Page 1

AN1542

®

THE THERMAL RUNAWAY LAW IN SCHOTTKY

INTRODUCTION

Nowadays,somecriticalapplicationsrequirevery

high available power supplies. Typically, these

applications are servers or telecommunication

base stations.

In such systems, the power supplies are built with

several power supplies connected in parallel in

order to be fault tolerant. Thanks to redundancy,

the total failure rate stays very low and the availability can exceed 99.99%.

The connection of several power supplies needs

the OR function, commonly built with diodes, to

tolerate faults in the SMPS.

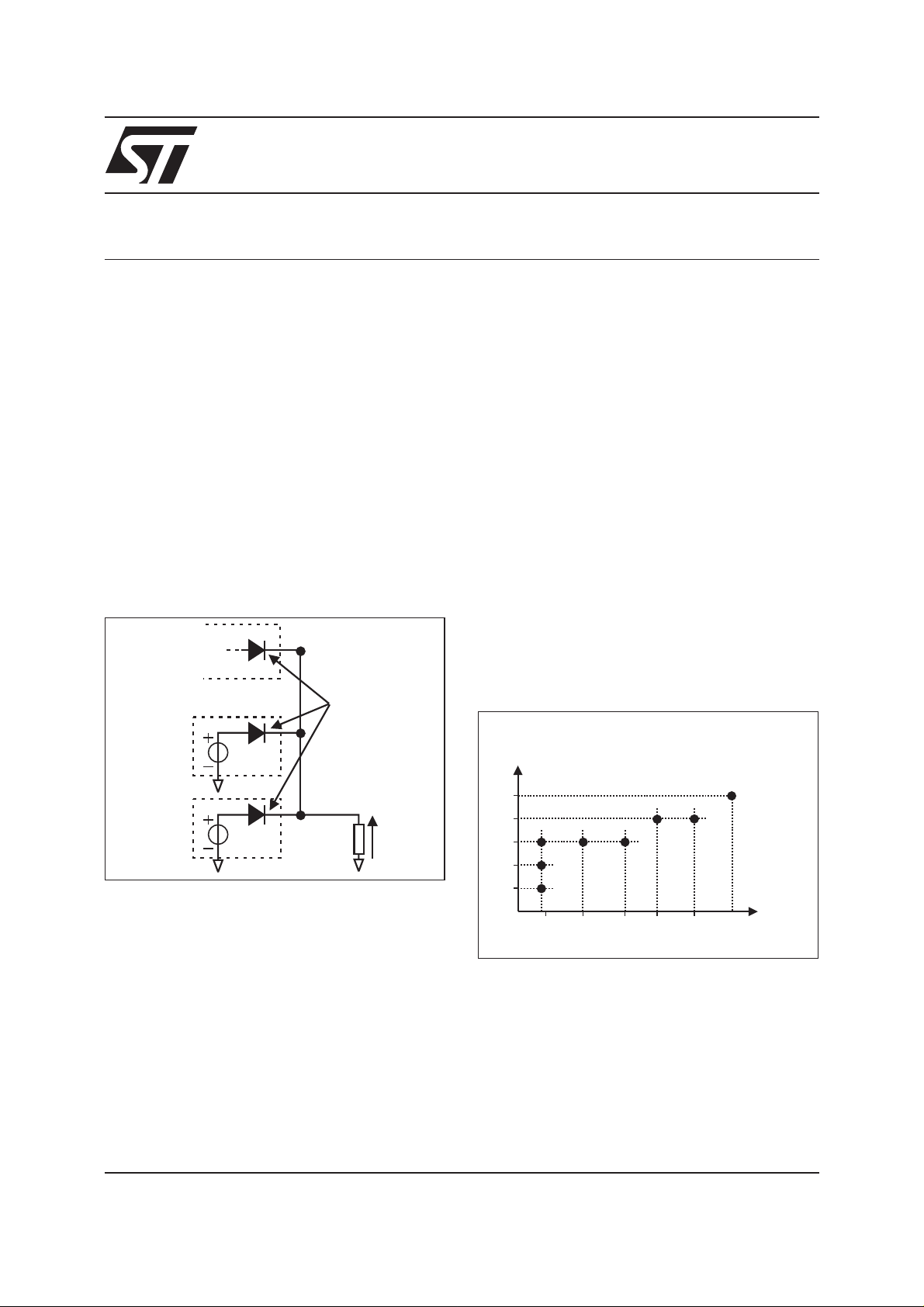

Fig. 1: Supplies connected in parallel

APPLICATION NOTE

USED IN OR-ing APPLICATION

by Y.LAUSENAZ

2. TYPICAL PREFERRED DEVICE

In normal operation the diode is conducting in

forward mode. So, the first requirement of the

component,irrespectiveof the maximum repetitive reverse voltage (V

ing (I

), is the forward voltage drop (VF).

