Page 1

AN1842

APPLICATION NOTE

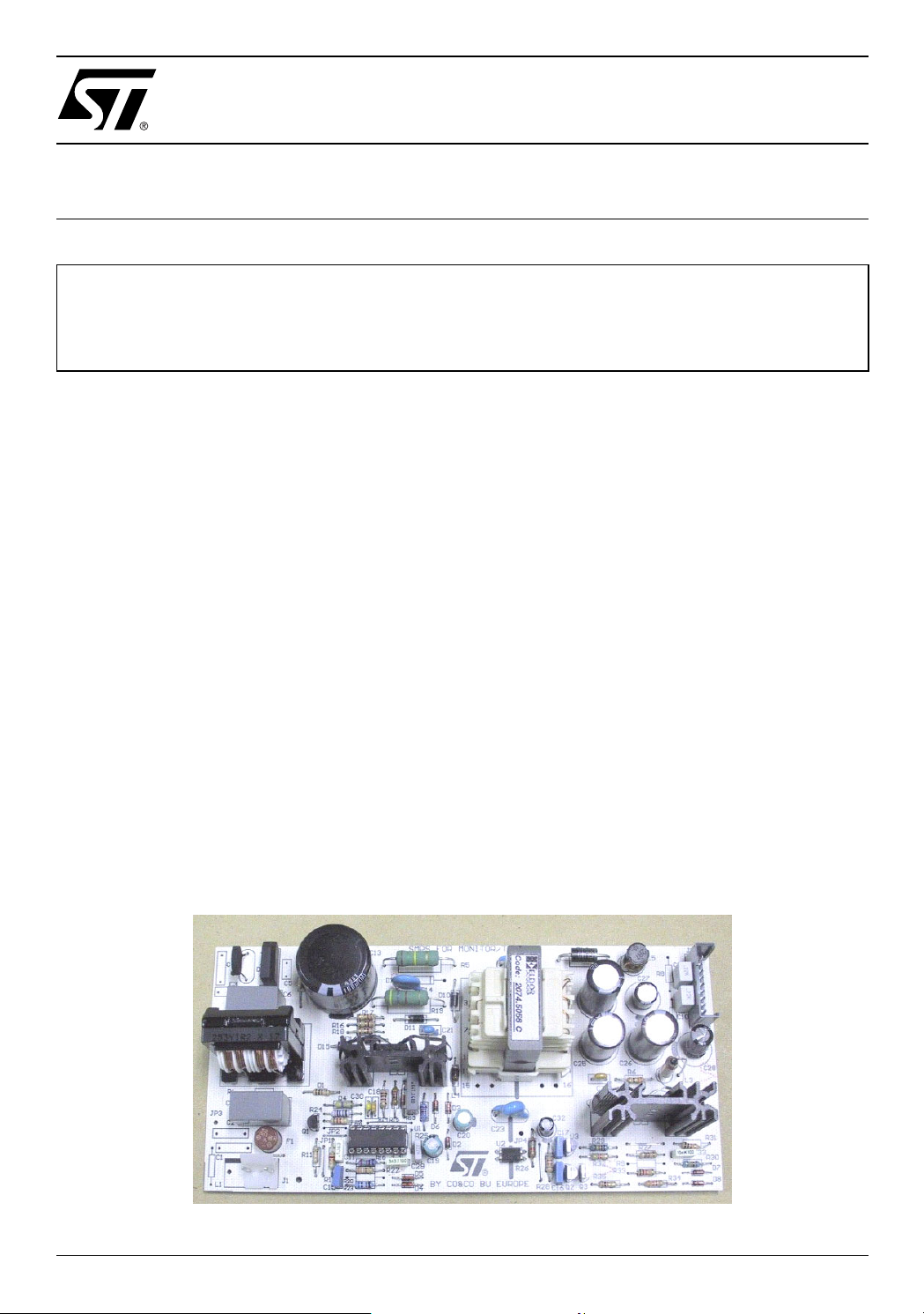

60W WIDE-RANGE POWER SUPPLY

FOR LCD MONITOR OR TV, USING THE L5991

by Claudio Spini

This document describes a reference design for a 60W Switch Mode Power Supply dedicated to LCD

TV sets or monitors. The board accepts full range input voltage (90 to 265Vrms) and delivers 5V and

12V. It has good efficiency and very good standby performance, able to meet the most stringent

standby rules.

Introduction

The LCD monitors and TVs are growing very fast, so to support this kind of applications, a dedicated reference design has been developed, taking into account all the requirements that are needed.

The proposed reference design can supply an LCD monitor or an LCD-TV as well, up to 22" panels, together with multimedia functions like audio. The SMPS accepts a full range input voltage and delivers 2

output voltages, a 5V dedicated to the scaler and µP, and a 12V dedicated to the backlight and audio. The

required standby power consumption is 0.8W at 230Vac, in order to satisfy the worldwide power saving

rules. The circuit is also fully protected against faults like output short circuit or over voltage. The market

cost pressure has requested a design approach with particular attention to the solution cost. The board

technology used is the standard thru-hole, but it can be changed very easily in SMT because most of components are available also in this technology. The circuit has been tested deeply in all the most salient

aspects with positive results and it has been integrated with a 22" LCD-TV application without showing

any problem.

Main characteristics

INPUT VOLTAGE: 90 ÷ 265 Vrms - 45-66 Hz

OUTPUT VOLTAGES: 5.1V±2% - @2A Dedicated to panel and digital circuitry for scaling

12V±10% - @4A Dedicated to backlight lamp inverters, audio and SCART

STANDBY Input power less than 0.8W @230Vac, delivering 30mA on 5.1V

FAULT PROTECTIONS: Short circuit on each output with auto-restart at short removal, Open loop

Safety&EMC: Safety: Acc. to EN60950, creepage and clearance minimum distance 6.4mm

