Page 1

AN1794

Application note

PractiSPIN evaluation system

configuration and set up guide

Introduction

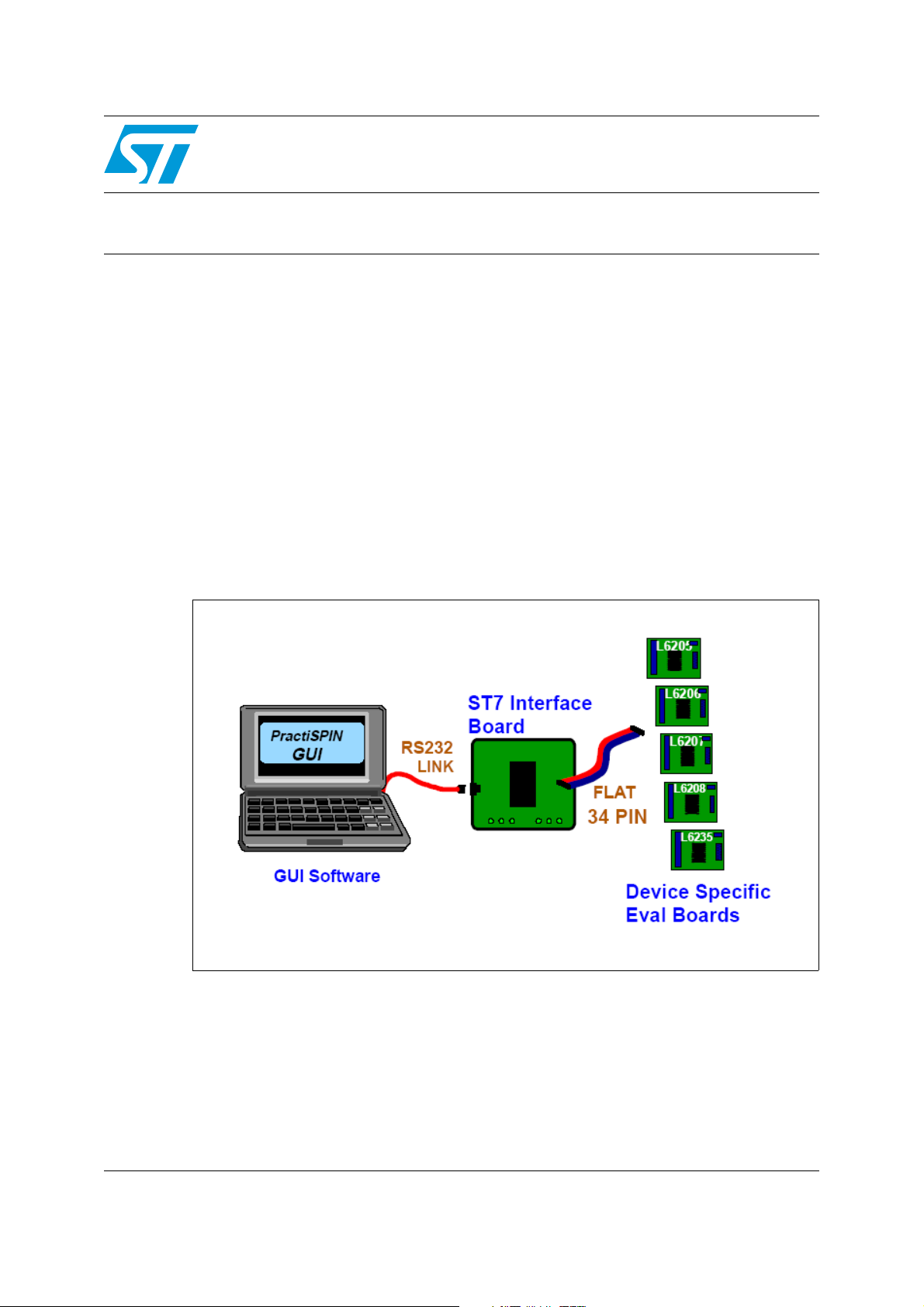

PractiSPIN is an evaluation and demonstration system that can be used with several

STMicroelectronics motor driver integrated circuit devices. The system consists of a

Graphical User Interface (GUI) program which runs on an IBM-PC under windows, a

common ST7 based interface board that communicates with the PC and the practiSPIN

software via a serial COMM port, and a device specific evaluation or target board that

connects to the ST7 interface board via a standard 34 pin ribbon cable interface, as shown

in Figure 1. The target PCB connects to the motor or motors and to a user supplied DC

power supply generally in the range of 12 to 48 Vdc.

The practiSPIN system is designed to operate the device being evaluated (the target device)

under control of the practiSPIN software. Depending on which target device is being used,

the practiSPIN software can operate the device to drive a stepper motor, 1 or 2 DC motors

or a brushless DC (BLDC) motor.

Figure 1. System block diagram

January 2008 Rev 2 1/34

www.st.com

Page 2

Contents AN1794

Contents

1 System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Target board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Control interface board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Starting practiSPIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Stepper motor drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Constant speed mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Indexing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 DC motor drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Dual DC motor control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 BLDC motor drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 BLDC motor control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 EVAL6205N board configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1 Vref offset adjustment (R18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Current scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 EVAL6206N board configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.1 Vref offset adjustment (R18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.2 Current scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 EVAL6206PD board configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1 Vref offset adjustment (R18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 Current scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9 EVAL6207N board configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.1 Vref offset adjustment (R18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.2 Current scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10 EVAL6208N board configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10.1 Vref offset adjustment (R18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/34

Page 3

AN1794 Contents

10.2 Current scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 EVAL6208PD board configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.1 Vref offset adjustment (R18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11.2 Current scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12 EVAL6235 board configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

12.1 Vref offset adjustment (R18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12.2 Current scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3/34

Page 4

List of figures AN1794

List of figures

Figure 1. System block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. ST7 interface board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. EVAL6205N schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 4. EVAL6206 schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 5. EVAL6206PD schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 6. EVAL6207N schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 7. EVAL6208N schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 8. EVAL6208PD schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 9. EVAL6235 schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4/34

Page 5

AN1794 System overview

1 System overview

To illustrate the operation of the practiSPIN system, we will look at one typical device

supported by the system.

The L6207 includes two independent full or H bridges with separate logic inputs and current

control functions.

The two bridges are designated A and B and their output pins designated as OUT1A,

OUT2A, OUT1B, and OUT2B. These outputs are controlled independently by logic inputs

IN1A, IN2A, IN1B, and IN2B respectively.

A logic high or low on any of these inputs will drive its corresponding output to the positive

supply rail or to ground. Both of the A outputs will be forced to an off (high impedance) state

if the ENA pin is taken logic low, as will the B outputs if ENB is taken low. The L6207 is thus

controlled by six logic inputs: IN1A, IN2A, and ENA controlling bridge A and IN1B, IN2B, and

ENB controlling bridge B. Each bridge also has an analog control signal, VREFA and

VREFB, which control the current.

1.1 Target board

The L6207 target board gives access to the bridge A and B outputs at connectors CN3 and

CN4 respectively.

When driving a stepper motor, the two wires from one of the motor windings will connect to

CN3 and the other winding will connect to CN4. Swapping between the two connectors or

swapping the polarity at a given connector will only reverse the sense of motor direction. DC

supply power in the range of 12 to 48 Vdc is connected at CN1. The polarity marked on the

board silkscreen must be strictly observed! The eight control signals are taken from the 34pin ribbon header (CN5) and are driven by the control interface PCB via a short flat cable.

