Page 1

AN1891

APPLICATION NOTE

APPLICATION IDEAS: DRIVING LEDS USING L497X, L597X,

L692X DC- D C CONVERT ERS FAMILIES

This application note, describes th e m ai n applications and dr i ving m et hods for LEDs. After

this, several appli cat io n ide as usi ng ST D C-DC converters are shown.

1 SUMMARY

1 SUMMARY....................................................................................................................... 1

2 INTRODUCTION..............................................................................................................2

3 DRIVING LEDS ................................................................................................................ 2

4 APPLICATION IDEAS ......................................................................................................4

4.1 DC BUS SUPPLY.................................................................................................... 4

4.1.1 L5970D APPLICATION IDEA.............................................................................5

4.1.2 L4973D APPLICATION IDEA.............................................................................6

4.1.3 L6902D APPLICATION IDEA.............................................................................6

4.2 BATTERY POWERED APPLICATION ...................................................................7

4.2.1 L6920D APPLICATION IDEA.............................................................................7

4.2.2 L6926D BOOST TOPOLOGY APPLICATION IDEA....................... .. ................ .8

4.2.3 L6926D BUCK-BOOST TOPOLOGY APPLICATION IDEA...............................9

4.2.4 L6926D BUCK TOPOLOGY APPLICATION IDEA...................... ................ .. ..10

5 CONCLUSION ...............................................................................................................10

AN1891/0604

REV. 2

1/11

Page 2

AN1891 APPLICATION NOTE

2 INTRODUCTION

LED (Light Emitting Diode) is a Light Emitted p-n junction Diode, under forward bias. If a forward bias is app lied between t he p -n la yers, elect ron s and hol es are meet ing i n the ac tive la yer, and recombine the ms elves, emitting photons. If a reverse bias i s applied, they don't move

in the active layer , and c onse quenti ally , no l ight is emit ted. LEDs gener at e pract ical ly a monochromatic light, with a focused beam of a single wavelength. Therefore, there is not wasted

energy, and no filt ers are re qui red to obt ain dif fere nt color s. The emitt ed radiat ion wavel en gth

depends on the dopants. Due to their construction technology, LEDs are not subjected to

shock, vibrations and heat, and this makes their life very long, measured in order of years

(Typically 100.000 hours with an operating temperature comprised between -40°C and

+85°C). Thanks to all these characteristics, LEDs are widely used in particular color-specific,

power-crucial and high reliability application:

■ Mobile appliances

● Mobile phone screen and keyboard backlight

● PDAs, MP3 players and digital camera backlight

■ Signs and displays

● Advertising signs

● Traffic variable messages signs

■ Automotive applications

● Interior appli cation: lights fo r instrumental panel and dashboard

● Exterior lighti ng stop/turn/tail li ghts

■ Signals

● Traffic signals

● Arrows and pedestrian signals

■ Illumination

● Flashlights

● Architectural and design lighting

● Emergency lighting

● Water features and pools

3 DRIVING LEDS

LEDs are devices where the light intensity (brightness), measured in millicandelas, or in Lumens, is proport ional to t he f orwar d curr ent fl owing through th em. Ther e are t wo main c ate gories of LEDs: the white-blue LEDs, with a typical voltage drop of 3-4V, and the green-redyellow ones, wit h a typical voltag e drop, which is about 2V. It is possible to make another di stinction based on th e forward current:

■ Low current LEDs, fr om 15mA to 50mA, mai nly used in th e portable market for backl ight and

signaling applications.

■ High current LEDs, with forward current between 350mA to 1000mA, typically used in

lighting applicat ions.