F(AV)

The lower the forward voltage drop, the lower the

forward losses in the diode, and the better the

SMPS efficiency.

For this reason, Power Schottky diodes are commonly used in OR-ing application. The L series

(for example STPS60L30CW) are optimized to

provide very low forward voltage drop:

= 0.33V (30A @125°C per diode).

V

F typ

The following graph presents the typical Schottky

used in OR-ing application on common voltage

outputs:

) and the current rat-

RRM

Or function

SMPS 2

SMPS 1

Load Vout

1. OR-ing FUNCTION PRESENTATION

TheOR-ing function iscommonlybuilt with diodes.

The diodehasto let the current pass through when

the associated SMPS is working in normal operation. When a SMPS fails in short circuit, the diode

has to block reverse voltage in order to maintain

output voltage on the load.

The purpose of the OR function is to prevent fault

propagation between supplies connected in parallel.

Fig. 2: Typical Schottky used as OR-ing function

on common voltage outputs

Output

voltage

48V

24V

12V

5V

3.3V

L15 L30L25 L45 L60 H100

Schottky

voltage

Using Schottky diodes provides very low forward

losses.But the mainimportanttechnology trade off

for Schottky is between forward voltage drop and

leakage current:

The optimization of forward voltage drop is inevitably made to the detriment of leakage current.

High leakage current gives rise to the thermal

runaway problem.

May 2002

1/6

Page 2

APPLICATION NOTE

3. THERMAL RUNAWAY RISK

The risk of thermal runaway comes from the fact

that leakage current increases quickly with the

junction temperature.

3.1. Problems

Using a Schottky as OR-ing function provides a

very low forward voltage drop. But when the diode

is blocking because its associated supply has a

fault in short circuit mode, the diode has to operate

in reverse mode with high junction temperature

(due toprecedingforwardlosses) and so with relatively high reverse current.

This high reverse current can generate high reverse losses, and so increase junction temperature, and so reverse current as well… This is the

thermal runaway phenomenon.

