Page 1

AN1729

APPLICATION NOTE

L6565-BASED LOW COST SMPS FOR TV WITH

LESS THEN 1W STANDBY CONSUMPTION

by: R.D. Stracquadaini, C. Leonardi

The need for energy consumption reduction brings to the design of more and more efficient power supplies. High efficiency is required not only when the system supplied is fully operating but also when it is

in standby condition and absorbs very little power. A common design target for many home appliances

is that their power consumption in standby mode be less than 1W.

In this paper a cost-effective solution for the power supply of a 60W 14" TV, with a standby power consumption of less then 1W is presented.

The topology used for t his Switch Mode Power Supply is a Quasi-resonant Flybac k Converter (See

AN1326) in order to reduce the switching losses (ZVS at turn-on) and then to increase efficiency. In order to increase the performance in standby condition the start up network was designed with particular

care and the 2

burst mode operation of the power supply when the system is in standby condition. The power MOS

STP7NK80 (BV

nd

level of overcurrent protection of the L6565 QR controller is used to obtain an enhanced

= 800V, R

DSS

= 1.5Ω ) is used as the power switch.

DSon

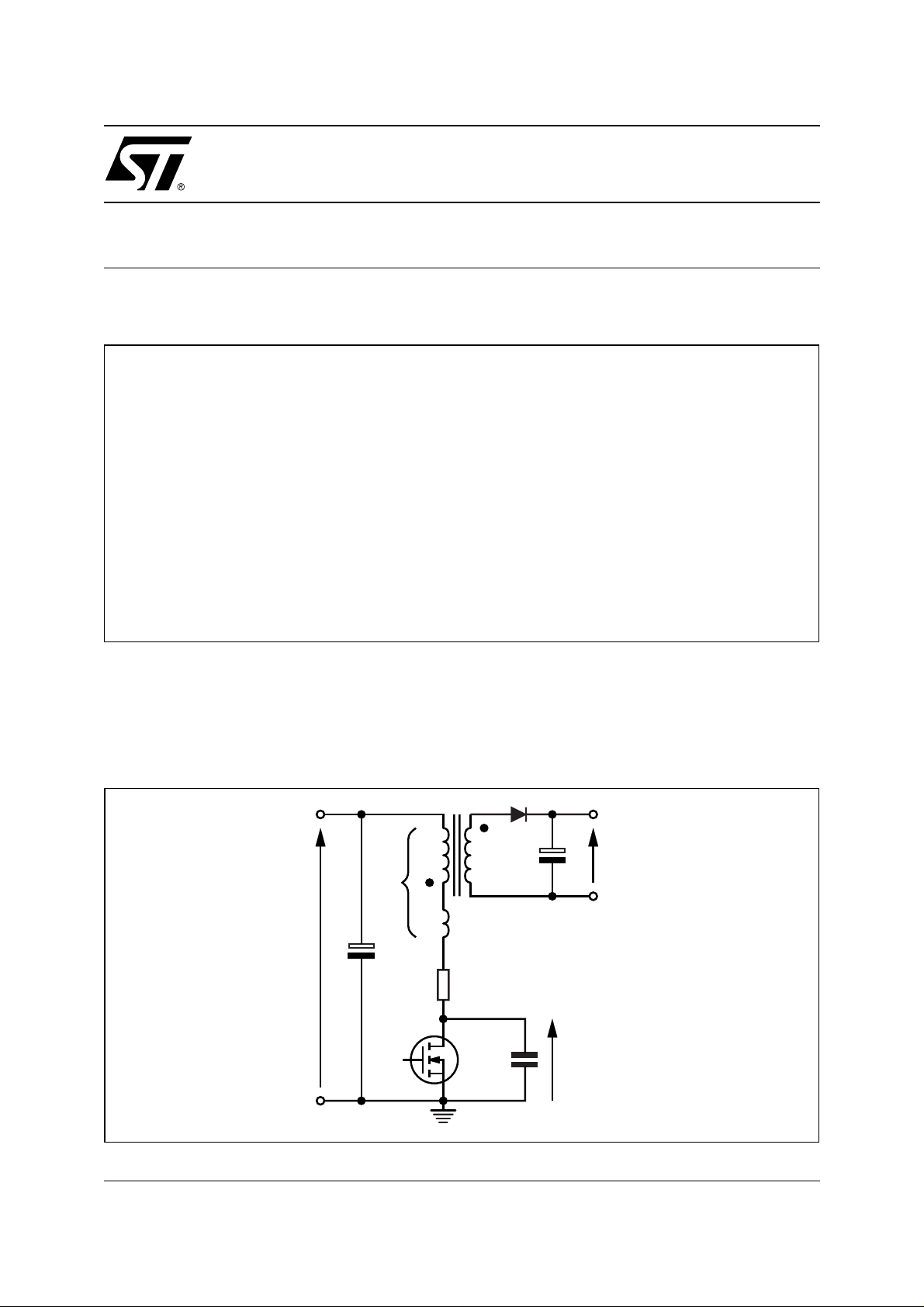

QR ZVS Flyback topology

In figure 1 a typical Flyback topology is illustrated. CD is the total capacitance of the drain node. It is the sum of

the Mosfet' s C

well as other contributions reflected from the secondary side.

