Page 1

Vref

AN1818

Reducing the Total No-Load Power Consumption of

Battery Chargers and Adapter Applications

1 Introduction

This paper describes how to reduce the power consumption, under no-load conditions, of battery

chargers and adapters by using STMi croelect ronics’s TSM famil y of seconda ry-side devices . This fam ily

of devices provides accurate voltage and current regulation, while incurring very low consumption at noload conditions. In fact, owing to these innovative, integrated devices, the total power consumption for the

entire system at no-load conditions can be reduced down to nearly 100mW. With the arrival of new power

consumption regulations, this capability is increasingly sought after.

The most innovative of S T’s devices are the TSM 101x family. These a re highly integrated solutions for

SMPS applications requiring CV and CC mode, integrating one voltage reference and two operational

amplifiers. The voltage reference combined with one operational amplifier makes them ideal voltage

controllers. The other operational am plifier, combined with the integrated voltage reference and a few

external resistors, can be used as a current limiter.

These products family are designed for use in battery chargers with a constant voltage and a limited

output current and in adapters.They can be used in every type of application requiring 0.5% and 1%

voltage reference precision.

2 Power dissipation under no-load conditions

In a typical system for battery charger and adapter applica tions, different factors contribute to the total

power dissipation under no-load conditions. However, in b road t erm s, the total power dissipation can be

divided into the dissipation o wing to the secondary-side (P

primary-side (P

).

