Page 1

AN1709

APPLICATION NOTE

EMC DESIGN GUIDE

FOR ST MICROCONTROLLERS

by Cyril Troise - Microcontroller Division Applications

INTRODUCTION

The continuing demand for more performance, complexity and cost reduction require the semiconductor industry to develop Microcontrollers with both high density design technology and

higher clock frequencies. This has intrinsically increased the noise emission and noise sensitivity. Applic ation dev elope rs therefor e, must no w app ly EMC “h ardening” te chniqu es in the

design of firmware, PCB layout and at system level. This note aims to explain ST Microcontroller EMC features and compliance standards to help application designers reach the optimum level of EMC performance.

1.0

AN1709/1003 1/38

1

Page 2

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 EMC DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 EMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 EMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 EMC CHARACTERIZATION OF ST MICROCONTROLLERS . . . . . . . . . . . . . . . . . . 5

2.1 ELECTROMAGNETIC SU SCEPTIBILITY (EM S) . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Functional EMS test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1.1 Functional ElectroStatic Discharge Test (F_ESD Test) . . . . . . . . . 5

2.1.1.2 Fast Transient Burst (FTB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1.3 ST Severity Level & Behavior Class . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Latch-Up (LU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.2.1 Static Latch-Up (LU) test: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.2.2 Dynamic Latch-Up (DLU) test: . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.3 Absolute Electrical Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.3.1 Human Body Model Test Sequence . . . . . . . . . . . . . . . . . . . . . . 12

2.1.3.2 Machine Model Test Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 ELECTROMAGNETIC INTERFERENCE (EMI) . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 EMI radiated test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.2 EMI level classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 ST MCU DESIGN STR ATEGY & EMC SPECIFIC FEATURE . . . . . . . . . . . . . . . . . . 17

3.1 SUSCEPTIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.1 Low Voltage Detector (LVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.2 Auxiliary Voltage Detector (AVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.3 I/O Features & properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.3.1 Electrostatic Discharge and Latch-up . . . . . . . . . . . . . . . . . . . . . 21

3.1.3.2 Protective Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1.3.3 Internal Circuitry: Digital I/O pin . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.3.4 Internal Circuitry: Analog Input pin . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.4 Multiple VDD & VSS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2 EMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.1 Internal PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.2 Global low power approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.2.1 Low powered oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

38

3.2.2.2 Internal Voltage Regulators (for MCUs with low power core). . . . 29

2/38

1

Page 3

Table of Contents

3.2.3 Output I/O Current limitation & edge timing control . . . . . . . . . . . . . . . . . . . . . . . . . 29

4 EMC GUIDELINES FOR MCU BASED APPLICATIO NS . . . . . . . . . . . . . . . . . . . . . 30

4.1 HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 HANDLING PRECAUTIONS FOR ESD PROTECTION. . . . . . . . . . . . . . . . . . . 34

4.3 FIRMWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4 WEB LINKS TO EMC RELATE D ORGANIS AT IONS . . . . . . . . . . . . . . . . . . . . 36

5 CONCLUSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3/38

Page 4

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

1 EMC DEFIN ITI ONS

1.1 EMC

ElectroMagnetic Comp atibility (EMC) is the cap ability of a system to work prop erly, undisturbed by the electromagnetic phenomena present in its normal environment, and not to

create electrical disturbances that would interfere with other equipment.

1.2 EMS

The ElectroMagnetic Susceptibility (EMS) l evel of a device is the resistance to electrical disturbances and conducted electrical noise. ElectroStat ic Discharge (ESD ) and Fast Transient

Burst (FTB) tests determine the reliability level of a device operating in an undesirable electromagnetic environment.

1.3 EMI

The ElectroMagnetic Interference (EMI) is the level of conducted or radiated electrical noise

sourced by the equipment. Conducted emission propagates along a cable or any interconnection line. Radiated emission propagates through free space.

4/38

2

Page 5

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

2 EMC CHARA CTERIZATION OF ST MICROC ONTROLLERS

2.1 ELECTROMAGNETIC SUSCEPTIBILITY (EMS)

Two different type of tests are performed:

■ Tests with device power-supplied (Functional EMS tests & Latch-up): The device behaviour

is monitored during the stress.

■ One test with device not powered supplied (Absolute Electrical Sensitivity): The device

functionality and integrity is checked on tester after stress.

2.1.1 Functional EMS test

Functional Tests are performed to measure the robustnes s of ST Microcontrollers running in

an application. Based on a simple program (toggling 2 LEDs through I/O ports), the product is

stressed by 2 different EMC events until a run-away condition (failure) occurs.

2.1.1.1 Functional ElectroStatic Discharge Test (F_ESD Test)

This test is performed on any new microcontroller devices.Each pin is tested individually with

a single positive or negative electrical discharge.This allows failures investigations inside the

chip and further application recommendations to protect the concerned Microcontroller sensitive pins against ESD.

High static voltage has both natural and man m ade origins. Some specific equipment can reproduce t his phenom e non i n orde r to te st t he devi ce un der r eal con di tions. Eq ui pmen t, test

sequence and standards are described here below.

ST Microcontroller F_ESD qualification test uses standards given in Table 1 as reference.

Table 1. ESD standards

EUROPEAN NORM INTERNATIONAL NORM DESCRIPTION

EN 61000-4-2 IEC 1000-4-2 Conducted ESD test

AEC-Q100-REUE is the Automotive controlling document.

F_ESD tests uses a signal source and a power amplifi er to generate a hi gh l evel fi eld into The

Microcontroller. The insulator is using a conical tip. This tip is placed on the Device or Equipment Under Test (DUT or EUT) and an electrostatic discharge is applied (see Figure 1.).

5/38

Page 6

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

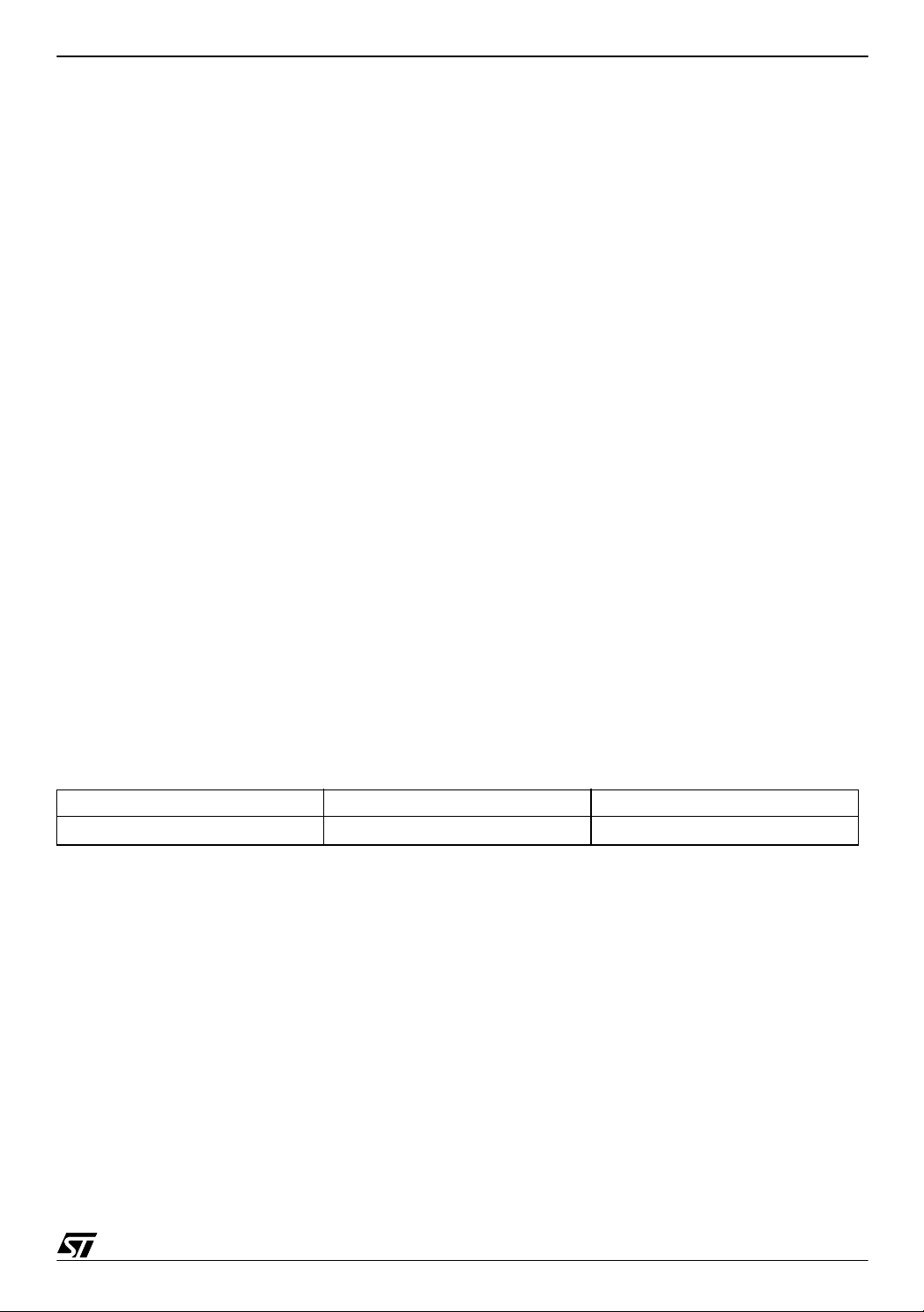

Figure 1. ESD test equipment

ground plane

ESD generator

insulation

EUT

mains

connections

The equipment used to perform F_ESD test is a Generator NSG 435 (SCHAFFNER) compliant with the norm IEC 1000-4-2. The discharges are directly applied on ea ch pin of the

MCU.

