Conversion Guide, uPSD3200 to uPSD3400 series

1 Introduction

The uPSD family currently consists of three series , uPSD3200, uPSD3300, and uPSD3400.

All three series are available in the same kind of packages (52-pin and 80-pin TQFP), but

there are a few differences in pin definitions. This document describes the differences and

suggests methods to easily migrate designs from the uPSD3200 series to uPSD3400. You

can implement simple techniques on y our printed circuit b oard to accept either a uPSD3200

or a uPSD3400 during manufacturing. Please see Application Note AN1724 for similar

information regarding migrating d esigns from the uPSD3200 series to the uPSD3300 series ,

and see AN1773 for migrating from uPSD3300 to uPSD3400 designs.

Pin differences will be presented two categories:

■ Mandatory pin function changes for all applications, and

■ Conditional pin function changes depending on the application.

AN1787

Application note

There are also differences in SFRs and interrupt vectors, which may impact firmware

depending on the application. These differences are identified to help you migrate your

firmware.

For simplicity, the uPSD3200 series will be referred in this document as 3200, and the

uPSD3400 series will be referred to as 3400.

May 2007 Rev 2 1/27

www.st.com

Contents AN1787

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Summary of differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 MCU Core Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.2 MCU Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.3 PWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.4 ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.5 LVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.6 Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.7 I/O characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.8 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.9 UART and I2C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.10 DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Summary of new uPSD3400 functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 MCU Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.3 MCU core timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.4 MCU core data pointers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.5 SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.6 ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.7 IrDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.8 PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.9 JTAG debug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.10 Debug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.11 MCU clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.12 MCU clock division . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.13 Cross-Bar I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.14 High Current I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.15 5V-tolerant I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Pin definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Mandatory pin changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 52-pin Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 80-pin devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/27

AN1787 Contents

4 PC layout suggestions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Conditional pin changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 PWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 52-pin devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 80-pin devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 PC Layout Suggestion for PWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 ADC, reassigned ADC channel numbers . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.6 ADC voltage scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.7 ADC reference voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.8 LVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Special function register (SFR) differences . . . . . . . . . . . . . . . . . . . . . 22

7 Interrupt vector differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3/27

1.1 Summary of differences

1.1.1 MCU Core Voltage

The 3400 MCU core requires a 3.3V supply, even when used in a 5V system. This means

two separate supplies (5V V

supply (3.3V V

V

supply, which is 5V VCC for 5V devices, or 3.3V VCC for 3.3V devices.

CC

1.1.2 MCU Core

The 3200 MCU requires 12 clocks per instruction but t he 3400 uses just 4 clocks. The 3400

does not have an optional 12-clock operation mode. No modifications are needed to 3200

firmware for standard 8032 functions unless timing was established with software loops.

Modifications ARE required for firmware controlling some peripherals when migrating to

3400.

1.1.3 PWM

The five 8-bit PWM channels of the 32 00 are implemented with the Programmable Counter

Array (PCA) in the 3400, which has six 16-bit timer/counter modules. There are new SFRs,

and some PWM pin number assignments have changed on the 3400.

) is required for a 3.3V system. In contrast, 3200 devices use only a single

CC

and 3.3V VCC) are required in a 5V system, but just one

DD

AN1787

1.1.4 ADC

The four 8-bit ADC channels of the 3200 are imple mented using f our of the eigh t 10-bit ADC

channels on the 3400. There are new SFRs, but there are no ADC input pin number

changes. The ADC reference voltage (V

devices and V

have an ADC V

voltage on any 3400 ADC input or reference is V

is shared internally with the 3.3V VCC core supply . 80-pin 3400 devices do

REF

pin, and its maximum input voltage is V

REF

1.1.5 LVD

Both 5V and 3.3V 3400 devices have Low-Voltage Detect (LVD) trip point set for the 3.3V

V

supply level (2.5V). This must be considered when designing 5V systems.

CC

1.1.6 Watchdog

The watchdog timer is enabled after reset on 3200 devices, but it is disabled after reset on

3400 devices.

1.1.7 I/O characteristics

The 3.3V 3400 devices have 5V tolerant I/O on ports 3, and 4, but ports A,B,C, and D are

not 5V tolerant. The 3.3V 3200 devices do not have any 5V tolerant I/O ports.

1.1.8 USB

) input pin is not available on 52-pin 3400

REF

(3.3V). The maximum input

(3.3V) even in a 5V system.

CC

CC

The 3200 supports low-speed USB 1.1 (1.5Mbps), the 3400 supports full-speed USB 2.0

(12Mbps). The 3400 has all new SFRs for the USB channel. Some USB bus pin numbers

have changed between the 3200 and 3400.

4/27

AN1787

1.1.9 UART and I2C

Minor changes to SFR definitions.

1.1.10 DDC

No DDC interface is on the 3400.

1.2 Summary of new uPSD3400 functions

Listed below are new functions on the 3400 that were no t available on the 3300:

1.2.1 USB

The 3400 supports USB 2.0 Full-Speed (12Mbps) and includes the USB physical interface.

There are a total of 5 pair of endpoints (each pair consists of In and Out ). One endpoint pa ir

is for USB Control transfer types, the remaining four endpoint pairs can be used for any

combination of USB Interrupt or USB Bulk transfer types . Each individual e ndpoint has a 64byte FIFO (10 FIFOs total) to maintain USB data throughput.

1.2.2 MCU Core

The 8032 MCU core of the 3400 operates on 4-clo cks per in struction, with a maximum cloc k

rate of 40MHz, yielding 10 MIPS (Million Instructions Per Second) maximum performance

for single-byte instructions. The 3400 MCU core has a 16-bit internal path from memory to

enhance performance, meaning that double-byte instructions are fetched in a single MCU

cycle, which pushes average performance close to the peak performance. No firmware

changes are required to take advantage of this enhancement. In summary, 3400 has 10

MIPS peak performance, but you can e xpect about 9 MIPS a ver age perf ormance, compared

to 3.3 MIPS peak and 3.0 MIPS average performance from the 3200.

1.2.3 MCU core timing

The 3400 Turbo MCU core has a six-deep instruction prefetch queue and a four-way

branching address cache to increase performance. Code in smaller localities operate very

fast. No special firmware is required to take advantage of the prefetch queue or branching

cache. Be aware that firmware timing loops will not be accurate because of the nondeterministic nature of pipeline and cache architecture. Please use one of the many

hardware timer modules to create timing functions, not firmware loops.

1.2.4 MCU core data pointers

The 3400 Turbo MCU core includes dual data pointers to speed data transfers of XDATA.

The pointers can auto-increment and auto-decrement, providing rapid data movement from

source to destination locations. The 3200 has one only data pointer.

1.2.5 SPI

An SPI bus master interface is provided on the 3400.

5/27

1.2.6 ADC

Eight 10-bit ADC inputs are provided, compared to only four 8-bit ADC inputs on the 3200.

1.2.7 IrDA

The 2nd UART channel supports IrDA protocol, which be connected directly to an IR

transceiver.

