Page 1

AN1602

APPLICATION NOTE

16-BIT TI MIN G OP ER ATIONS US ING ST 72 62 O R S T 7263 B

MCUs

Microcontroller Division Applications

INTRODUCTION

This Application Note describes how to us e the ST7262 or ST 7263B for 1 6-bit timin g operations. The intention of this document is to show how to perform pulse measurement and PWM

generation using the different timers available on each microcontroller type.

1 16-BIT TIMING MEASUREMEN TS

1.1 USING ST7262

The aim of this section is to describe how to use the ST7262 8-bit timer to perform pulse and

frequency measurements with 16-bit accuracy.

1.1.1 16-Bit Capture

1.1.1.1 Principle

The ST7262 architecture allows you to cascade the 8-bit Auto Reload Timer (ART) with the 8bit Time Base Unit (TBU) to obtain a 16-bit counter (The carry bit of the ART acts as the clock

for the TBU). Using t his configuration, the ARTCAR register represents the Least S ignificant

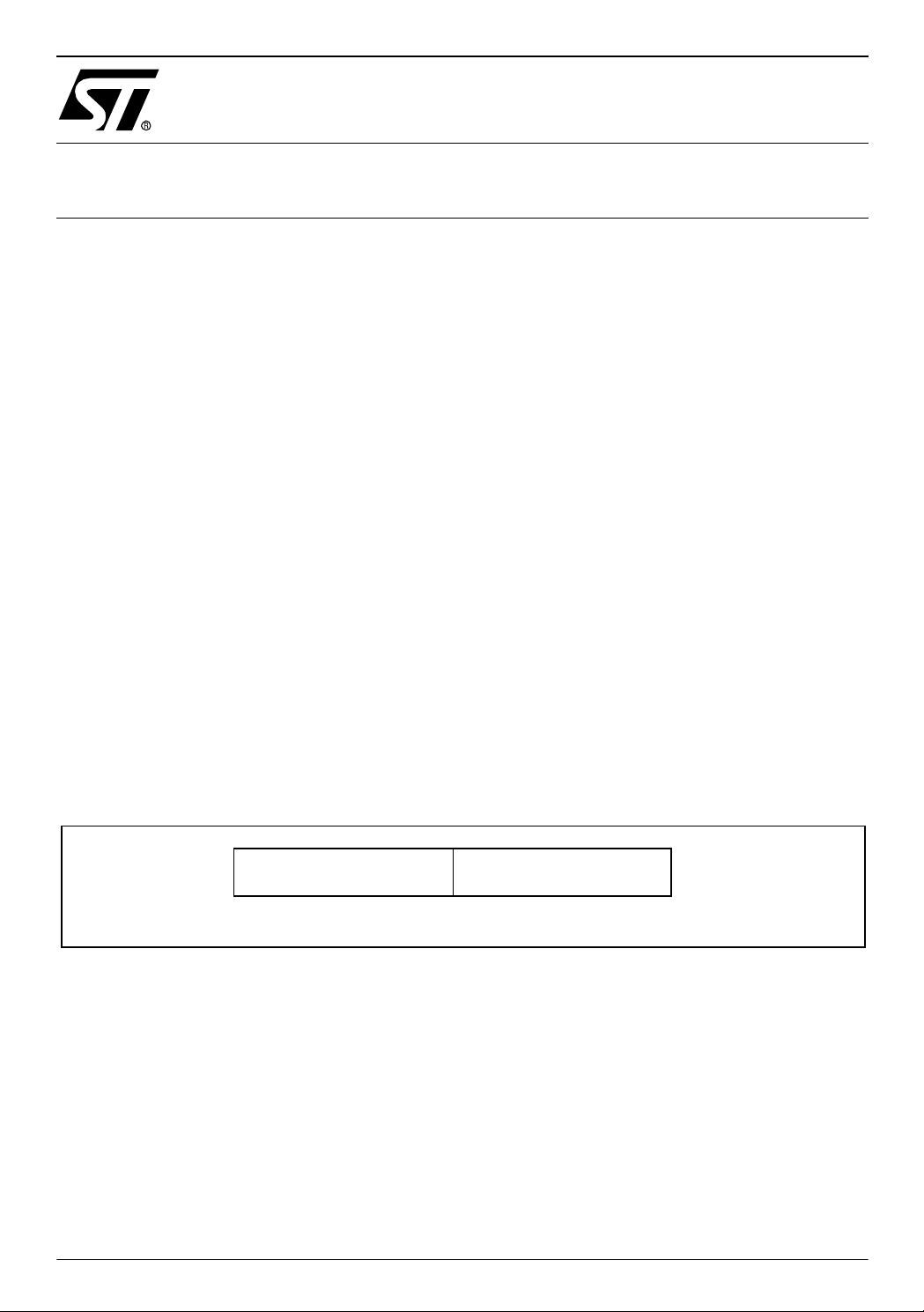

Byte and the TBUCV register represents the Most Significant Byte (see Figure 1).

Figure 1. TBU+ART 16-Bit Counter Value

TBU (MSB)

16 Bit Counter Value

On each valid input capture, the 16-bit counter value is obtained by:

– The ARTCAR register which is automatically latched.

– The TBUCV register which is saved by software in the Input Capture Interrupt routine.

This method ensures a “real-time” capture of the low bits, while the software delay needed to

save the TBUCV can be compensated.

ART (LSB)

AN1602/0503 1/21

1

Page 2

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

1.1.1.2 Delay Compensation method

The software delay introduced by the interrupt routine should be taken into account otherwise

the measurement value can be corrupted. This happens if the ART counter rolls over from FFh

to 00h while soft ware is s toring the TB UCV v alue afte r a v alid input cap ture interrup t. In this

case, the TB UCV is in cremen ted and a wr ong value oc curs in the 8th bit of th e 16-b it input

capture value.

