Page 1

AN1560

APPLICATION NOTE

Design Guide for the uPSD3200 Family

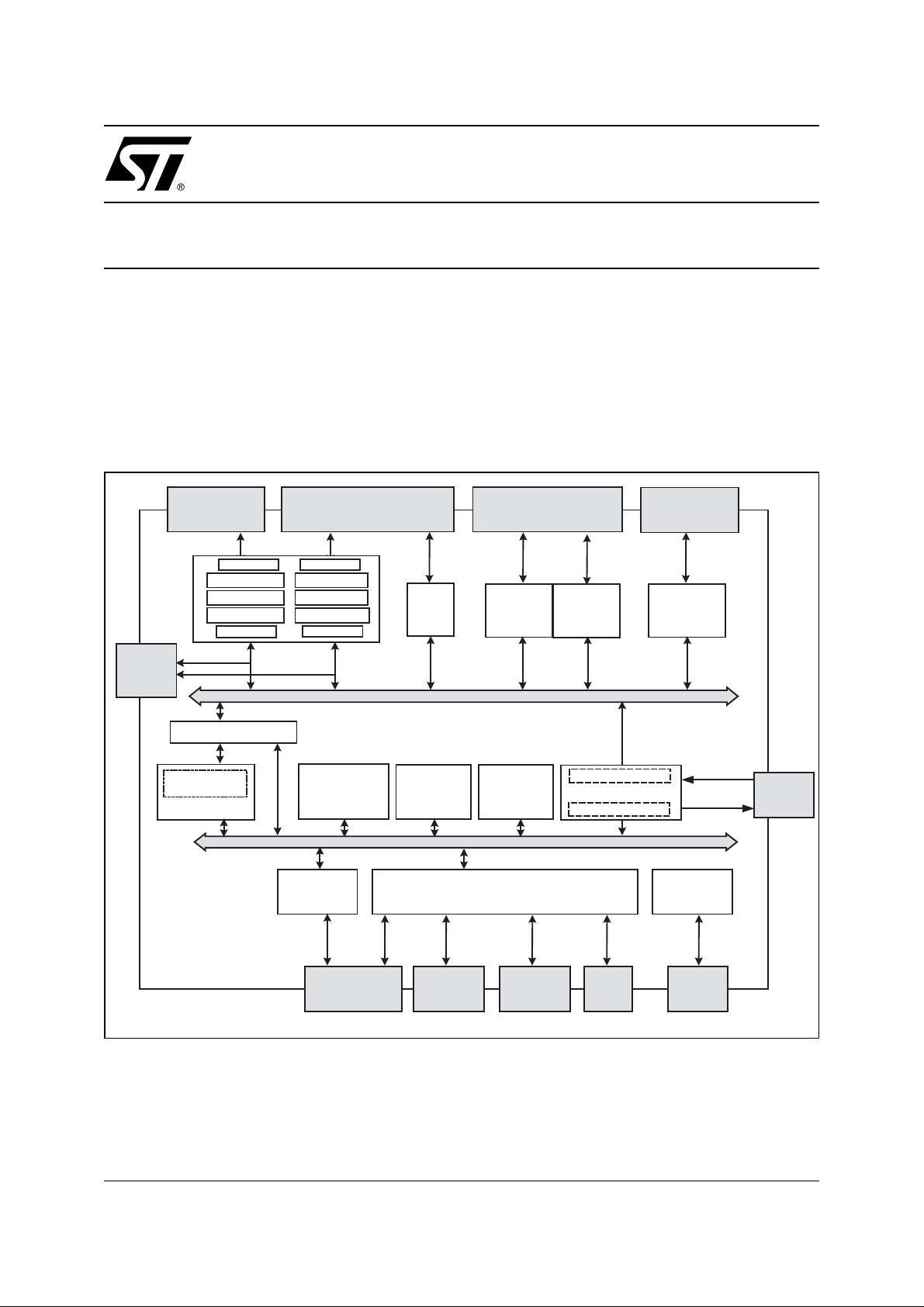

The uPSD3200 f amily is a s eries of 8 051-cl ass microc ontroll ers (MC Us) co nta ining a n 8032 core wi th a

large dual-bank Flash memory, a large SRAM, many peripherals, programmable logic, and JTAG In-System Programming (ISP) (see Figure 1.).

This document sh ows the ste ps to create a design using the DK3200 dev elopment boa rd, the so ftware

development tool PSDsoft Expre ss, and uVi sion 2 805 1 Integ ra ted Deve lop men t Env i ronme nt ( IDE) fr om

Keil Software.

Figure 1. uPSD3234A Block Diagram

Dedicated

Pins (80-

pin pkg

only)

Port 3, UART,

Intr, Timers

8032 Core

2 UARTs

Interrupts

Port 0

DATA

PSD MCU Interface

PSD Page

Register

Decode PLD

Port 1, Bit I/O and I2C,

2nd UART and ADC

Port 1Port 3

4 ADCs

3 Timer/Cntrs

256B SRAM

Port 2

ADDR

128K or 256K

Main Flash

Byte

I2C

Master /

Slave

8032 Internal Bus

32K Byte

Secondary

Flash

PSD Internal Bus

CPLD - 16 MACROCELLSJTAG ISP

Port 4, PWM and DDC Port

PWM

4 Channels

8K Byte

SRAM

DDC

w/ 256 Byte

SRAM

Low Vcc Detect

Reset Supervisor

Watchdog Timer

Dedicated USB

Transceiver

8032 reset

PSD Reset

Pins

USB 1.1

&

Reset Input

Reset Output

VCC, GND,

XTAL

Dedicated

Pins

uPSD3200

Port C,

JTAG, PLD I/O

and GPIO

Port A, PLD

I/O and

GPIO

Port B, PLD

I/O and

GPIO

Port D

GPIO

Dedicated

Pins

AI06868b

1/49February 2005

Page 2

AN1560

TABLE OF CONTENTS

Figure 1. uPSD3234A Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

uPSD3200 FAMILY OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DK3200 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. DK3200 Development Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DESIGN EXAMPLE BLOCK DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Design Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. 8032 Memory Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ENTERING DESIGN IN PSDSOFT EXPRESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Invoke PSDsoft Express and Create Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

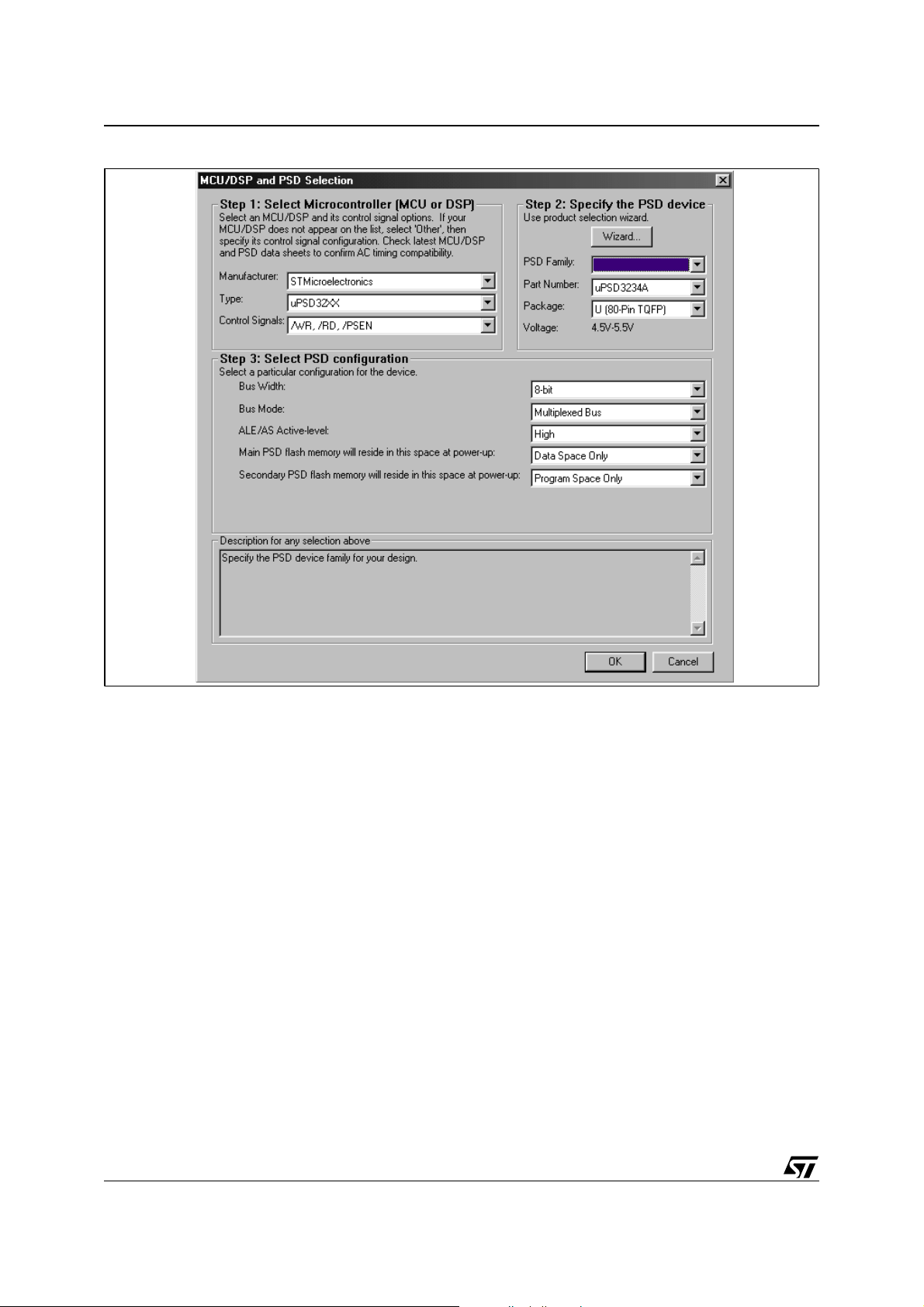

Select MCU and Initial Placement of Flash in Code Space or Data Space. . . . . . . . . . . . . . . . . 9

Pin Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. MCU Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Pin Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Memory Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

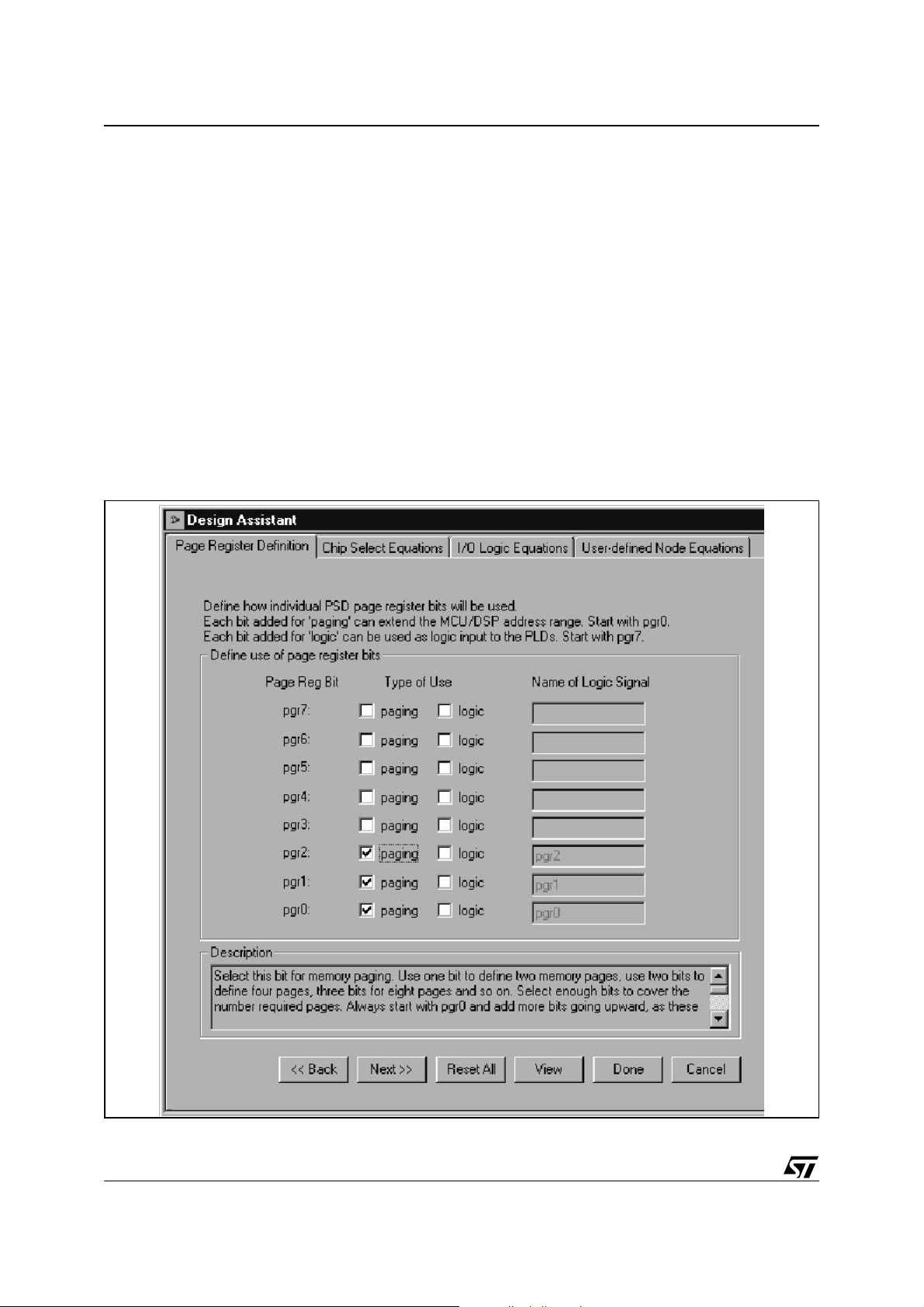

Page Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Page Register Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

