Page 1

AN1608

®

CHECK THE ROBUSTNESS OF CLT3-4BT6

CONTENT

DESCRIPTION OF THE CLT3-4BT6 PRODUCT

■

CLT3-4BC6 DEMONSTRATION BOARD

■

EMC REQUIREMENTS

■

ROBUSTNESS AND IMMUNITY OF THE

■

CLT3-4BT6 DEVICE

CONCLUSION

■

REFERENCES

■

1. DESCRIPTION OF CLT3-4BT6 PRODUCT

1.1. Functional description

TheCLT3-4BT6(CurrentLimitedTermination)isa

quadruple input digital termination device

designed for 24V DC automation applications. It

achieves the front-end circuitry of a digital input

module (I/O) in industrial automation.

Available in a four channels configuration, it offers

a high-density termination by minimizing the external component count. It is housed in a TSSOP20

surface mount package to reduce the printed

board size.

Made of a parallel input voltage protection, aserial

input-output current limiting circuit and an

opto-coupler driver, each channel circuit

terminates the connection between the logic input

and the associated high side sensor or switch.

The CLT3-4BT6 device is used between the sensors and the opto-coupler of an input module. The

current limiting circuit, connected between the input and the output pins, is compensated all over

the temperature range. Furthermore, each channel runs independently of the other. Thanks to its

low tolerance, the current limitation allows the

drastic reduction of the dissipation compared to a

resistive input: the overall module requires less

cooling capability and becomes smaller.

The output block of each termination channel

controls the operation of an opto-coupler that is

internally enabledbyaLightEmittingDiode.When

the input current is less than 1.5mA, an integrated

APPLICATION NOTE

CLT3-4BT6 DEMOBOARD:

output circuit derivates the input current to

maintain the opto-coupler off.

When the CLT input voltage V

(that corresponds to a module input voltage higher

than 11V with a 1.2kΩ serial resistor), a minimum

output current of 1.5mA secures the opto-coupler

in the on state.

The CLT3-4BT6 protects the input module against

transient electromagnetic interferences such as

those described in the IEC61131-2 standard.

The opto-coupler plays a role in the CLT3-4BT6

operation. The drop voltage of its input diode

introduces a voltage offset in series with the

CLT3-4BT6 channel: for a good CLT3-4BT6

operation, this drop voltage should remain below

2V (see

CLT3-4BT6 datasheet

1.2. Application requirements

A reverse blocking diode is connected between

the module ground connection and the common

pin COM of the CLT3-4BT6 device to protect the

module against spurious reverse supply

connection. This diode also protects the

CLT3-4BT6 device against negative surge

voltages.

An external output capacitor is placed either at the

input or the output of the CLT3-4BT6 to filter the

transient disturbances injected in the inputs of the

module and secure the immunity of the module

itself.

All immunity requirements are described by the

IEC61131-2 international standard.

is higher than 5V

IN

for more details).