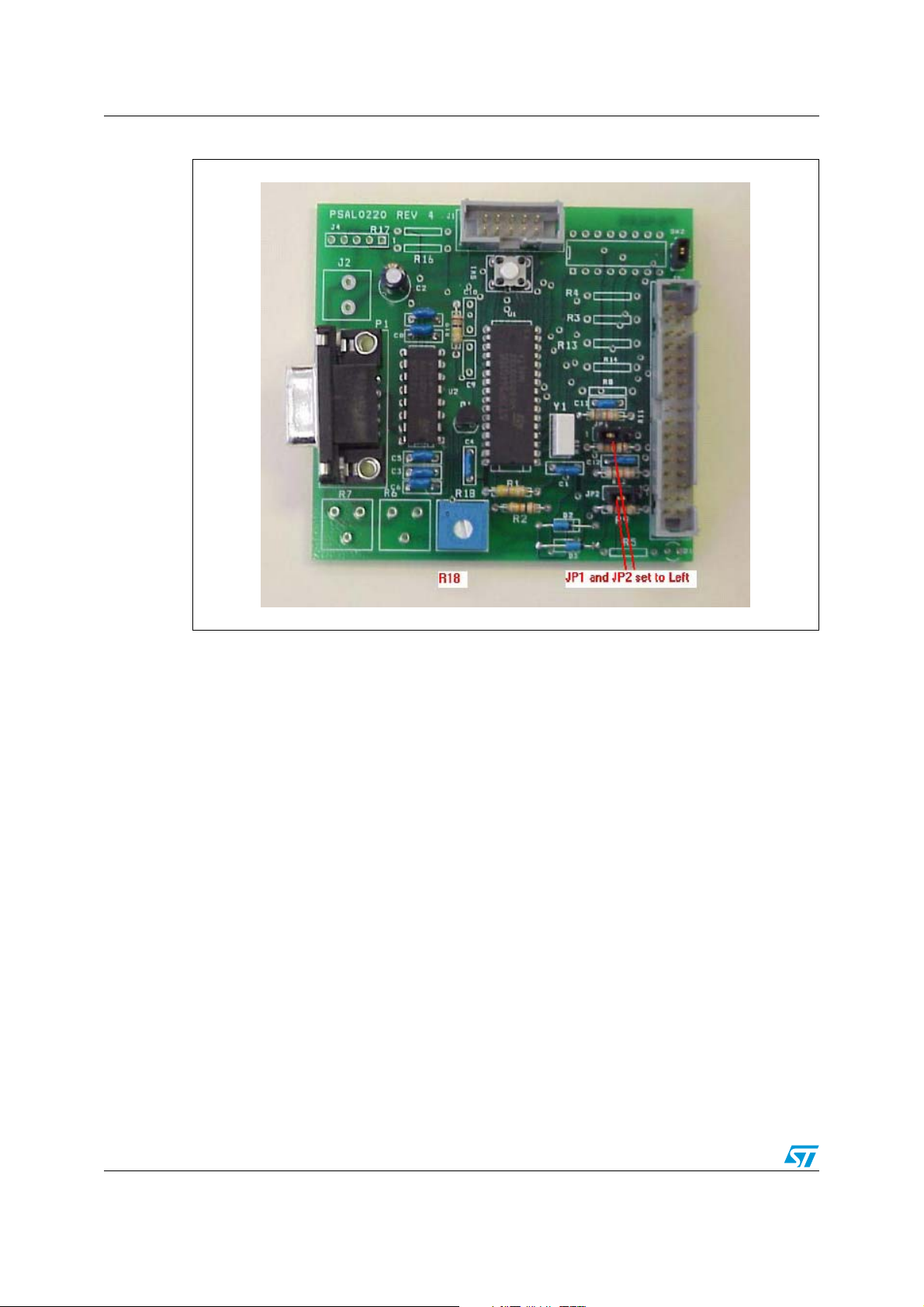

1.2 Control interface board

The control interface PCB is based on an ST72F264 microcontroller. The micro includes a

UART and communicates with the practiSPIN software via 9 pin D connector P1 employing

a standard RS232 interface.

The micro is based on flash memory and its firmware includes a write protected boot-loader

routine that allows the practiSPIN software to update or change the operating program in the

ST7 as required for different target boards. 5 Vdc power for the board is received via the 34pin ribbon cable from the target board or can be directly supplied at J2 if jumper WJ1 is

removed. The eight control signals for the target board are generated by the ST7 micro. The

six logic signals are generated directly by six of the eight pins of port B while the two analog

current references (VREFA and VREFB) are generated by pulse width modulated (PWM)

signals generated by the ST7 along with an offset adjusting circuit controlled by

potentiometer R18.

5/34

Page 6

System overview AN1794

Figure 2. ST7 interface board

6/34

Page 7

AN1794 Starting practiSPIN

2 Starting practiSPIN

Since the practiSPIN system is capable of supporting several driver IC's and driving different

types of motors the user must first select the type of motor to be driven and the driver IC that

will be evaluated.

1. Target board set up: configure the jumpers/switches on the target board and the ST7

interface board as described in the paragraph for the specific evaluation board being

used.

2. Control board - PC connection: connect the ST7 interface board to a serial COMM port

of the PC via a standard (straight through) 9 pin D connector cable.

3. Power up: energize the power supply.

4. Start practiSPIN software: on the PC, start the practiSPIN program.

5. Motor type selection: on the first screen of the practiSPIN software, the user can select

the appropriate type of motor for the device under evaluation. Click on the appropriate

motor type.

6. Communication settings: click the drop down list under "port selection" and select the

COMM port being used. Baud rate and other communication parameters are fixed on

both sides of the link and do not need to be set.

7. Establish COMM link: click the "Connect With ST7 Hardware". At this point the

practiSPIN software will transmit several commands to the ST7 to initialize the

processor. The practiSPIN software will read the revision code of the firmware currently

stored in the flash memory of the ST7 and determine if the correct version of firmware

resides in the ST7. If the practiSPIN software detects that a firmware update is

necessary, either because there is an old version of firmware or the firmware currently

in the flash memory is not the correct firmware for the motor type selected, one or more

dialogue boxes will appear asking if the program should proceed with the update.

Accept the updates and the practiSPIN software will automatically update the firmware.

The system will then initialize the settings to the last stored settings and open the

appropriate practiSPIN software for the selected motor type.

8. Calibrate current setting: when communication is established the user has the option to

adjust the offset and maximum current settings. If this is the first time you use the

system, calibration may be needed to adjust out the offset in the reference bias

circuitry. Calibration ensures that the reference voltage provided to L62XX IC follows

the practiSPIN software current settings. Calibration is a two-step process; first the

offset is adjusted then the maximum current is set.

a) To null out the offset, click on CALIBRATE ZERO then adjust R18 (on ST7 board)

until voltage at Vref pin(s) of the L62XX device is zero. Measurement points on

each board are listed in the set up section for each target board.

b) The maximum current, corresponding to 100% current setting in the practiSPIN

software, can be adjusted using the Vref potentiometers on the target board. If the

potentiometers are set to full scale (clockwise) the reference applied to the input of

the device is typically about 0.88 V. The full-scale peak current is equal to

Vref/Rsense where Rsense is the composite value of the sense resistor on the

board. To set the maximum current, click on CALIBRATE MAX and trim the Vref

potentiometer(s) on the EVAL62XX board to set the desired reference. If you plan

to use microstepping, consider reducing the maximum Vref to the real peak value

you will use, allowing setting the software current controls near to 100%, avoiding

poor Vref resolution.