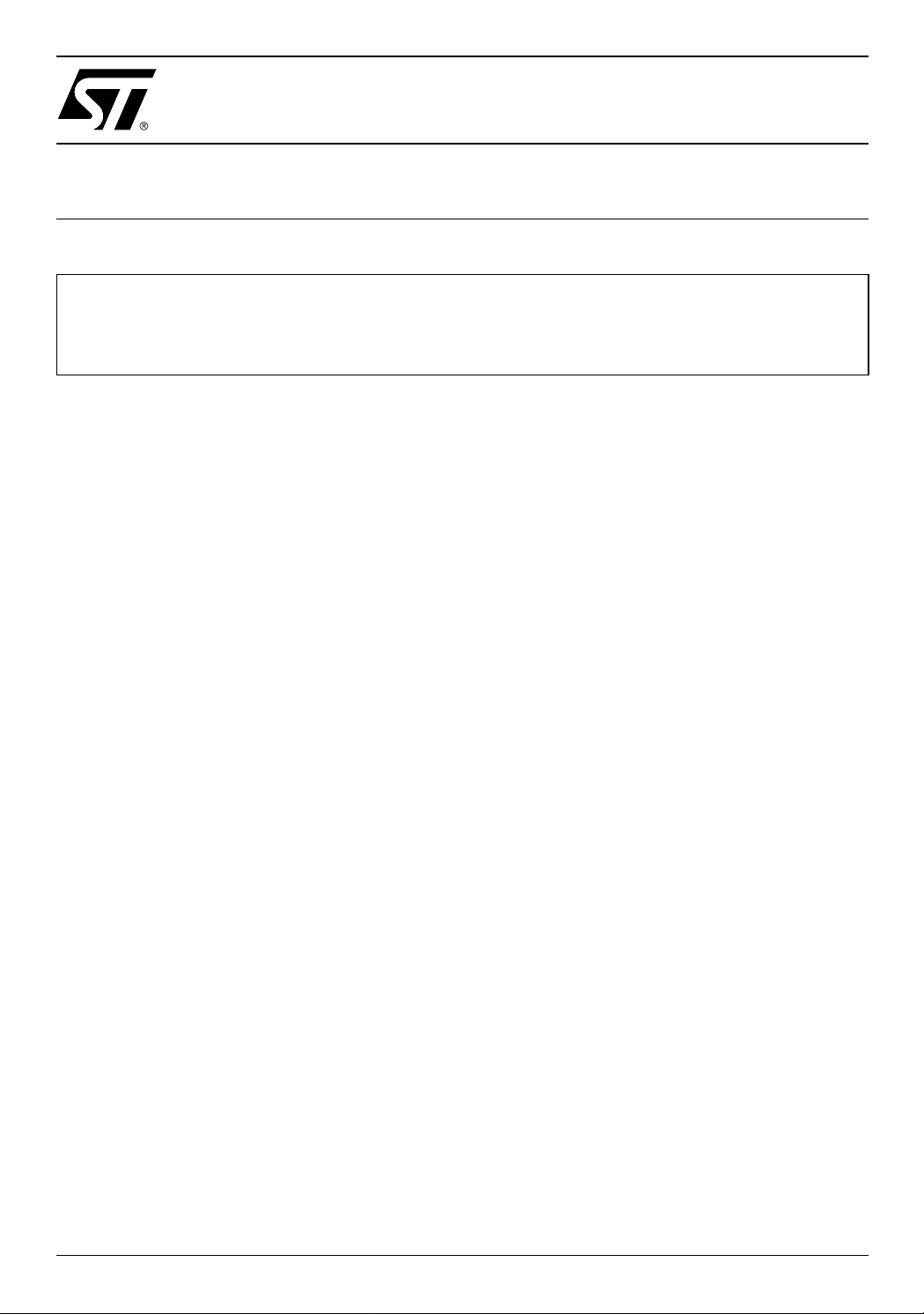

Moreover, applying the same forward voltage to different LEDs of the same type, the current

flowing through them can change significantly. This can be seen in Figure 1, showing the V-I

characteristic of different LEDs of the same type.

