Page 1

AN1893

Application note

Designing with L6925D, high-efficiency monolithic

synchronous step-down regulator

Introduction

This application note details the main features and application advantages of

STMicroelectronics’ new synchronous step-down regulator. After describing how the device

works and the main features, a step-by-step design section is provided in order to help with

the selection of the external components and the evaluation of the losses. The device

performances are shown in terms of efficiency and thermal results. In conclusion, some

application ideas are proposed.

This new product, realized in BCDV technology, is a high-efficiency monolithic synchronous

step-down regulator capable of delivering up to 800 mA of continuous output current and

regulating the output voltage from 0.6 V up to V

capability. The input voltage ranges from 2.7 V to 5.5 V. The control loop architecture is

based on a constant frequency peak current mode, while high efficiency at light loads is

achieved by a low consumption functionality. The very low quiescent current (25 µA) and

shutdown current (0.2 µA) make the device very suitable to supply battery-powered

equipment (particularly suitable for 1 Li-ion cell) like PDAs and hand-held terminals, DSCs

(digital still cameras) and cellular phones. The switching frequency is internally set at 600

kHz but the device can be externally synchronized up to 1.4 MHz. An internal reference

voltage of 0.6 V (typ), allows the device to regulate minimum output voltage of the same low

value. The low MOSFETs R

interesting features are: hysteretic UVLO, OVP, constant current short-circuit protection,

PGOOD and thermal shutdown. The MSOP8 package allows saving significant board

space.

ensures high efficiency at high output current. Additional

DS(on)

thanks to the 100% duty cycle operation

IN

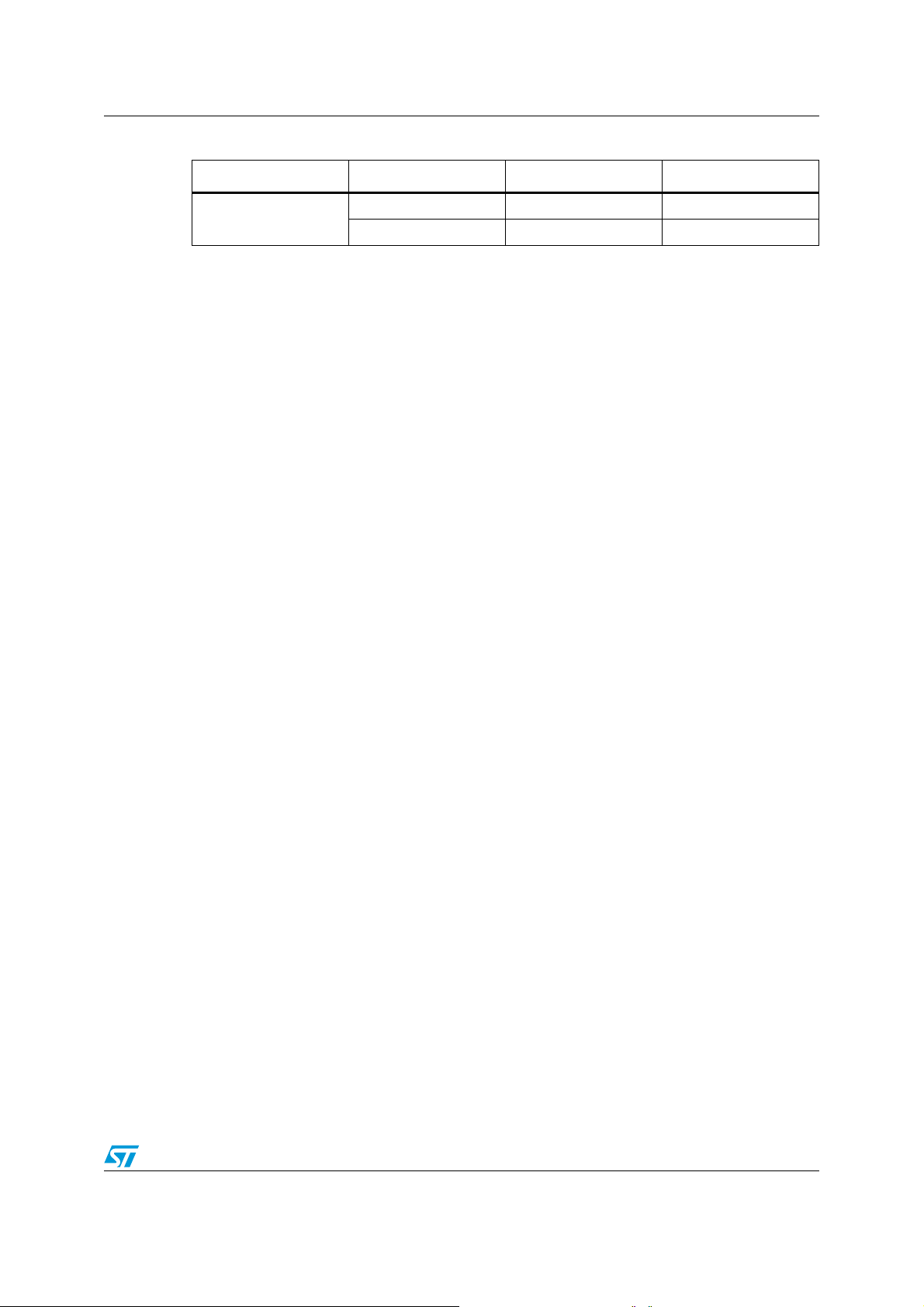

Figure 1. Application test circuit

February 2009 Rev 3 1/29

www.st.com

Page 2

Contents AN1893

Contents

1 Pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 LBI (low battery input)/LBO (low battery output) . . . . . . . . . . . . . . . . . . . . 7

3.2 UVLO (undervoltage lockout) operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Modes of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3.1 Low consumption mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3.2 Low noise mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 System stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.1 Current loop compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.2 Voltage loop compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 DROPOUT operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Adjustable output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 OVP (overvoltage protection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Hysteretic thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 External component selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Input capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.3 Inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.4 Compensation network (R

5.2 Losses and efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.1 Conduction losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.2 Switching losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.3 Gate charge losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1C3

6 Thermal considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/29

Page 3

AN1893 Contents

7 Application board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Efficiency results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9 Application ideas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.1 Buck boost topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.2 White LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.2.1 Driving white LEDs: buck topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.2.2 Driving white LEDs: boost topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.2.3 Driving white LEDs: buck-boost topology . . . . . . . . . . . . . . . . . . . . . . . 26

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3/29

Page 4

List of figures AN1893

List of figures

Figure 1. Application test circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Pin connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. MSOP8 package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5. Low consumption mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. Low noise mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 7. Slope compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 8. Equivalent circuit for the voltage loop analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 9. Equivalent circuits during the ON time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. Equivalent circuit during the OFF time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 11. Valley current limit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 12. Thermal performance results: V

Figure 13. RDS(on) vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 14. Application board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 15. Component placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 16. Top side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 17. Bottom side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 18. Schematic demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 19. Low noises vs. low consumption efficiencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 20. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 21. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 22. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 23. Positive buck boost application. 1 Li-Ion cell to 3.3 V at 0.25 A . . . . . . . . . . . . . . . . . . . . . 24

Figure 24. Buck topology schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 25. Boost topology schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 26. Buck-boost topology schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 27. PWM brightness control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 28. Analog brightness control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

