Page 1

AN1499

APPLICATION NOTE

DESIGNING A LOW COST POWER BOARD FOR THE

ST92141 MOTOR CONTROL MCU WITHOUT USING IPMs

By Motor Control Competence Center

INTRODUCTION

Power Modules ha ve been i n use for t wenty year s in industr ial m otor drive a pplicati ons. F or

power stage designs, they give the advantages of compactness and good thermal behavior.

Over the last few years a new family of Power Modules, called Intelligent Power Modules

(IPM), have tried to take the integration of motor drive power stages a step further.

These IPMs target lower power and lower cost motor drive system s compared to those targeted by standard Power Modules.

However it is an open question whether these IPMs suit high volume and very co st-sensitive

applications, such as the household appliance market.

Figure 1. General System View

AN1499/0202 1/21

1

Page 2

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 INTELLIGENT POWER MODUL ES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 ADVANTAGES OF IPMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.1 Assembly cost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.2 Co mpo nent coun t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.3 Reduction i n time to market . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.4 Higher reliabi lity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.5 Product compactness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.6 Package ind uc tance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 DRAWBACKS OF IPMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Lead fram e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 He atsink planarity and stiffness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.3 Embedded gate drive & filter cost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.4 Ext ernal bootstrap diodes and temperature pro tection neede d . . . . . . . . . . . . . . . . . 5

1.2.5 Co mpo nent choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 AN ALTERNATIVE SOLUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 ADVANTAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Assem bly & m ounting cons iderations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Reduction i n time to market . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3 Reliability considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.4 Therm al management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.5 Gate drive optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 DRAWBACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 Co mpo nent coun t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.2 PCB connec tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 CONCLUSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 MECHANICAL DATA: ST92141-PLATFO RM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 CONTROL BOARD LAYOUT (ORCAD FILES AVAILABLE) . . . . . . . . . . . . . . . . . . 20

2/21

1

21

Page 3

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

1 INTELLIGENT POWER MODULES

These products integrate in a single transfer molded package, six IGBTs, six free wheeling diodes and the interfacing circuits needed to enable direct control from a microcontroller.

In their low cost version they do not include the front-end rectification diodes, nor do they have

a switch or diode for active power factor correction.

External circuits are still needed, such as bootstrap supplies, current sensing and filtering, and

auxiliary supply decoupling.

This applic ation n ote a naly zes the a dvant age s an d d raw back s o f this p ower in tegr ation ap proach with regard to the constraints of cost sensitive motor drives.

An alternative solution is proposed that fits better to appliance and large volume applications

in term of optimization and cost.

1.1 ADVANTAGES OF IPMS

Out of all the advantages that are claimed, the major ones seem to be the following:

– Less assembly cost

– Lower component count

– Reduction in time to market

– Higher reliability

– Product compactness

– Low inductance package

These are general claims that need to be confronted with reality.

1.1.1 Assembly cost

Assembling an IPM requires placing it on the PCB, wave soldering and later on fixing the heatsink with s crew s. Th ese o perat ions ar e inde ed less exp ensive th an ass embli ng six d iscre te

components. You should note how ever that if an active power fac tor corrector is needed, external discrete power components are required.

1.1.2 Component count

This is a clear advantage because nine components are replaced by each IPM. However the

need for microcontroller and passive component assembly remains and IPMs do not r em o ve

any major manufacturing step.

1.1.3 Reduction in time to market

Layout of IGBT and MO SFET gate drives requires special expertise. U sing an IPM does not

require all this expertise, but a good understanding of EMI and parasitic inductance effects is

still strongly recommended!

3/21

2

Page 4

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

Assuming this expertise is available, the estimated saving will be hardly be more than the time

it takes to have a coffee break!

1.1.4 Higher reliability

From a silicon point of view , there are still about 1 5 dice inside the modu le with th eir own

MTBFs rela ted to j unction te mpe rature as well as m ore than 40 wire bo nds. So th e syst em

MTBF may increase because the connection and assembly count decreases. However it may

decrease if the heatsink is not perfectly flat below the whole IPM surface.

1.1.5 Product compactness

When just com paring power switches, IP Ms br ing c omp actnes s. But when ta lking ab out the

whole system, the difference i s negligible. Passive c omponents , heatsink, PCB and c onnectors are by far the most bulky parts.