October 2002 - Ed: 1

1/7

Page 2

APPLICATION NOTE

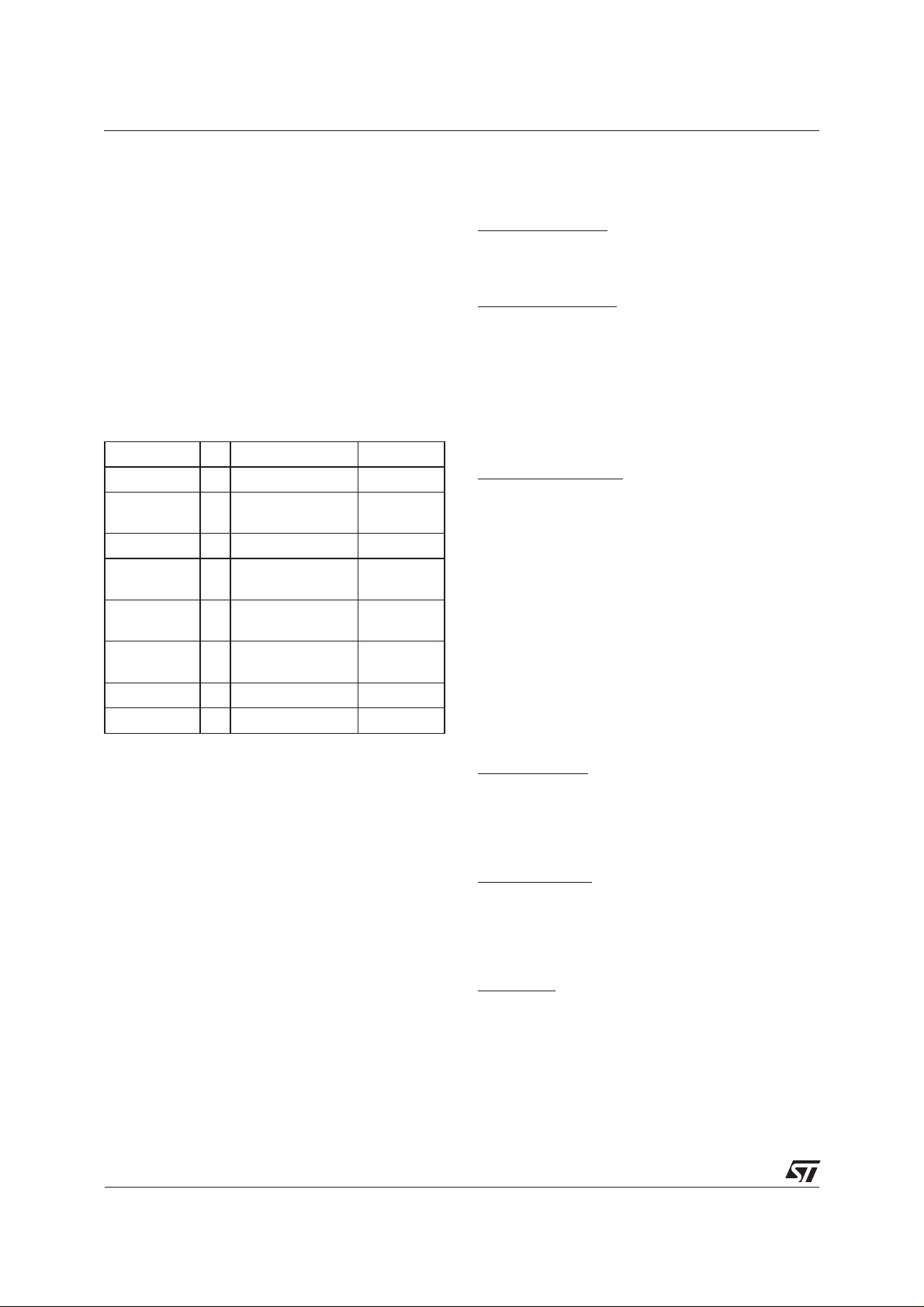

2. CLT3-4BT6 DEMONSTRATION BOARD

2.1. Description of the CLT3-4BT6 demoboard

This CLT3-4BT6 demonstration board allows the

evaluation of the function of the CLT3-4BT6

product. It can be easily inserted in a real

application, between sensors and digital bus

controller. The output LEDs give the state of each

line of the CLT3-4BT6, according to the state of

each input.

ThePCBofthedemonstration board hasthe structure described by the

figure 1

. It has been de-

signed and optimized with the components

table 1

presented in the

. This configuration gives a

good example of a robust interface design.

Table 1: bill of material.

Reference Nb Part description Package

J1, J2 2 Connector 6 pins 2.54 pitch

Rin1, Rin2,

4 1.2 kΩ, 0.25 W 1206

Rin3, Rin4

RC 1 4.7 kΩ, 0.33 W 1206

C1, C2, C3,C44 22 nF, 60 V 1206

R_LED 1 4 resitors array

1206

330Ω, 0.13W

LED1, LED2,

4 LED 10 mA 1206

LED3, LED4

U1 1 CLT3-4BT6 TSSOP20

U2 1 TLP281-4 SO-16

The copper surface under the CLT device improves the thermal dissipation capability of the

TSSOP20 package. The copper area on the PCB

demoboard is around 1.2cm², and makes it possible to decrease the Rth of the package to a value

lower than 100°C/W.