7/34

Page 8

Stepper motor drive AN1794

3 Stepper motor drive

After the system has established the connection to the interface board, it will initialize the

settings to the last stored settings and open the appropriate GUI for the selected motor type.

For the Stepper motor, the system can operate in either a constant speed or positioning

(indexing) mode. The constant speed mode can easily be used to see that the system is

working.

3.1 Constant speed mode

1. Speed control screen: a large blue button at the bottom of the screen should read,

"switch to INDEXING MODE". If the button reads, "switch to SPEED CONTROL

MODE", click the button once to go to speed control mode.

2. Stepping mode: in the stepping mode box, select either Normal or Half Step.

Microstepping mode is only available when using the L6208.

3. Device selection: in the device selection box, select the device being evaluated.

4. direction: in the direction box, click the toggle switch to pick forward or reverse. This is

somewhat arbitrary since we probably don't know what the direction sense of the motor

will be. Once the motor is running, toggle this switch to reverse the motor direction if

desired. To reverse the meaning of the forward and reverse designations, disable the

motor (orange disable button at bottom of screen) and then swap the motor wires at

either CN3 or CN4.

5. Decay mode: only the L6208 allows the selection of fast or slow decay. Set the toggle

switch to slow decay.

6. Accel rate: set the accel rate to about 1000 steps per second per second (steps/sec2).

In the practiSPIN system all motion parameters are given in terms of the basic units of

steps and seconds: position in steps, velocity in steps/sec, and accel/decel in

steps/sec2. In order to relate these settings to rotations, RPM, and RPM/second it is

necessary to know the number of steps (or half steps) per rotation for the stepper motor

being used. A common value is 200 steps or 400 half steps per rotation.

7. Running speed: set running speed to about 100 steps/sec.

8. Decel rate: set decel. rate to about 1000 steps/sec2.

9. Accel current: set accel current to about 25%. This is an initial guess as to the required

setting and may need further adjustment. Generally higher accel rate settings require

higher accel current settings so that the stepper motor does not start to "slip poles" and

fall behind the desired position. Since we have initially set the acceleration rate setting

quite low, 25% is probably adequate.

10. Running current: set the running current to 25%. In practice the running current can

often be set to a lower value than the accel current since the torque requirement is

generally less during the constant speed part of the move. A lower running current

setting can help to keep the device and the motor running cooler.

11. Decel current: set the decel current to 25%. Since friction aids in decelerating the motor

it may also be possible to set the decel current lower.

12. Holding current: set the holding current to 25%. Whenever the motor is stopped (after a

run,) this level of current will circulate in the motor so that it will hold position against

any mechanical disturbance.

8/34

Page 9

AN1794 Stepper motor drive

In the case of a strong static load (perhaps a gravity load of some sort) it may be necessary

to increase this setting. If not much holding torque is required, then the setting can be

reduced so that operating temperatures can be held to a minimum.

Note: Holding current will be turned off (bridge completely disabled) whenever the disable button

is clicked.

13. Run: make sure that the motor is free to turn in either direction and click the run button.

The motor should quickly come up to speed ((100 steps/sec) / (1000 steps/sec2) = 0.1

sec.). To change the motor direction, click the direction toggle switch. If the motor does

not run click the stop button, increase all four current settings to 50%, and click run

button. If the motor still does not run an oscilloscope and current probe should be used

to observe the motor current.

14. Stop: click stop to stop the motor.

After the basic operation of the system has been verified, the acceleration rates, top speed,

and current settings can be adjusted to see how the motor responds.

3.2 Indexing mode

The system can be switched to operate in the positioning (indexing) mode by clicking on

"switch to INDEXING MODE". In the indexing mode a new box appears on the right of the

screen. You can enter up to twelve indexed movements in the box and the wait time between

each movement. When started, the software will execute each movement by accelerating up

to the peak speed, moving the required number of steps and then decelerating back to a

stop so that the total distance moved is the number of steps indicated, then wait the

indicated time before starting the next movement. A negative number entered in the relative

position will cause the motor to run in the "reverse" direction.

9/34

Page 10

DC motor drive AN1794

4 DC motor drive

After the system has established the connection to the interface board, it will initialize the

settings to the last stored settings and open the appropriate practiSPIN software for the

selected motor type. For DC motor drive, the system operates in an open loop duty cycle

control mode with cycle-by-cycle current limit.

4.1 Dual DC motor control mode

1. Direction: in the direction box for each motor, click the toggle switch to pick forward or

reverse. This is somewhat arbitrary since we probably don't know what the direction

sense of the motor will be. Once the motor is running, toggle this switch to reverse the

motor direction if desired. To reverse the meaning of the forward and reverse

designations, disable the motor (orange disable button at bottom of screen) and then

swap the motor wires at either CN3 or CN4.

2. Braking: toggle the "Brake when Stop" switch to the OFF position for both motors. This

will cause the motor to coast to rest when stopped, with the bridge placed in a high

impedance state. If desired this function can later be toggled on but some care should

be exercised. Braking will effectively short out the motor armature through two

transistors in the bridge, which could cause excessive current and power dissipation if

the motor and load have a large moment of inertia (thus a large amount or stored

mechanical to be dissipated) or the motor has a very low resistance (resulting in a large

current flow). Most smaller DC motors with several ohms of resistance do not pose a

risk.

3. Current: set the current for both motors to approximately 25%. This is an initial guess

as to the required setting and may need further adjustment.

4. Voltage: set the voltage for both motors to approximately 50%.

5. Run: make sure that the motors are free to turn in either direction and click the run

button. the motors should come up to approximately half of the speed that would be

expected at this supply voltage. To change the motor direction, click the direction toggle

switch. If the motors do not run click the STOP button, increase both current settings to

50%, and click RUN button. If the motors still do not run an oscilloscope and current

probe should be used to observe the motor current

6. Stop: click stop to stop the motor.

After the basic operation of the system has been verified, adjust voltage, current, direction

and other parameters to evaluate the system.

10/34

Page 11

AN1794 BLDC motor drive

5 BLDC motor drive

After the system has established the connection to the interface board, it will initialize the

settings to the last stored settings and open the appropriate practiSPIN software for the

selected motor type. For BLDC motor drive, the system operates in an open loop duty cycle

control mode with cycle-by-cycle current limit.

5.1 BLDC motor control mode

1. Direction: in the direction box for each motor, click the toggle switch to pick forward or

reverse. This is somewhat arbitrary since we probably don't know what the direction

sense of the motor will be. Once the motor is running, toggle this switch to reverse the

motor direction if desired.

2. Braking: toggle the "Brake when Stop" switch to the OFF position. This will cause the

motor to coast to rest when stopped, with the bridge placed in a high impedance state.

If desired this function can later be toggled on but some care should be exercised.

Braking will effectively short out the motor armature through three transistors in the

bridge, which could cause excessive current and power dissipation if the motor and

load have a large moment of inertia (thus a large amount or stored mechanical to be

dissipated) or the motor has a very low resistance (resulting in a large current flow).

Most smaller BLDC motors with several ohms of resistance do not pose a risk.

