Page 1

AN1826

®

APPLICATION NOTE

TRANSIENT PROTECTION SOLUTIONS:

Transil™ diode versus Varistor

A. BREMOND / C. KAROUI

Since the seventies, electronic modules are more and more present in our life. This is the case for our

entertainment, automotive, telecommunication, production tools, house access equipment, and it is not

really a secret that these smart functions are very sensitive to transients coming from human body itself

1

), electromagnetic part switching and industrial transients (EOS2), atmospheric effects (lightning).

(ESD

These surges are more often lethal for the electronic functions and the constant decrease of silicon

elementary cell size (transistor) makes them more and more compact but more and more fragile.

To assume a correct definition of a protection stage, we have to ask the two following questions :

- what we have to protect?

- against what we have to be protected?

The answer to the first question depends on both the technology used to realize the part to be protected

and normal operating waveform of the signal on the line to be protected. Needed parameters are the

maximum voltage that technology can withstand, the type of normal operating signal (unidirectional : 0-V

or bi-directional : ±Vcc), the maximum and minimum voltages of this signal and its frequency. The answer to

the second one is closely linked to the environment where modules are operating. In each application we

have to focus on one type of disturbances, i.e. in telecom we are faced to atmospheric effects, in domestic

and industrial worlds, disturbances are EOS while in computer or mobile phones, the main surge cause is

due to ESD.

cc

To avoid dramatic consequences on systems submitted to over voltage transients, the best way is to use

protection devices based on clamping action.

In this kind of products we have the choice between two technologies :

- silicon devices named Transil™ - so called TVS

3

- and ceramic components - Varistor for instance.