Figure 1. Flyback topology

transformer intrawinding capacitance, st ray capacit ance due to the layout of t he ci rcuit as

OSS,

Vin

Lm Ls

Lp

Llk

Cin

Rp

Cd V

Vout

DS

D03IN1462

June 2003

1/10

Page 2

AN1729 APPLICATION NOTE

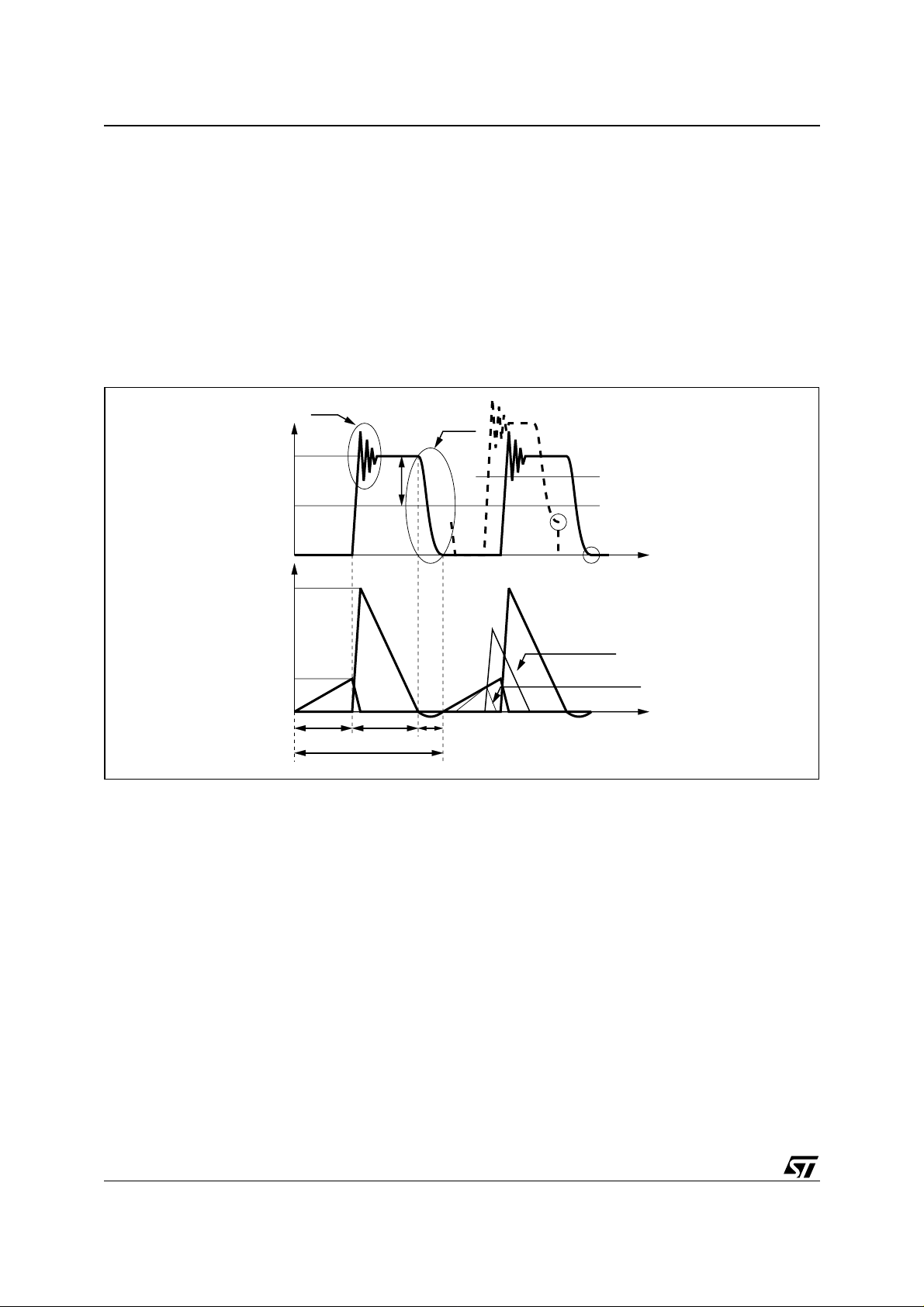

The Power Mos is turned off when the drain current reaches a threshold that is fixed by the controller depending

on the input and the out put v oltages. A s the secondary wi nding has run dry of energy, t he secondary rectif i er

no longer conducts and the Power Mos is still off, the tank circuit, made up L

It is an RLC circuit (considering the sum of dissipative effects concentrated in a equivalent resistor R

drain voltage follows the natural evolution of such circuit starting from the condition of C

= 0 (see waveforms in figure 2). R

is normally by far less than the critical damping impedance of the tank circuit.

P

At the point where the drain voltage has a valley (a minimum) we can turn on the Power MOS and we can have

a zero voltage turn on (if V

≤

VR) or a turn on where VD is as close as possible to zero compared w ith a square

in

wave flyback (see figure 2). This is Quasi-resonant (QR) operation.

Figure 2. Typical waveform s of QR operation

Llk & C

d

V

DS

V

DSs

V

V

in

L

& C

p

d

R

and CD, resonates.

P

VDS @ V

in2 >Vin

V

in2

charged at V

D

) and the

P

DSs

at t

in2 >Vin

Ip @ V

D03IN1463

ZVS

t

in2 >Vin

I

I

I

PKs

PKp

NO ZVS!

p

P

ri

T

ON

T = 1/f

Sec

Is @ V

T

sw

FW

T

V

The main advantages of this kind of control technique are:

1) At turn-on of the Power Mosfet the energy stored in the capacitor C

itself. Being the energy stored in C

proportional to V

D

2

, turning on the Mosfet when VD is minimum means

D

is dissipated into the power Mosfet

D

minimizing this kind of losses.

2) Probably the main benefit concerns the conducted EMI emission. In mains-operated applications, due to the

ripple appearing across the input bulk capacitor, the sw itching frequency is modulated at twice the mains

frequency, with a depth depending on the ripple amplitude. This causes the spectrum to be spread over frequency bands, rather than to be concentrated on single frequency values. Especially when measuring conducted emissions, with the average detection method, the level reduction can be of several dB

µ

V.

3) Another important be nefit is a high safety degree under short circuit conditions: since t he conduction cycles

of the Mosfet are inhibited until the transformer is full y demagnetised, flux run away and, therefore, transformer saturation are not possibl e. Moreover, as during a short ci rcuit the demagnetisation voltage i s v ery

low, th e s y ste m w ill be led to w o rk at v ery lo w fr equenc y, with a very s mall duty cycle. As a result, the power

that the converter will be able to carry is very low.

4) Finally, the way the system processes power does not change, thus designer's experience with standard

Flyback can be fully exploited and there is very little additional know-how needed.