PCB TYPE & SIZE: Cu Single Side 70 µm, CEM-1, 180 x 89 mm

EMC: According to EN50022 Class-B

January 2004

1/17

Page 2

AN1842 APPLICATION NOTE

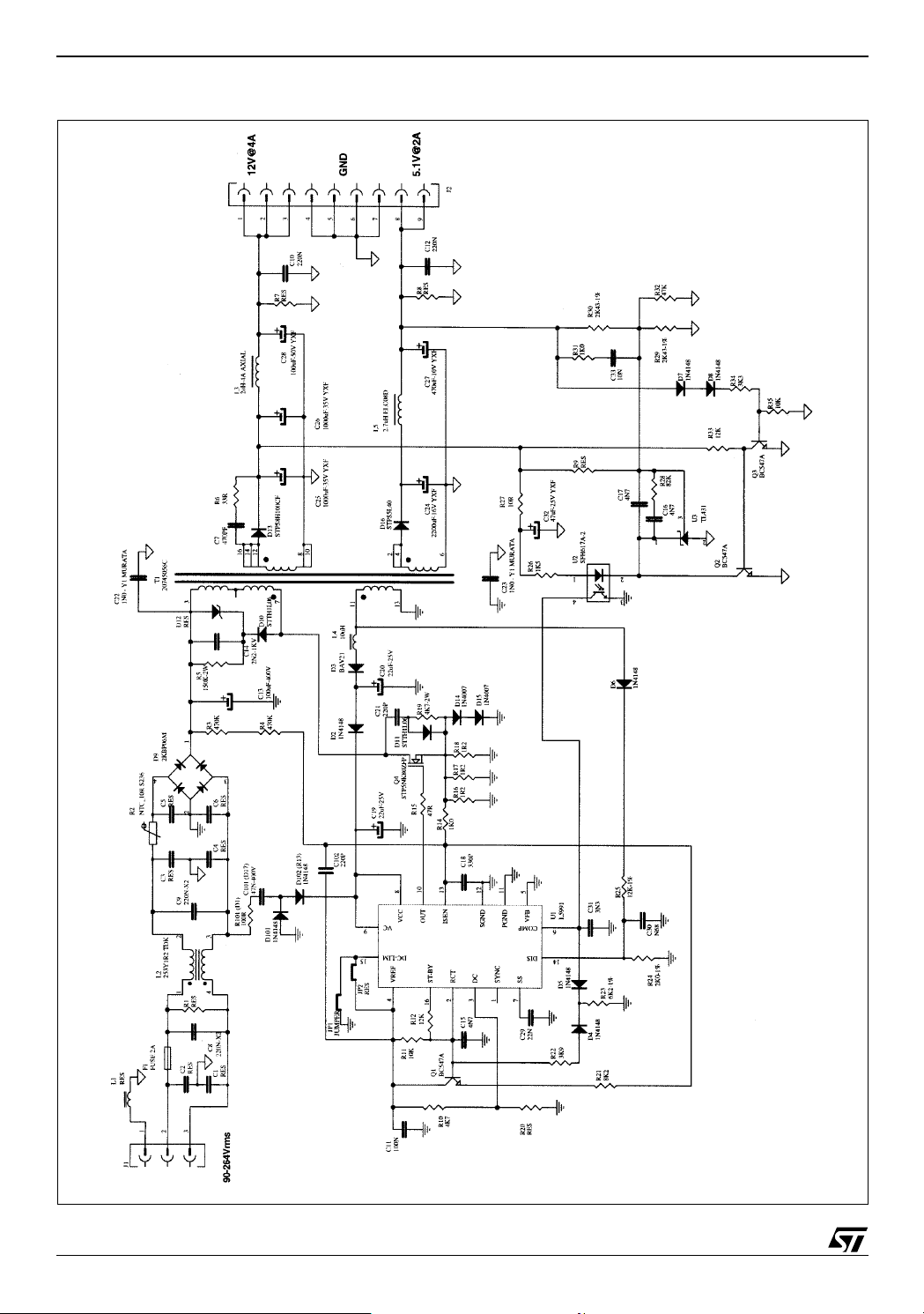

Figure 1. Electrical Diagram

2/17

Page 3

AN1842 APPLICATION NOTE

The converter topology of this SMPS is the standard fly back, working in discontinuous and continuous

current mode. The operating frequency of the circuit (~50 kHz) has been chosen in order to obtain a compromise between the transformer size and the input filter complexity. Hence, the input EMI filter is a simple

Pi-filter, 1-cell only, for differential and common mode noise, using a 4-sectors coil filter. A NTC limits the

inrush current at plug-in. The transformer is a slot type, manufactured by PULSE-ELDOR designed according to the EN60950. Ferrite size is ETD34, the reflected voltage is ~95V providing enough room for

the leakage inductance voltage spike with still margin for reliability.

The reflected voltage, the switching frequency and the primary inductance have been chosen to allow the

continuous current operation of the transformer at full load, all over the input voltage range. This helps to

decrease the output capacitor size thanks to the better ratio between the rms and peak current. The network D10, C14, R5 clamps the peak of the leakage inductance voltage spike ensuring reliable operation

of the PowerMOS, while C21, D11 and R19 limit the dv/dt of the drain voltage.

The PowerMOS is a low cost STP5NK80ZFP, offering a good trade-off between the V

and the equivalent C

, housed in standard TO-220 or TO-220FP packages. In this design, the TO-

OSS

(BR)DSS

220FP (TO-220 insulated) has been used, mounted on a heat sink and fixed by a spring. Core of this design is the current mode primary controller, the L5991 integrating all the required blocks to manage the

control and protection of an SMPS. It is available in either DIP-16 (L5991) or in SO-16 (L5991D) packages.

The switching frequency is programmable by means of a an RC network (R11, R12, C15): during normal

operation R11 and R12 are connected in parallel by an internal switch (pin 16); when a light load is detected by the controller this internal switch is opened and the resulting frequency becomes lower, programmed only from C15 and R11.

If the load is further decreased the network D4, D5, R23 provides an additional frequency reduction, proportional to the load, allowing very low power consumption from the mains. Pins 15 and 3 are set in order

to allow the full duty-cycle operation and so the use of most of the energy stored in the bulk capacitor during hold-up operations. Because of the current mode control and the possibility for the duty cycle to exceed

50%, a slope compensation circuitry has been added.

A latched, over voltage protection has been implemented by using the pin 14 and a simple resistor network: in case of loop failure the circuit senses the Vcc and, when the voltage at that pin exceeds the internal threshold, the controller stops the operation until its Vcc drops below the UVLO voltage. The startup is done using a non-dissipative charge pump circuit to save power during standby.

The output rectifiers have been chosen in accordance with the maximum reverse voltage and their power

dissipation. The 5V rectifier is Schottky barrier type STPS5L40, a 5A-40V axial rectifier that thanks to the

low-forward voltage drop is housed in a DO-201 package.

The 12V rectifier is an STPS8H100, an high voltage Schottky rectifier offering a good trade-off between

the forward voltage drop and the maximum operating junction temperature. It is available from STM in 5

different package versions. For this design, the ISOWATT220AC (similar to a standard insulated TO-220)

has been used, mounted on a heat sink and fixed by a spring.

