (not in scale)

Figur e 3: Assembly Solder Side (not in scale)

Figur e 4: PCB Layout (not in scale)

4/14

Page 5

AN1894 - APPLICATION NOTE

The PCB layout of the copper connections is depicted in Figure 4. The holes for through-hole

components are not seen in the picture.

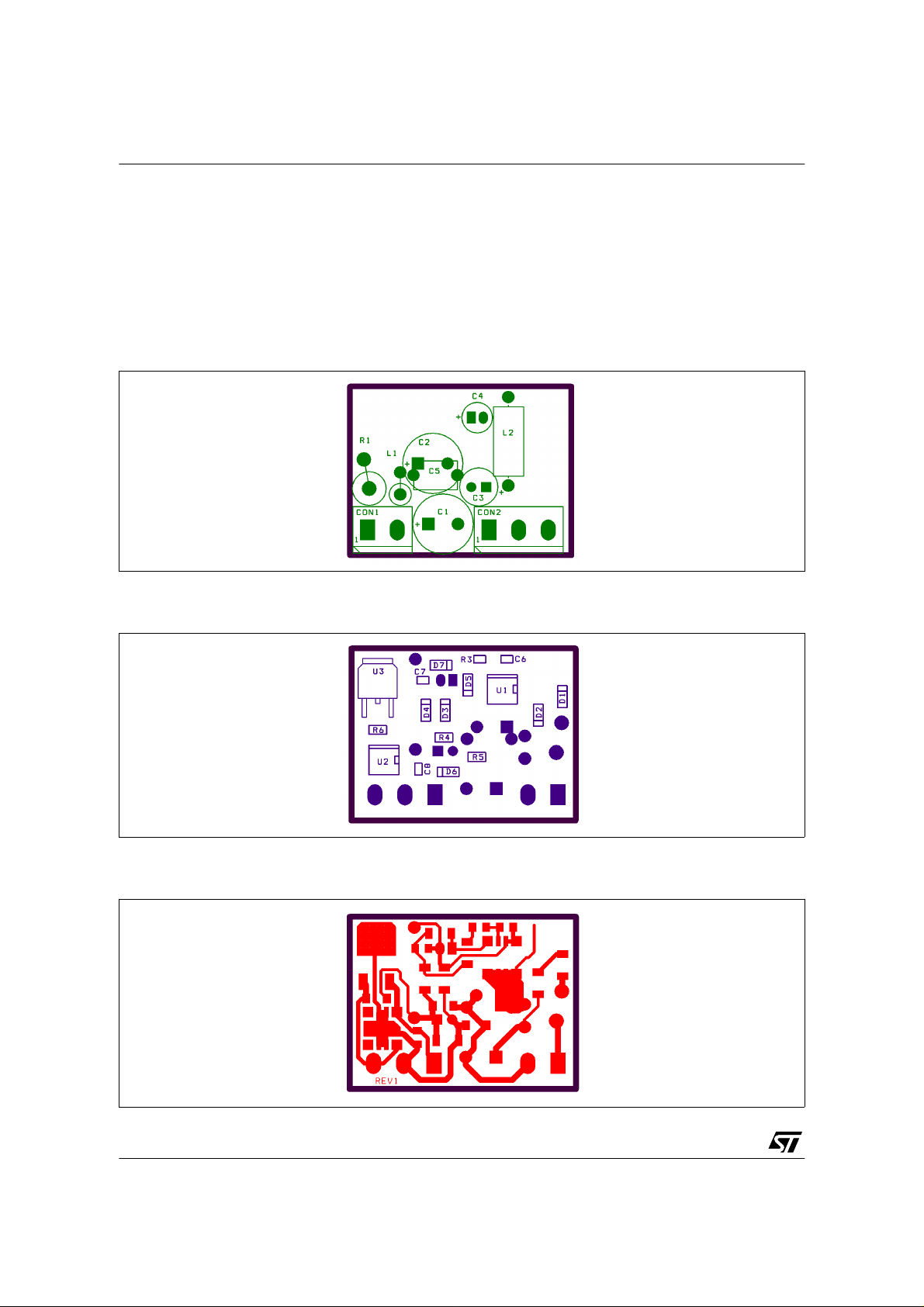

The physical appearance of the converter can be observed from Figure 5.