1.2.8 PCA

The Programmable Co unter Arra y unit has six 16-bit tim er/counter (TC) modules that can be

used for PWM, Capture/Compare, Timers, or Counters. Three of the six TC modules can

operate from one time base , and the ot her three TC modules can oper ate from another time

base if desired. These six TC modules are in addition to the standard th ree 16-bit time r units

inside the 8032 MCU core, bringing a total of nine 16-bit timer/counters. The 3200 provides

only the three standard 16-bit 8032 timers.

1.2.9 JTAG debug

The JTAG port now functions as a debug port in addition to In-System Programming (ISP).

This eliminates the need for conventional hardware In-Circuit Emulation (ICE) tools.

AN1787

1.2.10 Debug

The 3400 has a dedicated debug input/ output pin. As an output, it ca n signal that a specified

debug ev en t has occurred, as an input it can t rigger a debu g e v ent to begin (e .g., bre akpoint

or trace)

1.2.11 MCU clock

3.3V 3400 devices can be clocked up to 40MHz, unlike 3.3V 3200 with 24MHz maximum.

1.2.12 MCU clock division

The 8032 MCU clock can be divided internally for lower power operation. The MCU may

change the clock divider ratio on-the-fly using SFRs. This affects the MCU only, not

peripheral clocks.

1.2.13 Cross-Bar I/O

Peripheral functions on Port 1 are also av ailab le on P ort 4 (cross-bar s witch), pro viding more

flexibility. There is no need to sacrifice one peripheral function when two functions are

available on a single pin, just use the other port.

1.2.14 High Current I/O

Eight I/O pins on Port 4 are each capable of sinking or sourcing 10mA for both, 3.3V and

5.0V 3400. In contrast, 3.3V 3200 pins ar e cap able of sinking 4mA each, while the 5V 3200

can sink 8mA each.

6/27

AN1787

1.2.15 5V-tolerant I/O

The following pins are 5V tolerant on 3.3V, 52-pin 3400 devices: P1.1 through P1.7, P3.1

through P3.7, P4.1 through P4.7, and RESET_IN_.

On 3.3V, 80-pin 3400 devices, the following pins are also 5V tolerant: MCU_AD0 through

MCU_AD7, RD_, WR_, and _PSEN. In contrast, 3.3V 3200 devices had no 5V tolerant I/O

pins.

Note: PSD functions have NOT changed from the 3200 to 3400. These funct ions include PLD,

memory mapping, memory management (code space vs. data space, and pagin g), Flash

memories, SRAM memory, and PSD I/O. The wider 16-bit internal data path on the 3400

(compared to 8-bit path on 3200) is transparent to the user.

Please note the SRAM on the 3400 can not be configured to reside in code space.

