Page 1

AN1624

APPLICATION NOTE

STSR3 SIMPLIFIES IMPLEMENTATION OF

SYNCHRONOUS RECTIFIER IN FLYBACK CONVERTER

F. Librizzi - F. Lentini

1. ABSTRACT

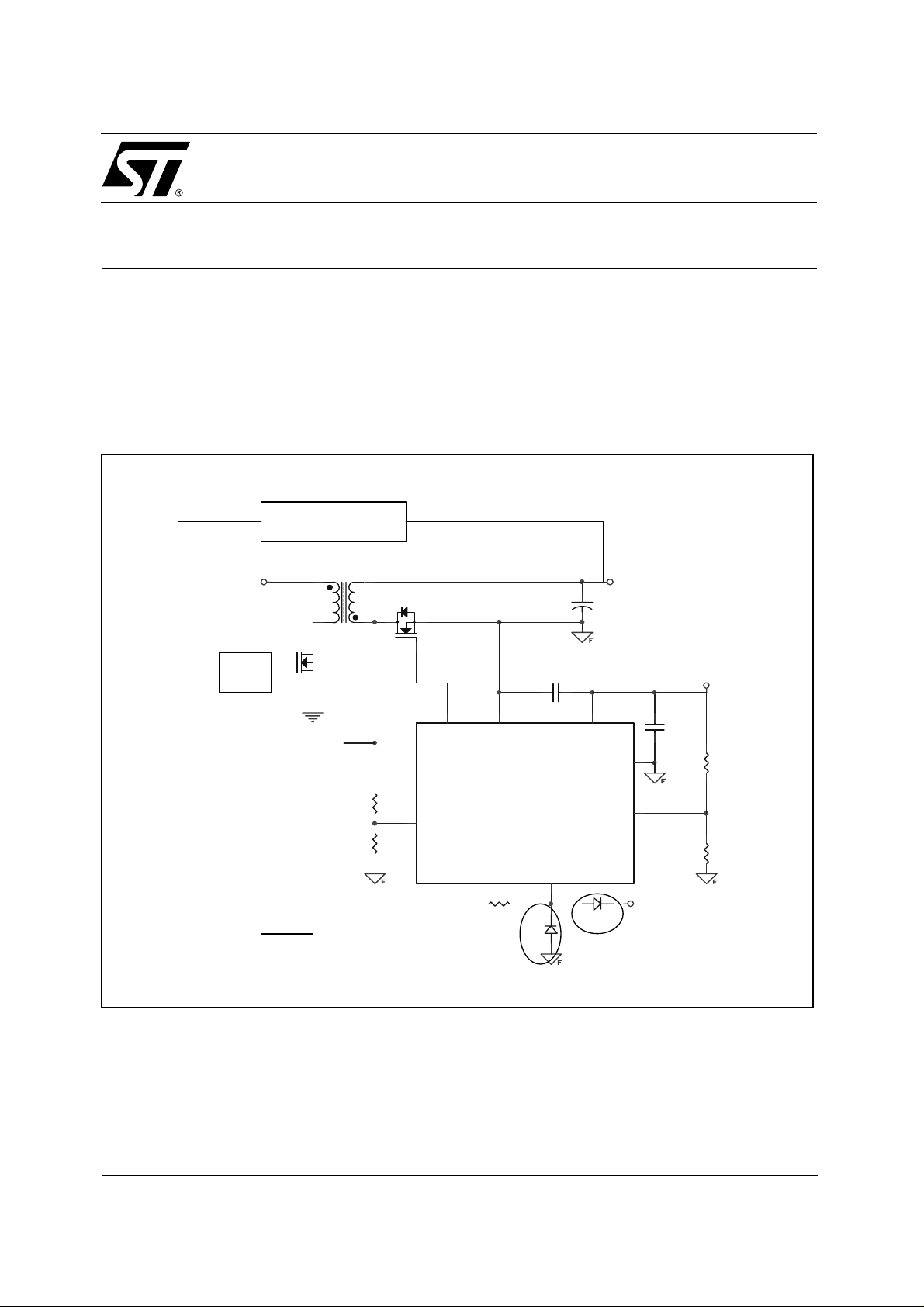

This paper describes the f unctionality and the operation of the STS R3 device used as the second ary

synchronous rectifier driver in Flyback topology switched mode power supplies. A Schematic and layout

description of a dem o board a ble to replace diode rectifica tion with synchron ous rectification in Fl yback

converters is shown below.

Figure 1: Typical Application Schematic

Feedback

Loop

TRANSFORMER

VoutVin

Cout

PWM

option

MosfetN

C1

100nF

7

R3

4

Ck

R4

OUTGate

8

PWRGND

STSR3

R5

D1

2

Vcc

SGLGND

SETANT

INHIBIT

5

D2

6

3

+5V

C2

100nF

+5V

R1

R2

January 2003

1/22

Page 2

AN1624 - APPLICATION NOTE

2. GENERAL DEVICE DESCRIPTION

The STSR3 Smart Driver IC provide s a high current output to properly drive secon dary Power Mosfets

used as Synchronous Rectifiers in high output current, high efficiency Flyback Converters. From a

synchronizing clock input, withdrawn on the secondary side of the isolation transformer, the IC generates

a driving signal with set dead times with respect to the primary side PWM signal.

The IC operation prevents secondary side shoot-through conditions at turn-on of the primary switch

providing anticipation in turn-off of the output. This sm art function is im plemented by a f ast cycle-aftercycle logic control mechanism, based on a hi gh frequency oscillator synchronized by the clock signal.

This anticipation is externally set through external components.

A special Inhibit function allows shut-off of the drive output by sensing the Synchronous Rectifier sourcedrain voltage and consequently turning it off when necessary. This feature makes a discontinuous

conduction mode possible and avoids reverse conduction of the synchronous rectifier in parallel

operation of the converter.

The STSR3 allows implementing Synchronous Rec tification in Discontinuous Mode PWM , Continuous

Mode PWM and Quasi Resonant Flyback Converters.

