Page 1

AN1798

Application note

How to use the STR71x A/D converter

and apply a conversion speed-up technique

Introduction

This application note describes how to use the Sigma-Delta Analog to Digital Converter

(ADC) in the STR71x microcontroller.

It describes the Sigma-Delta ADC calibration and linearization technique and shows how to

apply a conversion speed-up technique to reduce the conversion time.

November 2007 Rev 3 1/16

www.st.com

Page 2

Contents AN1798

Contents

1 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 STR71x ADC features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Clock timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 ADC output, Gain and offset features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Round-Robin and Single channel modes . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Conversion data availability and interrupt generation . . . . . . . . . . . . . . . . . 5

3 Calibration and linearization technique . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Hardware implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 STR71x ADC conversion speed-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Hardware implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2/16

Page 3

AN1798 Principle of operation

1 Principle of operation

Sigma-Delta converters, known also as oversampling converters, sample the input signal

many times for each output sample with a frequency rate much greater than the Nyquist

frequency (twice the input bandwidth). A Sigma-Delta converter consists of two blocks, the

first is the Sigma-Delta modulator which produces the bit stream to the second part which

consists of a digital filter and decimator.

Figure 1. A Sigma-Delta converter block diagram

Integrator

Vin

+

Σ

ADC

N bits of DATA

Digital filter

and Decimator

-

N bits

DAC

N bits

The STR71x ADC is a Sigma-Delta converter which composed of a second-order SigmaDelta modulator followed by a sinc3 digital filter and decimator.