7/27

Pin definitions AN1787

2 Pin definitions

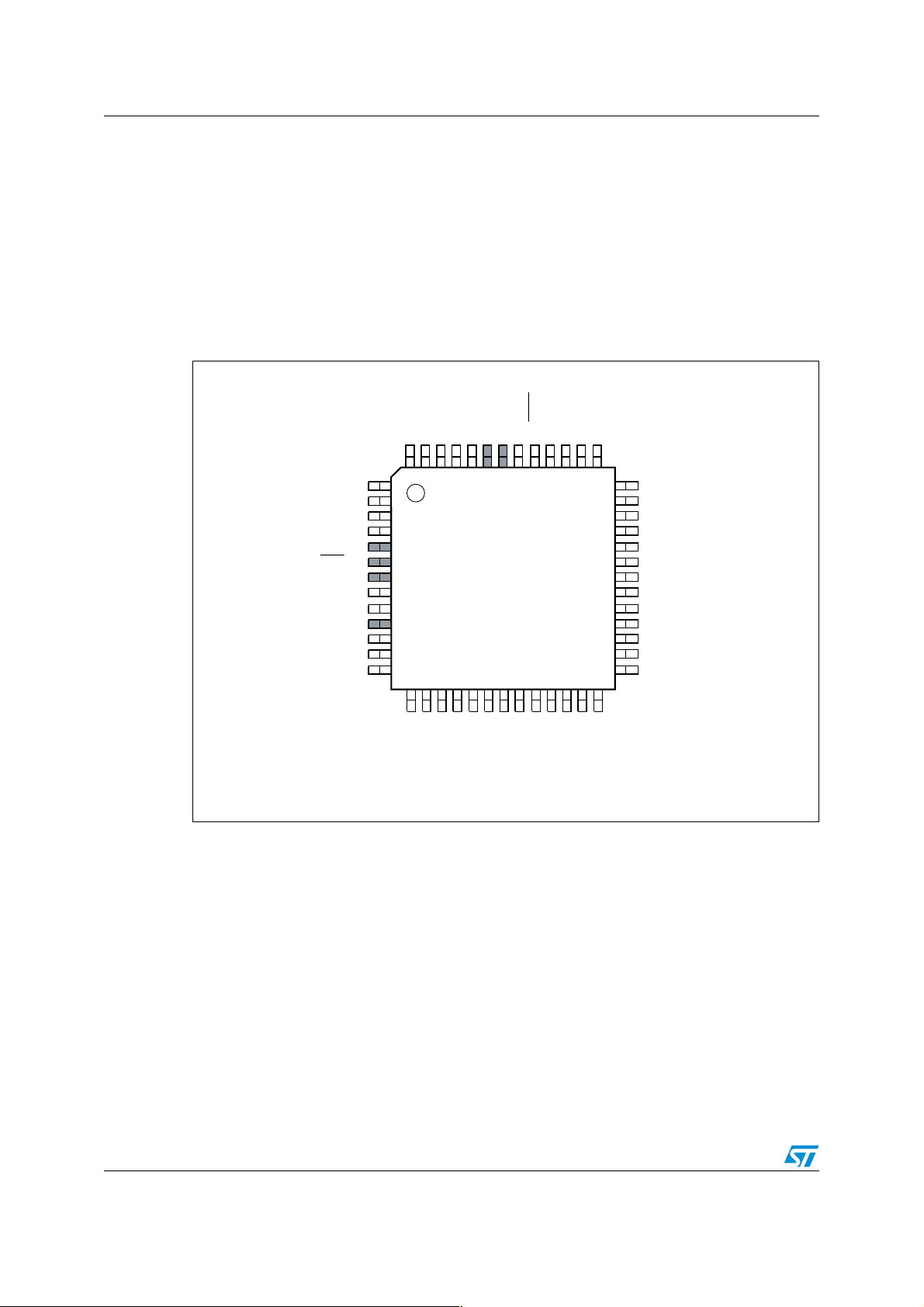

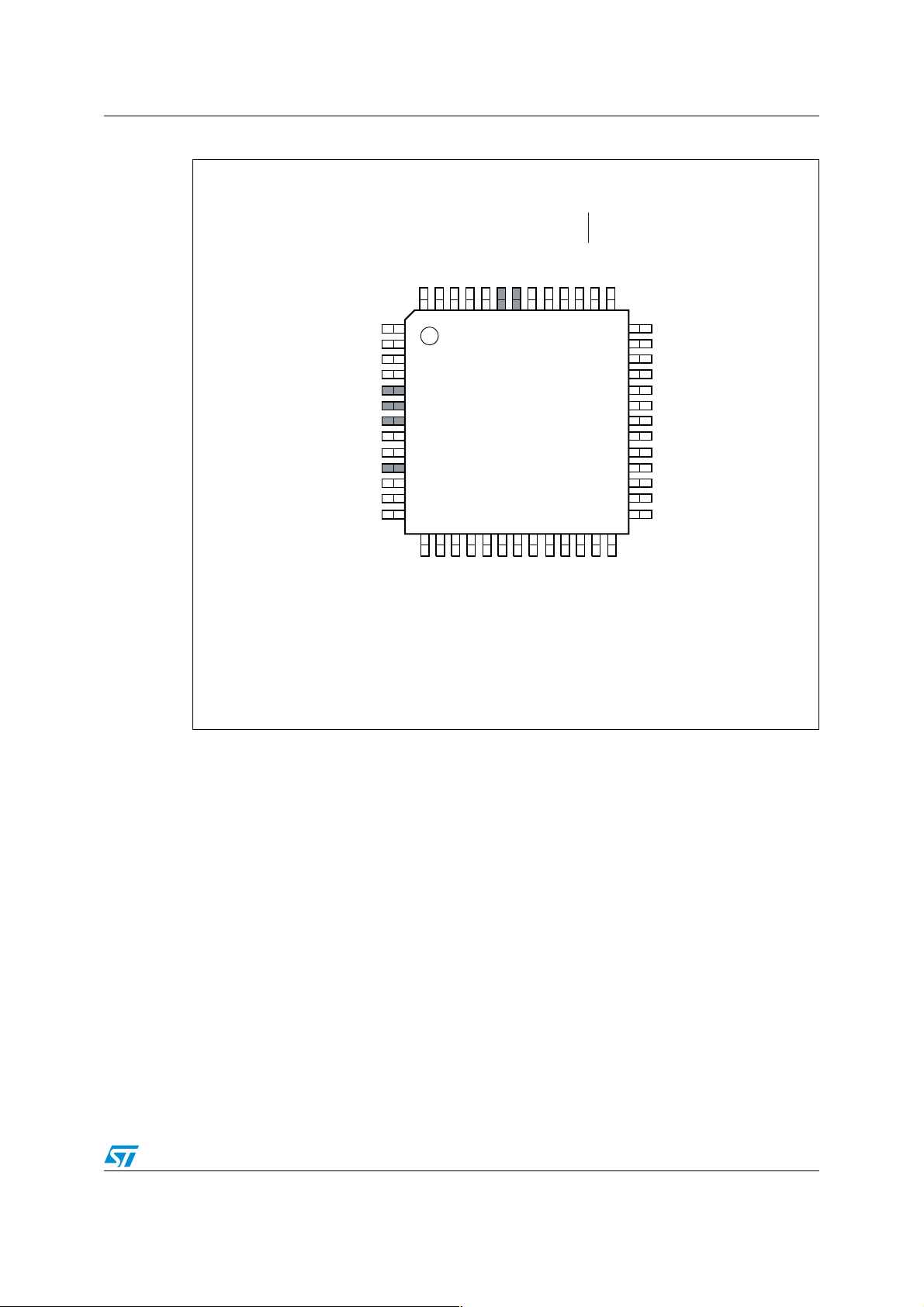

Figure 1 and Figure 2 show pin assignments of the 3200 and 3400 devices in both 52-pin

and 80-pin TQFP packages. Please see the 3200 and 3400 data sheets for detailed pin

function descriptions and physical dimensions of packages. Pins requiring mandatory

changes during migration are darkened in the figur es, this assume s that USB will be used in

both the 3200 and 3400 applications.

Note: 5V 3200 devices support USB while the 3.3V 3200 devices do NOT support USB.

Figure 1. uPSD3200 52-pin TQFP pin definition

REF

GND

RESET

PB6

PB7

P1.7/ADC3

PB0

PB1

PB2

PB3

PB4

PB5

V

52515049484746454443424140

P1.6/ADC2

PD1/CLKIN

PC7

JTAG TDO

JTAG TDI

USB–

PC4/TERR

USB+

V

GND

PC3/TSTAT

PC2/V

STBY

JTAG TCK

JTAG TMS

1

2

3

4

5

6

7

8

CC

9

10

11

12

13

14151617181920212223242526

P4.7/PWM4

P4.6/PWM3

P4.5/PWM2

P4.4/PWM1

uPSD32XX

52-pin TQFP

SYNC

GND

P4.3/PWM0

P4.1/DDC SCL

P4.2/DDC V

P3.1/TXD

P3.0/RXD

P4.0/DDC SDA

P3.2/EXINT0

P3.3/EXINT1

39 P1.5/ADC1

38 P1.4/ADC0

37 P1.3/TXD1

36 P1.2/RXD1

35 P1.1/T2X

34 P1.0/T2

33 V

CC

32 XTAL2

31 XTAL1

30 P3.7/SCL1

29 P3.6/SDA1

28 P3.5/T1

27 P3.4/T0

AI08885

8/27

AN1787 Pin definitions

Figure 2. uPSD3400 52-pin TQFP pin definition

/ADC6

/ADC7

(2)

RESET_IN_

PB6

PB7

(2)

P1.6/SPITXD

P1.7/SPISEL

(3)

REF

/V

CC

PB5

PB0

PB1

PB2

PB3

PB4

AV

GND

52515049484746454443424140

(1)

(2)

2

CSCL

2

CSDA

(2)

/ADC1

/ADC0

(2)

(2)

/ADC5

/ADC4

(2)

(2)

/ADC3

/ADC2

PD1/CLKIN

PC7

JTAG TDO

JTAG TDI

DEBUG

3.3V V

USB+

V

DD

GND

USB–

PC2/V

STBY

JTAG TCK

JTAG TMS

1

2

3

4

5

6

CC

7

(1)

8

uPSD34XX

52-pin TQFP

9

10

11

12

13

39 P1.5/SPIRXD

38 P1.4/SPICLK

37 P1.3/TXD1(IrDA)

36 P1.2/RXD1(IrDA)

35 P1.1/T2X

34 P1.0/T2

33 V

DD

32 XTAL2

31 XTAL1

30 P3.7/I

29 P3.6/I

28 P3.5/C1

27 P3.4/C0

14151617181920212223242526

GND

/TCM5/P4.6

/TCM4/P4.5

/TCM3/P4.4

(2)

(2)

(2)

/PCACLK1/P4.7

(2)

SPICLK

SPITXD

SPIRXD

SPISEL_

1. For 5V applications, VDD must be connected to 5.0V source. For 3.3V applications, VDD must be

connected to a 3.3V source.

/TCM2/P4.2

/TCM1/P4.1

(2)

(2)

/PCACLK0/P4.3

(2)

T2X

RXD1(IrDA)

TXD1(IrDA)

/TCM0/P4.0

(2)

T2

EXTINT0/TG0/P3.2

EXTINT1/TG1/P3.3

AI08887

TXD0/P3.1

RXD0/P3.0

2. These signals can be used on one of two different ports (Port 1 or Port 4) for flexibility. Default is Port 1.

3. V

and 3.3V AVCC are shared. ADC channels must use 3.3V as V

REF

for 52-pin package.