3. Current: set the current to approximately 25%. This is an initial guess as to the required

setting and may need further adjustment.

4. Voltage: set the voltage to approximately 50%.

5. Run: make sure that the motor is free to turn in either direction and click the run button.

The motor should come up to approximately half of the speed that would be expected

at this supply voltage. To change the motor direction, click the direction toggle switch. If

the motor does not run click the stop button, increase the current settings to 50%, and

click run button. If the motor still does not run an oscilloscope and current probe should

be used to observe the motor current.

6. Stop: click stop to stop the motor.

After the basic operation of the system has been verified, adjust voltage, current, direction

and other parameters to evaluate the system.

11/34

Page 12

EVAL6205N board configuration AN1794

6 EVAL6205N board configuration

The schematic of the EVAL6205N board is shown in Figure 3. To use the EVAL6205N board

with practiSPIN system, the following configuration settings must be made on the

EVAL6205N:

1. Component updates: depending on the revision of the board, some or all of the

following changes may be required (or desirable):

a) To assure safe overcurrent operation: change C6 and C7 to 5.6 nF Change R5

and R6 to 100 kΩ.

b) To assure an adequate 5 V supply, R2 may need to be changed. The minimum

value for R2 is (Vs-5)/(0.03+I) Ω . Where: Vs is the supply voltage and I is any

additional load placed on the 5 V supply (in amps).

2. JP1: place JP1 in the INT position to enable the on-board 5 Vdc supply.

3. JP2 and JP3: install JP2 and JP3 to assure proper timing operation of the L6205's

internal high side overcurrent protection.

4. JP4 and JP5: install JP4 and JP5 to configure the Vref circuits.

5. R17 & R21: adjust multi-turn trim potentiometers R17 and R21 fully clockwise.

Note: A slight click can be heard from the pot when it reaches its end of travel.

6. R23 Adjust multi-turn trim pot R23 to the middle of its range. This pot sets the

frequency of the cycle-bycycle current controller and can be fine tuned while observing

the motor current on an oscilloscope or by simply adjusting to raise the frequency of the

audible switching noise to an inaudible level if required.

7. Motor connections: connect the motor coils at CN3 and CN4. When driving a stepper

motor, one winding is connected to CN3 and the second winding is connected to CN4.

For operation with 2 DC motors one motor is connected to each connector.

8. Power supply: connect, but do not energize, a 12 to 48 Vdc power supply at CN1

(positive to V

9. Using a 34 pin ribbon cable connect the EVAL6205N board to the control interface

board. The two boards should be placed on the bench so that their 34 pin headers are

side by side with the ribbon cable going straight across. Set the following on the ST7

interface board.

10. WJ1: install WJ1 on the ST7 based control interface board. This allows 5 Vdc power to

be obtained from the target board.

11. JP1 and JP2 and R18: install the JP1 and JP2 jumpers to short the center and left pins

together as shown in Figure 2. This is critical as excessive motor current can result

from misplacement of these jumpers! Set potentiometer R18 to about 50%.

and negative to GND).

in

12/34

Page 13

AN1794 EVAL6205N board configuration

Figure 3. EVAL6205N schematic

IN2

IN4

LIMIT_A

ENA

1

2

1

CN1

D2

D1

2

CN2

GND

D3

R2

C5

VCCREF

int .

2

JP1

1 3

ext.

+5V

C3

U1

14

17

C4

R1

19

12

C2

C1

15

16

6

5

1

2

CN3

CN4

PullUp

7

18

4

OUT1 B

OUT2 A

OUT1 A

VSB

VSA

VCP

VBOOT

GND

GND

GND

GND

IN1

1

L6205

ENB

ENA

IN2

2

11

20

LIMIT_B

1

2

INT6

INT0

INT2

INT3

246

8

13579111315171921232527293133

ADC_REF

PullUp

13

OUT2 B

SENSEB

SENSEA

IN3

IN4

9

10

TINA0 P2.0

TOUTB0 P2.3

10121416182022242628303234

+5V

8

3

JP3

ENB

IN1

IN3

TOUTA1 P2.6

TINB0 P2.1

TO UTP B1 2.7

TI NA1 P2 .4

TINB1 P2.5

PullUp

CN5

VREF_A

OCMPB1/ICAPB1 P4.3

OCMPA1 P4.2

R16

VREFB

VREFA

JP4

CW

R15

PullUp

R17

R13

PullUp

R12

R11

R10

R9

R8

R7

C6

C7

SENSE_B

SENSE_A

_4

_3

_2

_1

R19

VREF_B

R20

C9

C12

9

U2

Vref2

17

Vref1Sync

GND

163

Vsense2

15

Vsense1

10

EN

4

Out4

11

Out3

12

Out2

13

Out1

14

CW

R21

JP5

C13

Osc_Out

2

R/C

1

In 4

8

In 3

7

L6506D ip

In2

6

In1

5

VCC

18

C11

R23

IN4

IN3

IN2

R22

IN1

PullUp

CW

R6

R4

PullUp

R3

R5

_2

_1

_3

ENB

ENA

JP2

R14

_4

1

2

3

4

LI MIT_ A

LI MIT_ B

R18

C8

SENSE_ A

C10

SENSE_ B

13/34

Page 14

EVAL6205N board configuration AN1794

6.1 Vref offset adjustment (R18)

Using a voltmeter monitor the voltage at jumper JP4 or JP5 the EVAL6205N board with

respect to GND (CN1) when calibrating the offset.

6.2 Current scaling

When potentiometers R17 and R21 are set full clockwise, a 100% current setting on the

practiSPIN software screen corresponds to a Vref of approximately 0.88 Vdc or a peak

motor current of about 2.64 A.

The peak current can be set to a lower value by adjusting R17 and R21. The reference

voltage inputs can be monitored at JP4 and JP5.

14/34

Page 15

AN1794 EVAL6206N board configuration

7 EVAL6206N board configuration

The schematic of the EVAL6206N board is shown in Figure 4. To use the EVAL6206N board

with practiSPIN system, the following configuration settings must be made on the

EVAL6206N:

1. Component updates: depending on the revision of the board, some or all of the

following changes may be required (or desirable):

a) To assure safe overcurrent operation:

– Change C6 and C7 to 5.6 nF

– Change R5 and R6 to 100 kΩ

b) To assure an adequate 5 V supply, R2 may need to be changed. The minimum

value for R2 is (Vs-5)/(0.03+I) Ω . Where: Vs is the supply voltage and I is any

additional load placed on the 5 V supply (in amps).

2. JP1: place JP1 in the INT position to enable the on-board 5 Vdc supply.

3. JP2 and JP3: install JP2 and JP3 to enable the L6206's internal high side overcurrent

protection.

4. JP4 and JP5: install JP4 and JP5 to set internal overcurrent threshold to maximum. If

desired, these jumpers can be left out and the overcurrent levels may be set using

potentiometers R7 and R8.

5. JP6 and JP7: install JP6 and JP7 to configure the Vref circuits.

6. R20 and R26 adjust multi-turn trim pots R20 and R26 fully clockwise.

Note: A slight click can be heard from the pot when it reaches its end of travel.

7. R29: adjust multi-turn trim pot R29 to the middle of its range. This pot sets the chopping

frequency of the L6506 current controller and can be fine tuned while observing the

motor current on an oscilloscope or by simply adjusting to raise the frequency of the

audible switching noise to an inaudible level if required.