3/16

Page 4

STR71x ADC features AN1798

2 STR71x ADC features

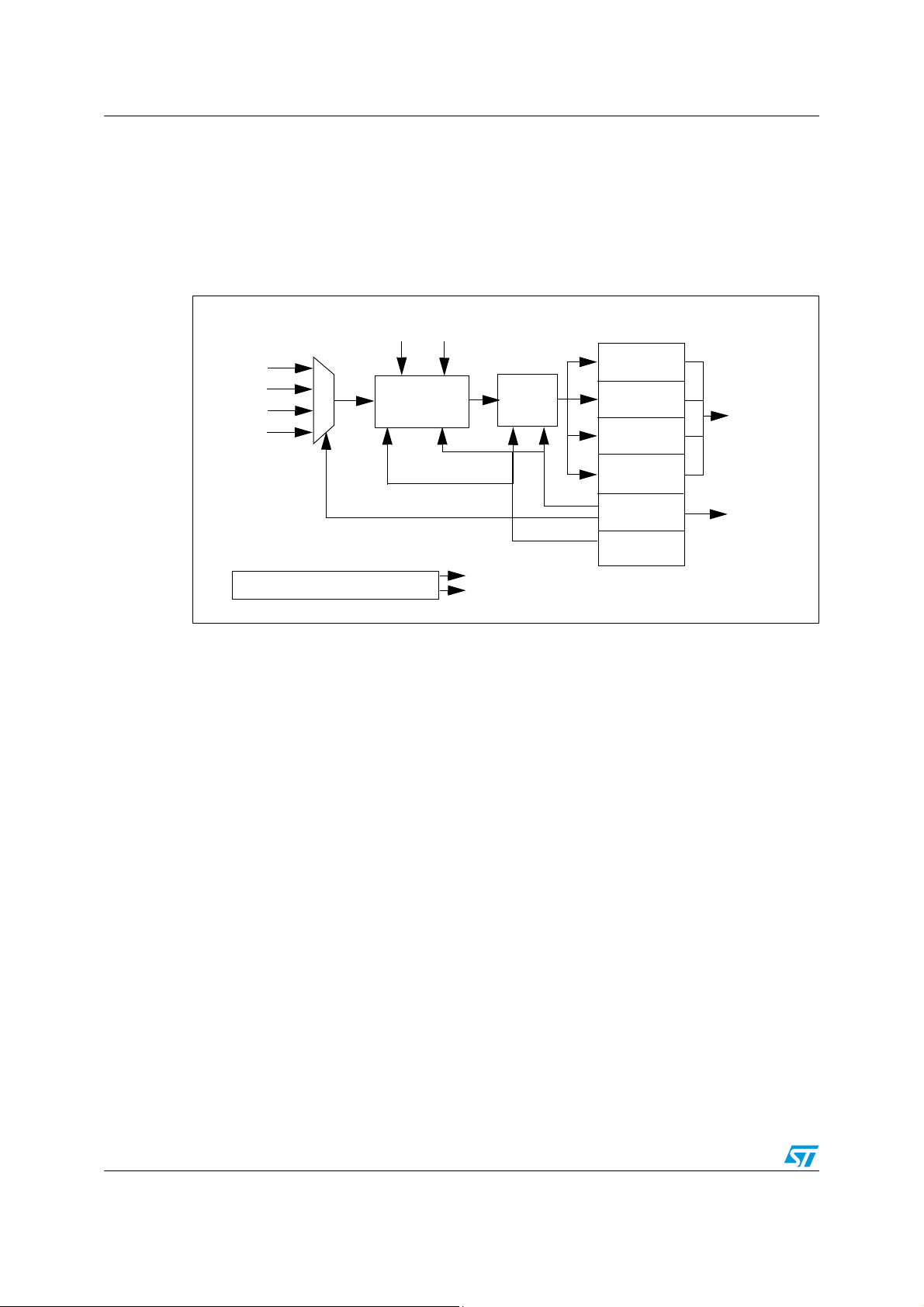

The STR71x ADC consists of four channels (Ip1 to Ip4 or AIN0 to AIN3) to convert signals

with an input range of 0 to 2.5 V into 12-bit format. The following figure shows the ADC

module of STR71x.

Figure 2. ADC STR71x block diagram

Ip1

Ip2

Ip3

Ip4

Bandgap Voltage Reference

2.1 Clock timing

Each channel supports up to 1 kHz for sampling frequency (fs), consequently the signal

frequency can not exceed 500 Hz (to respect the

f

(oversampling frequency) is the clock frequency which clocks the Sigma-Delta

Mod

modulator. This frequency can not exceed 2.1 MHz and therefore the maximum sampling

frequency is equal to 1 kHz (fs = 2.1 MHz / 512 * 4 = 1 kHz).

VCM VRef

Σ∆

Modulator

fs = f

Mod

Sinc3

Filter

VCM

VRef

/ 512 * 4

Registers

Ch0 Data

Ch1 Data

Ch2 Data

Ch3 Data

Control/

Status

Prescaler

Output

Data

Bus

IRQ

Nyquist frequency condition).

f

is generated by PCLK2 and divided down by the prescaler factors configured in the

Mod

ADC_CPR register. The prescaler output frequency must be not greater than 2.1 MHz.

f

= f

Mod

Example: if f

f

= fs * 512 * 4 = 1 kHz * 512 * 4 ~ 2 MHz

Mod

The Prescaling factor = f

= 16 MHz and the desired sampling frequency fs= 1 kHz.

PCLK2

PCLK2

PCLK2

/ f

= 16 MHz / 2 MHz = 8

Mod

This value being twice the prescaler register value: so, the value to be configured in the

ADC_CPR register is equal to 0x4. (see STR71x Reference Manual, ADC section: ADC

prescaler setting table)