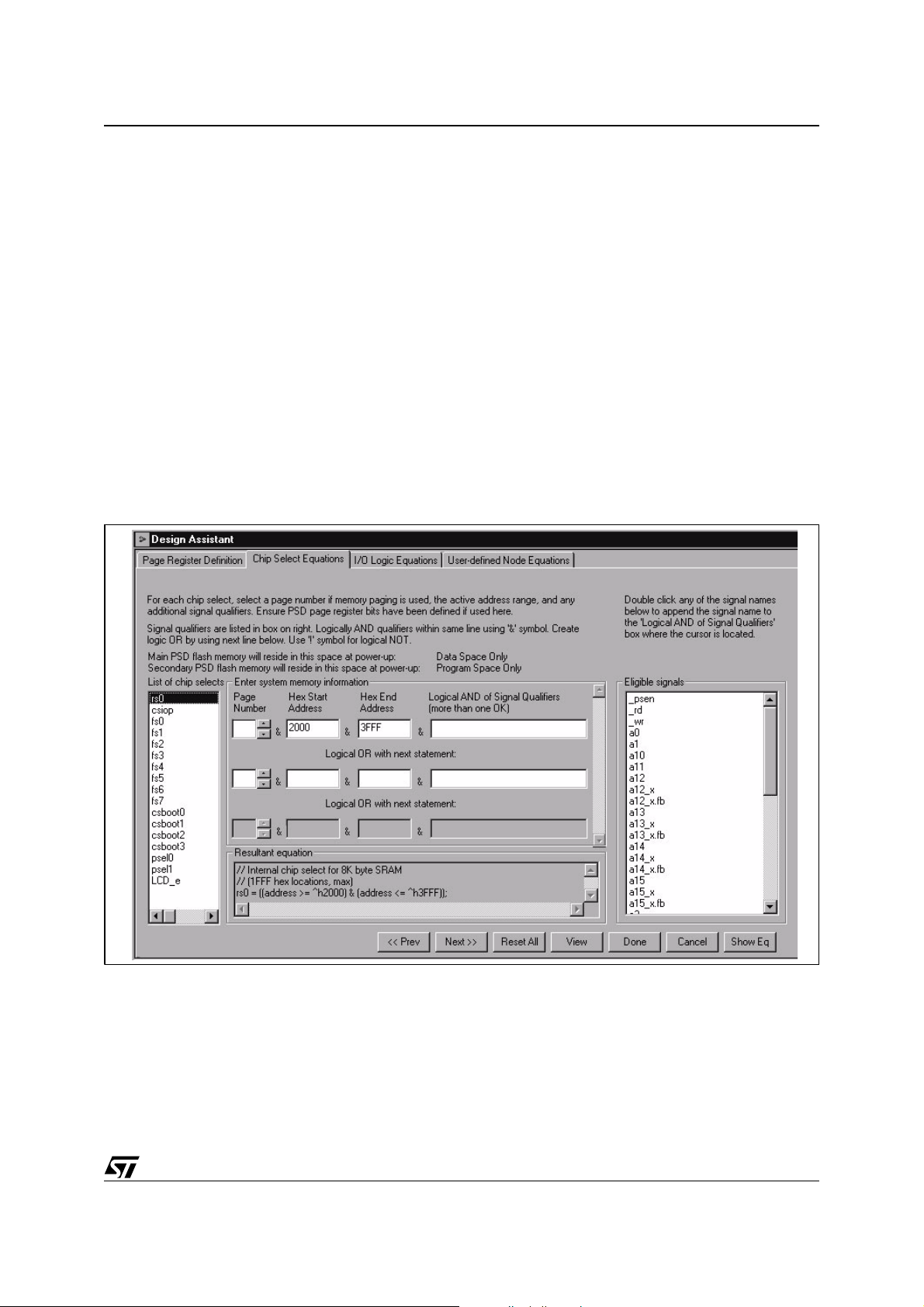

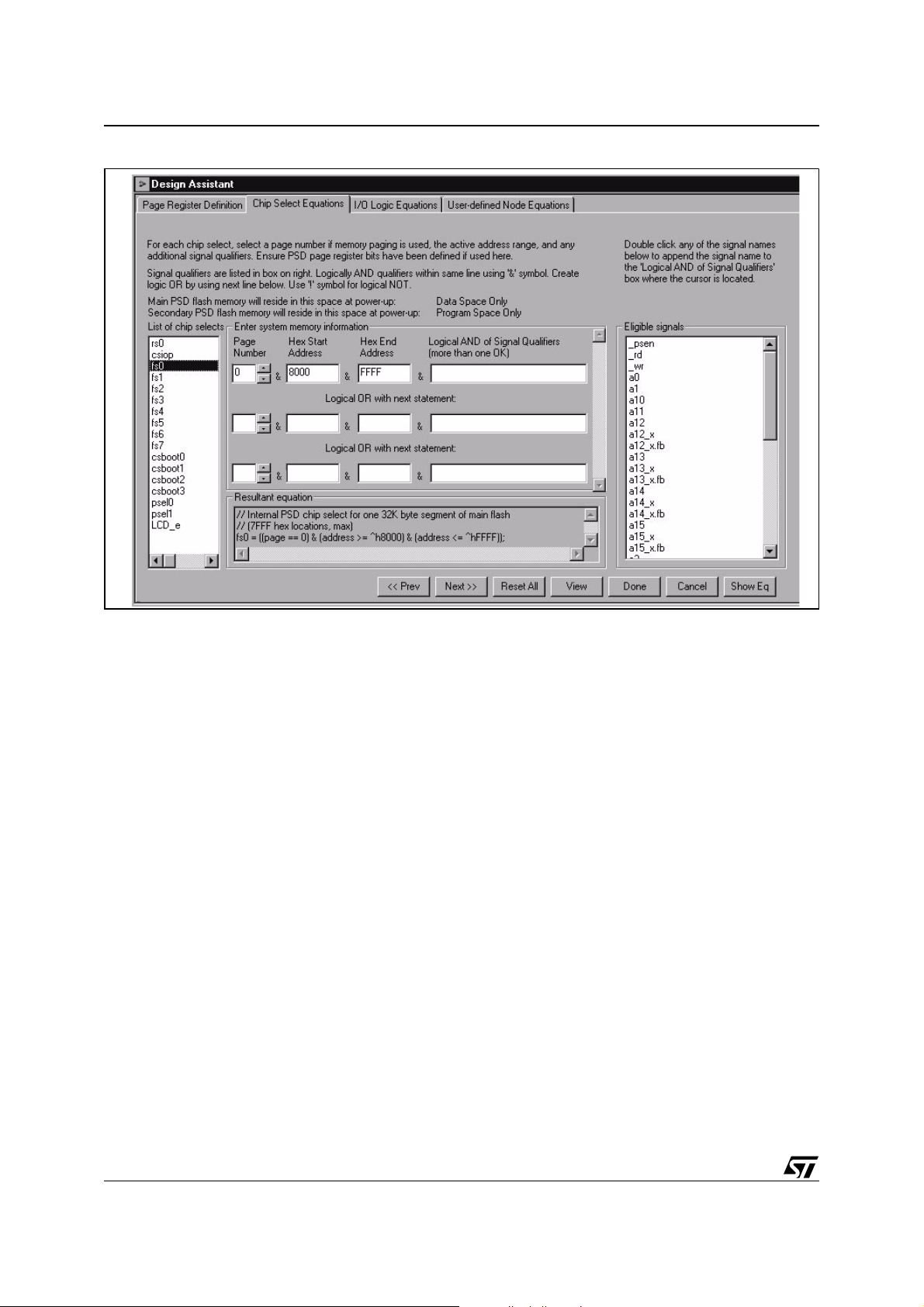

Chip-Select Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8. Chip-Select Definition for 8K byte SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9. Chip-Select Definition for Flash Memory Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

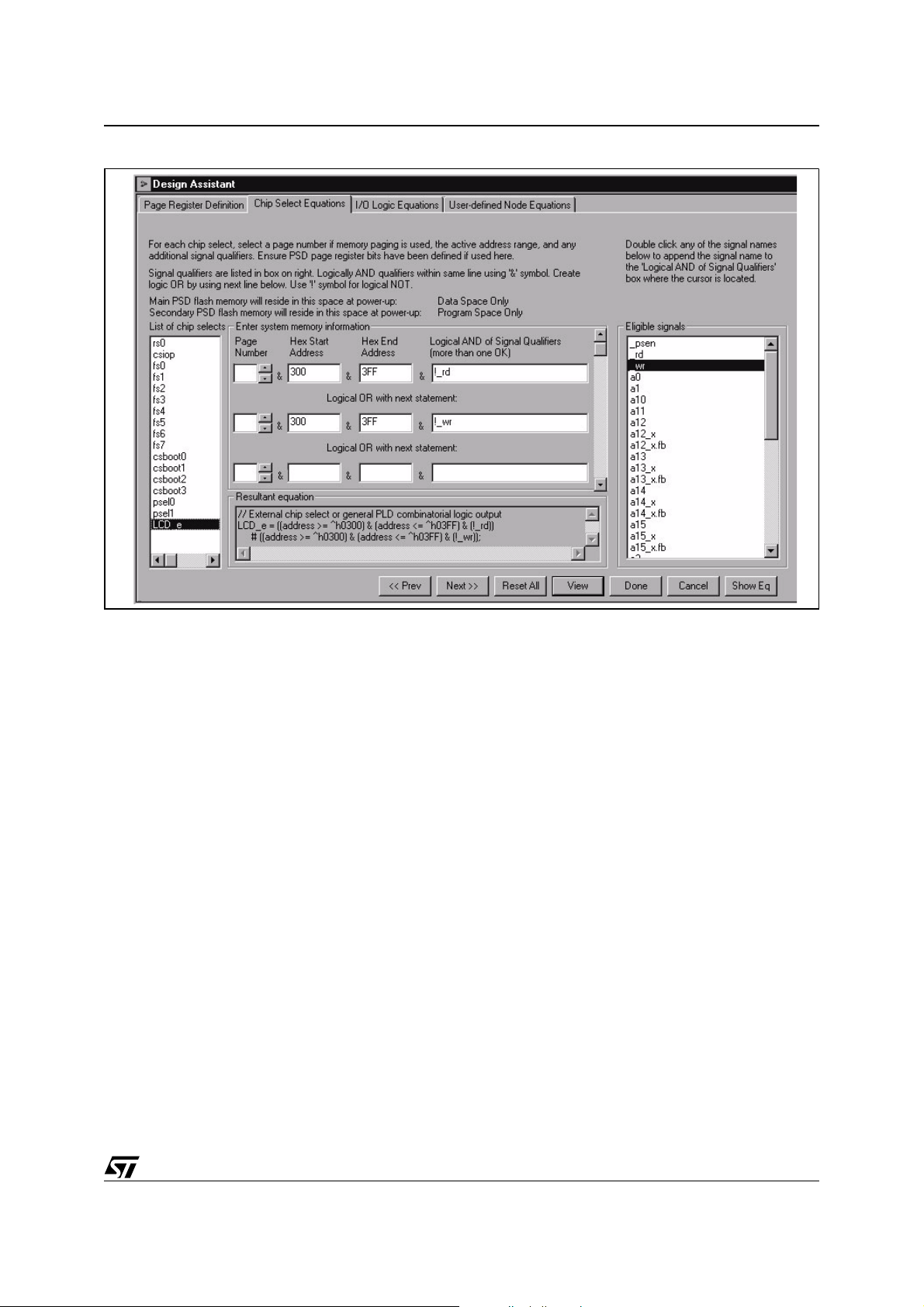

Figure 10.External Chip-Select Definition for LCD Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

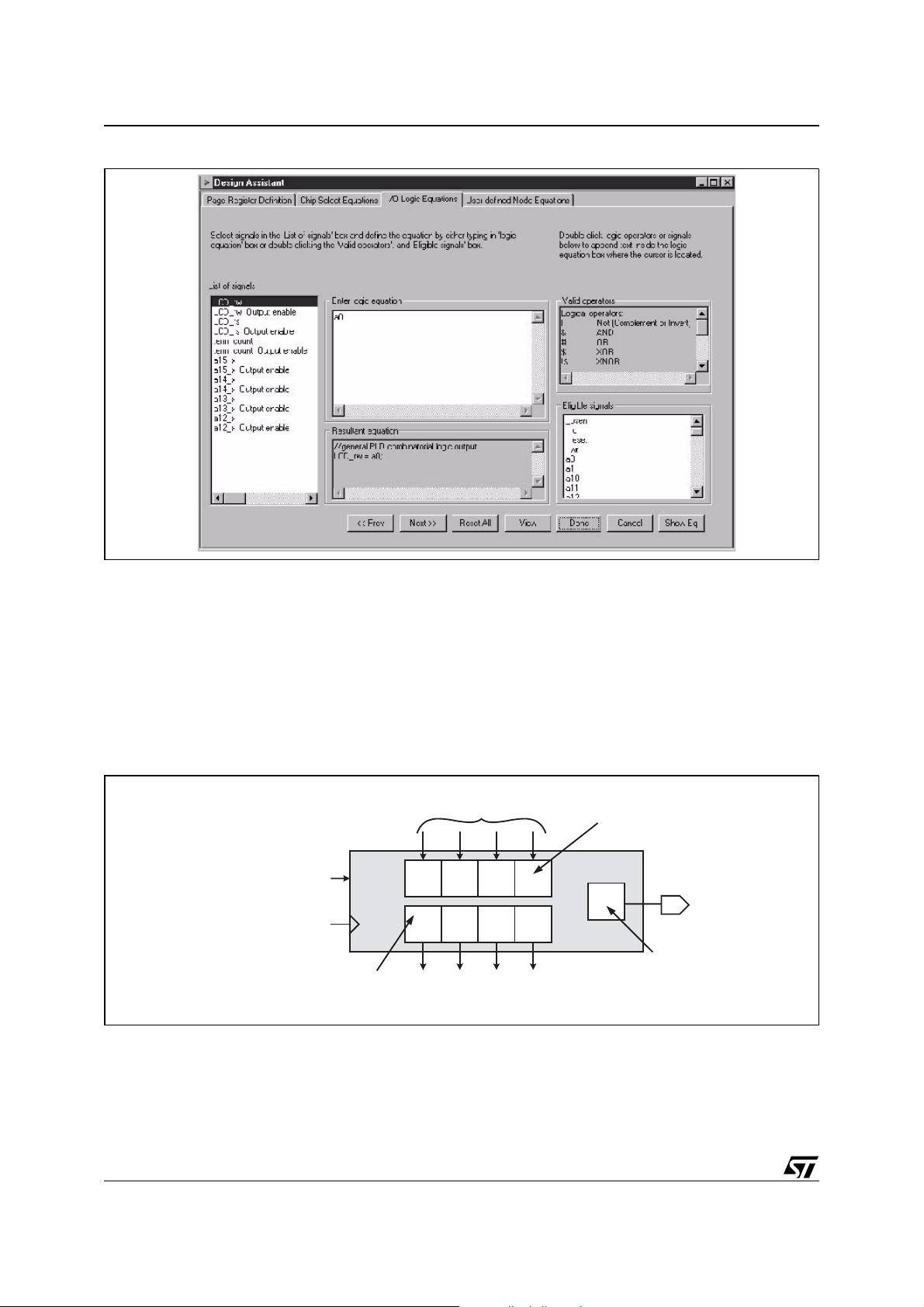

I/O Logic Equations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 11.Logic Equation for signal LCD_rw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

User-Defined Node Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 12.4-bit Down-Counter with Automatic Reload of Initial Count . . . . . . . . . . . . . . . . . . . . . . 16

Figure 13.D-register Node. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Edit ABEL HDL Statements for PLD Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14.Design Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Additional µPSD Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

C Code Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 15.Coded Example Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fitting Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Merging 8032 Firmware with µPSD Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 16.Firmware Merging Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 17.Merging the Example Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

JTAG Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 18.Programming with FlashLINK JTAG Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

WATCH IT RUN ON DK3200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

USING UVISION2 AND ISD51 DEBUGGER FROM KEIL SOFTWARE, INC.. . . . . . . . . . . . . . . . . . . 26

Loading a Keil uVision2 Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/49

Page 3

AN1560

Building the Project and Programming the µPSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Running the Keil ISD51 UART Debugger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 19.Debug icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 20.Keil ISD51 Just After it is Successfully Invoked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CONCLUSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

APPENDIX A.PSDSOFT EXPRESS PROJECT SUMMARY FILE, DK3200_1.SUM. . . . . . . . . . . . . . 29

APPENDIX B.PSDSOFT EXPRESS ABEL HDL FILE DK3200_1.ABL . . . . . . . . . . . . . . . . . . . . . . . 32

APPENDIX C.PSDSOFT EXPRESS FITTER REPORT DK3200_1.FRP . . . . . . . . . . . . . . . . . . . . . . . 36

APPENDIX D.DK3200 BOARD LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 21.DK3200 Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

APPENDIX E.DK3200 SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 22.DK3200 Schematics (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 23.DK3200 Schematics (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 24.DK3200 Schematics (3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 25.DK3200 Schematics (4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Figure 26.DK3200 Schematics (5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3/49

Page 4

AN1560

UPSD3200 FAMILY OVERVIEW

The uPSD3200 family is a standard 12-c lock per instruc tion 8032 MCU cap able of being cloc ked up to

40MHz at 5.0V and 24MHz at 3.3V at industrial oper ating temp erature ran ge. Currently ther e are seven

family members that are different comb inations of Flash memor y size, ope rating vo ltage, peri pheral set,

and packaging (see datash eet). The fullest featured pa rt, uPSD3234A-40U6, is used in this Applicati on

Note. The term µP SD i s us ed th ro ugh out the r e mai nde r of th e do cument for brevity. Se e µPSD block diagram in Figure 1..