2/11

Page 3

AN1891 APPLICATION NOTE

Figure 1. V-I chara cteristic of 8 white LEDs of the same type

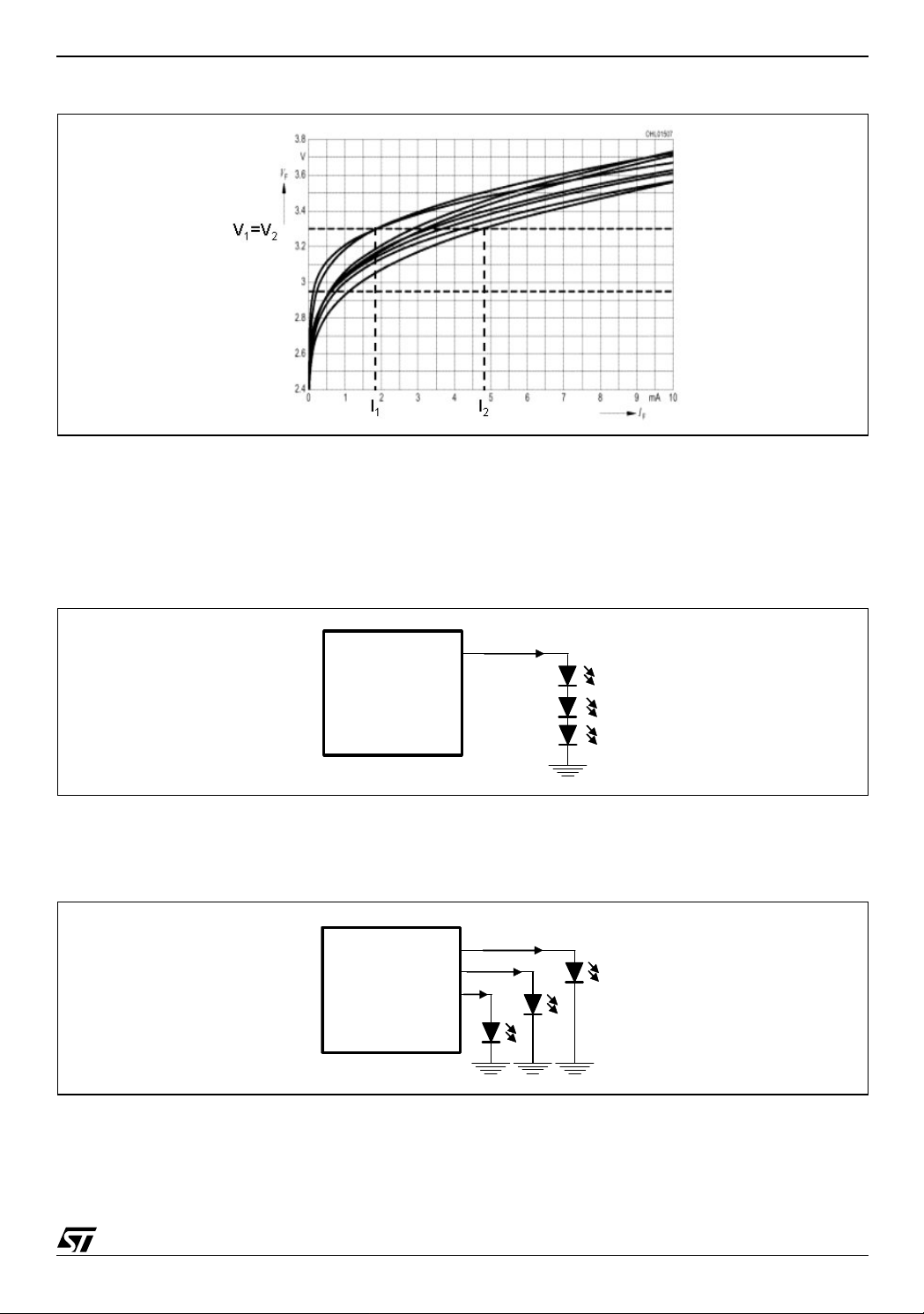

This is why, in order to have a bri ghtness mat ching betwee n differ ent LEDs, the y must be driven by matched constant current sources. Based on these considerations, it is clear that, in

principle, the easiest and cheapest way to drive LEDs is to connect them in series as shown

in Figure 2. However, this implies that the LED driver must provide an output voltage that is

the sum of the LEDs forward volta ge.