4/16

/ Prescaling factor

Page 5

AN1798 STR71x ADC features

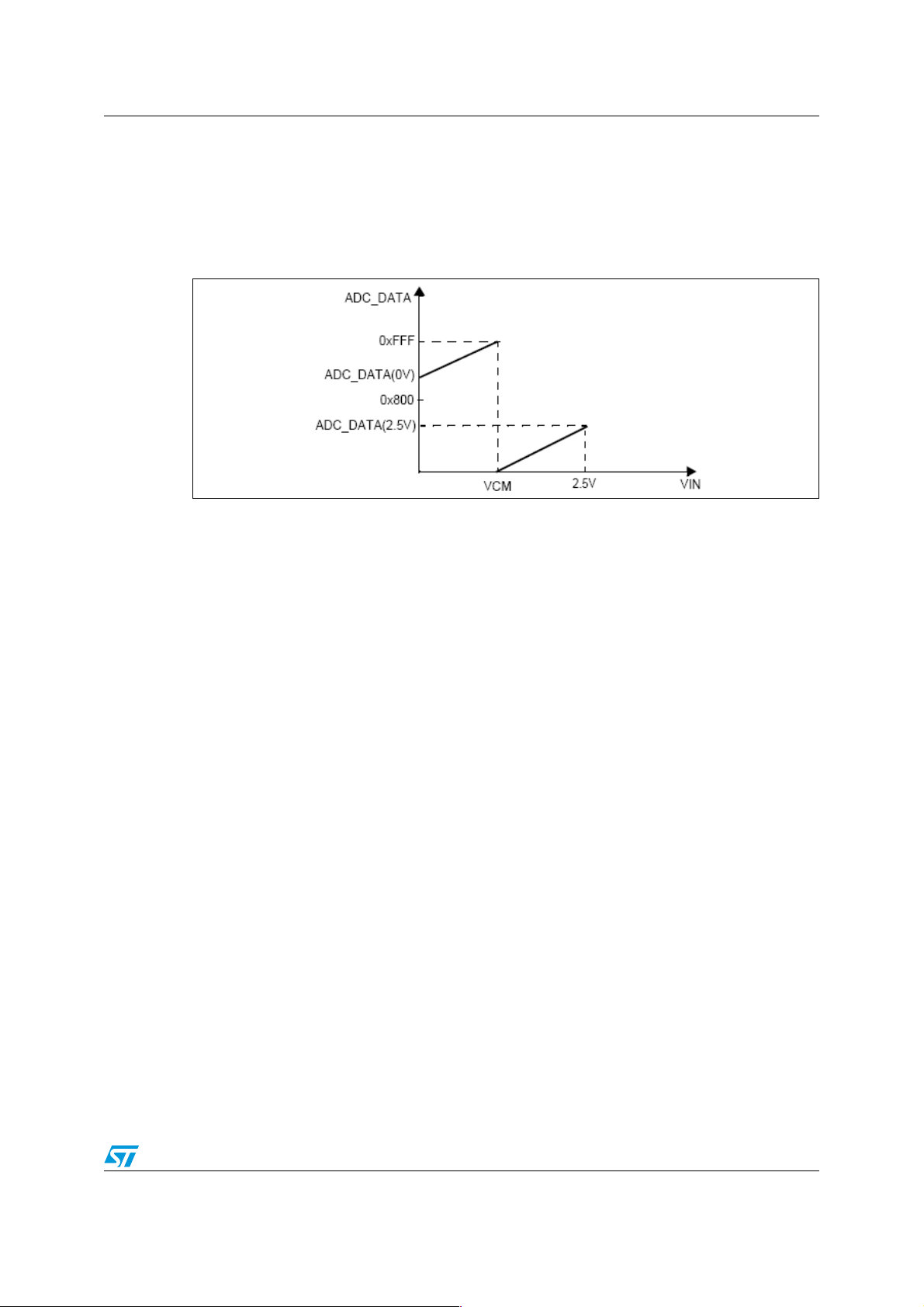

2.2 ADC output, Gain and offset features

The converted values stored in ADC_DATA[n] 16-bit register are signed two’s complement

values and only the 12 most significant bits are used.

The following figure gives the ADC output versus the input voltage.

Figure 3. ADC output

ADC_DATA(0V) and ADC_DATA(2.5V) are the conversion of 0V and 2.5V respectively.

The gain of the ADC is given by:

G = [0xFFF - ADC_DATA(0V) + ADC_DATA(2.5V)] / 2.5

The quantum is calculated by the following equation:

q = 2.5V / [0xFFF - ADC_DATA(0V) + ADC_DATA(2.5V)]

The offset is the digital unsigned value of 0V (ADC_DATA(0V)) and the application should

subtract this offset when reading all the conversion results.

2.3 Round-Robin and Single channel modes

These modes are provided to simplify the use of the ADC.

● Single channel mode selects one channel that is the only channel input to the Sigma-

Delta modulator. To use single channel mode, bit 6 in the ADC_CSR register must be

set to 1. A valid sample in this mode is produced every 2048 modulator clock cycles.

● Round-Robin mode (which is the normal mode) allows you to simplify your software

code and avoid using an endless loop (while (1)) to get the converted values of all

channels continuously. This process is repeated for each of the channels continually in

a round-robin fashion. A valid sample in this mode is produced every 512 modulator

clock cycles for each channel.