= 3.7 V V

IN

OUT

= 1.8 V I

= 800 mA . . . . . . . . . . . . . . 19

OUT

4/29

Page 5

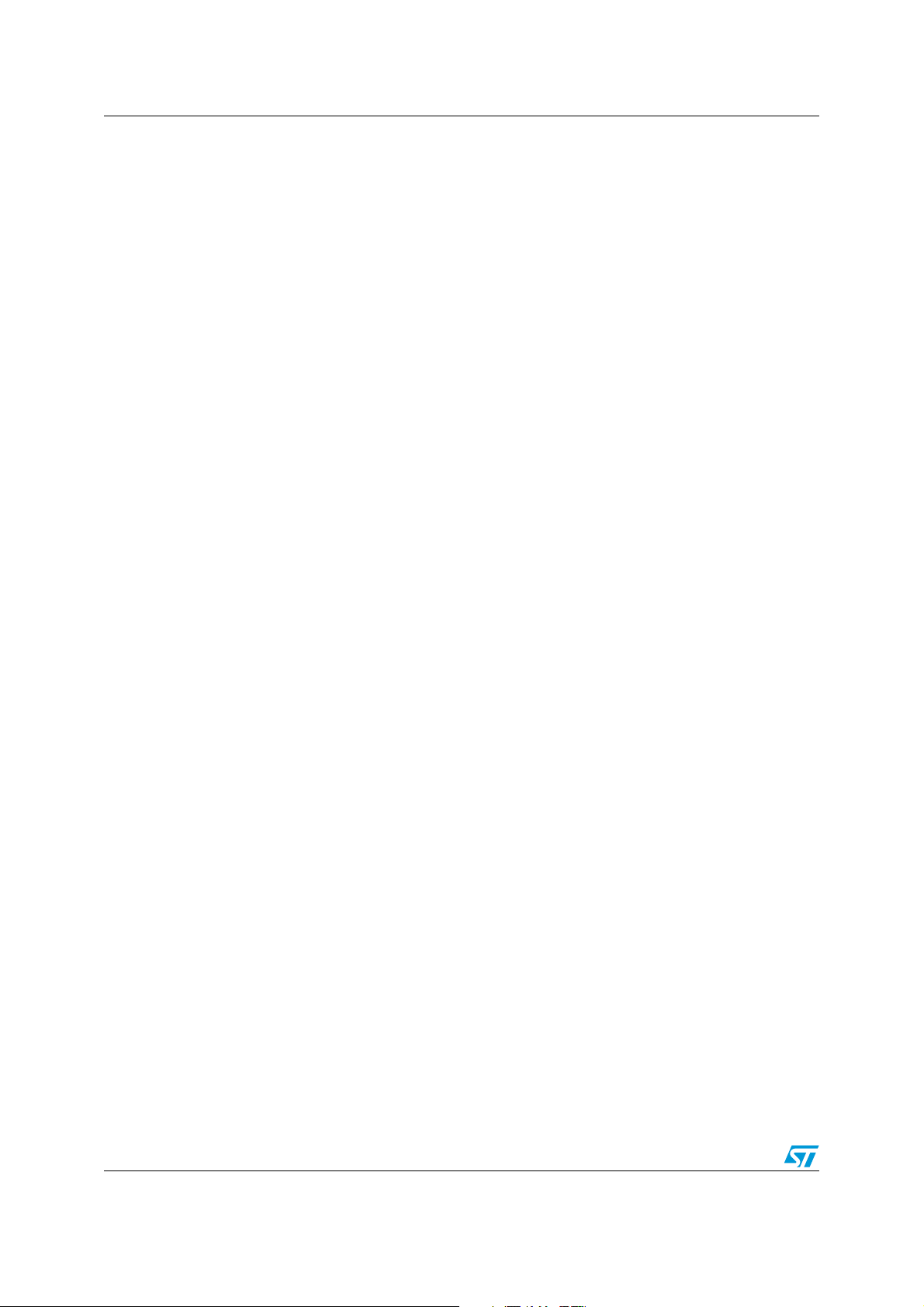

AN1893 Pin functions

1 Pin functions

Table 1. Pin description

N. Name Description

Battery low voltage detector input. The internal threshold is set at 0.6 V. The

1 LBI

2 COMP

3 VFB Error amplifier inverting external divider.

4 GND Ground.

5 LX Switches output node. Common point between high side and low side MOSFETs

6

VCC

7 SYNC

8 LBO

external threshold can be adjusted by using an external resistor divider (see

Section 3.1). If not used, the pin can be left floating.

Error amplifier output. A compensation network has to be connected to this pin.

Usually a 220 pF capacitor is enough to guarantee the loop stability (see

Section 3.3.1).

Input voltage. The startup input voltage is 2.8 V (typ) while the operating input

voltage range is from 2.7 V to 5.5 V. An internal UVLO circuit realizes a 200 mV

(typ) hysteresis.

Operating mode selector input. Low consumption mode when connected to a

higher voltage than 1.3 V (up to VCC). Low noise mode when connected to a lower

than 0.5 V (down to GND). Synchronization mode when connected to an external

appropriate clock generator. This pin must not be left floating.

Battery low voltage detector output. If the voltage at the LBI pin drops below the

internal threshold, the LBO pin goes low. The LBO pin is an open drain output. A

pull-up resistor should be connected between the pin and the output voltage. If not

used, the pin can be left floating.

Figure 2. Pin connections

Figure 3. MSOP8 package

5/29

Page 6

Block diagram AN1893

2 Block diagram

Figure 4. Block diagram

6/29

Page 7

AN1893 Functional description

3 Functional description

The main loop uses constant frequency peak current mode architecture. Each cycle, the

high side MOSFET is turned on, triggered by the oscillator, so that the current flowing

through it increases with a slope fixed by the operating conditions. When the sensed current

(a part of the high side current) reaches the output value of the error amplifier E/A, COMP

pin, the internal logic turns off the high side MOSFET and turns on the low side one until the

next clock cycle begins or the current flowing through it goes down to zero (ZERO-

CROSSING comparator). During the load transients, the voltage control loop keeps the

output voltage in regulation changing the COMP pin value, fixing a new turnoff threshold.

Moreover, during these dynamic conditions the choke must not saturate and the inductor

peak current must never exceed the maximum value. This value is in function of the internal

slope compensation (see Section 3.4.1).

3.1 LBI (low battery input)/LBO (low battery output)

A low battery input pin is available. The pin is internally connected to a comparator with a

threshold of 0.6 V. By using an external resistor divider connected between the battery

voltage and the ground it is possible to fix a threshold for the battery voltage. When the

voltage at the LBI pin goes lower than 0.6 V, the LBO pin is forced low. This feature can be

useful for example to have a warning signal when the battery is quite discharged.

3.2 UVLO (undervoltage lockout) operation

The device is particularly designed for equipment powered by a Li-ion battery. These types

of batteries are almost fully discharged when their voltage goes lower than approximately 3

V. For this reason, a UVLO is internally set at 2.8 V, with a hysteresis of 200 mV. Thanks to

this feature, when the battery is fully discharged, the device automatically turns off.

3.3 Modes of operation

3.3.1 Low consumption mode

At light load, the device operates in burst mode in order to keep the efficiency very high also

in these conditions.

While the device is not switching the load discharges the output capacitor and the output

voltage goes down. The COMP pin, due to the feedback loop, increases and when a fixed

internal threshold is reached, the device starts to switch again. In this condition the peak

current limit is set approximately in the range of 200 mA-400 mA, depending on the slope

compensation (see Section 3.4.1). Once the device starts to switch the output capacitor is

recharged. The repetition time of the bursts depend on parameters like input and output

voltages, load, inductor and output capacitors.

Between two bursts, most of the internal circuitries are off, thus reducing the device

consumption down to a typical value of 25 µA. During the burst, the frequency of the pulses

is equal to the internal frequency.

