AN1485

APPLICATION NOTE

MDmesh™ PERFORMANCE EVALUATION IN A

CONTINUOUS MODE PFC BOOST CONVERTER

G. Belverde - M. Melito - A. Raciti - M. Saggio - S. Musumeci

1. ABSTRACT

A new high voltage MOSFET structure is presented which results in static as well as dynamic

performances far ahead conventional Power MOSF ET devices. The impact of the particular features of

the device is analyzed and quant ified in a c ase stu dy regarding a DC-DC boost conv erter, which is used

in a power factor corrector (PFC) converter. Results obtained from the analysis of the electrical and

thermal behavior of the component in the specific are discussed.

2. INTRODUCTION.

Standard technology for high voltage suited Power MOSFETs has been dramatically improved, thus the

physical limit in terms of reduction of the device’s on-state resistance is going to be reached. In fact, such

a device parameter is strongly affected by the drain resistivity value, which is designed according to the

requirements of the high v oltage blocking capability. Recently, an innovative concept of Power M OS FET

design has been proposed that is able to enhance t he dev ice’s performance [1 , 2]. In these new devices

the charge balance makes the electric field constant over the whole drain volume in spite of t he low

resistivity in this conducting region. In breakdown conditions the electric field has a value almost equal to

the critical one for silicon.

In this paper the main issues of process technology are shortly recalled and discussed. The static and

dynamic characteristics are shown aiming to evaluate the advantages of the new device in comparison to

standard Power MOSFETs having both the same rated voltage and current carrying capability. Finally,

the evaluation of the performance is foc used on in a spec ific application, in particular in a bo ost-based

power factor corrector (PFC) converter.