Figure 2. Typical ESD Current Waveform in Contact -mode discharge

(EN 61000-4-2)

Current

100%

90%

I(30ns)

I(60ns)

6/38

10%

30ns

tr=0.7 to 1.0 ns

60ns

time

Page 7

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

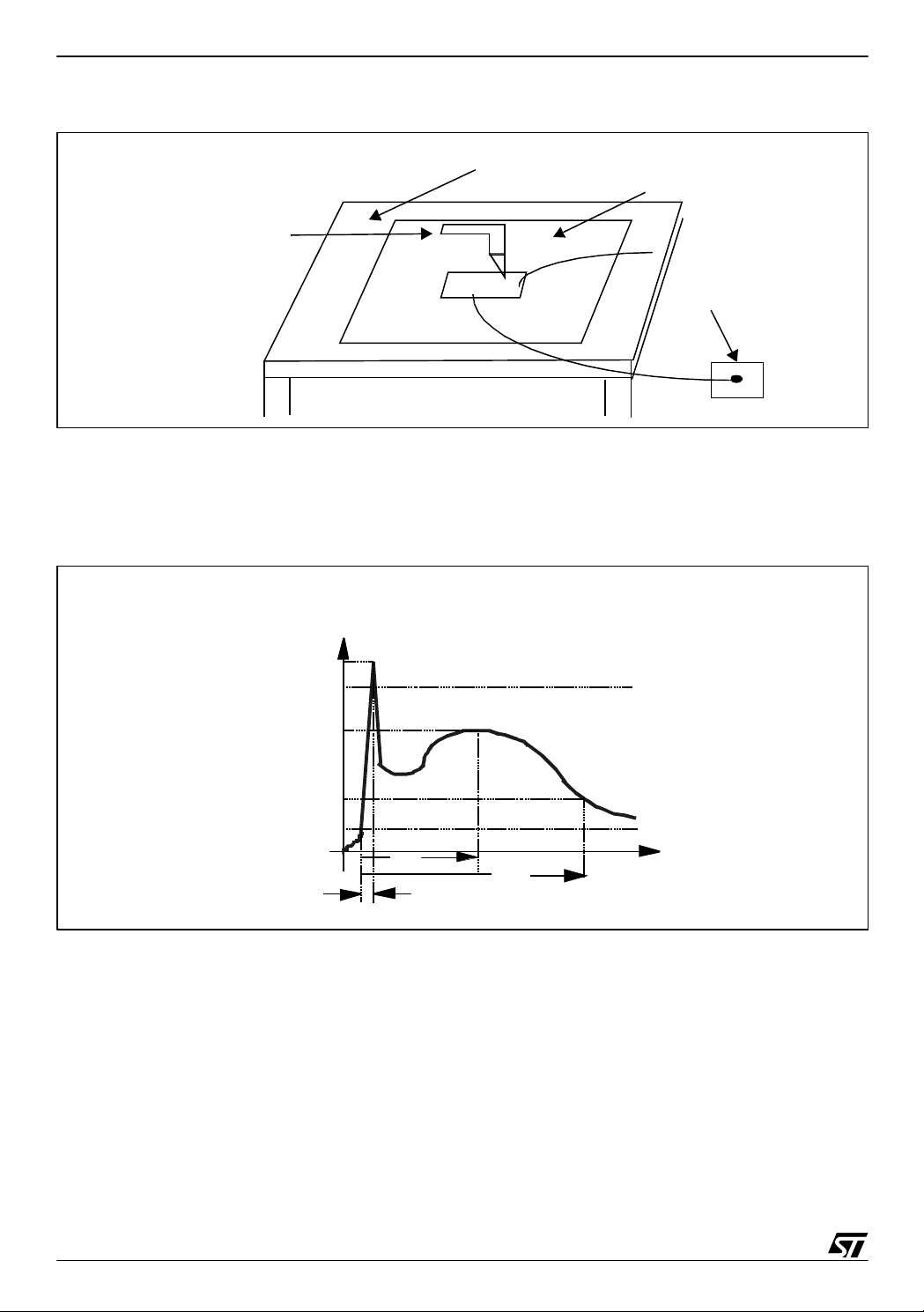

Figure 3. Simplified diagram of the ESD generator

Discharge

tip

Discharge return

connection

ESD

generator

Rch

Rd

HV relay

Cs = 150 pF

(Rch = 50MΩ; Rd = 330Ω)

2.1.1.2 Fast Transient Burst (FTB)

More complex than functional ESD, this test which su bmits the dev ice to a large quant ity of

emitted disturbances in a short time, is useful for detecting infrequent and unrecoverable

(Class B or C) Microcontroller states. FTB disturbances (see Figure 4.) are applied to the Mi-

crocontroller power lines through a capacitive coupling network.

ST Microcontroller FTB test correlates with the standards given in Table 2

Table 2. FTB standards

EUROPEAN NORM INTERNATIONAL NORM DESCRIPTION

EN61000-4-4 IEC 1000-4-4 Fast Transient Burst

Figure 4. FTB Waveform Diagram

Voltage

Burst

Time

Burst Length

15ms

Repetition Frequency: 5kHz; Bursts will

be repeated for at least 1 minute.

Burst Period

300ms

Voltage

Pulse

Bur

s

t

Time Time

Rising and Durat ion time (±3 0%) are referred to a 50Ω load

Volt age

0.9Vpk

0.1Vpk

5ns

Vpk

0.5Vpk

50ns

The spike frequency is 5 kHz. The generator produces bursts of spikes that last 15 ms every

300 ms (75 spikes).

The fast transients are coupled to the device DUT with capacitors C

(See Figure 5.).