1.1.6 Package inductance

The only circuit area where IPMs reduce the parasitic inductance is located between the gate

drivers and the pow er sw itches. T his is true for the h igh side g ate dri vers but not f or the low

side drivers.

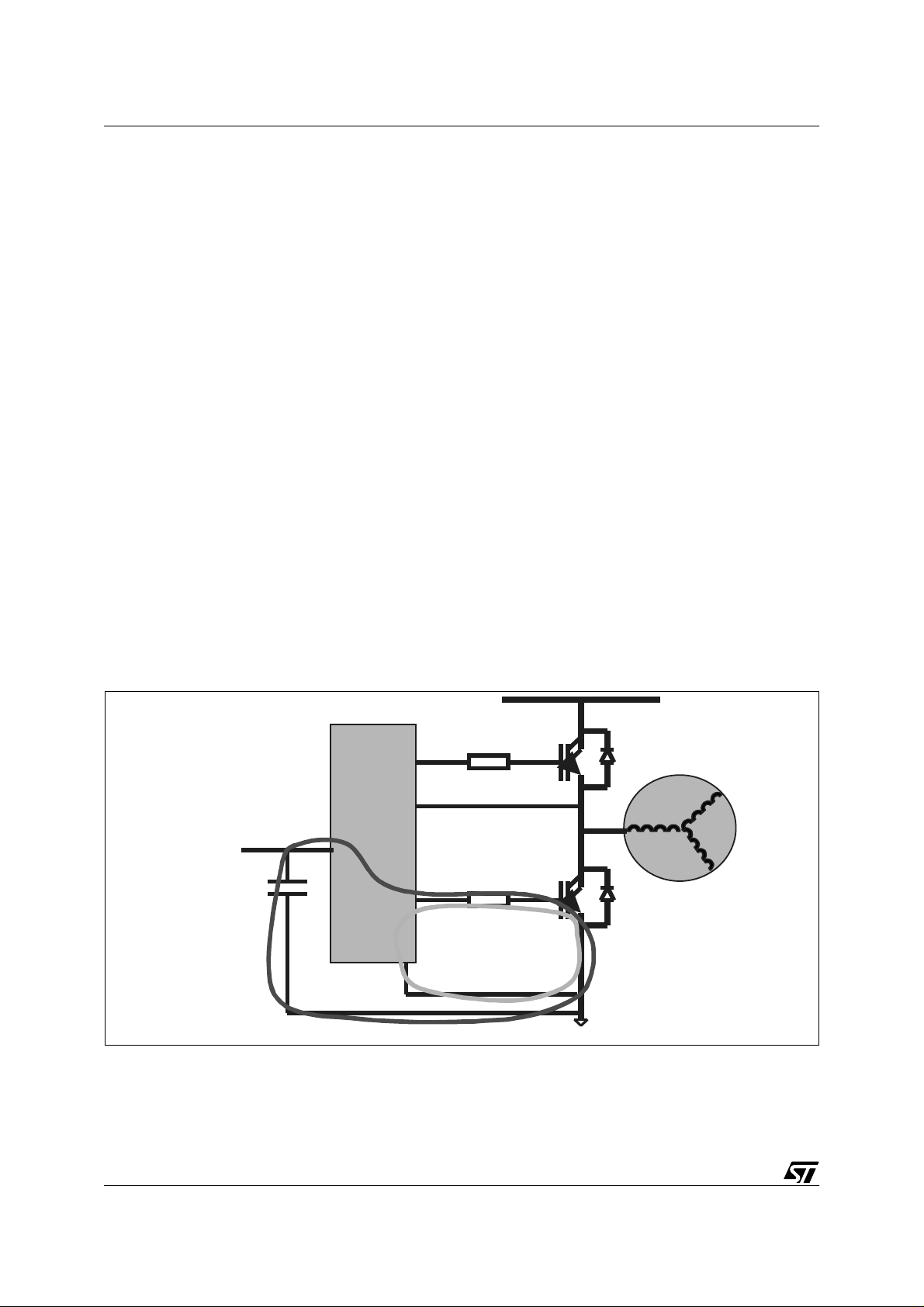

Figure 2 shows that during turn-on, the low side gate drive current loop (B) is not internal to the

module but goes outside. In this case, IPMs do not have a significant advantage over discrete

solutions.