7/29

Page 8

Functional description AN1893

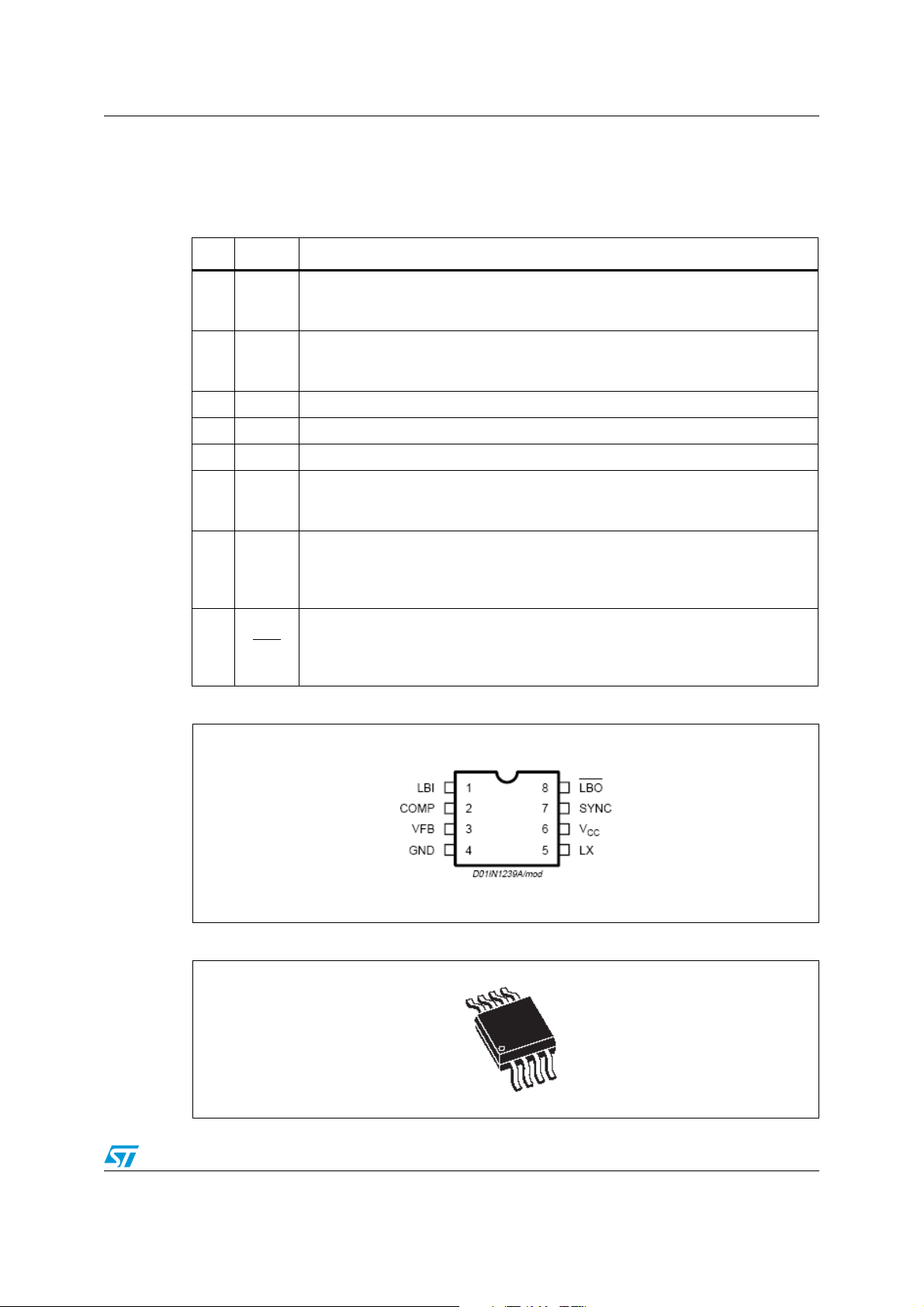

3.3.2 Low noise mode

In case the very low frequencies generated by the low consumption mode are undesirable,

the low noise mode can be selected. The efficiency is a little bit lower compared with the low

consumption mode conditions when working close to zero loads, while the trend is to reach

the efficiency of low consumption mode for intermediate light loads.

The device could skip some cycles in order to keep the output voltage in regulation. In

Figure 5 and 6 the LCM and LNM typical waveforms are shown.

Figure 5. Low consumption mode

Figure 6. Low noise mode

Measurement conditions: V

C

= 22 µF; RC = 40 kΩ; CC = 330 pF

OUT

= 4.2 V; V

IN

= 1.5 V; I

OUT

= 30 mA; L = 6.8 µH; CIN = 10 µF;

OUT

Figure 19 shows a comparison between the efficiency in low noise mode and the efficiency

in low consumption mode.

8/29

Page 9

AN1893 Functional description

3.4 System stability

Since the device operates with constant frequency peak current mode architecture, the

voltage loop stability is usually not a big issue. For most of the applications a 220 pF

connected between the COMP pin and ground is enough to guarantee the stability. In case

very low ESR capacitors are used for the output filter, such as multilayer ceramic capacitors,

the zero introduced by the capacitor itself can be shifted at a frequency well above the

resonance frequency of the L-C filter and the loop stability could be affected.

Adding a series resistor to the 220 pF capacitor can solve this problem. The right value for

the resistor can be determined by checking the load transient response voltage waveforms.

The current mode stability can be studied in two consecutive steps; first the inner loop is

closed (current loop) and then the second loop stability is considered (voltage loop).

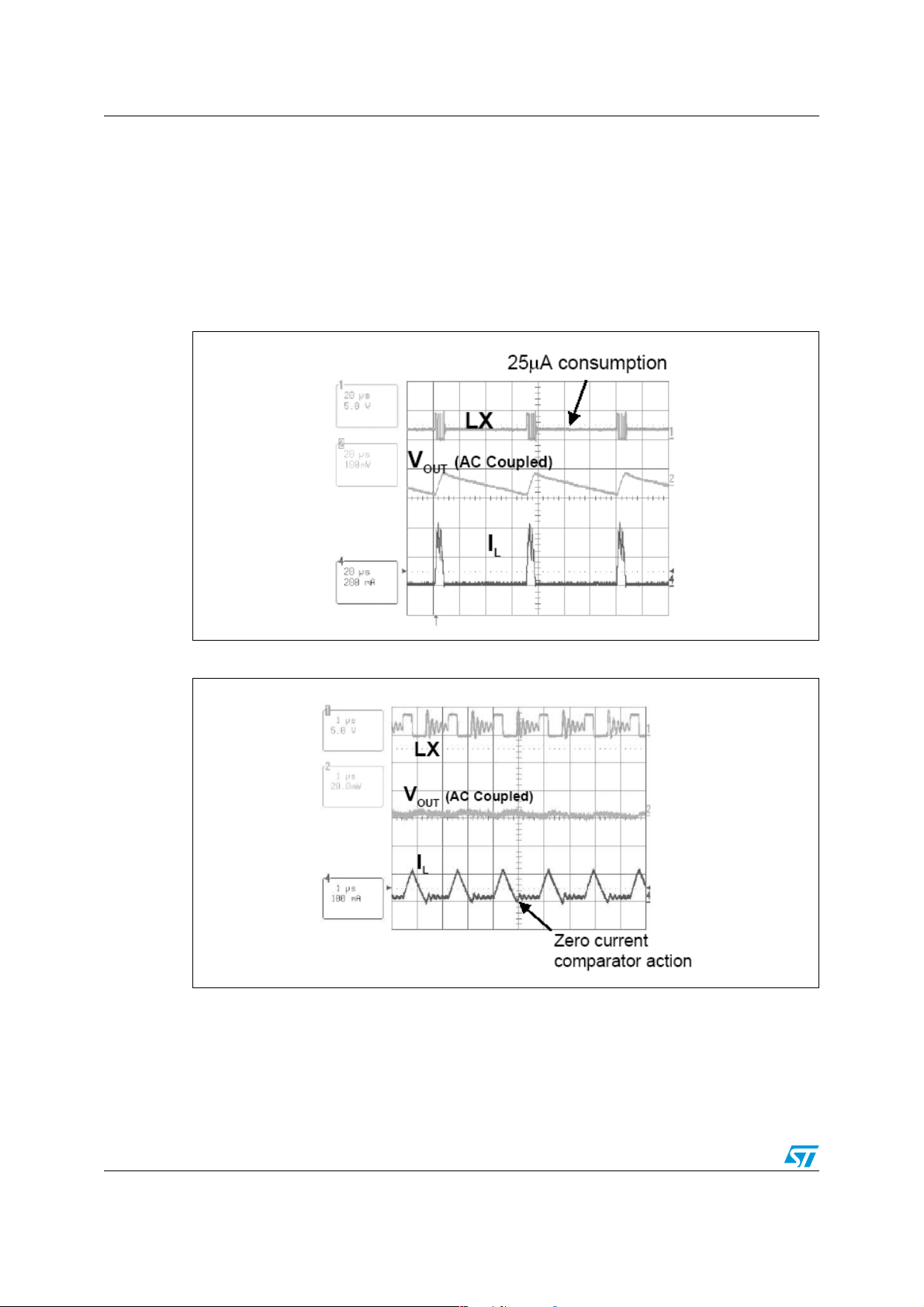

3.4.1 Current loop compensation

The selected control architecture brings many advantages: easy compensation with ceramic

capacitors, fast transient response and intrinsic peak current measurement that simplify the

current limit protection. A known drawback, however, is that the current loop becomes

unstable when the duty cycle exceeds 50%.

This phenomenon is known as "sub-harmonic oscillation" and can be avoided by adding a

slope compensation signal. Due to this fact, the current limit of the device decreases when

the slope compensation signal is applied. The slope compensation is internally implemented

from a duty around 30% and Figure 7 shows how the slope compensation affects the device

current limit.

Figure 7. Slope compensation

The amount of slope compensation depends on the inductor current slope during the OFF

time. This slope, for a given duty cycle, is inversely proportional to the inductor value. Since

the device can be synchronized at a higher frequency, it is reasonable to calculate the

inductor value in terms of it. Finally, the input voltage affects the OFF time slope as well.

This is obvious because, for a given duty cycle, the output voltage (and so the OFF time

inductor current slope) is directly proportional to the input one. In order to better manage

these issues, the amount of slope compensation depends not only on the duty cycle but also

on the switching frequency and the input voltage.