On both outputs, an LC filter has been added in order to filter out the high frequency ripple without increasing the output capacitors size or quality. The output voltage regulation is performed by the secondary feedback monitoring the 5.1V output. The feedback network is the typical one that uses a TL431 driving an

optocoupler, in this case an SFH617A-2, to ensure the required insulation between primary and secondary. The opto-transistor drives directly the COMP pin of the L5991. Here following some waveforms during

the normal operation at full load:

, the RDS(on)

3/17

Page 4

AN1842 APPLICATION NOTE

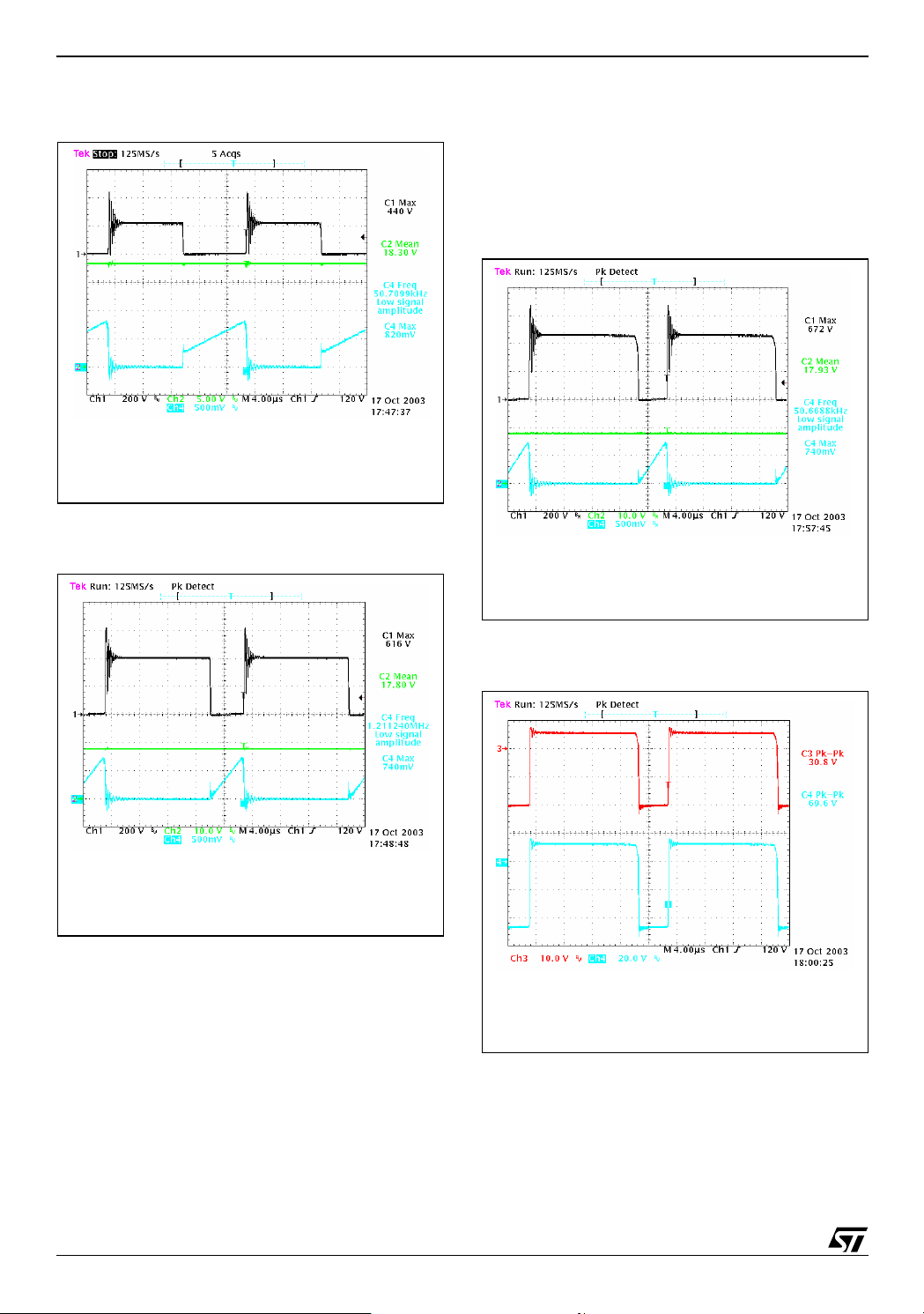

Figure 2. Drain voltage & current @115 VAC -

60Hz - full load

CH1: VQ4 - Drain

CH2: V

CH4: V

Figure 3. Drain voltage & current @230 V

(Vcc)

PIN8

(Drain Current)

R16

AC

50Hz - full load

ing the worst operating condition and they are indicated on the right of figure 5. The margin, with

respect to the maximum voltage withstood by each

diode, ensures safe operating conditions for these

devices.

Figure 4. Drain voltage & current @265 V

AC

-

50Hz - full load

-

CH1: VQ4 - Drain

CH2: V

CH4: V

(Vcc)

PIN8

(Drain Current)

R16

CH1: VQ4 - Drain

CH2: V

CH4: V

(Vcc)

PIN8

(Drain Current)

R16

The pictures here above show the drain voltage

and current at the nominal input mains voltage

during normal operation at full load. As visible, the

circuit works in CCM both at nominal high and low

mains.

The figure 4 shows the measurement of the drain

peak voltage at full load and maximum input mains

voltage. The measured voltage of 672V, ensures

a reliable operation of the MOSFET with a good

margin against the maximum BV

. Even the

DSS

maximum rectifiers PIV have been measured dur-

Figure 5. Maximum rectifiers PIV @Vin = 265

V

- 50 Hz and full load

AC

CH3: +5V RECTIFIER: Anode voltage

CH4: +12V RECTIFIER: Anode voltage

Here following the most salient controller IC signals are shown. In both pictures it is possible to

distinguish clean waveforms free of hard spikes or

noise that could affect the controller correct operation.