REF

9/27

Pin definitions AN1787

Figure 3. uPSD3200 80-pin TQFP pin definition

PD2

P3.3/EXINT

PD1

ALE

PC7

JTAG TDO

JTAG TDI

USB–

PC4/TERR

USB+

NC

V

GND

PC3/TSTAT

PC2/V

STBY

JTAG TCK

NC

P4.7/PWM4

P4.6/PWM3

JTAG TMS

PB0

P3.2/EXINT0

PB1

P3.1/TXD

PB2

P3.0/RXD

PB3

PB4

80797877767574737271706968676665646362

1

2

3

4

5

6

7

8

9

10

11

12

CC

13

14

15

16

17

18

19

20

21222324252627282930313233343536373839

PA7

PA6

PA5

P4.5/PWM2

P4.4/PWM1

PA4

P4.3/PWM0

uPSD32XX

80-pin TQFP

PA3

PB5NCV

SYNC

GND

P4.2/DDC V

REF

GND

RESET

PB6

PA2

PA1

P4.1/DDC SCL

P4.0/DDC SDA

PB7RDP1.7/ADC3

PA0

PSENWRP1.6/ADC2

AD0/P0.0

AD1/P0.1

AD2/P0.2

AD3/P0.3

61

40

P3.4/T0

60 P1.5/ADC1

59 P1.4/ADC0

58 P1.3/TXD1

57 P2.3/A11

56 P1.2/RXD1

55 P2.2/A10

54 P1.1/T2X

53 P2.1/A9

52 P1.0/T2

51 P2.0/A8

50 V

CC

49 XTAL2

48 XTAL1

47 P0.7/AD7

46 P3.7/SCL1

45 P0.6/AD6

44 P3.6/SDA1

43 P0.5/AD5

42 P3.5/T1

41 P0.4/AD4

AI08886

10/27

AN1787 Pin definitions

Figure 4. uPSD3400 80-pin TQFP pin definition

/ADC6

/ADC7

(2)

(2)

CC

PB0

P3.2/EXINT0/TG0

PB1

P3.1/TXD0

PB2

P3.0/RXD0

PB3

80797877767574737271706968676665646362

PB4

AV V

PB5

REF

V

GND

RESET_IN_

PB6

PB7RDP1.7/SPISEL

PSENWRP1.6/SPITXD

61

SPISEL_

SPITXD

P3.3/TG1/EXINT1

PD2

PD1

ALE

PC7

JTAG TDO

JTAG TDI

DEBUG

PC4/TERR

3.3V V

USB+

V

DD

GND

USB–

PC3/TSTAT

PC2/V

STBY

JTAG TCK

(2)

/PCACLK1/P4.7

(2)

/TCM5/P4.6

JTAG TMS

1

2

3

4

5

6

7

8

9

10

CC

11

(1)

12

uPSD34XX

80-pin TQFP

13

14

15

16

17

18

19

20

21222324252627282930313233343536373839

PA5

PA7

PA6

/TCM4/P4.5

(2)

SPIRXD

PA4

/TCM3/P4.4

(2)

/PCACLK0/P4.3

(2)

SPICLK

PA3

GND

/TCM2/P4.2

(2)

PA2

/TCM1/P4.1

(2)

(2)

T2X

PA1

PA0

/TCM0/P4.0

T2

MCU AD0

MCU AD1

MCU AD2

MCU AD3

60 P1.5/SPIRXD

59 P1.4/SPICLK

58 P1.3/TXD1(IrDA)

57 NC

56 P1.2/RXD1(IrDA)

55 NC

54 P1.1/T2X

53 NC

52 P1.0/T2

51 NC

50 V

49 XTAL2

48 XTAL1

47 MCU AD7

46 P3.7/I

45 MCU AD6

44 P3.6/I

43 MCU AD5

42 P3.5/C1

41 MCU AD4

40

P3.4/C0

(2)

/ADC5

(2)

/ADC4

(2)

/ADC3

(2)

/ADC2

(2)

/ADC1

(2)

/ADC0

(1)

DD

2

CSCL

2

CSDA

RXD1(IrDA)

TXD1(IrDA)

AI08888

1. For 5V applications, VDD must be connected to 5.0V source. For 3.3V applications, VDD must be

connected to a 3.3V source.

2. These signals can be used on one of two different ports (Port 1 or Port 4) for flexibility. Default is Port 1.

11/27

Mandatory pin changes AN1787

3 Mandatory pin changes

There are some pin changes (see Table 1 and Table 2) that are absolutely re q uir ed whe n

migrating from the 3200. These changes are a result of the additional voltage source

required by the 3400 MCU core and the reassignment of USB pins , which ar e highlighted as

dark colored pins in Figure 1 though Figure 4. It is assumed that USB was used in the 3200

and will be used in the 3400 design.

Note: 5V 3200 devices support USB while the 3.3V 3200 devices do NOT support USB.

3.1 52-pin Devices

Refer to Figure 1 and Figure 2.

● Pin 5

Pin 5 (USB–) on the 3200 must be pulled up to V

or not. The pull-up resistor value for 3.3V 3200 de vices is 2K Ω; the pull-up value f or 5V

3200 devices is 7.5KΩ.

Pin 5 on the 3400 device functions as a Debug input/output, and does not nee d a pullup to V

● Pins 6 and 10

The functions of pin 6 (PC4/TERR

CC

.

) and pin 10 (PC3/TSTAT) on 3200 devices have

been eliminated on the 52-pin 3400 devices to accommodate some pin function

reassignments. These two signals o n the 320 0 wer e used as general purpose I/O or as

optional JTAG ISP pins that reduce programming time.

Pin 6 on the 3400 is V

and must always be connected to a 3.3V VCC supply.

CC

Pin 10 on the 3400 is USB– and is connected to the USB bus for 3400 applications

(with no pull-up resistor).

● Pin 7

Pin 7 on both the 3200 and the 3400 is the USB+ signal and has not changed.

However, the 3200 supports low-speed USB, while the 3400 supports full-speed USB.

Low-speed USB requires a pull-up resistor on the USB– signal whereas the full-speed

USB requires a pull-up resistor on the USB+ signal for identification purposes. Since

3400 is full-speed, a pull-up resistor (1.5 KΩ) to 3.3V

should be in place on 3400 designs even if USB is not used.

● Pins 46 and 47

The functions of pins 46 and 47 have been swapped. Pin 47 on the 3400 must always

be connected to AV

The ADC V

(voltage reference) input was on pin 46 for the 3200, but is now on pin

REF

CC/VREF

.

47 for the 3400.

● V

CC

and V

DD

In a 3.3V system using a 3.3V 3400 device, pins 6, 8, 33, 47 must be connected to a

3.3V V

source.

CC

In a 5V system, using a 5V 3400 device, pins 6 and 47 should be connected to a 3.3V

V

source, and pins 8 and 33 should be connected to a 5.0V VDD source.