9/29

Page 10

Functional description AN1893

Table 2. Suggested inductor values for different switching frequencies, at V

3.6 V and V

FSW [kHz] Minimum inductor value [∝H]

600 6.8

1000 3.6

1400 2.7

OUT

=1.8 V.

Table 3. Suggested inductor values for different switching frequencies, at

V

= 5 V and V

IN

F

[kHz] Minimum inductor value [µH]

SW

600 8.2

1000 5.6

1400 3.6

OUT

=3.3 V

Ta bl e 2 and 3 indicate the minimum inductor values that ensure the current loop stability

with an input voltage of 3.6 V and 5 V. Also there is a maximum inductor value above which

the loop can become unstable. For example, if the inductor is too high the LC double pole

returns to the bandwidth.

3.4.2 Voltage loop compensation

=

IN

Ideally in a current mode control, after closing the current loop, the pole splitting effect

separates the complex double pole due to the inductor and the output capacitor in 2 different

poles. The pole due to the inductor shifts out of system bandwidth (i.e. the inductor ideally

acts like a current source), while the pole due to the output capacitor remains inside the

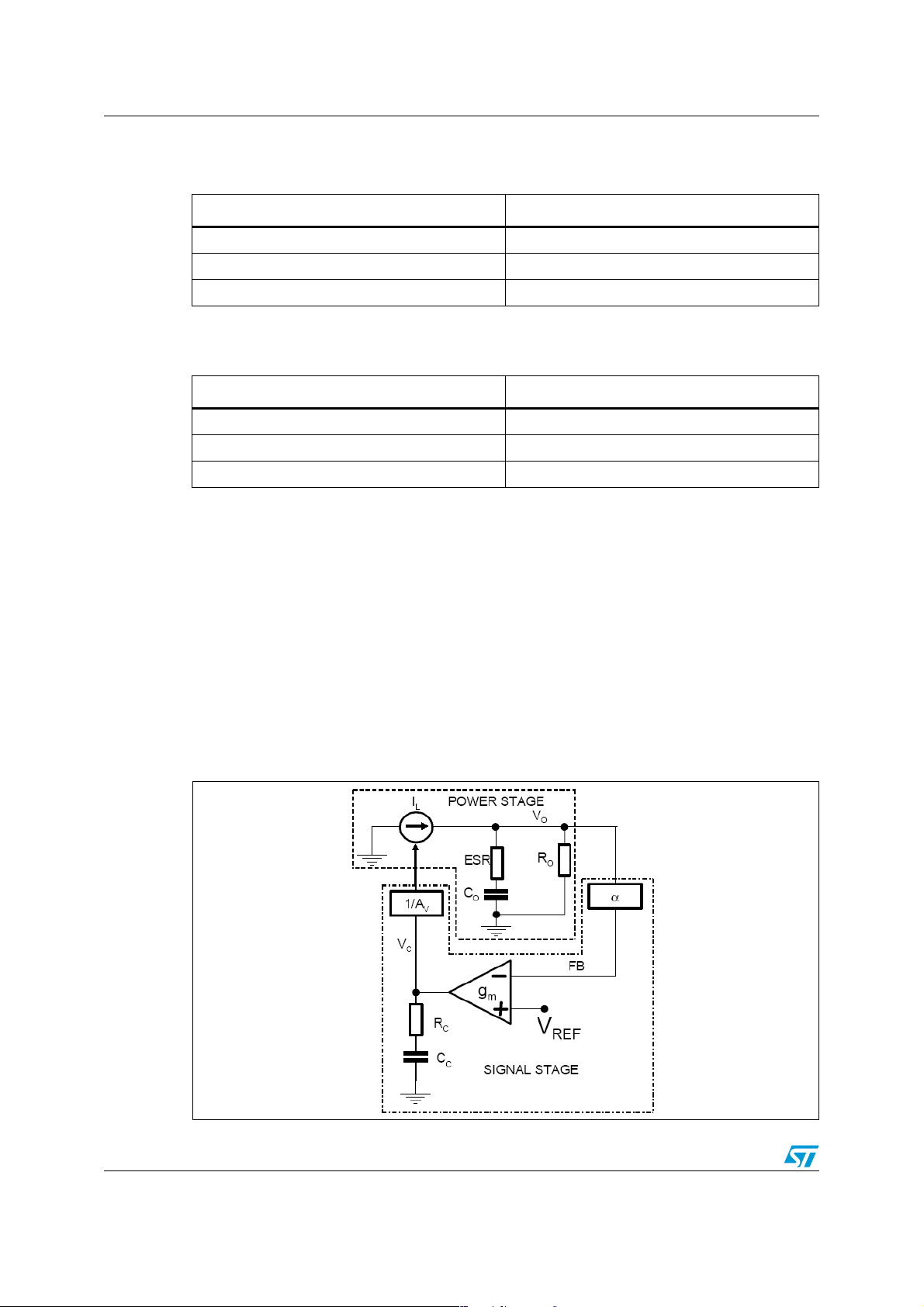

bandwidth. Figure 8 shows the equivalent circuit used to study the voltage loop

compensation:

Figure 8. Equivalent circuit for the voltage loop analysis

10/29

Page 11

AN1893 Functional description

In Equation 1 the power stage transfer function is shown:

Equation 1

s()

Hs()

V

O

--------------- -

I

L

sCOESR 1+()R

----------------------------------------------------- -==

s()

sCOESR RO+()1+

O

where R

is the output equivalent resistor load (VO/IO) and ESR is the series resistance of

O

the output capacitors. It can be seen that the pole due to the output capacitor shifts in

frequency based on the load value.

In order to have zero DC error in the voltage regulation, the feedback voltage loop is

implemented with an integrator stage. The transfer function of the signal stage is shown in

Equation 2.

Equation 2

sC

where g

α

g

m

-----------

Gs()

is the integrator transconductance (250 µS). The total gain loop is:

m

A

V

---------------------------- -

⋅=

CRC

sC

1+

C

Equation 3

R

α 1sESRC

+()sCCRC1+()

A

1sCOESR RO+()+()

VsCC

O

where A

(R

/(R2+R3).

2

Ogm

G

LOOP

is the current loop factor (1Ω typ.) and α is the feedback resistor divider ratio

V

s()

--------------------------------------------------------------------------------------------- -=

Once the gain loop is known the system is stabilized with the compensation network as

shown in Section 5.1.4.

11/29

Page 12

Short-circuit protection AN1893

4 Short-circuit protection

The device is provided with two limiting current circuitries, one on the high side and a

second on the low side MOSFET.

Due to the peak current mode architecture, the peak current flowing through the high side

switch is accurately sensed. When this current reaches the peak current limit threshold, the

internal high side MOSFET is turned off. In this way, the ON time, T

output voltage decreases. The minimum T

can be around 200 nsec (T

ON

short-circuit, the peak current could further increase because the intervention of the high

side limiting current is not fast enough. In this case, the valley current limits eliminate the

risks of device failure. To better understand this concept, it's useful to read the below

considerations on the current variation through the inductor during the ON and OFF time.

Equation 4

VINV

–()

∆I

ON

----------------------------------

OUT

⋅=

L

T

ON

(ON time slope)

Equation 5

V

OUT

∆I

OFF

--------------

L

T

⋅=

(OFF time slope)

OFF

, is reduced and the

ON

). In case of

MIN

When V

= 0 V, it can be seen that the inductor current doesn't decrease during the OFF

OUT

time. Therefore the current increases step by step during each cycle. In order to understand

when this phenomenon ends, some real parameters must be considered.