4/17

Page 5

AN1842 APPLICATION NOTE

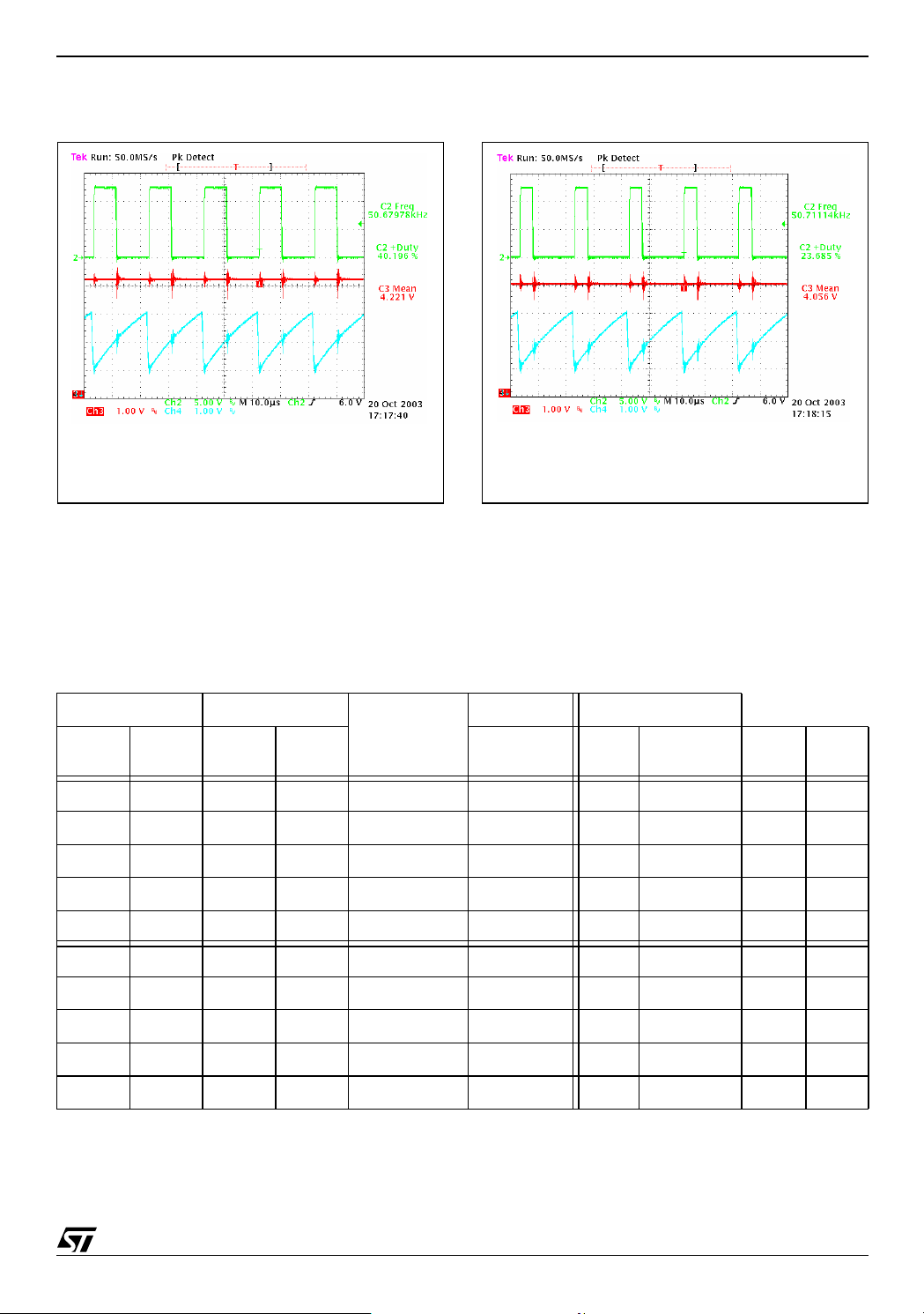

Figure 6. Drain voltage & current @115 VAC -

60Hz - full load

CH2: V

CH3: V

CH4: V

PIN10

PIN6

PIN2

(Out)

(Comp)

(RCT)

Figure 7. Drain voltage & current @230 VAC -

50Hz - full load

CH2: V

CH3: V

CH4: V

PIN10

PIN6

PIN2

(Out)

(Comp)

(RCT)

Cross regulation

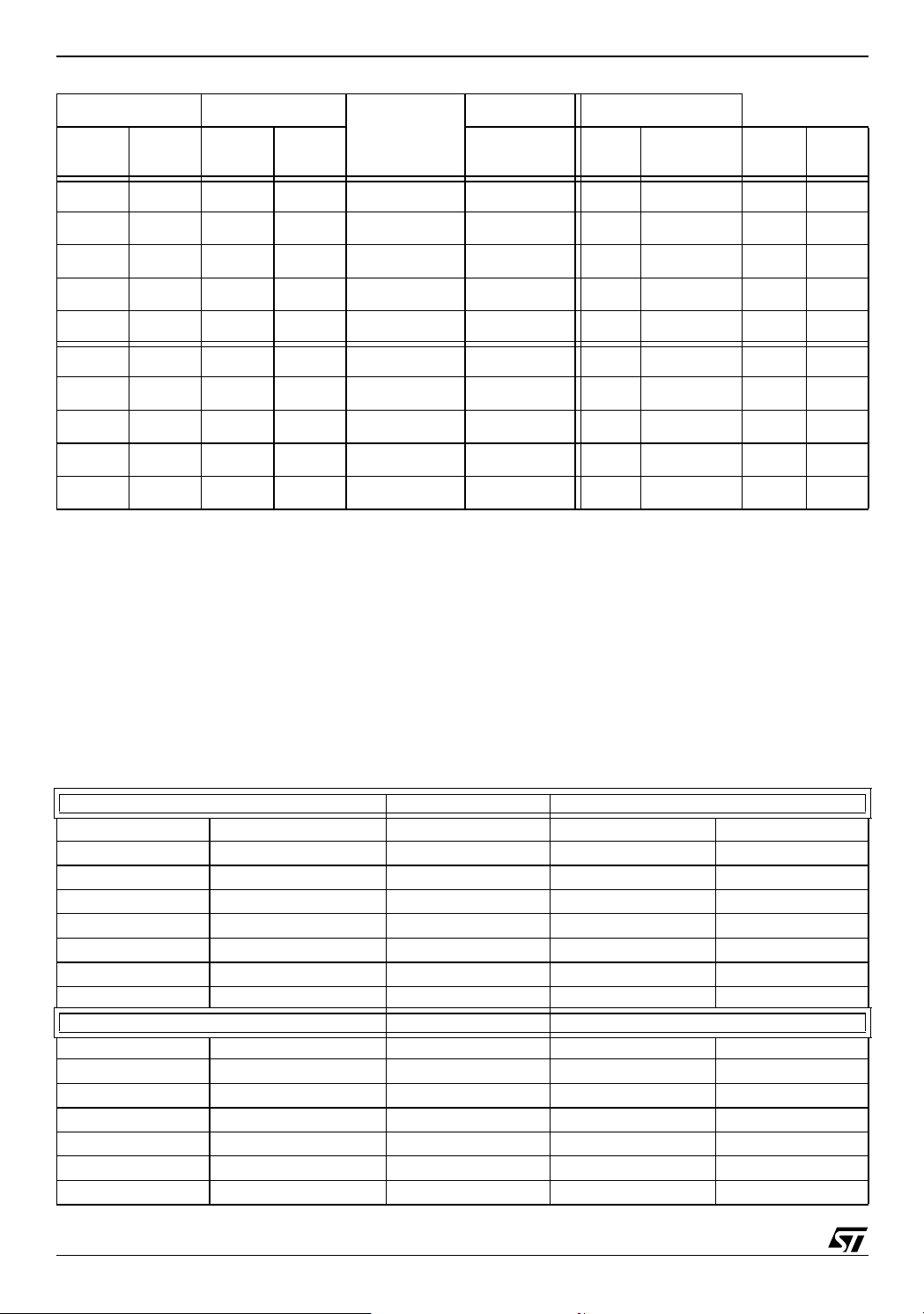

In the following tables it has been reported the output voltage cross regulation measurements with static