CC

● Pin 47 is dedicated to A/D Converter on the 3400 devices

, regardless of whether USB is used

CC

is required. This pull-up resistor

CC

12/27

AN1787 Mandatory pin changes

Table 1. 52-pin device changes

Pin 5 Pin 6 Pin 7 Pin 10 Pin 46 Pin 47

3200

3400 DEBUG 3.3V V

USB– (pull-

up)

PC4/TERR USB+ PC3/TSTAT ADC V

3.2 80-pin devices

Refer to Figure 3 and Figure 4. Table 2 summarizes the mandatory pin changes for 80-pin

devices.

● Pins 8

Pin 8 (USB–) on the 3200 must be pulled up to V

or not. The pull-up resistor value for 3.3V 3200 devices is 2KΩ, the p ull- up value for 5V

3200 devices is 7.5KΩ.

Pin 8 on 3400 devices functions as a Debug input/output, and does not need a pull up

to V

.

CC

● Pin 10

Pin 10 is the USB+ signal on 3200 de vices , b ut on 3400 it m ust alwa ys be con nected to

3.3V V

● Pin 11

Pin 11 on 3200 is not used, but on 3400 devices it is the USB+ signal and must be

pulled up to 3.3V V

● Pin 14

Pin 14 on 3200 is PC3/TSTAT which can be a general purpose I/O signal or an optional

JTAG ISP signal used to reduce programming time. If this signal was used in the 3200

design, you can connect it to pin 15 on the 3400 (not a mandatory signal).

Pin 14 on the 3400 is the USB– signal and is connected to USB bus (with no pull-up

resistor).

● Pins 16 and 17

Pin 16 on the 3200 is JTAG CLK used for ISP. Pin 16 on the 3400 is PC2/V

for general purpose I/O or for the battery input for SRAM backup. You will need to

reroute JTAG CLK to pin 17 on the 3400. JTAG CLK is a mandatory signal.

If PC2/V

PC2/V

● Pins 71 and 72

The functions of pins 71 and 72 have been swapped. Pin 72 on the 3400 must always

be connected to AV

● V

CC

In a 3.3V system using a 3.3V 3400 device, pins 10, 12, 50 must connect to 3.3V VCC

source.

In a 5V system, using a 5V 3400 device, pin 10 should be connected to a 3.3V V

source, and pins 12 and 50 should be connected to a 5. 0V V

● Pin 72 is dedicated to A/D Converter on 3400 devices.

CC

STBY

STBY

and V

.

(with 1.5KΩ) for USB identification purposes.

CC

was used in the 3200 design, you can connect it to pin 16 on the 3400.

is not a mandatory signal.

CC/VREF

DD

CC

USB+ (pull-

up)

REF

– PB5 AV

, regardless of whether USB is used

CC

CC/VREF

STBY

PB5

used

.

source.

DD

CC

13/27

PC layout suggestions AN1787

● Pin 51, 53, 55 and 57 are No Connect on 3400 devices. Address A8-A11 can be

brought out on PLD pins.

Table 2. 80-pin device changes

Pin 51,

Pin 8 Pin 10 Pin 11 Pin 14 Pin 16 Pin 17

53, 55, 57Pin 71 Pin 72

3200

USB–

(pull-up)

3400 DEBUG

USB+

3.3V

V

CC

No

Connect

USB+

(pull-up)

4 PC layout suggestions

You can plan your printed circuit board layout in anticipation of migrating from the 3200 to

the 3400 by using simple and low cost techniques. One method involves the use of zeroohm resistors (either surface mount or thru-hole) and multiple circuit traces on the printed

circuit board. The idea is to install or not install these zero-ohm resistors at the time of board

manufacture, depending on which uPSD is installed.

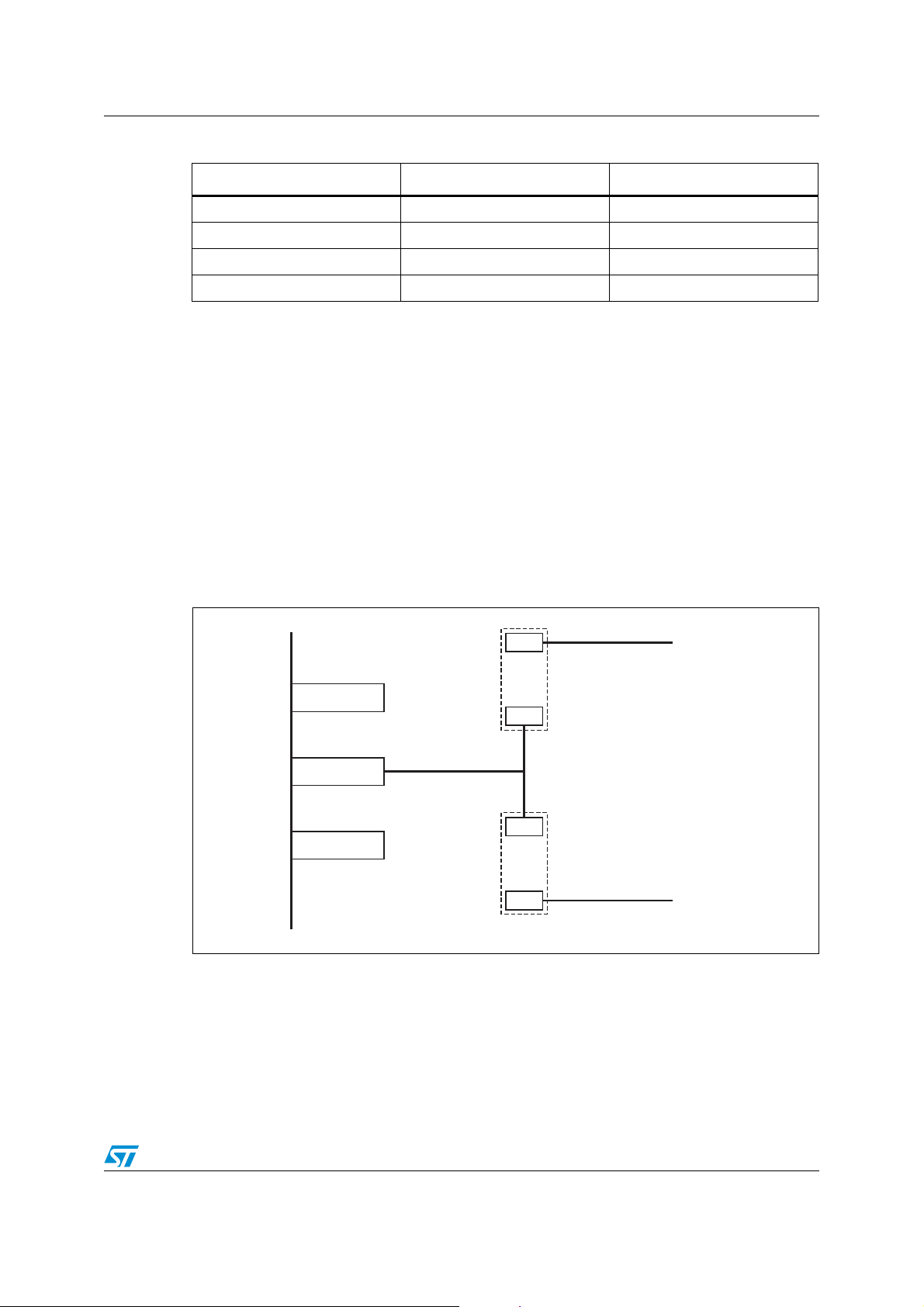

For ex ample, Figure 5 shows how you can use this method to handle the swapped functions

of pins 46 and 47 on the 52-pin uPSD. In this example, resistors are installed at some

locations, and no resistors are installed at other locations as specified in Table 3.