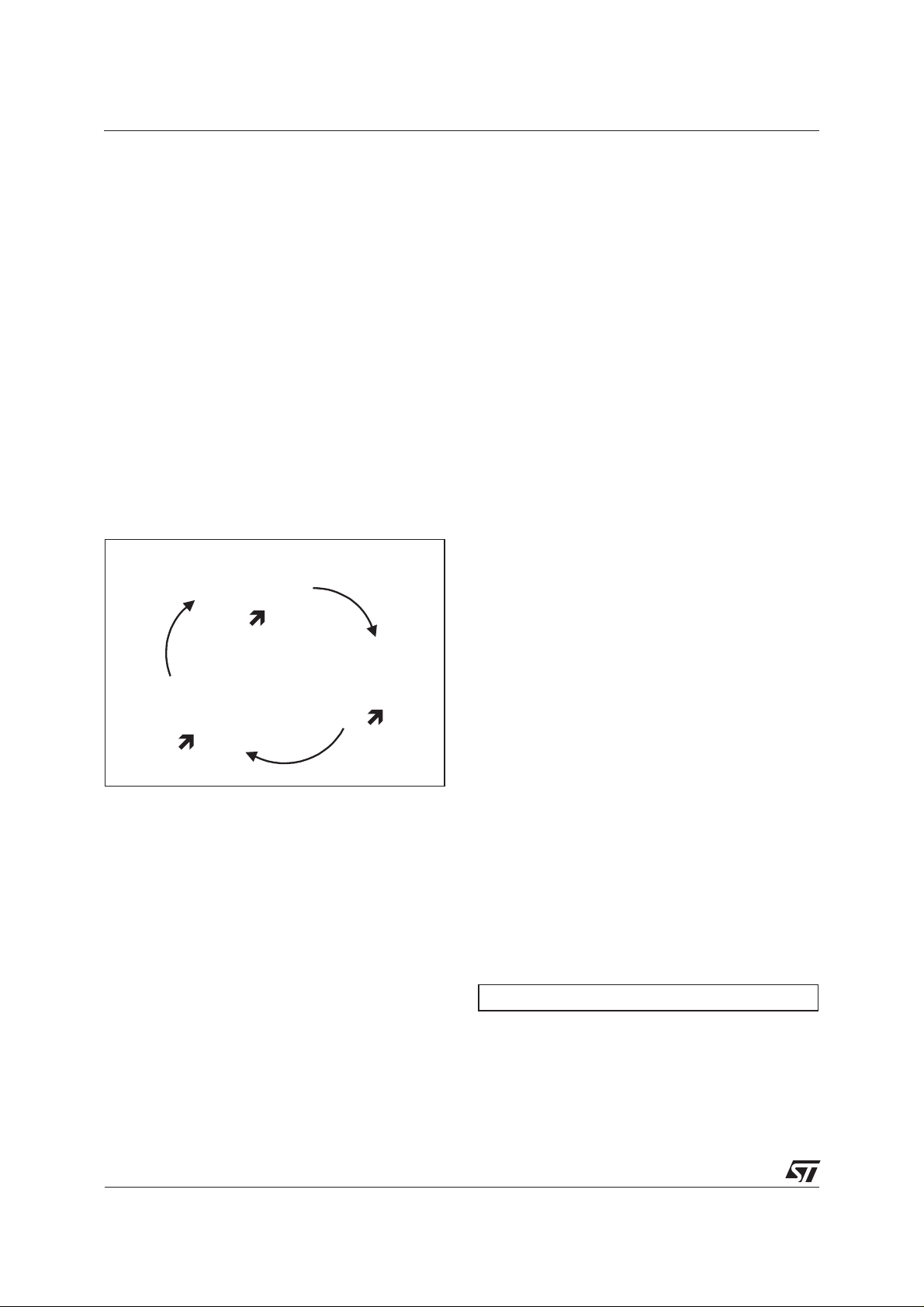

Fig. 3: Thermal runaway diagram

Reverse

current

Reverse

Junction

losses

temperature

The problem is to quantify the risk of thermal

runaway in order to prevent it.

3.2. Result in classical cases

In the classical simple case where both the following

assumptions are made:

Constant thermal resistance system

■

OR-ing diode on its own heatsink

■

The reverse losses in the Schottky diode, due to

associated SMPS short circuit failure, is a monotonous function of the time. Consequently the

thermal runaway diagram of fig. 3 is covered in

only one rotation- sense.

To determine if the Power Schottky will goes into

thermal runaway mode consists of finding the elements that will determine the rotation sense of

fig. 3.

During the forward mode, the forward current (I

defines the junction temperature (T

forward voltage (V

) and ambient temperature (T

R

th(j-a)

TT R IxV

=+

jambthjaFFI

), device thermal resistance

F

()

−() @

) (linked to

j

):

amb

fwd

F

During the fast mode change of the diode (from

the forward mode to the reverse one, the change

is fast in comparison to device thermal constant),

the junction temperatureduetothepreceding forwardmode stay continuous (c.f.fig.5) and willdetermine the leakage current (I

reverse voltage V

ITV I CV e

;;=°×

()( )

rev j rev rev rev

rev

):

100

) (linked to the

rev

−°

100

cT C

(

j

)

c ≈ 0.055°C-1(thermal constant)

This reverse current will determine the new junction temperature trend (linked to reverse voltage

and device thermal resistance). This variation

trend between the initial junction temperature (due

to forward mode) and the new one (due to reverse

mode)givesthe T

variationandthe rotation-sense

j

in fig. 3.

In a constant thermal resistance system, the ther-

mal stability can be determined by comparing forward losses (P

before the SMPS failure (t

losses (P

) occurring just after (t0+δt) the even-

rev

) in the power Schottky just

fwd

-δt) and the reverse

0

tual SMPS short-circuited fault.

)

2/6

The stability can be guaranteed if P

fwd>Prev@t0

Page 3

APPLICATION NOTE

Fig. 4: Typical loss variation in the OR-ing before

and after the SMPS failure

losses

Forward

mode

Reverse

mode

Thermal

runaway

Pfwd

Prev

SMPS

break down

t

0

Monotonous variation

time

Fig. 5: Typical junction temperature variation in

the OR-ing before and after the SMPS failure

Tj

Forward

mode

continuous

variation

Reverse

mode

Thermal

runaway

Fig. 6: Example of junction temperature variation

in non-constant thermal resistance system

Tj

Forward

mode

continuous

variation

SMPS

break down

t0

Reverse

mode

Fan switch

OFF

T

amb

NON-monotonous variation

Thermal

runaway

time

In these more complicated cases, device thermal

behavior can be simulated with tools like PSPICE.