loads. The overall efficiency of the converter is also calculated at the nominal input voltages.

To check the application circuit it has been tested keeping constant the current on the 5V and varying the

12V load. As visible in both tables, the voltages are within their tolerance at any load condition and the

circuit efficiency is good

.

5V ± 2% 12V ± 10%

Vout

[V]

@Iout

[A]

Vout

[V]

@Iout

[A]

TOLERANCE

Pout

[W]

TOT

Pin

[W]

115 Vac

Efficiency

Vaux

[V]

fs

[KHz]

5.106 2 12.11 4 OK 58.65 71.7 81.8% 18.3 51

5.107 2 12.23 3 OK 46.90 56.6 82.9% 17.4 51

5.108 2 12.40 2 OK 35.02 42.1 83.2% 16.7 51

5.110 2 12.72 1 OK 22.94 27.7 82.8% 16.5 51

5.110 2 13.11 0.5 OK 16.78 20.7 81.0% 16.6 51

5.108 1 11.85 4 OK 52.51 63.9 82.2% 17.5 51

5.108 1 12.00 3 OK 41.11 49.4 83.2% 16.7 51

5.110 1 12.15 2 OK 29.41 35.0 84.0% 16.2 51

5.112 1 12.39 1 OK 17.50 21.0 83.3% 15.9 51

5.112 1 12.66 0.5 OK 11.44 14.0 81.7% 15.9 51

5/17

Page 6

AN1842 APPLICATION NOTE

5V ± 2% 12V ± 10%

Vout

[V]

5.106 2 12.09 4 OK 58.57 69.3 84.5% 17.7 51

5.107 2 12.23 3 OK 46.90 55.3 84.8% 17.3 51

5.109 2 12.40 2 OK 35.02 41.2 85.0% 16.9 51

5.110 2 12.74 1 OK 22.96 27.6 83.2% 16.6 51

5.110 2 13.12 0.5 OK 16.78 20.8 80.7% 16.6 51

5.108 1 11.85 4 OK 52.51 63.9 82.2% 17.5 51

5.108 1 12.00 3 OK 41.11 49.4 83.2% 16.7 51

5.110 1 12.15 2 OK 29.41 35.0 84.0% 16.2 51

5.112 1 12.39 1 OK 17.50 21.0 83.3% 15.9 51

5.112 1 12.66 0.5 OK 11.44 14.0 81.7% 15.9 51

@Iout

[A]

Vout

[V]

@Iout

[A]

TOLERANCE

Pout

[W]

TOT

Pin

[W]

230 Vac

Efficiency

Vau x

[V]

fs

[KHz]

Standby operation

Like in the previous section, the output voltages and the efficiency have been checked, and the input power has been measured. It is clearly visible that with the required standby load (5V@30mA, 12V@0mA)

the input power consumption is well below 800mW at both the input voltage ranges. Besides, the circuit has been characterised at both the nominal input voltage values for different output load and the efficiency is high in all conditions. In the fig. 8, it is shown the output voltage variation as a function of the 5V

current.

During the standby operation the circuit works at reduced frequency, according to load and input voltage

therefore, thanks to this function, the switching losses are minimized. This allows reaching very low standby consumption because in a power switch the switching and the capacitive losses are directly proportional to the working frequency.

5V 115 Vac

Vout [V] @Iout [mA]

5.11 20 0.102 0.433 23.6%

5.11 30 0.153 0.515 29.8%

5.11 40 0.204 0.593 34.5%

5.11 50 0.256 0.667 38.3%

5.11 60 0.307 0.745 41.1%

5.11 80 0.409 0.881 46.4%

5.11 100 0.511 1.021 50.1%

5V 230Vac

5.11 20 0.102 0.493 20.7%

5.11 30 0.153 0.582 26.3%

5.11 40 0.204 0.672 30.4%

5.11 50 0.256 0.755 33.8%

5.11 60 0.307 0.842 36.4%

5.11 80 0.409 1.008 40.6%

5.11 100 0.511 1.168 43.8%

6/17

Pout

TOT [W]

Pin [W] Efficiency

Page 7

AN1842 APPLICATION NOTE

Figure 8. INPUT POWER @LOW LOAD

1.200

1.000

0.800

0.600

Pin @Stand-by

0.400

0.200

0.000

20 30 40 50 60 80 100

Pin @115Vac

Pin@220Vac

Iout +5V [mA]

Here following, in figures 9 ad 10 some waveforms

during standby are shown:

Figure 9. Standby @115 V

- 60Hz 5V @50mA

AC

load

Output voltage ripple @full load

Figure 11. Output voltage ripple @Vin = 115

Vac - 60 Hz and full load

CH3: +5V Output voltage

CH4: +12V Output voltage

In figure 11 the output voltage ripples at switching

frequency are measured. As shown, the ripple

and the spikes are very low thanks to the additional LC filters added on both output and avoiding the

use of bigger or expensive output capacitors.

The residual line frequency modulation is very low

at any input voltage.

CH1: VQ4 - Drain

CH2: V

CH4: V

PIN8

PIN6

(Vcc)

(Comp)

Figure 10. Standby @230 V

50mA load

CH1: VQ4 - Drain

CH2: V

CH4: V

PIN8

PIN6

(Vcc)

(Comp)

- 50Hz 5V @

AC

Dynamic Load Tests

Figure 12 shows the output voltage regulation for

a dynamic load variation of the 5V output. As

shown in the picture the voltage variation and the

response time are very good showing a good loop

behaviour. In fact, the 5V voltage variation is less

than 20mV (0,4%), and the spikes during the load

transition, due to the filter inductor on the output,

are only 75mV beyond the steady state (1,5%).

