Page 1

AN1772

APPLICATION NOTE

How to Control Power-up/Reset and Monitor the Voltage

in Microprocessor Systems using ST Reset Circuits

CONTENTS

■ INTRODUCTION

■ POWER-UP/ RESET

– Resistor-Capacitor Filter

Circuit

■ MONITORING THE

SUPPLY VOLTAGE

DURING OPERATIONS

– Resistor-Capacitor-Di-

ode Filter Circuit

■ INTEGRATED RESET

CIRCUITS

– Reset Thresholds

– Manual Reset

■ CONCLUSION

■ REFERENCES

■ REVISION HISTORY

This Application Note describes the prob lems with monitoring

the power supply during Power-up/Reset in a microprocessor

system. It also explains how the family of ST family of Reset

Circuits can be used to solve them.

Further information on Reset Circuits can be found in the

STM809, STM810, STM811, STM812 datasheet on

www.st.com.

INTRODUCTION

Today, our microprocessor driven digital world, cannot exist

without the correct power s upply voltage. Every microproces sor needs its pow er suppl y to be within a predef ined range, t o

be able to function properly. A small glitch in the power supply

can cause the system to crash. Incorrect power-up sequences,

slow ramp-up and glitches on the supply lines are common

problems that designers must take into account to minimize the

impact of faults resulting from the power supply.

There are several ways to solve these problems, some of

which are outlined in this document, but they all have certain

limitations and do not completely resolve the problem.

For this reason ST h as developed a new family of l ow-power

supervisory devices, called Reset Circuits, specifically to monitor power supplies. This new family, which includes the

STM809, STM810, STM811 and STM81 2, asserts a reset signal whenever the power supply drops below a preset threshold

value, and keeps it asserted, until the vo ltage rises above that

threshold, for a minimum period of time. The STM811 and

STM812 also provide a push-button reset input signal (MR

).

1/8November 2003

Page 2

AN1772 - APPLICATION N OTE

POWER-UP/ RESET

Power-up is the first thing that must be considered in a new design, as every system requires a time interval for internal initialization after the power supply has stabilized.

During the power-up sequence, microprocessors and other complex digital devices, wait for the clock signal to stabilize and load the interna l registers and boot -code required for the microprocessor to funct ion

properly. For this reason, they always require a predefined time for power-up/reset. If the reset time is not

long enough, the system may not function properly.