C

7/38

Page 8

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

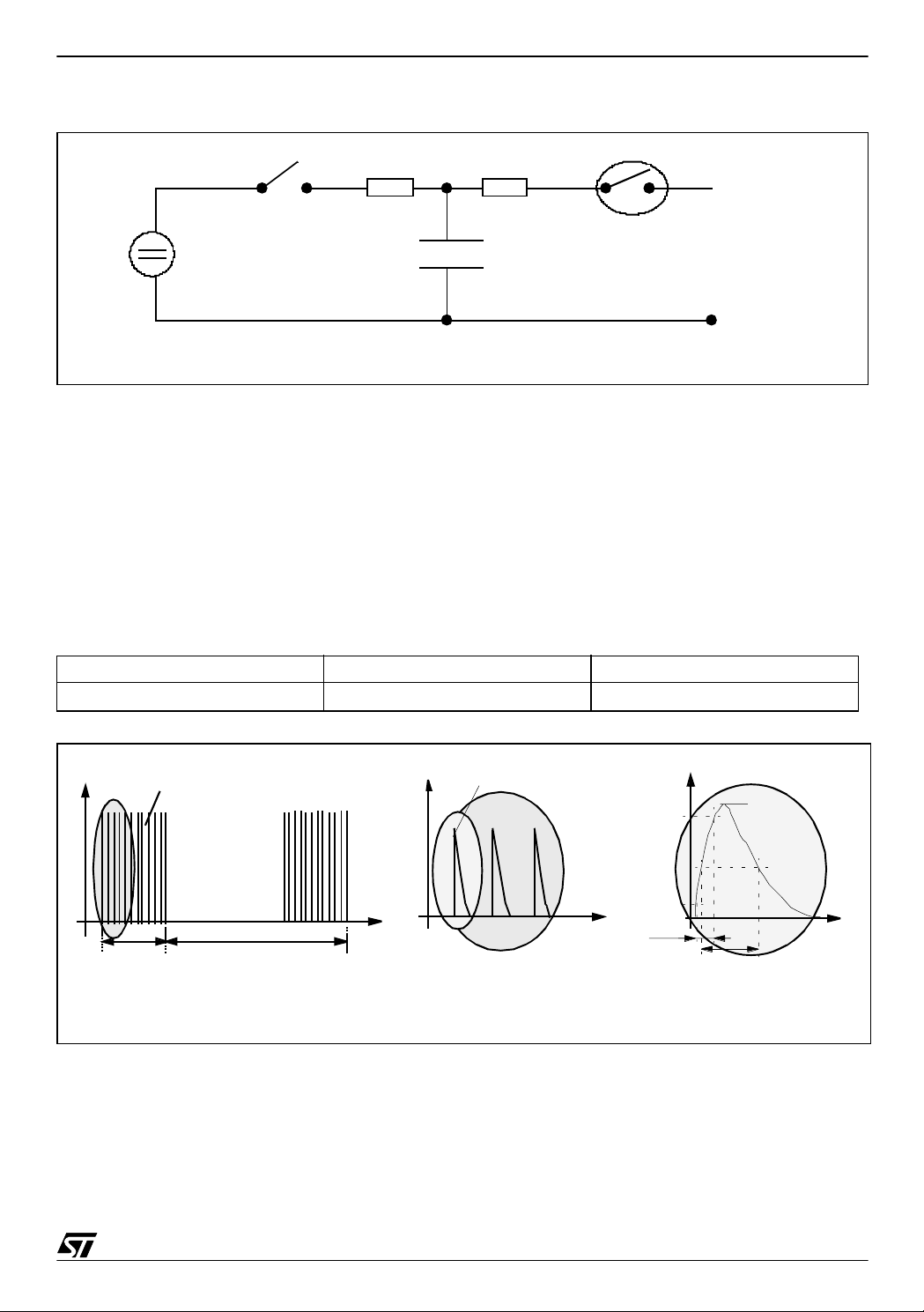

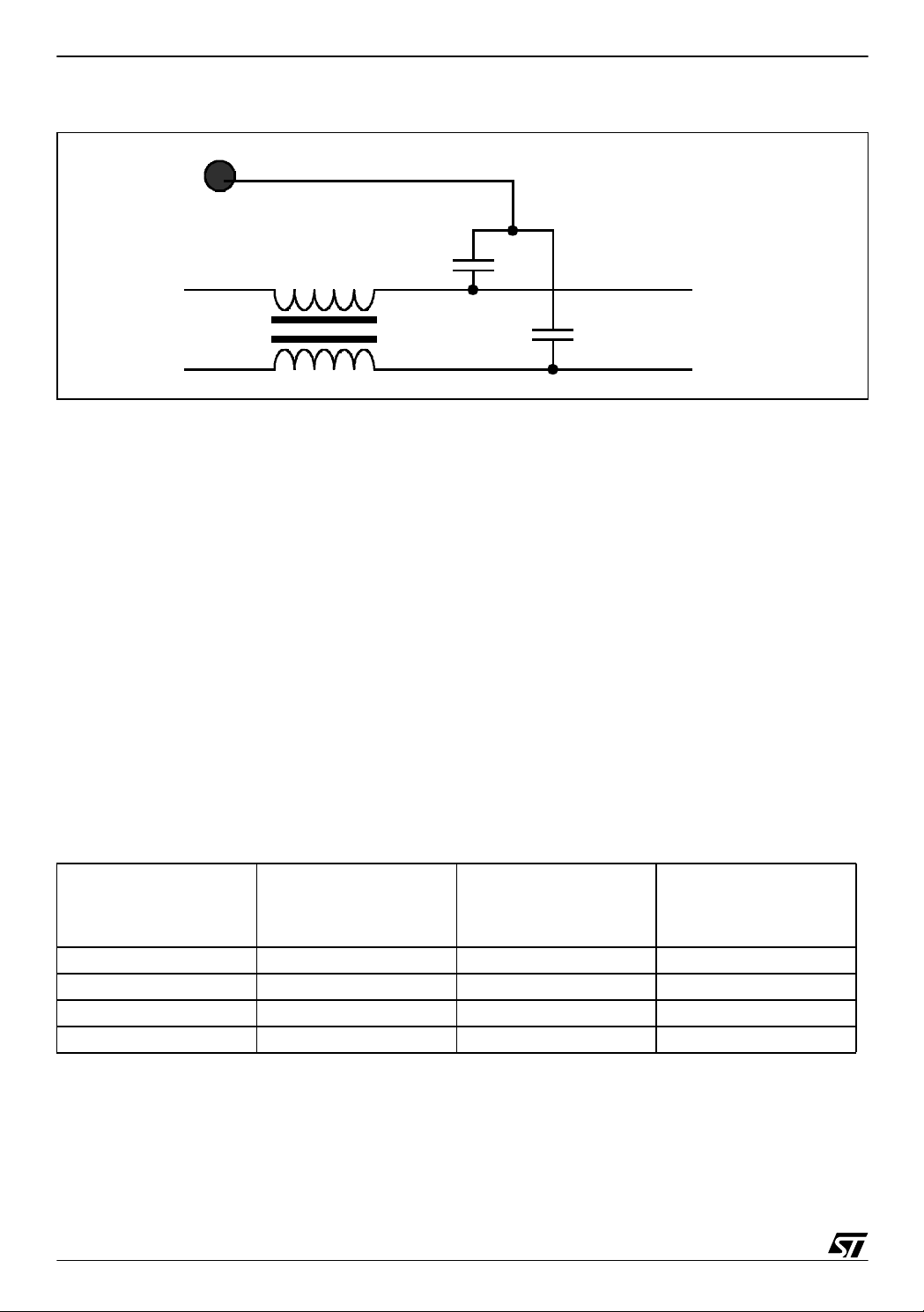

Figure 5. Coupling Network

NSG 2025

+V

POWER

SUPPLY

GND

DD

L

Cc

Cc

+V

DD

TO THE DEVICE

UNDER TEST

GND

Measurements are performed on a ground plane. The generator is connected to ground plane

by a short wire. The supply wires are 10 cm from the ground pl ane. The DU T is on the insulator 10 cm from the ground plane. The FTB voltage level is increased until the device failure.

Severity Levels and Class help application designers to determine which ST microcontrollers

are suitable for their target application, based on the susceptibility level (Severity level) and

type of behavior (Class) indicated in the datasheet.

2.1.1.3 ST Severity Level & Behavior Class

The 1000-4-2 and 1000-4-4 standards do not refer specifically to semiconductor components

such as microcontrollers. Us ually electromagne tic stress is app lied on other pa rts of the

system such a s connec tors, m ains , supp lies... Th e en ergy le vel o f th e F_E SD and FTB test

decreases before reaching the microcontroller, governed by the laws of physics. A large

amount of statistical data collected by ST on the behaviour of MCUs in various application environments has been used to develop a correlation chart between ST F_ESD or FTB test

voltage and 1000-4-2/1000-4-4 severity levels (See Table 3).

Table 3. ST ESD Severity levels

Severity Level

120.50-0.5

2410.5-1

3621-1.5

484>1.5

ESD (1000-4-2)

Equipment standard

(kV)

FTB (1000-4-4)

Equipment standard

(kV)

ST Testing Voltage

ST internal EMC test

(kV)

In addition to th is severity le vel, MCU beh aviour under ESD stress can be grouped into different Behaviour Classes (See Table 4) according to EN 50082-2 norm:

8/38

Page 9

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Table 4. ST Behavior Classes

Class A Class B Class C Class D

Needs an external user

action to recover normal

functionality

Normal functionality

cannot be recovered

No failure detected

Failure detected but self

recovery after disturbance

Any ST Microcontroller under the “acc eptance limits” is rejected as a fail. The “target level” is

the level used by ST to define good EMS performance.

Class B could be caused by:

– a parasitic reset correctly managed by the firmware (preferable case).

– deprogramming of a peripheral register or memory recovered by the application.

– a blocked status, recovered by a Watchdog or other firmware implementation.

Class C could be caused by:

– deprogramming of a peripheral register or memory not recovered by the application.

– a blocked application status requiring an external user action.

Table 5 shows ST target and acceptance limits.

Table 5. F_ESD / FTB target level & acceptance limit

Acceptance limit Target Level

F_ESD 0.5kV >1kV

FTB 0.5kV >1.5kV

Between “Acce ptance limit” and “T arget Level”, the dev ice is relatively suscep tible to noise.

Special care during system design should be taken to avoid susceptibility issues.

Table 6 shows how F_ESD / FTB test results are presented in ST datasheets.

Table 6. Example of F_ESD / FTB test results

Symbol Ratings Conditions Severity/Criteria

V

F_ESD

V

FTB

Voltage limits to be applied on any I/O

pin to induce a functional disturbance

Fast transient voltage burst limits to

be applied through 100pF on VSS and

VDD pins to induce a functional disturbance

T

=+25°C 2/A, 3/B

A

T

=+25°C 3/B

A

9/38

Page 10

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

2.1.2 Latch-Up (LU)

2.1.2.1 Static Latch-Up (LU) test:

The Latch-up is a phenomenon which is defined by a high current consumption resulting from

an overstress that triggers a parasitic thyristor structure and need a disconnection of the

power supply to recover the initial state.

NOTES

1 The overstress can be a voltage or current surge, an excessive rate of change of current or

voltage , or any other abno rmal conditi on th at caus es the paras itic th yrist or str ucture t o become self-sustaining.

2 Latch-up will not damage the device if the current through the low-impedance path is sufficiently limited in magnitude or duration.