3. TRENDS ON POWER MOSFET (MDmesh™) DEVICE TECHNOLOGY .

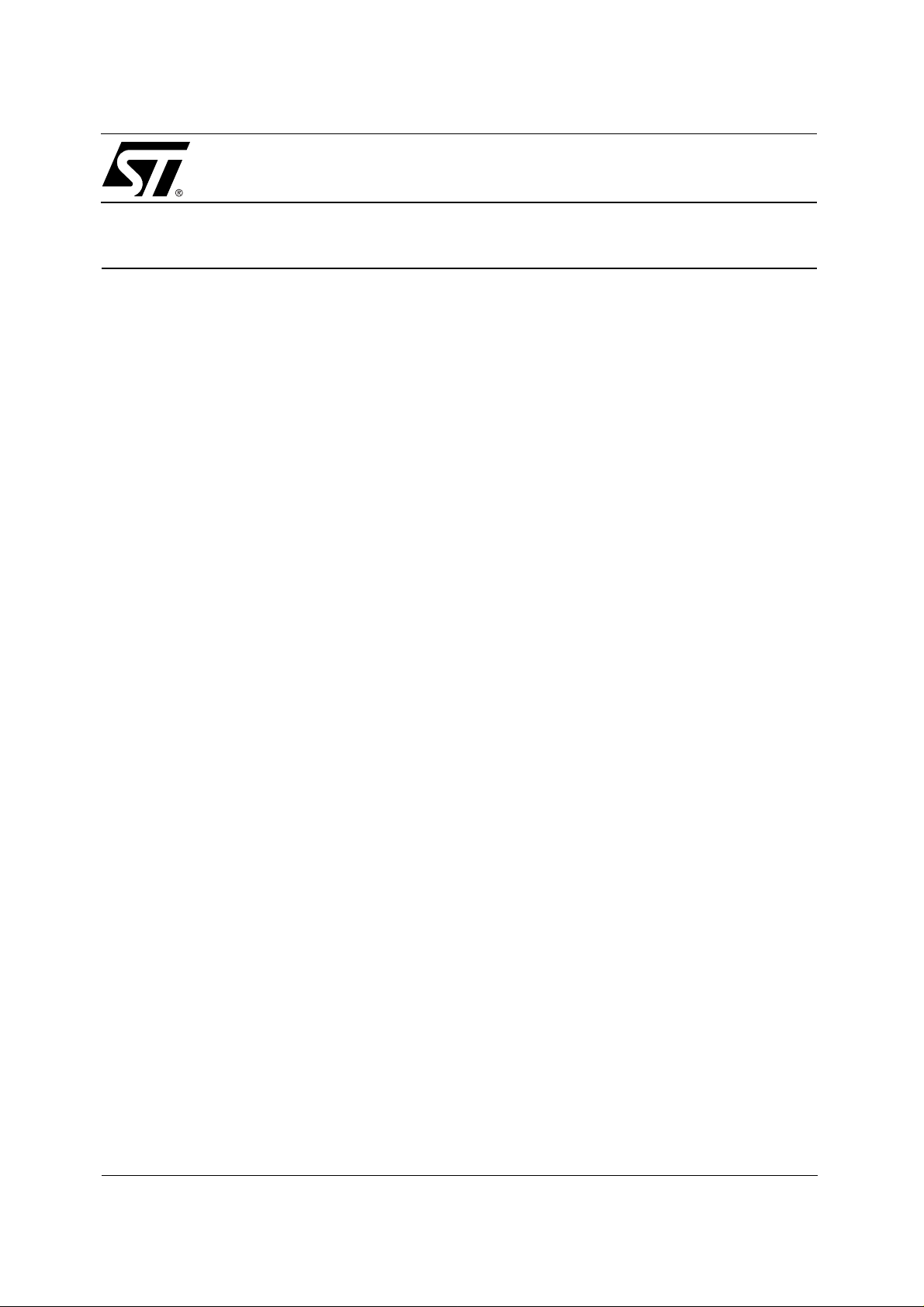

A revolutionary three-dimensional design of the drain device volume is at the basis of the MDmesh™

MOSFET device. The extensio n of the top strip layout to the whole drain volume, by p-doped column

insertion under device stripes, allows a strong resistivity reduction of the c onduction n-doped layer and

an impressive decrease of the device’s on-state resistance when com pared to a convent ional MOSFE T

[1]. The cross section of an MDmesh™ device is depicted in figure 1, where both the strip layout and the

column insertion under the de vice stripes are shown. As a consequence of this approach, the known

theoretical limit of performanc e for vertical Power MOS FET devices decreases. I n fact, the MDmesh™

MOSFET overcomes this limit allowing a mass production of devices with improved perform ance and

reduced area. For example, a 500V MDmesh™ MOSFET is almost three times smaller than a

conventional MOSFET having the same blockin g voltage.