Figure 2. Basic schematic of series driven LEDs

I

LED

Constant

Current

Source

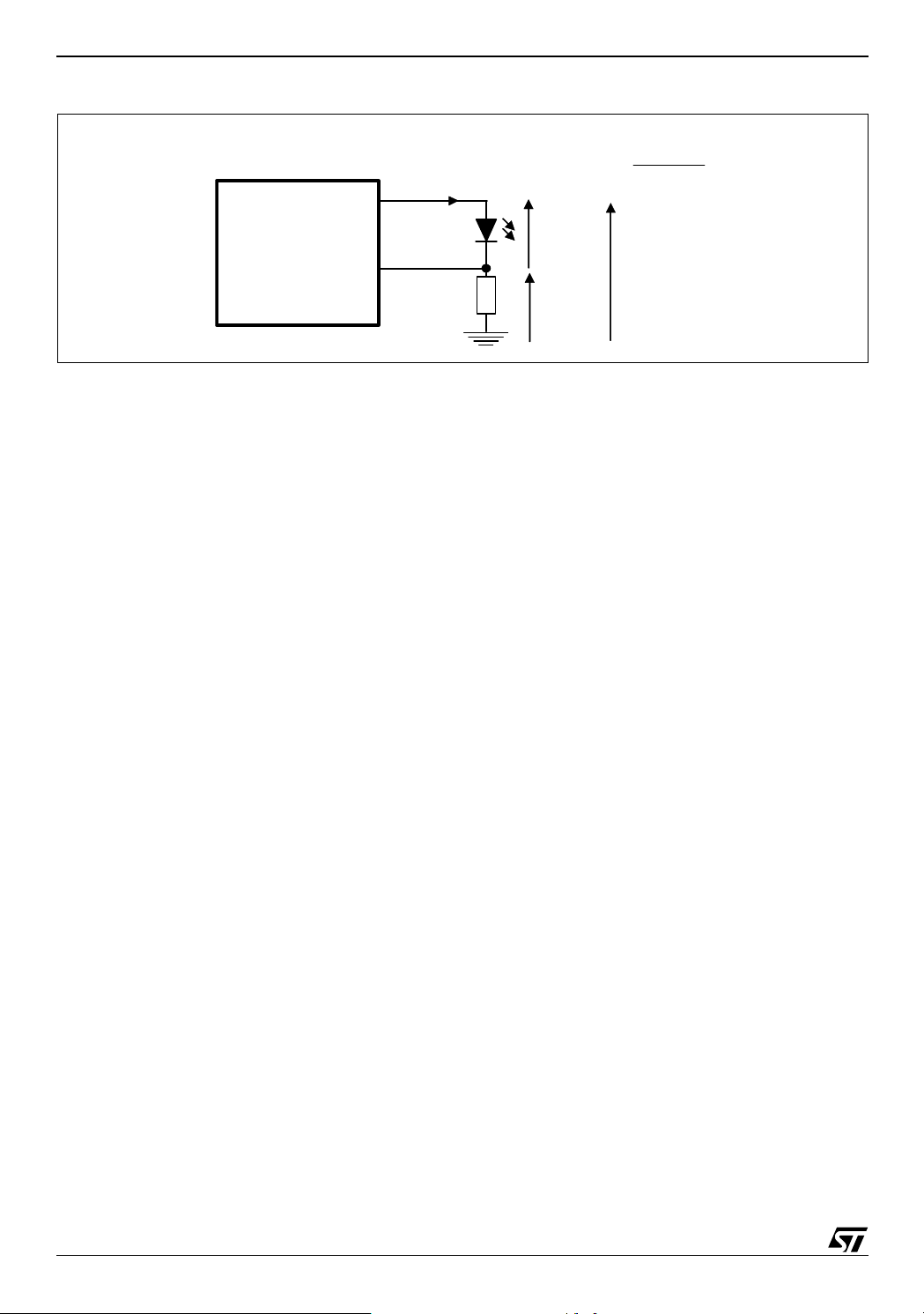

So, in other cases, the preferred solution is to drive LEDs in parallel, matching the different

current sourc es, as shown in Figure 3.

Figure 3. Basic schematic of parallel driven LEDs

I

LED1

Constant

Current

Sources

I

LED3

I

LED2

A typical way to rea li ze a constant current source to drive LEDs is t o use a DC-DC converter,

as shown in Fi gure 4. Since the voltage control loop of the device regulates the voltage at the

FB pin, a constant current source can be obtained simply connecting a resistor between this

pin and GND.

3/11

Page 4

AN1891 APPLICATION NOTE

FB

SENS

Figure 4. Basic schematic of a DC-DC driving LEDs

I

LED

I

LED

=

V

R

E

DC-DC

Driver

FB

R

V

V

OUT

V

The efficiency of the system is given by the general formula:

P

Eff

out

-----------=

P

in

Eq 1

In case of LEDs, the useful power (that is POUT), is the LEDs power, given by:

n

P

LED

V

=

∑

i1=

⋅

LEDiILEDi

Eq 2

So, the efficiency of the system is:

P

--------------=

LED

P

Eq 3

IN

Eff

The power dissipated on the RSENSE resistor is obviously not contributing to the output power and

so it should be minimized. This impl ie s tha t t he FB pin voltage should be as low as possib le.

4 APPLICATION IDEAS

The best device for a particular application can be selected based on its input voltage range,

output current capabil ity , outpu t voltage r ang e, as in standar d DC-DC choi ce. Howev er, some

particularity of the application emphasizes the importance of other parameters. For example,

a very low FB volt age, in or der to minimi ze the p ower di ssipat ion by the sens e resi stor, is ve ry

important. Besi de thi s, the poss ibil ity to change the volta ge acros s th e sense r esist or, in or der

to easily adjust the LEDs brightness, is often required. The following paragraphs show some

LEDs driving solutions, distinguishing two main application classes:

– DC bus supplied applic ati ons

– Battery powered app li cations

4.1 DC BUS SUPPLY

Most of automotive and lig hti ng applications belo ng to this category. The most common in put

voltages are 12V, 18V, 24V and 4 8V. For these applica tions L497 xD, L597xD and t he L6902 D

families of step-down monolithic DC-DC converters are suggested. Table 1, summarizes the

devices charac ter istics (devices are grouped by family and sor ted by output current):