The µPSD has a unique memory structure that includes two independent Flash memory arrays (main and

secondary) capab le of r ead-w hile-wr ite op eration. This is ideal for In-A ppli cation Pro grammin g (IA P) be cause the 8032 can fetch instructions from one Flash memory array while erasing/writing the other array.

Individual sectors of ea ch Flas h memory ar ray can be m apped to vi rtually an y 8032 addr ess by the De code PLD (DPLD) for total flexi bility. The µPSD al so contains a Page Register whose outputs feed the

inputs of the DPLD. This allows paging (or banking) of Flash memory to break the 8032’s inherent limit of

64K byte addresses. The 8032 may write to the Page Register at runtime.

For more complex designs, the µPSD is capable of placing each of the Flash memory arrays (Main or Secondary) into 8032 code address space, into 8032 data space, or into both code and data space on the fly.

Mapping flexibil ity li ke this supports IAP b ecause either Fl ash mem ory array may b e tempor arily pl aced

into data space while the firmware is updated, then moved back into code space when finished, all under

control of the 8032.

Many peripherals are ava ilable in this µ PS D, incl uding: USB v1.1 (lo w speed), two UART ch annels , four

PWM channels, one I

and projectors), a watch dog timer, low-V

GPIO.

All of the peripherals on Ports 1, 3, and 4 are controlled using 8032 Special Function Registers (SFRs). I/

O Signals on ports A, B, C , and D are controlled one of two ways: One, by a block of xdata memory

mapped control regis ters, whose b ase add ress (

by the programmable logic.

The JTAG ISP channel on Por t C is ideal for rapid code iterations during fir mware develo pment and for

Just-In-Time inventory management during manufacturing. JTAG ISP eliminates the need for sockets and

pre-programmed devices, and requi r es no partic i pati on of the 8032.

2

C channel, four 8-bit ADC channels, DDC (Data Display Channel for LCD monitors

detection with reset-ou t, a general purp ose PLD, and man y

CC

csiop

) can be mapped anywh ere usi ng the DPL D; Two,

4/49

Page 5

AN1560

DK3200 OVERVIEW

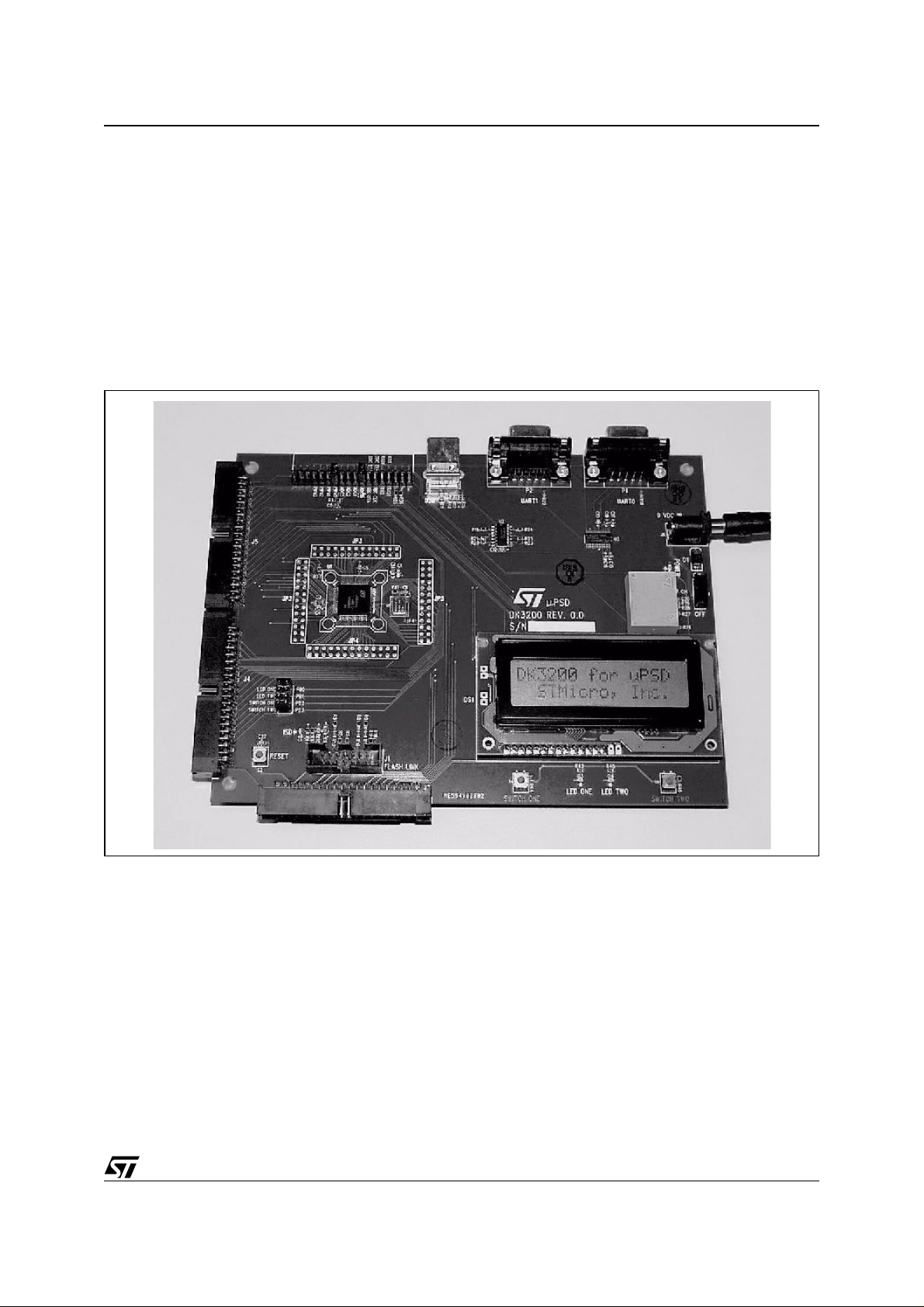

A picture of the DK320 0 board is shown in Figure 2.. Board layout and schematic s are in the Appen dix.

Connectors JP1, J3, J4, J5 provide easy access to all µPSD I/O signals for expansion or testing. JP1 accepts jumper shunts to wrap µ PSD ou tputs b ack into µ PSD i nputs f or tes ting. J 3, J4, J5 ca n conn ect directly to standard Agilent (HP) Logic analyzer pods. UARTs are available on P1 and P2. A USB host can

connect to the µPSD as a peri phe ral v ia J 2. The F lash LINK JTAG IS P cabl e co nnec ts at J1 . Conn ec tor s

JP2, JP3, JP4, JP5 allow direct connection of the In-Circuit Emulator from Nohau Corp, EMULuPSD3200-PC. JP6 ac cepts jumper s to c onnec t the sw itch es (SW 1, SW2) and the LEDs (LED 1, LED2)

to PSD port B. LED D5 indicates JTAG ISP Programming . The DK3200 also has a 2-line 16 character

LCD interface and a full featured real-time clock with SNAPHAT snap-on battery/crystal pack.

Figure 2. DK3200 Development Board

5/49

Page 6

AN1560

DESIGN EXAMPLE BLOCK DIAGRAM

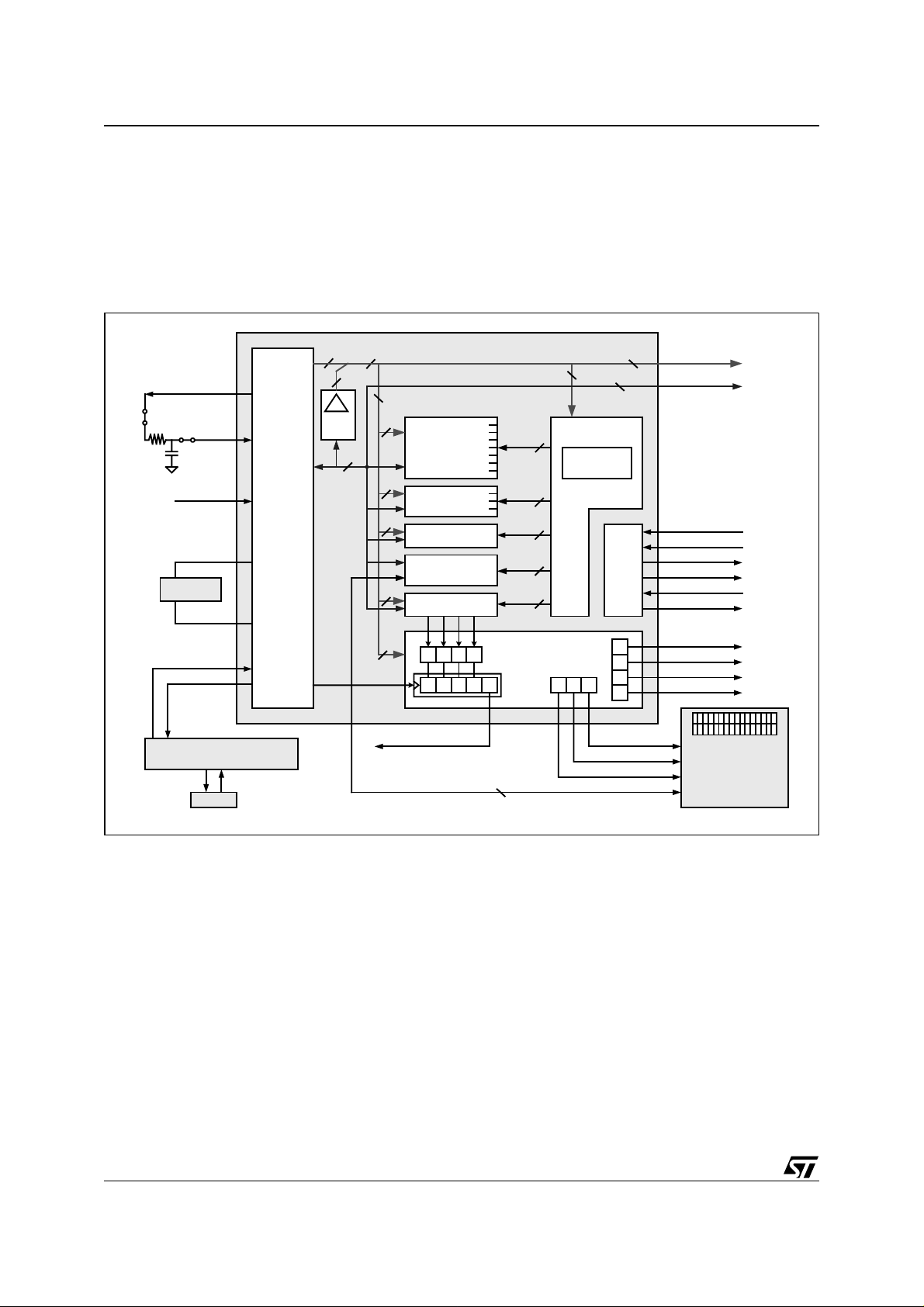

This simple design example is represented by the block diagram of Figure 3., and the memory map of

Figure 4.. All 16 macrocells of the PLD are used, Flash memory is paged, and few of the 8032 interfaces

(ADC, PWM, UART) are configured and used. The idea is to touch several aspects of the µPSD that may

be unfamiliar to a typica l 8051 user an d to give yo u an idea of how to use the des ign tools and be come

familiar with µPSD architecture.

Figure 3. Design Block Diagram

pin P4.7 (PMW0)

pin P1.4

(ADC0)

pin _RESET

pin XTAL1

40 MHz

pin XTAL2

pin P3.0 (RxD1)

pin P3.1 (TxD1)

RS-232 Transceiver

P1

A8 - A15

PWM0

ADC0

AD0-AD7

_RESET_IN

8032

XTAL1

XTAL2

RxD1

TxD1

Latch

ALE

8

8

DATA

ADDR

16

8

uPSD3234A-40U6

16

ADDR

15

256KB Main

Flash (data)

13

32KB 2ndary

Flash (code)

13

8KB SRAM

Data Bus

Repeater

8

256 Control Regs

16

pin PB4 (term_count)

16

fs0 - fs7

8

csboot0 -

csboot3

4

rs0

1

psel0 -

psel1

2

csiop

1

Initial Count

DownCounter

8

16 PLD

MarcoCells

pins PA0 - PA7 (LDC_d0 - LCD_d7)

ADDR

12

DATA pins P0.0 - P0.7

8

DPLD

Page Reg

(from Control

Regs)

JTAG

ISP

pin PB5 (LCD_rs)

pin PB6 (LCD_rw)

pin PB7 (LCD_e)

pins A0 - A11

pin PC0 (tms)

pin PC1 (tck)

pin PC3 (tstat)

pin PC4 (_terr)

pin PC5 (tdi)

pin PC6 (tdo)

pin PB0 (a12_x)

pin PB1 (a13_x)

pin PB2 (a14_x)

pin PB3 (a15_x)

REG SELECT

READ/WRITE

CHIP SELECT

D0 - D7

LCD

MODULE

AI07073

Figure 3. show s the de sign i mplem ented i n this appl ication note. Maj or el ements ar e the µ PS D, an LCD

module, and an RS-232 transceiver chip.

The 8032 outputs a repetitive PWM pulse train with a slowly varying pulse width to an RC network which

converts the pulse train in to a slowly sw eeping DC voltag e (0 to 5V). Th is DC signal i s looped back i nto

an ADC input. The 8032 will write the resulting Hexadecimal ADC conversion value to the LCD so you can

watch the results. The RC network and loop-back is implemented with two jumpers on the DK3200 board.

Additionally and independently, a 4-bit auto-reloading down-counter is created using PLD macrocells. The

8032 directly loads the initial count value into four macrocells, and that count is automatically loaded into

another four macrocells that create the 4-bit down-counter. Reloading occurs each time the counter reaches terminal count of zer o. Terminal count is indica ted externally by a puls e on a µPSD output pi n. The

down-counter is clocked by ALE signal (ALE was random choice, could be any signal). The 8032 may load

a different initial count at anytime, creating a variable divider of the ALE signal.

6/49

Page 7

AN1560

Four more macrocells a re us ed to outp ut the high four 8032 address sign als . T he 80-pi n µPSD only outputs the low twelve 8032 address signals on dedicated pins. If more address signals are needed externally, they have to be added this way using the PLD.

The LCD module is connected to the µPSD via a Port A for data and Port B for some glue logic and a chipselect signal. Port A is operating is an special data bus repeater mode this example, called Peripheral I/O

mode. 8032 data will pass through port A onl y for a given address range specifie d in PSDsoft Express

(illustrated later).