8. Motor connections: connect the motor coils at CN3 and CN4. When driving a stepper

motor, one winding is connected to CN3 and the second winding is connected to CN4.

For operation with 2 DC motors one motor is connected to each connector.

9. Power supply: connect, but do not energize, a 12 to 48 Vdc power supply at CN1

(positive to V

10. Using a 34 pin ribbon cable connect the EVAL6205N board to the control interface

board. The two boards should be placed on the bench so that their 34 pin headers are

side by side with the ribbon cable going straight across. Set the following on the ST7

interface board.

11. WJ1: install WJ1 on the ST7 based Control Interface Board. This allows 5 Vdc power to

be obtained from the target board.

12. JP1 and JP2 and R18: install the JP1 and JP2 jumpers to short the center and left pins

together as shown in Figure 2. This is critical as excessive motor current can result

from misplacement of these jumpers! Set potentiometer R18 to about 50% .

and negative to GND).

in

15/34

Page 16

EVAL6206N board configuration AN1794

Figure 4. EVAL6206 schematic

OCDA

ENA

1

2

1

2

CN2

CN1

1

2

CN4

CN3

OCDB

1

2

IN2

ENB

IN4

IN1

IN3

TOUTB0 P2.3

INT6

INT0

INT2

INT3

246

GND

D3

R2

C5

VCCREF

int.

2

JP1

PullUp

1 3

ext.

+5V

C3

5

8

16

U1

L6206

17

20

D2

R1

22

D1

C4

15

C2

19

C1

18

7

6

R4

PullU p

R3

21

OUT1A

OUT1B

OUT2A

VSB

VSA

VCP

VBOOT

GND

GND

GND

GND

IN1

IN2

ENB

ENA

1

2

R5

_2

_1

11

14

23

R6

ENB

ENA

8

10121416182022242628303234

13579111315171921232527293133

ADC_REF

PullUp

PullUp

OUT2B

SENSEB

10

SENSEA

3

PROGCLB

13

PROGCL A

24

OCDB

9

OCDA

4

IN3

IN4

12

1

2

3

4

_3

_4

TINB1 P2.5

TOUTA1 P2.6

TINB0 P2.1

TOUTPB1 2.7

TINA0 P2.0

+5V

R17

CW

CW

JP3

JP2

TINA1 P2.4

CN5

OCMPB1/ICAPB1 P4.3

OCMPA1 P4.2

VREFA

VREFB

PROGCLB

PROGCLA

CW

JP6

R20

R16

PullUp

R14

R13

R12

R11

R10

R9

R8

R7

C7

C6

R15

OCDA

OCDB

VREF_ A

VREF_ B

PullUp

R23

R25

R19

C9

C13

9

U2

L6506Dip

Vref2

Vref1Sync

EN

Out4

Out3

Out2

Out1

C10

Osc_Out

GND

Vsense2

R/C

Vsense1

In4

In3

In2

In1

VCC

18

R24

17

163

SENSE_B

15

10

SENSE_A

4

_4

11

_3

12

_2

13

_1

14

JP5

JP4

C8

R18

PROGCLA

R22

R21

PROGCLB

CW

R26

JP7

C15

2

1

8

7

6

5

C11

C12

SENSE_A

R29

IN4

IN3

IN2

IN1

PullUp

R27

SENSE_B

CW

R28

C14

16/34

Page 17

AN1794 EVAL6206N board configuration

7.1 Vref offset adjustment (R18)

Using a voltmeter monitor the voltage at jumper JP6 or JP7 the EVAL6206N board with

respect to GND (CN1) when calibrating the offset.

7.2 Current scaling

When potentiometers R20 and R26 are set full clockwise, a 100% current setting on the

practiSPIN software screen corresponds to a Vref of approximately 0.88 Vdc or a peak

motor current of about 2.64 A.

The peak current can be set to a lower value by adjusting R17 and R21. The reference

voltage inputs can be monitored at JP6 and JP7.

17/34

Page 18

EVAL6206PD board configuration AN1794

8 EVAL6206PD board configuration

The schematic of the EVAL6206PD board is shown in Figure 5. To use the EVAL6206PD

board with practiSPIN system, the following configuration settings must be made on the

EVAL6206PD:

1. Component updates: depending on the revision of the board, some or all of the

following changes may be required (or desirable):

a) To assure safe overcurrent operation:

– Change C6 and C7 to 5.6 nF

– Change R4 and R5 to 100 kΩ

b) To assure an adequate 5 V supply, R1 may need to be changed. The minimum

value for R1 is (Vs-5)/(0.03+I) Ω . Where: Vs is the supply voltage and I is any

additional load placed on the 5 V supply (in amps).

2. JP1: place JP1 in the INT position to enable the on-board 5 Vdc supply.

3. JP2 and JP3: install JP2 and JP3 to enable the L6206's internal high side overcurrent

protection.

4. JP4 and JP5: install JP4 and JP5 to set internal overcurrent threshold to maximum. If

desired, these jumpers can be left out and the overcurrent levels may be set using

potentiometers R6 and R7.

5. R16 and R22: adjust multi-turn trim pots R16 and R22 fully clockwise.

Note: A slight click can be heard from the pot when it reaches its end of travel.

6. R25 Adjust multi-turn trim pot R25 to the middle of its range. This pot sets the chopping

frequency of the L6506 current controller and can be fine tuned while observing the

motor current on an oscilloscope or by simply adjusting to raise the frequency of the

audible switching noise to an inaudible level if required.

7. Motor connections: connect the motor coils at CN3 and CN4. When driving a stepper

motor, one winding is connected to CN3 and the second winding is connected to CN4.

For operation with 2 DC motors one motor is connected to each connector.

8. Power supply: connect, but do not energize, a 12 to 48 Vdc power supply at CN1

(positive to V

and negative to GND).

in

9. Using a 34 pin ribbon cable connect the EVAL6205N board to the control interface

board. The two boards should be placed on the bench so that their 34 pin headers are

side by side with the ribbon cable going straight across.

Set the following on the ST7 interface board

● WJ1: Install WJ1 on the ST7 based control interface board. This allows 5 Vdc power to

be obtained from the target board.

● JP1 and JP2 and R18: install the JP1 and JP2 jumpers to short the center and left pins

together as shown in Figure 2. This is critical as excessive motor current can result

from misplacement of these jumpers! Set potentiometer R18 to about 50%.

18/34

Page 19

AN1794 EVAL6206PD board configuration

Figure 5. EVAL6206PD schematic

IN2

ENA

OCDB

1

1

2

1

CN1

2

CN2

D2

R1

CN3

2

1

2

CN4

OCDA

INT2

INT6

INT3

INT0

246

8

10121416182022242628303234

13579111315171921232527293133

A0IN6 P7.6

ADC_REF

A1IN6 P8.1

IN3

ENB

IN1

IN4

VREF_A

TINA0 P2.0

TOUTB0 P2.3

TINA1 P 2.4

TINB1 P2.5

TOUTA1 P2.6

TINB0 P2.1

TOUTPB1 2.7

CN5

OCMPA1 P4.2

OCMPB1/ICAPB1 P4.3

R14

VREF_B

R20

PullU p

R19

CW

R22

STMicroelectronics Industrial&Power Supply Application LAB

C5

VCCREF

int.

2

PullUp

1 3

ext.