Figure 9. Equivalent circuits during the ON time

Figure 10. Equivalent circuit during the OFF time

12/29

Page 13

AN1893 Short-circuit protection

Considering Figure 9 and 10, in particular during the OFF time, despite the output voltage of

zero, the output current generates on the parasitic resistances the voltage drop necessary

to produce a negative slope. So, the higher the output current is, the higher the negative

slope during the OFF time. In this way, the inductor current finds a stable value. This value

is given by:

Equation 6

I

LIM

----------------------------------------------------------------------------------------------------------------------------------------------------- -=

+()1T

R

NRL

VINT

⋅–()RPRL+()T

MINFSW

⋅()⋅

MINFSW

⋅()⋅+⋅[]

MINFSW

where T

resistance of the low side and high side MOSFETs respectively, R

resistance and R

conditions, the maximum current value depends both on the application conditions (like V

and F

is the minimum ON time, FSW is the switching frequency, RN and RP are the ON

MIN

is the equivalent output resistance. As it can be seen, in these extreme

O

), the inductor parasitic resistor RL, and the MOSFETS R

SW

is the inductor series

L

DS(on) RN

and RP . It does

IN

not depend on the peak current limit at all. In order to limit the output current to a safe value

even in extreme short-circuit conditions, a current limit has also been introduced on the low

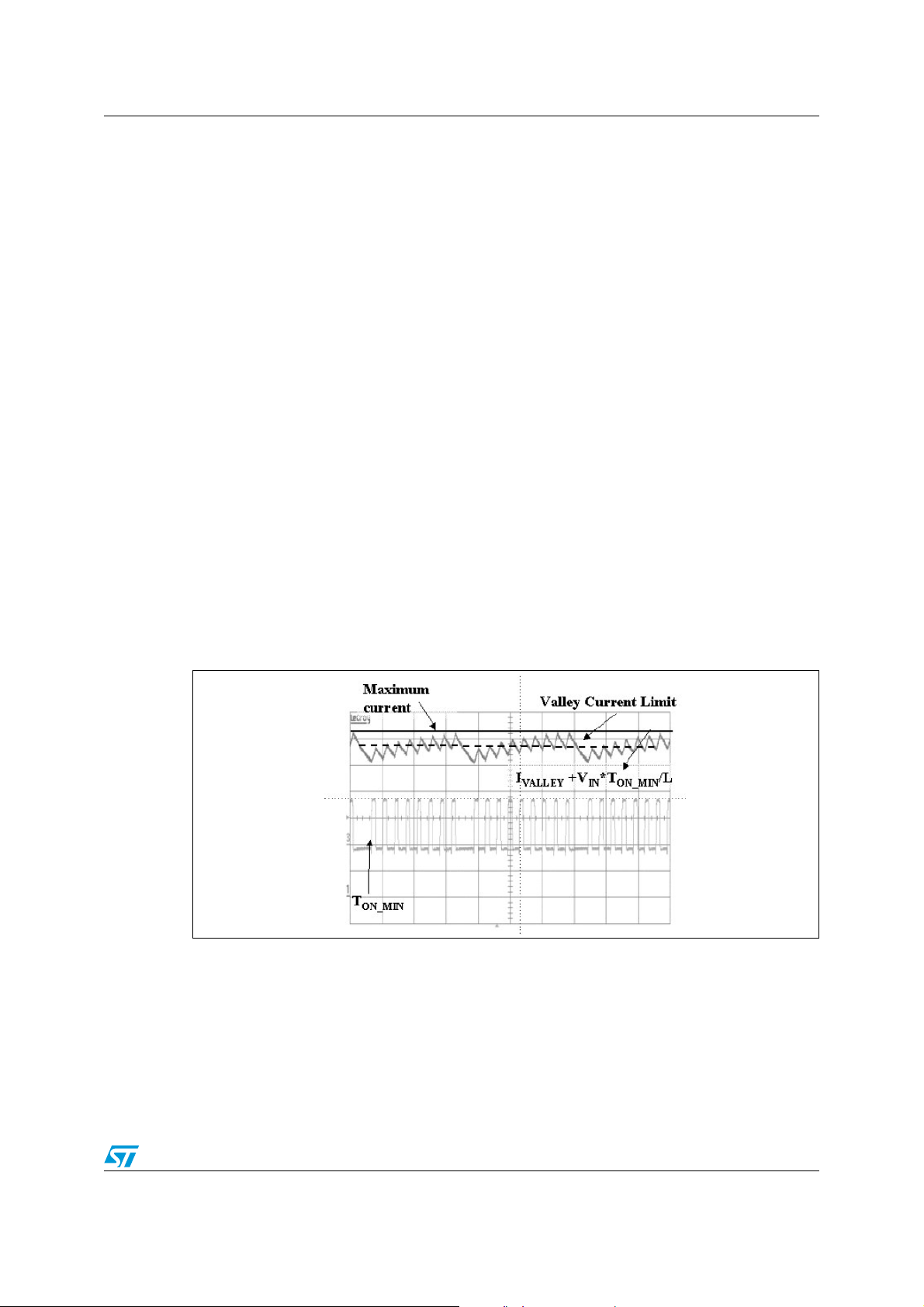

side MOSFET: this operates as a valley current limit, as shown in Figure 11. The high side

MOSFET does not turn on until the inductor current exceeds the valley current limit. This

implies that, depending on the over current conditions, the device skips some cycles, thus

reducing the equivalent switching frequency in order to limit the output current. With this

approach, the maximum peak current is definitively limited to:

Equation 7

VINT

I

LIMIVALLEY

MIN

----------------------+=

L

Figure 11. Valley current limit protection

4.1 Synchronization

The device can be synchronized with an external signal from 500 kHz up to 1.4 MHz through

the internal PLL. When the device is locked, the external signal and the high side turn-on

rising edges are aligned. In this case the low noise mode is automatically selected. The

device eventually skips some cycles in very light load conditions depending also on the

input/output conditions. The internal synchronization circuit is inhibited in short-circuit and

13/29

Page 14

Short-circuit protection AN1893

overvoltage conditions in order to keep the involved protections effective. The

synchronization signal amplitude can range typically from 1 V to V

and the duty factor can

CC

range typically from 20% to 80%. Sometimes, if the synchronization signal duty cycle is very

similar to the application duty factor, noise can be detected on the LX pin. In this case some

practical solutions are:

1. Change the synchronization signal duty factor

2. Decrease the synchronization signal amplitude

3. Add 20 pF capacitor between the Comp pin and ground.

The device switches at 600 kHz (typ.) if no synchronization signal is applied.

4.2 DROPOUT operation

When the input voltage is a Li-Ion battery, the voltage ranges from a minimum of 3 V or less

to 4.1 V - 4.2 V (depending on the anode material). In case the regulated output voltage is

from 2.5 V and 3.3 V, the device can work in linear mode or dropout operation. The minimum

input voltage necessary to ensure output regulation can be calculated as:

Equation 8

V

INMIN

---

VOIOR

DS on()HSMAXRL

+()⋅+=

where R

DS(on)_HS_MAX

is the maximum high side resistance and RL is the series inductor

resistance.

4.3 Adjustable output voltage

The output voltage can be adjusted by an external resistor network from a minimum value of

0.6 V up to the V

. The output voltage value is given by:

IN

Equation 9

V

OUT

Thanks to the very low FB leakage current (typ. 25 nA), high R3, R2 values can be chosen in

hundreds of kΩ increasing the system efficiency also at very low load.

4.4 OVP (overvoltage protection)

The device has an internal output overvoltage protection. If the output voltage goes higher

than 10% of its nominal value, the low side MOSFET is turned on until the output voltage

returns inside the nominal value tolerances. During the overvoltage circuit intervention, the

zero-crossing comparator is disabled so that the device is also able to sink current.

⎛⎞

0.6 1

⋅=

⎝⎠

R

3

------ -+

R

2

4.5 Hysteretic thermal shutdown

The device has also a thermal shutdown protection activated when the junction temperature

rises above 150°C. In this case both the high side MOSFET and the low side one are turned

off. Once the junction temperature falls back to about 95 °C, the device restarts normal

operation.

14/29

Page 15

AN1893 Application information

5 Application information

5.1 External component selection

5.1.1 Input capacitor

The input capacitor must be able to support the maximum input operating voltage and the

maximum RMS input current. Since step-down converters draw current from the input in

pulses, the input current is squared and the height of each pulse is equal to the output

current, neglecting the ripple across the inductor.

The RMS input current (flowing through the input capacitor) is:

Equation 10

I

RMSIO

2D2⋅

D

-------------- -–

η

2

D

------ -+⋅=

2

η

Where η is the expected system efficiency, D is the duty cycle and I

the output DC current.

O

Supposing η =1 this function reaches its maximum value at D = 0.5 and the equivalent RMS

current is equal to I

/2.

O

The maximum and minimum duty cycles are:

Equation 11

V

D

MAX

------------------=

V

INMIN

O

Equation 12

MIN

------------------- -=

V

INMAX

D

V

O

Depending on the output voltage value the worst case can be with the maximum or

minimum input battery voltage. Usually the best choice for the input capacitor is the MLCC

(multi layer ceramic capacitor) thanks to its very small size and very low ESR. Ta bl e 4

provides a list of some MLCC manufacturers.