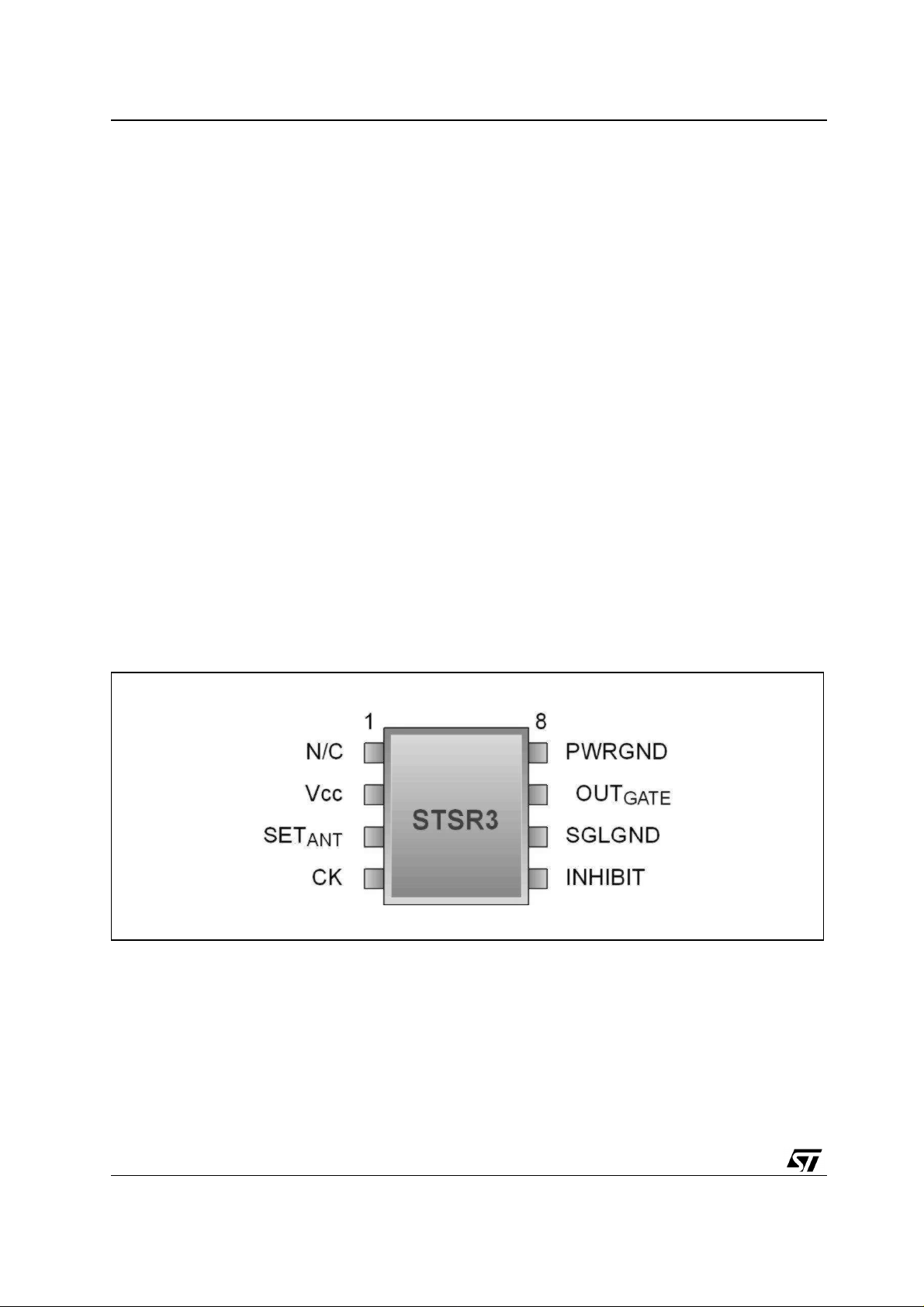

3. PIN CONNECTIONS AND DESCRIPTIONS

The STSR3 is hous ed in a n S O -8 pac kage for SMD as sembly. Device pin out is shown i n f igure 2

and table 1 briefly summarizes the device pin functionality.

Figure 2: Pin Configuration

2/22

Page 3

AN1624 - APPLICATION NOTE

Table 1: Pin Description

Pin Nu m ber Pin Name Pin Function

1 N/C Not internally connected

2 Vcc S uppl y input from 4V to 5.5V

3 SETANT Sets the anticipation in turning-off the OUT

4 CK Synchronization for IC’s operation

5 INHIBIT Discontinuous Mode Detector

6 SGLGND Reference for all the control logic signals

7 OU TG ate Output for MOSF E T G ate Dr ive

8 PWRGND Reference for power signals

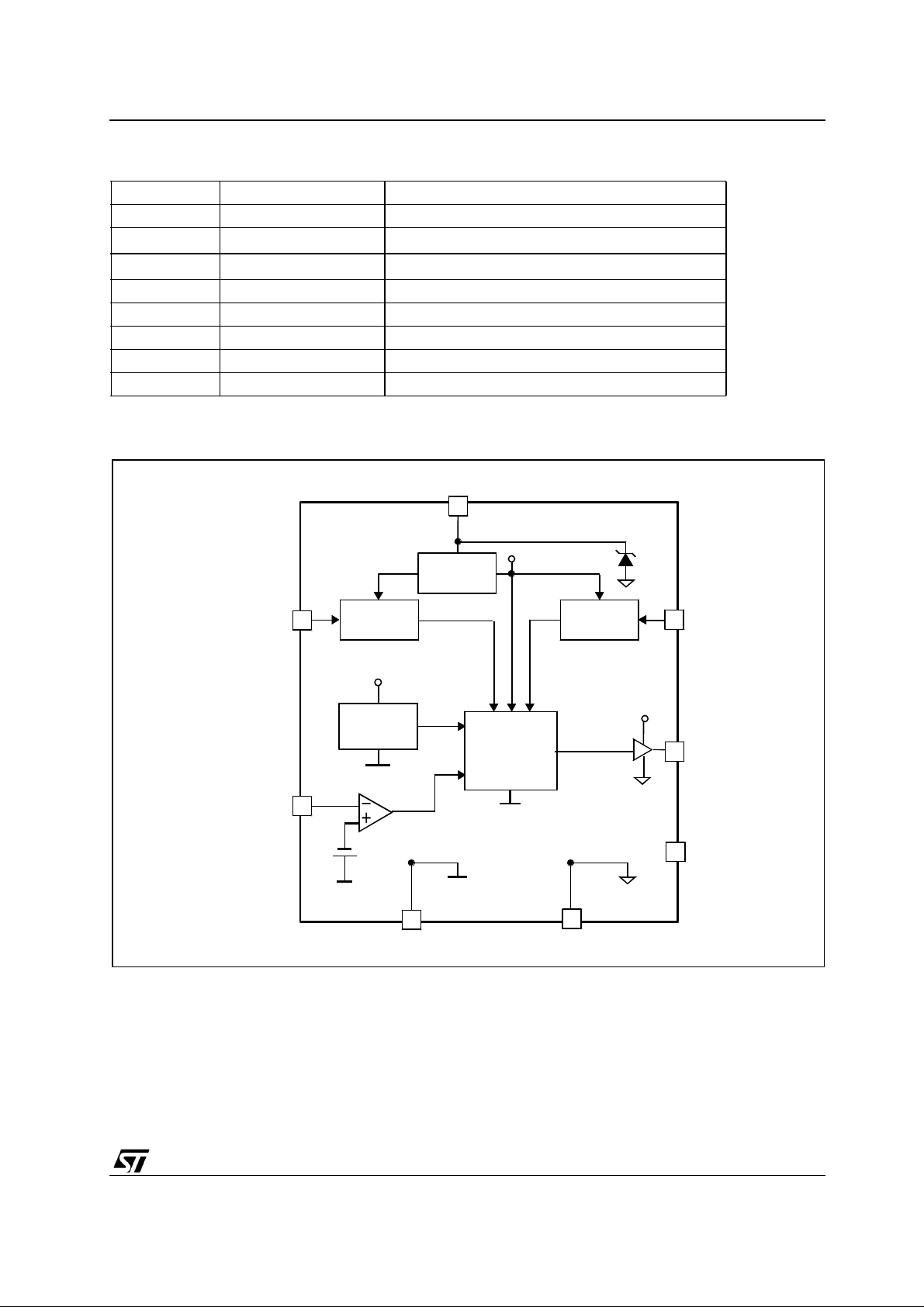

Figure 3: Block Schematic

Vcc

2

2

GAT E

CK

INHIBIT

output

buffer

5.7V

3

3

7

7

1

N/C

BIAS

UVLO

4

4

5

5

Peak

detector

High

frequency

oscillator

20mV

SGLGND

DIGITAL

CONTROL

6

Anticipation

SET

86

8

PWRGND

4. SUPPLY VOLTAGE AND UNDER VOLTAGE LOCK-OUT

The supply input range is from 4V to 5.5V. An internal zener diode limits the maximum voltage to 5.8V.