Figure 2. Low side gate drive current loop

Half

Bridge

driver

Vcc

A

B

4/21

Page 5

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

1.2 DRAWBACKS OF IPMS

Counterbalancing the advant ages listed above , IPMs have m ajor draw backs that m ake their

use in cost sensitive applications rather questionable.

Let’s review these drawbacks:

1.2.1 Lead frame

Due to manufacturing constraints, an IPM has leads on both sides of the pac kage. This means

that the PCB must be installed parallel to the pack age. So the heatsink must have its contact

base parallel to th e IPM and th e PCB. Whe n you are lo oking for a v ery cheap so lution, this

makes the choice of heatsink difficult.

1.2.2 Heatsink planarity and stiffness

Inside the IPM, power switches are soldered directly on a long and thin lead frame. Then this

lead frame is fully molded for isolation between the heatsink and the active parts. As a result,

these IPMs have a low stiffness and need to be assembled on a good quality heatsink to avoid

internal cracks. As a consequence, cheap heatsinks made of metal sheet are not recommended. This may lead to additional cost.

1.2.3 Embedded gate drive & filter cost

One sensitive parameter, in terms of optimizing the motor drive cost, is gate drive impedance.

By adjusting this imped anc e properly, you can find th e ri ght c ompr omis e b etwee n f ilter cos t

and heatsink cost. As IPMs do not give access to the gate drive impedance, you cannot adjust

the dV/dt commutation which may lead to additional filter cost.

1.2.4 External bootstrap diodes and temperature protection needed

Most IPMs available today do not hav e over-temperature protec tion. This requires additional

external circuits.

As bootstrap diodes are not integrated in the module, they need to be added externally. This

leads to additional cost.

1.2.5 Component choice

Needless to say the choice of IPMs today is very scarce and does not match the broad range

of power switch and interface circuits. This is a real drawback when cost is all-important.

5/21

Page 6

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

2 AN ALTERNATIVE SOLUTION

The basic idea behind the IPM solution consists of reducing the component count, simplifying

assembly and making board layout easier. However it has been shown that the cost benefit is

not always easy to determine when you calculate at system level.

Another way to split the system consists of grouping all the system SMD components on a

small size FR4 board, called the Control Board, and keeping all the power sw itches and discrete components on a mother board called the Power Board.

Figure 5, Figure 6 & Figure 7 show an AC motor drive application using this partitioning. An ex -

ample layout and parts list are given in Appendix 2.

It is worthwhile to review the advantages and drawbacks of this new partitioning.

2.1 ADVANTAGES

2.1.1 Assembly & mounting considerations

Figure 6 shows a contr ol bo ard s chem atic im plem enting a m icrocon troller, i ts pe ripheral c ir-

cuits and three High Voltage Integrated Circuits for interfacing directly to the Power Board

schem atic show n in Figure 7. This microcontroller is dedicated to AC motor control and is

housed in a shrink SO34 package (refer to the parts list in Appendix 2 and ST92141 and

L6386 datasheet on http:\\www.st.com).

The size of this type of control board is about 26mm by 87mm. This makes use of available

FR4 hardware . This board can be plugged into the Power Boar d next t o the discrete power

switches. T he Power Board layout is very easy and simple, even if low cost materials like

CEM1 are used. This makes the size of the Power Board smaller even if single side copper is

used.

The total volume of the Control Board and the power switches is very compact.

Moreover, the discrete Power switches can fit many different heatsink configurations, parallel

or perpendicular, with no planarity and stiffness constraints.

Another ad vantag e co mes f rom the s olderi ng proces s d ifferen ti ation: SM D com pon ents are

soldered using a reflow process, discrete components go through solder waves. This improves the production yield.

Finally, if an active power factor is needed, it is easy to add another switch to the power stage.

2.1.2 Reduction in time to market

The physical spli t between co ntrol circuits and power parts make the system easy to layo ut

and quick to debug. T he system power r ange or the input front end can be adapted w ithout affecting the Control Board and v ice versa. Any change of microcontroll er package or i ts peripheral circuits does not interfere with the power stage.

6/21

Page 7

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

In other words, the same Control Board can fit different Power Boards.