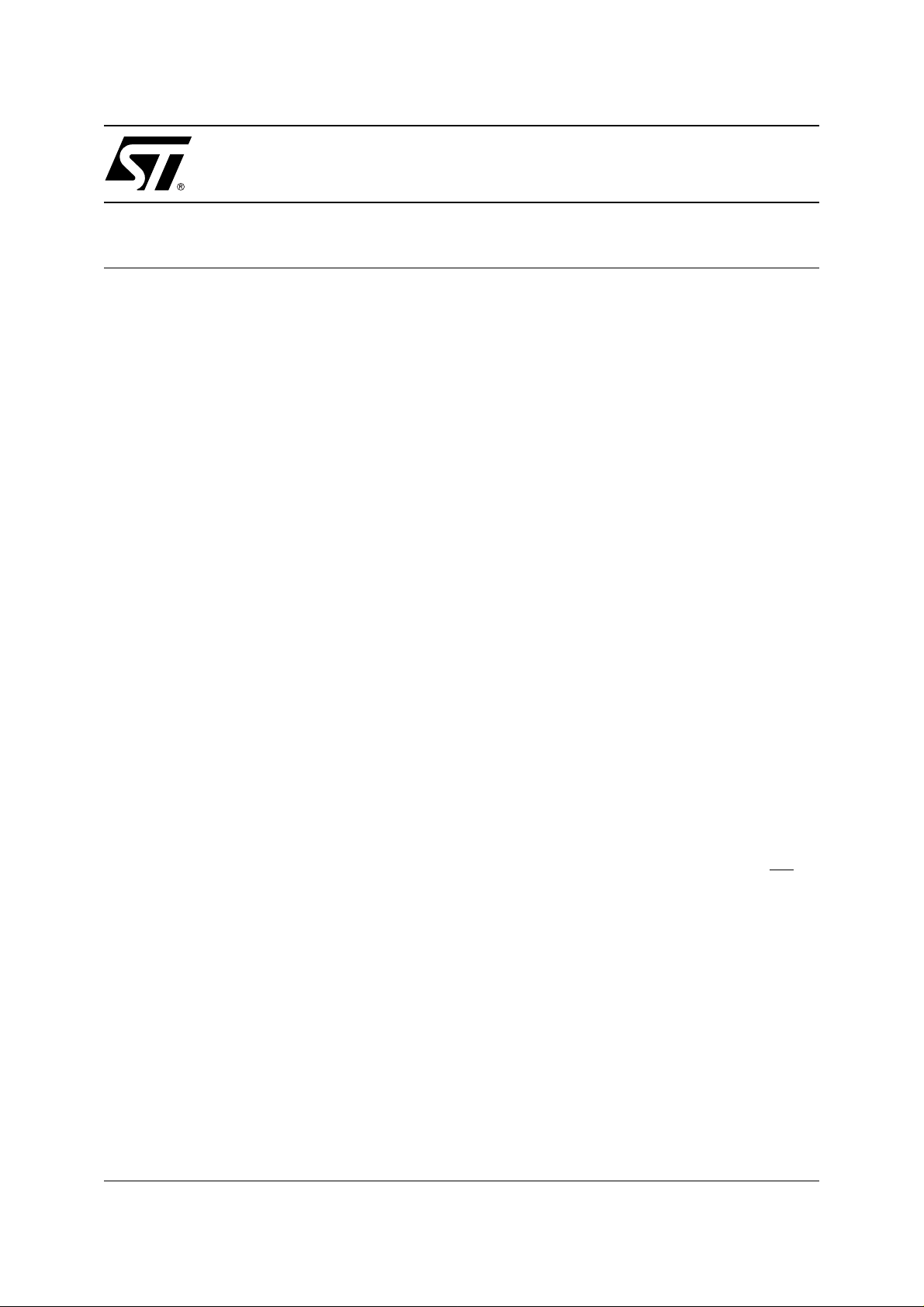

Resistor-Capacitor Filter Circuit

One possible approach to delay the reset signal after power-up, is to use a Resistor-Capacitor (RC) lowpass filter at the microprocessor reset (RST

to work in all circumstances. It uses an exponential RC rise time for the reset delay after power-up (see

Figure 1). The delay can be changed easily by selecting the appropriate RC circuit.

Unfortunately, this approach has two drawbacks.

■ The reset delay depends on the power-up voltage slew rate - if the slew rate is too slow then the RC

curve tracks this rising voltage and the reset delay may be inadequate (See the dashed line in top

diagram in Figure 1).

■ The slew rate of reset signal at the microprocessor’s input depends on the reset time (typically 110-200

ms) - if longer pulses are required, the RC circuit values must be increas ed, whic h will s low th e slew

rate of the reset signal and may cause the microprocessor to malfunction, due to insufficient overdrive

at the Reset input.

Some manufacturers implement power-up/reset functions in the microprocessor to avoid these problems,

however in most cases the monitoring is not very precise.

Another solution is to use an external Reset Circuit dev ice. ST Reset Circuits have precise , predefined

voltage thresholds and reset delays and so do not encounter any of the drawbacks of the RC Filter Circuit

(see Integrated Reset Circuits section).

) input. This solution is inexpensive, but cannot be guaranteed

2/8

Page 3

Figure 1. Resistor-Capacitor Filter Circuit - Reset Delay

AN1772 - APPLICATION NOTE

Different V

Power-up V

µP Reset Input

V

CC

R

Microprocessor

µP Internal Reset

Power-up slew rate, One RC reset delay.

CC

0.9 V

CC

CC

V

RC

V

TH

Slow V

slew rate gives

CC

shorter Reset delay

T

2

(T2 < T1)

T

1

RST

C

One V

Power-up slew rate, Different RC reset delay.

CC

Power-up V

µP Reset Input

CC

0.9 V

CC

V

RC

V

TH

Slow reset slew rate

can cause problems

Note: VRC = voltage on capacitor.

µP Internal Reset

T

1

T

(T1 < T2)

2

AI08625

3/8

Page 4

AN1772 - APPLICATION N OTE

MONITORING THE SUPPLY VOLTAGE DURING OPERATIONS

For the microprocessor and other devices in the system to function correctly, it is also necessary to mon itor the supply voltage during operations.