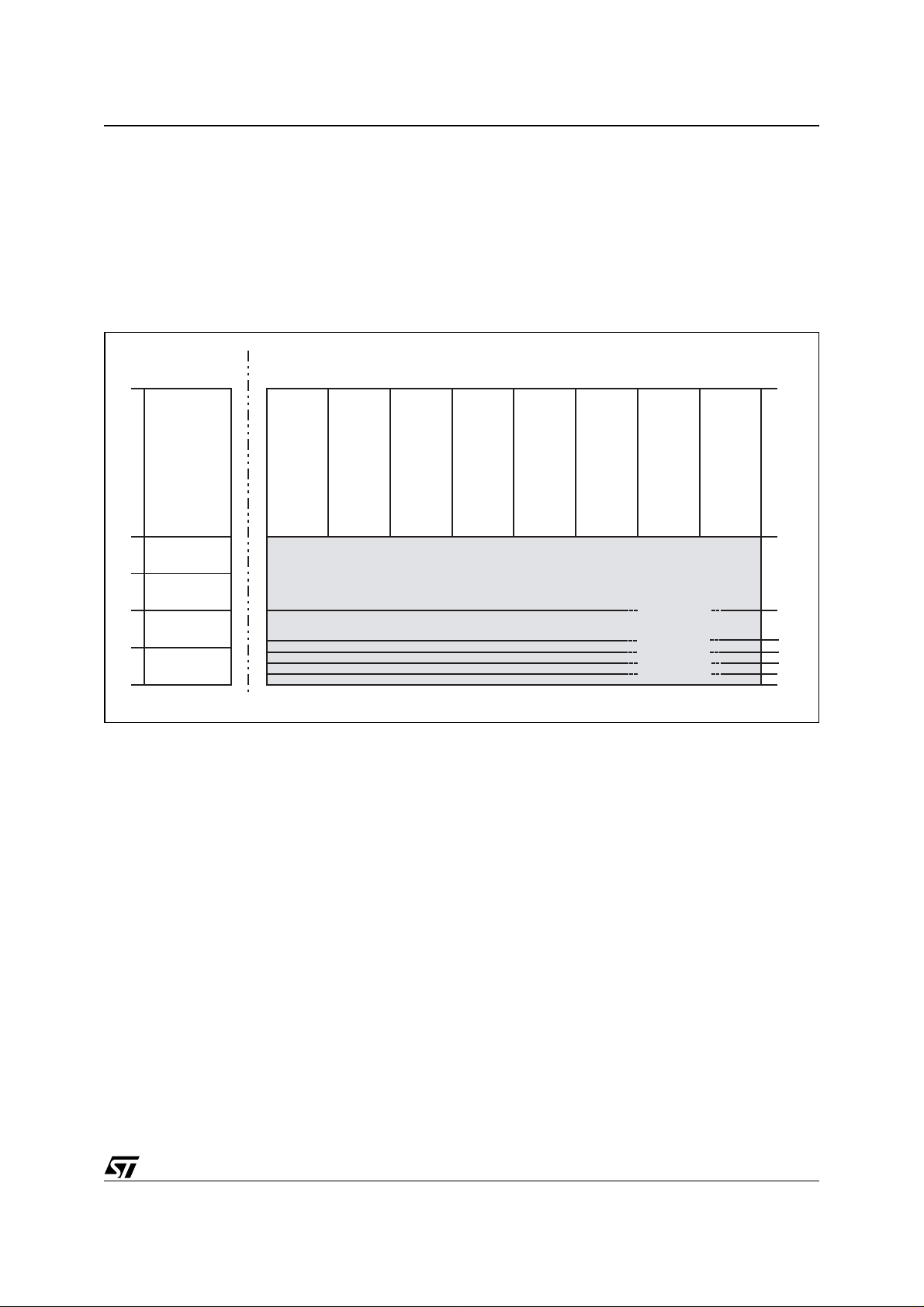

Figure 4. 8032 Memory Map

Code Space (_PSEN) Data Space (_RD and _WR)

FFFF

Page X Page 0

Page 3

Page 7Page 5 Page 6Page 4Page 2Page 1

FFFF

8000

7FFF

6000

5FFF

4000

3FFF

2000

1FFF

0000

nothing mapped

csboot3

8K bytes uPSD

Secondary Flash

csboot2

8K bytes uPSD

Secondary Flash

csboot1

8K bytes uPSD

Secondary Flash

csboot0

8K bytes uPSD

Secondary Flash

fs0

32K bytes uPSD

Main Flash

(xdata)

fs1

32K bytes uPSD

Main Flash

(xdata)

fs2

32K bytes uPSD

Main Flash

(xdata)

LCD_e and psel

32K bytes uPSD

Main Flash

(xdata)

nothing mapped

fs4

fs3

32K bytes uPSD

Main Flash

(xdata)

nothing mapped

, 8K bytes PSD SRAM (xdata)

rs0

chip select and data bus repeater for LCD module

csiop

, cntl regs for ports A, B, C, D (xdata)

fs5

32K bytes uPSD

Main Flash

(xdata)

fs6

32K bytes uPSD

Main Flash

(xdata)

Common

Memory

Across All

Data Pages

fs7

32K bytes uPSD

Main Flash

(xdata)

8000

7FFF

4000

2000 - 3FFF

0400 - 1FFF

0300 - 03FF

0200 - 02FF

0000 - 00FF

AI07074b

The memory map in Figure 4. shows th at th e 32K b yte sec ondary F lash me mory is used for 8032 co de,

and the 256K byte main Flash memory is used for 8032 data, banked over eight pages. The nomenclature

fsx, csbootx, rs0, csiop,

µPSD main Flash mem or y h as a total of e igh t 32K by te s egm ents (

memory has a total o f fo ur 8K byt e s eg men ts (

segment (

rs0

). A group of µ PS D co ntr ol regi st er s wh ic h c ont rol I/O ports A, B, C, and D li e i n a 2 56-by te

xdata address space whose base address is named

is enabled over a giv en address range as specified by

select signal,

LCD_e

and

psel

in Figure 4. refer to the individual internal µPSD memory segments. The

csboot0-csboot3

csiop

. The µPSD has a data bus repeater feature that

psel

. Figure 4. also shows one e xternal mem ory

fs0..fs7

). The µPSD 8K byte SRAM has a single

). The µPS D se condary Flash

, for the LCD module. This memory map is specified using the software tool PSDsoft

Express. Each memory segment can be placed at virtually any address, which provides an infinite number

of mapping schemes. This is just one example.

We’ll keep things simple for this particular application note, meaning the 8032 will “boot” and run code contained completely withi n the 32K byte seconda ry Flash memory i n code space and we’ll tr eat the 256K

byte main Flash me mory as data only. However, this memory map may grow with the need s of your

project. For example, if a large Flash memory is needed for code space and IAP is required, a slight variation of the map in Figure 4. can accomplish this. The 8032 can boot from secondary Flash memory (secondary Flash memory resides in code space from 0-7FFF as in Figure 4.), then the 8032 can calculate a

checksum on the main Flash memory and then program the main Flash memory if necessary (main Flash

memory resides in data space from 8000- FFFF on eight pa ges as in Figure4.). After the contents of main

7/49

Page 8

AN1560

Flash memory are verified, the 8032 c an write to s pecial register , called the VM regi ster within th e

register block, to “reclassify” the main Flash memory from data space to code space. After which, the 8032

will have access to 256K bytes of Flash memory for code in code space, paged across eight code pages

in upper memory (8000-FFFF), and the 8032 will have access to 32K bytes of Flash memory for code in

code space common to all pages in lower memory (0-7FFF). At that point no Flash memory will reside in

data space. Upon reset, the memory map is reset to look like Figure 4. again. The VM register can be accessed by the 8032 at runtime to perform a variety of manipulations. PSDsoft is used to set the initial value

of the VM register upon power-up. Future Application notes will illustrate various memory schemes.

csiop

8/49

Page 9

AN1560

ENTERING DESIGN IN PSDSOFT EXPRESS

Highlights of the design process will be given here. The steps are simple and navigation through PSDsoft

Express is easy. Invoke PSDsoft Express and follow along if you wish. PSDsoft Express is included in the

DK3200 CD, but you should check for latest updates. Updates are available from our web site at

www.st.com/psm, in the “Software Downloads” area.

Invoke PSDsoft Express and Create Project

■ Install PDSsoft Express (from the web or the included CD)

■ Start PSDsoft Express

■ Create a new project

■ Select your project folder and name the project (in this example, name the project “DK3200_1” in the

folder

PSDexpress\my_project\dk3200_dsn_1\

Note that the folder,

dk3200_dsn_1 under PSDexpress\my_project

ed.

Select MCU and Initial Placement of Flash in Code Space or Data Space

■ Select an MCU. In this case it is STMicroelectronics, then uPSD32xx, then uPSD3234A.

■ Select the main Flash memory to reside in 8032 data space at power-up (means that the 8032 _RD

and _WR signals are routed to the main Flash memory array)

■ Select the secondary Flash memory to reside in 8032 code space at power-up (means that the 8032

_PSEN signal is routed to the secondary Flash memory array)

Note: At runtime, the 8032 can alter the initial settings of code and data space by writing to the VM register.

Figure 5. shows what the screen should look like after you’ve made the selections.

Click OK. Now you will be asked i f you want to use the Desi gn Assis tant, Ex tended Design As sist ant, or

Example Template. Choose Example Template. This is a predefined design that matches this application

note and it runs on the DK3200 board. Next choose the template for the DK3200 Kit when prompted.

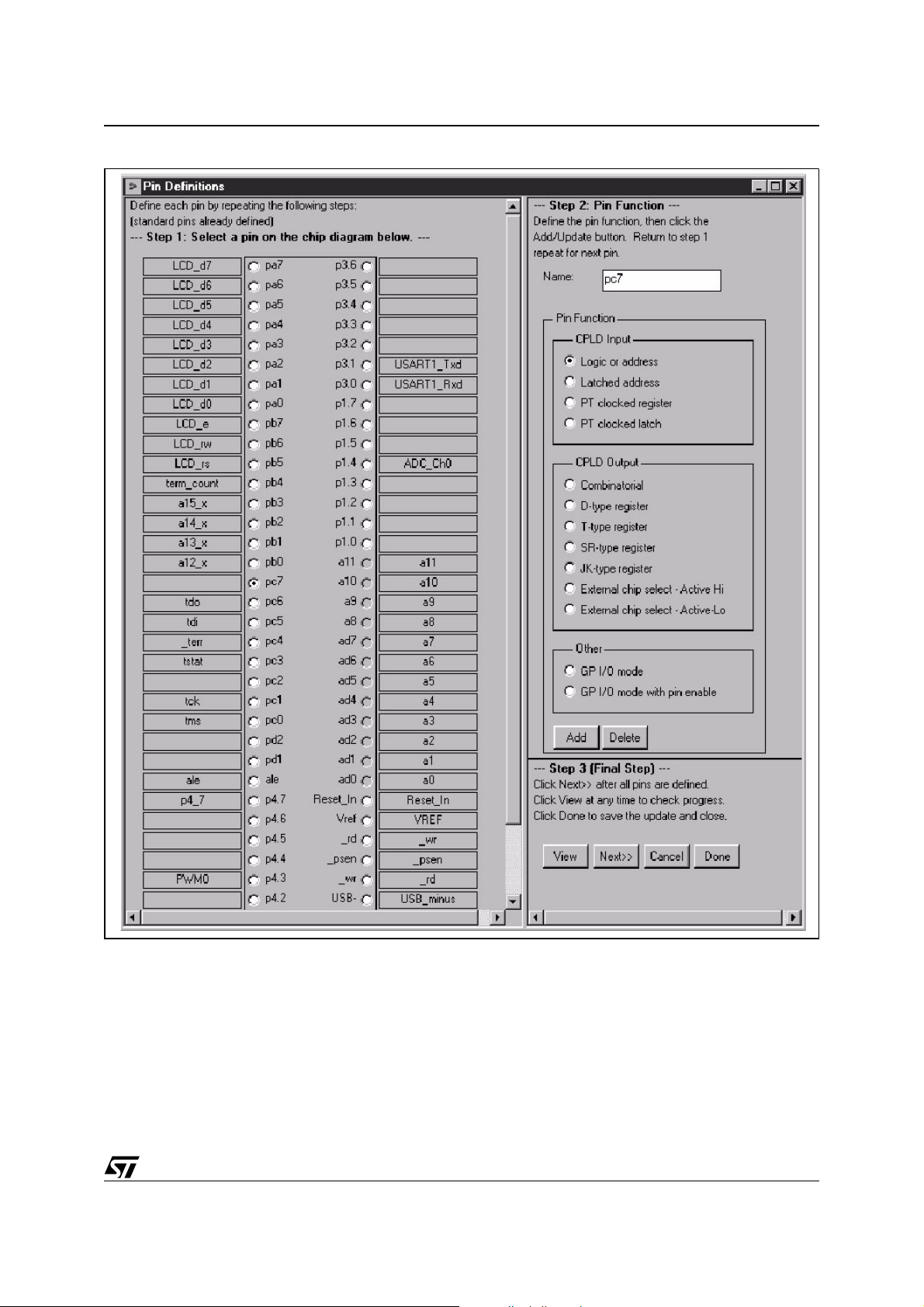

Pin Definitions

You will see the Pin Definitions screen appear. All of the pin definitions shown in block diagram of Figure 3.

are filled in. Click through the pins and see how they are configured and how they relate to Figure 3.. You’ll

notice that you cannot change the definition of some pins because they have a fixed function.

A comment about JTAG pins. Th is example us es 6-pin JTA G which is up to 30% fas ter than the defau lt

standard 4-pin JTAG. The two extra pins in the 6-pin JTAG configuration are

Now click “Next” to move on to the Design A ssistant fo r memory mapp ing and logic equations. You will

see the Page Register definition screen.

..

, does not exist and needs to be creat-

_tstat

and

terr

.

9/49

Page 10

AN1560

uPSD3000

Figure 5. MCU Selection

10/49

Page 11

Figure 6. Pin Definitions

AN1560

11/49

Page 12

AN1560

Memory Map

Defining the memory map requ ires defi ning the ad dress r ange of chip- sele cts for indiv idual me mory ele ments of the µPSD (memor y ex terna l to the 8032 c ore) . Defin ition of the use of the µPSD Page Regi ste r

is also required.

Four memory blocks (main Flash memory, secondary Flash memory, SRAM, and control registers) external to the 8032 core are available and are individually selected segment-by-segment when 8032 addresses are presented to the D ecode PLD (DPLD). E ach of these m emory segments ha s its own chip-se lect

name (

fs3, csboot1, rs0, c siop

must be specified using PSDsoft Express. For this example, chip-selects are defined to match the memory

map of Figure 4..

Page Register

Since eight memory pa ges (or banks) are ne eded as shown in Figure 4., thr ee paging bits (2

specified as sh ow n in Figure 7.. The µPSD supports up to 4 paging bits (pg0, pg1, pg2, pg3) for a total of

16 pages. Unused paging bits including pg4, pg5, pg6 and pg7 may be used for other functions. Note that

the paging bits used must be the LSB bits in the paging register. Click “Next”.

Figure 7. Page Register Definition

, etc.). Equations for these chip-s elect s, and fo r any e xternal chip-s elect s,

3

= 8) are

12/49

Page 13

AN1560

Chip-Select Equations

rs0

Now you will see the Chip- Sele ct de finition scr een. Clic k the chip- select signa l

SRAM, and see that its definition matches the memory map of Figure 4..

rs0

Notice that no page n umber is spe cified f or

dent). Additional signal qualifiers (8032 control signals

µPSD chip-selects as this is taken care of in silicon. The SRAM always defaults to 8032 data space.

At any time, you can click the “View” button to see how you are doing. A summary will appear.

csiop

Now click on the chip-select

control µPSD ports A, B, C, D, the Page Register, power management, and other functions. 40 of the 256

registers are used, se e µPSD datasheet for r egister definitions and th eir address offset from th e

base address. There i s no need to specify additional signal qu alifiers for

place

csiop

on a particular memory page. The

Next click on

Notice the page nu mbe r i s 0 for

Figure 4.. Cl ick on remain ing chip-selects f or main Flash m emory and notice the page number assign-

ments. No additional signal qualifiers are needed.