2/10

Page 3

AN1729 APPLICATION NOTE

For further information concerning a QR Flyback converter based on controller L6565 you can refer to the Application Note AN1326 and to the datasheet of the controller.

Standby Consumption Issues

When the TV set is in standby we need to supply the m icro controller, the LED and the IR receiver for the remote

control. This supply voltage can be obtained through a linear voltage regulator from one of the low voltage outputs of the converter. Under such conditions the load i s very light also because we have to consider that the

micro controller is in low consumption working mode.

Most of power consumption in a lightly loaded switching converter is due to the switching losses, thus the lower

the switching frequency the lower the losses. In most of the modern Pow er S upply circuits, when the converter

is very lightly loaded, a low frequency working mode is often used. The switching frequency cannot be too low

to avoid audible noise. In order to further lower switching frequency the converter can be operated in a "burst"

mode, where there are short periods of time where the MOS switches at the normal operation switching frequency spaced out by long periods of time where the MOS does not switch; in this way the average switching frequency can be very low and switching losses can be minimized.

Burst-mode operation

In a normal converter realized using the L6565 controller, when the load is very light, a burst-mode operation

automatically takes place thanks to the "frequency foldback function" (See App. Note AN1326 and the datasheet

of the L6565 controller for details). It is important to notice that with this kind of burst- mode operation the control

loop is still active and the output voltages are still regulated.

In a TV power supply, when the system is in s tandby mode, generall y we do not need to have al l the out put

voltages regulated, we need only to guarantee a minimum voltage at the i nput of the l inear voltage regul ator

that supplies the micro controller. Moreover, the loss reduction offered by the natural burst-mode described before is not enough to meet the "less than 1 Watt" target in this application. With a simple and low-cost additional

circuitry it is possible to have an enhanced burst-mode operation that decreases the average switching frequency to a very low value, hence considerably reducing the total losses in the converter. In that case the regulation

loop is skipped but the required minimum voltage at the input of the linear voltage regulator can be guaranteed.

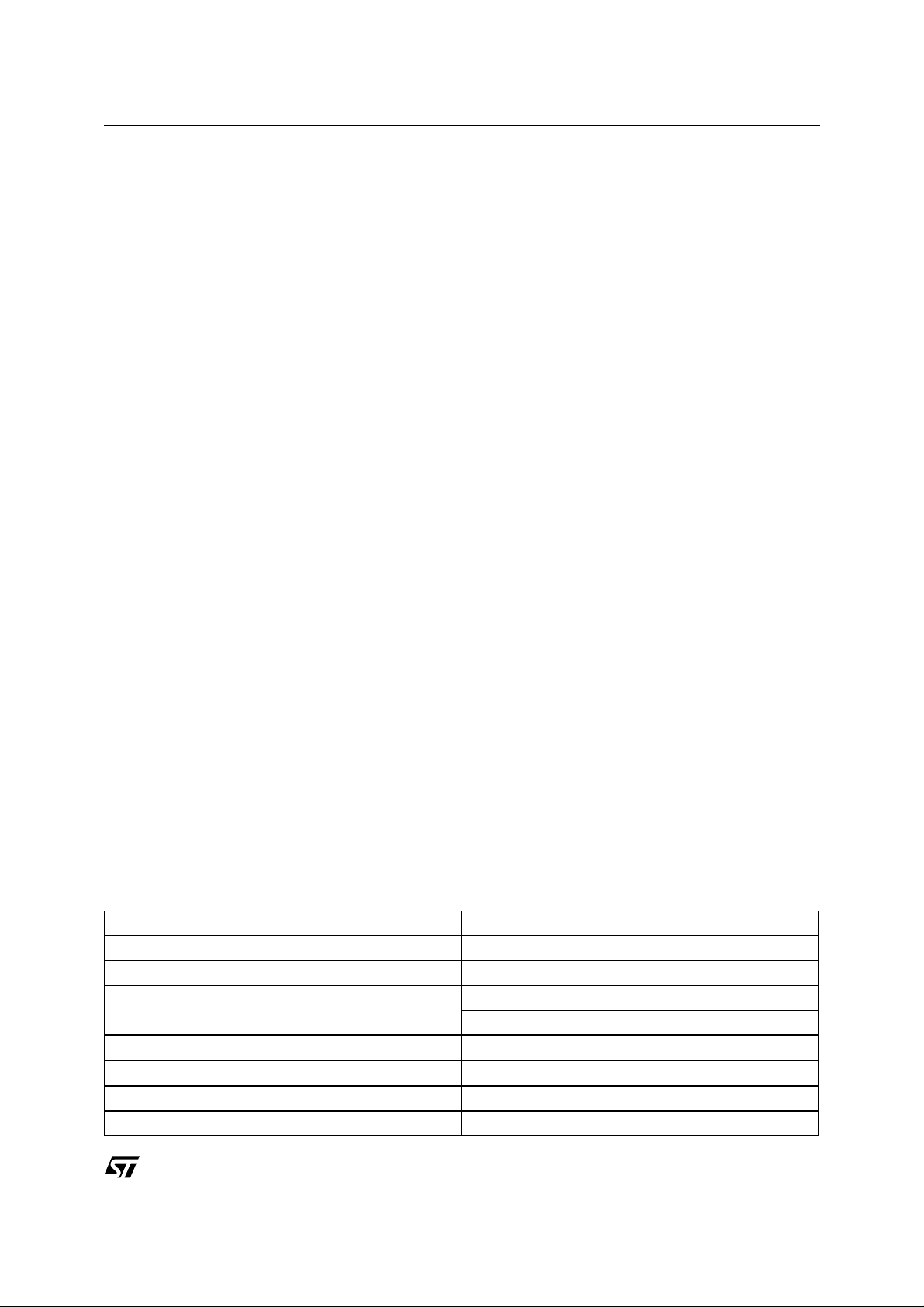

Description of the TV Set Power Supply circuit

The complete schematic of the realized circuit is shown in figure 3. It is a two output switch mode power supply

with a third output for the micro controller, obtained through a voltage regul ator (LE50C), from the secondary

output (V

=14V). The electrical specification is listed in table 1:

out2

Table 1.