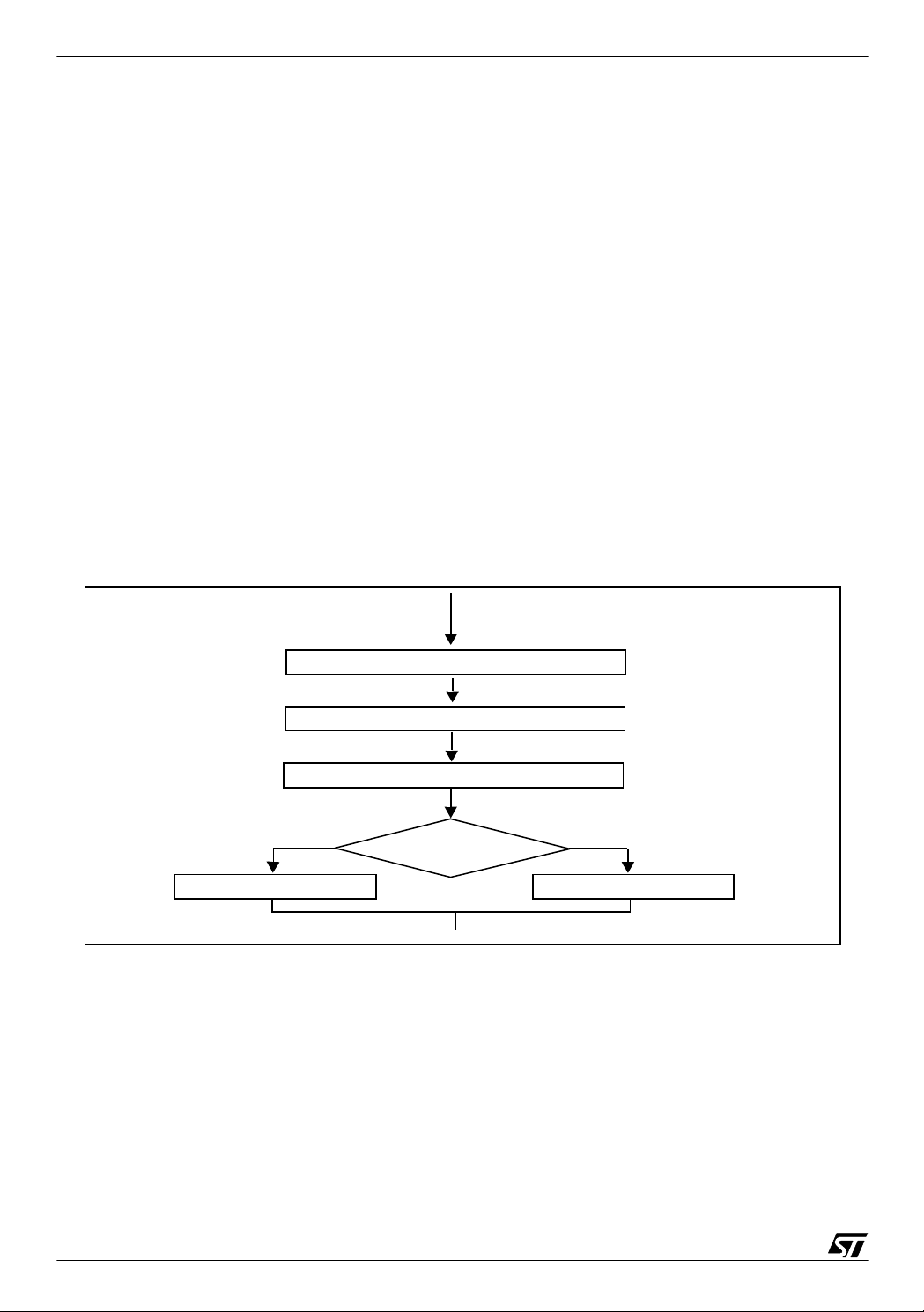

The delay compensation method is described in the following flowchart (Figure 2).

The first step consists of transferring both TBU and ART values into temporary variables

(TmpTBU1, TmpAR T, Tmp TBU 2) to be used later on. Then in t he s econd s tep we com pare

TmpART and ICxR. There are two cases to be considered:

– TmpART >= ICRx: This means that the ART counter value was incremented by a few cycles

but has not yet reached the maximum value (FFh). In this case we use TmpT BU1.

– TmpART < ICRx:This means that the ART counter was incremented beyond the maximum

value and has been reset. This means we should decrement TmpTBU2 once to get the right

value of TBUCV.

Figure 2. TBU Delay Compensation flowchar t

Interrupt From ICAP1 or ICAP2

Read & Store the TBUCV in TmpTBU1

Read & Store the ARTCAR inTmpART

Read & Store the TBUCV in TmpTBU2

Yes

TmpART >= ICxR

TBUok= TmpTBU1 TBUok= TmpT BU2 - 1

No

1.1.1.3 Example of an interrupt capture routine

The input capture inte rrupt rou tine given below ca n be us ed to get t he prec ise va lue of t he

input capture interrupt instant on ICAP1 pin. It can be used to detect a ri sing or falling edge depending on the configured edge in ARTICSR.

.Inp_Cap_Routine

;----------------------------------------;

Ld A , TBUCV ;Load the TBU counter value

2/21

2

Page 3

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Ld TmpTBU1 , A ;into TmpTBU1

Ld A , ARTCAR ; Load the ART counter Value

Ld TmpART1 , A ;into TmpART1

Ld A , TBUCV ; Load the TBU counter value into

Ld TmpTBU2 , A ;TmpTBU2

;----------------------------------------;

Ld A , TmpART1 ; Compare ART & ICR

Cp A , ARTICR2 ; If ART > ICR then Case 2

jrpl Case2 ;

Ld A , TmpTBU2 ; Case 1 : TBU = TBU2 - 1

Dec A ;

jra Next2 ;

.Case2 Ld A , TmpTBU1 ; Case TBU = TBU1

.Next2 Ld PulseEndHR , A ;load TBUCV into PulseEndHR

Ld A , ARTICR2 ;Load The ART Inp Capt 2 register

Ld PulseEndLR , A ;Value into PulseEndLR

Ld A , ARTICCSR ;Clear The input capture interrupt

Iret ;Exit From Interrupt

1.1.2 Pulse Length measurement

1.1.2.1 Measurement Principles

As first example in this application note, we will try to measure the pulse length of an external

signal applied to the input capture pins.