2.4 Conversion data availability and interrupt generation

The End of Conversion is indicated by four flags or by interrupt generation. The four flags

are the Data Available flags (DA[n]) in the Control Status register. They allow the application

software to determine which channel data register has a new sample ready to be read. Each

DA[n] flag corresponds to ADC channel n. They are set by hardware as soon as a new

sample on the corresponding channel is available and they are automatically cleared when

the corresponding data register is read.

5/16

Page 6

STR71x ADC features AN1798

The STR71x ADC is able to generate an interrupt at the end of conversion. This interrupt

depends on the conversion mode. In Single Channel mode an interrupt is generated if, in the

CSR register, the interrupt bit and Data Available flag for the selected channel are set. In

Round Robin mode, an interrupt is generated if all interrupt bits and all Data Available flags

in the CSR are set.

6/16

Page 7

AN1798 Calibration and linearization technique

3 Calibration and linearization technique

3.1 Principle

ADC calibration is done by software, it consists of a new calculation of the gain, the quantum

and the offset each time the application is executed.

Initially, the you have to obtain the ADC conversion digital result for 0 V and 2.5 V by

applying two stable voltage external sources (0 V and 2.5 V) to the ADC input in order to

calculate the ADC gain and the quantum.

Next, you need to calculate the average of these two values by reading each value n times

and dividing by n to reach the average values.

After that, calculate the unsigned values of ADC_DATA(2.5V) and ADC_DATA(0V) (these

values are two’s complement).

Then, calculate the ADC range or the sweep of conversion in count / volt:

sweep = Unsigned[ADC_DATA(2.5V)] - Unsigned[ADC_DATA(0V)].

Finally, calculate the gain and the quantum:

G = sweep / 2.5 V

q = 2.5 V / sweep

The principle of linearization is to shift the half-lines ‘A’ and ‘B’ respectively down and up to

obtain one segment: ‘C’. Then, subtract the offset as shown in the following figure.

Figure 4. Linearization

ADC_DATA

0xFFF

ADC_DATA(0V)

0x800

ADC_DATA(2.5V)

Offset

A

C

B

VCM=1.25V

Linearize the segments

2.5 V

then

subtract the

offset

Vin

ADC_DATA

0xFFF

Full scale

0x800

Offset

Offset

Counts off

C

Final segment

VCM=1.25 V

Subtract the offset

2.5 V

Vin

These segments are linearized by software by adding 0x800 if the reading value is positive

(the most significant bit is set to 0). If this value is negative (the most significant bit is set to

1) subtract its two’s complement from 0x800. Then, subtract the offset from this value. The

offset value is equal to Unsigned[ADC_DATA(0V)].

7/16

Page 8

Calibration and linearization technique AN1798

3.2 Hardware implementation

In order to calibrate the ADC, apply two stable voltage sources and read these values to

obtain the dynamic of the ADC.

This can be done by applying the 2.5 V source to one of four ADC channels (for example

AIN1) and connecting the ground to another channel (for example AIN0). Two channels are

reserved for hardware calibration.

It is possible to obtain the 2.5 V source by a zener diode (ex: TS824-2.5) and a dedicated

resistor.

The following figure shows the calibration hardware implementation:

Figure 5. Calibration hardware implementation

3.3 V

AVD D

0.1µF

AGND

STR71x

AIN0

AIN1

I

k

D1(*)

R1

1.6K

3.3 V

two channels for calibration

AIN2

AIN3

two available input channels

(*) D1 ex: TS824-2.5

The resistor value is chosen to have a current I

< 1mA (Reverse break down current).

k

This condition (see TS824-2.5 datasheet) allows to have a V

I

By choosing I

= 500µA < 1mA

k

Afterwards: R1 = (V

= (3.3 - 2.5) / 500 * 10

in

- V

Ref

) / I

k

= (Vin - V

k

-6

Ref

) / R1

= 1.6K

more stable than if Ik >1 mA.