2.2. Operating instructions of the CLT3-4BT6

demo-board

This paragraph provides some basic advices to

implement properly the demonstration board in order to evaluate the CLT3-4BT6 product.

■

Inputs / Outputs

The input connector gives access to the 4 input

signals of the module (In1, 2, 3 and 4), and the

power supply access of the CLT3-4BT6 (Vcc and

Com). It is then easy to connect this module directlyto any type ofsensor, especially those specified by the EN60947-5-2 standard.

Theoutput connector givesaccess to the4 outputs

of the module (output of the opto-coupler, Out1, 2,

3 and 4). Furthermore, this connector is also used

to connect the output power supply (Vcc2 and

Com2). It is then easy to connect the output of the

module directly on a digital bus controller.

Power supply

■

- Vcc power supply

The Vcc power supply shall be a 24Vdc voltage

supply. Actually, the CLT3-4BT6 device needs a

10 to 30Vdc voltage to work.

- Vcc2 power supply

The output power supply can be a 5Vdc voltage

supply. This voltage supplies the 4 collectors of

each opto-coupler output.

NOTE: Do not short the opto-coupler output to

ground. This may result in the destruction of the

output transistor of this opto-coupler.

Discrete components

■

- Discrete capacitors:

Some 22nF capacitors are used in order to improve the noise immunity of the whole module and

to filter the high frequency electrical noise in the off

state.

They can be placed at the output of the CLT (betweenthe CLT device and the opto-coupler) as described in the

datasheet

. This configuration meets

the minimum level of immunity described in the

IEC61131-2 standard. The configuration corresponding to capacitors placed at the input of the

CLT device (between input resistors and the CLT

device), as in the demonstration board topology,

allows an increase of this immunity. However, the

normal operation of the module remains within

specification whatever the position of the capacitors is.

- Input resistors:

The input resistors are used in order to limit the

current that could appear in case of voltage surge

clamped by the CLT3-4BT6. These resistors shall

then withstand the high overvoltage that may be

applied to the module during surge tests.

- LEDs resistors:

The value of these resistors shall be set according

to the input power supply value used, and the normal current of displaying LEDs. A resistor array

can be used to control these low power LEDs (reducing of the PCB size).

- Diode D1:

The diode used between the COM of the input

power supply, and the COM of theCLT3-4BT6 device can be a general purpose component as a

1000V 1A rectifier.

■

Opto-coupler

The opto-coupler should be chosen according to

its input diode drop voltage and should fit the wide

range output voltage of the CLT3 output (0.2V).

2/7

Page 3

APPLICATION NOTE

Fig. 1: Electrical diagram of the CLT3-4BT6 demonstration board for reinforced EMC.

Vcc2

16

C1

15

E1

14

C2

13

E2

12

C3

11

E3

10

C4

9

E4

Vcc

Vcc

RC

4.7k

U1

1

COM

C4

22nF

2

In1

3

ESD12

4

IN2

5

Vc

6

ESDc

7

In3

8

ESD34

9

In4

10

COM

CLT3-4

Input

1

2

3

4

5

6

J1

Rin1

1.2k

Rin2

1.2k

Rin3

1.2k

Rin4

1.2k

D1

C1

22nF

C2

22nF

C3

22nF

COM

Out1

COM12

Out2

COM

COM

Out3

COM34

Out4

COM

20

19

18

17

16

15

14

13

12

11

U2

1

2

3

4

5

6

7

8

A1

K1

A2

K2

A3

K3

A4

K4

Opto-coupler

45

678

Output

1

2

Vcc2

3

4

5

6

J2

123

R_LED

Fig. 2: Assembly top view of the demonstration board.