Figur e 5: Picture of the Converter

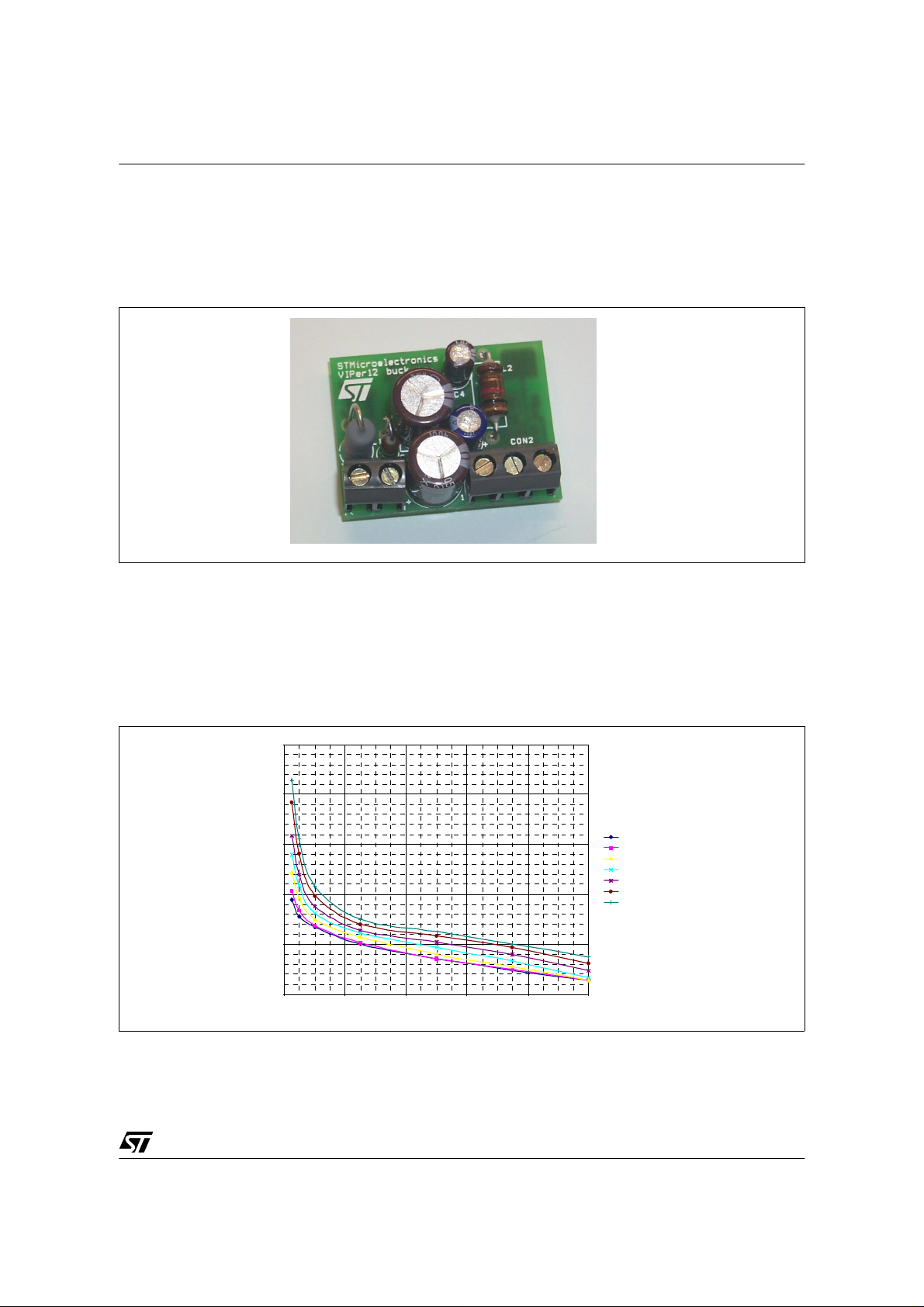

2.1.5 Buck Converter Evaluation and Measurements

The output regulation characteristics can be seen in Figure 6. It shows the variation of the output voltage

with output current at specific DC input voltage. The zener diode D6 was not connected during the

measurements

Figur e 6: Output Regulation Characteristics (Parameter is Vin)

19

18

17

16

Output Voltage [V]

15

14

0 0.020.040.060.080.1

Out put Current [A]

125VDC

150VDC

200VDC

250VDC

300VDC

350VDC

375VDC

Using the sam e me asure d v alues, Figure 6 can be redrawn using a different par ameter. Figure 7 shows

the variatio n of the outpu t voltage with inpu t DC voltage change. The output curr ent is the par ameter in

this case.

5/14

Page 6

AN1894 - APPLICATION NOTE

]

Figur e 7: Output Regulation Characteristics (Parameter is I

19

18

17

16

Output Voltage [V]

15

14

125 175 225 2 75 325 375

Input Voltage [V]

out

)

100mA

75mA

50mA

25mA

10mA

5mA

2.5mA

One of the most important and observed characteristics is the converter’s efficiency. Figure 8 depicts the

dependency of the effi cienc y on the inpu t vo ltage (parame ter i s outpu t curren t ) whil e Figur e 9 sh ows the

dependency on the output current (parameter is input voltage).