JP1

+5V

C3

15

2361416

NCNCNCNCNC

VSB

33

VSA

13

D1

C1

4

C4

2

C2

VCPPROGCL B

728

VBOOT

30

GND

19

GND

18

GND

1

GND

36

IN1

10

22532

17

20

2123313435

NC

NC

OUT1B

OUT2B

NCNCNCNCNC

OUT1A

OUT2A

U1

L6206PD

IN2

11

IN3

ENB

ENA

8

26

29

+5V

PullUp

SENSE_A

SENSE_B

VREFA

VREFB

PROGCLB

PROGCLA

CW

PullUp

R12

R16

R26

PullUp

SENSEB

25

SENSEA

12

R11

R10

R9

R8

R7

CW

PROGCL A

R6

9

CW

OCDB

24

C6

OCDA

13

IN4

27

JP3

C7

R13

C9

C13

C14

910

Vref2

Vref1Sync

EN

Out4

Out3

Out2

Out1

NC

11

R18

Osc_Out

2

GNDNC

Vsense2

R/C

1

Vsense1

In4

8

In3

7

In2

6

In1

5

VCC

20

C11

C10

IN4

IN3

IN2

IN1

PullUp

CW

R25

R24

19

183

SENSE_B

17

12

SENSE_A

4

_4

13

_3

14

_2

15

_1

16

U2

JP5

JP4

C8

R15

R17

R4

R3

PullUp

R2

_1

R5

_2

_3

ENB

ENA

JP2

R21

_4

OCDA

OCDB

PROGCLA

PROGCLB

SENSE_A

R23

C12

C15

SENSE_B

19/34

Page 20

EVAL6206PD board configuration AN1794

8.1 Vref offset adjustment (R18)

Using a voltmeter monitor the voltage at the junction of R12 and R16 or the Junction of R20

and R22 on the EVAL626PD board with respect to GND (CN1) when calibrating the offset.

8.2 Current scaling

When potentiometers R16 and R22 are set full clockwise, a 100% current setting on the

practiSPIN software screen corresponds to a Vref of approximately 0.88 Vdc or a peak

motor current of about 4.4 A. The peak current can be set to a lower value by adjusting R16

and R22.

20/34

Page 21

AN1794 EVAL6207N board configuration

9 EVAL6207N board configuration

The schematic of the EVAL6207N board is shown in Figure 6. To use the EVAL6207N board

with practiSPIN system, the following configuration settings must be made on the

EVAL6207N:

1. Component updates: depending on the revision of the board, some or all of the

following changes may be required (or desirable):

a) To assure safe overcurrent operation:

– Change C6 and C7 to 5.6 nF

– Change R3 and R4 to 100 kΩ

b) To assure an adequate 5 V supply, R2 may need to be changed. The minimum

value for R2 is (Vs-5)/(0.03+I) Ω . Where: Vs is the supply voltage and I is any

additional load placed on the 5 V supply (in amps).

2. JP1: place JP1 in the INT position to enable the on-board 5 Vdc supply.

3. JP2 and JP3: install JP2 and JP3 to assure proper timing operation of the L6207's

internal high side overcurrent protection.

4. R15 and R18: adjust multi-turn trim pots R15 and R18 fully clockwise.

Note: A slight click can be heard from the pot when it reaches its end of travel.

5. R6 and R7: adjust multi-turn trim pots R6 and R7 to the middle of their range. These

pots set the off time of the cycle by cycle current controller and can be fine tuned while

observing the motor current on an oscilloscope or by simply adjusting to raise the

frequency of the audible switching noise to an inaudible level if required.

6. motor connections: connect the motor coils at CN3 and CN4. When driving a stepper

motor, one winding is connected to CN3 and the second winding is connected to CN4.

For operation with 2 DC motors one motor is connected to each connector.

7. Power supply: connect, but do not energize, a 12 to 48 Vdc power supply at CN1

(positive to V

8. Using a 34 pin ribbon cable connect the EVAL6207N board to the control interface

Board. The two boards should be placed on the bench so that their 34 pin headers are

side by side with the ribbon cable going straight across. Set the following on the ST7

interface board

9. WJ1: install WJ1 on the ST7 based Control Interface Board. This allows 5 Vdc power to

be obtained from the target board.

10. JP1 and JP2 and R18: install the JP1 and JP2 jumpers to short the center and left pins

together as shown in Figure 2. This is critical as excessive motor current can result

from misplacement of these jumpers! Set potentiometer R18 to about 50%.

and negative to GND).

in

21/34

Page 22

EVAL6207N board configuration AN1794

Figure 6. EVAL6207N schematic

1

1

CN3

1

2

CN 1

R2

VCCRE F

int.

1 3

ext.

+5 V

C3

GND

1

2

CN 2

D3

C5

2

JP1

PullUp

2

2

CN4

ENA

LIMIT_B

LIMIT_A

RC A /INH

INT0

INT2

TINPA O P2.0

TOUTA O P2.2

246

8

10121416182022242628303234

13579111315171921232527293133

CN 5

ADC_R EF

A0IN6 P7.6

A1IN6 P8.1

VCCREF

SENSE_A

SENSE_B

+5 V

TINPB 0 P2.1

IN2

IN3

TOUTB 1 P2.7

ENB

IN4

TOUTA 1 P2.6

OCMPA 0/ICAPA0 P3. 2

OCMPA 1 P 4.2

OCMPB 0 P 3.3

OCMPB 1/ICAPB1 P4. 3

VREFB

VREFA

LIMIT_A

LIMIT_B

IN1

VSB

VSA

VCP

GND

GND

GND

GND

5

VBOOT

IN1A

1

2

IN1

U1

17

20

D2

D1

ENB

C4

R1

C2

C1

ENA

22

15

19

18

7

6

8

OUT2A

L6207

ENA

14

LI MIT _A

LIMITB

R4

16

OUT1B

OUT2B

IN1B

ENB

IN2B

11

12

LI MIT _B

IN3

IN4

JP3

JP2

SENSEB

SENSEB

10

SENSEA

SENSEA

3

RCB

9

RCA/I NH

4

VREF B

13

C9

VREF B

VREF A

24

VREF A

C8

PullUp

R5

C7

C6

R14

R1 3

R12

R1 1

R10

R9

CW

R7

C1 1

C10

R6

CW

R1 6

Pu llUp

R1 8

CW

R1 7

R15

R8

VRE F_A

VRE F_B

RCA/I NH

21

OUT1A

IN2A

23

IN2

LIMITA

R3

22/34

Page 23

AN1794 EVAL6207N board configuration

9.1 Vref offset adjustment (R18)

Using a voltmeter monitor the voltage at the VrefA or VrefB test point on the EVAL6207N

board with respect to GND (CN1) when calibrating the offset.

9.2 Current scaling

When potentiometers R20 and R26 are set full clockwise, a 100% current setting on the

practiSPIN software screen corresponds to a Vref of approximately 0.88 Vdc or a peak

motor current of about 2.64 A.

The peak current can be set to a lower value by adjusting R15 and R18. The reference

voltage inputs can be monitored at the VrefA or VrefB test point.

23/34

Page 24

EVAL6208N board configuration AN1794

10 EVAL6208N board configuration

The schematic of the EVAL6208N board is shown in Figure 7. To use the EVAL6208N board

with practiSPIN system, the following configuration settings must be made on the

EVAL620A:

1. Component updates: depending on the revision of the board, some or all of the

following changes may be required (or desirable):

a) To assure safe overcurrent operation:

– Change C6 to 5.6 nF

– Change R9 to 100 kΩ

b) To assure an adequate 5 V supply, R2 may need to be changed. The minimum

value for R2 is (Vs-5)/(0.03+I) Ω . Where: Vs is the supply voltage and I is any

additional load placed on the 5 V supply (in amps).