Figure 3. Pulse Length Measurement

Pulse Length

To perform this operation, two input captures are used together and they are configured as fol lows:

– Input capture1 pin (ARTIC1) configured to detect rising edges

– The input capture2 pin (ARTIC2) configured to detect falling edges

The ARTIC1 & ARTIC2 are connected together (Figure 4).

Two 16-b its vari ables ar e used t o hold th e 16-bi ts time r values on ea ch vali d input capture

edge (PulseStart for the rising edge and PulseEnd for the edge).The pulse length value can be

deduced later using a 16-bits substruction between PulseStart and PulseEnd

3/21

Page 4

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Figure 4. Input Capture Configuration

ST7262

ARTIC1

External Signal

ARTIC2

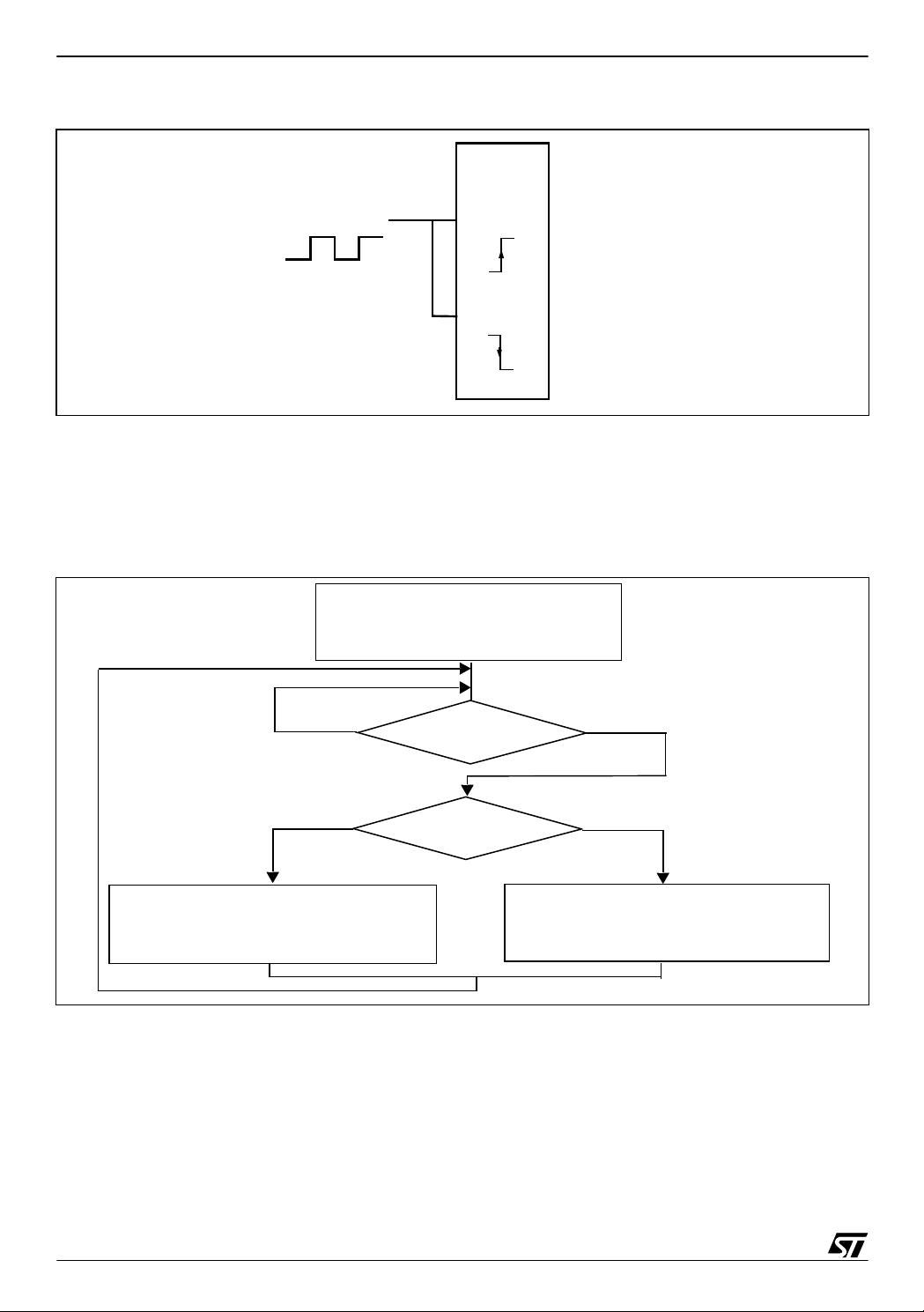

Figure 5 shows the steps that have to be followed to successfully measure the length of a

pulse in 16-bit accuracy.

Figure 5. Input Capture Sequence

- Configure Time clock frequency

- Select edge sensitivity on ICAP pins

- Cascade PWMART & TBU

No

Input capture interrupt

ICAP1

- Store the TBU counter Value

(Compensated value) in PulseStartHR

- Store the ICRx Value in PulseStartLR

ICAP1 Or ICAP2

- Store the TBU counter Value

(Compensated value) in PulseEndHR

- Store the ICRx Value in PulseEndLR

YES

ICAP2

1.1.2.2 Example of input capture interrupt rout ine

.Inp_Cap_Routine ;

Btjt ARTICCSR,#0,Flag1 ; Test If is ICAP(1 Or 2)

.Flag2 Ld A , ARTICR2 ; Latch the Input Cap Reg into

Ld IcapReg2 , A; IcapReg2

Ld A , ARTICCSR ; Clear Interrupt

4/21

1

Page 5

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Ld A , TBUCV ; Load the TBU counter value

Ld TmpTBU1 , A; into TmpTBU1

Ld A , ARTCAR ; Load the ART counter Value

Ld TmpART1 , A ; into TmpART1

Ld A , TBUCV ; Load the TBU counter value into

Ld TmpTBU2 , A; TmpTBU2

Ld A , TmpART1 ; Compare ART & ICR

Cp A , IcapReg2 ; If ART > ICR then Case 2

jrpl Case2 ;