Figur e 8: Efficiency variation with input voltage (Parameter is I

80

75

70

65

60

E ffi ci en c y [%

55

50

45

40

125 175 225 275 325 375

6/14

Input Voltage [V]

out

)

100mA

75mA

50mA

25mA

10mA

5mA

Page 7

Figur e 9: Efficiency variation with output current (Parameter is Vin)

]

80

75

70

AN1894 - APPLICATION NOTE

65

60

E ffi ci en c y [%

55

50

45

40

0 0.02 0.04 0.06 0.08 0.1

Output Cu rre nt [A]

125VDC

150VDC

200VDC

250VDC

300VDC

350VDC

375VDC

Following pictures starting from Figure 10 to Figure 17 show the most important voltage or current

waveforms at different input and output conditions. Channel 1 (pink) is the power MOSFET Source

terminal voltage of the VIPer12. Channel 4 (red) shows the inductor current. The purpose of those

pictures is to demonstrate the skippi ng cycle function at li ght or no-load condi tion and cycle-by-cycle

primary current limitation at overload or output shorted condition.

Figure 10: Vin=127VDC, I

=100mA Figure 11 : Vin= 127VDC, I

out

= 50mA

out

7/14

Page 8

AN1894 - APPLICATION NOTE

Figur e 12 : Vin= 373VDC, I

= 100mA Figure 13 : Vin= 373VDC, I

out

= 50mA

out

Figur e 14 : Vin= 373VDC, no-load Figure 15: Vin= 127VDC, no-load

Figure 16: Vin= 127VDC, output shorted Figure 17: Vin= 127VDC, output shorted, burst

magnified

8/14

Page 9

AN1894 - APPLICATION NOTE

Furthermore conducted emissions were measured in neutral and line wire using peak or average

detector. The measurements were performed at 230VAC input voltage and the 15V output was fully

loaded by 100mA load. The presented results depicted from Figure 18 to Figure 21 show the results. For

compliance with the EN 55014 standa rd, a small input fil ter ( X-capacitor, commo n mode choke) sho uld

be added, if there is no EMI filter for the complete system. Alternatively, a double sided pcb can be used.

Figure 18: Phase L, average detector Figure 19: Phase L, peak detector

Figure 20: Phase N, average detector Figure 21: Phase N, peak detector

2.2 Inverting Converter -15V/100mA (Variant 2)

2.2.1 Operating Conditions

Input Voltage range

Input Voltage Frequency range

Output

Total Maximum Output Powe r

90-264 VAC

50/60 Hz

-15V / 100mA

1.5W

9/14

Page 10

AN1894 - APPLICATION NOTE

2.2.2 Circuit Operation

The total sc hematic of the power su pply can be seen in Figure 22. The output current flowing to t he

output capacitor C3 is discontinuous for the buck-boost converter (unlike the above described buck

converter). Du ring p ri mar y swit ch ON -time the in ductor curr ent flows through th e indu c tor to gro und a nd

not to the output capacitor as for buck converter. As soon as the primary switch is turned off, the inductor

reverses the voltage between its terminals and current starts to flow through the forward biased D5 diode

and charges the outp ut capacitor C3. In this switc h-off phase the source termina l of the VIPer12 sees

negative level of forward biased D5 and negative output voltage (when referenced to ground). The

converter is called inverting. It i s because the output vo ltage is negative co mpared to the input v oltage

referred to the s ame common ground. B y removin g the jumper R5 an d placeme nt of the ju mper R4 the

buck converter can be easily changed to the inverting buck-boost converter.

Figure 22: Schematic Diagram of Non Isolated Buck-Boost Converter with Negative Output Voltage

D1

90...264V~

CON1

L

N

clamp

D2

L1

R1

10R

GL1M

1000V

1A

GL1M

1000V

1A

3W

L

1

2

N

BC

1.5mH 100mA

C1

+

4.7uF

400V

KMG

8

C2

+

4.7uF

400V

KMG

2

U1

VDD

Drain15Drain26Drain37Drain4

FB

Source11Source2

VIPer12AS

VDD

C4

4

10uF

50V

KME

3

C6

220pF

D7

LL4148

+

D3

ZMM13

R3

1k

C7

100nF

D4

RGL34J

600V

0.5A

R6

Layout Hints: C4, C6 have

to be close to VIPer12A

R4

0R

L2

1mH

200mA

D5

RGL34J

600V

0.5A

LBC

C3

+

56uF

35V

LXY

0R

CON2

3

2

1

clamp

-15V

2.2.3 Buck-Boost Converter Evaluation and Measurements

The output regulation characteristics can be seen in Figure 23. It shows the variation of the output

voltage with output c urrent at specific DC input v oltage. The zener diod e D6 was not connected duri ng

the measurements.