2. JP1: place JP1 in the INT position to enable the on-board 5 Vdc supply.

3. Switches place all four of the switches in the right (toward the L6208) position.

4. R20 and R24: adjust multi-turn trim pots R20 and R24 fully clockwise.

Note: A slight click can be heard from the pot when it reaches its end of travel.

5. R11 and R12: adjust multi-turn trim pots R11 and R12 to the middle of their range.

These pots set the off time of the cycle by cycle current controller and can be fine tuned

while observing the motor current on an oscilloscope or by simply adjusting to raise the

frequency of the audible switching noise to an inaudible level if required.

6. Motor connections: connect the motor coils at CN3 and CN4. When driving a stepper

motor, one winding is connected to CN3 and the second winding is connected to CN4.

For operation with 2 DC motors one motor is connected to each connector.

7. Power supply: connect, but do not energize, a 12 to 48 Vdc power supply at CN1

(positive to V

8. Using a 34 pin ribbon cable connect the EVAL6208N board to the control interface

Board. The two boards should be placed on the bench so that their 34 pin headers are

side by side with the ribbon cable going straight across. Set the following on the ST7

interface board.

9. WJ1: install WJ1 on the ST7 based control interface board. This allows 5 Vdc power to

be obtained from the target board.

10. JP1 and JP2 and R18: install the JP1 and JP2 jumpers to short the center and left pins

together as shown in Figure 2. This is critical as excessive motor current can result

from misplacement of these jumpers! Set potentiometer R18 to about 50%.

and negative to GND).

in

24/34

Page 25

AN1794 EVAL6208N board configuration

Figure 7. EVAL6208N schematic

1

2

CN1

D2

R2

int.

JP1

ext.

C3

1

2

CN2

GND

D3

VCCREF

2

PullUp

1 3

+5V

17

20

C4

R1

22

1

2

CN3

5

OUT1A

VSB

VSA

VCP

1

2

CN4

81516

21

OUT1B

OUT2A

OUT2B

DI A G

246

13579111315171921232527293133

CN5

PullUp

SENSEB

SENSEA

RCB

EN

RC A

8

10121416182022242628303234

+5V

U1

10

3

RCB

9

RESET

CW/ CCW

CL OC K

CON TROLC5HAL F /F UL L

CLOC K

VREFB

VREFA

R19

R18

R17

R16

R15

R14

CW

R12

D1

VBOOT

C2

RCA

L6208N

GND

19

GND

C1

EN

9

10

11

12

13

14

15

16

PullUp

8

7

CW

6

5

CCW

SLOW

4

3

FAST

HALF

2

1

FULL

S1

18

GND

7

GND

6

CLOC K

1

R8

R7

R6

R5

R4

PullUp

R3

PullUp

CL OC K

CLOC K

CONT ROL

CW/ CCW

2

CW/ CCW

HALF /FULL

13

CONT ROL

HALF /FULL

VREFB

VREF A

EN

RESET

142312

R9

DIA G

EN

RESET

DIA G

RCA

4

RCA

C8

11

VREF B

24

C7

VREF A

C6

R1 0

PullUp

C10

C9

R11

CW

R21

PullUp

CW

R2 4

CW

R20

R13

VREFA

R22

VREFB

25/34

Page 26

EVAL6208N board configuration AN1794

10.1 Vref offset adjustment (R18)

Using a voltmeter monitor the voltage at the VrefA or VrefB test point on the EVAL6208N

board with respect to GND (CN1) when calibrating the offset.

10.2 Current scaling

When potentiometers R20 and R21 are set full clockwise, a 100% current setting on the

practiSPIN software screen corresponds to a Vref of approximately 0.88 Vdc or a peak

motor current of about 2.64 A.

The peak current can be set to a lower value by adjusting R15 and R18. The reference

voltage inputs can be monitored at the VrefA or VrefB test point

After tube recognition the microcontroller will set the right run frequency for the connected

lamp.

26/34

Page 27

AN1794 EVAL6208PD board configuration

11 EVAL6208PD board configuration

The schematic of the EVAL6208PD board is shown in Figure 8. To use the EVAL6208PD

board with practiSPIN system, the following configuration settings must be made on the

EVAL6208PD:

1. Component updates: depending on the revision of the board, some or all of the

following changes may be required (or desirable):

a) To assure safe overcurrent operation:

– Change C12 to 5.6 nF

– Change R21 to 100 kΩ

b) To assure an adequate 5 V supply, R1 may need to be changed. The minimum

value for R1 is (Vs-5)/(0.03+I) Ω . Where: Vs is the supply voltage and I is any

additional load placed on the 5 V supply (in amps).

2. JP1: place JP1 in the INT position to enable the on-board 5 Vdc supply.

3. Switches: place all four of the switches in the right (toward the L6208) position.

4. R8 and R17: adjust multi-turn trim pots R8 and R17 fully clockwise.

Note: A slight click can be heard from the pot when it reaches its end of travel.

5. R10 and R11: adjust multi-turn trim pots R10 and R11 to the middle of their range.

These pots set the off time of the cycle by cycle current controller and can be fine tuned

while observing the motor current on an oscilloscope or by simply adjusting to raise the

frequency of the audible switching noise to an inaudible level if required.

6. Motor connections: connect the motor coils at CN3 and CN4. When driving a stepper

motor, one winding is connected to CN3 and the second winding is connected to CN4.

For operation with 2 DC motors one motor is connected to each connector.

7. Power supply: connect, but do not energize, a 12 to 48 Vdc power supply at CN1

(positive to V

8. Using a 34 pin ribbon cable connect the EVAL6208PD board to the control interface

board. The two boards should be placed on the bench so that their 34 pin headers are

side by side with the ribbon cable going straight across. Set the following on the ST7

interface board.

9. WJ1: install WJ1 on the ST7 based control interface board. This allows 5 Vdc power to

be obtained from the target board.

10. JP1 and JP2 and R18: install the JP1 and JP2 jumpers to short the center and left pins

together as shown in Figure 2. This is critical as excessive motor current can result

from misplacement of these jumpers! Set potentiometer R18 to about 50%.

and negative to GND).

in

27/34

Page 28

EVAL6208PD board configuration AN1794

Figure 8. EVAL6208PD schematic

1

1

2

CN1

1

2

CN2

1

CN3

2

2

CN4

RCA

DIA G

D2

R1

C5

VCCREF

int.

2

PullUp

JP 1

1 3

ext.