This test conforms to the EIA/JESD 78 IC latch-up standard.

True LU is self-sustaining and once triggered, the h igh current c ondition w ill remain unt il the

power supply voltage is removed from the device. A temporary LU condition is considered to

have been induced if the high current condition stops when only the trigger voltage is removed.

Two complementary static tests are required on 10 parts to assess the latch-up performance:

■ Power supply overvoltage (applied to each power supply pin) simulates a user induced

situation where a transient over-voltage is applied on the power supply.

■ Current injection (applied to each input, output and configurable I/O pin) simulates an

application induced situation where the applied v oltage to a pin is greater than the maximum

rated conditions, such as sev ere overshoot abov e V

or undershoot below ground on an

DD

input due to ringing.

Table 7 shows how LU test result is presented in ST datasheets.

Table 7. Example of the LU test result on ST72F521

Symbol Parameter Conditions Class

T

=+25°C

A

=+85°C, TA=+125°C (de-

T

LU Static latch-up class

1. Class description: “A” class is an STMicroelectronics internal specification. All its limits are higher

than the JEDEC specifications, that means when a device belongs to Class A it exceeds the JEDEC

standard. “B” Class strictly covers all the JEDEC criteria (international standard).

A

pending on the temperature

range of the device)

1)

A

2.1.2.2 Dynamic Latch-Up (DLU) test:

The product is evaluated for its LU susceptibility to ES D discharges when the microcontroller

is “running.”

10/38

Page 11

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Increasing electrostatic discharges are supplied to every pin of the component until a Latch-up

occurs. Result is the maximum tolerated voltage without Latch-up.

DLU Test methodology and characterization: Electro-Static Discharges (one positive then one

negative test) are applied to each pin of 3 samples when the microcontroller is running to assess the latch-up performance in dynamic mode. Power supplies are set to the typical values,

the oscillator is connected as near as possible to the pins of the microcontroller and the component is put in reset mode.

Table 8 shows how the DLU test result is presented in ST datasheets.

Table 8. Example of DLU test Result on ST72F521

Symbol Parameter Conditions Class

=5V

V

DD

DLU Dynamic latch-up class

1. Class description: “A” class is an STMicroelectronics internal specification. All its limits are higher

than the JEDEC specifications, that means when a device belongs to Class A it exceeds the JEDEC

standard. “B” Class strictly covers all the JEDEC criteria (international standard).

f

OSC

T

=+25°C

A

=4MHz,

1)

A

LU/DLU test equipment is same as the one used for the functional EMS (see Figure 1.).

2.1.3 Absolute Electrical Sensitivity

This test is performed to assess the components immunity against destruction caused by

ESD.

Any devices that fails this electrical test program is classified as a failure.

Using automatic ESD tester, Electro-Static D ischarges (a positive then a negative pulse sep-

arated by 1 second) are applied to the pins of each sample according to each pin combination.

The sample size depends of the number of supply pi ns of the device (3 parts*(n+ 1): n= supply

pins). Two models are usually simulated: Human Body Model (HBM) and Machine Model

(MM). All parts are re-test ed on the production tester to veri fy the static and dynamic parameters still comply with the device datasheet (See Figure 6.).

This test co nforms to th e JES D22-A11 4A/A 115A s tandar d. See Figure 6. and the following

test sequences.

11/38

Page 12

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 6. Absolute Electrical Sensitivity test models

HIGH VOLTAGE

PULSE

GENERATOR

S1

R=1500W

CL=100pF

HUMAN BODY MODEL MACHINE MODEL

µC

HIGH VOLTAGE

S2

PULSE

GENERATOR

S1

CL=200pF

R=10k~10MW

µC

S2

2.1.3.1 Human Body Model Test Sequence

The HBM ESD pulse simulates the direct transfer of electrostatic charge, from the Human

Body, to a test device. A 100pF capacitor is discharged through a switching component and a

1.5 Kohm series resistor. This is currently the m ost reques ted industry model, for classifying

device sensitivity to ESD.

– C

is loaded through S1 by the HV pulse generator.

L

– S1 switches position from generator to R.

– A discharge from C

through R (body resistance) to the µC occurs.

L

– S2 must be closed 10 to 100ms after the pulse delivery period to ensure the µC is not left in

charge state. S2 must be opened at least 10ms prior to the delivery of the next pulse.

2.1.3.2 Machine Model Test Sequence

The MM ESD pulse em ulates the rapid direct transfer of electrostatic charge, from a charged

conductive object, such as a metallic tool or fixture, to a test device. This model consists of a

discharged 200pF capacitor, with no series resistor. The demand for MM ESD testing has increased, with the replacement of individual packaging by automated systems.

is loaded through S1 by the HV pulse generator.

– C

L

– S1 switches position from generator to the µC.

– A discharge from C

to the µC occurs.

L

– S2 must be closed 10 to 100ms after the pulse delivery period to ensure the µC is not left in

charge state. S2 must be opened at least 10ms prior to the delivery of the next pulse.

R (machine resistance), in series with S2, ensures a slow discharge of the µC.

Table 9 shows how HBM/MM ESD test results are presented in ST datas heets.

12/38

Page 13

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Table 9. Example of HBM/MM ESD test results on ST72F521

Symbol Ratings Conditions

V

ESD(HBM)

V

ESD(MM)

Notes:

1. Data based on characterization results, not tested in production.

Electro-static discharge voltage

(Human Body Model)

Electro-static discharge voltage

(Machine Model)

T

=+25°C 2000

A

T

=+25°C 200

A

Maximum value

1)

Unit

V

2.2 ELECTROMAGNETIC INTERFERENCE ( EMI)

2.2.1 EMI radiated test This test correlates with the SAE J1752/3 standard.

This test gives a good evaluation of the contribution of the microcontroller to radiated noise in

an application environment. It takes into acco unt the MCU chip and also the package which

has a major influence on the noise radiated by the device.

Below is the package EMI contribution from the highest to the lowest:

SDIP/DIP

SOP

QFP

TQFP

The test is per for med in a Trans verse Elect romagn etic Mod e Ce ll (TEMCELL) w hich al lows

radiated noise measurement in two directions, rotating the test board by 90°

Test description:

The firmware running is based on a simple application, toggling 2 LEDs through the I/O ports.

The main directives for an SAE PCB are (Figure 8.):

– 100 x 100mm square board

– At least 2-layer board (ideally 4-layer).

– 5mm conductive edges on both sides connected to ground for contact with TEMCELL.

Figure 7. shows a typical example of an MCU EMC te st board sche m atics.

13/38

Page 14

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 7. Example of test board schematics for ST7

BP1

10k

LED 1

PB1

Xtal 1

Xtal 2

PB2

220

LED 2

220

+5v

PB3

VddA

Vdd1

Vdd2

Vdd3

100 nF

VssA

14/38

BP2

4.7k

GND

Reset

Vss1

Vss2

Vss3

GND

Vpp

10k

GND

Page 15

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 8. Test Printed Circuit Board specification according J1752/3 SAE st andard

15/38

Page 16

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

2.2.2 EMI level classification

The EMI classifications are dir ectly based on the absolute frequency and amplitude of the

emitted noise. Several international norms exist, based on different measurement methodologies, or emission levels, but the classification principle remains the same.

The standardized diagram (see Figure 9. ) is us efu l to get a s ynthes is a nd a cla ssification o f

EMI results, according to a standard framework. Each ST microcontroller EMI result is classified according to 4 SAE levels.

Figure 9. EMI level classification:

dbu V

60

Level 4

40

30

Level 3

Level 2

20

10

Level 1

0

-20

0.1 1 10 30 100 1000

MHz

Below is the potential risk associated with each EMI level:

_ higher than 4. high risk due to EMI level.

_ Level 4. may require cost for EMI compliance.

_ Level 3. moderate EMI risk.

_ Level 2. minimal EMI risk.

Table 10 shows how EMI test results are presented in ST datasheets.

for

Table 10. Example of EMI results

To give a synthetic view of the emi ssion sp ectrum, the highes t emiss ion level of 3 r anges of

ST72F521

frequency is indicated. EMI data are provided with relevant information such as the device

package and CPU frequency.

16/38

Page 17

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

3 ST MCU DESIG N STR ATEGY & EMC SPECIFIC FEATURE

At the initial specification of a new product, EMC dedicated features are implemented after an

identification of EMC constraints imposed by the MCU target applications. You should refer to

the specific product datasheet to know which of these feature described here are embedded.

Figure 10. Overview of specific features embedded in ST Microcontrollers

Low Power Oscillator

Multi Oscillator

Watchdog

(Firmware Management

refer to AN 1015)

I/O Protection

Controlled Slope

LVD/AVD

Embedded features

for EMC in

ST Microcontrollers

Internal Voltage Regulators

(For MCUs with low power core)

Internal PLL

3.1 SUSCEPTIBILITY

3.1.1 Low Voltage Detector (LVD)

The purpose of the LVD is to ensure that the Microcontroller will always work in its safe operating area (see Figure 12.). In terms of EMS, the presenc e of the LVD makes the M CU more

robust, ensuring that if any outside disturbance affects the power supply, the application can

recover safely.