in

) and the power dissipation owi ng to the

out

Secondary-side power dissipation

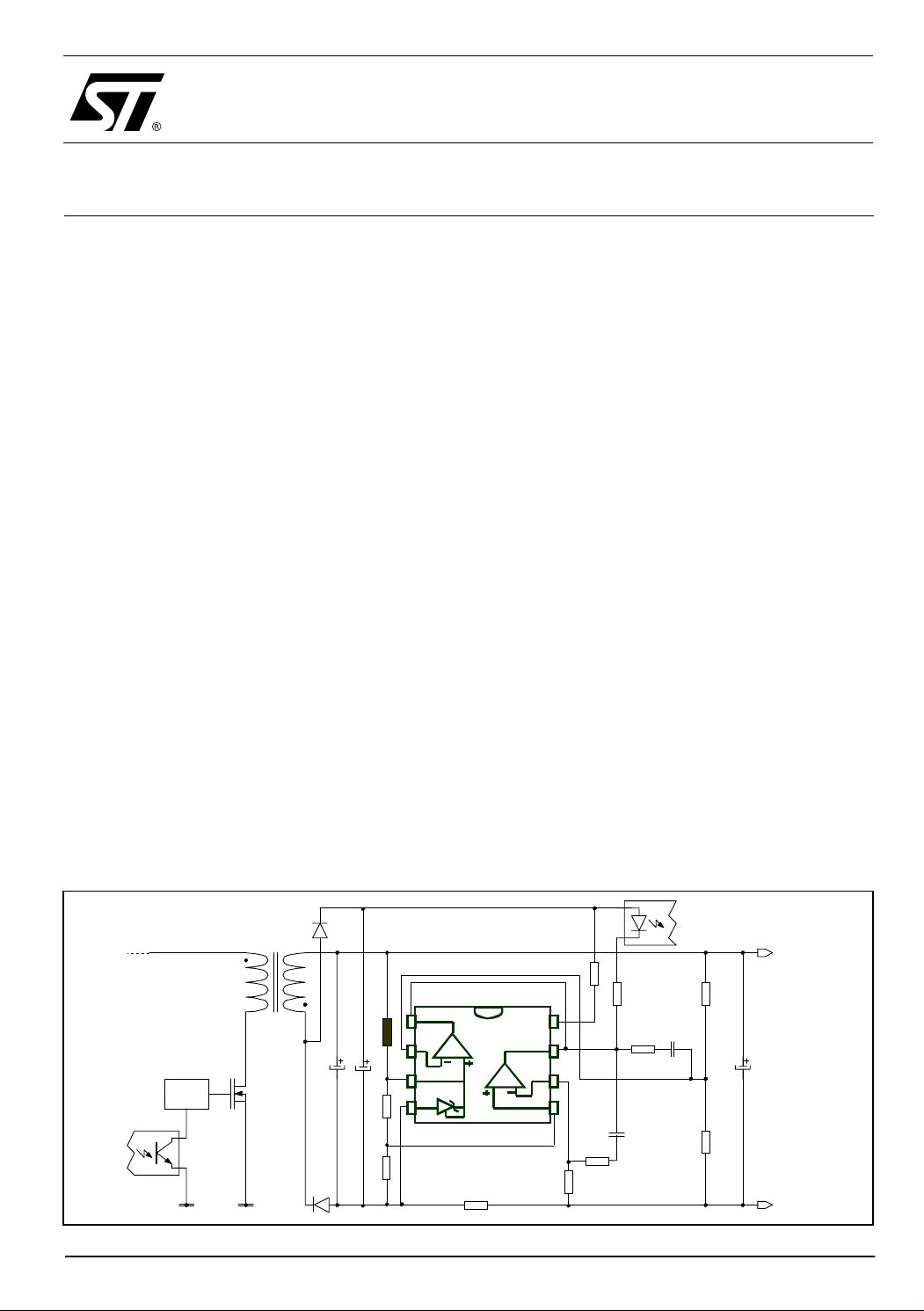

This article deals with reducing the secondary-side power dissipation, so let us begin by conside ring a

typical schematic of the secondary-side of an SMPS application, shown in Figure 1.

Figure1: Typical application using CC-CV Standard in SMPS

Cvc1

optocoupler

secondary side

R2

R1

OUT+

C3

OUT-

CC-CV Standard

OP1

Rsense

OP2

Ric2

Rlimit

R3

Rvc1

Cic1

Ric1

PWM

controller

optocoupler

primary s ide

D2

Rref

C1

C2

R4

R5

D1

AN1818/100 4 Revision 1 1/6

Page 2

AN1818 Power dissipation under n o-load conditions

The CC-CV (Constant Current - Constant Voltage) standard is a monolithic IC that includes one

independent op-amp and another op-amp for which the non-inverting input is wired to a 2.5V fixed voltage

reference. A good example of such a secondary-side device is ST’s TSM103W.

Normally the CC-CV voltage reference is “shunted”, meaning that the internal current generator requires

an external power supply in order to polarize and fix the voltage reference at 2.5V (V

If we assume that V

is connected to a discharge ba ttery, the resulting ch aracteristic curve, V

out

shown in Figure 2.

- I

Figure2: Characteristic V

25

25

20

20

15

15

Vout (V)

Vout (V)

10

10

out

for adapter application

out

= 2.5V).

ref

out-Iout

, is

5

5

Vout_min in CC mode

0

0

0123456

0123456

Iout (A)

Iout (A)

Vout_min in CC mode

In Figure 2, we can see that the load charges gradually, by increasing the current and the voltage in order

to reach a minimal voltage drop. This gradual increase guarantees a limited and stable current. Following

this, the voltage value increases (while the current stays constant) up to the constant voltage value.

A typical adapter application will have V

out_max

= 20V (at no-load conditions) and V

= 5V (which is

out_min

the minimal voltage necessary to have a constant current).

In order to have V

out_min

= 5V, V

= 5V. If the minimum current value to bias V

cc_min

is 1mA, this means

ref

that:

R

ref

Therefore, in order to have V

= 5V, we must fix R

out_min

Now that we have fixed the value of R

I

V

outminVref

--------------------------------------- -

I

ref

, let's consider a no-load condition where V

ref

ref

–

1mA=

5V 2.5V–

------------------------ 2.5k Ω===

ref

1mA

= 2.5kΩ.

out_max

= 20V. It

follows that:

V

–

I

ref

outVref

-----------------------------

R

ref

20 2.5–

------------------ - 7 mA===

2.5

2/6

Page 3

Power dissipation under n o-load conditions AN1818

The total value of the secondary-side power dissipation is calculated using:

Equation 1

where

P

out

I

totIccIrefIopto

V

⋅=

outItot

++=

Equation 2

and I

This means that for a typical system at no-load conditions where V

I

opto

is the current needed to drive an optocoupler — typically about 1.5mA.

opto

= 20V, I

out

= 1.5mA, giving a secondary-side power dissipation (P

) equal to:

out

= 7mA, Icc = 1.5mA and

ref

Equation 3

P

out

V

outItot

⋅()V

outIrefIccIopto

++()⋅()20V 7mA 1.5mA 1.5mA++()⋅()20V 10mA⋅()200mW=====

Primary-side power dissipation

Now to turn our attention to the primary side of a typical adapter application. The primary side of an SMPS

application consists of a number of functional blocks (such as the PFC and PWM), each contributing to

the overall power consumption of the device. But in general, the overall power dissipation owing to

primary side functions can be assumed to be about 80mW under no-load conditions (for battery chargers

and adapters in the range 5W).