LED4

LED1

LED2

LED3

3/7

Page 4

APPLICATION NOTE

3. EMC REQUIREMENTS

3.1. Description of the procedure to evaluate

the robustness of the CLT3-4BT6

The reference to evaluate the robustness of the

CLT3-4BT6 product is the IEC61131-2 international standard. This international standard gives

all requirements and conditions of tests that must

be performed on the programmable logic controllers PLC and their associated peripherals.

Thispaper focuses on the most stressfully tests for

the CLT3-4BT6 product. The immunity of the

CLT3-4BT6 is tested according to the standards.

The IEC61131-2 standard specifies the

Electromagnetic Compatibility (EMC) requirements

and the nature of the tests to perform in order to

determine if the system meets these requirements

paragraph 7: "EMC requirements" and paragraph 8:

(

"EMC type tests and verifications" of the Ed2 of the

standard

). The levels of each test depend on the zone

where the system will be installed. The most typical

industrial environmental levels correspond to zone B:

local power distribution zone and dedicated power

distribution zone (

of the IEC61131-2-Ed2 standard

see table 28: "EMC immunity zones"

). The following

paragraphs recall the test levels for this zone.

3.4. Surge test (according to the IEC61000-4-5)

Since the voltage surge consists in a single but energetic pulse, the CLT3-4BT6 device embeds an

over-voltage protection on each point. The absorbed energy complies at least with the requirements of the IEC61131-2 standard. The high

energy surge test must be applied on all input pins

of the system. For all analog inputs, the coupling

method is a 47Ω serial resistance and a 0.5µF capacitor.For dc power line, thecoupling is 2Ω, 18µF

with differential mode, and 12Ω, 9µF with common

mode.

The required voltage surge levels are:

analog or dc I/O: 0.5kV (line to line and line to

■

earth coupling modes),

dc power line: 0.5kV (line to line),

■

dc power line: 1kV (line to earth).

■

The PLC system shall continue to operate as intended. Temporary degradation of the performance is acceptable during the test, but the

system must recover by itself after the test (

rion according to the IEC61131-2 standard

B crite-

).

3.5. Conducted disturbance tests (according to

the IEC61000-4-6)

3.2. ESD tests (according to the IEC61000-4-2)

The electrostatic discharge test shall be applied to

operator accessible devices. This means that these

tests have to be performed on each connector pin.

The required levels are:

■

air discharge: +/-8kV

■

contact discharge: +/-4kV

The PLC system shall continue to operate as intended. Temporary degradation of the performance is acceptable during the test, but the

system must recover by itself after the test (

rion according to the IEC61131-2 standard

B crite-

).

3.3.Burst tests (according to the IEC61000-4-4)

Thefast transient burst tests must be applied on all

the input pins of the system. A capacitive

clamp-coupling device (50-200pF) must be used

as described in the IEC61000-4-4 standard.

The required burst voltage levels are:

■

analog or dc I/O: +/-1kV,

■

dc power line: +/-2kV.

The PLC system shall continue to operate as intended. Temporary degradation of the performance is acceptable during the test, but the

system must recover by itself after the test (

rion according to the IEC61131-2 standard

B crite-

).

The conducted radio frequency interference test

mustbe applied onall input pinsof the system.The

frequency range is 150kHz to 80MHz, with a 80%

amplitude modulation by a 1kHz sinusoidal wave.

A CDN (Coupling Device Network) or a current

coupling clamp (as described in the IEC61000-4-6

standard) has to be used to apply the stress to the

system.

The required level is:

■

3Vrms, whatever the tested system input is.

The PLC system shall continue to operate as intended. No loss of function or performance is acceptable (

IEC61131-2 standard

"A" criterion according to the

).

3.6. Reverse analog input polarity tests

The test procedure is described by the

IEC61131-2 standard (

Ed2 of the standard

paragraph 5.4.4.5 of the

). A signal of reverse polarity

(negative voltage) for unipolar analog inputs is applied for 10s. The result of this test shall be as

stated by the manufacturer.

Each input of the CLT3-4BT6 device may be biased to a reverse polarity. This case corresponds

to a connection mistake, or a reverse biasing that

is generated by the demagnetization of a monitored inductive solenoid.