Ref

8/16

Page 9

AN1798 Calibration and linearization technique

3.3 Firmware description

The calibration, the linearization and offset compensation are done by software. As

described in Section 3.1, the ADC conversation range, the gain and the quantum are

computed. Figure 6 shows an example flowchart of the software:

Figure 6. Calibration firmware implementation

Calibration section

Start of calibration

Configure ADC inputs to high

impedance analog inputs

Configure the prescaler

Configure the conversion mode:

Single

Start the conversion

Select ADC Channel 1

Compute the average of the

converted value: 2.5V (ADC_MAX)

Select ADC Channel 0

Compute the average of the

converted value: 0V (ADC_Min)

Compute the unsigned value of

2.5V: Unsigned_MAX

Compute the unsigned value of

0V: Unsigned_Min

Get calibrated conversion results

section

Start of conversion

polling on Channel 3

Select Channel 3

Get the conversion:

Conversion_Result

Compute the unsigned value of

Conversion_Result:

Unsigned_Result

Calibrated_Result_Data =

Unsigned_Result - Unsigned_Min

Calibrated_Result_Volt =

Calibrated_Result_Data * q

Compute the sweep of conversion

sweep = Unsigned_MAX - Unsigned_Min

Compute the quantum q

q = 2.5V/sweep

End of Calibration

Note: The delivered software and

flowcharts are compatible with

the following hardware configuration:

Channel_0 to read the ground value

Channel_1 to read the 2.5 V value

Channel_3 to convert the signal

Please refer to Figure 5.

You can modify the hardware configuration

but then you have to change also

the software to be in line with your hardware.

9/16

Page 10

Calibration and linearization technique AN1798

Figure 7. Compute the unsigned value of a converted value

Begin

Get the converted value from ADC_DATA register

Value > 0?

Yes

No

value=

value+0x800

Return value

End

value=

0x800- [(~value)-1]

Figure 8. Compute the average of the converted value

Begin

i = 0, N: number of times the

channel is converted

i < N?

Yes

value = ADC_value

No

Average = sum/N

sum = sum + value

i++

10/16

Return Average

End

Page 11

AN1798 Calibration and linearization technique

Example of results with this software:

The software determine the averages of the two voltage levels (0 and 2.5 V) which are

applied to Channel 0 and Channel 1 respectively and these results are shown in the

debugger:

ADC_Min: 0x963 (0 V) = 2403 decimal (average value)

ADC_Max: 0x66E (2.5 V) = 1646 decimal (average value)

Then, the software determines their unsigned values:

Unsigned_Min (0 V) = 0x800 - ((~0x963 & 0xFFF) + 1)

= 0x165

= 357 decimal

Unsigned_Max (2.5 V) = 0x800 + 0x66E

= 0xE6E

= 3694 decimal

Then the software determines the sweep of conversion:

Sweep = Unsigned_Max - Unsigned_Min

= 0xE6E - 0x165

= 0xD09

= 3337 decimal

Finally it determines the gain G and the quantum q:

G = 3337 / 2.5 V = 1334.8 Volt

-1

q = 2.5V/3337 = 749 µV

For example a voltage level = 1.60 V is applied to Channel 0, we get:

Conversion_Result = 0x124

Unsigned_Result = 0x800 + 0x124 = 0x924

The calibrated conversion result after subtracting the offset is:

Calibrated_Result_Data = Unsigned_Result - Unsigned_Min

= 0x9C0 - 0x165

= 0x85B

= 2139 decimal

It is possible also to determine the applied voltage value in Channel 0 by multiplying this

result by the quantum:

Calibrated_Result_Volt = 2139 * 749 µV = 1602111µV ~ 1.60 V

Ideally 1.60V converted value is: 1334.8 * 1.60 = 2136

The accuracy of conversion is: 2136 / 2139 = 99.8%

11/16

Page 12

STR71x ADC conversion speed-up AN1798

4 STR71x ADC conversion speed-up

This section gives an example of how to reduce the conversion time of the A/D Converter of

the STR71x microcontroller, when only one input channel needs to be converted. This is

achieved using Round Robin mode instead of Single Channel mode to convert an analog

input signal which must be connected to all four analog input pins of the converter. By

configuring the conversion time to 1ms per channel, the conversion Speed-Up technique

allow conversion time to be reduced down to 250 µs.