Brownout condi tions, or gl itche s on the power suppl y li nes, c an cause unwanted changes in the internal

registers, which can lead to instructions being incorrectly executed, incorrect output signals and errors in

the operations results.

The RC filter solution proposed for monitoring the voltage during power-up and reset is not sufficient to

monitor the voltage correctly during operations. It can filter out fast undershoots, however, as the microprocessor is unaware that the voltage dropped below the threshold, due to the time constant of the RC

delay, it continues to operate, which can lead to instructions being incorrectly executed.

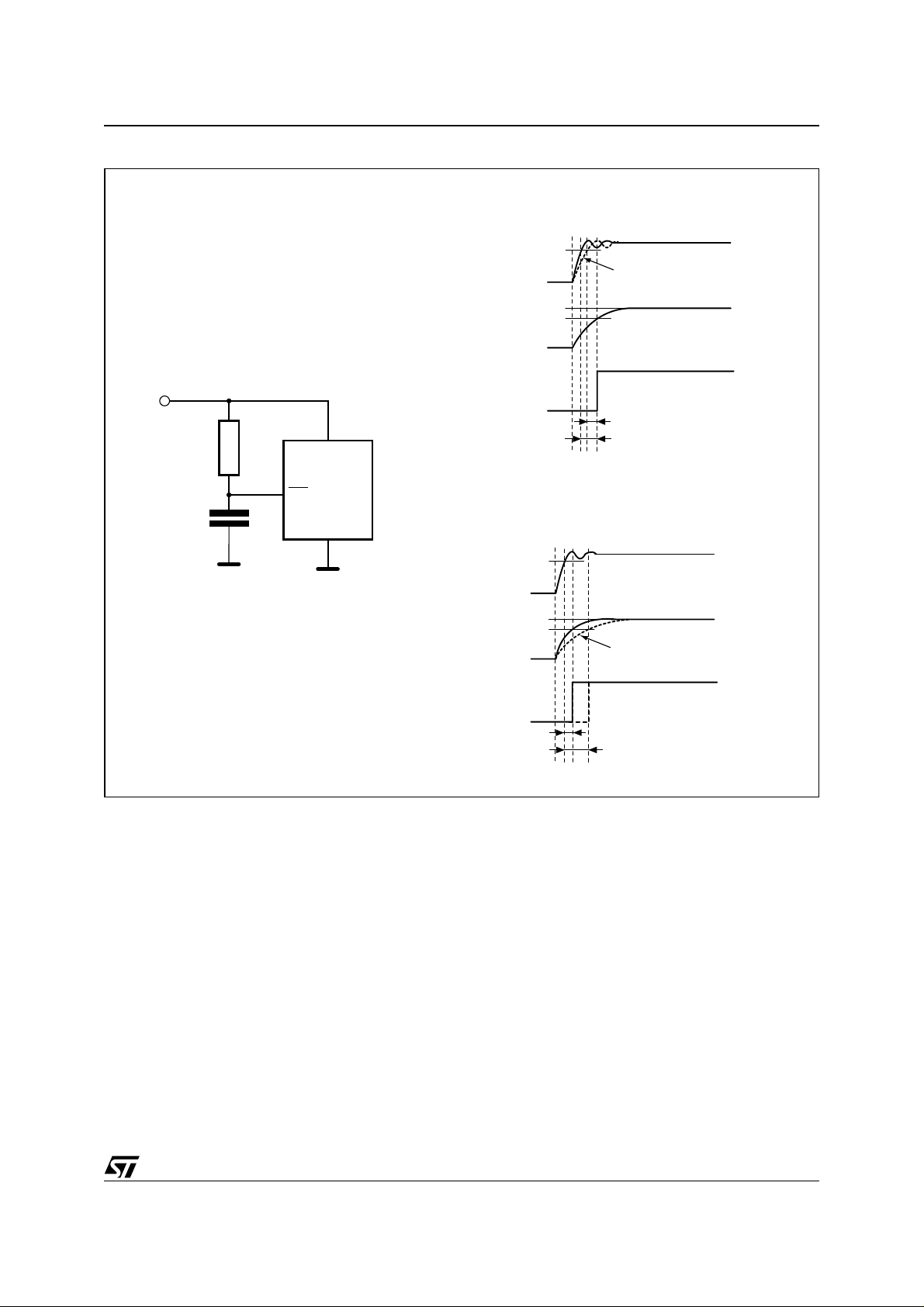

Resistor-Capacitor-Diode Filter Circuit

A Resistor-Capacitor-Diode (RCD) filter circuit (the same as the RC circuit with a diode added parallel to

the resistor), can improve the response time to fast undershoots, but the drop in the voltage level must be

greater than the forward turn-on voltage of the diode, before the diode can start to pull RST

Another limitation of this solution is that, the RCD filter circuit can only monitor drops in the voltage supply,

that are greater than the microprocessor’s tolerance voltage plus the diode drop.