This makes the first design shorter and the future re-design even faster.

2.1.3 Reliability considerations

The reflo w proces s u s ed to sold er the Co nt rol B oa rd is prov en to be m ore rel iable t han the

wave process.

The connection between both boards is done during the wave process. Figure 5 shows a typical implementation and Appendix 1 gi ves the results of the v ibration test performed on this assembly.

2.1.4 Thermal management

Assembling the d iscr ete comp onen ts b y c lips e nab les the d issip ation to b e spre ad ov er t he

whole heatsink surface. This avoids concentrating the losses on a small ar ea and allows you

to use cheap heatsink technology made of metal sheet.

2.1.5 Gate drive optimization

Figure 8 shows the influence of the gate drive impedance on the conducted noise. As the

whole gate drive is available on the Control Board, it is easy to adapt the noise level according

to the filter attenuation at any time. This noise level optimization can save time and cost.

Moreover the Control Board design allows t he use of ad vanced High Voltage Integrated Circuits that integrate a bootstrap diode and comparators (refer to L6386 on http:\\www.st.com).

The is true for power switch selection (see the fully insulated TO220 products like

STGP7NB60HDFP on http:\\www.st.com).

2.2 DRAWBACKS

The main drawbacks relate to:

2.2.1 Component count

Compared to the IPM solution, both the Control Board and the Power Board each implement

about six components more.

2.2.2 PCB connections

The double sided Control Board soldering totals 68 contacts that are processed during wave

soldering.

7/21

Page 8

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

3 CONCLUS ION

This comparison between two different system partitioning methods has shown that the Intelligent Module approach is not the most flexible and cheap solution when designing c ost sensitive motor control applications.

The alternative solution that is presented gives several advantages that are decisive when

cost is the overriding factor:

– Access to low cost heatsink technology and better thermal management

– Use of different processes for SMD and through-hole components to improve the production

yield

– Fexibility to adapt the Power Board with no impact on the Control Board and vice versa

– Access to gate drive impedance to optimize the EMI level at any time

– Choice of a large portfolio of interface ICs and power switches

For further details about the Control Board hardware and software features, refer to AN1498.