The measured recovery time is few tens of microseconds. The variations induced on the 12V output have been also checked without showing any

abnormal variation. Besides, the circuit response

has been verified at minimum, nominal and maximum input voltage, showing no significant change.

7/17

Page 8

AN1842 APPLICATION NOTE

Figure 12.

CH3: +5 Vout

CH4: +12 Vout

+5V Dynamic load 1.5 ÷ 2A, 70Hz

+12V: FULL LOAD - @115 V

AC

- 60Hz

In Figure 13 it is reported the response of the output voltages for a load variation of the 12V output

as detailed on top of the picture. The measurement has been done varying the 12V load from

50% to 100% load: the voltage variation is around

340mV and the 5V output is almost unaffected.

Therefore, the conclusion is that there is no abnormal behaviour of the SMPS generated by a load

change, allowing a good confidence for the integration of the SMPS in the equipment.

Figure 13. +12V Dynamic load 2 ÷ 4A, 70Hz

+5V: FULL LOAD - @115 V

- 60Hz

AC

starts to operate and the output voltages begin to

rise up to the nominal value, where the control

loop provides for the regulation. The wake-up time

at 115Vac is 1.2 s, which is a quite typical time for

this kind of Power Supplies. Besides, on the picture it is clearly visible that no any overshoot, undershoot, dip or lost of control happens during the

power supply start-up phase.

Figure 14. Wake-up time @115 V

CH1: VQ4 - Drain

CH2: V

CH3: +5 Vout

CH4: +12 Vout

PIN8

(VCC)

- 60Hz

AC

Figure 15. Start-Up Behaviours @full load -

@90 V

- 60Hz

AC

CH3: +5 Vout

CH4: +12 Vout

Start-Up Behaviour @full load and Wake-up time

In figure14 the wake-up time is measured at the

lower nominal input mains and the controller startup sequence is shown. The Vcc capacitor is

charged by the charge pump circuit and when its

voltage reaches the start-up threshold the device

8/17

CH3: +5 Vout

CH4: +12 Vout

In the above picture the rising slopes at full load of

the output voltages at minimum input mains voltage are captured and the rise time is measured.

As shown in the pictures, the rising time is monotonic and it is almost constant overall the input

mains range. No any overshoot or abnormal behaviour is present overall the input main range.

Page 9

AN1842 APPLICATION NOTE

Turn-Off and Hold-up time

In figure 16 the most salient waveforms at turn-off

are shown. Even at turn off the transition is clean,

without abnormal behaviour like restarting attempts or loss of control by the loop. The Hold-up

time, in evidence between the vertical lines, is 13.6

ms at 115Vac-50Hz, full load and becomes around

67ms at 230Vac.

Figure 16. Hold-up @115 V

CH1: V

CH3: +12V Vout

CH4: +5V Vout

C13

-50Hz - full load

AC

Figure 17. Short circuit on 5V @90 V

full load

CH1: VQ4 - Drain

CH2: VPIN8 (Vcc)

CH4: +5V short circuit current

Figure 18. Short circuit on 5V @265 V

- full load

- 60Hz -

AC

- 50Hz

AC

Short-Circuit Tests at Full Load

The short circuit tests have been done under several conditions, all over the input mains range. To

avoid any catastrophic failure of the circuit due to

overstress, a deep check of component stress has

been done. The main circuit parameters that have

been checked are the Mosfet drain voltage and the

mean value of the output current. The drain voltage is an important parameter to be monitored

during short circuits because an excessive increase due to the transformer leakage inductance

and the overcurrent flowing in the primary can

cause the MOSFET BV

to be exceeded. In the

DSS

proposed circuit, thanks to the low leakage inductance of the transformer and to the start-up component correct dimensioning, in case any output is

shorted, the MOSFET drain voltage is below its

and the mean value of the output current is

BV

DSS

low too, thus preventing component overheating

because of the excessive power dissipation. In this

case the reliability against long term-shorts is not

affected even at 264Vrms. The auto-restart at

short removal has been also checked and it is correct in all conditions.

CH1: VQ4 - Drain

CH2: VPIN8 (Vcc)

CH4: +5V short circuit current

As clearly indicated by the waveforms in figure 17

and 18, the circuit works in hiccup mode, keeping

the mean value of the current at levels compatible

with the component rating. As visible the circuit

working time is constant because it depends only

on the auxiliary capacitor value, while the dead

time is inversely proportional to the input mains

voltage. In the following figures 19 and 20 the

waveforms relevant to the 12V output in short circuit at both the nominal input mains voltage are reported: as visible, the circuit protects itself and the

load.

9/17

Page 10

AN1842 APPLICATION NOTE

Figure 19. Short circuit on 12V @90 VAC - 60Hz

- full load

CH1: VQ4 - Drain

CH2: V

CH4: +12V short circuit current

Figure 20.

(Vcc)

PIN8

Short circuit on 12V @265 VAC - 50Hz

- full load

tions of the equipment, with a consumption halved

with respect to the maximum output power levels

(I

+12V

= 2A, I

+5V

= 1A).

– At Vin = 90Vac: shorting each output the over

current protection works correctly, providing for

the hiccup mode.

– At Vin = 265Vac: the circuit behaves correctly.

Figure 21. Short circuit on 5V @265 V

- half load

- 50Hz

AC

CH1: VQ4 - Drain

CH2: V

CH4: +12V short circuit current

PIN8

(Vcc)

Short Circuit Protection @ Low Load

After the full load tests, some checks on the short

circuit protection with reduced loads have been

done, as reported here following. The tests have

been done even at minimum and maximum input

voltage with the same results, as the previous

tests.

@Half Load

The waveforms of figure 21 are relevant to a short

circuit test simulating a fault during normal opera-

CH1: VQ4 - Drain

CH2: V

CH4: +5V short circuit current

PIN8

(Vcc)

@Reduced Load

This condition simulates a fault during an operating transition of the equipment, with the backlight

off and a reduced consumption of the other output

(I

+12V

= 0A, I

= 0.5A).

+5V

– At Vin = 90Vac: shorting each output the over

current protection works correctly, providing for

the hiccup working mode.

– At Vin = 265Vac: the behaviour of the circuit is

correct like at 90Vac.

–

@Standby

This condition simulates a fault during the standby

operation of the equipment, with the backlight and

the scaler off, and the µP working with a reduced

consumption (I

+12V

= 0A, I

= 33mA).

+5V

– At Vin = 90Vac: shorting each output the over-

current protection works correctly, providing for

the hiccup working mode.

– At Vin = 265Vac: the behaviour of the circuit is

correct like at 115Vac.