A similar method can be used for an 80-pin device, using pins 71 and 72 instead of pins 46

and 47, respectively.

Figure 5. PC layout example for pin swapping

PC3/

TSTAT

USB–

JTAG

TCK

PC2/V

TBY

S

No

Connect

JTAG

TCK

A8-A11

No

Connect

No

Connect

PB5 AV

PB5

CC

uPSD

(52-pin)

Pin 47

Pin 46

R3

R4

14/27

R1

R2

R5

3.3V V

R6

PB5

V

REF

AI08892

CC

AN1787 PC layout suggestions

Table 3. 52-pin uPSD (0Ω) resistor installation example

R1 R2 R3 R4 R5 R6

3200 0Ω Blank Blank 0Ω Blank 0Ω

3400 Blank 0Ω 0Ω Blank 0Ω Blank

Figure 6 illustrates one way to handle the differing functions of Pins 5 through 10 on the 52-

pin uPSD. For this example, resistors are installed at some locations, and no resistors are

installed at other locations as specified in Table 4.

Note: The Deb ug signal is only for laboratory use and typically will be routed to a test point on the

circuit board.

Figure 6. PC Layout Example for 52-pin Devices

uPSD

(52-pin)

Pin 10

Pin 9

Pin 8

3.3V for 3400,

5.0V for 3200

GND

R3

R4

R1

PC3 / TSTAT

R2

USB–

1.5K

Pin 7

Pin 6

Pin 5

Table 4. 52-pin uPSD Resistor Installation Example (for Pins 5 through 10)

7.5K

R6

USB+

R5

PC4 / TERR

R7

DEBUG

AI08891

R1 R2 R3 R4 R5 R6 R7

3200 0Ω Blank 0Ω 7.5KΩ Blank 0Ω 0Ω

3400 Blank 0Ω 1.5KΩ Blank 0Ω Blank Blank

Figure 7 illustrates one way to handle the differing functions of pins 5 through 17 on the 80-

pin uPSD. For this example, resistors are installed at some locations, and no resistors are

installed at other locations as specified in the following Table 5.

Note: The Debug signal is only for laboratory use and typically will be routed to a test point

on the circuit board.

15/27

PC layout suggestions AN1787

Figure 7. PC layout example for 80-pin devices

uPSD

(80-pin)

Pin 17

R1

JT A G TCK

Pin 16

Pin 15

Pin 14

Pin 13

Pin 12

Pin 11

Pin 10

GND

1.5K

R9

R3

R5

R7

3.3V for 3400,

5.0V for 3200

R10

R8, 7.5K

R2

R4

R6

R11

R12

PC2 / V

STBY

PC3 / TSTAT

USB–

USB+

Pin 9

Pin 8

Table 5. 80-pin uPSD resistor installation example (for pins 5 through 17)

R1 R2 R3 R4 R5 R6 R7 R8 R9 R10 R11 R12 R13

3200 Blank 0Ω Blank

7.5

Blank 0Ω Blank 0Ω Blank Blank Blank 0Ω 0Ω

KΩ

3400 0Ω Blank 0Ω Blank 0Ω Blank 0Ω Blank

16/27

R13

1.5

0Ω 0Ω Blank Blank

KΩ

PC4/TERR

DEBUG

AI08890

AN1787 Conditional pin changes

5 Conditional pin changes

There are some pin changes that may or may not apply to your design, depending on your

application. These changes must be considered when migrating to the 3400 and you have

used the PWM or ADC peripherals of the 3200. There is also a conditional change

regarding the use of the Low-Voltage Detect (LVD) feature in 5V 3400 devices.

5.1 PWM

There are five PWM outputs on th e 3200, and six PWM outputs on the 3400. If y ou have

used any of PWM outputs PWM1, PWM2, or PWM3, on the 3200 then there are no pin

changes when migrating to the 3400. However, if you have used PWM outputs PWM0 or

PWM4 on the 3200, then you will have to connect to different pins on the 3400.

The Programmable Counter Array (PCA) on the 3400 has six Timer/Counter I/O pins,

labeled TCM0 through TCM5, that can be used for PWM outputs, and the PCA also has two

clock input pins labeled PCACLK0 and PCACLK1. These eight PCA pins are all on P ort 4. It

is the two PCA clock input pins of the 3400 that conflict with the PWM0 and PMW4 pin

assignments of the 3200.

5.2 52-pin devices

Refer to Figure 1 and Figure 2.

If you are using up to three of the five PWM outputs on the 3200, do not use output s PMW0

or PWM4. Instead, use outputs PWM1, PWM2, or PWM3 and there will be no pin conflicts

when migrating to the 3400.

If you are using f our or more PWM outputs on th e 3200, then PWM0 on pin 18, o r PWM4 on

pin 14, they will have to be moved to one of the following pins on the 3400: pins 15, 16, 17,

20, 21, or 22.

5.3 80-pin devices

Refer to Figure 3 and Figure 4.

If you are using up to three of the five PWM outputs on the 3200, do not use output s PMW0

or PWM4. instead, use outputs PWM1, PWM2, or PWM3 and there will be no pin conflicts

when migrating to the 3400.

If you are using f our or more PWM outputs on th e 3200, then PWM0 on pin 27, o r PWM4 on

pin 18, they will have to be moved to one of the following pins on the 3400: pins 19, 23, 25,

30, 31, or 33.

17/27

Conditional pin changes AN1787

5.4 PC Layout Suggestion for PWM

Figure 8 is an example of how to move PWM output PWM0 on a 3200 device to the PCA

output TCM2 on a 3400 device (52-pin). When a 3200 is installed, R1 is populated with a

zero-ohm resistor and R2 is blank. When a 3400 is installed, only R2 is popula ted. A similar

method can be used for an 80-pin device using pins 27 and 30 instead of pins 18 and 20,

respectively.

Figure 8. PC layout example to swap PWM outputs

uPSD

(52-pin)

R2

Pin 20

R1

Pin 18

5.5 ADC, reassigned ADC channel numbers

The 3200 has four ADC inputs (8-bit resolution), and the 3400 has eight ADC inputs (10-bit

resolution). The physical ADC input pin numbers have not been changed, but the logical

ADC channel numbers change when migrating from 3200 to 3400. This means no changes

to the PC board are required, but MCU firmware must change to account for different

channel numbers. Firmware changes must occur anyway because there are SFR changes,

identified in the next section. Table 6 refers to 52-pin uPSD devices and Table 7 refers to 80pin uPSD devices.