Input Voltage range 88 to 264 Vac

Mains frequency 50-60 Hz

Maximum output power 60 W

Output voltages Vout1 = 114V; Pout1 = 55 W

Vout2 = 14V; Pout2 = 4.2 W

Output of the voltage regulator Vout

Minimum switching frequency 70 kHz

Target efficiency η > 80%

Maximum standby consumption (@ 220 Vac) < 1W

=5V; Iout

3

= 70mA; Iout

wup

stand-by

=10mA

3/10

Page 4

AN1729 APPLICATION NOTE

n

m

n

m

Figure 3. Complete schematic of the 60W SMPS for 14" TV

Grou

Grou

14V 4.2

114V 555V 350

14V 4.2

114V 555V 350

J8

CON41234

J8

CON41234

J8

CON41234

114V 50W

114V 50W

114V 50W

T3

T3

T3

176

176

176

R15

R15

R15

82k 1/2W

82k 1/2W

82k 1/2W

C4

C4

C4

100uF 1 60V

100uF 1 60V

100uF 1 60V

D4 STTH1L06

D4 STTH1L06

D4 STTH1L06

R14

C7

R14

C7

R14

C7

220 pF630V

220 pF630V

220 pF630V

91411

8

91411

8

91411

8

3

3

3

14V 4.2W

14V 4.2W

14V 4.2W

820

820

C8

4.7u

C8

4.7u

C8

4.7u

13

13

13

U1

U1

U1

56

56

56

Trasformer

Trasformer

Trasformer

2

2

2

OUTIN

OUTIN

OUTIN

Grou nd

Grou nd

Grou nd

LE05/TO92

LE05/TO92

LE05/TO92

C9

C9

C9

4700uF 25V

4700uF 25V

4700uF 25V

D5 STTH102

D5 STTH102

D5 STTH102

820

R16

R16

R16

DZ2

DZ2

DZ2

BZX7 9C 10

BZX7 9C 10

BZX7 9C 10

R11

R11

R11

D7

1N4148

D7

1N4148

D7

1N4148

ISO1

PC817

ISO1

PC817

PC817

12

12

12

4

3

4

3

4

3

R21

220

R21 ISO1

R21

220

220

R17

82K

R17

82K

R17

82K

20k

20k

20k

trim117

trim117

trim117

C14

C14

C14

10k

10k

10k

R19

270

R19

270

R19

270

Q3

Q3

Q3

123

123

123

BC547

BC547

BC547

1 2

1 2

1 2

DZ3

DZ3

DZ3

BZX79C7V5

BZX79C7V5

BZX79C7V5

R20

2.2K

R20

2.2K

R20

2.2K

C13

180pF

C13

180pF

C13

180pF

3.3 nF

3.3 nF

3.3 nF

R18

220k

R18

220k

R18

220k

IC3

TL431

IC3

TL431

IC3

TL431

3

3

3

2 1

2 1

2 1

DIODE

DIODE

DIODE

D8

D8

D8

R22

180

R22

180

R22

180

SW1

SW1

SW1

1 2

1 2

1 2

D9

D9

D9

1N4148

1N4148

1N4148

Q2

STP7NC80Z

Q2

STP7NC80Z

Q2

STP7NC80Z

2

3

2

3

2

Drain

Drain

Drain

D1

D1

D1

R3

220k 1W

R3

220k 1W

R3

220k 1W

STTH 1L 06

STTH 1L 06

STTH 1L 06

C3

C3

C3

47nF 450V

47nF 450V

47nF 450V

Q5

Q5

Q5

2

3

2

3

2

3

1

1

1

RH1

4.7M

RH1

4.7M

RH1

4.7M

RH2 4.7M

RH2 4.7M

1nF 40 0V

1nF 40 0V

1nF 40 0V

3

3

3

Filtred_AC+

Filtred_AC+

Filtred_AC+

L1

L1

L1

4

4

4

AC_Main+

AC_Main+

AC_Main+

RH2 4.7M

4

4

4

BR1

BR1

BR1

3

3

3

STBR406

STBR406

STBR406

-+

-+

-+

1

1

1

CY1

CY1

CY1

CX2

CX2

CX2

100nF 450V

100nF 450V

100nF 450V

2

2

2

27mH

27mH

27mH

1

1

1

Cx1

Cx1

Cx1

100nF 450V

100nF 450V

100nF 450V

AC_Main-

AC_Main-

AC_Main-

Filtred_AC-

Filtred_AC-

Filtred_AC-

High_Voltage_Bus

High_Voltage_Bus

High_Voltage_Bus

Br in +

Br in +

Br in +

NTC1 22R

NTC1 22R

NTC1 22R

F1 FUSE

F1 FUSE

F1 FUSE

Auxiliar_Output

Auxiliar_Output

Auxiliar_Output

RH3

10 k

RH3

10 k

RH3

10 k

STQ1NC60

STQ1NC60

STQ1NC60

R1A

R1A

R1A

C1

C1

C1

150uF 450V

150uF 450V

150uF 450V

2

2

2

CY2

CY2

CY2

C17 2.2nF 2k V

C17 2.2nF 2k V

C17 2.2nF 2k V

D10

D11

15V

D10

D11

15V

D10

D11

15V

1 2

1 2

1 2

2.2M

2.2M

2.2M

R1B

2.2M

R1B

2.2M

R1B

2.2M

1nF 40 0V

1nF 40 0V

1nF 40 0V

3

R8

15

R8

15

R8

1

1

1

D3

D3

D3

1N4148

1N4148

1N4148

123

123

123

Q6

Q6

Q6

BC547

BC547

BC547

R23

22k

R23

22k

R23

22k

R24 100k

R24 100k

R24 100k

Vcomp_Pin

Vcomp_Pin

Vcomp_Pin

Voltage_Feed_Forward_Pin

Voltage_Feed_Forward_Pin

Voltage_ Fe ed_ Fo r ward _Pi n

15

1N4148

1N4148

1N4148

R7

100

R7

100

R7

100

D2

1N4148

D2

1N4148

D2

1N4148

Gate_Driver

Gate_Driver

Gate_Dri ver

R4 10

R4 10

R4 10

Vcc

Vcc

Vcc

C4A

22uF 25V

C4A

22uF 25V

C4A

22uF 25V

C4B

C4B

C4B

100nF (220 nF)