The following analogies have to be used:

Thermal: Electrical:

Temperature Voltage

Power Current

Resistance Resistance

SMPS

break down

Tamb

time

Monotonous variation

3.3. Results in more complicated cases

More complicated cases, where the assumptions

of §3.2 do not exist, can be considered.

For example:

■

OR-ing diode not on its own heatsink.

The OR-ing diode can be mounted on common

heatsink with other dissipative devices. In this

case, the junction temperature of the OR-ing diode can be influenced by the other devices,

thanks to coupling thermal resistance.

■

Non constant thermal resistance system:

The convection can be forced by a fan connected to the Anode side of the OR-ing diode. In

case of SMPS failure, the fan will stop and the

R

will increase. In this case, the junction

th(j-a)

temperature variation will not be monotonous.

Fig. 7: Thermal / electric analogy for simulation

Junction

P (losses)

Rth(j-c)

Rth(c-a)

Tamb

Tjunction

Case

Tcase

Ambiant

This analogy can be use to analyze any complex

thermal problem.

3/6

Page 4

APPLICATION NOTE

4. FROM THERMAL RUNAWAY TO PRODUCT

OPTIMIZATION

STMicroelectronics has developed a Schottky

family dedicated to the OR-ing function. This “L”

family demonstrates very low forward voltage in

orderto reduce conduction losses. Consequently,

the leakage current is relatively high.

For example, the “L15" family (V

=15V) is op-

RRM

timized for 3.3V, 5V and eventually 12V output

as OR-ing diode.

Due to the specific thermal runaway law of the

Schottky in OR-ing application, we can optimize

the device choice in order to improve the SMPS

efficiency, while keeping the risk of thermal runaway under control.

For example, let’s take a 3.3V 35A output, with a

STPS40L15C as OR-ing diode. The two diodes

have to be considered like connected in parallel:

Fig. 8: SMPS output synopsis

STPS40L15C

I = 35A (=2I )out fwd

V = 3.3Vout

P V I T V diodes in parallel

=× ⋅

2332

rev out rev j

V

=× ⋅

2

out

1

c C thermal cons

0 055

š

.

I C V per diode datasheet

100 3 3° ;. ( , )

()

rev

−

;. ( )

()

100

−°

cTj C

ICVe

100 3 3

°×

()

rev

()

;.

tan

(

t

)

Note that it is very important to use maximum reverse current values to evaluate reverse losses.

Actually, the worst case must be considered to

evaluate junction temperature in order to be sure

to avoid thermal runaway.

The limit of the thermal runaway criteria being defined by P

ture T

PVICVe

rev out rev

T

j

max

fwd=Prev

corresponds to P

j max

=× ⋅ ° ×

2 100 3 3

max

00

°+

=

1

137

=°

, the maximal junction tempera-

rev max=Pfwd

;.

P

fwd

×⋅ °

VI C V

()

out rev

C

()

1

In

2 100 3 3

c

C

:

−°

100

cT C

(

j

max

;.

The maximum junction temperature reachable in

forward mode before the risk of thermal runaway

occurs is so high, that we can consider a well

adapted device. This one will have a lower forward

voltage so a highest reverse current.

The same process can be applied to different

devices

)

P = 115.5Wout

In the forward mode, the forward losses can be

calculated as:

PVIRI

=× ⋅ + ⋅

2

fwd T fwd d fwd

()

0

.. (

=× +

2 018 8 010

.= 11 2

IId

()

fwd fwd

W

Theses losses decrease the global SMPS efficiency about 9.7%.

The risk of thermal runaway can be evaluated by

calculating the maximum junction temperature

that must not be reached in forward mode to

avoid reverse losses being higher than forward

losses, thus avoiding thermal runaway.

2

−

32

atasheet

STPS80L15C

Forward losses P

fwd

= 9.0W

The efficiency loss about 7.8%.