Ld A ,TmpTBU2; Case 1 : TBU = TBU2 - 1

Dec A ;

jra Next2 ;

.Case2 Ld A , TmpTBU1 ; Case TBU = TBU1

.Next2 Ld PulseEndHR , A; load TBUCV into PulseEndHR

Ld A , IcapReg2 ; Load The ART Inp Capt 2 register

Ld PulseEndLR , A; Value into PulseEndLR

Iret ; Exit from Interrupt

.Flag1 Ld A , ARTICR1 ; Latch the Input Cap Reg into

Ld IcapReg1 , A; IcapReg1

Ld A , ARTICCSR ; Clear Interrupt

Ld A , TBUCV ; Load the TBU counter value

Ld TmpTBU1 , A; into TmpTBU1

Ld A , ARTCAR ; Load the ART counter Value

Ld TmpART1 , A ; into TmpART1

Ld A , TBUCV ; Load the TBU counter value into

Ld TmpTBU2 , A; TmpTBU2

Ld A , TmpART1 ; Compare ART & ICR

Cp A , IcapReg1 ;

jrpl Case1 ;

Ld A , TmpTBU2; Case : TBU = TBU2 - 1

Dec A ;

jra Next1 ;

.Case1 Ld A , TmpTBU1 ; Case TBU = TBU1

.Next1 Ld PulseStartHR , A; load TBUCV into PulseEndHR

Ld A , IcapReg1 ; Load The ART Inp Capt 2 register

Ld PulseStartLR , A; Value into PulseEndLR

Iret ; Exit from Interrupt

1.1.3 Frequency Measurement

1.1.3.1 Measurement Principles

Frequency measurement is a little bit different from pulse length measurement. To get the frequency, we measure the full signal period which can be defined by the time interval between

two consecutive rising edges (Figure 6)

5/21

Page 6

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Figure 6. Frequency Measurement

Frequency= 1 / Period

In this example w e will al so use two 16 -bit variables to h old the 1 6-bit timer v alue eac h tim e

an input c aptur e oc c urs ( Sta r tPer iod: for the f irst ri sing e dge and E nd Peri od f or the s e cond

falling edge). In addition to thes e two variables, we will nee d an extra variable (FirstEdge)

which is used to indicate the first rising edge or the second edge.

– FisrtEdge =0: First Rising edge (PeriodStart)

– FisrtEdge =1: Second Rising edge (PeriodEnd)

In this case we will need only one input capture pin (ARTIC1) c onfigured to detect only rising

edge.

The capture steps are shown in Figure 7. After selecting the timer frequency and the input

capture edge we wait for an input capture interrupt. Depending on the FirstEdge value the

input capture parameters (ICxR and the TBU) are transferred into PeriodStart or PeriodEnd.

Figure 7. Input Capture Sequence

- Configure Time clock frequency

- Select sensitive edge on ICAP pins

- Cascade PWMART & TBU, FirstEdge = 0

No

0

- Store the TBU (compensated value)

in PeriodStartHR

- Store the ICxR in PeriodStartLR

input capture

First Edge =?

- Store the TBU (compensated value)

in PeriodEndHR

- Store the ICxR Value in PeriodEndLR

YES

1

6/21

Page 7

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

1.1.3.2 Example of input capture interrupt rout ine

.Inp_Cap_Routine ;

Ld A , ARTICR1 ;

Ld CurrentICAP , A ;

;------------------------------------------;

Ld A, ARTICCSR ;

;------------------------------------------;

Ld A , TBUCV ;Load the TBU counter value

Ld TmpTBU1 , A ;into TmpTBU1

Ld A , ARTCAR ;Load the ART counter Value

Ld TmpART1 , A ;into TmpART1

Ld A , TBUCV ;Load the TBU counter value into

Ld TmpTBU2 , A ;

;------------------------------------------;

Btjf FirstEdge,#0,FirstRisingEdge ;TmpTBU2

;------------------------------------------;

;.SecondRisingEdge ;

Ld A , TmpART1 ;Compare ART & ICR

Cp A , CurrentICAP ;If ART > ICR then Case 2

jrpl Case2 ;

Ld A , TmpTBU2 ;Case 1 : TBU = TBU2 - 1

Dec A ;

jra Next2 ;

.Case2 Ld A , TmpTBU1 ;Case TBU = TBU1

.Next2 Ld PeriodEndHR , A ;load TBUCV into PeriodEndHR

Ld A , CurrentICAP ;Load The ART Inp Capt 1 register

Ld PeriodEndLR , A ;Value into PeriodEndLR

Clr FirstEdge ;

Iret ;

.FirstRisingEdge ;

Ld A , TmpART1 ;Compare ART & ICR

Cp A , CurrentICAP ;

jrpl Case1 ;

Ld A , TmpTBU2 ;Case : TBU = TBU2 - 1

Dec A ;

jra Next1 ;

.Case1 Ld A , TmpTBU1 ; Case TBU = TBU1

.Next1 Ld PeriodStartHR , A ;load TBUCV into PulseEndHR

Ld A , CurrentICAP ;Load The ART Inp Capt 1 register

Ld PeriodStartLR , A ;Value into PulseEndLR

Inc FirstEdge ;

Iret ;

7/21

Page 8

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

1.2 USING ST7263B

This section describe how to use the ST7263B 16-bit timer to perform 16-bit timing

operations such as period and pulse length measurement.

1.2.1 The Input Capture operation

In the case of the ST 7263B both ICA P1 and ICAP2 are as sociated with 16 -bit registers

(TIC1HR, TIC1LR, TIC2HR and TIC2LR). These registers are used to hold the corresponding

16-bit timer value at each valid input capture (see Figure 8).

Figure 8. Input Capture Registers

TIC1LR (LSB)

TIC2LR (LSB)

ARTIC1(16-bit Register)TIC1HR (MSB)

ARTIC2(16-bit Register)TIC2HR (MSB)

1.2.2 Pulse Length measurement

1.2.2.1 Measurement principles

To measu re p ulse len gth , two input captu res a re us ed tog ether. The input captu re1 pin

(ICAP1) is configured to detect rising edge and the input capture2 pin (ICAP2) is configured to

detect falling edge. The ICAP1 & ICAP2 pins are connected together and on each input capture: rising edge or falling edge two 16-bit variables are used to hold the 16-bit timer value.