Figure 8. Chip-Select Definition for 8K byte SRAM

fs0. fs0 .. fs7

are chip-selects for the eight 32K byte segments of µPSD main Flash memory.

(Chip Select I/O Por t). This is a band o f 256 xdata registe rs used to

fs0

, and the address range is 8000 - FFFF as shown in memory map of

since the SRAM is c ommon to all pages (page i ndepen -

_rd, _wr, _psen, ale

) are NOT needed for internal

csiop

csiop

must be xdata address space.

for the 8K byte xdata

csiop

, and it is not allowed to

13/49

Page 14

AN1560

Figure 9. Chip-Select Definition for Flash Memory Segments

Now click on

ary Flash memory. Check the address assignments for each of these chip-selects and notice there are no

page numbers assigned. The secondary Flash memory is common to all pages.

Next click on

Peripheral I/O Mode to dr i ve the LCD m odule. Port A pins were ear lier sp ec ified a “Peripheral I/O M ode ”

which acts like a ‘245 bus tr ansceiver chi p connecting the 8032 d ata bus to exter nal peripher als over a

given address range specified by the label

trolled automatically in silicon by the 8032

have to do is click on

range as shown in Figure 4., with no Page Number assignment.

eral I/O feature is active for the logical OR of

And finally, clic k on

chip-select, we mus t include signal qualifiers

when the 8032 presents an a ddres s in the r ang e of 3 00 to 3F F AND wh en e ithe r 8032 co ntr ol signal

is true, OR when 8032 cont rol sig nal

Figure 10.. Since both signals

are specified as qualifiers. Signal qualifiers may be added by setting the cursor where you want the signal

name to go, then just double click on the signal name in the list of eligible qualifiers.

Click “next” to move on to logic definitions.

csboot0. csboot0 .. csboot3

psel0

. This address range specifies when Port A pins will behave like a data bus repeater in

psel0

and enter the address range 300 to 3FF to enable this feature for that address

LCD_e

. This is an external chip-select for the LCD module. Since this is an external

_rd

and

are chip-selects for the four 8K byte segments of µPSD second-

psel0

or

psel1

. The direction of this transceiver function is con-

_rd

and

_wr

signals. See µPSD data sheet for details. So all we

psel1

is not needed because the Periph-

psel0

or

psel1

.

_rd

and

_wr.

In this design,

_wr

is true. To create this log ic, in format ion is entere d as shown in

_wr

are active low, the logical NOT operator (!) is used when they

LCD_e

is true (active hi) only

_rd

14/49

Page 15

Figure 10. External Chip-Select Definition for LCD Module

AN1560

I/O Logic Equations

Defined here are equations for PLD outputs for the LCD interface signals, the additional 8032 address outputs, and the terminal count output signa l from the down-cou nter. The De sign Assista nt (DA) will c reate

HDL logic statements using the ABEL language in the background after you enter logic in this point-andclick design entry environment. The DA will also create all the declaration statements in ABEL. This saves

much typing and reduces the c han ce of err or . For m ore co mpl ic ate d lo gic PSDs oft al lo ws you to edit the

ABEL statements d irec tl y. In th is ex am pl e you’ ll s ee si mpl e l og ic entered point-and- clic k st yl e, a nd yo u’l l

see the 4-bit down-counter entered by editing the ABEL file directly.

Click on “

output signal “

logic operators are also available for general purpose logic.

LCD_rw

” as shown in Figure 11., and notice t hat the inter nal sign al a0 is assigned to drive the

LCD_rw

”. Although this was a very simple logic equation, AND, OR, XOR, NOT, and other

15/49

Page 16

AN1560

Figure 11. Logic Equation for signal LCD_rw

Click through the remaining signal names and observe the logic assigned. Notice there is no logic equation

assigned to

term_count

because that assignment will be mad e by editing the ABEL file directly. Click

“Next”.

User-Defined Node Equations

Here you will see how internal logic nodes are created. In this example there are four registers (or nodes)

to hold the initial count of t he 4-bit down- counter, and four additio nal registers to create th e actual 4 -bit

down-coun ter. See Figure 12..

Figure 12. 4-bit Down-Counter with Automatic Reload of Initial Count

4-bit auto-reloading

down-counter

8032 writes to OMCs in

control register space (csiop)

to load inital count

ALE

4 nodes to form

LOAD

counter

8032 data bus

(initial count)

D3D2D1D

AB0AB3 AB2 AB1

AB4AB7 AB6 AB5

QDQCQBQ

4 nodes to hold

0

A

initial count

term_count

1 PLD output

defined for

terminal count

AI07076

These nodes were crea ted by cl icking the “Def Node..” button, na ming the no de, and then selecti ng the

type node (combinato rial, D-register, J-K regi ster, etc.). In this example , all eight nodes are D-regi ster

type. When a regi ster is creat ed, you c an specify i t’s source of Input, C lock, Reset, as Set illu strated in

Figure 13..

16/49

Page 17

Figure 13. D-register Node

AN1560

Set

Input

Clock

PRE

CLR

Reset

QD

AI07077

Click though the sign al name s and loo k at the assign ments. Notice the re are n o defin itions fo r inp uts on

any of the eight nodes. For the

the

init_count

nodes, no log ic inpu t (or cl ock in put ) is s pecif ied becau se the 8032 will load the n odes di-

down_count

nodes, the inputs are defined elsewhere (the ABEL file). For

rectly by writing to the appropriate Output MacroCell register that resides the ban d of 256 registers of

csiop

.

It may seem odd to divide the design entry this way (some point-and-click entry and some direct ABLE file

editing), but many d eclarat ion s tatemen ts ar e auto maticall y cre ated i n the b ackgro und by th e p oint-and click entry. You wil l see that wh en it is time to e nter ABE L equations for the down-cou nter, ther e is very

little typing involved.

Click “Done”. Now you will see the m ain PS Dsoft flow di agram that wil l guide you throu gh the re maining

steps. You can see a summary report at this time by pulling down the “Report” selection in the main menu

bar at the top of the screen, then select “D esign Assista nt Summary ”. Your repo rt will match th e one in

Appendix A.

Edit ABEL HDL Statements for PLD Design

If your PSDsoft flow diagram does not include the block “Edit/Add Logic Statements” as shown in

Figure 14., then pull down the “Project” selection in the main menu bar at the top of the screen, then select

“Preference”. Click the box that says “Enable ABEL Editing Capability”, then “OK”.

17/49

Page 18

AN1560

Figure 14. Design Flow Diagram

Click the “Edit/Add Logic Statements” box. You will see an “HDL Assistant” window pop up. Browse

through this to see ABEL logic and syntax examples that you can cut and paste into future designs. Close

the HDL Assistant and you will see the ABEL HDL so urce file. All the declar ations and logic equat ions

generated from the Design Assistant are there, and should match Appendix B.

There are only two regions in the ABEL file in which you can type statements, otherwise the DA will overwrite what you have typed next time you get into the DA.

The first safe region is for ABEL dec larations and lies between the two st atements: “// Begin user preserved declarations” and “// End user preserved declarations”.

18/49

Page 19

AN1560

The second safe regio n is for logic equa tions and lies betwee n the two statements: “// Begin user pre served equations” and “// End user preserved equations”.

Scroll down to the declaration region in the ABEL file, it should look like:

// Begin user preserved declarations (not affected by iterations of DA usage) ===================

WSIPSD PROPERTY 'DataBus_OMC D[7:4]:down_count[3:0] MCELLAB'; // This statement forces the alignment

// of down_count bits [3..0] to the MCU data bus bit positions [7..4].

// If this WSIPSD PROPERTY statement was not present, then PSDsoft

// would pick random MCU bit positions. The WSIPSD PROPERTY is needed

// only if the MCU will read or write to MicroCells and only if a

// particular MCU data bus position is required by the designer.

WSIPSD PROPERTY 'DataBus_OMC D[3:0]:init_count[3:0] MCELLAB'; // This statement forces the alignment

// of init_count bits [3..0] to the MCU data bus bit positions [3..0].

DCOUNT = [down_count3..down_count0]; // 4-bit down counter

INIT = [init_count3..init_count0];// 4-bit initial count from MCU

//INIT = [0,1,0,0];

// End user preserved declarations (not affected by iterations of DA usage) ===================

Notice the WSIPSD PROPERTY statements. These are needed whenever you want to dictate the placement of certain mac rocel ls o f the PLD. If you do no t ente r any WS IPSD PROPERT Y d eclara tions state ment, then the PSDsoft “fitter” process will place the macrocells in random order. This is not a problem for

most designs. But in this example we want to load an initial count for the down-counter from the 8032 data

bus so we must ma ke s ur e the ou tpu t macrocells holding the initial co unt ar e in the c or rec t b it or der a nd

the correct position in the bank of eight output macrocells. The property statement:

WSIPSD PROPERTY ‘DataBus_OMC D[7:4]:down_count[3:0] MCELLAB’

forces the order of the bits of the down-counter and places them on the upper half of the 8032 data bus.

The property statement:

WSIPSD PROPERTY ‘DataBus_OMC D[3:0]:init_count[3:0] MCELLAB’

forces the order of the bits of the initial count and places them on the lower half of the 8032 data bus. Now

when the 8032 writes to the O MCAB regi ster at addr ess csiop +20h, the l ow four bits o f the byte wi ll get

loaded into the initia l count. There i s also a OMCAB mask registe r at csiop+22h that is used to prevent

the 8032 from disturbing the other bits in the OMCAB register while writing.

If the PROPERTY statements above ended with MCELLBC instead of MCELLAB, then the other bank of

eight output macrocells wo uld be used for the c ounter. See the µ PSD data sh eet and PSDsoft Express

User’s Guide for more details.

The next declaration statements DCOUNT and INIT create a shorthand notation for use in the logic equations.

Now scroll down in the ABEL file to the logic equations until you see:

// Begin user preserved equations (not affected by iterations of DA usage) ===================

term_count = (DCOUNT == 0); // term_count true when count reaches zero

when term_count then DCOUNT := INIT; // automatically reload counter with initial

// value after a count of zero is reached

else DCOUNT := DCOUNT - 1; // specify down count action

// End user preserved equations (not affected by iterations of DA usage) ===================

19/49

Page 20

AN1560

These three statements define the down-counter and the PLD output that appears on pin PB4

(term_count).

So you can see that very little typing is needed to im plement log ic desig ns. The sam e approach is used

to create state machines, shifters, etc.

Close the ABEL file and you will see the PSDsoft flow diagram again.

Additional µPSD Configuration

Click the box “Additional PS D Confi gur at ion ”. This is where yo u c an c hoos e to set the security bit to prevent a device prog rammer from ex amini ng or co pying the c ontents of th e µ PSD. The only way to def eat

the security bit is to erase the entire µPSD, then it can be u sed again as a blank pa rt. Yo u c an als o cl ic k

through the other s he ets o n this screen to set the J T AG USE RCO DE v al ue and s et sec tor p rotec ti on on

individual µPSD Non-Volatile memory segments. Just click “OK” for now.

C Code Generation

Clicking on the "Generate C Code" box pops up the message shown in Figure 15., directing you to the ST

web site where the example code can be downloaded. Click on the web site link (

software

From this web page in the "DK3200 - Software" section, download the "

dk32dsn1.zip

for this application note and it runs on the DK3 200 boa rd . It co n tai ns al l th e K eil s ourc e an d p ro ject fi le s

as well as all the PSD soft Express proj ect files. The PSDs oft Express proje ct files are not u sed in this

case since a new projec t is be ing cr ea ted b y fo ll owing this application note. The Keil sour ce and p ro je ct

files will be used later in this application note.

) in this window and it will launch the PC's web browser and direct it to the ST web page.

" file and unzip it to

C:\PSDexpress\my_project\dk3200_dsn_1

http:\\www.st.com\psm-

Example code file (1) -

. This is the comp let e pr ojec t

Figure 15. Coded Example Generation

In this screen you can specify a folder in which the ZIPPED project files will be written, along with a readme

file with instructi ons. The selecti on shown in Figure 15. is the complete project for this application note and

it runs on the DK3200 board. It contains all the Keil source and project files as well as all the PSDsoft Express project files. Now close the C Code Generation window.

Fitting Design

Click the next highl ig hted bo x i n the des ig n fl ow, “Fi t De si gn to S i lic on ”. PS Dsoft wil l co mpi le al l th e c on figuration selections and present a report (also available in Appendix C). The fitter report documents how

pins are configured and how the programmable logic is allocated. It also shows how many programmable

logic product terms are used, which is needed to estimate power consumption.

20/49

Page 21

AN1560

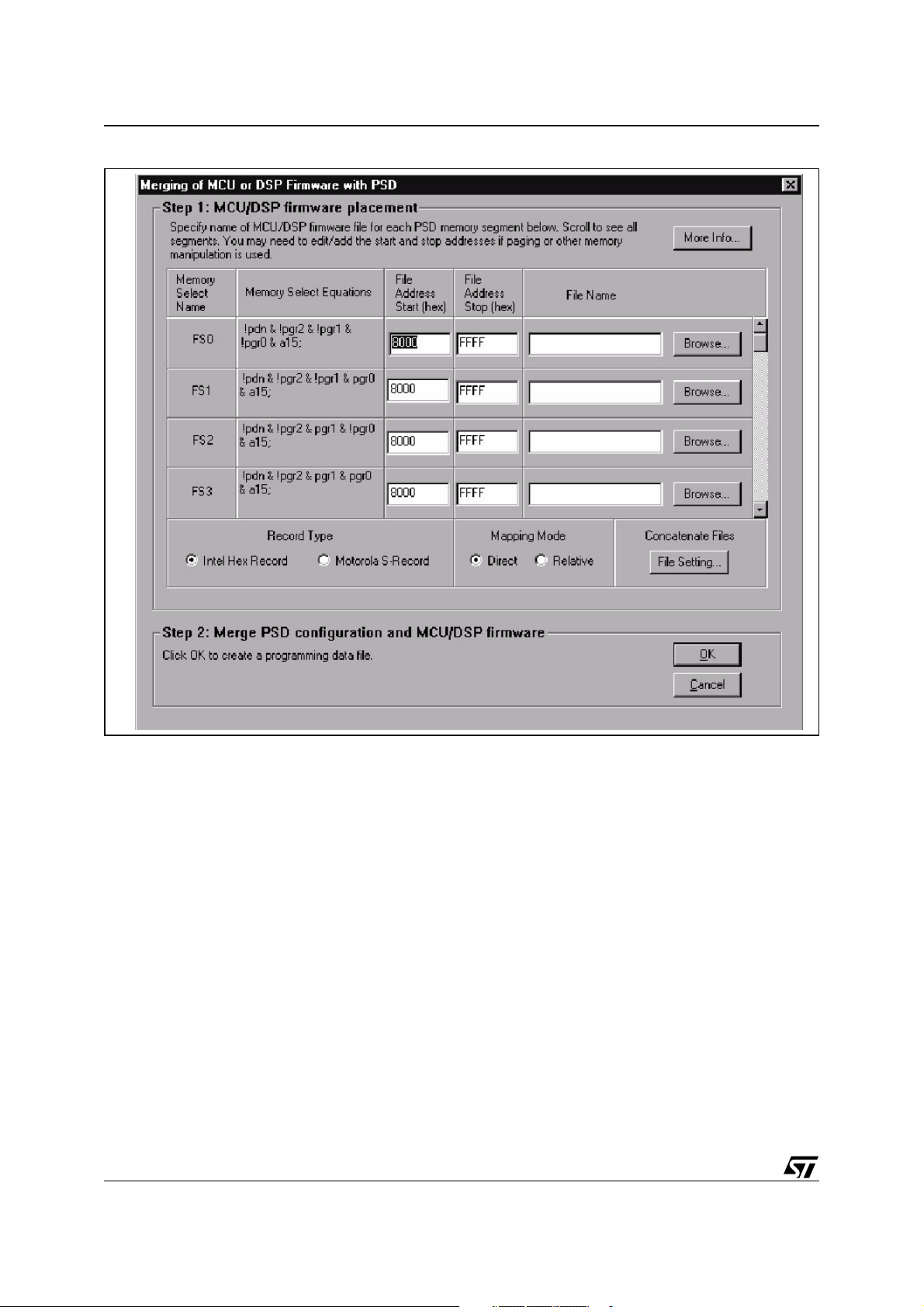

Merging 8032 Firmware with µPSD Configuration

Now that all µPSD pins and configuration settings have been defined, PSDsoft Express will create a single

object file (*.obj) that is a composite of the 8032 firmware (*.hex) and the µPSD configuration. FlashLINK

or third party progr ammer tools can u se thi s objec t fil e to pr ogram a µ PSD devic e. PS Dsoft Ex press will

create

During this merging process, PSDsoft Express will input firmware files from the 8032 compiler/linker in Srecord or Intel HEX format. It will map the content of these files into the physical memory segments of the

µPSD according to the ch oic es t hat were mad e in the ‘Ch ip Sele ct Eq uations’ screen. This mapp in g pro cess translates the absolute system addresses inside 8032 firmware files into physical internal µPSD addresses that are used by a programmer device to program the µPSD. This address translation process is

transparent. All you need to do is type (or browse) the fil e nam e that was gen er ated from the 803 2 lin ke r

into the appropriate boxes and PSDsoft Express does the rest. Y ou can specify a single file name for more

than one µPSD chip-select, or a different file name for each µPSD chip-select. It depends on how the 8032

linker has created the firmware file(s). For each µPSD chip-select in which you have specified a firmware

file name, PSDsoft Express will extract firmwa re from that file on ly between the spec ified start and stop

addresses, and ignore firmware outside of the start and stop addresses.