Figure 3. Control Board high voltage in ter facing side

8/21

Page 9

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

Figure 4. Control Board microcontroller side

Figure 5. Control Board plugged into the Power Board next to the discrete parts

9/21

Page 10

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

Figure 6. Typical Control Board circuit for AC motor control applications

+15V

C46

100nF

84

IC5A

+5V

7$&+20(7(5

J4

J6

C2

100nF

J10

J11

J13

J15

J16

J19

J20

J22

J24

J25

J27

J28

J34

R10

100K

C11

C10

10nF

10nF

R19

100K

R28

R29

100K

100K

C24

C23

10nF

10nF

R38

100K

100K

R1

10K

BAS16

10nF

R39

C25

D1

R4

10K

D2

BAS16

+5V

R2

10K

Q7

BC817-25

C3

100nF

+5V

R11

R12

100K

100K

C13

C12

10nF

10nF

R20

R21

100K

100K

+5V

R31

R30

100K

100K

C26

C27

10nF

10nF

R41

R40

100K

100K

+5V

R6

1

100R

R13

100K

C14

47pF

R22

100K

R32

100K

10nF

R42

100K

S

2

Q

3

W

4

VSS

R14

100K

R23

100K

R33

100K

R34

100K

C29

C28

10nF

R43

R44

100K

100K

TP8

C38

1uF

6&+(0$&$57(67(1*

Rq: All footprint components are 0603 packages except when noticed

U2

M95040

DATA

+5V

100nF

BAS16

HOLD

R45

220R

VCC

C33

D3

CK

1M

1

LM358D

8

7

6

5

C31

10nF

R49

U1A

+5V

C39

100nF

+5V

1

VDD

2

P3.0/MOSI

3

P3.1/MISO

4

P3.2/WKUP3/SCK

5

P3.3/SSN

6

P3.4/EXTRG/OCMPB

7

PS3.5/OCMPA/INT6

8

P3.6/ICAPA/WKUP2

9

NC

10

AVDD

11

AVSS

12

P5.7/AIN7/INTCLK

13

P5.6/AIN6/CK_AF

14

P5.5/AIN5

15

P5.4/AIN4

16

P5.3/AIN3/WDOUT

17

P5.2/AIN2/INT0/WDIN

+5V

84

3

+

2

-

R50

100K

R53

750R

1%

Rshunt

J1

LM358D

3

+

1

2

-

R52

33.2K

1%

C44

1uF

16V

C43

10nF

C15

470nF

TACHO

VPP_TEST

WKUP1/ICAPB/P5.0

WKUP0/NMI/P5.1

RESETN

OSCOUT

OSCIN

IC3

+5V

ST92T141K4M6

ST92141-Eng2

Rshunt

J33

C45

1nF

R54

47K

VSS

VH

VL

WH

WL

UH

UL

NC

VSS

VDD

C32

470nF

IC5B

LM358D

5

+

7

6

-

R56

1.5K

1%

R55

1.5K

D26

1%

BAS16

J3

J2

+5V

R17

10K

TP2

TP6

TP4

TP5

TP3

TP1

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

HSIC1

+5V

LSIC1

HSIC2

LSIC2

HSIC4

R35

LSIC4

100K

C21

470nF

XT1

CSTCC-MG 5MHz

(XT_CSTCCMG)

+5V

R63

390R

This drawing may not be reproduced to a third party unless permission is obtained in writing from ST MICROELECTRONICS

+15V

C5

470nF

25V

R18

1K

+15V

C16

C19

10nF

470nF

25V

TP7

+15V

C34

470nF

25V

C20

1nF

R26

2.7K

C35

1nF

R48

R80 6.8K

LSIC1

C6

1nF

LSIC2

HSIC2

LSIC4

HSIC4

HSIC1

2.2nF

820R

IC1 L6386D

1

2

3

4

5

6

7

R9

0R

1

2

3

4

5

6

7

C17

1

2

3

4

5

6

7

C36

1nF

1%

1%

C1

C40

470nF

470nF

16V

16V

14

LIN

VBOOT

SD

HVG

HIN

OUT

VCC

NC

DIAG

NC

CIN

LVG

GND

GND

IC2 L6386D

LIN

VBOOT

SD

HVG

HIN

OUT

VCC

NC

DIAG

NC

CIN

LVG

GND

GND

R27

1K

IC4 L6386D

LIN

VBOOT

SD

HVG

HIN

OUT

VCC

NC

DIAG

NC

CIN

LVG

GND

GND

R51

1%

4.7K

Title:

Organisation name: Approved by:

Size

Custom

Date: Sheet

D20

13

BAS16

12

11

10

9

8

D21

BAS16

C8

C41

470nF

470nF

16V

16V

14

13

12

11

10

9

8

14

13

12

11

10

9

8

D22

BAS16

D23

BAS16

C22

C42

470nF

470nF

16V

16V

D24

BAS16

R86

82R

67(1*

MCCC Rousset

Document Number Rev

<Doc>

34 pins connector

44 spaces used

1.905mm pin to

pin spacing

100pF

100pF

100pF

100pF

C4

100pF

C30

C37

100pF

220R

220R

C7

220R

C9

220R

C18

220R

220R

R5

R8

R16

R25

R37

R47

Drawn by:

BC807-25

Q1

remove 2 pins to

keep isolation

BC807-25

Q2

remove 2 pins to

keep isolation

BC807-25

Q3

remove 2 pins to

keep isolation

BC807-25

Q4

BC807-25

Q5

BC807-25

Q6

J-M RAVON

<OrgAddr2>

11Friday, November 16, 2001

of

board edge

remove 2 pins to

keep isolation

remove 2 pins to

keep isolation

R3

82R

R81

82R

R7

82R

R82

82R

R15

82R

R83

82R

R24

82R

R84

82R

R36

82R

R85

82R

R46

82R

D25

BAS16

J5

J7

J8

J9

J12

J14

J17

J18

J21

J23

J26

J29

J30

J31

J32

10/21

Page 11

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

Figure 7. Typical Power Board circuit fo r A C m otor control applications

R73

0RWRU

3RZHU

,&

H3

1

2

3

4

H5

1

2

:DWHU/HYHO

33K

NTC1

4.7R

12

TP26

TP23

12

TP22

6SHHG5HIHUHQFH

43

43

TP9

R76

10K

J17

7DFKR0HWHU

J16

EI48

L3

23

D40

-+

4

1

STBR408

0.047R

+5V

J2

*

R75

4.7K

QRWPRXQWHG

12

43

IC8

SFH617A

J14

J13

TP25

TP24

J15

1

2

3

SW1

1K2

1

2

3

SW2

1K2

J8

H6

J11

AVDD

1

2

1

H7

This drawing may not be reproduced to a third party unless permission is obtained in writing from ST MICROELECTRONICS