Figure 9. Input Capture sequence

- Configure Time clock frequency

- Select edge sensitivity edge on ICAP

No

ICAP1

- Store the TIC1HR in PulseStartHR

- Store the TIC1LR in PulseStartLR

input capture

ICAP1 or ICAP2

YES

ICAP2

- Store the TIC2HR in PulseEndHR

- Store the TIC2LR in PulseEndLR

Whenever a valid rising edge is captured, the timer counter value is automatically stored in the

TIC1HR & TIC1LR registers. These two registers act together as one 16-bit register that holds

the counter value to be transferred into PulseStart (PulseStartHR & PulseStartLR).Whenever

a valid falling edge is captured, the timer counter value is automatically stored in the TIC2HR

8/21

Page 9

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

& TIC2LR registers. These two register s act together as one 16-bit register that holds the

counter value to be stored in PulseEnd (PulseEndHR & PulseEndLR).

1.2.2.2 Example of input capture interrupt rout ine

.Input_Capt_Rt

Btjt TSR , #7 , Flag1 ; Test Rising or falling edge ?

.Flag2 ; Falling Edge

Ld A , TSR ; Clear Interrupt Flag

Ld A , TIC2HR ; Load TIC2R ( HR & LR ) into

Ld PulseEndHR , A; PulseEnd ( HR & LR )

Ld A , TIC2LR ;

Ld PulseEndLR , A;

Iret ;

.Flag1 ; Rising Edge

Ld A , TSR ;Load TIC1R ( HR & LR ) into

Ld A , TIC1HR ; PulseStart ( HR & LR )

Ld PulseStartHR , A;

Ld A , TIC1LR ;

Ld PulseStartLR , A;

Iret ;

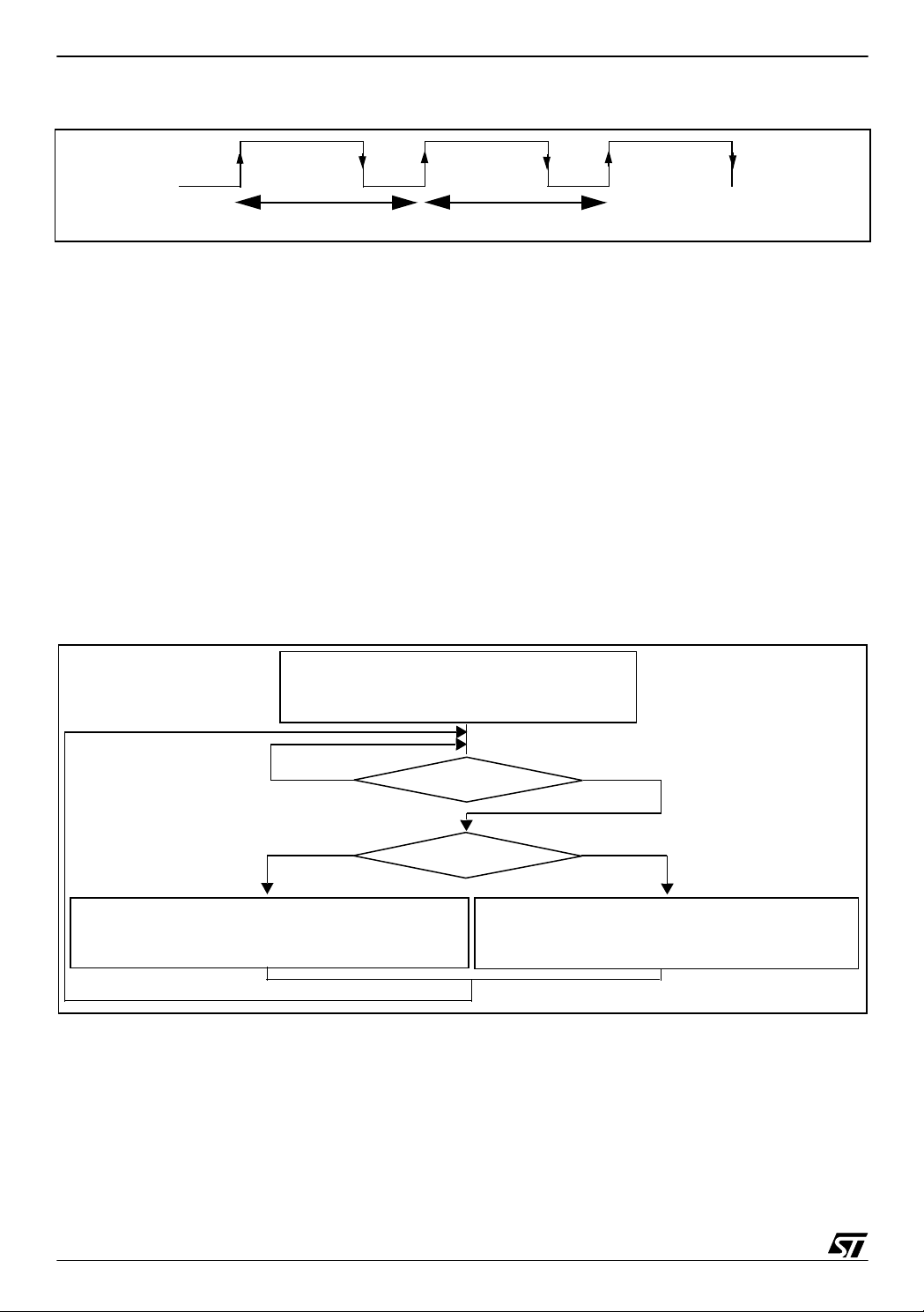

1.2.3 Frequency Measurement

1.2.3.1 Measurement principles

To measure frequency we will us e the same technique we us ed for the ST7262 (see Sec tion

1.1.3). We need only one input capture pin configur ed to detect rising edg es and two 16-bit

variables to hold the 16-bit timer value at each input capture occurrence (StartPeriod) and

(EndPeriod). We w ill n eed a lso Fi rstEdge w hich indicate s the first r ising edg e or the s econd

edge.