4/7

Page 5

APPLICATION NOTE

The involved input withstands the high reverse

current up to 20mA; its opto-coupler is off and protected by the conducting input diode. The other inputs remain operational, and some extra

dissipation can happen in their clamping

protections.

Considering the supply operation, a reverse blocking diode can be connected between the module

ground and the common pin COM to protect the

CLT3-4BT6 device against any spurious reverse

supplyconnection. Then, the whole module supply

voltage rating is extended to +/-30V.

The thermal management of this accidental situation, is described in the §5.

4. ROBUSTNESS AND IMMUNITY OF THE

CLT3-4BT6 DEVICE

The

table 2

shows the minimal requirements of the

IEC61131-2 Ed2 international standard. Furthermore, it gives an overview of the high immunity

that a CLT3-4BT6 device will ensure to the whole

interface module.

Table 2: Immunity of the CLT3-4BT6 device.

Minimum requirements of

international standards

Tests conditions Levels Tests conditions Levels Behavior of the CLT

ESD test

IEC61000-4-2

Burst test

IEC61000-4-4

Surge test

IEC61000-4-5

Conducted

disturbance test

IEC61000-4-6

Reverse input

polarity test

Air discharge ± 8kV RC= 4.7kΩ

Contact discharge ± 4kV RC= 4.7kΩ

Analog input ± 1kV RIN= 1.2kΩ C = 22nF ±4kV No failure,

DC power line ± 2kV RC= 4.7kΩ

Analog input 42Ω, 5µF

DC

power line

150kHz

to 80MHz

-Vcc applied to one input during 10s -30VDCapplied to one input,

differential and

common mode

2Ω, 18µF

differential mode

12Ω, 9µF

common mode

22nF capacitors

at the output

± 0.5kV Analog input RIN= 1.2kΩ ± 1kV

± 0.5kV DC power line RC= 4.7kΩ ± 1kV

± 1kV ± 1kV

3V

RMS

AM ± 80%

The ambient temperature to take into account is obviouslythe air temperatureclose to the component.

The main equation corresponds to the following:

TTTPRth

=−=⋅

∆

ja j a d ja

−−

With:

Tj: junction temperature,

■

Ta: ambient temperature,

■

Pd: power to dissipate,

■

Rth

■

: junction to ambient thermal resistance.

j-a

This paragraph presents the method to evaluate

the dissipated power, and also the evolution of the

Rth value versus the copper surface on the PCB.

The maximal ambient temperature fixes the maximal allowed ∆T

. To estimate the maximal power

j-a

dissipation, it is possible to refer to the parameter of

the datasheet that gives the maximal specification

of the limitation of current. The purpose is to make

the sum of all "thermal supplies" inside the die.

Thereare 3 main sources origins of thepower dissipation: the 2 current limiters embedded in each line

of the CLT device (see

figure 3

low current consumption of the V

Robustness of the CLT3-4BT6 demoboard

RIN= 1.2kΩ

RIN= 1.2kΩ

150kHz to

80MHz

+30VDCon the others

RIN= 1.2kΩ

C = 22nF

at the INPUT

± 8kV

± 6kV

10

VRMS

AM ± 80%

on page 6), and the

pin (IC).

C

No failure,

no disturbance

no disturbance

No failure,

temporary disturbance

No failure,

no disturbance

No failure, no cross talk

5. THERMAL MANAGEMENT

TheCLT3-4BT6 device limits the current that flows

across each line. This causes an increase of the

junction temperature. The maximal allowed junction temperature of the CLT3-4BT6 is 150°C.

The TSSOP20 package has a thermal resistance

specified in the datasheet. This parameter allows

the determination of the maximal ambient temperature during the operation of the device.

Then, the maximal power dissipation can be estimated as follow:

PV IV IVI

=⋅ ⋅ ⋅ + ⋅ ⋅ + ⋅4075 025(.)(.)