A 100nF ceramic capacitor must be connected between Vcc and SGLGND pin in order to assure a stable

supply voltage. This capacitor must be placed very close to the device. Another 100nF capacitor must be

connected between Vcc and PWRGN D.

3/22

Page 4

AN1624 - APPLICATION NOTE

Under Voltage Lock Out feature guarantees proper start-up while it avoids undesirable driving during

eventual dropping of the supply voltage.

As shown in the Block Diagram, the V cc voltage also supplies also the output driver, consequently the

maximum driving voltage is 5.5V, so the use of logic gate threshold mosfets is recommended.

5. SYNCHRONIZATION

An innovative feature of the STSR3 is the capability to operate in the secondary side without any

synchronization signal coming from the primary side. The STSR3 synchron ization is obtained directly

from the secondary side using the voltage across the Synchron ous mosfet as the information for the

switching transitions. The Ck pin is the input for the synchronization signal; the internal threshold is set at

2.6V. As can be seen in figure 3, a Peak Det ect or is present at the in put of the Ck pin . This block is able

to distinguish between the p rimary mosfet switching transitions and the e ventual sinusoidal waveform

caused by discontinuous mode operation or resonant reset configurations (see figure 4). A wrong

synchronization causes wrong driving of the synchronous rectifier.

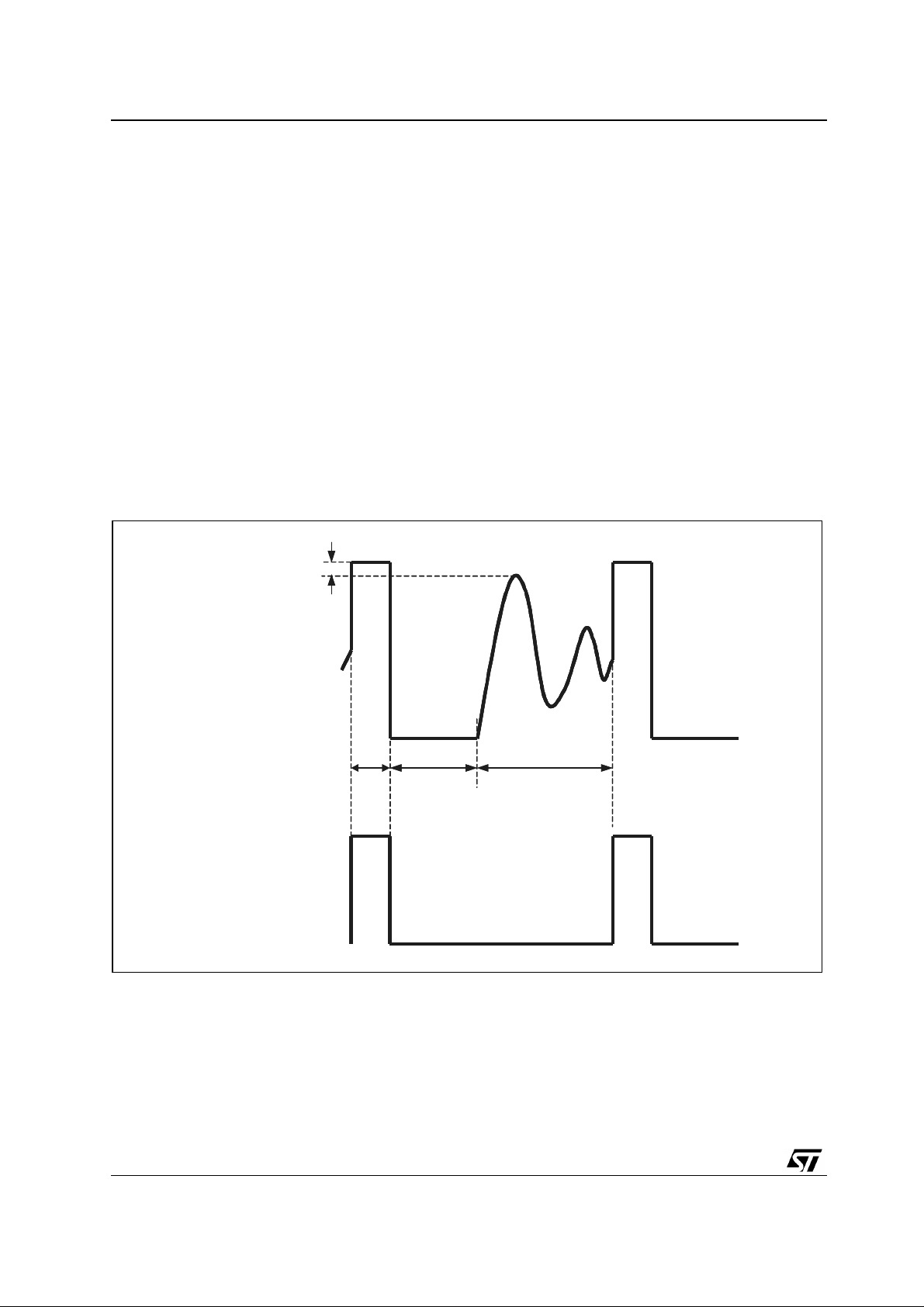

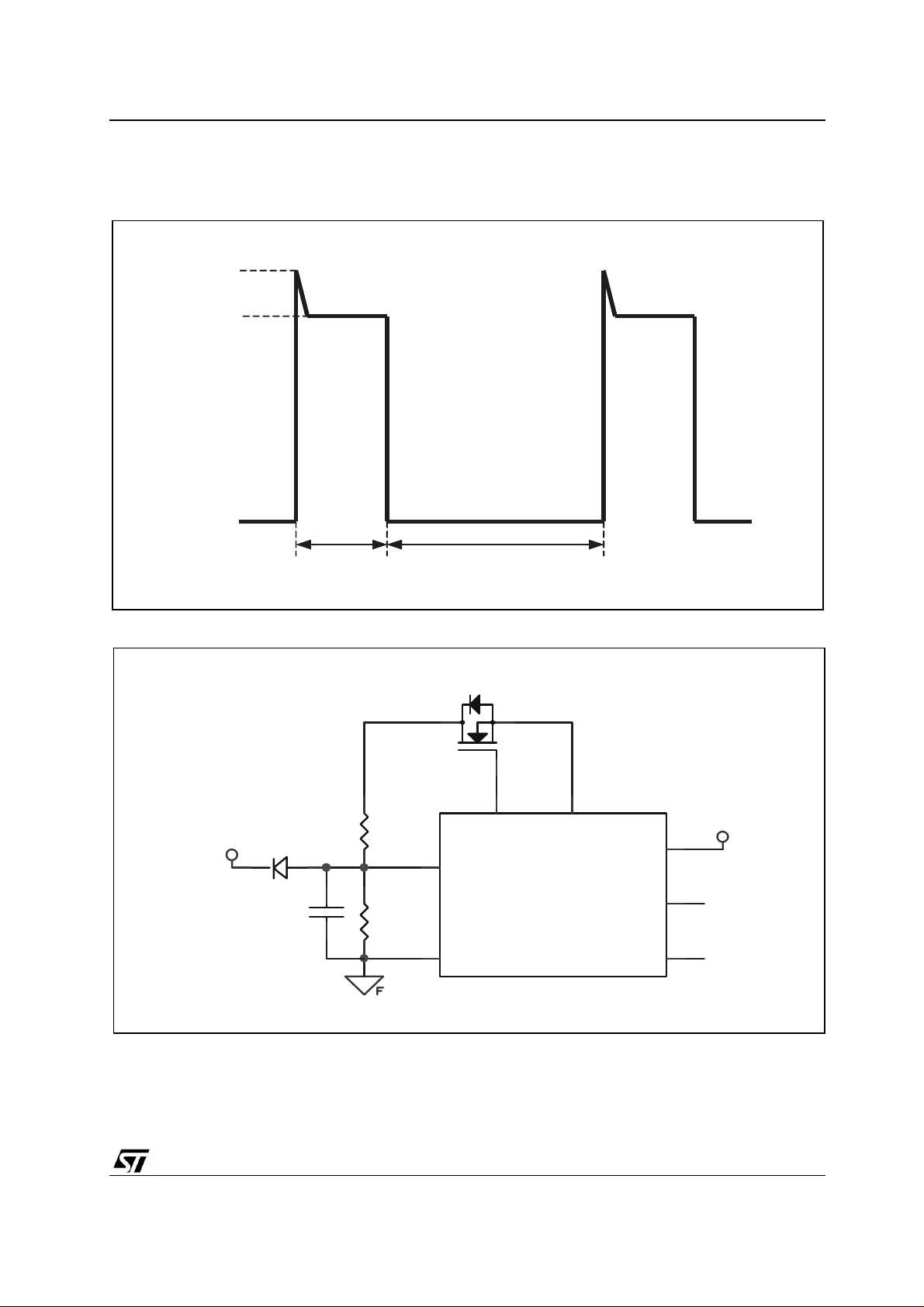

Figure 4: DCM waveform

V

V

1

1

Peak

Peak

Detector

Detector

Input

Input

Peak

Peak

Detector

Detector

Output

Output

5.1 Continuous Conduction Mode

On

On

Time

Time

Off Time Dead Time

Off Time Dead Time

When the Flyback conv erter is working in continuous mode the voltage across the source and d rain of

the synchronous mosfet has a square shape. This voltage can be applied to the Ck pin using two