9/21

Page 10

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Figure 10. Input Capture Sequence

- Configure Time clock frequency

- Select sensitive edge on ICAP pin

- FirstEdge = 0

No

0

- Store the IC1HR Value in PeriodStartHR

- Store the IC1LR Value in PeriodStartLR

- Increment FirstEdge

Input capture interrupt

First Edge =?

- Store the ICP2HR Value in PeriodEndHR

- Store the ICP2LR Value in PeriodEndLR

-Decrement FirstEdge

1.2.3.2 Example of input capture interrupt rout ine

.Input_Capt_Rt

Ld A , TIC1HR ; Lock The TICR

Btjf FirstEdge ,#0, FirstRisingEdge ; Test First Or Second Edge

.SecondRisingEdge ;

Ld PeriodEndHR , A; Load PriodEnd Values

Ld A , TIC1LR ;

Ld PeriodEndLR , A;

Ld A , TSR ;Clear ICAP interrupt Flag

Ld A , TIC1LR ;

Clr FirstEdge ;

Iret ;

.FirstRisingEdge ;

Ld PeriodStartHR , A ; Load PriodStart Values

Ld A , TIC1LR ;

Ld PeriodStartLR , A ;

Ld A , TSR ;Clear ICAP interrupt Flag

Ld A , TIC1LR ;

Inc FirstEdge ;

Iret ;

YES

1

10/21

Page 11

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

1.3 PERIOD MEASUREMENT CAPABILITY

This section describes a comparison based on period measurement capability (rising edge to

rising edge measurement) between the ST7262 16-bit timer (ART + TBU) and ST7263B 16-bit

timer. All comparisons and measurement range values are calculated using the software provided with this application note and at f

= 8 MHz.

CPU

1.3.1 Using the ST7262 ART & TBU in cascading mode

Analyzing the ST7262 period measurement capability in the cascading mode can be done by

focusing o n tw o imp ortan t p oints : t he m axim um period and th e m inimu m p erio d t hat c an be

measured using this mode.

1.3.1.1 Maximum period

In cascading mode, the timer acts as a 16-bit free running counter. At f

imum period can reach t

max

t

= FFFFh * Timer

max

= 65535 Timer

clk

clk

= 8 MHz, the max-

CPU

Table 2 shows the time measurement range covered by the ST7262 ART & TBU timer.

Table 1. Time M easurement Range using ART & TBU

Prescaler Timer Frequency Maximum Period Resolution

1

2

4

8

16

32

64

8 MHz 8,192 ms 0.125 µs

4 MHz 16,384 ms 0.250 µs

2 MHz 32,767 ms 0.500 µs

1 MHz 65,535 ms 1 µs

500 kHz 131,07 ms 2 µs

250 kHz 262,14ms 4 µs

125 kHz 524,28 ms 8 µs

128

62.5 kHz 1048,56 ms 16 µs

1.3.1.2 Minimum period

The minimum period that can be meas ured using the ST7262 16-bit timer depends on several

parameters such as the software delay introduced by interrupt routine execution time and the

hardware delay required to enter and exit the interrupt subroutine.

11/21

Page 12

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Figure 1 1 sho ws the nor m al be havio ur of t he in put ca ptur e r out ine: e ach r isi ng e dg e is d etected and the inp ut captur e interr upt routine is ex ecuted aft er the T0 del ay. In t his c ase the

period measurement operation can be easily done.

Figure 11. Case 1: Interrupt routine execution sh orter than period to be measured

T

T

1

T

0

T: Period of the external signal to be measured

T

: Interrupt routine execution time

1

T

: Delay needed to activate the interrupt routine

0

T

T

1

T

0

T

0

The minimum period that can measured depends strongl y on the number of rising edges

during the interrupt routine execution.

A single rising ed ge d uring the ex ecution of the in terrupt r outine does n ot c orrupt the meas urement value and the period measure ment o peration ca n be achieved s uccessfully (F igure

12).

Figure 12. Case 2: Interrupt routine execution lo ng er than period to be measured

T

T

T

1

T

0

T: Period of the external signal to be measured

T

: Interrupt routine execution time

1

T

: Delay needed to activate the interrupt routine

0

T

: Delay needed to exit from interrupt routine

2

T

1

T

2

However, any addi tional r ising edg e leads to a corr upted measur ement. As s hown in Figur e

12, the second rising edge is ignored, in fact before executing the input capture interrupt triggered by the second rising edge, a third one occurs and overwrites the previous ICxR value.

For this reason the period measurement operation result is corrupted

(result = 2 * T).

12/21

Page 13

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

So the minimum period (the maximum frequency) that can be measured using the ST7262 16bits cascaded timer can be calculated using the following formula.

Figure 13. Minimum measurable period (max. frequency)

123123

T

T

1

T

0

T0: Time needed to activate the interrupt routine (10 t

ternal clock rising edge (about 2 t

: Time needed to execute the interrupt routine. Using the example software supplied in this

T

1

application note, the input capture interrupt routine needs about 62 t

: The time needed to exit from the interrupt routine (9 t

T

2

: This represents the period of time from the start of the interrupt routine until the ICxR reg-

T

3

ister is read (about 3 t

in the example software).

CPU

T

2T > T

CPU

T

T

0

0+T1+T0+T2+T3

).

T

3

2

T

1

), and the time need to wait for the in-

CPU

.

CPU

).

CPU

Using the above values based on the software example:

= 10, T1 = 62 t

T

0

CPU

, T2 = 9 t

CPU

, T3 = 3 t

CPU

2 T > T

2 T > (12 + 62 + 12 + 9 + 3) * t

0+T1+T0+T2+T3

CPU

> 98 * 0.125 µs

> 12.25

So we can calculate the minimum period Tmin = 6.125 µs.

1.3.2 Using the ST7263B 16-bit timer

1.3.2.1 Maximum Period

Using the ST7263B 16-bit timer, the ma ximum meas urable period t

can be expressed as

max

follows:

= FFFFh * Timer

t

max

= 65535 Timer

clk

clk

So the maximum period that can meas ured using the S T7263B 16- bit timer and the ST7262

cascaded timer is the same, however the minimum period is different.