100nF (220 nF)

100nF (220 nF)

857

857

857

GD

GD

GD

Vcc

Vcc

Vcc

IC1

IC1

IC1

INV

Comp

INV

Comp

INV

Comp

1

2

3 6

1

2

3 6

1

2

3 6

Source

Source

Source

R10B

0.8 1/2W

R10B

0.8 1/2W

R10B

0.8 1/2W

R10A

0.8 1/2W

R10A

0.8 1/2W

R10A

0.8 1/2W

R26

3.3k

R26

3.3k

R26

3.3k

R5 47k

R5 47k

R5 47k

R9 680

R9 680

R9 680

Zero_Current_Detect

Zero_Current_Detect

Zero_Current_Detect

ZCD

ZCD

ZCD

L6565

L6565

L6565

VFF GND

CS

VFF GND

CS

VFF GND

CS

Current_Sense_Pin

Current_Sense_Pin

Current _Se nse _P in

4

4

4

R2

22k

R2

22k

R2

22k

1nF

1nF

1nF

C2

C2

C2

SW1 close - normal mode

SW1 open - stand-by mode

SW1 close - normal mode

SW1 open - stand-by mode

Instead of the Sw the microcontroller

control the stand-byfunction

Instead of the Sw the microcontroller

control the stand-byfunction

R25

5.6k

R25

5.6k

R25

5.6k

C16

0.56uF

C16

0.56uF

C16

0.56uF

4/10

Page 5

AN1729 APPLICATION NOTE

Enhanced Burst-Mode Operation

The start-up circuit plays an important role and it is important to look at its schematic redrawn in fig. 4.

The circuit is basically a current generator including a high-voltage MOS (Q5) that can be disabled through the

switch Q6 driven by the output of the error ampli f ier of t he L6565 (COMP). Note that the i nvert ing input of t he

error amplifier (INV) is connected to ground, while the non-inverting one is internally connected to a voltage reference of 2.5V. When the L6565 is on, the voltage on pin COMP (V

the controller is off, COMP is floa ting.

) is high (always > 2.5V) and, when

COMP

During the start-up phase the high voltage MOS is on and the current that charges the capacitor C4 on the V

pin flows through it. As soon as the L6565 is turned on, V

goes high, which turns on Q6 and, consequently,

COMP

CC

turns off Q5. Thus, the current flowing i n t he star t up network duri ng normal operation i s only t hat t hrough the

two resistors RH1 and RH2 (4.7M

Ω

each), therefore a really low power is dissipated (10 mW @ 220 Vac).

As previously said, the start-up circuit is arranged as a constant current generator, with the advantage of having

a start-up time of the converter independent of the mains voltage. The analytic expression of the current delivered by the generator is:

VzV

I

st up–

V

is the breakdown voltage of the Zener Diode DZ1, V

z

-------------------------------------------=

–+

DropVth

RH3

(Eq.1 )

is the voltage drop across D10 and Vth is the con-

Drop

duction threshold gate-source voltage of the MOS Q5 (STQ1NC60).

Figure 4. Sta rt up cir c ui t

Main s

R24 10 0K

R24 22K

Bulk

Capacitor

Q6

BC547

RH1

RH2

DZ1

D10

1N4148

Q5

STQ1NC60

RH3

comp

Pin8 V

CC

C4

Pin1 Inv

Pin2 V

L6565

In the circuit shown in the schematic of figure 3, the L6565 internal E/A is not used in the feedback loop. During

the normal operation of the converter his output (V

) is always at his maximum value of 5.8V. The feedback

COMP

loop is closed summing the feedback signal to the current sense signal through a resistor (R9 in the schematic)

between the current sense resistor and the current sense pin of the L6565. Thi s arrangement allows real izing

the enhanced burst-mode operation during standby through the circuit whose schematic is redrawn in figure 5.

If a large current is forced to flow in the resistance R9, the voltage on the current sense pin will exceed the second overcurrent protection threshold and this will disable the gate driver. To re-enable the driver, first the IC

must be turned off, that is the V

voltage must fall below the UVLO threshold.

CC

5/10

Page 6

AN1729 APPLICATION NOTE

When the micro controller of the TV gives the standby command, the switch SW1 is open and the 14V output

turns on the small signal bipolar transistor Q3. As a result, a big current (as compared to the current that flows

during normal operation) is forced to flow in the LED of the opto-coupler and thereby in both the phototransistor

and R9. As explained before, this big current will disable the gate driver of the L6565.

When the gate driver is disabled the quiescent current i s unchanged and, since no energy is coming from the

self-supply circuit, the V

the start-up generator will be enabled and a new start-up cycle will begin. The resulting behaviour will be a low

frequency intermittent operation that we will refer to as "enhanced burst-mode operation". With such operation

the regulation loop used in normal operation of the converter is skipped; another kind of regulation takes place.

The Secondary output of the converter starts to rise until it reaches a threshold V

DZ3 as V

+VBE+Vd where VBE is the base emitter voltage of the small signal transistor Q3 (BC547) and Vd

DZ3

is the voltage drop of the diode D8 (1N4148) (we can neglect the voltage drop on resistor R21). At this point the

gate driver of the controller is di sabled and switching is st opped. The length of this idl e period is fi xed by the

discharge time of the capacitor C4 as above explained. During this idle period the output voltages will go down

and the minimum values that they reach depends on their individual load.

In order to obtain some design equations we can divide the burst-mode period in three time intervals:

– Phase 1. From the moment when the L6565 controller has been just turned off and the start-up circuit

starts to re-charge the V

that is the V

– Phase 2. From when the L6565 is turned on until the transistor Q3 is turned on and the L6565 stops.

– Phase 3.From when the L656 5 stops to when the V

threshold and the L6565 is turned off.

capacitor (C4) will be discharged below the UVLO threshold after some time. Then

CC

fixed by the Zener diode

Omax

capacitor C4, to the moment when the controller is turned on,

CC

voltage exceeds the turn-on threshold.