4/11

Page 5

AN1891 APPLICATION NOTE

Table 1. DC-DC converters with DC bus supply

Device

L4976D 1 0.5 to 50 8 to 55 Up to 300 5.1V Vref Minidip/SO16W

L4971D 1.5 3.3 to 50 8 to 55 Up to 300 Minidip/SO16W

L4978D 2 3.3 to 50 8 to 55 Up to 300 Minidip/SO16W

L4973Dx3.3 3.5 0.5 to 50 8 to 55 Up to 300 5.1V Vref DIP18/SO20

L4973Dx5.1 3.5 5.1 to 50 8 to 55 Up to 300 DIP18/SO20

L6902D 1 0.5 to 35 8 to 36 250 Constant current control, 3.3V

L5970D 1 0.5 to 35 4.4 to 36 250 3.3V Vref SO8

L5972D 1.5 1.23 to 35 4.4 to 36 250 SO8

L5973AD 1.5 0.5 to 35 4.4 to 36 500 3.3V Vref HSOP8

L5973D 2 0.5 to 35 4.4 to 36 250 3.3V Vref HSOP8

Iout

(A)

Vout (V) Vin (V) Fsw (KHz)

Additional

Features

Vref

Packages

SO8

4.1.1 L5970D APPLICATION IDEA

The L5970D is a monolithic step-down power switchin g regulator, capable to deli ver up to 1A

of continuous output curre nt. The input voltage range is comprised between 4.4V to 36V. The

feedback voltage is 1.23V, but with a resistor divider connected with the internal reference of

3.3V, is possi ble to re duce the sen se resi stor volt age. This h elps in or der to r educe the was ted

power and to adjust the LEDs brightness.