different configurations: with a resistor divider (figure 6) or with a diode and pull-up resistor (figure 7). In

most cases a spike is present during turn-off of the synchronous mosfet; this spike must be eliminated at

the Ck pin in order to avoid false synchronization.

4/22

Page 5

AN1624 - APPLICATION NOTE

Using the resistor divider, the spike is eliminated by adding a small capacitor (C1) as shown in figure 6.

Figure 5: CCM waveform and Ck circuit

Turn-Off

Turn-Off

Spike

Spike

On Time Off Time

On Time Off Time

Figure 6: Synchronization with a resistor divider

SYNC RECT

R1

+5V

D1

C1

R2

4

6

Ck

SGLGND

7

OUTGate

STSR3

8

PWRGND

SETANT

INHIBIT

Vcc

+5V

2

3

5

As an exam ple , in a Flybac k co nver ter fo r teleco m app licat ion , the DC inp ut vo ltage has a 1:2 variab ility

range (typically 36V-72V). Consequently, the secondary winding voltage also has 1:2 variability. The

resistor divider can be calculated in order to have about 2.8V at the Ck pin at 36V input; at 72V input, the

5/22

Page 6

AN1624 - APPLICATION NOTE

Ck pin reaches 5.6V. Even if this value is higher than the maxim um voltage on the CK pin it can be

accepted, limiting the current flowing into the pin to 10mA.

The value of capacitor C1 is depende nt on the amount of sy nchronous mos fet turn-off spike and on the

value of R1. In order to reduce the delay introduced by R1 and C1 together , the minimum capacitor value

should be used.

In the case of an Adaptor Flyback converter , workin g with 85VAC to 270VAC input, the variabilit y range is

1:3. At the minimum inpu t voltage, 2.8V must be guaranteed at the Ck pin , consequently at maximum

input voltage, the voltage at the Ck pin will be 8.9V or higher. This voltage exceeds the absolute

maximum ratings of the device. If R1 limits the current flowing into the Ck pin to a value below the

maximum Ck current valu e indicated in the datasheet, the device can still working properly; otherwise

diode D1 must be added to protect the device.