13/21

Page 14

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Table 2. Time measurement range using ST7263B

Prescalers Timer Frequency Maxi Period Resolution = 1 t

2 4 MHz 16,384 ms 0.250 µs

4

8

2 MHz 32,767 ms 0.500 µs

1 MHz 65,535 ms 1 µs

CLK

1.3.2.2 Minimum Period

In the case of ST7263B, on each valid input capture, the 16-bit counter value is latched automatically into the 16-bit input capture registers ( TICxHR & TICxLR) without any additional software routin e. So co mpared to th e ST7 262 , th e ST 7 26 3B need s les s tim e to st ore the i np ut

capture parameters into temporary variables.

Using the same method as for the ST7262 (see Figure 13):

2T > T

0+T1+T0+T2+T3

And with the following parameters:

T

0

= 12 t

CPU

(10 t

for the interrupt activation and 2 t

CPU

the maximum time needed to syn-

CPU

chronise the interrupt flag with the internal CPU frequency).

T

1

= 26 t

CPU

=9 t

T

2

CPU

T3 = 23 t

(from the start of the interrupt routine until the interrupt flag is cleared).

CPU

Using the above values based on the software example:

= 12, T1 = 26 t

T

0

CPU

, T2 = 9 t

2 T > T

, T3 = 23 t

CPU

0+T1+T0+T2+T3

2 T > (12 + 26 + 12 + 9 + 23) * t

CPU

CPU

> 82 * 0.125 µs

> 10.25 µs

So we can calculate the minimum period Tmin = 5.125 µs.

1.3.2.3 Period Measurement Comparison Chart

The follo win g tabl e can be u sed to sel e ct t he b es t presc aler v alue f or a preci se tim e or fre quency measurement with the appropriate resolution.

14/21

Page 15

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Table 3. Period Measurement Capability Com parison Chart

Max.

ms

16-Bit Timer

ART & TBU

(ST7262)

Re-

solution

16 µs 0.953 Hz

Freq.

8-Bit Timer

ART

(ST7262)

Max.

Measure

Pre-

scaler

1 31,875 µs 0.125 µs

2 63,750 µs 0.25 µs

4 127,5 µs 0.5 µ s

8 255 µs 1 µs

16 510 µs 2 µs

32 1.02 ms 4 µs 998 Hz 262, 14 ms 4 µs 3,815 Hz

64 2.04 ms 8 µs 499 Hz 524, 28 ms 8 µs 1.907 Hz

128 4.08 ms 16 µs 249,5 Hz

ment

Period

Re-

solution

Freq.

31,372

kHz

15,686

kHz

7,843

kHz

3,921

kHz

1,996

kHz

Measure

ment

Period

8,192 ms 0.125 µs 122,1 Hz

16,384 ms 0.250 µs 61.05 Hz 16 ,384 ms 0.25 µs 61.05 Hz

32,767 ms 0.5 µs 30.52 Hz 32 ,767 ms 0.5 µs 30.52 Hz

65,535 ms 1 µs 15.26 Hz 65,535 ms 1 µs 15.26 Hz

131,07 ms 2 µs 7.63 Hz

1048,56

Max.

Measure

ment

Period

16-Bit Timer

(ST7263B)

Re-

solution

Freq.

For example, to measure an external signal pulse with a period not exceeding 50 ms, we have

to choose a prescaler greater than or equal to 8 (8,16, 32, 64,128) with the ART and TBU in

cascad ing mod e. How eve r, usin g a presc aler of 8 give s a mo re preci se me asurem ent ( the

error is about 1 µs)

2 PWM MODE

Definition of terms

– PWM Period: The PWM period is the time interval needed by the PWM patter n to repeat it-

self.

– PWM Frequency: The PWM frequency is 1/PWM period.

– PWM Resolution: The PWM resolution is the step with which the duty cycle is modulated

– High Level period: period of time when the PWM signal is at high Level

– Low Level period: period of time when the PWM signal is at Low Level

15/21

Page 16

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Figure 14. PWM Level definition

Low Level

Period

High Level

Period

2.1 USING ST7262

2.1.1 16-Bit PWM generation

2.1.1.1 Principles

The ST7262 can be used to generate of PWM signals through the PWMx pins. This func tion

can be selected using the OEx bit in the PWM Control register (PWMCR). All the PWM signals

have the same frequency which is controlled by the counter period and the A RTAR R register

value.

f

PWM

= f

COUNTER

/ (256 - ARTARR)

The registers used to perform the PWM signal generation are all 8-bit wide registers, so they

cannot generate 16-bit PWM signals. To by-pass this hardware limitation the following method

can be used.

The main idea of the method is to split all the 16-bit PWM parameters (Duty Cycle, Low level

period, full signal period) into 8-bit parts .

For example if we consider that we have to generate a PWM signal with the following characteristics:

– PWM Full period = 700 µs

– PWM Duty Cycle = 5/7 ( PWM high level = 500 µ s )

Timer

= 0.5 µs

with T

The High level period will be divided into 8-bit parts as described below .

High Level period = 500 µs

= 1000 * T

= 3E8h * T

Timer

Or 3E8h = (3 * FFh + EBh)

Timer

So to generate the high level part of the PWM signal we have to:

– Generate three elementary PWM waves all at high level , each wave has a period length of

FFh .

– Then generate an additional wave at high level but with a period length of EBh

16/21

Page 17

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Once the high level of the wave is split up we will use the same technique to generate the low

level.

Low Level period = 200 µs

= 400 * T

= 190h * T

Timer

Timer

= 1* FFh + 91h

So to generate the low level part of the PWM signal we have to:

– Generate an elementary PWM wave at low level

– Then generate the last wave at low level with a period of 91h

These different waves are computed and then cascaded by soft ware using the Interrupt routine.

For this reason, a minimum PWM period has to be respected to allow enough ti me to complete

the interrupt routine task. In the software provided with this application note the minimum time

to be respected is the following :

The minimum DutyCycle = 55 Tcpu with LowLevel period >= 85 Tcpu.

with Ttimer = 0.125 µs we were able to generate a PWM signal with high level period=10.6 µs

and Lowlevel period = 16.63 µs .