Table 6. Reassigned ADC Channel Numbers, 52-pin uPSD

Pin Number on 52-pin TQFP 3200 Device 3400 Device

38 ADC Channel 0 ADC Channel 4

39 ADC Channel 1 ADC Channel 5

40 ADC Channel 2 ADC Channel 6

PWM_out

AI08889

41 ADC Channel 3 ADC Channel 7

18/27

AN1787 Conditional pin changes

Table 7. Reassigned ADC Channel Number, 80-pin uPSD

Pin Number on 80-pin TQFP 3200 Device 3400 Device

59 ADC Channel 0 ADC Channel 4

60 ADC Channel 1 ADC Channel 5

61 ADC Channel 2 ADC Channel 6

64 ADC Channel 3 ADC Channel 7

5.6 ADC voltage scaling

For all 3400 devices, both 3.3V and 5V, the maximum input voltage level on any of the eight

ADC inputs is the MCU core voltage, V

are to be sampled in a 5V 3400 system, they must be scaled down t o 3.3V V

for 5V 3200 de vices, if 5V signals are sampled, they do not ha v e to be scaled down because

the maximum ADC input voltage is 5V Vcc (5.5V max).

Figure 9 illustrates one way to scale a 0-5V analog signal down to 0-3.3V when a 3400

device is used. For example, if a 3400 device is installed, resistor R1 is populated with a

332KΩ resistor, and R2 is populated with a 665KΩ resistor. Precision 1% resistors are

recommended. Alternately, if a 3200 is installed, R1 is populated with a zero-ohm resistor

and R2 is left blank because no scaling is needed.

(3.6V maximum). This means that if 5V signals

CC

. In contrast,

CC

Figure 9. Scaling 5V signal for 3.3V ADC Input

uPSD

ADC Input

5.7 ADC reference voltage

The maximum ADC Reference Voltage (V

V

(3.6V max), for both 3.3V and 5V 3400 devices. In contrast, f or 5V 3200 devices the

CC

maximum ADC reference voltage is 5V V

switch the source for V

populated with a zero-ohm resistor and R2 is blank. If a 5V 3400 is installed, only R2 gets

during manufacturing if needed. If a 5V 3200 is installed, R1

REF

ANALOG

INPUT,

0-5V Range

R1

R2

GND

AI08882

) allowed on the 3400 is the MCU core v oltage,

REF

(5.5V max). Figure 10 shows one method to

CC

19/27

Conditional pin changes AN1787

the zero-ohm resistor. This ONLY applies to 80-pin uPSD devices because 52-pin 3400

devices do not have a V

input as discussed in the MANDATORY PIN CHANGE section

REF

and in Figure 5.

Figure 10. Switching sources of V

5.8 LVD

The Low Voltage Detect (LVD) circuitry on all 3400 devices (both 3.3V and 5V) will generate

an internal reset signal whenever the MCU 3.3V V

fine for 3.3V systems using a 3.3V 3400 device. However, for 5V systems using a 5V 3400

device, it is recommended to use an external LVD circuit to drive the RESET_IN_ pin if it is

desired to monitor the 5.0V V

Regarding the 3200, there is no problem with 5V devices because the LVD circuitry has an

internal trip point at 4.0V.

uPSD

(80-pin)

Pin 70

ADC V

REF

in 80-pin uPSD devices

REF

5.0V V

for 3200

R1

R2

3.3V V

for 3300

AI08883

voltage level dips below 2.5V. This is

CC

system supply in addition to the 3.3V VCC supply.

DD

CC

CC

RESET_IN_ is an active-low, open-drain, 5V tolerant input. RESET_IN_ is located at pin 44

on 52-pin devices, or pin 68 on 80-pin devices.

Figure 11 illustrates a scheme that may be used when migr ating from a 5V 3200 de vice to a

5V 3400 device . In this e xample , R1 is populate d with a zero -ohm resistor only when a 3400

is installed, but R1 is left blank when a 3200 is used (supervisor device is optional when

3200 is used). R2 is always populated with a 10K resistor. Since the pin RESET_IN_ is

open-drain, it may be driven by multiple open-drain sources.

Suggestion: If a real-time cloc k (R TC) is needed in the system, choose an R TC that also has

an LVD reset output so you can use it as shown in Figure 11. There are many types of these

devices available from ST at www.st.com/nvram.

Note: An external LVD circuit is not needed for 3.3V 3400 devices in a 3.3V system.

20/27

AN1787 Conditional pin changes

Figure 11. Applying External LVD Circuit to 3400 5V System

uPSD

RESET_IN_

R2

10K

R1

5V

RESET_S_

RESET_J_ from

JTAG connector

RESET_B_ from

Push-button

Supervisor

Device or

discrete

LVD circuit

AI08884

21/27

Special function register (SFR) differences AN1787

6 Special function register (SFR) differences

The are a number of SFRs in the 3200 that ha ve changed compared to t he 3400. Ther e are

also a number of ne w SFRs in the 3400 t o control ne w peripherals a nd f eatures . None of th e

standard 8032 SFRs have changed (those defined in standard Intel 8032 archite cture).

Please see the full 3400 data sheet for a detailed description of new and changed SFRs.

Below is a summary of the differences for those SFRs that have changed functi on or

location (the SFRs with black background in Table 8). Please adjust your firmware for these

changes.

● 87: PCON

New POR Bit to determine source of last reset.

● 91: P3SF1

Used to be P1SF1. P1SF1, but it now has new meaning since it is linked to P4SF1

(please see the full 3400 data sheet).

● 96: ADAT1

Now different because 3400 has a 10-bit ADC, not an 8-bit ADC.

● 97: ACON

New bits to control ADC interrupt.

New bit to access eight ADC channels instead of four channels.

● A7/A8: ICA/IA

New Interrupt Enable bits for Debug, ADC, SPI, and PCA.

● B7/B8: IPA/IP

New Interrupt priority bits f or Debug, ADC, SPI, and PCA.

● D8/D9: SCON1/SBUF1

2nd UART control and data buffer. Same function as 3200, but new SFR address

location in 3400.

● DC: S1CON

STO and STA Bits do not have to be cleared by soft w are as they did in 3200. The 3400

has hardware (silicon) to assist, which improves I

overhead.

● DD: S1STA

More efficient use of INTR and ACK_REP_ Bits for I

● MANY USB SFRS

There are 19 new SFRs related to th e Full-Speed USB interface, all of which start with

the letter “U” and the CCON1 SFR.

2

C performance and reduces softw are

2

C.