Click on 'Merge MCU Firm ware' in t he mai n flow dia gram. You will see an information wi ndow pop up to

remind you to be sur e y ou h av e confi gu re d the fi rm ware c om pil er and linker to suppo rt a paged memory

mapping scheme. “OK” and you'll see this screen:

DK3200_1.obj

for this design example.

21/49

Page 22

AN1560

Figure 16. Firmware Merging Utility

In the left column ar e µPSD memory segment chip-sele cts (FS 0, F S 1, etc. ). T h e n ex t c ol umn s how s the

logic equations for selection of e ach µPSD mem ory segment. These equations reflect the choices that

were made while defini ng µPSD internal chip-s elect equations in an earlier st ep. In the middle of the

screen are hexadeci mal start and stop addr esses that PS Dsoft Express h as filled in base d on the chip select equations. On the right are fields to enter (browse) the 8032 firmware files.

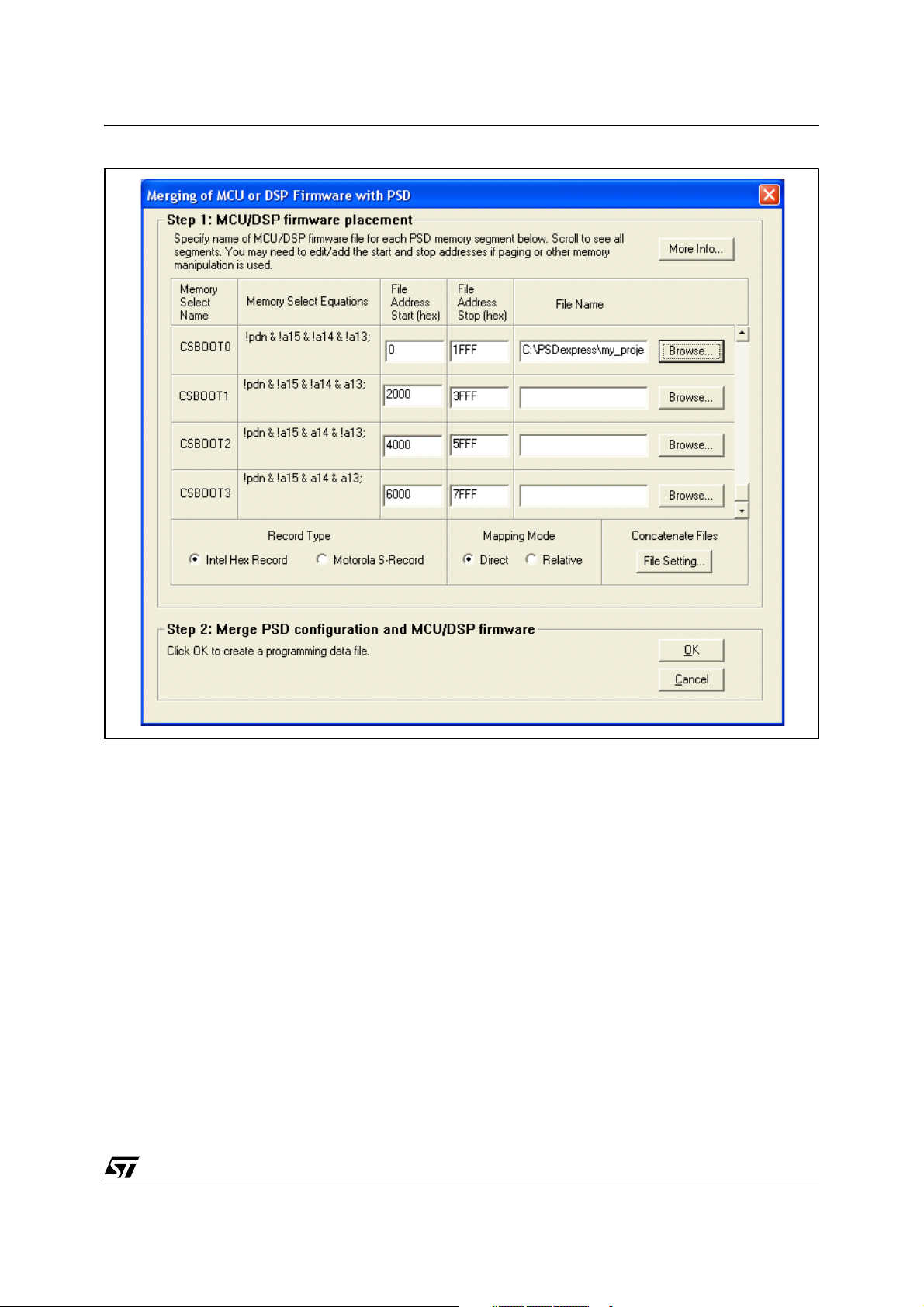

Select 'Intel Hex Record' for 'Record Type' as shown. Now slide the bar on the right side all the way down

to the bottom until you see CSBOOT0. Use the 'Browse' button and select the firmware file for CSBOOT0,

\PSDexpress\my_project\dk3200_dsn_1\dk3200_1_c\dk3200_1.hex

that exercises the PWM and ADC c hannels of t he µPS D on the DK320 0 board, and this code fits c ompletely within the 8K byte Flash memory segment CSBOOT0. The screen should look like this:

22/49

. This is a small example program

Page 23

Figure 17. Merging the Example Firmware

AN1560

This specificatio n places firmw are in secon dary PS D Flash memor y segment csboo t0. PSDsoft Expres s

will extract any firmware that lies in side the file

and place it in PSD memory segment csboot0. Click OK to generate the composite object file,

DK3200_1.obj

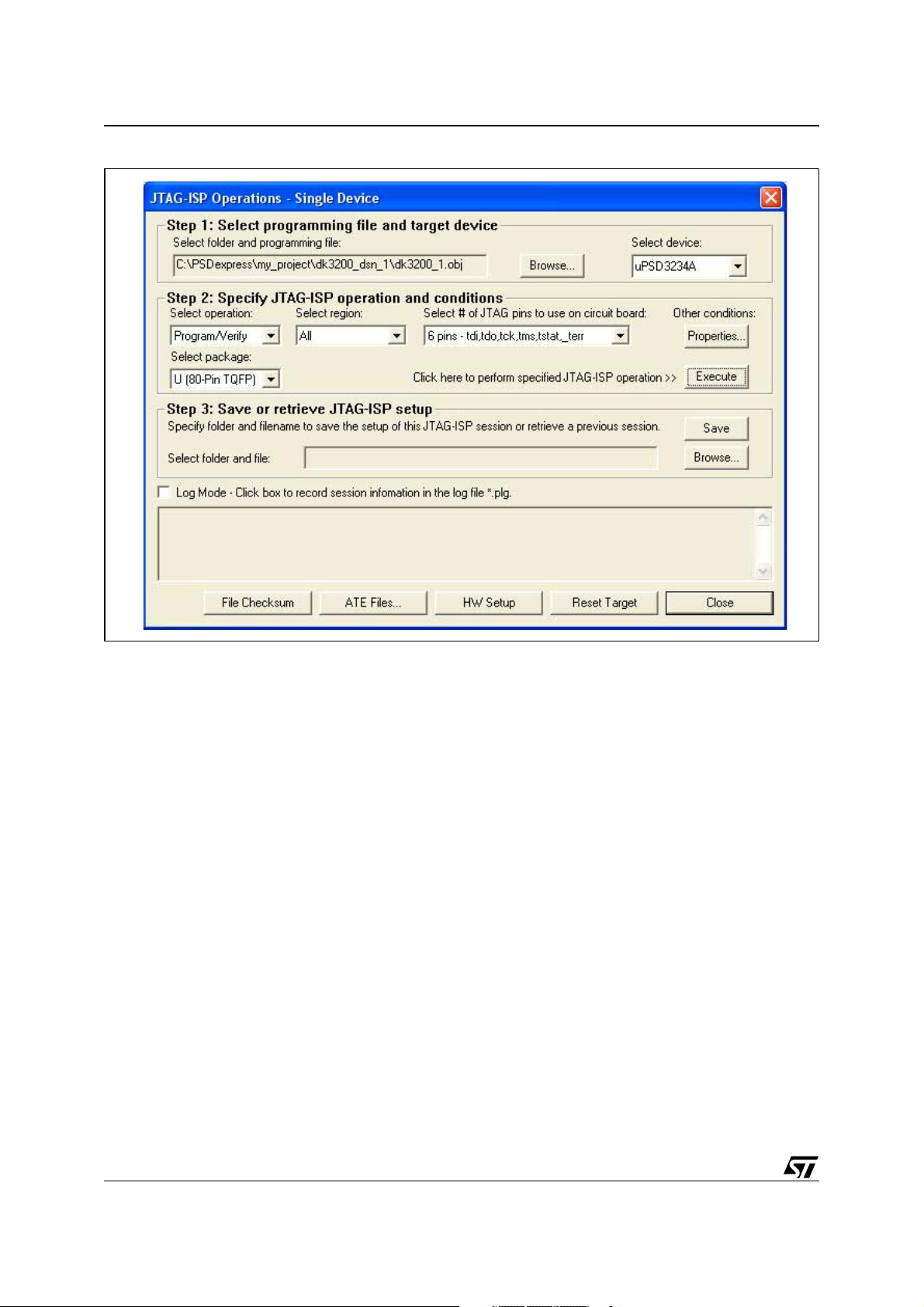

JTAG Programming

Now click the “STMicroelectronics JTAG/ISP” box to program the µPSD. You’ll be asked how many JTAG

devices are on the target circuit board, choose “Only One”. You’ll see the screen shown in Figure 18..

.

DK3200_1.hex

between MCU addresses 0000 and 1FFF

23/49

Page 24

AN1560

Figure 18. Programming with FlashLINK JTAG Cable

This window enables you to perform JTAG-ISP operations and also offers a loop back test for your

FlashLINK cable. If this is your first use, test your FlashLINK cable and PC parallel port by clicking the 'HW

Setup' button, then click 'LoopTest' button and follow the directions.

Now let's define our JTAG-ISP environment. For this example project, PSDsoft Express should have filled

in the folder and filename o f the obje ct file to progr am, the PSD devic e, and the JTAG-ISP operation, as

shown in the screen above. For this design example, we have chosen to use all six JT AG-ISP pins (instead

of four), so the screen should indicates 6-pin JTAG is being used.

To begin programming, connect the JTAG cable to the target sys tem, power-up the target syst em, and

click 'Execute' on the JTAG screen. The Log window at the bottom of the JTAG screen shows the progress.

Programming should just take a few seconds, the ISP LED at D5 on the DK3200 will light during programming.

There are optional choices available when the 'Properties.." button is clicked. One choice includes setting

the state of all pins on port A, B, C, or D during JTAG-ISP operations (make them inputs or outputs). The

default state of these pins is "input", which is fine for this design example. The other choice allows you to

specify a USERCODE value to compare before any JTAG-ISP operation starts. This is typically used in a

manufacturing environment (see on-screen description for details).

After JTAG-ISP operations are complete, you can save the JTAG setup for this programming session to a

file for later use. To do so, click on the 'Sav e' butt on. To restore the setup of a different previous sessi on,

click the 'Browse..' button.

24/49

Page 25

AN1560

WATCH IT RUN ON DK3200

After JTAG programming completes in just a few seconds, you should see a message appear on the LCD:

DK3200 for µPSD

PWM to ADC DEMO

Then you’ll see the Hexadecimal value of the ADC conversion sweep up and down between 00h and FFh

as the PWM pulse width changes. If you do not see the ADC value change, make sure there are two jumpers installed on the DK320 0 boa rd . On JP1, in sta ll one j ump er acr oss the two op pos i te rows of pin s ne xt

to the word “PWM0”, and the other jumper across the opposite rows of pins next to the word “ADC0”. Remove the jumper next the word “ADC0” and watch the ADC value on the LCD drop to 00h.

25/49

Page 26

AN1560

USING UVISION2 AND ISD51 DEBUGGER FROM KEIL SOFTWARE, INC.

This next section will briefly highlight the features of the Keil uVision2 IDE (Integrated Development Environment). Keil’s evaluation software was used for this example. This software is supplied on the DK3200

CD and can be ins talled by doubl e clicki ng on th e instal lation p rogram found in the Kei l subdire ctory. In

the case of version 7.20, the installation program is named

tation for more details.

Loading a Keil uVision2 Project

The file

source and proje ct f iles need ed to build this desig n in Keil’s uVision2. O nc e d ownl oa ded save the file on

your hard drive and unz ip it to the fo lder of your c hoice. The ZI P file contains two folders, DK 3200_1_c

and

for this application note.

Copy the folder

..

Now open the uVision2 project that you just got from the ZIP file at

.

.\keil\c51\DK3200_1_C\DK3200_1.uv2

Building the Project and Programming the µPSD

You can build the project for this application note which will create a new Intel HEX-80 file,

Invoke PSDsoft Express and open the project

this new HEX file at

merge, then program the DK3200 board with FlashLINK cable just as before. The LCD should display the

PWM/ADC demo information.

Running the Keil ISD51 UART Debugger

This simple demo program has the ISD51 UART debugger linked into the code. This is a new debug tool

from Keil that only consumes 700 bytes of code space and is royalty-free so it can stay in your end product

all the time. Unlike the older UART debugger, MON51, this debugger does not require you to debug code

in small sections a t a time f rom x data SRAM . And unlike M ON51, t his de bugger does not requi re yo u to

combine your code and data space (tie _PSEN and _RD together). See Keil documentation for details.

This proj ect,

rial COM1 port at 19.2 kbaud with no hardware handshaking. It also assumes there is a 40MHz crystal on

the DK3200 board. Connect a DB-9 (nine-pin) male-female straight-through (pins 2 and 3 are not

swapped) serial cable to COM1 port1 on your PC and to the UART0 (P1) connector on the DK3200 board.