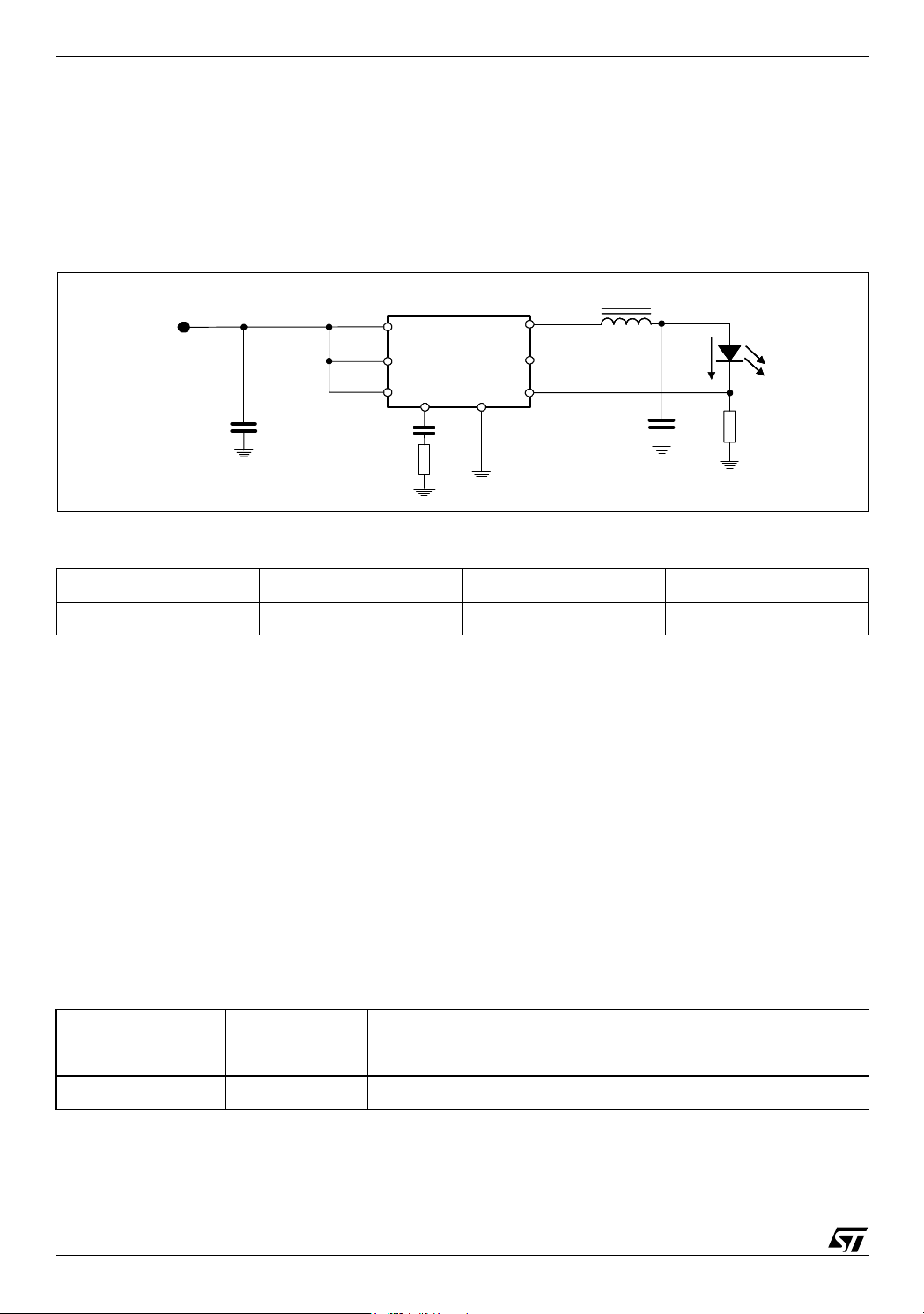

Figure 5. L5970D driving up to 6 high current white LEDs

VIN

12V to 24V

10µF

25V

220pF

22nF

4.7KΩ

VCC

COMP

L5970D

GND

INH

OUT

VREF

FB

Vref-Vfb

40KΩ

I

=350 mA

LED

15KΩ

R1

Vfb -Vsense

STPS2L25U

R2

Figure 5 shows how to drive 6 LEDs in series.

The V

SENSE

is reduced down to 0.45V, in order to minimize the wasted power. The formula

used to reduce it is:

V

V

SENSE

V

FB

------------------------------------

–=

–()

REFVFB

R

1

R

⋅

15 µH

2

I

LED

330µF

25V

Rsense

Up to

6 LEDs

1.3Ω

Vled

Vsense

=0.45V

Eq 4

The table below shows the ef fi ciency of the applicat ion.

5/11

Page 6

AN1891 APPLICATION NOTE

e

Table 2. Efficiency results of the L5970D driving series LEDs

Efficiency 1 LED 2 LEDs 3 LEDS 4 LEDs 5LEDS 6LEDs

Vin=12V

Iout=350mA 76% 89% 93.5%

Vin=18V

Iout=350mA 83.5% 90% 95% 90%

Vin=24V

Iout=350mA 86.5% 90% 94.5% 97.5%

4.1.2 L4973D APPLICATION IDEA

This application is really closed to the previous one. The substantial different is in the input

voltage, up to 55V. The device can deliver up to 3.5A of continuous output current. Thus, it is

possible to drive more white LEDs connected in series. Figure 6 shown the schematic circuit

of L4973D supplied with a 48V bus. It is driving up t o 12 high current white LEDs. Even in th is

case, the voltage drop across the sense resistor is minimized for efficiency reasons, by the

same trick used for the L5970D.

Figure 6. L4973D driving up to 12 high current white LEDs

16

5.1V

4,5,6

13,14,15

GND

Vref-Vfb

50KΩ

12

Vfb

9

Boot

2.3

Out

R1

220nF

63V

D1

Vfb-Vsense

78KΩ

R2

150µH

Iled

3x100µF

40V

Up to

12

LEDs

Vled

Vin=48V

220nF

63V

20KΩ

2.7nF

470nF

220nF

Osc

SS

7,8

Vcc

1

17

Comp

18

Sync

L4973V3.3

10

11

INH

9.1KΩ

22nF

Iled=350mA

Rsense

1.4Ω

Vsens

0.5V

The efficiency of this application is given by the following table.

Table 3. Efficiency of L4973D driving up to 12 LEDs

Efficiency 8 LEDs 10 LEDs 12 LEDs

Vin=48V

Iout=350mA 95% 96% 98%

4.1.3 L6902D APPLICATION IDEA

The L6902D is a simple and complete step down switching regulator, with adjustable current

limit. This device is a good solution for LEDs lighting applications, thanks to its inner current

loop that allo ws regulating a cons tant current at the output wit h a minimum voltage dro p across

the external sense re si stor ( 100mV). Fi gure 7 shows a sche mati c appli cati on of L6902D, driving up to 6 high current white LEDs. The device works in current limit mode, set to 350mA;

each LED current is 350mA. The losses on RSENSE are only 70mW.