CC

voltage goes down under the low UVLO

CC

Our purpose is to obtain simple equations, so some approximations will be introduced. An optimisation can be

done, looking at the measurement results, in order to have as good performance as possible.

– Phase 1.

After the VCC voltage has fallen below the UVLO off threshold, the start-up cycle begins. The high voltage low

current Mos Q5 is on and the capacitor C4 is charged through it and the resistor RH3. The starting value of the

voltage on C4 is the UVLO off threshold. The voltage value on C4 when the L6565 is turned on is t he turn-on

threshold. Their difference is the hysteresis V

of the capacitor C4 the charging time of C4 (T

T

ch C4–

V

th on–

------------------------------------------------------------- -

V

–()C4⋅

th off–

I

st up–

. Considering the equation 1 that gives the charging current

CCHys

) is the following:

ch-C4

Hys

V

Z

RH3 C4⋅⋅

–+

DropVth

(Eq. 2)

Vcc

------------------------------------------------- -==

V

– Phase 2.

When the L6565 is turned on the voltage on the secondary output is V

the output voltages rise. As soon Vout2 reaches the threshold V

DZ3

, the MOSFET starts switching and

Omin

+ V

+ Vd the BJT Q3 will be turned on

BE

and the gate driver of t he L6565 di sabled. The durati on of this switc hi ng phase i s t ypi call y much shorter than

the others and will be neglected.

– Phase 3.

The converter is stopped until the VCC voltage falls under the UVLO off thres hold. Let' s call Iq the quiescent

current of the L6565; the time for discharging the C4 capacitor is:

6/10

Page 7

AN1729 APPLICATION NOTE

T

disch C4–

Vcc

--------------------------------=

Hys

I

q

C4⋅

(Eq. 3 )

Summarizing, the total period of the enhanced burst-mode cycl e will be:

T

ch C4–

T

disch C4–

Vcc

------------------------------- -

⋅

HysC4

I

q

Vcc

Hys

------------------------------------------------- -+=+

V

z

RH3 C4⋅⋅

V

DropVth

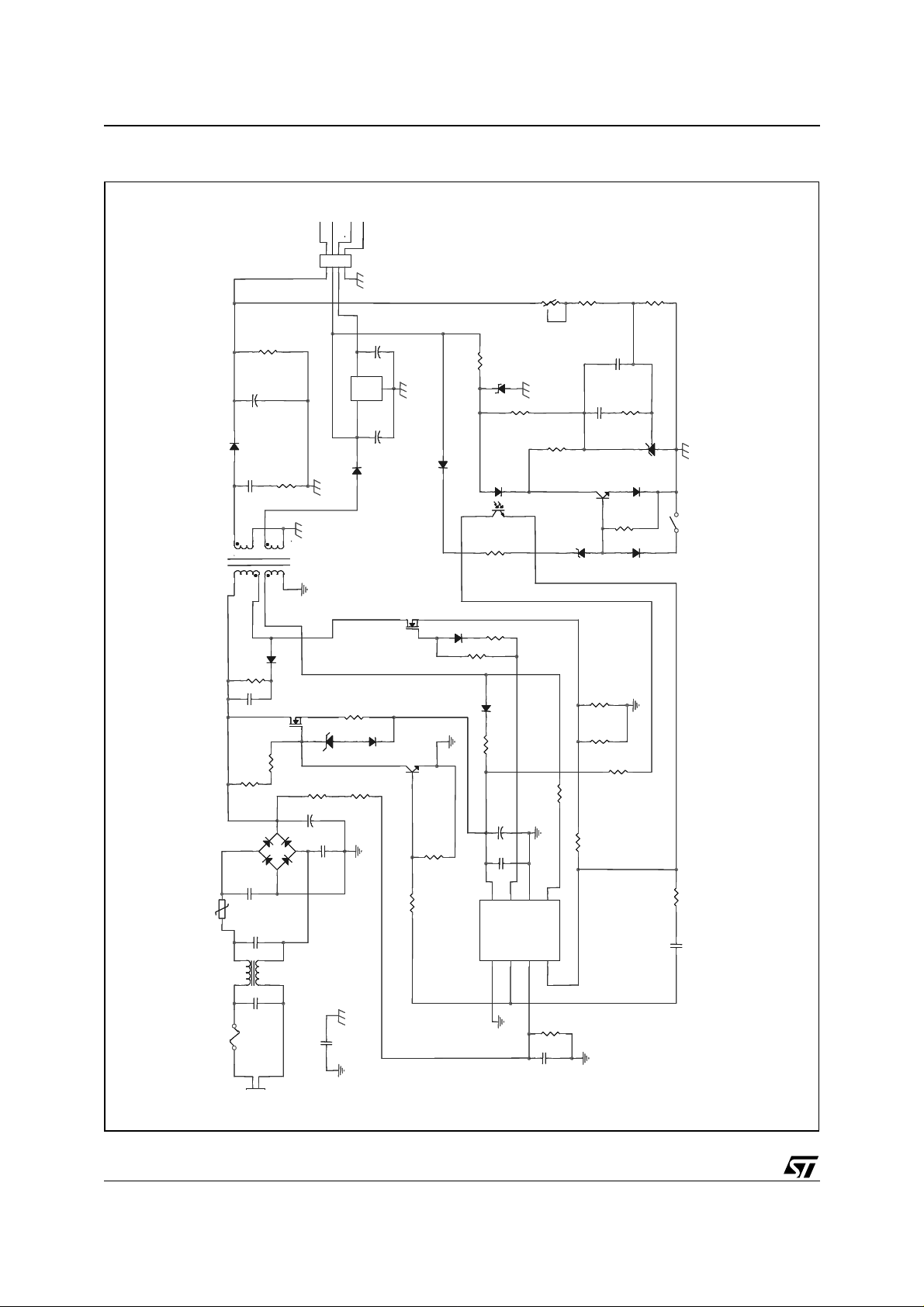

Figure 5. Stand by Circuit

R10A//R10B

(Rsense)

R26

R9

Stand by

Circuit

DZ3

BZX79C7V5

R22

STTH102

R21

D8

D5

Q3

R19

TL1431

Secondary Output

C

9

R11

Compensation

network

–+

(Eq. 4)

Equivalent Load

LE50C

µC

R.C.