4.1 Hardware implementation

In Single Channel mode, a valid sample for the selected channel is produced only every

2048 clock cycles, with the same output frequency as Round Robin mode which samples

the four channels (512 clock cycles for each channel). Consequently, the conversion time for

one analog voltage can be reduced by using Round Robin mode instead of Single Channel

mode.

The four ADC inputs have to be connected to the same analog voltage input in order to use

Round Robin conversion mode. As shown in Figure 9, only one input can be used when this

technique is applied.

Figure 9. Speed-Up hardware implementation

3.3V

0.1µF

AVD D

AGND

STR71x

4.2 Firmware description

To use the procedure described above, the ADC has to be driven in polling mode because in

Round Robin mode, an interrupt is generated only when the four input channels have been

converted and all the Data Available flags in the Control Status Register (CSR) are set. In

polling mode, it is possible to get the conversion result of the channel corresponding to the

DAn flag that has been set without waiting for the end of conversion on all the channels.

AIN0

AIN1

AIN2

AIN3

Analog input

(only one input possible)

Note: you must connect the 4 channels

together.

First, all the STR71x analog pins must be configured as high impedance analog inputs.

Next, the STR71x ADC has to be selected in Round Robin conversion mode. Then, the

prescaler has to be configured. Next, the ADC has to be enabled by setting the ADC_En bit

in the PCU_BOOTCR register. To speed-up the ADC conversion you have to check all the

12/16

Page 13

AN1798 STR71x ADC conversion speed-up

Data Available flags DA[n] and each time a flag is set you have to read the corresponding

data register ADC_DATA[n] to get the last converted value. Thus, after every 512 cycles of

the oversampling clock, a new conversion value becomes available in the ADC_DATA[n]

register, the next new conversion value will be available after 512 cycles in the

ADC_DATA[n+1] register. The converted value to be read after the ADC_DATA4 one will be

ADC_DATA0. The following flowchart shows how to implement this procedure.

Note: To obtain the desired results with this software, you must follow the hardware configuration

shown in Figure 9: connect the four channels together.

13/16

Page 14

STR71x ADC conversion speed-up AN1798

Figure 10. Speed-Up software implementation

Start

GPIO_Config (GPIO1, 0x1, GPIO_HI_AIN_TRI);

Configure all ADC inputs to

High impedance Analog inputs

GPIO_Config (GPIO1, 0x2, GPIO_HI_AIN_TRI);

GPIO_Config (GPIO1, 0x4, GPIO_HI_AIN_TRI);

GPIO_Config (GPIO1, 0x8, GPIO_HI_AIN_TRI);

Initialize the converter

Configure the prescaler

Configure ADC in

Round Robin mode

Start the conversion

No

Any DA[n]=1?

Yes

Get the conversion result

ADC12_Init();

ADC12_PrescalerConfig(1000);

ADC12_ModeConfig (ADC12_ROUND);

ADC12_ConversionStart();

while(1) {

do

{

EOC_Flags = ADC12->CSR ;

}

while ((!ADC12_FlagStatus(ADC12_DA0))&&

(!ADC12_FlagStatus(ADC12_DA1))&&

(!ADC12_FlagStatus(ADC12_DA2))&&

(!ADC12_FlagStatus(ADC12_DA3)));

switch(EOC_Flags & 0x000F)

{

case 1:

Conv_Res = ADC12_ConversionValue(ADC12_CHANNEL0);

break;

case 2:

Conv_Res = ADC12_ConversionValue(ADC12_CHANNEL1);

break;

case 4:

Conv_Res = ADC12_ConversionValue(ADC12_CHANNEL2);

break;

case 8:

Conv_Res = ADC12_ConversionValue(ADC12_CHANNEL3);

break;

}

} /* End while(1) */

14/16

Page 15

AN1798 Revision history

5 Revision history

Table 1. Document revision history

Date Revision Changes

21-Jan-2004 1 Initial release

11-Feb-2007 2 Revised and updated

Added Section 1: Principle of operation

21-Nov-2007 3

Section 2: STR71x ADC features

Section 3: Calibration and linearization technique

Updated Section 4: STR71x ADC conversion speed-up.

15/16

Page 16

AN1798

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

16/16

Loading...

Loading...