R74

+5V

3RVLWLRQ6HQVRU

2

C70

220uF

385V

STTA106

D43

D41

D42

BZX55C15

C73

2.2uF

1 2

25V

C75

22nF

1N4148

J20

4

C72

9''

10uF

25V

0.23V

3

)%

t°

LM335Z

+

1 2

U2

S1

AVDD

'5$,1

SET

RES

6285&(

TP11

D44

STTA106

8

1

J6

X1

X2

567

IC6

VIPER12ADIP

1mH

2

GREEN LED

J3

Trimmer 50K

X3

X4

L2

D47

P1

TSL1112

R79

1.5K

J5

Trimmer 50K

+15V

BZX85C16

P2

J30

J4

J12

J9

J19

TP3

D46

12

1

C71

BZX85C5V1

25V

100uF

D45

1 2

J33

J34

J31

J32

J28

J29

J26

J27

J25

J23

J24

J21

J22

TP4

+5V

IC7

L78L05ACZ

3

Vin

Vout

GND

2

J1

STGP7NB60HDFP

T1

STGP7NB60HDFP

T2

2XTP15

STGP7NB60HDFP

T3

STGP7NB60HDFP

T4

STGP7NB60HDFP

T5

STGP7NB60HDFP

T6

:$6+(53/$7)250(1*

Title:

Organisation name:

Size

Document Number

<Doc>

Date: Sheet

J7

TP14

R72

0.047R

2W

MCCC Rousset

R70

1M

R71

12K

2XTP5

2XTP17

2XTP7

C74

47nF

400V

2XTP19

J18

Drawn by:

Approved by:

11Wednesday, November 21, 2001

H1

1

2

3

4

5

H2

1

2

2XTP10

2XTP2

F1

5A Slow

SUP FUSE 3527

TP27

R77

4.7K

29

'$7

IC9

SFH617A

&/.

9

R78

4.7K

SFH617A

IC10

J10

J-M RAVON

<OrgAddr2>

of

Rev

11/21

Page 12

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

Figure 8. Conducted noise depending on gate drive impedance

On the left: Rg = 220R on the right: Rg = 82R

12/21

Page 13

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

APPENDIX 1: Vibration test results of Control Board and Power Board assembly

VIBRATIONS, SINUSOIDAL

(Stantard: IEC 68-2-6, test Fc)

Electrical limits were tested on two modules after a Vibrations, sinusoidal as below

specified:

Puma Sine Test Synopsis

Test Results:

Reason For Shutdown: Normal Test Completion

Elasped Test Time: 0002:052:054

Elasped Sweeps: 20.00

Remaining Sweeps: 0.00

Points Per Sweep: 800

Test Range: 5.00(Hz) to 2000.00(Hz)

Control Parameters

Control Strategy: Average

Filter Type: Proportional

Filter Specification: 80.00%

Sweep Mode: LOG

Sweep Rate: 1.00 (Oct/Min)

Shaker Limits

Acceleration: 45.0000

Velocity: 59.0551

Displacement: 0.9843

Velocity: 12.0000

Symetric Limits: Yes

Resonance Search And Dwell Setup

Max Resonances: 10

Hysteresis: 3

Minimum Q Value: 1.00

Smoothing: Low

Channel Number: Control

Profile Settings

Status Frequency Type Acceleration Velocity Displacement

#00 On 5.0 Displacement 0.0755 0.023562 1.500000 3.0 3.0 6.0 6.0

#01 On 57.6 Displacement 10.0001 0.271203 1.500000 3.0 3.0 6.0 6.0

#02 On 2000.0 Acceleration 10.0000 0.007804 0.001242 3.0 3.0 6.0 6.0

Sample N. Visual Inspection

At 25 C (Before and after test)