When V

is below the « Min Working VDD» the behaviour of the Microcontroller is no longer

DD

guarantee d. There is no t enough power to decode/ execut e the instruc tions an d/or read the

memory. When V

is below the LVD level the M icrocontr oller enters in reset state (in ternal

DD

reset High) in order to prevent unpredi ctable behaviour . There are 2 level s with 25 0mV h ysteresis in order to avoid oscillating when the micro restarts. When a LVD reset occurs, a bit is

set by HW. This bit can be used to recover an application.

The Low Voltage Det ector func tion genera tes a static rese t when the V

below a V

reference value. This means that it secures the power-up as w ell as the power-

IT-

supply voltage is

DD

down keeping the Microcontroller in reset.

17/38

Page 18

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

The V

reference value for a voltage drop is lower than the V

IT-

reference value for power-on

IT+

in order to avoid a parasitic r eset when the MCU starts running and si nks current on the supply

(hysteresis).

The LVD Reset circuitry generates a reset when V

–V

when VDD is rising

IT+

–V

when VDD is falling

IT-

is below:

DD

The LVD function is illustrated in Figure 11..

The voltage threshold can be configured by option byte to be low, medium or high.

Provided the minimum V

value (guaranteed for the oscillator frequency) is above V

DD

IT-

, the

MCU can only be in two modes:

– under full software control

– in static safe r eset

In these conditions, secure operation is always ens ured for the application without the need

for external reset hardware.

During a Low Voltage Detector Reset, the RESET pin is held low, thus permitting the MCU to

reset other devices.

Notes:

The LVD allows the device to be used without any external RESET circuitry.

The LVD is an optional function which can be selected by option byte. Refer to product spec-

ification.

Figure 11. Low Voltage Detector vs Reset

V

DD

V

hys

V

IT+

V

IT-

RESET

18/38

Page 19

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 12. Max. Operating frequency vs. supply voltage.

16Mhz

8Mhz

Freq.

LVD low

LVD med.

Safe 8Mhz

area

LVD high

Safe 16MHz

area.

3.5V Reset

issued

Absolute working

window

Safe 16Mhz

area

3.8V Reset

issued

Vsupply

The minimum value of each supply range is l i mited by the LVD threshold which can be confi gured at one of three levels (low, medium or high) depending on the application.

3.1.2 Auxiliary Voltage Detector (AVD)

Like the LVD, this feature improves EMS performance by ensuring that the microcontroller behaves safely when the power supply is disturbed by external noise.

The AVD feature can be use d only if the LVD is acti vated. AV D has also differen t levels

(around 200mV above LV D le vels), enabling a early warning before t he reset c aused by the

LVD. Then, when AVD threshold is crossed, an interrupt is generated, requesting for example

some user a ction or prepar ing th e applic ation t o shut do wn in the i nterru pt routi ne unti l the

power supply returns to the correct level for the device (refer to the product datasheet).

Example: If f

The Voltage Detector func tion (AVD ) is b ased on an analog c ompariso n between a V

V

reference value and the VDD main supply. The V

IT+

lower than the V

is between 8 MHZ and 16 MHZ the min. working level is 3.5 volt.

CPU

reference value for falling voltage is

IT-

reference value for ris ing volt age in or der to avoid par asitic detecti on (hys-

IT+

IT-

and

teresis).

The output of the A VD c omparator is directly readable by the a pplication softw are th rough a

real time status bit (VDF). This bit is read only.

The AVD voltage thres hold value is rela tive to t he selected LVD thre shold configured b y op-

tion byte (see Microcontroller spec).

19/38

Page 20

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

If the AVD interru pt is enable d, an interr upt is gen erated when the vo ltage cros ses the

V

IT+(AVD)

or V

IT-(AVD)

threshold (AVDF bit toggles).

In the case of a drop in voltage, the AVD interrupt acts as an early warning, allowing software

to shut down safely before the LVD resets the microcontroller. (See Figure 13.).

The interrupt on the rising edge is used to inform the application that the V

warning state is

DD

over.

If the voltage rise time t

of the Microcontroller), no AVD interrupt will be generated when V

is greater than 256 or 4096 cycles then:

If t

rv

– If the AVD interrupt is enabled before the V

is less than 256 or 4096 CPU cycles (depending on the reset del ay

rv

is reached.

IT+(AVD)

IT+(AVD)

threshold is reached, then 2 AVD interrupts will be received: the first when the AVDIE bit is set, and the second when the threshold

is reached.

– If the AVD interrupt is enabled after the V

IT+(AVD)

threshold is reached then only one AVD

inte rrupt will occur.

Figure 13. Using the AVD to Monitor V

V

DD

DD

Early Wa rn in g Interru pt

(Power has droppe d, MCU not

not yet in reset)

V

V

IT+(AVD)

V

IT-(A VD)

V

IT+(LVD)

hyst

20/38

V

IT-(LVD)

AVDF bit 0 0RESET VALUE

AVD IN TERRUPT

REQUEST

IF AVDIE b it = 1

INTERRUPT PROCESS

LVD RESET

t

VOLTAGE RISE TIME

rv

11

INTERRUPT PROCESS

Page 21

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

3.1.3 I/O Features & properties

Although i nteg r ated c irc uit da ta she et s p r ovi de t he u se r with c on serv at ive limi ts an d con di tions in order to prevent damage, sometimes it is useful for the hardware system designer to

know the internal failure mechanisms: the risk of exposure to illegal voltages and conditions

can be reduced by smart protection design.

It is not possible to classify and to predict al l the possible damage resulting from violating maximum ratings and conditions, due to the large nu mber of v ariables th at come in to play in de fining the failures: in fact, when an overvoltage condition is applied, the effects on the device

can vary signi ficantly d epending on lot-to -lot proces s variatio ns, ope rating tempe ratu re, external interfacing of the Microcontroller with other devices, etc.

In the following sections, background technical information is given in order to help system designers to reduce risk of damage to the Microcontroller device.

3.1.3.1 Electrostatic Discharge and Latch-up

CMOS integrated circuits are generally sensitive to exposure to high voltage static electricity,

which can induce permanent damage to the device: a typical failure is the breakdown of thin

oxides, which causes high leakage current and sometimes shorts.

Latch-up is another typical phenomenon occurring in integrated circuits: unwanted turning on

of parasitic bipolar structures, or silicon-controlled rectifiers (SCR), may overheat and rapidly

destroy the de vice. Th ese unintent ional str uctures are compos ed of P and N regions wh ich

work as emitters, bases a nd collectors of parasitic bipolar transistors : the bulk resistance of

the silicon in the wells and substrate act as resistors on the SCR structure. Applying voltages

below V

or above VDD, and when the level of current is able to generate a voltage drop

SS

across the SCR parasitic resistor, the SC R may be turned on; to turn off the SCR it is necessary to remove the power supply from the device.

ST Microcontroller design implements layout and process solutions to decrease the effects of

electrostatic discharges (ESD) and latch-up. Of course it is not possible to test all devices, due

to the destructive nature of the mechanism; in order to guarantee product reliability, destructive tests are carried out on groups of devices, according to STMicroele ctronics internal

Quality Assurance standards and recommendations (see 2.1.2 Latch-Up (LU)).

21/38

Page 22

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

3.1.3.2 Protective Interface

Although ST Microcontroller input/output circuitry has been designed taking ESD and Latchup problems into account, for those a pplications and s ystems where ST Micr ocontroller pins

are exposed to illegal voltages and high current injections, the user is strongly recommended

to implement hardware solutions which reduce the risk of damage: low-pass filters and clamp

diodes are usually sufficient in preventing stress conditions.

The risk of having out-of-range voltages and currents is greater for those signals coming from

outside the system, where noise effect or uncontrolled spikes could occur with higher probability than for the internal signals; it must be underlined that in some cases , adopti on of filters

or other dedicated interface circuitries might affect global microcontroller performance, inducing undesired timing delays, and impacting the global system speed.

Figure 14. Digital Input/Output - Push-Pull

I/O CIRCUITRY

PIN

ESD PROTECTION

CIRCUITRY

P

OUTPUT

BUFFER

N

P

EN

PORT CIRCU ITRY

EN

P

INPUT

BUFFER

N

N

P

22/38

Page 23

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

3.1.3.3 Internal Circuitry: Digital I/O pin

Figure 14. shows a schematic representation of an ST Microcontroller pin able to operate ei-

ther as an input or as an output is shown. The circuitry implements a standard input buffer and

a push-pull configuration for the output buffer. It is evident that al though it is possible to disable

the output buffer when the input section is used, the MOS transistors of the buffer itself can still

affect the behaviour of the pin when exposed to illegal conditions. In fact, the P-channel transistor of the output buffer implements a di rect di ode to V

to the pin and N-well connected to V

a diode to V

(P-substrate connected to VSS and N-diffusion of the drain connected to the

SS

), while the N-channel of the output buffer implements

DD

(P-diffusion of the drain connected

DD

pin). In par allel to the s e di ode s, d edic ated c ircuitr y is impl em ent ed to p rote ct the logi c f rom

ESD events (MOS, diodes and input series resistor).