As for the Power-up/Reset phase, a better solution is to use an external Reset device like the ST Reset

Circuits, which are also ideal for monitoring the voltage level during operations (see Integrated Reset Circuits section).

low.

Figure 2. Resistor-Capacitor-Diode Filter Circuit

V

CC

D

Note: VD = Voltage acr oss diode, VRC = voltage on capacitor.

R

C

Microprocessor

RST

Power-up V

µP Reset Input

µP Internal Reset

CC

V

D

V

RC

V

TH

RC constant, without parallel diode,

filters out fast voltage undershoots

AI08626

4/8

Page 5

AN1772 - APPLICATION NOTE

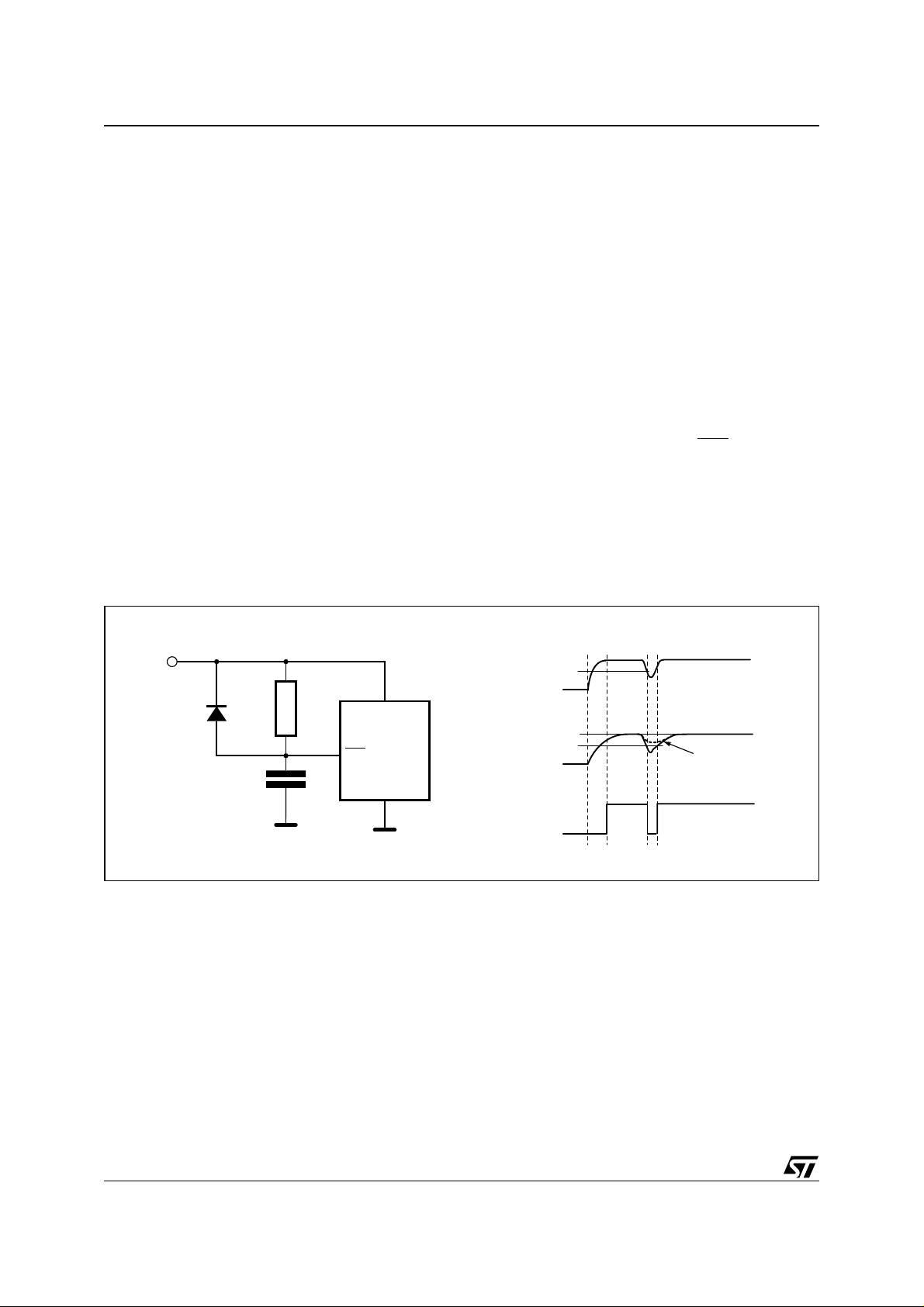

INTEGRATED RESET CIRCUITS

Integrated Reset Circuits, like the STM809 -812, are devices that are dedicated for reset and monitoring

purposes. They monitor the input voltage supply and send a reset signal to the microprocessor for a preset

time interval, if the voltage supply goes outside the preset limit.

A typical reset device consists of a voltage reference, a voltage comparator, a supply voltage resistor-divider network, a fixed delay time circuit and an output driver (see Figure 3).

The internal voltage comparator monitors the input voltage supply and compares it with a predefined voltage reference. If the supply voltage is under the threshold, a reset signal RST

mains asserted until the supply voltage reaches the threshold and stays above it for a preset time interval.

The output of the Reset Circuit is independent of the Power-up slew rate, glitches and other brownout conditions.

Figure 3. Integrated Reset Circuit

V

MR

CC

V

RST

(1)

COMPARE

Delay

DEBOUNCE

, is asserted. The signal re-

Output

RST

Note: 1. STM811/812 only.