Click the Debug icon shown in Figure 19., the debugger will start and it will compare contents of the Flash

memory in the µPSD Flash memory with the source files, then program execution will begin running to the

C source line until just after the function, ISD_check(), then it will stop and wait for your debug command.

The screen should look like Figure 20..

dk32dsn1.zip

DK3200_1_p. DK3200_1_c

\Keil\C51\DK3200_1_c

DK3200_1.Uv2

is available from the ST web site (

has all the Keil files,

DK3200_1_c

. Invoke Keil uVis io n2, p ul l down the “Project” menu, th en s elec t “ Op en Pr oje ct”.

and all of its contents to your Keil folders as follows,

. Everything should be ready to go.

DK3200_1

\keil\c51\DK3200_1_C\DK3200_1.hex

has ISD51 already selected for the debugger tool, connected through PC se-

EK51V720.exe

http:www.st.com/psm-software

DK3200_1_p

has the PSDsoft Express project files

. Please refer to Keil documen-

). It contains all the

DK3200_1.hex

, go to the “Merge MCU Firmware” section, select

for the Flash memory segment

csboot0

and

.

Figure 19. Debug icon

26/49

Page 27

Figure 20. Keil ISD51 Just After it is Successfully Invoked

AN1560

Now you can set breakpoints, single-step, view 8032 internal registers and SFRs, view blocks of memory,

etc. For example, in t he mem or y wind ow in the lower-right co rn er of the IDE scr een , th e by te of mem or y

at Hexadecimal addres s 96h is the SF R named “ADAT”, which is the resulting 8-bi t value fr om the ADC

channel from the last voltage co nversion before the 8032 stop ped. The value at address 96h is BF h in

Figure 20.. If y ou set a breakpoi nt on the functio n uPSD_ADC_Read( 0), then run the prog ram, you will

see the data byte at address 96h change value in the memory watch window, and that same data byte will

be showing on the LCD. Each t ime to run un til the br eakp oint, y ou sho uld s ee a ne w valu e appea ring in

the memory watch window at address 96h and the same value on the LCD. Click the debug icon again to

exit the debugger ISD51.

27/49

Page 28

AN1560

CONCLUSION

Congratulations! You have seen the majority of steps to implement a µPSD design on the DK3200 board.

Now you have a basis to understand more detail as you read the µPSD data sheet and the documentation

from Keil Software Inc.

28/49

Page 29

AN1560

APPENDIX A. PSDSOFT EXPRESS PROJECT SUMMARY FILE , DK3200_1.SUM

***********************************************************************

PSDsoft Express Version 8.30

Summary of Design Assistant

***********************************************************************

PROJECT : DK3200_1 DATE : 09/28/2004

DEVICE : uPSD3234A TIME : 16:35:05

MCU/DSP : uPSD32XX

***********************************************************************

Initial setting for Program and Data Space:

===========================================

Main PSD flash memory will reside in this space at power-up: Data Space Only

Secondary PSD flash memory will reside in this space at power-up: Program Space Only

Pin Definitions:

================

Pin Signal Pin

Name Name Type

------------ ------------------------- -----------pa7 LCD_d7 Peripheral I/O mode

pa6 LCD_d6 Peripheral I/O mode

pa5 LCD_d5 Peripheral I/O mode

pa4 LCD_d4 Peripheral I/O mode

pa3 LCD_d3 Peripheral I/O mode

pa2 LCD_d2 Peripheral I/O mode

pa1 LCD_d1 Peripheral I/O mode

pa0 LCD_d0 Peripheral I/O mode

pb7 LCD_e External chip select - Active Hi

pb6 LCD_rw Combinatorial

pb5 LCD_rs Combinatorial

pb4 term_count Combinatorial

pb3 a15_x Combinatorial

pb2 a14_x Combinatorial

pb1 a13_x Combinatorial

pb0 a12_x Combinatorial

tdo tdo Dedicated JTAG - TDO

tdi tdi Dedicated JTAG - TDI

pc4 _terr Dedicated JTAG - /TERR

pc3 tstat Dedicated JTAG - TSTAT

pc2 vstby SRAM standby voltage input

tck tck Dedicated JTAG - TCK

tms tms Dedicated JTAG - TMS

ale ale ALE output

p4.7 PWM4 GP I/O mode

p4.3 PWM0 PWM0 Output

p3.1 USART1_Txd UART1 TxD

p3.0 USART1_Rxd UART1 RxD

p1.4 ADC_Ch0 ADC channel0 input

a11 a11 Address line

a10 a10 Address line

a9 a9 Address line

a8 a8 Address line

ad7 a7 Data/Address line

ad6 a6 Data/Address line

ad5 a5 Data/Address line

ad4 a4 Data/Address line

29/49

Page 30

AN1560

ad3 a3 Data/Address line

ad2 a2 Data/Address line

ad1 a1 Data/Address line

ad0 a0 Data/Address line

_Reset_In Reset_In Reset In

Vref VREF VREF input

_rd _wr Bus control output

_psen _psen Bus control output

_wr _rd Bus control output

USB- USB_minus USB- bus

USB+ USB_plus USB+ bus

Xtal1 Xtal1 Xtal1

Xtal2 Xtal2 Xtal2

User defined nodes:

===================

Node Node

Name Type

------------ -----------down_count0 D-type register

down_count1 D-type register

down_count2 D-type register

down_count3 D-type register

init_count0 D-type register

init_count1 D-type register

init_count2 D-type register

init_count3 D-type register

Page Register settings:

=======================

pgr0 is used for paging

pgr1 is used for paging

pgr2 is used for paging

pgr3 is not used

pgr4 is not used

pgr5 is not used

pgr6 is not used

pgr7 is not used

Equations:

==========

rs0 = ((address >= ^h2000) & (address <= ^h3FFF));

csiop = ((address >= ^h0200) & (address <= ^h02FF));

fs0 = ((page == 0) & (address >= ^h8000) & (address <= ^hFFFF));

fs1 = ((page == 1) & (address >= ^h8000) & (address <= ^hFFFF));

fs2 = ((page == 2) & (address >= ^h8000) & (address <= ^hFFFF));

fs3 = ((page == 3) & (address >= ^h8000) & (address <= ^hFFFF));

fs4 = ((page == 4) & (address >= ^h8000) & (address <= ^hFFFF));

fs5 = ((page == 5) & (address >= ^h8000) & (address <= ^hFFFF));

fs6 = ((page == 6) & (address >= ^h8000) & (address <= ^hFFFF));

fs7 = ((page == 7) & (address >= ^h8000) & (address <= ^hFFFF));

csboot0 = ((address >= ^h0000) & (address <= ^h1FFF));

csboot1 = ((address >= ^h2000) & (address <= ^h3FFF));

csboot2 = ((address >= ^h4000) & (address <= ^h5FFF));

csboot3 = ((address >= ^h6000) & (address <= ^h7FFF));

psel0 = ((address >= ^h0300) & (address <= ^h03FF) & (_psen));

30/49

Page 31

LCD_e = ((address >= ^h0300) & (address <= ^h03FF) & (!_rd))

# ((address >= ^h0300) & (address <= ^h03FF) & (!_wr));

LCD_rw = a0;

LCD_rw.oe = Vcc;

LCD_rs = a1;

LCD_rs.oe = Vcc;

a15_x = a15;

a15_x.oe = Vcc;

a14_x = a14;

a14_x.oe = Vcc;

a13_x = a13;

a13_x.oe = Vcc;

a12_x = a12;

a12_x.oe = Vcc;

down_count0.ck = ale;

down_count0.re = !_reset;

down_count0.pr = Gnd;

down_count1.ck = ale;

down_count1.re = !_reset;

down_count1.pr = Gnd;

down_count2.ck = ale;

down_count2.re = !_reset;

down_count2.pr = Gnd;

down_count3.ck = ale;

down_count3.re = !_reset;

down_count3.pr = Gnd;

init_count0.ck = Gnd;

init_count0.re = !_reset;

init_count0.pr = Gnd ;

init_count1.ck = Gnd;

init_count1.re = !_reset;

init_count1.pr = Gnd;

init_count2.ck = Gnd;

init_count2.re = !_reset;

init_count2.pr = Gnd;

init_count3.ck = Gnd;

init_count3.re = !_reset;

init_count3.pr = Gnd;

AN1560

31/49

Page 32

AN1560

APPENDIX B. PSDSOFT EXPRESS ABEL HDL FILE DK3200_1.ABL

module DK3200_1

LCD_d7 PIN 21; “Reserved for Peripheral I/O mode

LCD_d6 PIN 22; “Reserved for Peripheral I/O mode

LCD_d5 PIN 24; “Reserved for Peripheral I/O mode

LCD_d4 PIN 26; “Reserved for Peripheral I/O mode

LCD_d3 PIN 28; “Reserved for Peripheral I/O mode

LCD_d2 PIN 32; “Reserved for Peripheral I/O mode

LCD_d1 PIN 34; “Reserved for Peripheral I/O mode

LCD_d0 PIN 35; “Reserved for Peripheral I/O mode

LCD_e PIN 66;

LCD_rw PIN 67;

LCD_rs PIN 72;

term_count PIN 73;

a15_x PIN 74;

a14_x PIN 76;

a13_x PIN 78;

a12_x PIN 80;

tdo PIN 6; “TDO

tdi PIN 7; “TDI

_terr PIN 9; “/TERR

tstat PIN 14; “TSTAT

vstby PIN 15; “SRAM standby voltage input

tck PIN 16; “TCK

tms PIN 20; “TMS

ale PIN 4; “ALE output

PWM4 PIN 18; “GP I/O

PWM0 PIN 27; “PWM0 Output

USART1_Txd PIN 77; “UART1 TxD

USART1_Rxd PIN 75; “UART1 RxD

ADC_Ch0 PIN 59; “ADC channel0 input

a11 PIN 57; “Address line

a10 PIN 55; “Address line

a9 PIN 53; “Address line

a8 PIN 51; “Address line

a7 PIN 47; “Data/address bus line

a6 PIN 45; “Data/address bus line

a5 PIN 43; “Data/address bus line

a4 PIN 41; “Data/address bus line

a3 PIN 39; “Data/address bus line

a2 PIN 38; “Data/address bus line

a1 PIN 37; “Data/address bus line

a0 PIN 36; “Data/address bus line

Reset_In PIN 68;

VREF PIN 70; “VREF input

_wr PIN 65;

_psen PIN 63;

_rd PIN 62;

USB_minus PIN 8; “USB- bus

USB_plus PIN 10; “USB+ bus

Xtal1 PIN 48; “Xtal1

Xtal2 PIN 49; “Xtal2

psel0 node;

rs0 node;

csiop node;

fs0 node;

fs1 node;

fs2 node;

fs3 node;

32/49

Page 33

fs4 node;

fs5 node;

fs6 node;

fs7 node;

csboot0 node;

csboot1 node;

csboot2 node;

csboot3 node;

_reset node 543;

a12 node 512;

a13 node 513;

a14 node 514;

a15 node 515;

pgr2..pgr0 node;

down_count0 NODE istype ‘reg_D’;

down_count1 NODE istype ‘reg_D’;

down_count2 NODE istype ‘reg_D’;

down_count3 NODE istype ‘reg_D’;

init_count0 NODE istype ‘reg_D’;

init_count1 NODE istype ‘reg_D’;

init_count2 NODE istype ‘reg_D’;

init_count3 NODE istype ‘reg_D’;

jtagsel node;

X = .x.;

address = [a15..a0];

page = [pgr2..pgr0];

Vcc = 1;

Gnd = 0;

AN1560

// Begin user preserved declarations (not affected by iterations of DA usage)

===================

WSIPSD PROPERTY ‘DataBus_OMC D[7:4]:down_count[3:0] MCELLAB’; // This statement forces the

alignment

// of down_count bits [3..0] to the MCU data bus bit positions

[7..4].

// If this WSIPSD PROPERTY statement was not present, then PSDsoft

// would pick random MCU bit positions. The WSIPSD PROPERTY is needed

// only if the MCU will read or write to MicroCells and only if a

// particular MCU data bus position is required by the designer.

WSIPSD PROPERTY ‘DataBus_OMC D[3:0]:init_count[3:0] MCELLAB’; // This statement forces the

alignment

// of init_count bits [3..0] to the MCU data bus bit positions [3..0].

DCOUNT = [down_count3..down_count0]; // 4-bit down counter

INIT = [init_count3..init_count0];// 4-bit initial count from MCU

//INIT = [0,1,0,0];

// End user preserved declarations (not affected by iterations of DA usage)

===================

equations

33/49

Page 34

AN1560

jtagsel = !_reset;

rs0 = ((address >= ^h2000) & (address <= ^h3FFF));

csiop = ((address >= ^h0200) & (address <= ^h02FF));

fs0 = ((page == 0) & (address >= ^h8000) & (address <= ^hFFFF));

fs1 = ((page == 1) & (address >= ^h8000) & (address <= ^hFFFF));

fs2 = ((page == 2) & (address >= ^h8000) & (address <= ^hFFFF));

fs3 = ((page == 3) & (address >= ^h8000) & (address <= ^hFFFF));

fs4 = ((page == 4) & (address >= ^h8000) & (address <= ^hFFFF));

fs5 = ((page == 5) & (address >= ^h8000) & (address <= ^hFFFF));

fs6 = ((page == 6) & (address >= ^h8000) & (address <= ^hFFFF));

fs7 = ((page == 7) & (address >= ^h8000) & (address <= ^hFFFF));

csboot0 = ((address >= ^h0000) & (address <= ^h1FFF));

csboot1 = ((address >= ^h2000) & (address <= ^h3FFF));

csboot2 = ((address >= ^h4000) & (address <= ^h5FFF));

csboot3 = ((address >= ^h6000) & (address <= ^h7FFF));

psel0 = ((address >= ^h0300) & (address <= ^h03FF) & (_psen));

LCD_e = ((address >= ^h0300) & (address <= ^h03FF) & (!_rd))

# ((address >= ^h0300) & (address <= ^h03FF) & (!_wr));

LCD_rw = a0;

LCD_rw.oe = Vcc;

LCD_rs = a1;

LCD_rs.oe = Vcc;

a15_x = a15;

a15_x.oe = Vcc;

a14_x = a14;

a14_x.oe = Vcc;

a13_x = a13;

a13_x.oe = Vcc;

a12_x = a12;

a12_x.oe = Vcc;

down_count0.ck = ale;

down_count0.re = !_reset;

down_count0.pr = Gnd;

down_count1.ck = ale;

down_count1.re = !_reset;

down_count1.pr = Gnd;

down_count2.ck = ale;

down_count2.re = !_reset;

down_count2.pr = Gnd;

down_count3.ck = ale;

down_count3.re = !_reset;

down_count3.pr = Gnd;

init_count0.ck = Gnd;

init_count0.re = !_reset;

init_count0.pr = Gnd ;

init_count1.ck = Gnd;

init_count1.re = !_reset;

init_count1.pr = Gnd;

init_count2.ck = Gnd;

init_count2.re = !_reset;

init_count2.pr = Gnd;

init_count3.ck = Gnd;

init_count3.re = !_reset;

init_count3.pr = Gnd;

// Begin user preserved equations (not affected by iterations of DA usage)

===================

34/49

Page 35

AN1560

term_count = (DCOUNT == 0); // term_count true when count reaches zero

when term_count then DCOUNT := INIT; // automatically reload counter with initial

// value after a count of zero is reached

else DCOUNT := DCOUNT - 1; // specify down count action

// End user preserved equations (not affected by iterations of DA usage)

===================

end DK3200_1

35/49

Page 36

AN1560

APPENDIX C. PSDSOFT EXPRESS FITTER REPORT DK3200_1.FRP

****************************************************************************************

**

PSDsoft Express Version 8.30

Output of PSD Fitter

****************************************************************************************

**

PROJECT : DK3200_1 DATE : 09/28/2004

DEVICE : uPSD3234A TIME : 16:33:47

FIT OPTION : Keep Current

DESCRIPTION: Example design for uPSD3234A in Application Note AN1560.