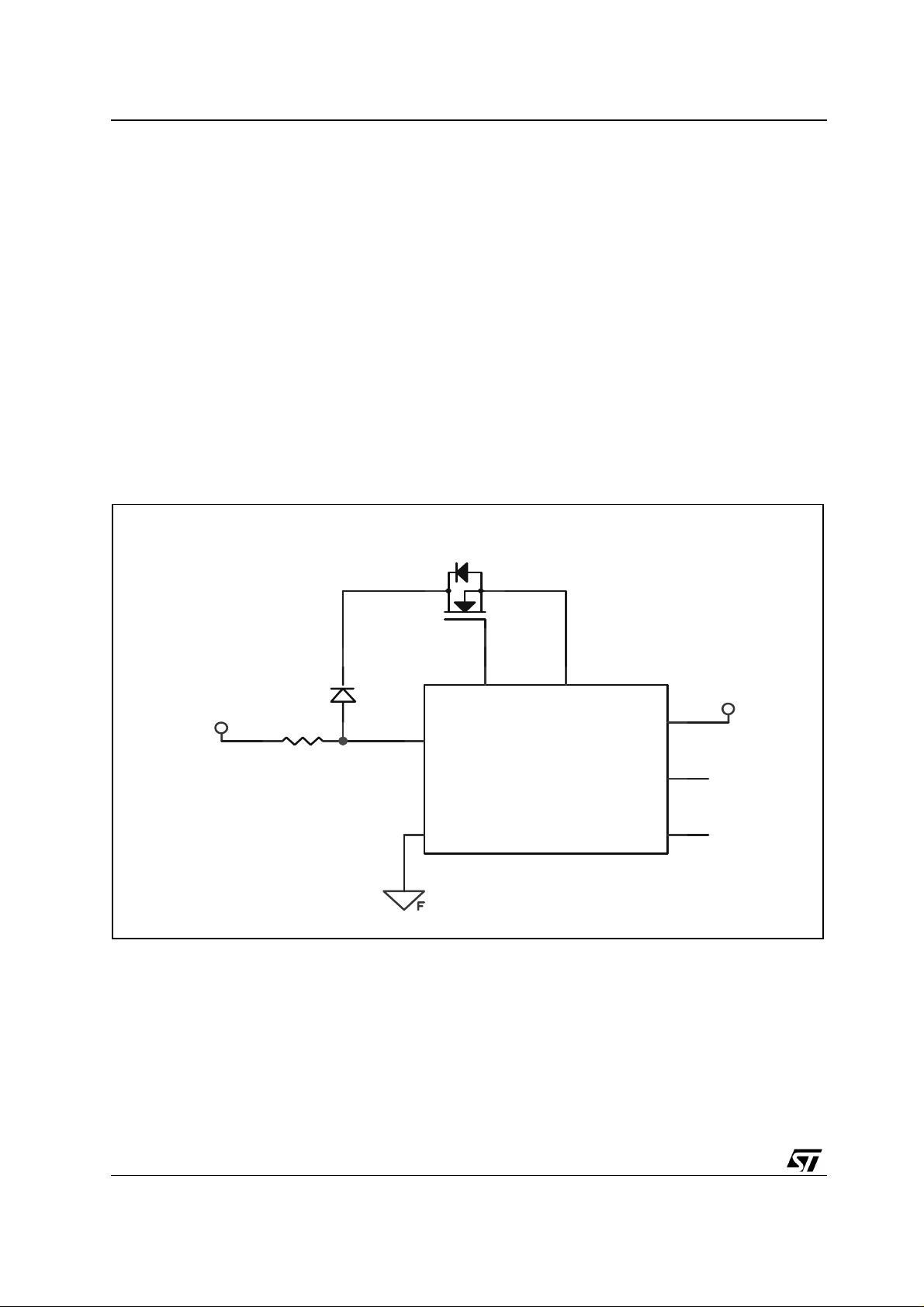

Figure 7 shows the synchronization circuit with diode and pull-up resistor. In this case there is no

problem with the turn-off spike and maximum CK pin voltage. This circuit cannot work properly in

Discontinuous Mode due to the ringing present in the voltage drain of the synchronous rectifier.

Figure 7: Synchronization with a diode and pull-up resistor

SYNC RECT

D1

7

8

+5V

+5V

R1

4

6

Ck

OUTGate

SGLGND

PWRGND

SETANT

INHIBIT

Vcc

2

3

5

STSR3

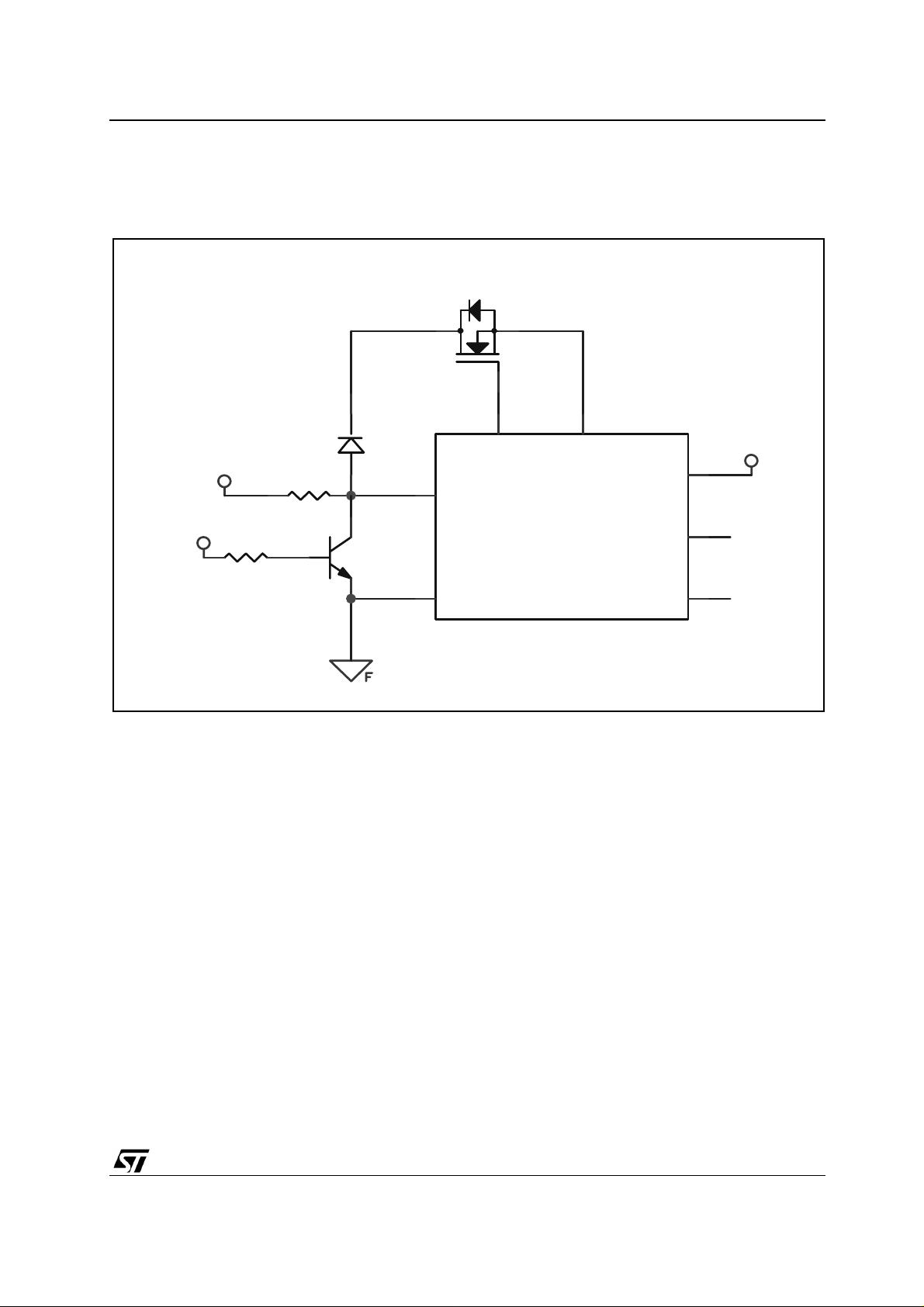

The STSR3 can be turned off easily adding a NPN transistor between Ck and SGLGND. This transistor

forces the CK pin to GND when the signal OFF is high. In this condition the OUTGate will be in a low

state turning off the Synchronous Mosfet.

6/22

Page 7

AN1624 - APPLICATION NOTE

Figure 8 shows the turn-off circuit when using a diode and pull-up resistor to synchronize the STSR3, the

same configuration of Q1 and R2 can be used with a resistor divider circuit.

Figure 8: Shut down circuit

SYNC RECT

D1

7

8

+5V

+5V

OFF

R1

Q1

4

Ck

OUTGate

PWRGND

Vcc

SETANT

2

3

NPN

R2

6

SGLGND

INHIBIT

5

STSR3

5.2 Discontinuous Conduction Mode

As shown in figure 4, in d iscontinuous mode operat ion there can be some problems in detecting the

primary switching transitions. The internal peak detector is only able to determine the peak value

reached by the signal at the Ck pin, neglecting all signals that have a lower value. Referring to figure 4, a

minimum voltage difference V

waveform must be assured in order to allow the Peak Detector to work properly.