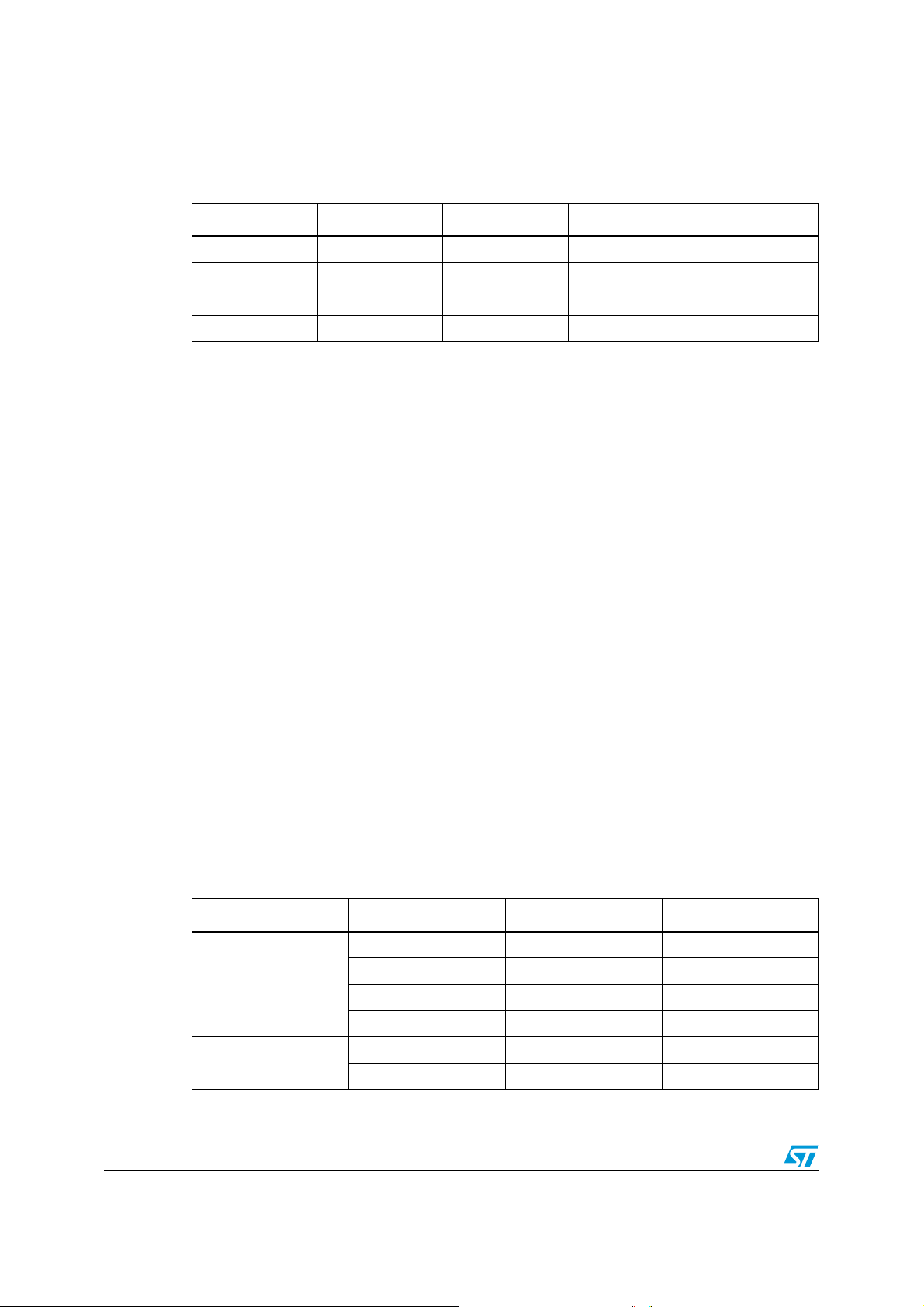

Table 4. Recommended input capacitors

Manufacturer Series Cap value (µF) Rated voltage (V) ESR at 600 kHz (m.)

PANASONIC ECJ 10 to 22 6.3 10

TAIYO YUDEN JMK 10 to 22 6.3 10

5.1.2 Output capacitor

The output capacitor is very important to satisfy the output voltage ripple requirement. Very

small inductor values reduce size and cost of the application but increase the current ripple.

This ripple, multiplied by the ESR of the output capacitor, is the output voltage ripple.

Tantalum and ceramic capacitors are usually good for this use. Ceramic capacitors have the

lowest ESR for a given size so, for very compact applications they are the best choice.

POSCAP capacitors from Sanyo are also a good choice for the output filter.

15/29

Page 16

Application information AN1893

Ta bl e 5 gives a list of some capacitor manufacturers.

Table 5. Recommended output capacitors

Manufacturer Series Cap value (µF) Rated voltage (V) ESR (m.)

PANASONIC ECJ 10 to 47 6.3 10

PANASONIC EEF 22 to 47 6.3 60 to 90

TAIYO YUDEN JMK 10 to 47 6.3 10

SANYO POSCAP TPA 47 to 100 6.3 80 to 100

5.1.3 Inductor

The inductor value fixes the ripple current flowing through the output capacitor. The ripple

current is usually fixed at 20% - 30% of the output current and is approximately obtained by

the following formula:

Equation 13

–()

V

INVOUT

----------------------------------

L

⋅=

T

I∆

ON

For example, with V

and I

= 600 mA and ∆I = 200 mA, the inductor value is about 6 µH. The peak current

O

= 3.3 V, VIN = 4.2 V (Li-ion battery fully charged), FSW = 600 kHz

OUT

through the inductor is given by:

Equation 14

I

PKIO

I∆

---- -+=

2

It can be seen that if the inductor value decreases, the peak current (that has to be lower

than the current limit of the device) increases. This peak current must be lower than the

saturation current of the choke.

This is particularly important when using ferrite cores because they can hardly saturate (the

inductance value decreases abruptly when the saturation threshold is exceeded thus

causing an abrupt increase of the current flowing through it). The inductor should be

selected also considering the system stability, (see Section 3.4.1). Moreover the inductor

selection should be made, taking into account the inductor parasitic resistance because a

value that is too high can decrease the efficiency. Ta bl e 6 lists some inductor manufacturers.

Table 6. Recommended inductors

Manufacturer Series Inductor value (µH) Saturation current (A)

DO1607C 6.8 to 15 0.72 to 0.96

Coilcraft

DT1608C 6.8 to 15 0.6 to 1

LPO1704 6.8 to 10 0.8 to 0.9

DO1606T 6.8 to 10 1 to 1.1

Panasonic

16/29

ELL6RH 6.2 to 22 0.7 to 1.4

ELL6GM 6.8 to 10 0.93 to 1.1

Page 17

AN1893 Application information

Table 6. Recommended inductors (continued)

Manufacturer Series Inductor value (µH) Saturation current (A)

To ko

D62CB 10 to 22 0.71 to 1.07

D62C 10 to 22 0.63 to 0.99

5.1.4 Compensation network (R1C3)

As shown in Section 3.4 the system stability can be studied with the loop transfer function

given by Equation 3. If the output capacitor is a ceramic type, the zero due to the ESR

generally is out of the system bandwidth, so the stability of the system is ensured by the

cancellation between the pole due to the output capacitor and the equivalent load and the

R

zero. In Equation 15, a simplified gain loop expression, valid around the transition

1C3

frequency f

Equation 15

Supposing C

system bandwidth), and the output voltage equal to 1.8 V, the R

Equation 16

The nearest standard E12 series value is R

The higher the bandwidth is, the faster the transient response but the bandwidth (and so the

R

value) must be lower than fSW/10 to avoid the effect due to the sampling effect poles as

1

mentioned in Section 3.2. The zero due to the compensation network must be at least 5

times lower than the frequency transition, so the C

is given by:

T

G

= 22 µF, the transition frequency at 0 dB equal to 30 kHz (fT is equal to the

2

R

1

LOOP s()

2π fTC

-------------------

gmα

= 47 kΩ .

1

gmR1α

------------------ -=

sC

2

2

48k Ω==

value:

3

value can be calculated as:

1

Equation 17

The nearest standard value is C

ESR zero is in the system bandwidth and it can be used to stabilize the system so the zero

due to the compensation network is useless (the C

5.2 Losses and efficiency

There are losses affecting the efficiency of the application. Some of these losses are related

to the device and others are related to the external components. The most important losses

are explained in the following paragraphs.

5.2.1 Conduction losses

These losses are basically due to the non-negligible resistances of the internal switches and

the external inductor. Usually the current ripple across the inductor is negligible and in order

to estimate the conduction losses of the inductor, the average output current can be

C

3

2π f

= 470 pF. If the output capacitors are tantalum type the

3

17/29

TR1

500pF==

is necessary to the integrator function).