The most important characteristic of these extra devices is that the y must not di sturb normal

operating mod es, while acti ng during exp osure to ov er limit conditi ons, avoiding permane nt

damage to the logic circuitry.

According to t he MCU u sed, som e I/O pins can be prog ramm ed t o wo rk also as o pen-dr ain

outputs, by simply writing in the corresponding register of the I/O Port. The gate of the Pchannel of the output buffer is disabled: it is important to highlight that physically the P-channel

transistor is still present, so the diode to V

voltage applied to the pin is higher than the V

works. In some applications it can occur that the

DD

value (supposing the external line is kept

DD

high, while the Microcontroller power supply is turned off): this condition w ill inject curren t

through the diode, risking permanent damages to the device.

In any case, programm ing I/O pins as open-drain can help when several pins in the system

are tied to the same point: of course software must pay attention to program only one of them

as output at any time, to avoid output driver contentions; it is adv isabl e to configure these pins

as output open-drain in order to reduce the risk of current contentions.

23/38

Page 24

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 15. Digital Input/Output - True Open Drain Output

I/O CIRCUITRY

PIN

ESD PROTECTION

CIRCUITRY

OUTPUT

BUFFER

N

EN

P

N

EN

PORT CIRCUITRY

INPUT

BUFFER

N

P

In Figure 15. a true open -dra in pin s chem atic i s s hown. In this c as e all pa ths to V

are re-

DD

moved (P-cha nne l dr iv er, E SD p rote cti on dio de, i nter nal w eak pul l-up ) i n or der to a llow t he

system to turn off the power supply of the microcontroller and keep the voltage level at the pin

high without injecting current in the device. This is a typical condition which can occur when

several devices interface a seri al bus: if one device is not i nvolved in the communication, it can

be disabled by turning off its power supply to reduce the system current consumption.

When an illegal negative voltage level i s appli ed to the Microcontroller I/O pi ns (both versions,

push-pull and true open-drain output) the clamp diode is always present and active (see ESD

protection circuitry and N-channel driver).

24/38

Page 25

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

3.1.3.4 Internal Circuitry: Analog Input pin

Figure 16. shows the internal circuitry used for analog input. It is primarily a digital I/O with an

added analog m ultiplexer for the sel ection of the input cha nnel of the Analog to Digital Con verter (ADC).

The presence of the multiplexer P-channel and N-channel can affect the behaviour of the pin

when exposed to illegal voltage conditions. These transistors are controlled by a low noise

logic, biased through AV

and AVSS including P-channel N-well: it is important to always

DD

verify the input voltage value with respect to both analog power supply and digital power

supply, in order to avoid uni ntentional current injections which (i f not limited) could destroy the

device.

Figure 16. Digital Input/Output - Push-Pull Output - Analog Multiplexer Input

I/O CIRCUITRY

P

PIN

E

SD PROTECTION

CIRCUITRY

OUTPUT

BUFFER

N

P

EN

N

P

N

N

EN

P

INPUT

BUFFER

P

PORT CIRCUITRY

P

25/38

Page 26

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

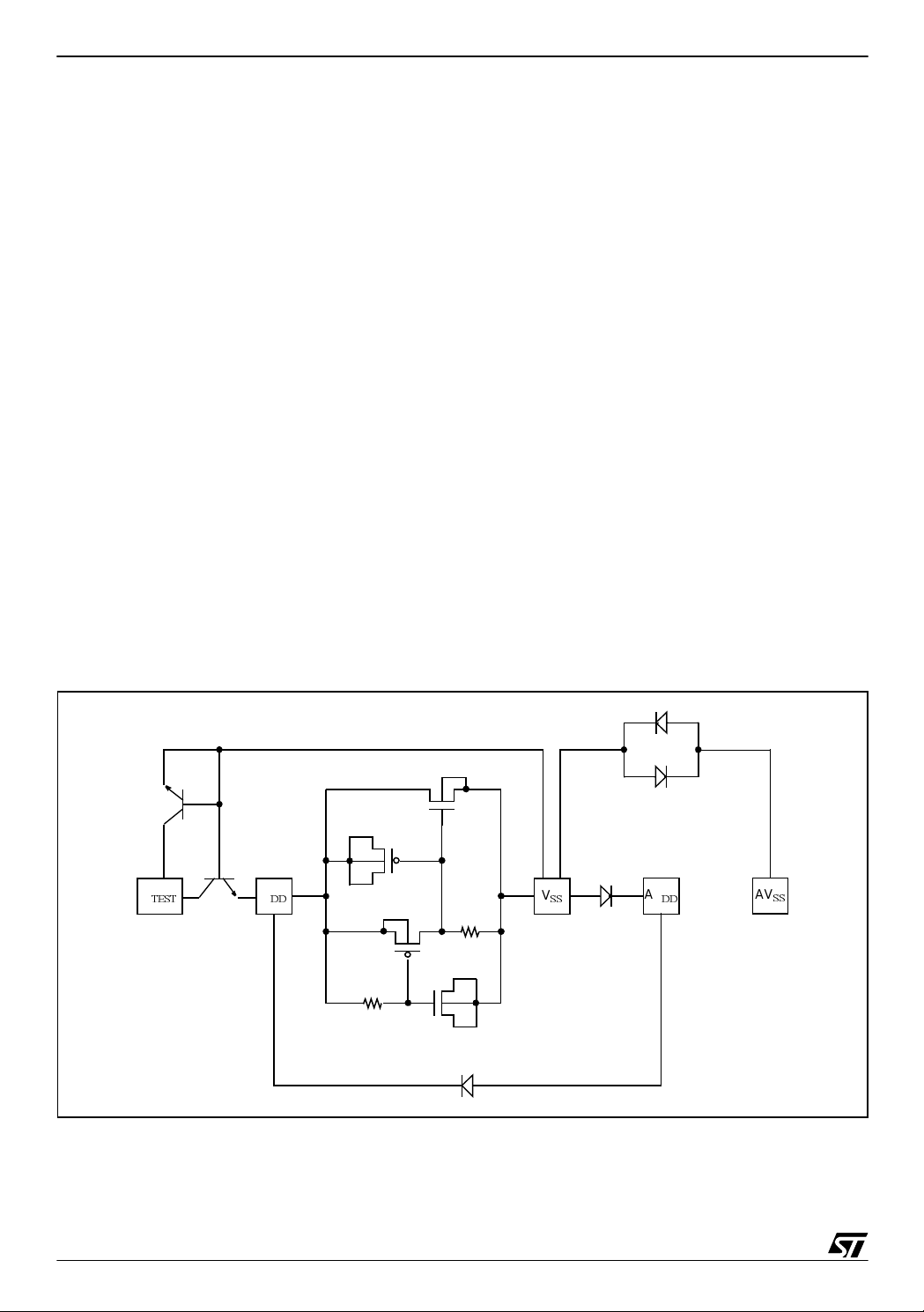

3.1.4 Multiple VDD & VSS.

As already said for the I/O pins, in order to ens ure ST Microcontroller c ompliance with respect

to Quality Assurance recommendations concerning ESD and Latch-up, dedicated circuits are

added to t he differ ent pow er suppl y and gro und pi ns (digit al and an alog). T hese s tructure s

create preferred paths for the high curr ent injected duri ng discharges, avoiding damage to active logic and circuitry. It is important for the system designer to take this added circuitry into

account, when applying different current levels and voltages to the power supply and ground

pins. Figure 17. shows schematically the protection net implemented on ST Microcontroller

devices, composed of diodes and other special structures.

The clamp structure between the V

and VSS pins is designed to be active during very fast

DD

transitions (typical of electrostatic discharges). Other paths are implemented through diodes:

they limit the possibi lity of pos itively differenti ating AV

considerations are valid for AV

and VSS due to the back-to-back diode structure imple-

SS

mented between the two pins. Anyway, it must be highlighted that, because V

and VDD (i.e . A VDD > VDD); similar

DD

and AVSS are

SS

connected to the sub strate o f the silicon die (even though in d ifferent areas o f the die itself),

they represent the reference point from which all other voltages are measured, and it is recommended to never differentiate AV

Note: If m ore than one pair of pins for V

from VSS.

SS

SS

and VDD is available on the device, they are con-

nected internally and the protection net diagram remains the same as shown in Figure 17..

Figure 17. Power Supply and Ground Configuration (on ST9)

N

P

26/38

V

TEST

V

DD

P

N

V

SS

AV

DD

AV

SS

Page 27

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

3.2 EMISSION

3.2.1 Internal PLL

Some ST Microco ntrollers have a n embe dded program mab le PLL Clock Gener ator allowing

the usage of standard 3 to 5 MHz crystals to obtain a l arge range of internal frequencies (up

to 24MHz). By these means, ST Microcontroller can operate with cheaper, medium frequency

crystals, while still providing a high frequency internal clock for maximum system performance. The high clock frequency source i s contained inside the c hip and does not go thr ough

the PCB (Printed Circuit Board ) tracks and external com ponents. This reduce s the potential

noise emission of the application.