Simple memory map with 32K secondary flash in code space, and

256K main flash paged in data space. Down-Counter built in

PLD. Runs on DK3200 board.

****************************************************************************************

**

==== Pin Layout for U (80-Pin TQFP) Package Type ====

---------------------------- | |

|1 ] pd2 adio4 [41| Address Bus

a4/Data Port d4, ad4

|2 ] p3_3 p3_5 [42|

|3 ] pd1 adio5 [43| Address Bus

a5/Data Port d5, ad5

ale |4 ] pd0 p3_6 [44|

|5 ] pc7 adio6 [45| Address Bus

a6/Data Port d6, ad6

tdo, TDO |6 ] pc6/TDO p3_7 [46|

tdi, TDI |7 ] pc5/TDI adio7 [47| Address Bus

a7/Data Port d7, ad7

USB_minus |8 ] USBm Xtal1 [48| Xtal1

_terr, TERR |9 ] pc4/TERR Xtal2 [49| Xtal2

USB_plus |10] USBp VCC [50|

|11] N/C adio8 [51| Address Bus a8, a8

|12] VCC p1_0 [52|

|13] GND adio9 [53| Address Bus a9, a9

tstat, TSTAT |14] pc3/TSTAT p1_1 [54|

vstby |15] pc2 adio10 [55| Address Bus a10, a10

tck, TCK |16] pc1/TCK p1_2 [56|

|17] N/C adio11 [57| Address Bus a11, a11

PWM4 |18] p4_7 p1_3 [58|

|19] p4_6 p1_4 [59| ADC_Ch0

tms, TMS |20] pc0/TMS p1_5 [60|

LCD_d7 ,Peripheral I/O Mode |21] pa7 p1_6 [61|

LCD_d6 ,Peripheral I/O Mode |22] pa6 cntl0 [62| _rd

|23] p4_5 cntl2 [63| _psen

LCD_d5 ,Peripheral I/O Mode |24] pa5 p1_7 [64|

|25] p4_4 cntl1 [65| _wr

LCD_d4 ,Peripheral I/O Mode |26] pa4 pb7 [66| LCD_e

PWM0 |27] p4_3 pb6 [67| LCD_rw

LCD_d3 ,Peripheral I/O Mode |28] pa3 Reset_In [68| Reset_In

|29] GND GND [69|

|30] p4_2 Vref [70| VREF

|31] p4_1 N/C [71|

LCD_d2 ,Peripheral I/O Mode |32] pa2 pb5 [72| LCD_rs

|33] p4_0 pb4 [73| term_count

LCD_d1 ,Peripheral I/O Mode |34] pa1 pb3 [74| a15_x

36/49

Page 37

AN1560

LCD_d0 ,Peripheral I/O Mode |35] pa0 p3_0 [75| USART1_Rxd

ad0, Address Bus a0/Data Port d0 |36] adio0 pb2 [76| a14_x

ad1, Address Bus a1/Data Port d1 |37] adio1 p3_1 [77| USART1_Txd

ad2, Address Bus a2/Data Port d2 |38] adio2 pb1 [78| a13_x

ad3, Address Bus a3/Data Port d3 |39] adio3 p3_2 [79|

|40] p3_4 pb0 [80| a12_x

| |

---------------------------- ==== Global Configuration ====

Data Bus : 8-Bit

Address/Data Mode : Multiplexed

ALE/AS Signal : Active High

Control Signals : /WR, /RD, /PSEN

Main PSD flash memory will reside in this space at power-up : Data space

Secondary PSD flash memory will reside in this space at power-up : Program space

Enable Chip-Select Input(/CSI) : OFF

Standby Voltage Input (PC2) : ON

Standby-on Indicator (PC4) : OFF

RDY/Busy function (PC3) : OFF

Load Micro-Cell on : edge

Security Protection : OFF

==== DataBus_IMC access information ====

CSIOP

Location Address Offset Register Name Signals

--------------------------------------------------------

===== Resource Usage Summary =====

Total Product Terms Used: 72

Device Resources used / total

-----------------------------------------------Port A: (pins 35 34 32 28 26 24 22 21)

I/O Pins : 8 / 8

GP I/O or Address Out : 0

Peripheral I/O : 8

Logic Inputs : 0

Address Latch Inputs : 0

PT Dependent Latch Inputs : 0

PT Dependent Register Inputs : 0

Combinatorial Outputs : 0

Registered Outputs : 0

Other Information

Microcells : 8 / 8

Micro-Cells AB :

Buried Microcells : 8

Output Microcells : 0

Product Terms : 15 / 24

Control Product Terms : 24 / 34

Port B: (pins 80 78 76 74 73 72 67 66)

I/O Pins : 8 / 8

GP I/O or Address Out : 0

Logic Inputs : 0

Address Latch Inputs : 0

PT Dependent Latch Inputs : 0

37/49

Page 38

AN1560

PT Dependent Register Inputs : 0

Combinatorial Outputs : 8

Registered Outputs : 0

Other Information

Microcells : 8 / 8

Micro-Cells AB :

Buried Microcells : 0

Output Microcells : 0

Micro-Cells BC :

Buried Microcells : 0

Output Microcells : 8

Product Terms : 9 / 32

Control Product Terms : 8 / 34

Port C: (pins 20 16 15 14 9 7 6 5)

I/O Pins : 7 / 8

GP I/O or Address Out : 0

Logic Inputs : 0

Address Latch Inputs : 0

PT Dependent Latch Inputs : 0

PT Dependent Register Inputs : 0

JTAG signals : 6

Standby Voltage Input : 1

Rdy/Bsy signal : 0

Standby On Indicator : 0

Combinatorial Outputs : 0

Registered Outputs : 0

Other Information

Microcells : 8 / 8

Micro-Cells BC :

Buried Microcells : 8

Output Microcells : 0

Product Terms : 9 / 32

Control Product Terms : 0 / 34

Port D: (pins 4 3 1)

I/O Pins : 1 / 3

GP I/O or Address Out : 0

Logic Inputs : 0

Chip-Select Input : 0

Clock Input : 0

Control Signal Input : 1

Fast Decoding Outputs : 0

Other Information

Product Terms : 0 / 3

Control Product Terms : 0 / 3

==== OMC Resource Assignment ====

Resources PT User

Used Allocation Name

--------------------------------------------------------Micro-Cell AB :

Micro-Cells 0 - init_count0 => Register

Micro-Cells 1 - init_count1 => Register

Micro-Cells 2 - init_count2 => Register

Micro-Cells 3 - init_count3 => Register

Micro-Cells 4 - down_count0 => Register

38/49

Page 39

Micro-Cells 5 - down_count1 => Register

Micro-Cells 6 - down_count2 => Register

Micro-Cells 7 - down_count3 => Register

Micro-Cell BC :

Micro-Cells 0 - a12_x (mcellbc0) => Combinatorial

Micro-Cells 1 - a13_x (mcellbc1) => Combinatorial

Micro-Cells 2 - a14_x (mcellbc2) => Combinatorial

Micro-Cells 3 - a15_x (mcellbc3) => Combinatorial

Micro-Cells 4 - term_count (mcellbc4) => Combinatorial

Micro-Cells 5 - LCD_rs (mcellbc5) => Combinatorial

Micro-Cells 6 - LCD_rw (mcellbc6) => Combinatorial

Micro-Cells 7 - LCD_e (mcellbc7) => Combinatorial

External Chip Select :

========= Equations =========

DPLD EQUATIONS :

=======================

fs0 = !pdn & !pgr2 & !pgr1 & !pgr0 & a15;

fs1 = !pdn & !pgr2 & !pgr1 & pgr0 & a15;

AN1560

fs2 = !pdn & !pgr2 & pgr1 & !pgr0 & a15;

fs3 = !pdn & !pgr2 & pgr1 & pgr0 & a15;

fs4 = !pdn & pgr2 & !pgr1 & !pgr0 & a15;

fs5 = !pdn & pgr2 & !pgr1 & pgr0 & a15;

fs6 = !pdn & pgr2 & pgr1 & !pgr0 & a15;

fs7 = !pdn & pgr2 & pgr1 & pgr0 & a15;

csboot0 = !pdn & !a15 & !a14 & !a13;

csboot1 = !pdn & !a15 & !a14 & a13;

csboot2 = !pdn & !a15 & a14 & !a13;

csboot3 = !pdn & !a15 & a14 & a13;

csiop = !pdn & !a15 & !a14 & !a13 & !a12 & !a11 & !a10 & a9 & !a8;

rs0 = !pdn & !a15 & !a14 & a13;

psel0 = !pdn & _psen & !a15 & !a14 & !a13 & !a12 & !a11 & !a10 & a9 & a8;

jtagsel = !_reset;

PORTA EQUATIONS :

=======================

init_count0.D := 0;

init_count0.PR = 0;

init_count0.RE = !_reset;

init_count0.C = 0;

39/49

Page 40

AN1560

init_count1.D := 0;

init_count1.PR = 0;

init_count1.RE = !_reset;

init_count1.C = 0;

init_count2.D := 0;

init_count2.PR = 0;

init_count2.RE = !_reset;

init_count2.C = 0;

init_count3.D := 0;

init_count3.PR = 0;

init_count3.RE = !_reset;

init_count3.C = 0;

down_count0.D := (!down_count0.Q & !term_count.PIN)

# (init_count0 & term_count.PIN);

down_count0.PR = 0;

down_count0.RE = !_reset;

down_count0.C = ale;

down_count1.D := (down_count1.Q & down_count0.Q & !term_count.PIN)

# (!down_count1.Q & !down_count0.Q & !term_count.PIN)

# (init_count1 & term_count.PIN);

down_count1.PR = 0;

down_count1.RE = !_reset;

down_count1.C = ale;

down_count2.T := (!down_count1.Q & !down_count0.Q & !term_count.PIN)

# (!down_count2.Q & init_count2 & term_count.PIN)

# (down_count2.Q & !init_count2 & term_count.PIN);

down_count2.PR = 0;

down_count2.RE = !_reset;

down_count2.C = ale;

down_count3.T := (!down_count3.Q & init_count3 & term_count.PIN)

# (down_count3.Q & !init_count3 & term_count.PIN)

# (!down_count2.Q & !down_count1.Q & !down_count0.Q & !term_count.PIN);

down_count3.PR = 0;

down_count3.RE = !_reset;

down_count3.C = ale;

PORTB EQUATIONS :

=======================

a12_x = a12;

a12_x.OE = 1;

a13_x = a13;

a13_x.OE = 1;

a14_x = a14;

a14_x.OE = 1;

a15_x = a15;

a15_x.OE = 1;

term_count = !down_count3.Q & !down_count2.Q & !down_count1.Q & !down_count0.Q;

term_count.OE = 1;

40/49

Page 41

term_count.LE = 1;

LCD_rs = a1;

LCD_rs.OE = 1;

LCD_rw = a0;

LCD_rw.OE = 1;

LCD_e = (!_rd & !a15 & !a14 & !a13 & !a12 & !a11 & !a10 & a9 & a8)

# (!_wr & !a15 & !a14 & !a13 & !a12 & !a11 & !a10 & a9 & a8);

LCD_e.OE = 1;

PORTC EQUATIONS :

=======================

PORTD EQUATIONS :

=======================

--- End ---

AN1560

41/49

Page 42

AN1560

APPENDIX D. DK3200 BOARD LAYOUT

Figure 21. DK3200 BOARD LAYOUT

1

42/49

Page 43

APPENDIX E. DK3200 SCHEMATICS

Figure 22. DK3200 SCHEMATICS (1)

ADDR[11..8]

RD_

ALE

PSEN_

E

AD[7..0]

WR_

DDC_SYNC

DDC_CLK

PWM[4..0]

I2C_DATA

DDC_DATA

I2C_CLK

AN1560

of

TXD

TXD1

PA[7..0]

PB[7..0]

ADC[3..0]

PD1

{Doc} A

DK3200 Eval Board

B

Title

Size Document Number Rev

15Monday, June 10, 2002

E

Date: Sheet

D

AD1

AD2

AD3

AD4

AD5

AD6

AD7

1

.01

C4

.01

C3

1

VCC_1

50

12

U1

C5

.01

AD0

3637383941434547515355

AD0/P0.0

VREF

70

CPU_CLK

R1

4

U7

R41

4.7K

C2

C1

VCC_1 VCC_1

C

B

VCC_1

C6

A

.01

AD1/P0.1

AD2/P0.2

VCC_2

VCC_1

48

100

3

VCC

OE

1

AD3/P0.3

AD4/P0.4

XTAL_1

OUT

AD5/P0.5

AD6/P0.6

AD7/P0.7

XTAL_2

49

GND

ADDR8

A8/P2.0

P3.2/INT0

79

2

CMX750PCCH

ADDR9

ADDR10

A9/P2.1

P3.3/INT1

2

ADDR11

57

A10/P2.2

A11/P2.3

P3.4/T0

40

656246863

RD/CTRL1

WR/CTRL0

T1/P3.5

42

ALE/PD0

PSEN/CTRL2

CNT2/P1.0

PWM0

PWM2

PWM1

PWM3

DDC_CLK

PWM4

272523191830313344

PWM0/P4.3

PWM1/P4.4

PWM2/P4.5

PWM3/P4.6

PWM4/P4.7

VSYNC/P4.2

TRG2/P1.1

PC0

PC1

PC2

PC3

PC4

PC5

976

5452201615

14

DDC_DATA

DSCL/P4.1

DSDA/P4.0

PC6

PC7

5

465658

ISCL/P3.7

ISDA/P3.6

USB_D+

USB_D-

8

TXD/P3.1

P3.0/RXD

757710

TXD1/P1.3

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

353432282624222180787674737267

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

P1.2/RXD1

P1.4/ADC0

P1.5/ADC1

P1.6/ADC2

P1.7/ADC3

PD1

PD2

3

596061

VCC_1

1

64

R36

4.7K

R35

4.7K

PB4

PB4

PB5

PB6

PB5

RESET

PB7

66

PB6

PB7

GND_3

GND_2

GND_1

JP1

12

34

R37

10K

U1

69

29

13

uPSD3234

I2C_CLK

TXD1

ADC0

I2C_DATA

TXD

56

78

910

11 12

13 14

RXD1

RXD

DDC_CLK

DDC_DATA

R3

4.7K

S2

PWM2

ADC2

ADC3

ADC1

PWM1

PWM0

15 16

17 18

19 20

21 22

23 24

25 26

27 28

C8

.1

SW PUSHBUTTON

C27

.01

PWM3

PWM4

HEADER 18X2

29 30

31 32

33 34

35 36

D

C

B

A

CNT2

TRG2

TMS

V_BAT

TSTAT

TERR_

TDI

TDO

RXD

T0

T1

INTR1

TCK

3 3

INTR0

4 4

USB_D

PC7

USB_D_

RXD1

INT1

PD2

PFO

2 2

RESET_

CLK_32K

1 1

AI07078

43/49

Page 44

AN1560

Figure 23. DK3200 SCHEMATICS (2)

E

D

PB0

PB1

PB2

JP6

12

34

PB3

HEADER 4X2

56

78

{Doc} A

Emulator Connections

B

Title