AI08627

5/8

Page 6

AN1772 - APPLICATION N OTE

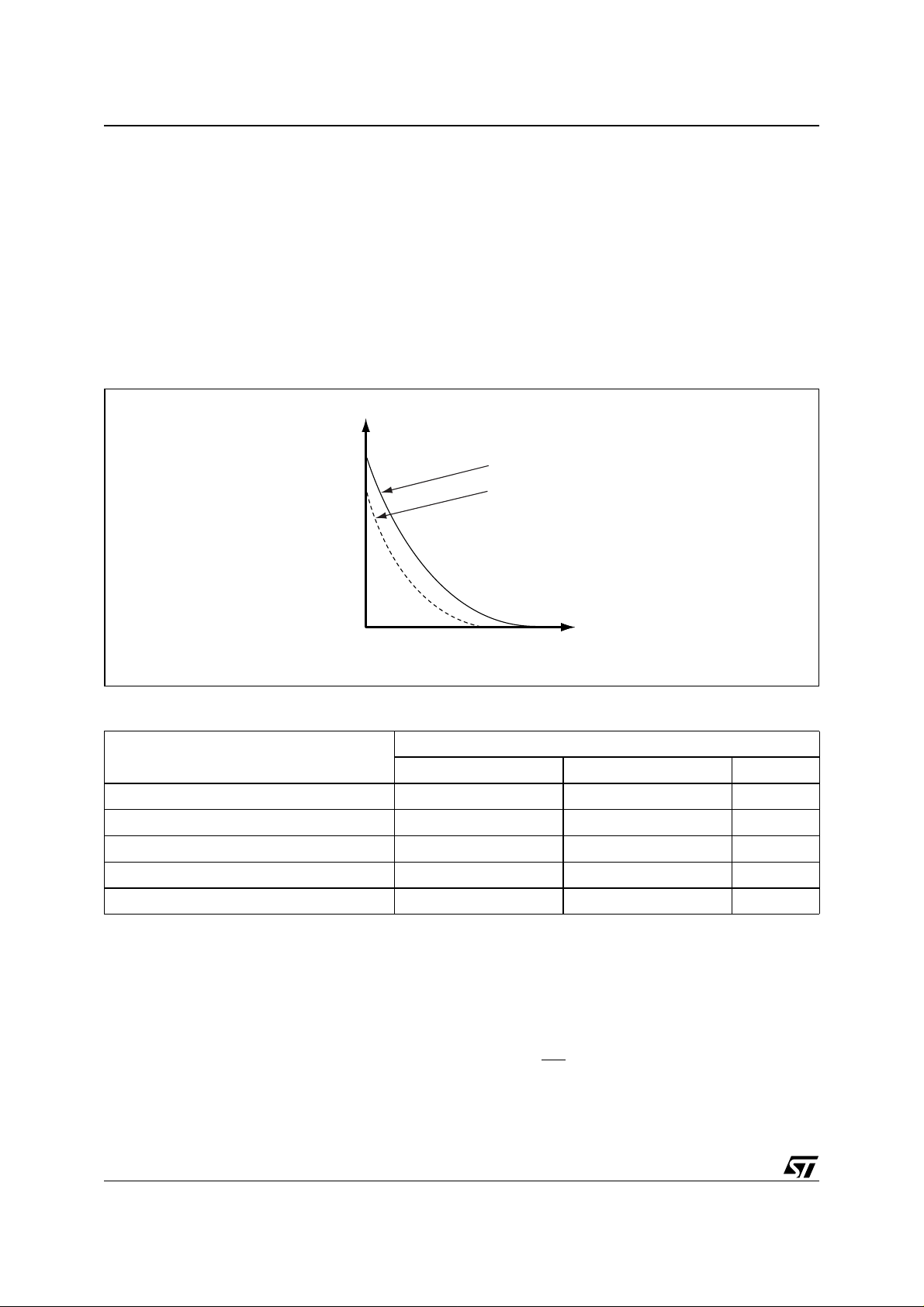

Reset Thresholds

The Reset Circuits are available with multiple threshold voltages (refer to Table 1), so the designer can

choose the reset threshold level best suited to the system’s power supply.

The sensitivity of the Reset Circuit depends on:

■ the duration of the voltage undershoot,

■ the magnitude of the undershoot below the minimum threshold.

The generation of the res et signal d epends o n, the ma ximum vol tage tran sient durat ion versus t he re set

comparator overdrive, as is shown in Figure 4. Conditions falling into the area below the curve are filtered

and therefore do not generate a reset signal.

Figure 4. Reset Thresholds

µS

STM8xxL/ M

STM8xxR/S/T

(not producing reset pulse)