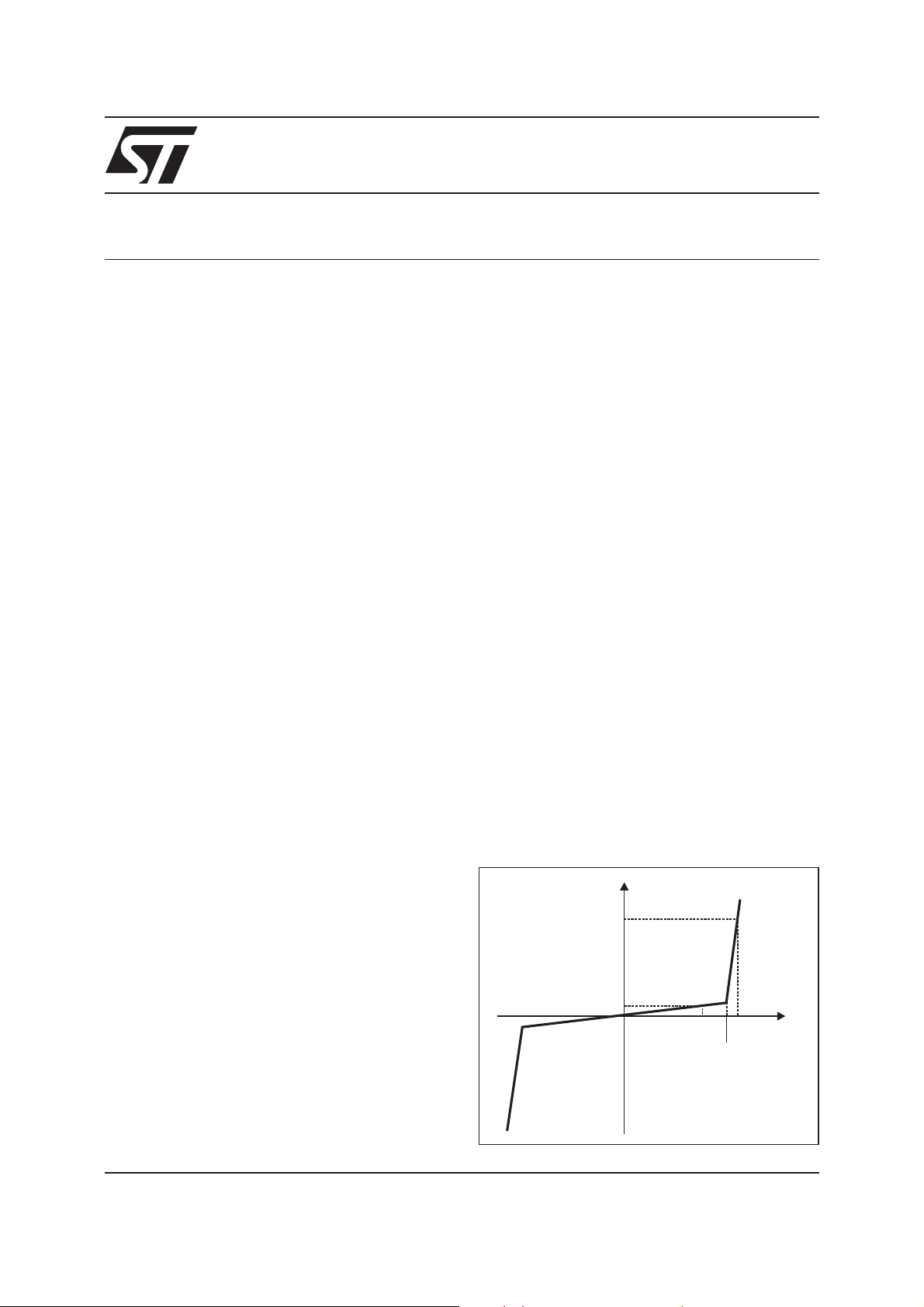

Figure 1

clamping device, this curve has two areas.

The first one located between 0V axis and V

the normal operating zone; in this area the signal is

shows the electrical characteristics of a

4

RM

Fig. 1: Electrical characteristics of bi-directional

clamping devices.

I

I

PP

is

not be affected by the transient suppressor (low

leakage current and negligible intrinsic capacitance).

The second one is the surge suppression zone in

which the surge is clamped at VCL

VV RI

=+×

CL BR d PP

6

V

: knee voltage of the I/V curve

BR

: dynamical resistance.

R

d

: current value during surge.

I

PP

AN1826/0104

5

.

I

RM

RM

V

CL

V

BR

1/5

V

V

Page 2

AN1826 - APPLICATION NOTE

In this zone, the main property of the protection device is to have a clamping voltage as close as possible to

the operating voltage. This property is defined by the clamping factor C

V

C

CL

=

F

V

BR

.