10/17

Page 11

AN1842 APPLICATION NOTE

Figure 22. Short circuit on 5V @265 VAC - 50Hz

- standby load

CH1: VQ4 - Drain

CH2: V

CH4: +5V current in short circuit

Figure 23. Short circuit on 12V @265 V

PIN8

(Vcc)

AC

-

50Hz - standby load

turn-off, preventing the hiccup mode. To avoid

this, the circuit around Q2 and Q3 has been added, providing the hiccup mode anyway. As visible

in the pictures, the SMPS is always protected even

in this very critical load condition.

Over Voltage Protection

The open-loop operation is a very dangerous

event that could happen in case of a feedback circuitry failure. In this case, the SMPS output voltages can increase up to dangerous values,

depending on the load by each output and the

transformer coupling between the windings. Thus,

if the circuit is not properly protected, the rectifiers

and the output capacitors can be overstressed and

be destroyed or even worse, to catch light. To

avoid this, the safety rules ask that the SMPS have

a protection against the mentioned safety risks. In

the proposed circuit, in case of a control loop failure, a L5991 internal comparator stops the controller operation when the voltage at pin 14 (DIS)

reaches 2.5V and remains latched until the Vcc

voltage decreases below the UVLO threshold. So,

a very safe protection with the L5991 is realized

just by means of few passive components.

The circuit has been tested opening the loop, the

output voltages have been measured giving the

following results overall the mains input voltage

range:

230Vac – 50Hz

@FULL LOAD

5V @ 2A 12V @ 4A 5V @ 0.03A 12V @0A

V

: 5.7V V

5V

13.5V V5V: 6.24V V

12V:

230Vac – 50Hz

@STANDBY

: 15.8V

12V

CH1: VQ4 - Drain

CH2: V

CH4: +5V current in short circuit

PIN8

(Vcc)

The main circuit parameter measurements have

been done also during the test at reduced load or

standby. In detail, during standby short it is possible to check the perfect functionality of the protection. This load condition in fact, is critical because

all the power available from the converter can be

delivered to one output only, because the others

are lightly loaded or unloaded, and this can bring

to the destruction of the rectifier of the shorted output. Besides, during standby operation, the transformer coupling and the leakage inductance may

be capable of supplying the controller charging the

V

capacitor by the spikes generated at Mosfet

DD

As shown in the table, in both conditions the measured voltages are not critical for the circuitry.

Conducted Noise Measurements (Pre-Compliance Test)

The following pictures are the peak conducted

noise measurements at full load and nominal

mains voltages. The limits shown on the diagrams

are those specified by the EN55022 CLASS-B,

which is the most widely used for Information

Technology Equipment intended for domestic use,

in the bandwidth 150KHz 30MHz. The filter configuration used is the 2-wires one, without the ground

connection at mains plug, suitable for domestic

equipment like LCD-TVs. As visible on the diagrams, there is a good margin between the peak

measures with respect to the AVG limits (lower

ones), and this assures that the QP and Average

measures will be within their respective limits.

11/17

Page 12

AN1842 APPLICATION NOTE

Figure 24. EN55022 Class-B Peak Measure

@115 V

- 60Hz - FULL LOAD

AC

Figure 25. EN55022 Class-B Peak Measure 230

VAC - 50Hz - FULL LOAD

Thermal measures

In order to check the reliability of the design a thermal mapping by means of an IR camera has been done.

In the table here below the temperature of some salient components is reported at 115Vac and 230Vac

input voltage, at ambient temperature (24°C).

@115Vac @230Vac

Point Reference Description Temperature Temperature

A D9 BRIDGE RECTIFIER 74°C54°C

B L2 FILTER COIL 56°C40°C

CQ4 POWERMOS 70°C58°C

D T1 POWER TRANSF. 53°C56°C

E D16 +5V RECTIFIER 61°C60°C

F D13 +12V RECTIFIER 64°C64°C

As visible in the above table there are not component working at a temperature level that can be considered critical for their reliability.

12/17

Page 13

Board lay-out

Figure 26. Board silk-screen and bottom plane (not in scale)

AN1842 APPLICATION NOTE

■ Original size: 89x180mm

■ Copper thickness: 70µm

■ Material: CEM-1

Conclusions

An SMPS for LCD monitors or LCD-TV sets has been completely designed, assembled and tested using

the L5991. All the different aspects (Component Electrical Stress, Functions, Protections, Conducted

EMI, Thermal Stress) have been checked, giving positive results. The design meets also low-cost and lowcomplexity requirements, key factors in the Consumer Electronic market.

13/17

Page 14

AN1842 APPLICATION NOTE

References

[1] "L5991 Data Sheet"

[2] "AN1537: A simple trick enhances L5991's standby function"

ANNEX1: Transformer spec

Transformer General Description

APPLICATION TYPE: Consumer, Home Appliance

TRANSFORMER TYPE: Open, Varnished only

WINDING TYPE Slot

COIL FORMER: Vertical type, 7+7 pins

MAX. TEMP. RISE: 45°C

MAX. OPERATING AMB. TEMP. : 60°C

MAINS INSULATION: ACC. WITH EN60065 - EN60950

Electrical Characteristics

CORE TYPE/GRADE: ETD34 - 3C90 or equivalent

PRIMARY INDUCTANCE: 825 µH ±10% @1KHz - 0.25V

LEAKAGE INDUCTANCE: 15 µH MAX @ 10KHz - 0.25V [1]

PEAK PRIMARY CURRENT: 2 Apk

[1]: Measured between pins 3-7 with all secondary shorted

PROVIDED BY PULSE-ELDOR P/N: 2074.5056C

Figure 27. Electrical Diagram

3

PRIM.