BZX79C10

How to set the timing of the enhanced burst-mode operation.

To have a well working circuit a minimum input voltage on the linear voltage regulator (V

) has to be guar-

OMin

anteed considering its dropout specification. We can summarize the power absorbed by the load (in thi s case

the micro controller, the LED, the receiver for the remote control of the TV and, of course, the power consumption of the voltage regulator) with a constant current source because of the linear voltage regulator.

The consumption of the micro controller that has to be considered in the design i s that feat ured between the

turn-on instant and the complete exit of the system from the standby condition.

This is due to the fact that if the TV is turned on at the beginning of the idle phase of the burst period, the discharge of the output capacitor will be faste r bec aus e th e mic ro is on and absorbs more current. We have to guarantee the correct voltage on the voltage regulator with the micro in on state until t he complete restart of the

converter. Let us call I

the total output current absorbed duri ng the stand by condition and I

stb

(wake up

Wup

current) the total output current at the turn on of the micro.

Most of the power in standby condition will be dissipated by the start up network and can be written as:

C4 Vcc

⋅⋅

PD

st up–

-------------------------------------------- -=

HysVin

T

burst

(Eq. 5)

7/10

Page 8

AN1729 APPLICATION NOTE

being Vin the DC voltage on the input bulk capacitor.

Switching losses, the power dissipated on the output rectifier diode, and the power dissipated in the input stage

are not easy to be evaluated analyti cally but they are anyway almost i ndependent from the burst period and

considerably lower than PD

Another quantity that can be evaluated is the power absorbed by the load:

P

Load

.

stup

V

OMaxVOmin stb–

----------------------------------------------------------------------- -=

+()I

2

⋅

stb

(Eq. 6)

V

Omin-stb

greater than V

in the valley voltage at the input of the linear regulator whil e this is absorbing I

, which corresponds to I

Omin

have a minimum possible value of T

calculated (P

Dstb

+ P

is 70% of the total power consumption i n st andby. Hence, c onsidering t he 1W con-

Load)

consumption. We can use the previous equations in order to

Wup

and, as a rule of thumb, we can assume that the power consumption

burst

and it is therefore

stb

sumption target, we have:

C4 Vcc

⋅⋅

T

burst

----------------------------------------------- -≥

700 mW P

From equation 5 we see that increasing T

sired, however there is a maximum limit to T

Considering that a minimum voltage on the input of the voltage regulator has to be guaranteed, T

to the maximum voltage that we have at the input of the voltage regulator V

HysVhV

–

Load

burst

burst

(Eq. 7 )

the power consumption in standby can be made as low as de-

.

is relate d

burst

(Fixed by the Zener diode DZ3)

OMax

and at the value of the output capacitor C9, according to the following equation:

T

⋅

burstIWup

V

Omax

V

in any case has to be lower then the output voltage of the converter during the normal operation; if it were

Omax

V

Omin

-------------------------------- -+=

C9

(Eq. 8)

not, the normal control loop would be activated and the behaviour of the converter would be different from what

is required. Fixing a low value for V

as it can be seen, it is not a big part of the total power consumption. At this point the value of T

values of C9 and V

is a trade-off between lowering the standby consumption and a not too big output ca-

OMax

means decreasing the power consumption of the voltage regulator but,

OMax

and then the

burst

pacitor.

Once fixed all the component values, the V

V

Ominstb

V

Omax

Omin-stb

can be calculated as:

T

⋅

burstIstb

-----------------------------–=

C9

(Eq. 9)

Standby calculations in the experimental board

In the board assembled for testing the standby function the Zener diode DZ3 has a Zener voltage of 7.5V.

It means that the V

from Eq. 8 the maximum T

T

BurstMax

value is about 7.5V+0.6V+0.6V=8.7V. The output Capacitor (C9) value is: 4700µF so

OMax

value has to be:

burst

V

--------------------------------------------------------------------------- -

–()C9 0.8⋅()⋅

OMaxVOMin

I

wupId

8.7V 5.5V–()

+

----------------------------------- - 3760 µF164ms=⋅==

70mA 3 mA+

where the tolerance of the electrolytic capacitor C9 (-20%) and the maximum quiescent current Id of the linear

voltage regulator has been considered.

The maximum discharge time of the capacitor C4 can be calculated as:

8/10

T

disch C4– Max–

---------------------------------------------

Vcc

Hys

I

qMin

C4 1.2⋅⋅

4.3 26.4µF⋅

------------------------------- - 71ms===

1.6mA

Page 9

AN1729 APPLICATION NOTE

The value of the capacitor C4 has been multiplied by 1.2 to account for its tolerance, the value of the quiescent

current is the minimum from the datasheet of the controller and also the maximum hysteresis of the on/off V

thresholds has been considered.

CC

The charge time of the capacitor C4 has to be less then T

erations and using eq. 2, a minimum I

, of 1.2 mA is needed. As a result, the values of 10kΩ, for the resis-

st-up

burstMax-Tdisch-C4-Ma x

. Following the previous consid-

tance RH3, and 15V, for the zener voltage of the zener diode DZ1, were chosen.