Maximal junction temperature before thermal runaway: T

jmax

= 127°C

STPS120L15

Forward losses: P

fwd

= 7.6W

The efficiency loss is about 6.6%

Maximal junction temperature before thermal run-

)

away: T

= 100.3°C

jmax

STPS20L15 (the 20A average current specified is

only indicative value)

Forward losses: P

= 16.1W

fwd

The efficiency loss is about 13.9%

Maximal junction temperature before thermal runaway: T

= 155.9°C

jmax

The comparison between the 4 parts considered

on the 3.3V 35A output can be summarized on the

following graph:

4/6

Page 5

APPLICATION NOTE

Fig. 9: Comparison between 4 parts, forward

losses, efficiency loss and T

Efficiency

Forward

16.1W

11.2W

9.0W

7.6W

losses

loss

13.9%

T = 156°Cjmax

9.7%

7.8%

6.6%

STPS L1520 STPS L15C40 STPS L15C80 STPS L15120

T = 137°Cjmax

.

jmax

V = 3.3V

I = 35A

T = 127°Cjmax

out

out

T = 100.3°Cjmax

Using the specific thermal runawaylaw,theSMPS

designer can optimize the OR-ing diode choice in

order to improve the global efficiency.

The risk of thermal runaway is controlled by limiting

the junction temperature during the forward mode

below the maximum value evaluated.

CONCLUSION

STMicroelectronicsisdeveloping “L” family diodes

dedicated to the OR-ing application. This family

shows very low forward voltage in order to reduce

conduction losses and to improve efficiency:

STPSXXL15, STPSXXL25, STPSXXL30,

STPSXXL45, and STPSXXL60.

With the very simple law presented, it becomes

straightforward to optimize devices choice by

evaluating the risk of thermal runway in Schottky

used in OR-ing function in SMPS.

This reliable and accurate law allows the optimization of the devices used in order to improve

converter efficiency while controlling the risk of

thermal runaway risk.

ANNEXE: EVALUATION OF MAXIMUM REVERSE CURRENT FROM DATASHEET

To evaluate the limit before thermal runaway, the

maximum value of the reverse current has to be

considered. Actually, this parameter is critical for

thermal runaway and the worst case must be considered.

To evaluate the maximum reverse current of a

power Schottky, take the typical value given in

figure. Apply the ratio between typical and maximal value given in the table (in the adapted V

and Tjfield). Finally, use the adapted formula to

get the expected junction temperature.

Example: STPS80L15C (twin diode in parallel)

under 3.3V @125°C

Figure 5 of the STPS80L15C datasheet gives the

typical value of the reverse current @100°C for

3.3V (per diode):

Fig. 5: Reverse leakage current versus reverse

voltage applied (typical values

IR(mA)

1E+3

1E+2

1E+1

220mA

1E+0

1E-1

0123456789101112131415

(100°C ; 3.3V) = 220mA

I

rev typ

Tj=100°C

Tj=75°C

Tj=25°C

3.3V

, per diode).

VR(V)

Thestatic electrical characteristics tablegives the

ratio between typical and maximum values (per

diode):

STATIC ELECTRICAL CHARACTERISTICS (per diode).

Symbol Parameter Tests conditions Min. Typ. Max. Unit

* Reverse leakage

I

R

current

Pulse test :*tp=380µs,δ <2%

Tj=25°CVR=5V 4 mA

Tj = 100°C 280 400

Tj=25°CV

Tj = 100°C 0.44 1.1 A

Tj=25°CV

Tj = 100°C 0.53 1.3 A

= 12V 11

R

= 15V 16 mA

R

R

5/6

Page 6

APPLICATION NOTE

ICV mA

()

rev

max

;.100 3 3 220

400

280

314°=×=

IT V I C V e

()

Thefollowingformula allows the calculation ofthe

reverse current in a power Schottky for every

junction temperature from a reference value:

ICVICVe

100

−°

cTj C

;. ;.

33 100 33

()( )

rev j rev

cCth

.

0 055

š

125 3 3 100 3 3

()()

rev rev

=° ×

1

−

ermal cons t

°=°×

;. ;.

A

12

=

.

tan

(

)

125 100

−

c

(

So, the global maximum reverse current value for

the two diodes of the STPS80L15C connected in

parallel under 3.3V @125°C is:

)

ICVA

125 3 3 2 12

()

rev

max

;. .

°=×

A

.

24

≈

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

ofuse of such informationnor for any infringementof patents or otherrights of third partieswhich may result fromits use. No licenseis granted

by implication or otherwise under anypatent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subjectto

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

6/6

Loading...

Loading...