This limitation applies only when working with values lower than FFh.

2.1.1.2 Generation Sequence

In general cases, the following variables are used to define the PWM signal in 16-bit mode:

– DutyCycleHR: 8-bit variable that defines the PWM signal duty cycle High register

– DutyCycleLR: 8-bit variable that defines the PWM signal duty cycle low register

– LowLevelHR: 8-bit variable that defines the PWM signal low level period High Register

– LowLevelLR: 8-bit variable that defines the PWM signal low level period Low Register

The pair of 8 -bit variables (Duty Cyc leHR, D utyC ycleLR ) are us ed to h old the 16-bit value of

the PWM high level. The second pair of registers used to hold the low level period are LowlevelHR and LowLevelLR.

Figure 15. PWM Paramet e rs

Duty Cycle

Low Level

DutyCycleHR (MSB)

LowLevelHR (MSB)

DutyCycleLR (LSB)

LowLevelLR (LSB)

To generate a PWM signal with 16-bit resolution, perform the steps shown in Figure 16.

17/21

Page 18

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Figure 16. 16-bit PWM generation

- Configure Time clock frequency

- Enable PWM pin & Select Polarity

NO

Timer Interrup t

YES

- Generate High Level (Period = FFh)

- Decrement DutyCycleHR

YES

- Generate High Level ( The wave period depends on ARTARR value )

- Clear DutyCycleLR

YES

- Generate Low Level (Period = FFh)

- Decrement LowLevelHR

YES

- Generate Low Level ( The wave period depends on ARTARR value )

- Clear Low LevelLR

YES

DutyCycleHR #0

DutyCycleLR #0

LowLevelHR#0

LowLevelHR#0

NO

NO

NO

NO

Reload All values: DutyCycleHR,DutyCycleLR, LowLevelHR, LowLevelLR.

2.1.1.3 Optimization method

To get ar oun d the l imita tion impos ed by t he mi nimum PW M per iod, an op timiza tion m ethod

has been implemented in the software.

To generate a PWM signal with a duty cycle of 0504h , we have to generate 05 waves at high

level (period = FFh) then the last wave with a period of 04 (see Figure 17) which is impossible

( generation of a signal with a period equal to 04 ) due to the time needed by the interrupt routine .

18/21

Page 19

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

Figure 17. Without Optimization

1

23

45

5 PWM waves with a period of FFh

The last PWM wave perio d is too sm all (04 Ttim er )

to be generated

Using the optimization method we will generate only 04 waves (period = FFh) then two

additional waves with a period of 82h (Figure 18) which provide the necessary delay for the

interrupt routine.

Figure 18. With Optimization

1

4 PWM waves with a period of FFh

23

1

4

2

Two PWM waves with period (82h *Ttimer )

2.2 USING ST7263B

2.2.1 Principles

The Pulse Width Modulation (PWM) mode in the ST7263B, enables the generation of a PWM

signal with a frequency and pulse length controlled by the value of the OC1R and OC2R registers. To use Pulse Width Modulation mode we have to follow the steps described below:

Step 1. Load the OC2R register with the value corresponding to the period of the signal using

the following formula

OCiR t Fcpu

×()

Prescale r

()⁄

5–=

With:

t = Signal or pulse period (in seconds)

= CPU clock frequency (in hertz)

F

CPU

Prescaler = Timer prescaler factor

Step 2. Load the OC1R register with the value corresponding to the period of the pulse using

the same formula as above.

Step 3. Configure CR1 register:

– Using the OLVL1 bit, select the level to be applied to the OCMP1 pin after a successful com-

parison with OC1R register.

19/21

Page 20

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

– Using the OLVL2 bit, select the level to be applied to the OCMP1 pin after a successful comparison with OC2R register.

Step 4. Configure the CR2 register:

– Set the PWM bit.

– Select the timer clock (CC[1:0]).

2.2.2 Example

For example, to generate a PWM signal with the same characteristics as the example for the

ST7262 (see Section 2.1.1):

= 8 Mhz, So T

F

cpu

Timer

= 0.5 µs

High Level period = 500 µs

= 1000 * T

= (3E8h) * T

Timer

Timer

Low Level period = 200 µs

= 400 * T

= (190h) * T

Timer

Timer

PWM signal full period = 700 µs

= (578h) * T

Timer

So we can calculate the following values:

OC2R = 578h - 5h = 573h

OC1R = 3E8h - 5h = 3E3h

OLVL1 = 1 & OLVL2 = 0

20/21

Page 21

16-BIT TIMING OPERAT IONS USING ST7262 OR ST7263B MCUs

“THE PRESENT NOTE WHICH IS FOR GUIDANCE ONLY AIMS AT PROVIDING CUSTOMERS WITH INFORMATION

REGARDING THE IR PRO DUCT S IN OR DER FO R THEM TO SAV E TIME . AS A RES ULT, STMIC ROEL ECTR ONI CS

SHALL NOT BE HELD LIABLE FOR ANY DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES WITH RESPECT TO

ANY CL AIM S AR IS IN G FR OM T HE CO N TENT OF S UC H A NO TE A ND /O R T HE U SE M AD E BY C US TO ME RS O F

THE INFORMATION CONTAINED HEREIN IN CONNECTION WITH THEIR PRODUCTS.”

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent ri ghts of STM i croelectr oni cs. Spec i fications mentioned i n this publication are subje ct

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi thout the express written approv al of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectronics

2003 STMicroelectronics - All Rights Reserved.

STMicroelectronics Group of Compan i es

Purchase of I

2

C Components by STMicroelectronics conveys a license under the Philips I2C Patent. Rights to use the se components in an

2

I

C system i s granted pro vi ded that the sy stem conforms to the I2C Standard Specification as defined by Philips.

Australi a - B razil - Canada - China - Finl and - France - Germany - Hong Kong - Ind ia - Israel - Italy - Japan

Malaysi a - M al ta - Morocco - Singapore - Spain - Sw eden - Switz erland - United Kingdom - U.S.A.

http://www.st.com

21/21

Loading...

Loading...