The use of PLL network also filters CPU clock against external sporadic disturbances

(glitches) .

3.2.2 Global low power approach

3.2.2.1 Low powered oscillator

The oscillator is an major source of noise. To reduce this noise emission, the current driven by

the oscillator is limited.

The main clock of some of ST Microcontrollers can be generated by four different source types

coming from the multi-oscillator block (MO). This allows the designer to easily select the best

trade-off in terms of cost, performance and noise emission. The clock sources are listed below

in order from the most noisy to the least noisy:

■ an external source

■ crystal or ceramic resonator oscillators

■ an internal high frequency RC oscillator

Each osc illat or is o ptimi zed fo r a giv en fre que ncy ran ge in t erm s of cons um ption an d is se lectable through the option byte. The associated hardware configurations are shown in Table

11. Refer to the electrical characteristics section of the datasheet for more details in each

case.

External Clock Source

In external clock mode, a clock signal (square, sinus or triangle) with ~50% duty cycle has to

drive the OSC1 pin while the OSC2 pin is tied to ground.

Crystal/Ceramic Oscillators

This family of oscillators has the advantage of producing a very accurate rate on the ma in

clock of the microcontroller. The selection within a list of 5 os cillators with different frequency

ranges has to be done by option byte in order to reduce consumption (refer to the Microcontroller datasheet for more details on the frequency ranges). In this mode of the multi-oscillator,

the resonator and the load capacitors have to be placed as c lose as possible to the oscillator

27/38

Page 28

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

pins in order to minimize output distortion and start-up stabilization time. The loading capacitance values must be adjusted according to the selected oscillator.

These oscillators are not stopped during the RESET phase to avoid the del ay needed for the

the oscillator start-up.

Internal RC Oscillator

The internal RC osci llator is the most c ost ef fective s oluti on, with the draw back of lower frequency accuracy. Its frequency is in the low single digit MHz range. In this mode, the two oscillator pins have to be tied to ground.

Process variations will also bring some differences from lots to lots (20 to 60%).

Some S T Mic roc ontr oller s (ref er to p rodu ct sp ecif icat ion) em bed a pro cess c omp ens ation .

This feature is called “Tri mmable internal RC”. A procedure duri ng test operati on anal yzes the

process variation and calibrate the internal oscillator accordingly. This brings the internal RC

accuracy to 1%. This procedure can be also performed by the user:

Refer to AN1324 “Calibrating the RC oscillator of the ST7FLITE0 using the mains”

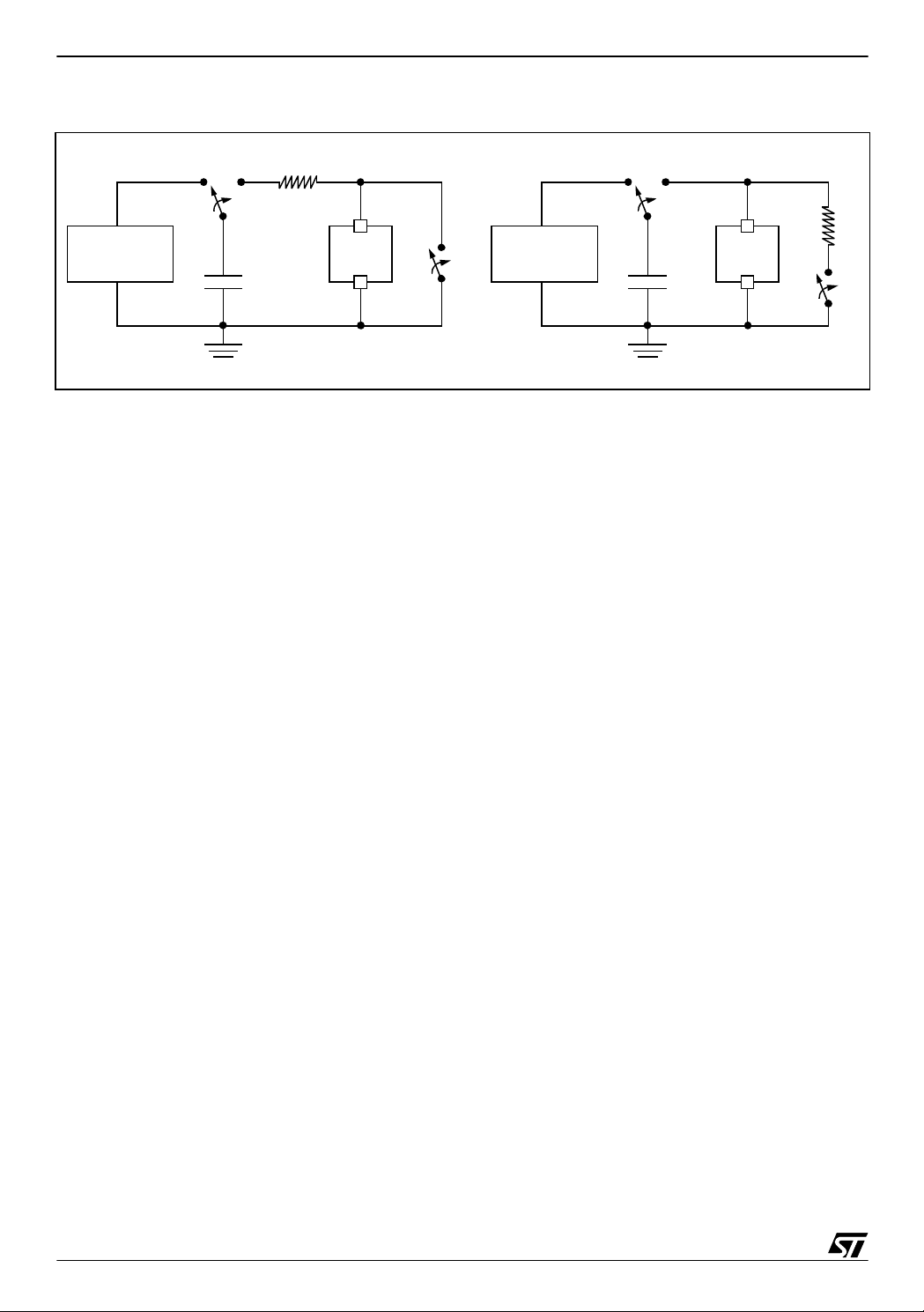

Table 11. ST7 Clock Sources

Hardware Configuration

ST7

OSC1 OSC2

R

EX

OSC1 OSC2

ST7

C

EX

External Clock

Crystal/Ceramic Resonators

OSC1 OSC2

EXTERNAL

SOURCE

OSC1 OSC2

C

L1

CAPACITORS

ST7

ST7

LOAD

External RC Oscillator

C

L2

Internal RC Oscillator

The ST mu lti-os cillator s y stem i s de signe d f or f lexibility an d to a llow the s ystem des igner to

find the best compromise between emission, accuracy and cost criteria.

28/38

Page 29

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

3.2.2.2 Internal Voltage Regulators (for M CUs with low power core).

An internal Voltage Regulator is used to power some ST Microcontrollers Cores starting from

the external power supply.

The Voltage Regulator reduces EMI due to the MCU Core with 2 effects:

– Lower CPU Supply Voltage

– Isolate CPU Supply from external MCU supplies.

3.2.3 Output I/O Current limitation & edge timing control

Output buffers are embedded in ST Microcontrollers, their switching speed is controlled in

order to avoid parasitic oscillations when they are switched. The MCU design makes a tradeoff between noise and speed.

29/38

Page 30

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

4 EMC GUIDELINES FOR MCU BASED APPLICATIONS

The following guidelines result from experience gained in a wide variety of applications.

4.1 HARDWARE

The major noise receptors and generators are the tracks and wiring on the Printed Circuit

Board (PCB), especially those near the MCU. The first actions to prevent noise problems thus

concern the PCB layout and the design of the power supply.

In general, the smaller the number of components surrounding the MCU, the better the immunity versus noise. A ROMless solution, for instance, is typically more sensitive to and a bigger

generator of noise than an embedded memory circuit.

Optimized PCB layout

Noise is basically r eceived and transm itte d throu gh track s and comp onents wh ich, o nce excited, act as antennas. Each loop and track includes parasitic inductance and capacitance

which radiate and absorb energy once submitted to a variation of current, voltage or electromagnetic flux.

An MCU chip itself presents high immunity to and low generation of EMI since its dimensions

are small versus the wave lengths of EMI signals (typically mm versus 10's of cm for EMI signals in the GHz range). So a single chip solution with small loops and short wires reduces

noise problems.

The initial action at the PCB level is to reduce the number of possible antennas. The loops and

wires connec ted to the M CU s uch as supply, os cillator an d I /O s hould be cons idere d with a

special attention . The osc illator loop ha s to be especially sma ll si nce it o perate s at hig h frequency Figure 18.