F

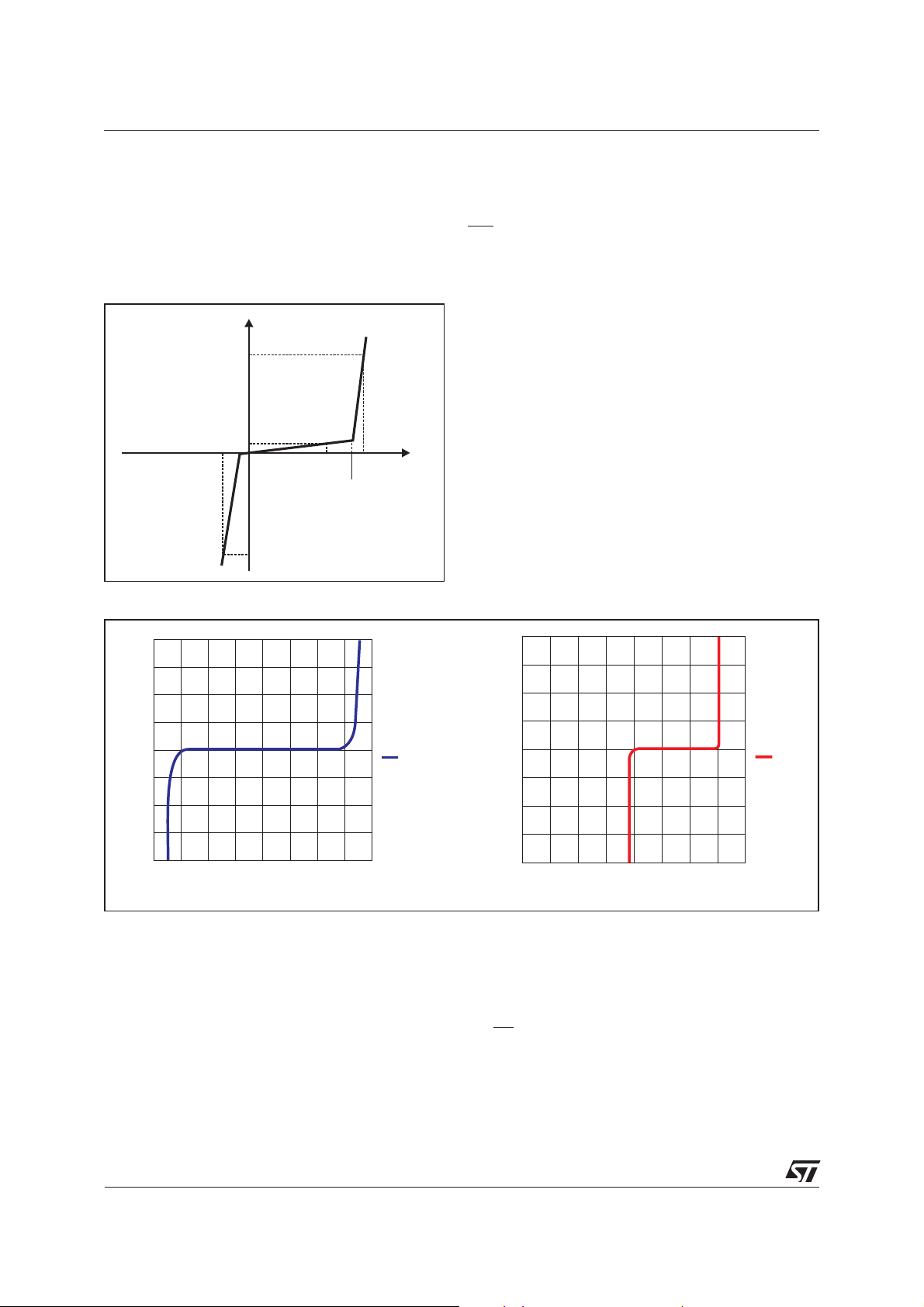

Fig. 2: Electrical characteristics of unidirectional

clamping devices.

When the signal moving through the line to be

protected is unidirectional (0 to +V

the surge suppressor has to be unidirectional,

I

I

PP

otherwise the protection function is not optimized.

Figure 2

unidirectional clamping device. In this case the

positive behavior of the device is still the same

while the negative one is totally different.

Negative over voltage occurring on the protected

I

RM

I

R

V

RM

V

V

BR

V

CL

line is clamped to a typical forward drop voltage of

a diode.

Figure 3

Transil™ diode and Varistor measured on curve

tracer. Both tested components have been chosen

in the same power and voltage (14V) ranges in

order to make an accurate comparison.

V

R

Fig. 3: Electrical characteristics measured on curve tracer.

200

150

100

50

cc

shows the electrical characteristics of a

gives the electrical characteristics of both

200

150

100

50

or -Vccto 0)

0

-50

Current (µA)

-100

-150

-200

-20 -10 0

Varistor

10 20

Voltage (V)

0

-50

Current (µA)

-100

-150

-200

-20 -10 0

Transil

10 20

Voltage (V)

The first remark we can do, regarding these curves, is that the Varistor operates uniquely in bi-directional

mode while the Transil™ diode can be both uni or bi-directional (here this is a unidirectional type). The

second point is the leakage current which is higher for the Varistor particularly close to the knee of the

curve. The third point to focus on is the slope of these characteristics in the clamping zone (vertical part of

the curve after V

And taking into account that the curve slope represents

), here one can easily see that the Transil™ diode slope is tighter than the Varistor one.

BR

1

, so for the same surge current the clamping

R

d

voltage will be lower for the Transil™ and then its clamping factor will be better.

To verify this point we performed measurements on both Transil™ and Varistor during EOS and ESD

surge test conditions. The EOS tests are based on IEC61000-4-5 1.2/50µs (8/20µs current) composed

waveform while ESD surges were performed in accordance with IEC61000-4-2 system standard.

2/5

Page 3

Fig. 4: Varistor and Transil™ diode EOS electrical behaviors.

AN1826 - APPLICATION NOTE

Tek Run: 10.0MS/s

2

1

10.0V Ch2 Ch2200mV M 5.00µs 96mV

Ch1

Figure 4

shows the behavior of both Varistor and Transil™ when submitted to EOS surges. Tests were

Sample

[ ]

T

Trig?

Varistor

V @10A=37.2V

CL

Current

Voltage

Tek Run: 10.0MS/s

21

5.0 V Ch2200mV M 5.00µs 96mV

Ch1

Sample

[ ]

T

Current

Ch2

Trig?

Transil™ diode

V @10A=24.6V

CL

Voltage

performed with 10A peak current, in such a condition the Varistor clamps at 37.2V while remaining voltage

across the Transil™ in the same condition is only 24.6V. That means in such a surge condition the

protected IC's input will see 12.6V less in case of Transil™ diode use; that leads to a better clamping factor

for Transil™ diode versus varistor.