6/11

Page 7

Figure 7. L6902D driving up to 6 high current white LEDs

µ

µ

AN1891 APPLICATION NOTE

VIN

12V-24V

10

25v

100mV

H

22

Vcc

OUT

COMP

22nF

L6902D

F

220pF

5.1K

GND

Vref

CS+

CS-

FB

STPS340U

100 µF

25v

Up to

6 LEDs

R1

R2

The additional benefit of thi s device is that its v oltage loop can be used to pe rform an over vo ltage protection as in dicated in figure 7.

The table 4 indicate s the efficiency values of this application.

Table 4. Efficiency of L6902D driving up to 6 LEDs

Efficiency 1 LED 2 LEDs 3 LEDS 4 LEDs 5LEDS 6LEDs

Vin=12V

Iout=350mA 75% 89%

Vin=18V

Iout=350mA 86% 89% 96.5%

Vin=24V

Iout=350mA 84% 88% 90% 94% 97.5%

4.2 BATTERY POWERED APPLICATION

Battery powered applications are characterized by lower input voltages compared to the applications shown in the previous pages. In these applications, the input voltage changes with

the battery disch arge profile. The battery types for this kind of applications are:

– Li-Ion cell, with the vol tage range comprised between 4.2V and 2.7V or less;

– Ni-MH cell, with the voltage range between 1.5V to 0.9V.

As a consequence, the Buck topology is not the commonest one. Boost or Buck-Boost topologies are often required. We will focus our application examples on L692xD family, including

a step-up converter (L6920D) and step-down converters (L6925D-L6926D) that can be used

in both Boost a nd i n Buck- Boos t top ology. Some appli catio n ideas are s how b elow, in ord er to

explain how to use these devices in LEDs applications, using external references and dimming.

Table 5. DC-DC converters for battery powered applications

Device Iout (A) Vout (V) Vin (V) Fsw (KHz)

L6920D 1 2 to 5.2 0.6 to 5.5 Not fixed 1.23 TSSOP8

L6925D 0.8 0.6 to Vin 2.7 to 5.5 Up to1400 0.6 MSOP8

L6926D 0.8 0.6 to Vin 2 to 5.5 Up to 1400 0.6 MSOP8

Vfb

Additional Features Packages

(V)

4.2.1 L6920D APPLICATION IDEA

The L6920D is a high efficiency Step-up converter. The start up is guaranteed at 1V, but the

operating input voltage can goes down to 0.6V. With a maximum voltage of 5.5V the device

7/11

Page 8

AN1891 APPLICATION NOTE

can be supplied with many battery types: from 1 Li-Ion cell, or 1 to 3 Ni-MH-Alkaline cells. In

figure 8 is shown the typical application schematic of the device. The voltage Feedback is

1.23V. With the resistor divider, connected to the external reference, it is possible to reduce

the sense voltage down to 0.4V, or less, in order to maximize the efficiency. In table 6 are reported the effic iency result of this appl ication.

Figure 8. L6920D with external reference

100nF

LBI

GND

VREF

Lx

7

2 8

6

L6920D

4 5

1

FB

12.5K Ω

R1

Vext -Vfb

VOUT

____

LBO

3

______

SHDN

1µF

L3.3 µH

R2

5K Ω

Vfb-Vsense

External

Reference

3.3V

10µF

D1

R sense

Iout=350mA

1.15 Ω

Table 6. Efficiency of L6920D driving a 350mA LED

Vin (V) 2 2.5 3 3.5 3.7

Eff (%) 88 88 90 86 84

47µF

Vsense=

0.4V

4.2.2 L6926D BOOST TOPOLOGY APPLICATION IDEA

The L6926D is a h igh efficiency monolithic synchr onous Step-down regulator, with a n operating input voltage ran ge comprised bet ween 2V to 5.5V. The feedback voltage is equal to 0. 6V;

this allows low l osse s on the s ense r esist or. T he dev ice can be use d in di ffer ent top ologi es. In

particular when the input voltage is l ower than the typical LED voltage drop, a Boost topology

can be impl emented, as shown i n Figure 9. This topology i s possible only because the supply

is a battery, not referred to Ground. As typical in Boost topology, this configuration doesn't

have an effe cti ve short cir cuit protection. A battery discharge ca n be generated, when the device is turned o ff. The br ightness c ontrol c an be done by usi ng a PWM sign al. Varying t he duty

cycle of the sign al is possible to change the medium curr ent val ue, in order to adju st the brightness. In this case, the maximum intensity is achieved when the duty cycle of the PWM signal

is equal to 0%. The minimum intensit y is when the duty cycle reaches the 100% .