Experimental results

In this section the results of experimental tests on a board manufactured according to the schematic in figure 3

are reported. In table 2 the measured standby consumption at different values of the input voltage are shown:

Table 2. Standby Input Power Measurements

V

P

in-stand-by

in

88Vac 110Vac 220Vac 264Vac

320mW 390mW 682mW 83 5mW

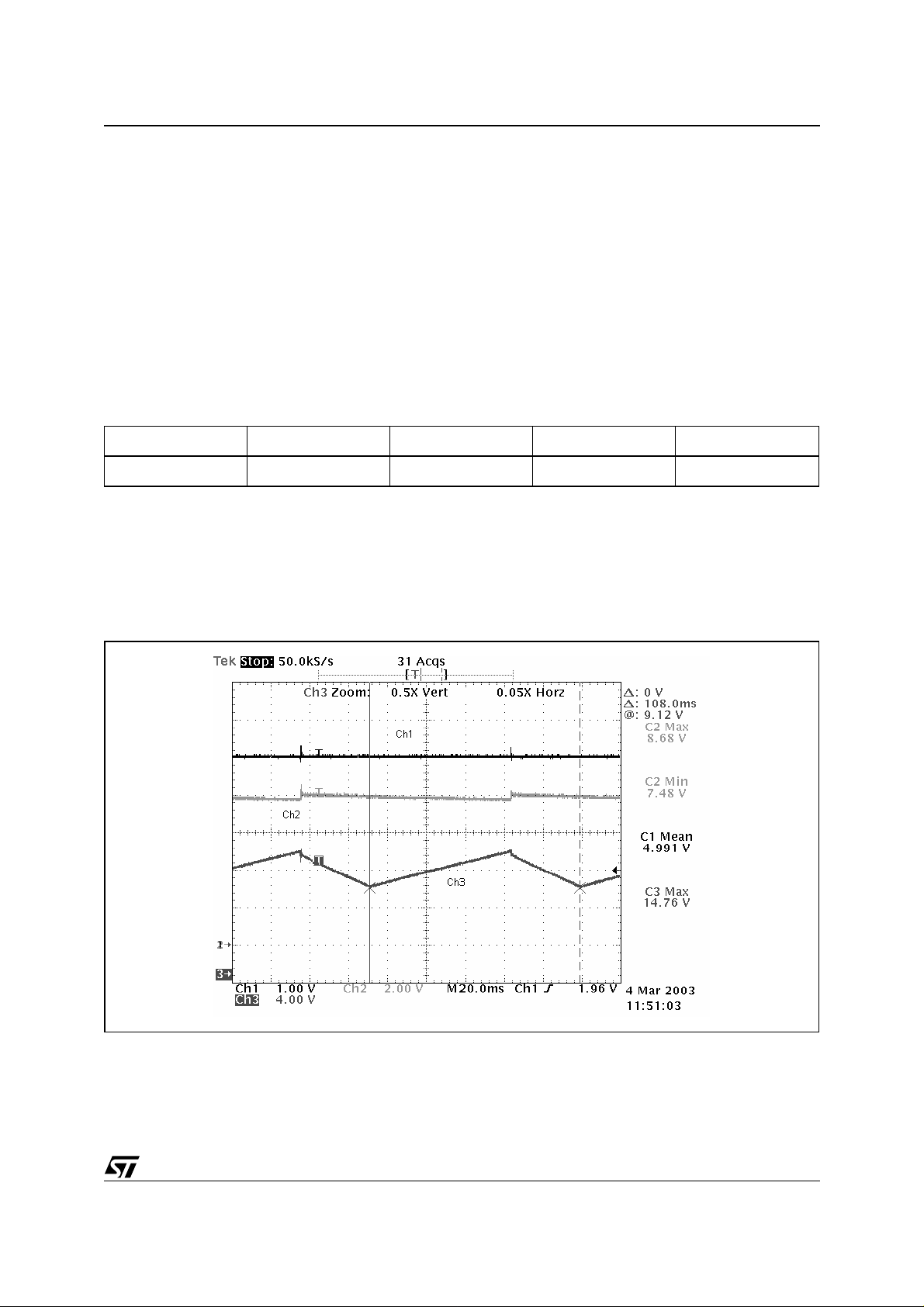

Fig. 6 shows the measured waveforms of the output voltages and of the Voltage at the VCC pin.

Channel 1 is the output of the voltage regulator and i ts value is c onstant (~5V). Channel 2 is t he input of the

voltage regulator and here we can see that during the idle phase the voltage decreases linearly (the output capacitor is discharged with a constant current I

output voltage rises up from V

Ominstb

(Ch2Min = 7.48V) to V

), during the switching phase (note, it is actually very short) this

STB

(Ch2Max = 8.68V).

OMax

Figure 6. Standby waveforms: steady state with 10 mA load curr ent

Channel 3 shows the voltage on VCC pin of the controller L6565. As soon as this voltage reaches the UVLO onthreshold the system starts switching but, as soon as the voltage regulator input voltage reaches a value such

that the small signal bipolar Q3 is turned on, the gate driver of the L6565 is disabled, the switching is stopped

and the V

voltage decreases until the UVLO off-threshold. At this point the start-up network is on again and

CC

9/10

Page 10

AN1729 APPLICATION NOTE

the voltage on VCC pin starts rising.

In Fig. 7 the measured waveforms with 70mA load are shown. 70mA load is used to simulate the wake-up of

the micro controller. As can be seen, the voltage regulator input voltage (Ch2) minimum value (V

something more then the minimum voltage input for the LE50C Voltage regulator.

Figure 7. Standby waveforms: steady state with 70mA load cu rren t

OMin

) is 5.52V,

Conclusions

A low-cost solution for implementing an enhanced burst-mode operation, externally activated, that guarantees

a very low consumption in standby condition was proposed. It is based on a different but v ery simple strategy

of control that does not affect the behaviour of the circuit in normal operation. An analytic method to design the

standby circuit and estimate the power consumption of the converter in such condition was explained.

References

[1] "L6565 Quasi-Resonant Controller" (AN1326)

[2] L6565 datasheets

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent r i ght s of STMi croelectr oni cs. Specifications menti oned in thi s publicati on are subj ect

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical components in li f e support dev i ces or systems without express writ t en approval of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMic roelectroni cs - All Rig hts Reserved

Austra lia - Brazil - Canada - Ch i na - F i nl and - France - Germany - Hong Kong - India - Israel - Italy - Japan -Malay si a - Malta - Morocco -

Singap ore - Spain - Sw eden - Switzerland - Uni ted Kingdom - United St ates.

STMicroelectronics GROUP OF COMPANIES

http://www.s t. com

10/10

Loading...

Loading...