=400mV between the switching transition wavef orm and the sinusoidal

1

As mentioned in the previous paragraph, if the input voltage variability range is higher than 1:2, diode D1

must be added to clamp the voltage on the Ck pin. In these conditions, both switching transition

waveform and the sinusoidal waveform are clamped, and the peak detector is unable to operate correctly

causing false triggering of the STSR3 (see figure 9). In this case, using an external peak detector, like the

one shown in the next paragraph, solves the proble m.This allows correct ope ration of t he dev ice bot h i n

continuous and discontinuous mode.

7/22

Page 8

AN1624 - APPLICATION NOTE

Figure 9: DCM clamped

V

V

CC

CC

Peak

Peak

Detector

Detector

input

input

On

On

Time

Time

Peak

Peak

Detector

Detector

output

output

Off Time

Off Time

Dead Time

Dead Time

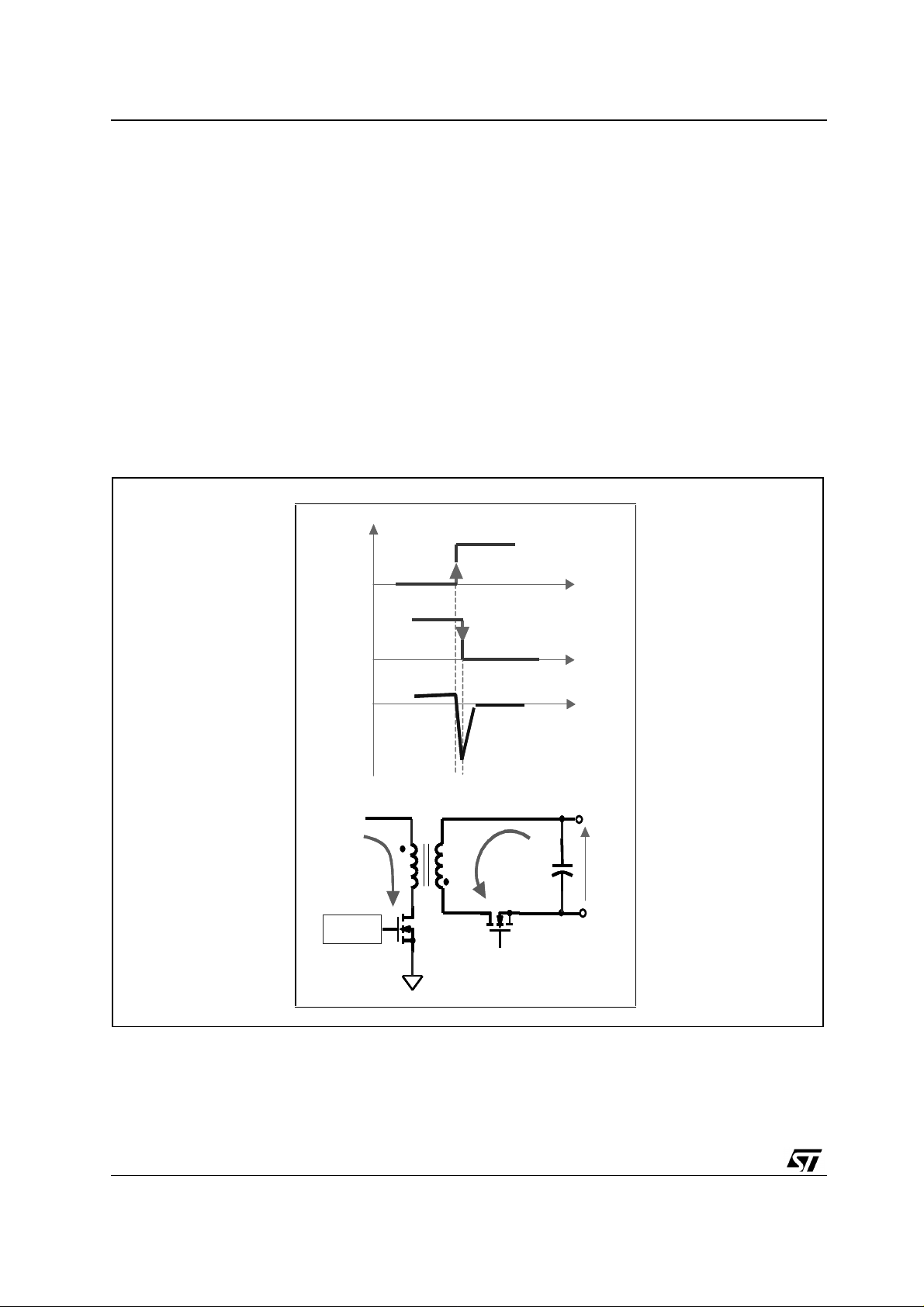

6. EXTERNAL CLOCK DETECTOR

The external clock detector is a circuit to be used when the input voltage variability is higher than 1:2.

This circuit substitutes the circuit of figure 5-6 and assures correct operation of the STSR3 both in

discontinuous and continuous conduction mode, providing a pure square waveform to CK.

R20 is a pull up resistor, when the SR mosfet is on or its body diode is conducting, the voltage V1 is low.

When the mosfet is Off (at the time of the primary switch), the voltage V1 is at 5V. R22 and C10 form a

low pass filter, which allows provision of a correct synchronized s ignal even when the ring ing is almost

zero (see Figure 11). But R22 and C10 also cause an undesired delay, so the R21 and C9 group reduce

this delay during fast swit ching transitions. The ST l ogic port 741T70 eliminates the noise, which coul d

false trigger the internal peak detector of the STSR3.

In paragraph 11 sugges ted v alues for this circuit are given.

8/22

Page 9

Figure 10: External Clock Detector Circuit

AN1624 - APPLICATION NOTE

+5V

R21

C9

C10

Figure 11: The ringing voltage near to zero can cause false trigger of the IC

R20 D14

V1

R22

+5V

74V1T70

MOSFET Drain

R23

STSR3 Ck

Mosfet Drain

Mosfet Drain

On

On

Off Time Dead Time

Off Time Dead Time

Time

Time

7. INHIBIT OPERATION

One of the differences between diode rectification and synchronous rectification is the possibility for

Mosfets to conduct the current in both directions while diodes conduct just in one direction. In

discontinuous mode with diode rectification, when the inductor c urrent reaches zero it cannot reverse

9/22

Page 10

AN1624 - APPLICATION NOTE

because the diode does not allow current flowing from c athode to anode. Using mosfets as rectifiers,

when the inductor cu rrent reaches zero, it continues to decrease becoming neg ative and flowing from

drain to source of the synchronous mosfet. In this condition the converter works as if it was in continuous

mode.

If discontinuous mode operation is required, the synchronous mosfet must be turned off when the current

is zero, consequently the body diode operates as a common rectifier, avoiding reversal of the inductor

current.

The INHIBIT pin is able to turn off the synchronous mosfet when its current is approaching zero allowing

discontinuous mode operation of the converter.