The key factor concerning the overall power consumpt ion on the primary-side is its efficiency rating,

which is at best about 50%. This means that to transfer 1mW of power to th e secondary side, 2mW of

power are generated in the primary side.

Returning to our cal culation in Equation 3 above, this means that if we require 200mW of power on the

secondary-side in no-load conditions, 400 mW will be generated on the primary side, and an additional

80mW will be necessary to drive the primary-side functions.

This relationship means that for any given redu ction in no-load power dissipation on the secondary side,

the beneficial effect will be twice as great on the primary side.

3/6

Page 4

AN1818 Optimizing your system

CC-

3 Optimizing your system

Typically, when one designs a battery charger or adapter application, a t arget power consumption is s et

for the application under no-load conditions. This target may be 500mW, or even 300mW, but until

recently, it seemed impossible to reach a no-load total power consumption of as low as 100mW.

In this section, we will look at three example syste ms:

a A typical secondary side configuration, as s een in Figure 1, and using a general-purpose second-

ary-side integrated circuit, such as ST’s TSM103.

b An advanced secondary side circuit schematic (see Figure 3), using an integrated circuit such as

ST’s TSM1011 which includes a self-polarizing voltage reference. The inclus ion of a self-polarizing voltage reference permits the elimination of the resistor R

of I

.

ref

c An advanced secondary -side schematic (see Figure 3) using a very advan ced integrated circuit,

ST’s TSM1012, which draws only 150µA under no-load conditions.

Figure3: Advanced secondary-side schematic for battery-charger/adapter application

Rlimit

D2

, and by consequence, eliminati on

ref

optocoupler

secondary side

PWM

controller

optocoupler

primary side

TSM1012

Vref Vcc

1 R3

5

R4

C2

C1

D1

3

R5

Rsense

2,5V

CV+

CC+

2

Ric2

Gnd

CV

CC

8

R2

28V

Out

7

4

CV-

6

Ric1

Rvc1

Cic1

Cvc1

C3

R1

In addition to considering the typical (Figure 1) and advanced (Figure 3) secondary side schematics,

there are now on the market optocoupl ers that need as little as 0.5mA . As we will see bel ow, u sing such

an optocoupler can allow power consumption to drop very low indeed.