Max. voltage transient duration

Reset Comparator Overdrive, mV

AI08628

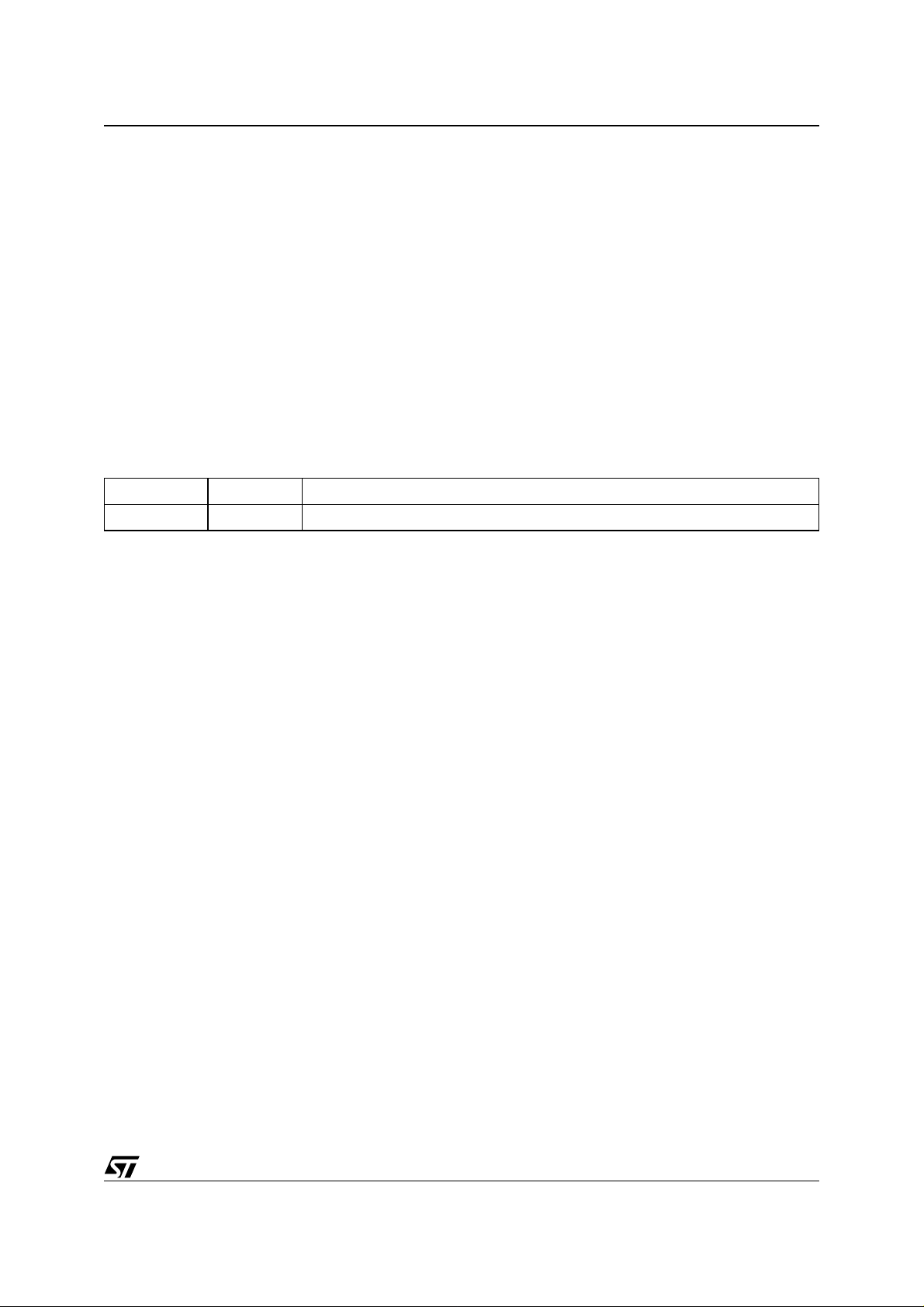

Table 1. Reset Threshold Levels

Device

Min Max Unit

STM8xxL 4.50 4.75 V

STM8xxM 4.25 4.50 V

STM8xxT 3.00 3.15 V

STM8xxS 2.85 3.00 V

STM8xxR 2.55 2.70 V

Reset Threshold Voltage

Manual Reset

A manual reset is useful in many applications, from debugging new systems to waking-up from an idle or

sleep mode.

Usually an external reset is done with a switch, however switches are not ideal because of switching

bounce (voltage spikes that can occur during the switching phase). The problem can be overcome by designing a specific circuit, but this requires additional discrete logic gates. The STM811 and STM812 Reset

Circuits solve the problem with a push-button reset input signal (MR

). These devices have an internal debounce circuit (see Figure 3), usually with an internal pull-up resistor, so there are no requirements for any

other discrete circuits connected to the device.

6/8

Page 7

AN1772 - APPLICATION NOTE

CONCLUSION

ST Reset Circuits are small devices, that take little board space, but monitor the most important thing in

the system - the power supply. They are b ecoming increasingly popular with de signers, thanks to their

dedicated features and low cost. They are available in small SOT23 and SOT143 packages; they require

only a low supply current, typically in the 5-10 µA range and offer a wide range of voltage thresholds.

They can be used in many different appl ications f rom b attery devices with low power requirements to industrial machines with reliability constraints.