A reduction of both the inductance and the c apacitance of a track i s gener ally difficult. Prac tical experience suggests that in most cases the inductance is the first parameter to be minimized.

30/38

Page 31

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 18. PCB Board Oscillat or Layout Examples

The reduction of inductance can be obtained by making the lengths and surfaces of the track

smaller. This can be obtained by placing the track loops closer on the same PCB layer or on

top of one another (Figure 19.). The resulting loop area is small and the electromagnetic fields

reduce one another.

The ratio in order o f ma gnitude relat ing to the inductanc e va lue a nd the a re a de fined b y the

wire loop is around 10nH/cm2. Typical examples of low inductivity wires are coaxial, twisted

pair cables or mul tiple lay er PCBs with one gr ound and one s upply layers. T he curr ent dens ity

in the track can also be smaller due to track enlargement or the paralleling of several small capacitances mounted in the current flow.

In critical cases, the distance between the MCU and the PCB, and therefore the surfaces of

the loops betwee n an MCU and its env ironment, has also to be minimize d. This can be

achieved by removing any socket between the MCU package and the PCB, by replacing a ceramic MCU package by a plastic one or by using Surface Mounting instead of Dual In Line

packages.

Note: Board vias are inductances. Try to avoid them. If needed, use multi vias.

31/38

Page 32

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 19. Reduction of PCB Tracks Loop Surfaces

High Inductance

Low Inductance

Note: T his test is done with a double sided PCB. Insulator thickness is 1.5mm, copper thick-

ness is 0.13mm. The overall board size is 65 x 200mm.

Power supply filtering

The power supply is used by all parts of the circuit, so it has to be considered with special attention. The supply loops have to be decoupled to make sure that signal levels and power currents do not i nterfere. Thes e loops c an b e sepa rated using star wiring wi th one node des ignated as common for the circuit (Figure 20.).

The decoupling capacitance should be placed very close to the MCU supply pins to minimize

the resultant loop. It should be also large enough to absorb, without significant voltage increase, parasitic currents coming from the M CU via the input protection diode s. The decoupling of the board can be done with electrolytic capacitors (typ. 10µF to 100µF) since the dielectric used in such capacitors provides a high volumic capacitance. However these capacitors behave like induc tances at high fr equency (ty p. above 10M Hz) while ceram ic or plastic

capacitors keep a capacitive behaviour at higher frequency. A c eramic capacitance of, for instance, 0.1µF to 1µF should be used as high frequency supply decoupling for critical chips operating at high frequency.

32/38

Page 33

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 20. Power Supply Lay-out Examples

I/O configuration

An open (floating) pin is a potential hazard to the circuit.

I/O pins whic h a re n ot used i n the ap plic ation shou ld b e pr efera bly confi gure d in output low

state. This will also minimize the current consumption.

A major source of emission in Microcont roller bas ed applicat ions can be du e to high spe ed

digital I/O and commu nic ation in terfaces s uch as SPI, I2C c locks, U SB or P WM... Th e Rise/

Fall times are critical. Typical designs add RC low pass filters.

Shielding

Shielding can help in reducing noise sensitivity and emission, but its success depends directly

on the material chosen as shield (high permeability, low resistivity) and on its connection to a

stable voltage source including a decoupling capacitance via a low serial impedance (low inductance, low resistance).

If the generator of major disturbances is near to the MCU board and can be identified as a

strong dV/dt generator (i.e. a transformer or Klystron), the noise is carried mainly by the electrostatic field. The critical coupling between the noise generator and the control board is capacitive. A highly conductive shield (i.e. copper) creating a Faraday cage around the control

board may strongly increase the immunity.

33/38

Page 34

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

If the strongest source of perturbations is a dI/dt generator (i.e. a relay), it is a high source of

electromagnetic fields. Therefore, the permeability of the s hielding ma terial (i.e. alloy) is crucial to increase the immunity of the board. In addi tion, the number and size of the hol es on the

shield should be reduced as much as possible to increase its efficiency.

In critical cases, the implantation of a ground plane below the MCU and the removal of sockets

between the device and the PCB can reduce the MCU noise sensitivity. Indeed, both actions

lead to a reduction of the apparent surface of loops between the MCU, its supply, its I/O and

the PCB.

4.2 HANDLING PRECAUTIONS FOR ESD PROTECTION.

Electronic components have to be protected fr om the hazard of static electricity from the manufacturing stage down to where they are utilized in order to avoid ESD related destruction. A

specific no-compromise strategy is implemented at ST for all ESD sensitive products.

From the wafer level to the shipping of finished goods, each workstation and processing step

is guaranteed. For final packing, ST uses anti -static tubes . This solution ensures full ESD protection of devices. However, the supplier's greatest efforts are in vain if the end user does not

provide the same level of protection and care in the application.

A relative humidity of 50% to 65% is the best to prevent el ectrostatic problems (the lower the

relative humidity, the higher the electrostatic voltage). Nevertheless, the person handling the

semiconductors as well as the equipment will be charged to a certain level. T he work environment is very important to protect devices against static electricity

Anti-static electricity measures during work

(1) Conductive mat

(2) Wrist

(3) Conductive floor mat

(4) Work suit with anti-static measure

(5) Conductive shoes grounding the human body

34/38

Page 35

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Figure 21. Grounding the Human Body

(1) Wrist ring

(2) Grounding wire: threaded copper wire, vinyl covered, about 1 meter

(3) 250 KW to 1 MW resistance is built in

Device handling:

Static control wrist straps, used and connected properly, must be worn.

All tools, persons, testing machines, which could come in contact with device leads, must be

conductive and gr ounded. Each tabletop mu st be protected with a cond uctive mat , properly

grounded. Use static control shoe strap. Use vacuum pipes.

Storage box:

Keep parts in the original packing bags up to the very last moment of the production line.

If bigger containers ar e used for i n-plant transport of dev ices or PC boards, they must be elec-

trically conductive like the carbon-loaded types. Avoid use of high dielectric materials (like polystyrene) for sub-assembly construction, storing, and transportation.

35/38

Page 36

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

Equipment and tools:

Use Ionized air blowers to neutralize static charges of non-conductive materials.

Use only the grounded tip variety of soldering iron.

Use proper power supply systems in testing and application.

Supply voltage should be applied before and removed after input signals.

Insertion and remova l of component s from sockets sh ould be carried out with no po wer ap-

plied .

An open (floating) pin is a potential hazard to the circuit. Each “Non Connected” pin should be

grounded or connected to V

through a resistor whenever possible.

DD

4.3 FIRMWARE

This part is Treated by a dedicated Application Note (AN1015) available on ST Website.

4.4 WEB LINKS TO EMC RELATED ORGANISATIONS

FCC: Federal Communication Commission

http://www.fcc.gov

EIA: Electronic Industries Alliance

http://www.eia.org/

SAE: Society of Automotive Engineers

http://www.sae.org

IEC: The International Electrotechnical Commission

http://wwwiec.ch

CENELEC: European Committee for Electrotechnical Standardisation

http://ww.cenelec.be

JEDEC: Joint Electron Device Engineering Council

http://www.jedec.org

36/38

Page 37

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

5 CONCLUS ION

For any microcontroller application, EMC requirements must be considered at the very beginning of the developm en t project. Standar ds, featu res an d param eters g iven i n ST Microcon troller datasheets will help the system designer to determine the most suitable component for

a given a pplic atio n. Ha rdw a re and fi rmw are precau ti on s h av e to b e ta ke n to o pt im ize E M C

and system stability.

37/38

Page 38

EMC DESIGN GUIDE FOR ST MICROCONTROLLERS

“THE PRESENT NOTE WHICH IS FOR GUIDANCE ONLY AIMS AT PROVIDING CUSTOMERS WITH INFORMATION

REGARDING THE IR PRO DUCT S IN OR DER FO R THEM TO SAV E TIME . AS A RES ULT, STMIC ROEL ECTR ONI CS

SHALL NOT BE HELD LIABLE FOR ANY DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES WITH RESPECT TO

ANY CL AIM S AR IS IN G FR OM T HE CO N TENT OF S UC H A NO TE A ND /O R T HE U SE M AD E BY C US TO ME RS O F

THE INFORMATION CONTAINED HEREIN IN CONNECTION WITH THEIR PRODUCTS.”

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent ri ghts of STM i croelectr oni cs. Spec i fications mentioned i n this publication are subje ct

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi thout exp res s written ap proval of STMi croelectr onics.

The ST logo is a registered trademark of STMicroelectr oni cs.

All other n am es are the pro perty of thei r respectiv e owners

© 2003 STMi croelectronics - All rights reserved

STMicroelectronics GROUP OF COMPANIES

Australi a – B elgium - Brazil - Canada - China – Czech Republ i c - Finland - F rance - Germany - Hong Kong - India - Is rael - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

www.st.com

38/38

Loading...

Loading...