Lo

Alarm

Electrical Test

Hi

Alarm

Lo

Abort

Hi

Abort

1 Passed Passed

2 Passed Passed

13/21

Page 14

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

Figure 9. Sinusoidal profile

14/21

Page 15

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

ANNEX 2: Contro l Board parts list

Bill Of Materials October 17,2001 11:46:37P age1

Item Quantity Re ference Value Voltage % Footprint

1 6 C1 470nF 16V X7R 0805

C8 470nF 16V X7R 0805

C22 470nF 16V X7R 0805

C40 470nF 16V X7R 0805

C41 470nF 16V X7R 0805

C42 470nF 16V X7R 0805

2 5 C2 100nF Y5V 0603

C3 100nF Y5V 0603

C33 100nF Y5V 0603

C39 100nF Y5V 0603

C46 100nF Y5V 0603

3 6 C4 100pF 0603

C7 100pF 0603

C9 100pF 0603

C18 100pF 0603

C30 100pF 0603

C37 100pF 0603

4 3 C5 470nF 25V Y5V 0805

C19 470nF 25V Y5V 0805

C34 470nF 25V Y5V 0805

5 5 C6 1nF 0603

C20 1nF 0603

C35 1nF 0603

C36 1nF 0603

C45 1nF 0603

6 11 C10 10nF 63V 0603

C11 10nF 63V 0603

C12 10nF 63V 0603

C13 10nF 63V 0603

C23 10nF 63V 0603

C24 10nF 63V 0603

C25 10nF 63V 0603

C26 10nF 63V 0603

C27 10nF 63V 0603

C28 10nF 63V 0603

C29 10nF 63V 0603

7 1 C14 47pF 63V 0603

8 3 C15 470nF Y5V 0805

C21 470nF Y5V 0805

C32 470nF Y5V 0805

15/21

Page 16

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

Item Quantity Re fe rence Value Voltage % Footprint

9 3 C16 10nF 0603

C31 10nF 0603

C43 10nF 0603

10 1 C17 2.2nF 0603

11 1 C38 1uF X7R 0805

12 1 C44 1uF 16V Y5V 0805

13 10 D1 BAS16 SOT-23

D2 BAS16 SOT-23

D3 BAS16 SOT-23

D20 BAS16 SOT-23

D21 BAS16 SOT-23

D22 BAS16 SOT-23

D23 BAS16 SOT-23

D24 BAS16 SOT-23

D25 BAS16 SOT-23

D26 BAS16 SOT-23

14 3 IC1 L6386D SO-14

IC2 L6386D SO-14

IC4 L6386D SO-14

15 1 IC3 ST92T141K4M6 SO-34/P1.016

16 2 U1 LM358D SO-8

IC5 LM358D SO-8

17 6 Q1 BC807-25 SOT-23

Q2 BC807-25 SOT-23

Q3 BC807-25 SOT-23

Q4 BC807-25 SOT-23

Q5 BC807-25 SOT-23

Q6 BC807-25 SOT-23

20 1 Q7 BC817-25 SOT-23

21 4 R1 10K 0603

R2 10K 0603

R4 10K 0603

R17 10K 0603

22 12 R3 82R 0603

R15 82R 0603

R24 82R 0603

R36 82R 0603

R46 82R 0603

R81 82R 0603

R82 82R 0603

R83 82R 0603

R84 82R 0603

R85 82R 0603

16/21

Page 17

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

Item Quantity Reference Value Voltage % Footprint

R86 82R 0603

23 7 R5 220R 0603

R8 220R 0603

R16 220R 0603

R25 220R 0603

R37 220R 0603

R45 220R 0603

R47 220R 0603

24 1 R6 100R 0603

25 1 R9 0R 0603

26 26 R10 100K 0603

R11 100K 0603

R12 100K 0603

R13 100K 0603

R14 100K 0603

R19 100K 0603

R20 100K 0603

R21 100K 0603

R22 100K 0603

R23 100K 0603

R28 100K 0603

R29 100K 0603

R30 100K 0603

R31 100K 0603

R32 100K 0603

R33 100K 0603

R35 100K 0603

R38 100K 0603

R39 100K 0603

R40 100K 0603

R41 100K 0603

R42 100K 0603

R43 100K 0603

R44 100K 0603

R50 100K 0603

27 2 R27 1K 0603

R18 1K 0603

28 1 R26 2.7K 0603

29 1 R48 820R 1% 0603

30 1 R49 1M 0603

31 1 R51 4.7K 1% 0603

32 1 R52 33.2K 1% 0603

33 1 R53 750R 1% 0603