4/6

Page 5

Optimizing your system AN1818

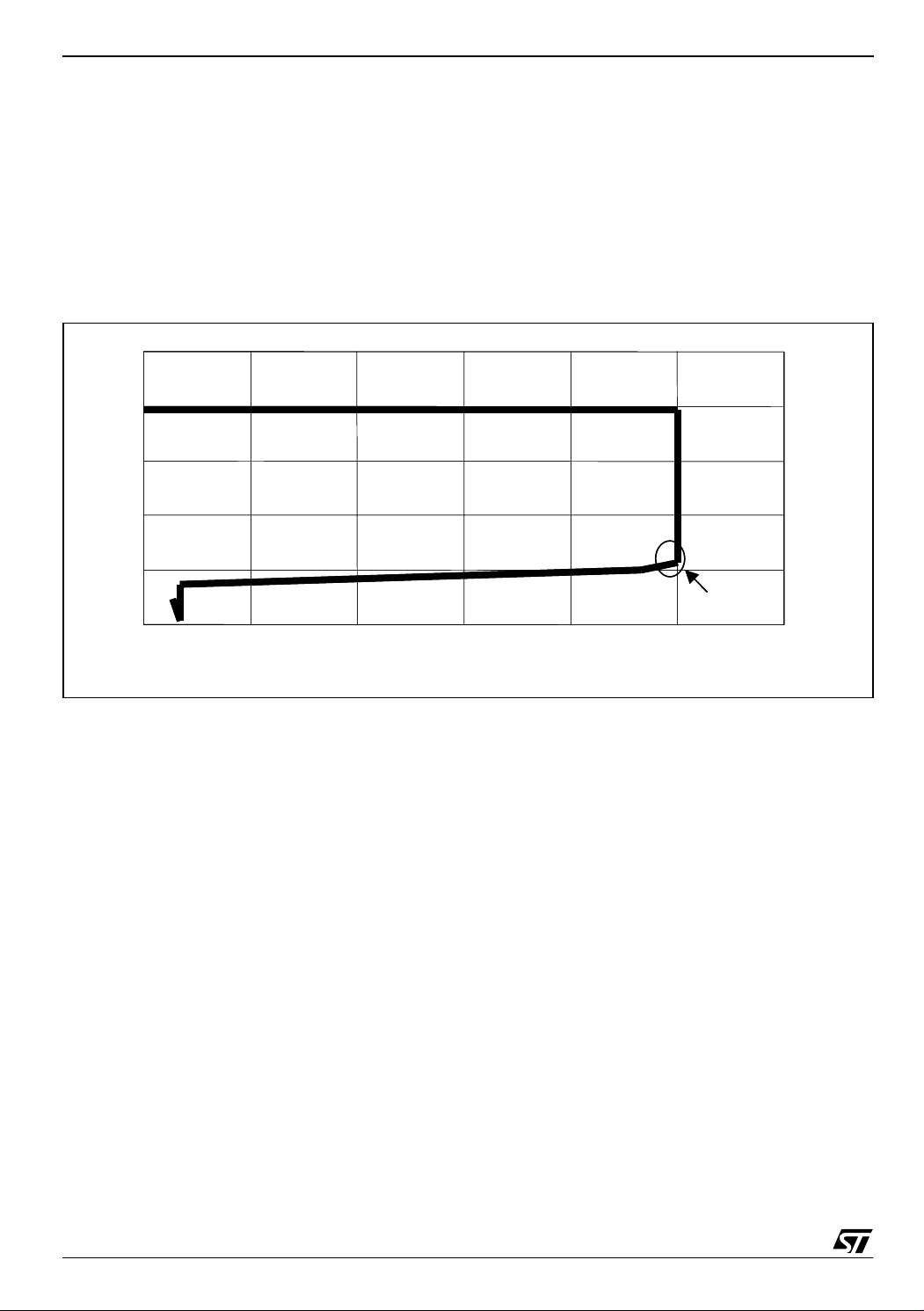

The following table summarizes the parameters for each of the above systems:

System A

“Typical

Configuration”

System B

“Optimized

Configuration”

System C

“Highly-Optimized

Configuration”

Secondary-side IC TSM103 TSM1011 TSM1012

V

ref

R

ref

I

ref

I

cc

I

(standard)

opto

I

= I

tot

V

out

+ Icc+ I

ref

under

opto

no-lo ad condi tion

P

out

P

in

Primaryfunction power

dissipation

2.5V (externally polarized) self-polarizin g self-polarizing

2.5kΩ none none

7mA none none

1.5mA 1mA 0.1mA

1mA 1mA 1mA

9.5mA 2mA 1.1mA

20V 20V 20V

190mW 40mW 22mW

380mW 80mW 44mW

80mW 80mW 80mW

Total Power Consumption

Target consumption window

460mW 160mW 124mW

<500mW <200mW <150mW

Using a low - po we r op t ocoupler:

(low power)

I

opto

I

tot

P

out

P

in

Primaryfunction power

dissipation

Total Power Consumption

Target consumption window

0.5mA 0.5mA 0.5mA

9mA 1.5mA 0.6

180mW 30mW 12mW

360mW 60mW 24mW

80mW 80mW 80mW

440mW 140mW 104mW

<500mW <150mW ~100mW

We can see from the above comparison that by using the TSM1012 and a low-consumption optocoupler,

an economy of nearly 80% in power consumption can be obtained relative to the “typical” CC-CV

secondary side s olutio n. And m ost impo rtant ly, i t is possibl e wi th this advance d syst em to desc end t o only

104mW in no-load conditions.

However, we can also see that only imp roving the optocouple r and retaining a standard secon dary-side

device (such as the TSM103) does not significantly improve the overall power consumption.

5/6

Page 6

AN1818 Conclusions

4 Conclusions

The new family of TSM101x secondary-s ide power management devices from STMi croelectronics for

adapter and battery charger applications open new horizons in total power consumption reductions.

These devices, coupled with innovative application schemes permit access to extremely efficient

solutions.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or oth erwise unde r any patent or patent r i ghts of STMi croelectronics. Spec i fications me ntioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are no t

authoriz ed for use as crit i cal components in life support devices or systems wit hout express written approval of STMicroelectronics.

The ST logo i s a registered trademark of STM i croelect ronics

All other nam es are the prop erty of their re spective owners

© 2004 STMi croelectroni cs - All rights res erved

Australi a - Belgium - Brazil - Canad a - China - Czech Republic - Finl and - France - Germany - Hong Kong - India - Is rael - Italy - Ja pan -

Malaysia - M al ta - Morocco - Singapore - Sp ai n - Sweden - Switzerland - United Kingdom - United S tates of America

STMicroelectronics group of companies

www.st.com

6/6

Loading...

Loading...