10/14

Page 11

Figure 23: Output Regulation Characteristics (Parameter is Vin)

17

AN1894 - APPLICATION NOTE

16

Output Voltage [V]

15

14

0 0.02 0.04 0.06 0.08 0.1

Output Current [A ]

125VDC

150VDC

200VDC

250VDC

300VDC

350VDC

375VDC

Using the same measured values, Figur e 23 can be redrawn using a different param eter. Figu re 24

shows the variation of the output voltage with input DC voltage change. The output current is the

parameter in this case.

Figure 24: Output Regulation Characteristics (Parameter is I

17

out

)

16

Output Voltage [V]

15

14

125 175 225 275 325 375

Input Voltage [V]

100mA

75mA

50mA

25mA

10mA

5mA

2.5mA

11/14

Page 12

AN1894 - APPLICATION NOTE

]

]

Figure 25 d epicts the dependency of the efficiency on the inp ut voltage (parameter is out put current)

while Figure 26 shows the dependency on the output current (parameter is input voltage).

Figure 25: Efficiency variation with input voltage (Parameter is I

80

75

70

65

60

55

E ffi ci en c y [%

50

45

40

35

125 175 225 275 325 375

I nput Voltage [V]

out

Figure 26: Efficiency variation with output current (Parameter is Vin)

)

10 0m A

75 mA

50 mA

25 mA

10 mA

5mA

12/14

80

75

70

65

60

E ffi ci en c y [%

55

50

45

40

0 0. 02 0.0 4 0.06 0. 0 8 0.1

Output C urrent [A]

125VDC

150VDC

200VDC

250VDC

300VDC

350VDC

375VDC

Page 13

AN1894 - APPLICATION NOTE

Following pictures starting from Figure 27 to Figure 34 show the most important voltage or current

waveforms at d ifferent in put a nd output conditio ns. The ch annel 1 (pink ) is the p ower M OSFET Sour ce

terminal vo ltage of the VIPer12. The channel 4 (red) sho ws the inducto r current. The pur pose of those

pictures is to demonstrate the skippi ng cycle function at li ght or no-load condi tion and cycle-by-cycle

primary current limitation at overload or output shorted condition.

Figure 27: Vin= 127VDC, I

Figure 29: Vin= 373VDC, I

= 100mA Figure 28: Vin= 127VDC, I

out

= 100mA Figure 30: Vin= 373VDC, I

out

= 50mA

out

= 50mA

out

Figure 31: Vin= 373VDC, no-load Figure 32: Vin= 127VDC, no-load

13/14

Page 14

AN1894 - APPLICATION NOTE

Figure 33: Vin= 127VDC, output shorted Figure 34: Vin= 127VDC, output shorted, burst

magnified

Waveforms look very simi lar to th ose p resented f or the b uck con verter. One shou ld notice the neg ative

voltage pres en t o n t he VIP er 12 source after internal swit ch t urn- off. T he lev el of thi s n egati ve vol tage is

equal to the output voltage level.

3. CONCLUSION

A reference board w ith the monol ithic sw itcher V IPer1 2AS was presente d. The way, how the refere nce

board can be easi ly s witc hed between tw o basi c non- iso lated top ol ogies bu c k and buck - boost conv erte r

was described. Depi cted output regulation and over all converter efficiency charact eristics measured at

different working conditions show good performance of this simple VIPer12AS application in such difficult

working environment. The circuit is EMI compliant (both emission and immunity), when a small input filter

is added.

Information furnished is believed to be accurate and r eliable. However, STMicroelect r onics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may results from its use. No license is

granted by implication or otherwi s e under any patent or patent rights of STMicroel ec tronics. Specificat ions mentioned in this publication are

subject to c hange without notic e. This publicatio n s upersedes and rep lac es all information previously supplied. STMicroelec tronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

Australia - Brazil - Canada - China - Finland - France - Germany - Ho ng K ong - India - Israel - It aly - J apan - Malaysia -

Malta - Moro c c o - S ingapore - Spain - Sweden - Switzerland - Unite d K ingdom - U.S.A.

The ST logo is a trademark of STMicroelectronics

2004 STMicroelectronics - Prin ted in ITALY- All Rights Reserved.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

14/14

Loading...

Loading...