8/11

Page 9

AN1891 APPLICATION NOTE

Figure 9. L6926D in boost topology with digital adjustable brightness control

10µF

6.3V

Sync

Vcc

RUN

7

6

1

L6926D

2

COMP

1µF

4

GND

5

PGOOD

8

3

LX

VFB

1K

L=10 µH

22µF

5K

1µF

6.3V

+

Vbatt

-

100

Iled

350mA

D1

1.7

3.3V PWM Signal

100%=LED Off

0%=LED On

2.2K

22K

1nF

Table 7. L6926D in boost topology with digital adjustable brightness control

Vin (V) 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4

Eff (%) 76 79 80 82 83 85 86 86 87 88 89 89 90 91

4.2.3 L6926D BUCK-BOOST TOPOLOGY APPLICATION IDEA

If a single Li -Ion ce ll i s used t o supp ly the device , the Buc k- Boost t opology is usual ly r equir ed.

In fact, the voltage drop across a white LED is comparable with the Li-Ion cell voltage. The

advantage of this application is that the input voltage range can be higher or lower than the

output ones and so the battery can be used over the full load range. Moreover, when the device is turned off, there isn't current flowing from the input to the output. An actual shutdown

and short circuit protection are allowed. The typical application schematic is shown in figure

10.

Figure 10. L6926D in Buck-Boost topology

VIN=2.7V – 4.2V

C1

10uF

6.3V

Ceramic

Sync

Vcc

RUN

7

6

1

330pF

L6926D

2

COMP

4

GND

LX

5

PGOOD

8

VFB

3

4.7uH

STT5NF20V

STPS1L30M

C2

1uF

6.3V

Iled 350mA

1.7Ω

The efficiency of thi s system is reported in the table below:

Table 8. Efficiency of L6926D driving a 350mA LED in Buck-Boost topology

Vin (V) 2.9 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 4.0 4.1 4.2

Eff (%) 58 59 60 61 61 62 62 63 63 64 64 64 64 65

9/11

Page 10

AN1891 APPLICATION NOTE

4.2.4 L6926D BUCK TOPOLOGY APPLICATION IDEA

An USB port give s a volt age ra nge be tween 4. 75V t o 5.25V, and pr ovides a maxi mum curr ent

of 500mA. This is a good solution to drive a single high current white LED, in Buck topology.

Infact, the USB voltag e is al ways hi gher t han the o utp ut vol tage r equire d dr ivin g the LED. The

output voltage is given by the sum of the LED drop and the feedback voltage. The Figure 11

shows the applicati on schematic while the Table 9 reports the efficiency results.

Figure 11. L6926D supplied by USB port

Vin=5V

10µF

6.3V

Sync

Vcc

Vcc

RUN

RUN

C3

220pF

R1

10K

7

7

6

6

1

1

L6926D

L6926D

2

2

COMP

4

4

GND

5

5

PGOOD

PGOOD

8

8

3

3

LX

LX

VFB

L=6.8 µH

Iled

350mA

10µF

6.3V

1.7 Ω

Table 9. Efficiency of L6926D driving a 350mA LED in Buck topology

Vin (V) 5 5.5 5.96

Eff (%) 85 84 84

All the battery p owered ap plication i deas shown i n this pa per, are pe rformed wi th a white LED,

which has a voltage drop of approximately 3.3V, and a forward current of 350mA.

5 CONCLUSION

The aim of this pape r is to sho w how monolit hic DC-DC conver ters can b e used to dri ve LEDs.

The right choice between all the ICs belonging to L497xD, L597xD and L692xD families depends on the final application requirements (power source, number of LEDs, additional functions etc...).

This paper shows only few application ideas about LEDs driving: it is possible to find much

more details o n the speci fic IC s in the dedicated Datasheet and Applic ation Not es availabl e on

ST web site.

Table 10. Revision History

Date Revision Description of Changes

March 2004 1 First Issue

June 2004 2 Add. summary, changed any textes, changed style look.

10/11

Page 11

AN1891 APPLICATION NOTE

The present note which is for guidance only, aims at providing customers with information regarding their products in

order for them to save time. As a result, STMicroelectronics shall not be held liable for any direct, indirect or

consequential damages with respect to any claims arising from the content of such a note and/or the use made by

customers of the information contained herein in connection with their products.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such inf orma tio n nor for any i nfr inge ment of pa tent s or oth er ri ght s of thi rd pa rti es wh ich m ay re sul t fr om it s use . No li cense is granted

by implica tio n o r ot he rw is e un d er a ny pa te nt o r pa te nt righ ts of S TM ic ro el ec tro nic s. Sp ec ific at io ns m e nt ion ed in this pu bl ica tion are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicr oe le ct ron ic s GR O U P OF CO MP A NI ES

www.st.com

11/11

Loading...

Loading...