3

5

-------------------

Page 18

Application information AN1893

considered. The conduction losses of the switches depend also on the duty cycle of the

application. The RMS current flowing through the high side MOSFET is (I

RMS current flowing through the low side MOSFET is (I

)2 · (1-D). So, the total conduction

O

)2 · D while the

O

losses are:

Equation 18

P

MOSIO

2

RPD() RN1D–()RL+⋅+⋅()⋅=

where R

respectively and R

and RN are the series resistance of the high side and low side MOSFETs

P

the series resistance of the inductor. The conduction losses due to the

L

ESR of the input and output capacitors are usually negligible, particularly when using

ceramic caps (very low ESR). Anyway, in case of high ESR values for these caps, their

conduction losses are:

Equation 19

P

where ∆I is the current ripple flowing through the choke and D is the duty cycle of the

application. The conduction losses are particularly important at high current because they

depend on its squared value.

5.2.2 Switching losses

The switching losses are due to the turn on and off of the internal high side MOSFET.

Equation 20

where T

are approximately in the range of 15 ns to 20 ns.This loss is important at high frequency.

ON

and T

OFF

2

CIN COUT,

I

O

P

SWITCHINGVINIOFSW

D1D–()⋅()ESR

⋅⋅ ⋅=

I2∆

------- -

⋅+⋅⋅=

CIN

T

ONTOFF

----------------------------------- -

ESR

12

+()

2

COUT

are the turn-on and turnoff times of the internal high side switch. These

5.2.3 Gate charge losses

The gate charge losses derive from switching the gate capacitance of the internal

MOSFETs. The gate capacitances (C

MOSFETs) are charged and discharged with the input voltage at the switching frequency.

Equation 21

P

GATECHARGEVINCHCL

These losses are also directly proportional to the switching frequency and input voltage but

are usually negligible compared with the conduction and switching losses.

18/29

H

-

for the high side MOSFETs and CL for the low side

+()F

⋅⋅=

SW

Page 19

AN1893 Thermal considerations

6 Thermal considerations

Depending on the electrical application conditions (input voltage, switching frequency, and

output current) and ambient temperature, the heat produced by device losses could

increase the junction temperature over its absolute maximum rating. The following relation

can be used to estimate the junction temperature of the device:

Equation 22

TJTAR

where T

is the ambient temperature of the application, R

A

junction to ambient of the package and P

R

equal to 180 °C/W. P

depends a little bit on the application board but it can be considered approximately

TH_JA

is given by:

TOT

Equation 23

P

TOTPMOSPSWITCHINGPGATECHARGE

++=

TOT

⋅+=

THJAPTOT

is the thermal resistance

TH_JA

is the overall power dissipated by the device.

-

Figure 12. Thermal performance results: V

Figure 13. R

vs. temperature

DS(on)

= 3.7 V V

IN

OUT

= 1.8 V I

= 800 mA

OUT

For a better estimation of the power dissipated, it can be useful to consider the MOSFET’s

R

variation with the temperature, as shown in Figure 13.

DS(on)

19/29

Page 20

Application board AN1893

7 Application board

Figure 14. Application board

Demonstration board layout

In the figures below the demonstration board layout is shown.

Figure 15. Component placement

Figure 16. Top side view

20/29

Page 21

AN1893 Application board

Figure 17. Bottom side view

Demonstration board schematic

The very small package and high switching frequency allows a very compact application.

The demonstration board circuit is shown in Figure 18:

Figure 18. Schematic demonstration board

Table 7. Bill of material

Reference Part number Description Manufacturer

C1 ECJ3XBOJ106K 10 µF 6.3 V Panasonic

C2 ECJ4XBOJ226M 22 µF 6.3 V Panasonic

C3 C0406C221J5GAC 220 pF, 5% 50 V Kemet

R1 10 kΩ 1% 0402 Neohm

R2 450 kΩ 1% 0402 Neohm

R3 100 kΩ 1% 0402 Neohm

21/29

Page 22

Application board AN1893

Table 7. Bill of material (continued)

Reference Part number Description Manufacturer

R4 100 kΩ 1% 0402 Neohm

R5 200 kΩ 1% 0402 Neohm

R6 100 kΩ 1% 0402 Neohm

L1 ELL6GM100M 10 µH 0.9 A Panasonic

Figure 19. Low noises vs. low consumption efficiencies

22/29

Page 23

AN1893 Efficiency results

8 Efficiency results

Some efficiency results are shown below in Figure 20, 21, and 22.

Figure 20. Efficiency vs. output current

Figure 21. Efficiency vs. output current

Figure 22. Efficiency vs. output current

23/29

Page 24

Application ideas AN1893

9 Application ideas

9.1 Buck boost topology

In portable applications, the input voltage changes a lot due to the battery discharge profile

that often depends on many parameters like temperature, discharge rate, battery ageing,

etc… Moreover, in particular applications, the output voltage requirements can also change.

This could imply that is not possible to provide the desired regulated output voltage by using

simple buck topology. This problem is often present, for example, in systems using a single

Li-Ion cell, whose voltage profile changes from 4.2 V down to 2.7 V or less. In fact, in these

systems, a 3.3 V output is normally required to power processor I/O, memory and logic.

Adopting buck topology, the 3.3 V output can be regulated until the battery voltage is

approximately 3.4 V, also depending on the minimum dropout of the regulator. Depending

on the battery type and conditions, this would leave unused some 20% - 30% of its capacity.

Another application, even more critical, is the power management of 3G phones, where a

3.7 V or more can be required to power the RF power amplifier (PA).

In order to use the full battery capacity also in these applications, a positive buck_boost

topology can be used. Figure 22 shows how to implement it. This topology can be more

suitable, compared to a standard buck, depending on the battery discharge profile and the

load conditions. In fact, the efficiency loss of the buck-boost topology can be translated into

an equivalent loss in battery capacity. This can then be compared with the gain in battery

capacity due to the fact that it is used over the full voltage range.

Figure 23. Positive buck boost application. 1 Li-Ion cell to 3.3 V at 0.25 A

9.2 White LEDs

White LEDs are now widely used both for LCD backlighting and for illumination. Since their

brightness is proportional to the current flowing through them, a current control loop must be

implemented instead of a voltage one. The device can be used in current control

architecture by simply inserting a sense resistor between the FB and GND pins and

connecting the LED in series with it. The loop sets 0.6 V across the sense resistor, and thus,

a constant current flowing through the LED. The current, and by consequence, the

brightness, can be adjusted by changing the resistor value or the voltage across it (by

24/29

Page 25

AN1893 Application ideas

partitioning the FB pin voltage). The forward voltage across a white LED is approximately