On the INHIBIT pin, there is an internal comparator with a -25mV threshold. This pin is connected

through a resistor to the drain of the synchronous mosfet. At the beginning of the off time (when Ck goes

to low level), OUTGate goes high. The INHIBIT voltage is monitored for 250ns: if the voltage on INHIBIT

is higher than -25mV, OUTGate becomes low; if the voltage on INHIBIT is lower than -25mV OUTGate is

kept high until the v oltage reaches -25m V. This is because when the sy nchronous mosfet is conducting,

the voltage on its drain is: Vds= -Rds(on)*Idrain. If Vds is hig her than -25m V, it means that the current is

decreasing and discontinuous mode is approaching, so OUTG ate is turned-off allowing operation of the

body diode of the mosfet (see figure 12). When the converter is in continuous mode the INHIBIT voltage

is always lower than -25mV and OUTGate is kept high.

During transition in which the primary mosfet is turned off, the INHIBIT vol tage must f all f rom hig h val ue

to -25mV in less than 250ns. The resistor value R26 must be chosen in order to fit this specification.

When the converter operates in parallel with other power supplies, the INHIBIT pin, detecting the voltage

across the synchronous mosfet, also avoids the converter to sink current from the output.

Figure 12: INHIBIT waveforms

SR MO SFET

SR MO SFET

source-drain

source-drain

voltage

voltage

Off Time Dead Tim e

Off Time Dead Tim e

Inductor

Inductor

Current

Current

INHIBIT

INHIBIT

Voltage

Voltage

SR MO SFET

SR MO SFET

G a t e V o lta g e

G a t e V o lta g e

-15mV

-15mV

On Time

On Time

10/22

Page 11

AN1624 - APPLICATION NOTE

Although the INHBIT pin allows operation in Discontinuous Mode, the -25mV threshold could be sensitive

to the ringing present at the SR Mosfet drain during turn off of the primary switc h, causing incomplete

turn on of OUTGat e. This inconvenience can be avoid ed using the clock signal to provide a ne gative

voltage to the INHIBIT pin act ing as a blanking time. Th is ne gat ive vol tage can be easily generated with

some discrete components as shown in figure 13.

Figure 13: Circuit to provide negative voltage to INHBIT

CK

C11

R24D15

INHIBIT

R25

Mosfet Drain

R26

The blanking time value is determined by C11 and R25. This time has to last the necessary time to cover

the ringing caused by the primary switch turn off (see Figure 14).

Figure 14: Ringing during turn off of the primary switch

11/22

Page 12

AN1624 - APPLICATION NOTE

8. ANTICIP ATION

One of the maj or problems of synchronous rectification is th e generation of proper driving signals to

avoid cross conduction between the Synchronous rectifier and the primary switch.

Referring to figure 15, when the primary Mosfet is turned-on, t he voltage Vs tends to go negative. If the

synchronous mosfet is turned off with some delay, a short circuit loop between primary side and

secondary sides o ccurs. In order t o avoid this undesired condition, the s ynchronous mosfet must be

turned off before the primary mosfet is turned on; this means th at a certain amount of ’anticipation’ is

needed.

Figure 16 shows the detailed timing of Ck and O UTGate signals in normal operation. Time interval t

provides the required anticipation to avoid any short circuit con dition. For t

it is possible to choose

ant

between three different values using the SETAnt pin according to table 2:

Figure 15: Short circuit in the secondary side

Primary

Primary

Mosfet ON

Mosfet ON

VS

VS

t

t

VGS(SR)

VGS(SR)

t

t

I

I

SR

SR

t0

t0

t1

t1

t

t

ant

12/22

PWM

PWM

SR

SR

VOUTVs

VOUTVs

Page 13

Table 2: Anticipation values

Parameter Condition Value Unit

AN1624 - APPLICATION NOTE

0<SETAnt<

1

Vcc

75 ns

3

tant

1

3

Vcc

2

Vcc

<SETAnt<

< SETAnt<Vcc

2

3

Vcc

150 ns

225 ns

3

The voltage on the SETAnt pin can be obtained using a resistor divider of the supply voltage (see Table

2).

The Digital Control Block generates these anticipations by counting the number of high frequency pulses

included within the switching period. Due to the digital nature of this system, some bits can be lost during

the counting, causing a jitter in the output driving signal. The value in the table is an average value, which

takes into account this jitter. Figure 17 shows the jitter during turn off of OUTGate.

Figure 16: STSR3 Timing

CK

OUT

Ant

Tp2

GATE

Tr Tf

13/22

Page 14

AN1624 - APPLICATION NOTE

Figure 17: OUTGate turn off Jitter

9. NO LOAD AND LIGHT LOAD OPERAT IO N

When the duty-cycle is lower than 14%, an internal feature of the STSR3 allows a total shutdown of

OUTGate and of most inte rnal parts of the device, causing a reduction in power consum ption. In these

conditions the low output current of the converter is carried by the body diode of the mosfet. The IC starts

to operate again when the duty-cycle is higher than 18%, therefore having a 4% of hysteresis. This

feature allows correct operation when primary the PWM controlle r imposes burst mode due to the very

light output load.

10. OUTPUT DRIVERS

The output driver has a high current capability, being able to source up to 2A and to sink up to 3.5A peak

current. Consequently, the synchronous mosfet is switched very quickly, allowing paralleling of several

mosfets to reduce conduction losses. The high level driving voltage is equal to Vcc voltage; therefore the

device drives only mosfets with logic level gate thresholds.

14/22

Page 15

Figure 18: Rds(on) source/sink vs Temp

1.4

1.4

1.2

1.2

1

1

]

]

Ω

Ω

0.8

0.8

0.6

0.6

Rds on [

Rds on [

0.4

0.4

0.2

0.2

0

0

-40 -20 0 20 40 60 80 100

-40 -20 0 20 40 60 80 100

Source

Source

Sink

Sink

T [ °C]

T [ °C]

AN1624 - APPLICATION NOTE

11. TRANSIENT BEHAVIOR

During very heavy load changes, the duty cycle can vary very fast from a low value to high value and vice

versa in a few switching periods.

Being the anticipation time for OUTGate based on the calculation of the switching period (frequency) and

not on duty cycle, even during fast duty cycle changes the anticipation t ime is provided correctly, always

providing correct driving for the Synchronous Mosfet.

Figure 19a: Duty Cycle very fast variation

5 µs

5 µs

5.0 V

5.0 V

CK

CK

5 µs

5.0 V

OUTGate

33.0 µs

15/22

Page 16

AN1624 - APPLICATION NOTE

@ 5V (m

Figure 19b: Duty Cycle very fast variation

1 µ s

1 µ s

0.47 V

0.47 V

CK

CK

1 µ s

1 µ s

-4.38 V

-4.38 V

OUTGate

OUTGate

53.6 µ s

53.6 µ s

∆ t 131.5 ns

∆ t 131.5 ns

1

1

/

7.605 MHz

/

7.605 MHz

∆ t

∆ t

Figure 19a shows the condition in which the duty cycle passes from 50% to 80% in one cycle and back to

50%. OUTGate is provided correctly, and in figure 19b the anticipation time of 131ns is shown.