17/21

Page 18

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

Item Quantity Reference Value Voltage % Footprint

34 1 R54 47K 0603

35 2 R56 1.5K 1% 0603

R55 1.5K 1% 0603

36 1 R63 390R 0603

37 1 R80 6.8K 1% 0603

38 6 TP1 TPshort PAD

TP2 TPshort PAD

TP3 TPshort PAD

TP4 TPshort PAD

TP5 TPshort PAD

TP6 TPshort PAD

39 2 TP8 TP0 PAD

TP7 TP0 PAD

40 1 U2 M95040 SO-8

41 1 XT1 CSTCC-MG 5MHz (XT_CSTCCMG)

18/21

Page 19

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

4 MECHANICAL DATA: ST92141-PLATFOR M

Figure 10. Mechanical Data

19/21

Page 20

DESIGNING A LOW COST POWER BOARD F OR ST92141 MOTOR CONTROL MC U ...

5 CONTROL BOARD LAYOUT (ORCAD FILES AVAILABLE)

Figure 11. Microcontroller side

C21

C32

XT1

R35

C31

R32

R42

R41

C27

TP8

R31

R30

R29

R28

R14

R40

R39

R38

R23

C26

C25

C24

C23

U1

C33

R45

D3

R50

R49

C38

C14

R82

ST92141-ENG3

C41

R83

R84

C42

R85

D24D23D22D21

Figure 12. High voltage interfacing side

TP5TP6

C15

R17

Q7

R12

R13

R6R4R2

C2

R1

D2

D1

R22

R21

C3

C13

C12

TP1TP2

TP3TP4

IC3

R34

R33

R11

R10

R44

R43

R20

R19

C10

C11

C29

C28

C44

R54

R56

C46

D26

ST92141-ENG3

TP7

C20

R18

R16

R9

C8

R8

R7

C9

Q3

R86

D25

C34

C36

C35

R48

R51

R46

R47

Q6

C22

IC4

C30

R37

R24

Q5

R36

C37

C43

R80

U2

C39

R63

C19

C17

R26

C16

R27

IC2 IC1

C18

R15

R25

Q4

1

C5

C6

C1

R5

R3

C7

Q2

C4

Q1

20/21

Page 21

DESIGNING A LOW COST POWER BOARD FOR ST92141 MOTOR CONTROL MCU ...

“THE PRESENT NOTE WHICH IS FOR GUIDANCE ONLY AIMS AT PROVIDING CUSTOMERS WITH INFORMATION

REGARDING THE IR PRO DUCT S IN OR DER FO R THEM TO SAV E TIME . AS A RES ULT, STMIC ROEL ECTR ONI CS

SHALL NOT BE HELD LIABLE FOR ANY DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES WITH RESPECT TO

ANY CLAIMS ARISING FROM THE CONTENT OF SUCH A NOTE AND/OR THE USE MADE BY CUSTOMERS OF

THE INFORMATION CONTAINED HEREIN IN CONNEXION WITH THEIR PRODUCTS.”

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or p atent rights of STMi croelectr oni cs. Spec i fications mentioned i n this publicatio n are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi t hout the exp ress written approval of STM i croelectronics.

The ST logo is a registered trademark of STMicroelectronics

2002 STMicroelectronics - All Rights Reserved.

STMicroelectronics Group of Compan i es

http://www.s t. com

Purchase of I

2

C Components by STMicroelectronics conveys a license under the Philips I2C Patent. Rights to use the se components in an

2

C system i s granted pro vided that th e sy stem confo rm s to the I2C Standard Specification as defined by Philips.

I

Australi a - Brazil - Canada - China - Fi nl and - France - Germany - Hong Kong - Ind i a - Is rael - Ital y - J apan

Malaysi a - M al ta - Morocco - Singapore - Spain - Sw eden - Switz erland - Unit ed Kingdo m - U. S. A.

21/21

Loading...

Loading...