VIN

13

R1 8

2

D1

C1

C2

S1

EN

9

10

11

12

13

14

15

16

Pul lUp

8

7

CW

6

5

CCW

SLOW

4

3

FAST

HALF

2

1

FULL

Pul lUp

PullUp

JUMPER 3x1

+5V

C3

NCNCNCNCNC

VSB

VSA

VCP

VBO OT

GND

GND

GND

GND

CLOCK

10

CL OCK

CL OCK

15

CW/ CCW

11

CW/ CCW

2361416

U1

33

4

7

C4

30

19

18

36

1

GND

R7

R6

R5

R4

R3

R2

22532

17

20

2123313435

NC

NC

L6208PD

27

NCNCNCNCNC

OUT1B

OUT2B

SENSEB

25

SENSEA

12

RCB

24

RCA

13

VREFB

26

VREF B

VREF A

9

EN

HAL F/FUL L

29

R21

EN

HAL F/FUL L

VREF A

RESE T

8

C1 2

Pul lUp

DIAG

RES ET

OUT1A

OUT2A

CONTROL

28

CON T RO L

246

13579111315171921232527293133

CN 5

ADC_R EF

PullUp

SENSEB

SENSEA

R1 1

R10

C9

C6

R1 6

R9

VREF_A

EN

TOUTA 0 P2.2

TINA0 P2.0

TOUTB 0 P2.3

8

10121416182022242628303234

+5V

R1 5

R1 4

R1 3

R1 2

CW

C8

C7

CW

PullUp

R8

CW/ CCW

CONTROL

HAL F/FUL L

CL OCK

RES ET

TOUTB1 P2.7

TOUTA 1 P2.6

TINB1 P2.5

TINA1 P2.4

CON34A

STMicroe lectr onics Industria l &Power S upply Ap plicatio n LAB

OCMPA 1 P 4.2

OCMPB1 /ICAPB1 P4.3

VREFB

VREFA

CLOCK

CW

R2 0

R1 7

CW

R1 9

VREF_B

RC A

28/34

Page 29

AN1794 EVAL6208PD board configuration

11.1 Vref offset adjustment (R18)

Using a voltmeter monitor the voltage at the VrefA or VrefB test point on the EVAL6208PD

board with respect to GND (CN1) when calibrating the offset.

11.2 Current scaling

When potentiometers R8 and R17 are set full clockwise, a 100% current setting on the

practiSPIN software screen corresponds to a Vref of approximately 0.88 Vdc or a peak

motor current of about 4.4 A. The peak current can be set to a lower value by adjusting R15

and R18. The reference voltage inputs can be monitored at the VrefA or VrefB test point.

29/34

Page 30

EVAL6235 board configuration AN1794

12 EVAL6235 board configuration

The schematic of the EVAL6235 board is shown in Figure 9. To use the EVAL6235 board

with practiSPIN system, the following configuration settings must be made on the

EVAL6235:

1. Component updates: depending on the revision of the board, some or all of the

following changes may be required (or desirable):

a) To assure safe overcurrent operation:

– Change C6 and C7 to 5.6 nF

– Change R6 to 100 kΩ and remove R2

b) To assure an adequate 5 V supply, R1 may need to be changed. The minimum

value for R1 is (Vs-5)/(0.03+I) Ω . Where: Vs is the supply voltage and I is any

additional load (such as Hall sensors) placed on the5 V supply (in amps).

2. JP1 and JP2: install JP1 and JP2 to enable the on-board 5 Vdc supply.

3. Switches: place all four switches in the down (away from U2) position.

4. R22: adjust multi-turn trim pot R22 fully clockwise.

Note: A slight click can be heard from the pot when it reaches its end of travel.

5. R10: adjust multi-turn pot R10 to the middle of its range. This pot sets the off time of the

cycle by cycle current controller and can be fine tuned while observing the motor

current on an oscilloscope or by simply adjusting to raise the frequency of the audible

switching noise to an inaudible level if required.

6. Hall sensors: connect the hall sensors of the BLDC motor at CN5. Connect the power

supply wires from the hall sensors at pins GND and P5V. Hall sensors are notorious for

being destroyed by reversed polarity! Know, don't guess, the proper polarity! Connect

H1, H2, and H3 signals to their respective pins.

7. Motor connections: connect the three motor armature wires at CN3 being careful to

match the phasing to the hall sensor connections. Please refer to the L6235 data sheet

for a description of the proper phase relationship between the motor phases and the

Hall sensors.

Note: There are six possible ways to connect the three armature wires to CN3. While only one

connection will give proper performance, one or two of the other possible connection may

cause the motor to turn but with very poor performance and, perhaps, high motor currents

even if the system is unloaded.

8. Power supply: connect, but do not energize, a 12 to 48 Vdc power supply at CN1

(positive to V

9. Using a 34 pin ribbon cable connect the EVAL6208PD board to the control interface

board. The two boards should be placed on the bench so that their 34 pin headers are

side by side with the ribbon cable going straight across. Set the following on the ST7

interface board.

10. WJ1: install WJ1 on the ST7 based control interface board. This allows 5 Vdc power to

be obtained from the target board.

11. JP1 and JP2 and R18: install the JP1 and JP2 jumpers to short the center and left pins

together. This is critical as excessive motor current can result from misplacement of

these jumpers! Set potentiometer R18 to about 50%.

30/34

and negative to GND).

in

Page 31

AN1794 EVAL6235 board configuration

Figure 9. EVAL6235 schematic

H3

BRAKE

FRW/REW

H1

RC/INH

ENABL E

1

2

CN1

R1

JP1

D2

R5

D1

C2

C1

PullUp

S1

FW

9

10

11

12

13

14

15

16

8

R4

7

REV

6

R3

5

BRAKE

EN

4

R2

3

TRQ

2

SPEED

1

CN2

D3

JP2

C5

VCCREF

PullUp

+5V

C3

5

16421

OUT1

OUT3

U1

L6235

VSB

17

VSA

20

C4

VCP

22

15

GND

19

GND

18

GND

7

GND

6

R6

OUT2

L6235

VBO OT

H1

H2

FWR/ RE W

BRAKEH3ENABLE

1

23

1110142412

R8

R7

123

1

2

CN3

DIAG

IN T2

IN T3

P2 .2

246

8

10121416182022242628303234

13579111315171921232527293133

CN4

ADC_R EF

A0IN6 P7.6

VCCREF

+5V

SENSE

SENSE2

SENSE1

3

RCPUL SE

TACHO

RCOFF

VRE F

DI AG

R9

R11

9

8

R10

C8

13

C7

2

PullUp

C6

DIAG

TINA0 P2.0

R14

R13

R12

H2

P2 .6

P2 .1

P2 .4

P2 .5

P2 .7

P3.1

OCMPA 1 P4.2

H1

VREF

C10

+5V

R16

TP

7

U2B

LM358

84

+

5

TP

TP

U2A

LM358

-

6

R21

R19

1

-

2

C12

+5V

8 4

+

3

CW

C9

CW

R18

R15

Pullup

PullUp

C11

R17

R20

VREF

H1

H2

H3

+5V

CW

R22

H2

H3

ENABLE

H1

BRAKE

FRW/REV

CN5

12345

HALL CON

31/34

Page 32

EVAL6235 board configuration AN1794

12.1 Vref offset adjustment (R18)

Using a voltmeter monitor the voltage at the junction of R17 and R20 on the EVAL6235N

board with respect to GND (CN1) when calibrating the offset.

12.2 Current scaling

When potentiometer R22 is set full clockwise, a 100% current setting on the practiSPIN

software screen corresponds to a Vref of approximately 0.88 Vdc or a peak motor current of

about 4.4 A. The peak current can be set to a lower value by adjusting R22. The reference

voltage inputs can be monitored at the junction of R17 and R20.

32/34

Page 33

AN1794 Revision history

13 Revision history

Table 1. Document revision history

Date Revision Changes

21-Jun-2004 1 Initial release

29-Jan-2008 2 Document reformatted. No content change

33/34

Page 34

AN1794

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

34/34

Loading...

Loading...