12. DEMOBOARD DESCRIPTION

The schematic of figure 20 presen ts a test board for the STSR3. This board replac es the diode in a

Flyback converter and includes all the components needed by the STSR3 to operate, plus the

synchronous mosfet. Synchronization is obtained with the external clock detector making the board

usable in every kind of Flyback converter, both AC/DC and DC/DC. Some parts of the circuit shown in

fig.20 might not be necessary depending on the kind of the application. For example if there is no ringing

at turn-off of the primary switch, the components R24, D15, R25 and C11 can be omitted.

A Synchronous Mosfet in the TO220 package can be mounted on board. ST provides suitable

Synchronous Mosfets for this application:

P/N VD

STP100NF03L-03 30 4.5 100

STP80NF03L-04 30 5 80

STP90NF03L 30 12 90

STP85NF3LL 30 9 85

STP70NF3LL 30 12 70

STP100NF04L 40 5 100

STP80NF55L-06 55 8 80

STP60NF06L 60 16 60

STP80NF75L 75 13 80

STP40NF10L 100 36 40

(V) RDS

SS

(on)

) I

Ω

D(cont)

(A)

16/22

Page 17

AN1624 - APPLICATION NOTE

The board allows us to easily pass from diode rectification to synchronous rectification in Flyback

converter applications. Table 3 shows detailed components selection.

Figure 20: Demo board Schematic

+5V

C9

C10

R20

R21

C11

R22

+5V

U3

D15 R24

R25

R26

74V1T70

+5V

D14

R23

CON1

D16

+5V

CON2

7

R4

R19

OUTGate

STSR3

C8

8

PWRGND

c

PWRGND

SGLGND

SETANT

Vcc

CON4

c

Vout

JP1

3

VI

C2

78L05

C5

2

6

3

C6

D10

JP4

Vo

GND

2

R7

JP5

R13

+5V

1

C3

JP6

c

C1

R1

D1

M1

D13

D2

U2

4

Ck

5

INHIBIT

D7

17/22

Page 18

AN1624 - APPLICATION NOTE

Table 3: Demo Board Components

Compone nt Notes

Supply

C5, C6

U1

C2 78L05 input capa citor (330nF ceramic)

C3 78L05 output capacitor (150nF ceramic)

D10 P rotects Vcc from voltages higher than 5.6V

JP1 Close this jumper if a 5V is already available on the board

Synchr onization

D2 Protects Ck pin from voltages higher than Vcc (not necessary if U3 is used)

D14 Blocks the high voltage coming from the SR Drain

R20

R21

R22

R23

C9 Speed up capa citor (22pF)

C10 Low pass filter capacitor (10pF)

U3 Non Inverting Buffer ST 74V1T70

INHI BIT

R26 Limits the current to diode D16 when SR Drain voltage is higher than Vcc

D16

D7 Protects INHIBIT pin from negative voltages.

D15 Prevents C11 to be discharged

R24 Blank ing circuit summing resistor

R25 Blank ing Time resistor

C11 Blank ing Time capacitor

Anticipation

R7, R13

JP6 Sets the maximum anticipation time

JP5 Sets the medium anticipation time

JP4 Sets the minimum anticipation time

Power

M1 Synchronous Mosfet TO220

R4 Gate pul l down resistor

R19

C8 Gate capacitor to avoid dv/dt turn-on of the SR Mosfet (Not ne cessary in common application))

D13 Speed up turn-off of SR Mosfet if R19 is used.

D1

C1, R1 A small snubber reduces synchronous Mosfet turn-off spike

Vcc bypass capacitors

100nF ceram ic

Standard voltage regulator to p rovide 5V supply voltage (SOT89). Omit this component and close

jumper JP1 if 5V is already present on the board

L78L05ACU

Pull–up resistor (3.3kΩ)

Speed up resistor (10kΩ)

Low pass filter resistor (10kΩ)

Ck series resistor (1kΩ)

Protects INHIBIT pin from voltages higher than Vcc. Not nece ssary if the current flowing into

INHIBIT pin is less than 10m A.

Resistor divider which provides voltage level to set Anticipation time

R7=R13= 10kΩ

Gate series resistor (Typically 0Ω)

A Schottky Rectifier in parallel to synchronous mosfet can increase convert er efficiency due to low

drop voltages during Gate drive dead time

18/22

Page 19

AN1624 - APPLICATION NOTE

13. PCB LAYOUT

Any Switch Mode Power Supply requires a good PC B (Printed Circuit Board) design layout in order to

achieve maximum performance in terms of system functionality and emitted radiations. Component

placing, traces routing and width are the major issues. Some fundamental rules will be given so that the

PCB designer can produce a good layout for the STSR3

All traces carrying current should be drawn on the PCB as short and thick as possible. This should be done

to minimize resistive and induc tive paras itic effect s, gaining in system efficiency and radiated emissions.

Current return routing is another crucial issue. Signal ground (SGLGND) and power ground (PWRGND)

must be routed separately and connected to a single ground point.

The INHIBIT pin, due to the -25mV comparator could be sensitive to layout, so make the INHIBIT

connection as short as possible.

As a rule of thumb, traces carrying signal currents should be placed far from traces carrying pulsed

currents or quickly swinging voltages avoiding any coupling effect between them.

Figure 21a: Board Layout - Components (two times actual size)

19/22

Page 20

AN1624 - APPLICATION NOTE

Figure 21b: Board Layout - Top Side (two times actual size)

Figure 21c: Board Layout - Bottom Side (two times actual size)

20/22

Page 21

AN1624 - APPLICATION NOTE

14. HOW TO USE THE BOARD

The demo board is meant t o implement synchronous rec tification in a Flyback converter. If the diode is

mounted on the board, it must be rem ov ed. Connect the Demo Boa rd as depict ed i n f igure 22. If Vout is

equal or higher than 5V connect Vs to Vout (as in the figure 22). If Vout is lower than 5V, connec t Vs

together with FW Drain.

Figure 22: Connecting the Demo Board

Feedback

Feedback

Loop

Loop

Vs

Vs

VoutVin

VoutVin

PWM

PWM

Drain

Drain

PWRGND

PWRGND

15. CONCLUSION

A new device for controlling synchronous rectifiers in high efficiency AC/DC and DC/DC Flyback

Converters is presented. The device is completely transparent to the primary PWM controller, and it

works in the secondary side requiring no interaction with the primary side. The device is able to operate

with any kind of topological configuration providing the correct driving signal for the synchronous

MOSFET.

The presented board allows implementation of synchronous rectification in any existing Flyback

converter in an easy and effective way.

21/22

Page 22

AN1624 - APPLICATION NOTE

Information furnished is b elieved to be accurate a nd reliable. Howe ver, ST Microelectronics a ssumes no resp onsibility

for the consequences of use of such information nor for any infringement of patents or other rights of third parties

which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of

STMicroelectronics. Specification ment ioned in this p ublication are subject to change without notice. This publication

supersedes and repla ces a ll information pre viously su pplied. STM icr oelectro nics pr oducts are not authorized for use

as critical components in life support devices or systems without express writt en approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics - Printed in Italy - All rights reserved

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Isreal - Italy - Japan - Malaysia -

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

22/22

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

Loading...

Loading...