3.6 V and so, depending on the input source, appropriate topologies must be used.

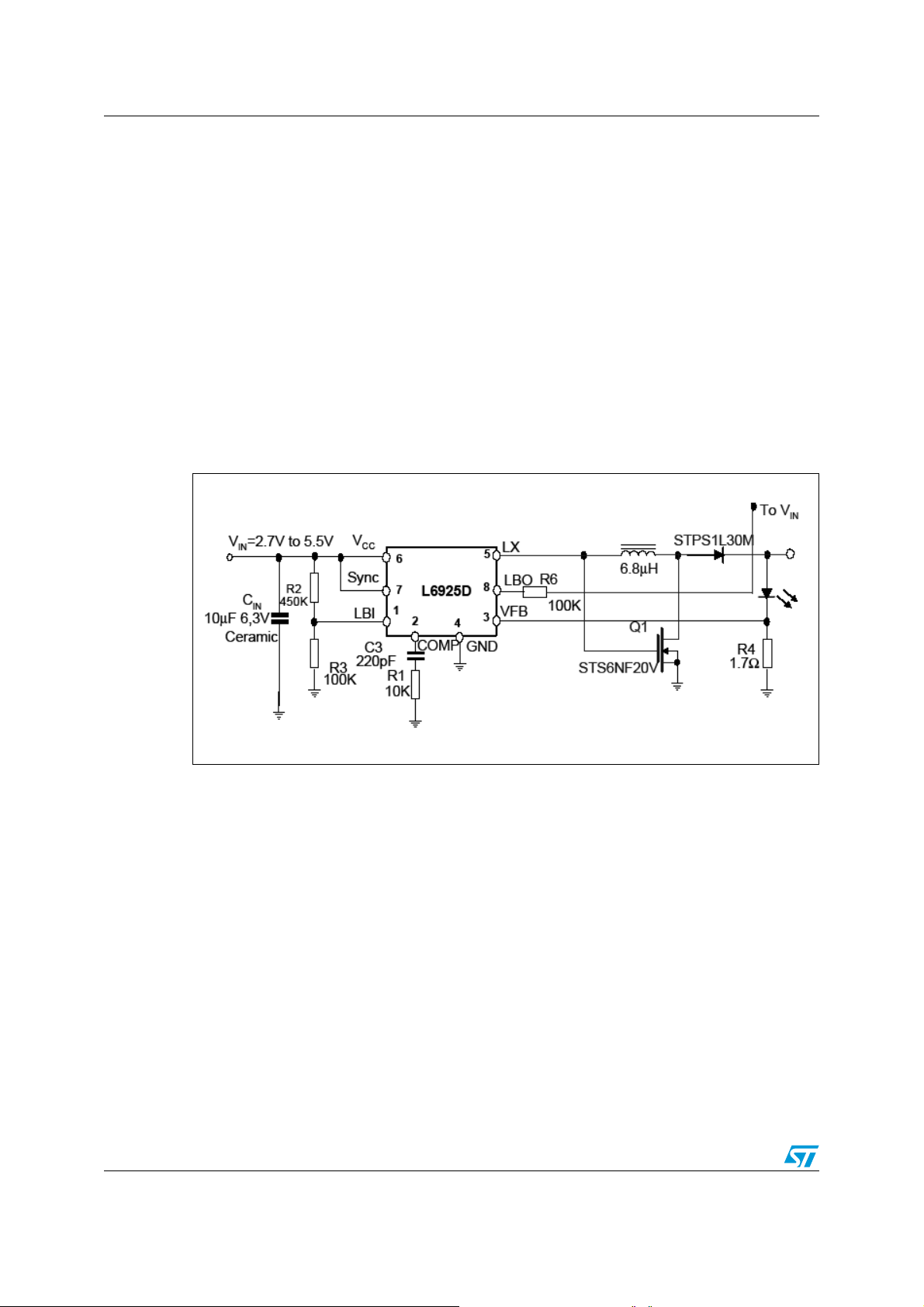

9.2.1 Driving white LEDs: buck topology

The simple buck topology can be used when the input voltage source is higher than

approximately 4.5 V which is the case, for example, with the USB bus.

Figure 24. Buck topology schematic

In this case, the maximum device current (800 mA, continuous) can be delivered to the LED.

Moreover, in this topology, the efficiency is maximized.

9.2.2 Driving white LEDs: boost topology

When the input voltage source is always lower than 3 V (which is the case, for example, of 2

cells of a NiMH battery) a boost topology must be implemented, as shown in Figure 25.

Figure 25. Boost topology schematic

25/29

Page 26

Application ideas AN1893

In this case, according to the boost topology, the maximum current that can be delivered

depends on the duty cycle. The relation between the output current and the internal switch

current (assuming a negligible current ripple and 100% efficiency) is given in Equation 24:

Equation 24

I

OUTISWITCH

1D–()=

This topology is possible because the input source is a battery, and so it must not be

referred to ground. A drawback of this approach, intrinsic in the boost topology, is that a path

between the input and output is always present. This does not allow an effective short circuit

protection and can generate a battery discharge also when the device is turned off.

9.2.3 Driving white LEDs: buck-boost topology

In case a single Li-Ion cell is used at the input, a buck-boost topology can be used, as

shown in Figure 26.

Figure 26. Buck-boost topology schematic

The relation from the output current and the switch current is the same as the boost

topology. An advantage of this topology compared with boost topology, is that when the

device is turned off, there is no current path between the input and the output. This allows

an effective short-circuit protection and minimizes the current drawn from the battery when

the device is turned off.

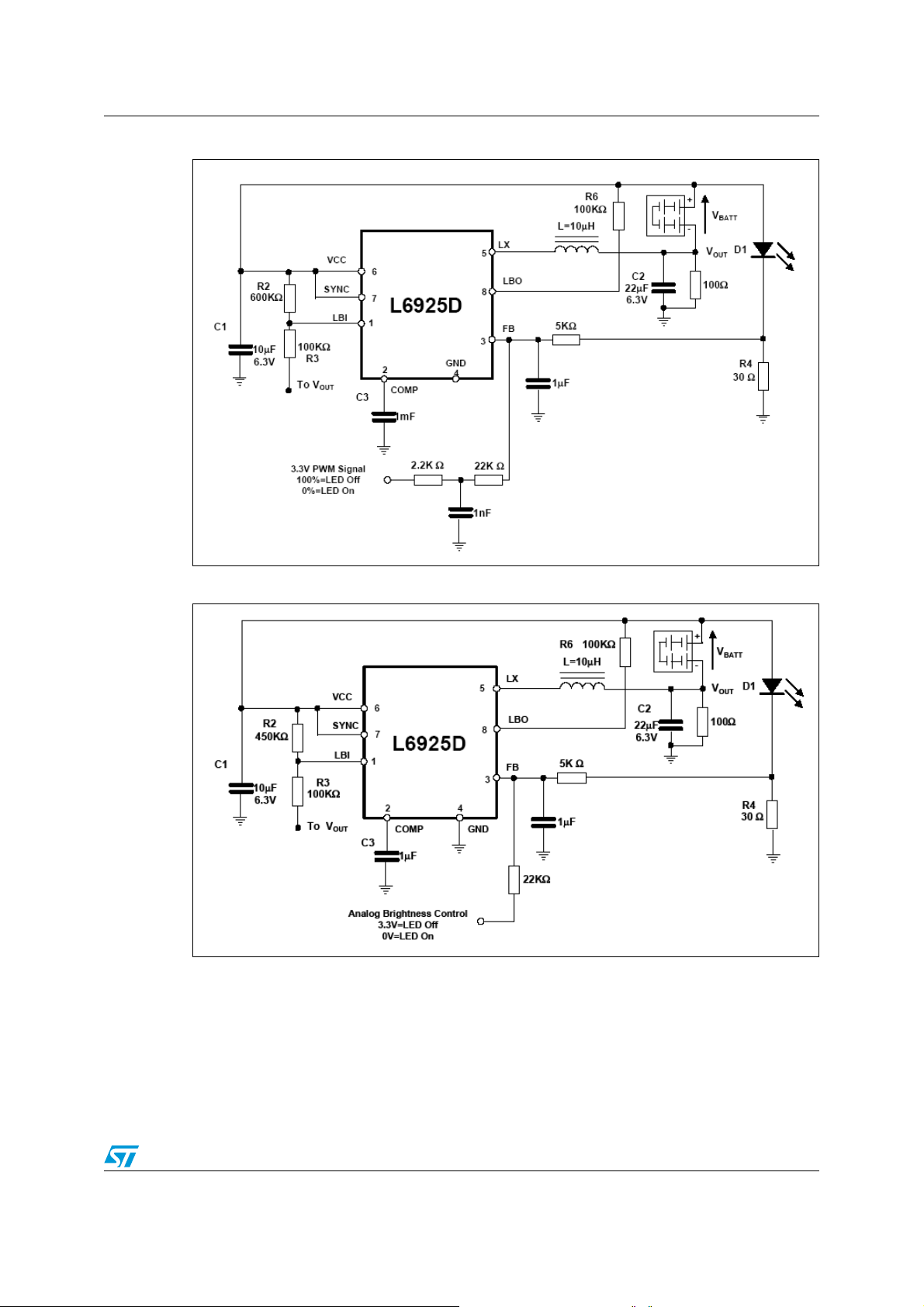

A dimming control can be developed by turning on and off the device with a frequency

around 100-200 Hz in order to avoid LED flickering. Another way to implement the LED

dimming is to reduce the voltage drop across the resistor in series to the LED to a partition

of the FB voltage. Figure 27 and 28 show the relative circuits.

26/29

Page 27

AN1893 Application ideas

Figure 27. PWM brightness control

Figure 28. Analog brightness control

Note: The present application note which is for guidance only, aims at providing customers with

information regarding their products in order for them to save time. As a result,

STMicroelectronics shall not be held liable for any direct, indirect or consequential damages

with respect to any claims arising from the content of such a note and/or the use made by

customers of the information contained herein in connection with their products.

27/29

Page 28

Revision history AN1893

10 Revision history

Table 8. Document revision history

Date Revision Changes

03-Nov-2007 1 Initial release

17-Apr-2008 2

26-Feb-2009 3 Modified: Section 5.1.1

– Document reformatted. No content change

– Changed: Figure 13.

28/29

Page 29

AN1893

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

29/29

Loading...

Loading...