REFERENCES

■ STM809, STM810, STM811, STM812 datasheet

REVISION HIST ORY

Table 2. Document Revision History

Date Version Revision Details

27-Nov-2003 1.0 First Issue.

7/8

Page 8

AN1772 - APPLICATION N OTE

s

d

t

t

If you have any questions or suggestion concerning the matters raised in this document please send them

to the following electronic mail address:

ask.memory@st.com (for general enquiries)

Please remember to include your name, company, location, telephone number and fax number.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequence

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is grante

by implic ation or otherwise under any patent or patent ri ghts of STM i croelectronics. Sp ecifications menti oned in thi s publicati on are subjec

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are no

authoriz ed for use as cri t i cal components in life support dev i ces or systems without express writ ten approv al of STMicro el ectronics.

The ST logo is a registered trademark of STMicroe lectronics .

All other nam es are the pro perty of thei r respective owners

© 2003 STMi croelectronics - All ri ghts reser ved

STMicroelectron ics GROUP OF COMPANIES

Australi a - Belgium - Brazil - Ca nada - China - Czech Republi c - Finland - F rance - Germany - Hong Kong - India - Is rael - Italy - Japan -

Malaysia - M al ta - Moroc co - Singapore - Spain - Sweden - Swit zerland - United Kingdom - United States

www.st.com

8/8

Loading...

Loading...