Table 1: Clamping factor comparison.

Varistor Transil™

typ.(V) @ IPP= 10A

V

CL

typ. (V) @ 1mA

V

BR

C

F=VCL/VBR

37.2 24.6

18.4 15.2

2.02 1.62

Fig. 5: Varistor and Transil™ diode ESD electrical behaviors.

Varistor

Transil™ diode

3/5

Page 4

AN1826 - APPLICATION NOTE

Figure 5

gives their behavior when submitted to ESD strikes. In this case the Transil™ diode is much faster

than the Varistor to clamp and to derivate surge energy. Turn-on time measured on a Transil is typically

below the 10 picosecond level, while a Varistor will be in the range of 500 to 1000 ps at the best. In the first

few ns, the parasitic inductance and reaction time generate >70V peak for the Varistor while this value is

limited to 55V only for the Transil™. After this phase, the maximum voltage is 30V for the Varistor while we

see only 15V across the Transil™ diode (very close to V

BR

).

Another point to take into account is the system reliability. So ensuring device reliability and avoiding

ageing phenomena are two major concerns. To check these two points, repetitive ESD tests have been

performed (100 pulses versus IEC61000-4-2 system standard 15kV contact).

Fig. 6: Varistor and Transil™ repetitive ESD test results.

Varistor

200

150

100

50

0

-50

Cur re nt ( µA)

-100

-150

-200

-20 -10 0 10 20

Voltage (V)

Before

After

200

150

100

50

0

-50

Curre nt (µA)

-100

-150

-200

-20 -15 -10 -5 0 5

Voltage (V)

Transil

TM

Before

after

Figure 6

shows after these tests, Varistor leakage current drastically increases, while Transil™ one

remains the same. This phenomena is called ageing . So the integrity of the protected system will be

greatly dependent on the choice of the protection component.

Transil™ diode technology can be easily used in more complex integration where dedicated ESD

protection is required and space saving is a major concern. For instance this is particularly true in computer

and mobile phone applications. This is the case for USB link, which is based on plug and play connection.

This kind of surges is always omnipresent.

Figure 7

gives downstream port dedicated circuit USBDF01W5,

which integrates either the ESD protections, the line matching resistors (Rt), the filtering capacitors (Ct)

and the pull down resistors. All this internal component are required by the USB standard.

Fig. 7: USBDF01W5 circuit.

Table 2: Comparison sum-up.

Varistor Transil™

D+ In

Gnd

D- In

Rt

Ct

15k

D+ Out

Leakage current

ESD ruggedness

Protection efficiency

C

F=VCL/VBR

15k

Ct

D- Out

Rt

Ageing

Security

-- ++

+++ +++

-- ++

-++

--- +++

-- +++

4/5

Page 5

CONCLUSION

AN1826 - APPLICATION NOTE

Transil™ devices assume better efficiency in terms of ESD protection and can be uni and bi-directional

suppression functions. The MOV

7

are uniquely bi-directional devices and then are not optimized to protect

sensitive ICs inputs, because these are 90% of the time dedicated to uni-directional normal operating

signals. So IC inputs to be protected will be submitted to high voltages in the negative way during surge

clamping.

Remaining voltage (V

) for both EOS and ESD across the line is lower in the case of Transil™ than for

CL

Varistor.

Low leakage current for Transil™ device is an important parameter to take into account when portable

equipment (as mobile phone or mobile computer) are concerned. This point will improve autonomy of

these kinds of equipment. In term of reliability Transil™ device has no ageing phenomena regarding ESD

events while Varistors are subjected to it.

In many applications safer failure are requested, this characteristic consists on a failure in short circuit

when an over sized surge occurs across the protection device. This is the failure mode of Transil™ which

assumes total security of the protected equipment.

1

ESD: ElectroStatic Discharge

2

EOS: Electrical Over Stress

3

TVS: Transient Voltage Suppressor

4

VRM: Stand off voltage

5

VCL: Clamping voltage

6

VBR: Breakdown voltage

7

MOV: Metal Oxyde Varistor

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such information nor for any infringement of patents or other rightsof third parties which may result from its use. No license is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not au

thorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners.

© 2004 STMicroelectronics - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany -

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore - Spain -

Sweden - Switzerland - United Kingdom - United States

www.st.com

5/5

-

Loading...

Loading...