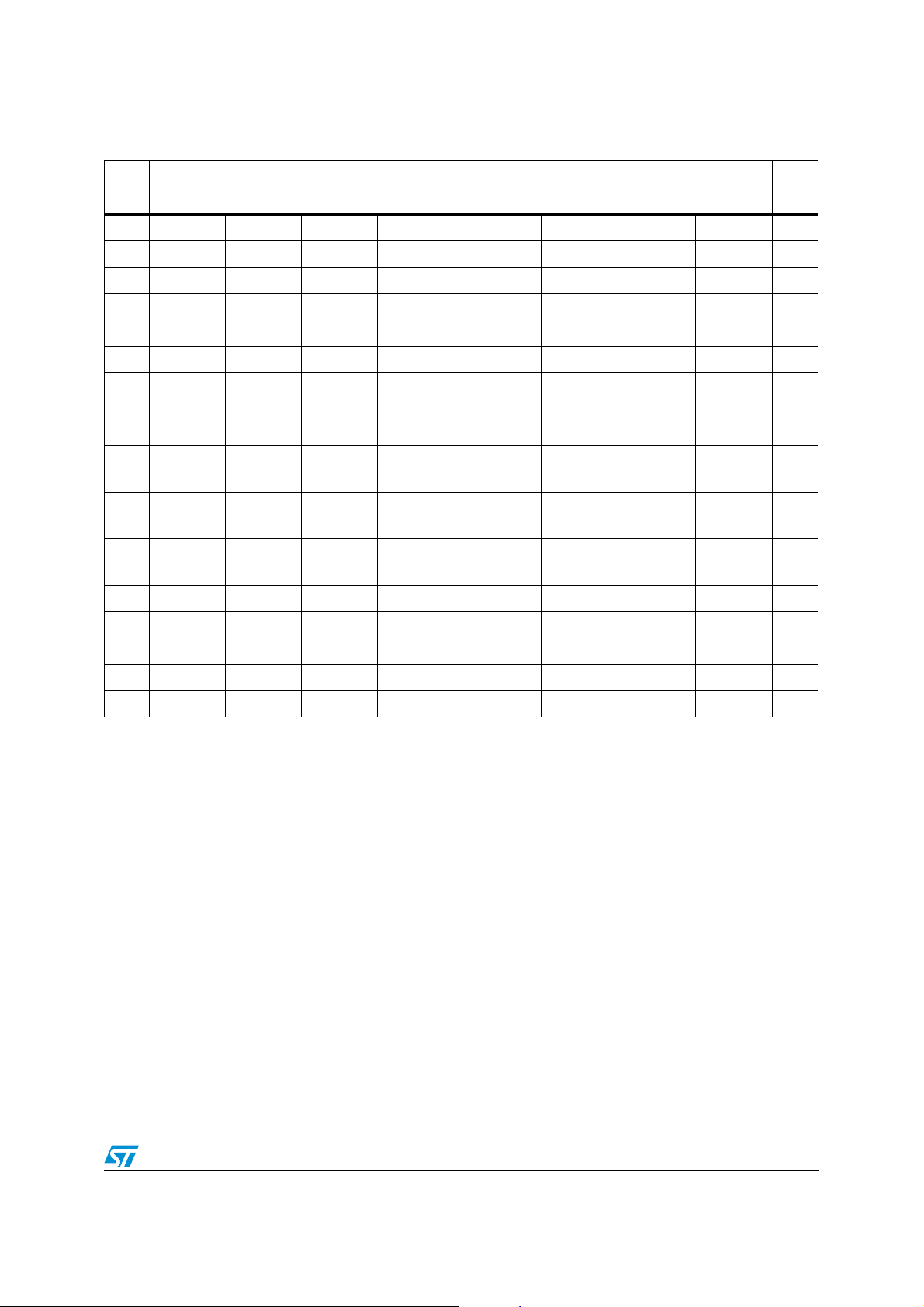

Table 8 shows all the 3400 SFRs. Those with a black background and white letters indicate

3400 SFRs that have changed from the 3200 definition. Those with a gray background and

black letters are new SFRs in the 3400.

22/27

AN1787 Special function register (SFR) differences

Table 8. SFRs in the 3400

SFR

Addr

F8 CCON0 CCON1

(1)

(1)

USIZE

UIF2

F0 B UCON

(1)

E8 UIF0

UIF1

E0 ACC UADDR

D8 SCON1

(2)

SBUF1

(2)

(1)

SFR Register Name

(1)

CCON2 CCON3 FF

(1)

UBASEH

(1)

UPAIR

S1SETUP S1CON

UIF3

(1)

(1)

(1)

UBASEL

UCTL

UIE0

(1)

(1)

(2)

(1)

USCI

USTA

UIE1

S1STA

(1)

(1)

((1)

(1)

USCV

USEL

(1)

UIE2

(2)

S1DAT S1ADR DF

UIE3

(1)

(1)

D0 PSW SPICLKD SPISTAT SPITDR SPIRDR SPICON0 SPICON1 D7

C8 T2CON RCAP2L RCAP2H TL2 TH2 IRDACON DSTAT CF

C0 P4

B8 IP

B0 P3

A8 IE

(2)

(2)

CAP

COML3

CAP

COMH1

TCM

MODE0

A0 P2 PCACL0 PCACH0 PCACON0 PCASTA WDRST IEA

CAP

COMH3

CAP

COML4

CAP

COMH4

PCACL1 PCACH1 PCACON1

CAP

COML2

TCM

MODE1

CAP

COMH2

TCM

MODE2

PWMF0 IPA

CAP

COML0

CAP

COML5

TCM

MODE3

CAP

COMH0

CAP

COMH5

TCM

MODE4

WDTKEY

PWMF1 C7

TCM

MODE5

(2)

CAP

COML1

(2)

98 SCON0 SBUF0 BUSCON DIR DVR 9F

90 P1 P3SFS

(2)

P4SFS0 P4SFS1 ADCPS ADAT0 ADAT1

(2)

ACON

(2)

88 TCON TMOD TL0 TL1 TH0 TH1 P1SFS0 P1SFS1 8F

80 P0 SP DPL DPH DPTC DPTM PCON

1. New SFRs in uPSD3400

2. SFRs changed in uPSD3400

(2)

SFR

Addr

F7

EF

E7

BF

B7

AF

A7

97

87

23/27

Interrupt vector differences AN1787

7 Interrupt vector differences

There are new interrupt vectors for the 3400, an d some interrupt priority levels have

changed. See Table 9 for comparison of interrupt vectors of 3200 and 3400 and their relati ve

priorities. Please adjust your firmware accordingly.

Table 9. interrupt vector tables and priority

Interrupt Source 3400 Priority

JTAG Debug 0 (high) 0063 N/A N/A

External INT0 1 0003 0 0003

Timer 0 2 000B 2 000B

External INT1 3 0013 4 0013

Timer 1 4 001B 6 001B

UART0 5 0023 8 0023

Timer 2 + EXF2 6 002B 9 002B

SPI 7 0053 N/A N/A

USB 8 0033 7 0033

2

C 9 0043 3 0043

I

ADC 10 003B N/A N/A

PCA 11 005B N/A N/A

UART1 12 (low) 004B 1 004B

DDC N/A N/A 5 003B

3400 Vector

Address (hex)

3200 Priority

3200 Vector

Address (hex)

24/27

AN1787 Conclusion

8 Conclusion

The suggestions for methods to easily migrate designs from the uPSD3200 series to

uPSD3400 allow the user to implement firmware and software settings, as well as simple

techniques on the printed circuit board to accept either a uPSD3200 or a uPSD3400 during

manufacturing.

For current information on ST Flash uPSD products, please consult our pages on the world

wide web:

www.st.com/micropsd

For application support:

apps.psd@st.com (please include your name, company, location, telephone number, and

fax number)

25/27

Revision history AN1787

9 Revision history

Table 10. Document revision history

Date Revision Changes

26-Apr-2004 1 First Issue

14 -May-2007 2

Document reformatted.

Updated page 4, 6, 8,10, 11 and 12.

26/27

AN1787

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products a nd services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therei n.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

27/27

Loading...

Loading...