[]

CLT ININ INCC

The worst case scenario occurs when IINand I

are maximal. These maximal values are given in

datasheet

the

:

ImA

=37.

IN

IA

=µ800

C

5/7

C

Page 6

APPLICATION NOTE

Fig. 3: Equivalent circuit of 1 line when the

CLT3-4BT6 limits the current.

Vcc

Sensor

V

SENSOR

R

xI

IN IN

I

IN

V

IN

0.25 x I

V

0.75 x I

IN

CLT

1.5mA

IN

i

1

+

V

OUT

To calculate the drop voltage across the CLT device,the circuit of

figure3

givesthe following equa-

tions:

VV V RI

=− −⋅

IN CC SENSOR IN IN

VVV

=−

CLT IN OUT

The worst case scenario corresponds to the maximal supply voltage value (V

drop voltage across the sensor (V

across the diode of the opto-coupler (V

), and to the minimal

CC

SENSOR

).

OUT

) and

For example:

■ V

= 30Vmax

CC

■ V

■ V

SENSOR

OUT

= 0Vmin

= 0.7Vmin

⇒ P

TOTAL

= 395mW

In case of a maximal allowed ambient temperature

equal to 100°C, the thermal resistance must be

lower than 127°C/W. Since the maximal Rth value

of the TSSOP20 package (0cm²) is 120°C/W,The

CLT3-4runs correctly at this ambienttemperature.

In case of a maximal allowed ambient temperature

equal to 100°C, the thermal resistance must be

lower than 95°C/W.

The

figure 4

is taken from the datasheet of the

CLT3-4BT6 device. It gives the junction to ambient

thermal resistance as a function of the copper surface used as a heatsink (FR4 epoxy PCB, 35µm

for the thickness of the copper). The 95°C/W can

be reached with the use of 1.6cm² of copper surface.

Fig. 4: Typical junction to ambient thermal resistance versus PCB layout surface for the

TSSOP20.

(°C/W)

R

th(j-a)

160

140

120

100

80

60

40

20

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

S(cm²)

As an example, the copper surface on the demo

board is equal to 1.2cm² allowing operation ambient temperature up to 100°C.

6. CONCLUSION

But,there is anothercase to take into account, with

higher power dissipation: spurious reverse supply

connection (

see §3.6

take as a reference the

). In that case, it is possible to

figure 6

of the

datasheet

that gives typical currents in this case. For example, referring to current and clamping voltage described by the datasheet, we can consider:

PVIVIVI

=⋅ ⋅ + ⋅ + ⋅34()

TOTAL CL IN CC CC D

With I

the reverse connection supply: I

corresponding to the current in the line with

4

4=I1+I2+I3+IC.

This current flows across the diode, and causes

⇒ P

.

D

TOTAL

= 528mW

the drop voltage V

6/7

The demonstration board allows the evaluation of

the robustness of the CLT3-4BT6 product against

electromagnetic disturbances.

Thanks to the use of the CLT3-4BT6, the immunity

of a PLC system exceeds the requirement standard levels, providing an extra safety to the application.

Furthermore,the demo board shows the functional

characteristics of this new product, and gives an

example of application.

The layout has been designed as versatile as possible, and can be used in most industrial or automotive applications.

Page 7

7. REFERENCES

Datasheet of the CLT3-4BT6 product.

■

EN60947-5-2: "Low-voltage switchgear and

■

controlgear - Part 5-2: Control circuit devices

and switching elements - Proximity switches".

IEC61131-2: "Programmable controller; Part2:

■

Equipment Requirements and tests".

IEC61000-4-2: "Electrostatic discharge

■

immunity test".

IEC61000-4-4: "Electrical fast transient/burst

■

immunity test".

IEC61000-4-5: "Surge immunity test".

■

IEC61000-4-6: "Immunity to conducted

■

disturbances, induced by radio-frequency

fields".

APPLICATION NOTE

Informationfurnishedisbelieved to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

useofsuch information nor for any infringement of patents or other rights of thirdpartieswhich may result from its use. No license is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

7/7

Loading...

Loading...