7

11

AUX

13

12

10

2-

6-

+5V

PINS:

7-3 PRIMARY 0.84 A

2/4-6/8 5V 2.6 A

12-10 12V 5.3 A

11-13 15V (AUX) 0.05 A

PRIMARY SECONDARY

DC OUTPUT

VO LTAG E:

RMS

CURRENT:

RMS

RMS

RMS

RMS

NUMBER OF

TURNS:

53

3

7

9

14/17

Page 15

AN1842 APPLICATION NOTE

ANNEX2:

Part List

Designator

C1 RES NOT MOUNTED

C10 220N - 50V CERCAP AVX

C101 (D17) 47N-400V POLIESTER FILM CAP MKT R66 - ARCOTRONICS

C102 220P - 50V CERCAP AVX

C11 100N - 50V CERCAP AVX

C12 220N - 50V CERCAP AVX

C13 100uF-400V ALUMINIUM ELCAP LP4 SERIES - ELNA

C14 2N2-1KV HR HV CERCAP DEHR33A222K - MURATA

C15 4N7 - 50V CERCAP AVX

C16 4N7 - 50V CERCAP AVX

C17 4N7 - 50V CERCAP AVX

C18 330P - 50V CERCAP AVX

C19 22uF-25V ALUMINIUM ELCAP RUBYCON

C2 RES NOT MOUNTED

C20 22uF-25V ALUMINIUM ELCAP RUBYCON

C21 220PF-2KV HR HV CERCAP DEHR33A221K - MURATA

C22 1N0 - Y1 Y1 SAFETY CAP. DE1E3KX102M - MURATA

C23 1N0 - Y1 Y1 SAFETY CAP. DE1E3KX102M - MURATA

C24 2200uF-16V YXF ALUMINIUM ELCAP RUBYCON

C25 1000uF-35V YXF ALUMINIUM ELCAP RUBYCON

C26 1000uF-35V YXF ALUMINIUM ELCAP RUBYCON

C27 470uF-10V YXF ALUMINIUM ELCAP RUBYCON

C28 100uF-50V YXF ALUMINIUM ELCAP RUBYCON

C29 22N - 50V CERCAP AVX

C3 RES NOT MOUNTED

C30 N68 - 50V CERCAP AVX

C31 3N3 - 50V CERCAP AVX

C32 47uF-25V YXF ALUMINIUM ELCAP RUBYCON

C33 10N - 50V CERCAP AVX

C4 RES NOT MOUNTED

C5 RES NOT MOUNTED

C6 RES NOT MOUNTED

C7 470PF - 50V CERCAP AVX

C8 220N-X2 X2 FILM CAPACITOR

C9 220N-X2 X2 FILM CAPACITOR

D10 STTH1L06 FAST REC. RECTIFIER STMicroelectronics

D101 1N4148 GEN. PURPOSE DIODE WISHAY

D102 (R13) 1N4148 GEN. PURPOSE DIODE WISHAY

D11 STTH1L06 FAST REC. RECTIFIER STMicroelectronics

D12 RES NOT MOUNTED

D13 STPS8H100CF POWER SCHOTTKY RECT. STMicroelectronics

D14 1N4007 RECTIFIER DIODE WISHAY

Part Type/

Part Value

Description Supplier

R46-KI 3220 00 L2M - ARCOTRONICS

R46-KI 3220 00 L2M - ARCOTRONICS

15/17

Page 16

AN1842 APPLICATION NOTE

Part List (continued)

Designator

D15 1N4007 RECTIFIER DIODE WISHAY

D16 STPS5L40 POWER SCHOTTKY RECT. STMicroelectronics

D2 1N4148 GEN. PURPOSE DIODE WISHAY

D3 BAV21 GEN. PURPOSE DIODE WISHAY

D4 1N4148 GEN. PURPOSE DIODE WISHAY

D5 1N4148 GEN. PURPOSE DIODE WISHAY

D6 BAV21 GEN. PURPOSE DIODE WISHAY

D7 1N4148 GEN. PURPOSE DIODE WISHAY

D8 1N4148 GEN. PURPOSE DIODE WISHAY

D9 2KBP06M BRIDGE RECTIFIER WISHAY

F1 FUSE T2A FUSE 2 AMP. TIME DELAY WICKMANN

J1 INPUT CONNECTOR, 2/3 POLES, 7.5MM MOLEX

J2

JP1 JUMPER WIRE JUMPER

JP2 RES NOT MOUNTED

L1 RES NOT MOUNTED

L2 253Y1R2 25mH-1.2A - CM FILTER INDUCTOR TDK

L3 2uH-4A 2uH-4A AXIAL FILTER INDUCTOR B82111 SERIES - EPCOS

L4 10uH RF AXIAL CHOKE B78108-S1103-K - EPCOS

L5 2.7uH DRUM COIL 2.7uH-4A ELC08D SERIES - PANASONIC

Q1 BC547A SMALL SIGNAL NPN BJT STMicroelectronics

Q2 BC547A SMALL SIGNAL NPN BJT STMicroelectronics

Q3 BC547A SMALL SIGNAL NPN BJT STMicroelectronics

Q4 STP5NK80ZFP POWER MOSFET STMicroelectronics

R1 RES NOT MOUNTED

R10 4K7 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R101 (D1) 100R - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R11 10K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R12 12K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R14 1K0 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R15 47R - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R16 1R2 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R17 1R2 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R18 1R2 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R19 4K7 - 2W - 5% POWER RESISTOR 2W BEYSCHLAG

R2 NTC_10R S236 NTC THERMISTOR EPCOS

R20 RES NOT MOUNTED

R21 8K2 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R22 3K9 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R23 6K2 - 1/4W - 1% METAL FILM RESISTOR BEYSCHLAG

R24 2K0 - 1/4W - 1% METAL FILM RESISTOR BEYSCHLAG

R25 12K - 1/4W - 1% METAL FILM RESISTOR BEYSCHLAG

R26 1K5 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

Part Type/

Part Value

Description Supplier

OUTPUT CONNECTOR, 9 POLES, 2.54MM

MOLEX

16/17

Page 17

AN1842 APPLICATION NOTE

Part List (continued)

Designator

R27 10R - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R28 82K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R29 2K43 - 1/4W - 1% METAL FILM RESISTOR BEYSCHLAG

R3 470K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R30 2K43 - 1/4W - 1% METAL FILM RESISTOR BEYSCHLAG

R31 1K0 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R32 47K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R33 12K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R34 3K3 - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R35 10K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R4 470K - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R5 150K - 2W - 5% POWER RESISTOR 2W BEYSCHLAG

R6 33R - 1/4W - 5% STANDARD FILM RESISTOR BEYSCHLAG

R7 RES NOT MOUNTED

R8 RES NOT MOUNTED

R9 RES NOT MOUNTED

T1 2074.5056C POWER TRANSFORMER PULSE-ELDOR

U1 L5991 PRIMARY CONTROLLER WITH STANDBY STMicroelectronics

U2 SFH617A-2 OPTOCOUPLER INFINEON

U3 TL431ACZ SHUNT REGULATOR STMicroelectronics

Part Type/

Part Value

HEAT SINK FOR Q4

HEAT SINK FOR D13

Rth

Rth

Description Supplier

= 15°C/W P/N 6098B THERMALLOY WITH

HS-AMB

CLAMP

= 10°C/W P/N 6099B THERMALLOY WITH

HS-AMB

CLAMP

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicroelectronics GROUP OF COMPANIES

www.st.com

17/17

Loading...

Loading...