November 2001

1/14

AN1485 - APPLICATION NOTE

SUBSTRATE

DRAIN

10

Vgs=10V

Figure 1: Three-Dimensional Cross Section Of MDmes h™ Device

N-SOURCE

P-MESH

GAT E

FINGER

BACK METAL

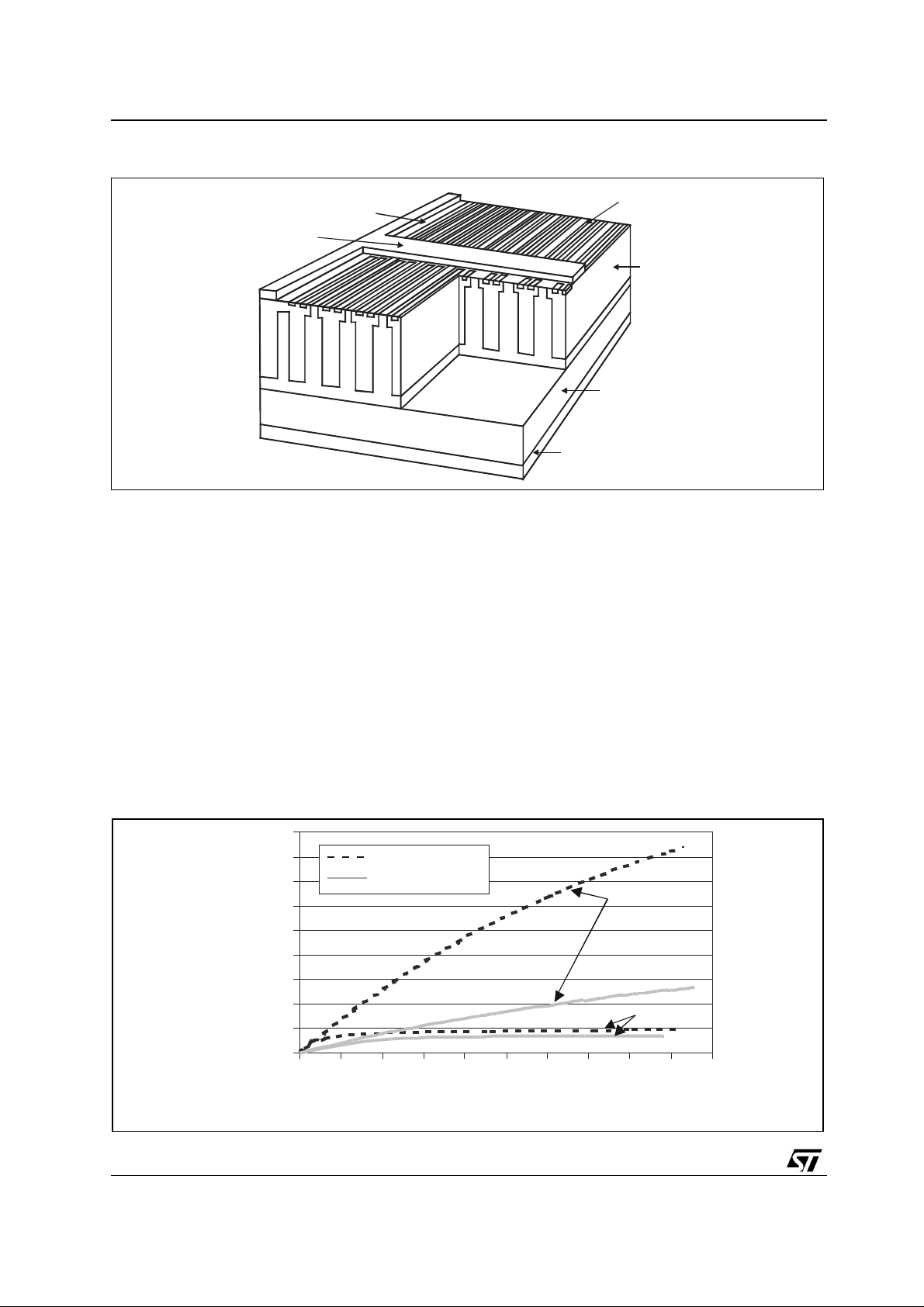

The static output characteristics o f a n M Dme sh ™ MO SF ET i n c om parison to a s tandard dev ice wit h the

same silicon area a re reported in figure 2. Moreover, simulation anal ysis and theoretical consi derations

show that in MDmesh™ t echnology the device’s on-state resistance increases linearly as funct ion of t he

breakdown voltage, according to the traces shown in figure 3. The direct consequenc e of this result is

that the extension of the M Dmesh™ MOSFETs towards higher blocking voltage values will continually

increase the advantages of this technology . The fabrication of a 1000V MDmesh™ MOSFET will require,

as expected from the design, a silicon area seven (7) times smaller than a conventional M OSFET with

the same on-state resistance and blocking voltage capability. This will cause a package reduction and a

major improvement in any appli cation based on these devices, as c onsequenc e of the st rong reduction

obtained on volume and weight of the board. The extension to very high blocking voltage of MDmesh™

MOSFETs will represent a real revolution in high voltage converter applications.

Figure 2: Static Output Characteristics (I/V Curves) Of An MDmesh™ (STP12NM50) And A

St andard MO S FET Having Equal Si l icon Area

18

16

14

MDmesh™

Std Technology

12

10

Ids (A)

8

6

4

Vgs=6V

2

0

0123456789

Vds(V)

2/14

AN1485 - APPLICATION NOTE

Figure 3: Standard MOSFET and MDmesh™ Depend ence Of On-State Resistance As A Function

Of The Breakdown Voltage

1000

1000

t

t

i

i

m

m

i

i

l

l

l

l

a

a

e

e

d

d

i

i

n

n

o

o

c

c

i

i

l

l

i

i

S

S

D

D

M

M

T

T

E

E

]

]

2

2

o

o

i

100

100

Ron Area [mΩ cm

Ron Area [mΩ cm

10

10

100 1000

100 1000

i

t

t

n

n

e

e

v

v

n

n

o

o

C

C

y

y

g

g

o

o

l

l

o

o

hn

hn

c

c

e

e

t

t

l

l

a

a

n

n

F

F

S

S

O

O

M

M

Breakdown Voltag e [V]

Breakdown Voltag e [V]

Another important feature obtained b y the proposed approach reduction of the intrinsic c apacitances [3],

in comparison to the one of a more t raditional device, as seen in table 1. In switch m ode power supply

(SMPS) and PFC applications the reduction of the intrinsic parasitic capacitance allows a com mutation

time decrease, thus enabling the increase of the switching frequency. As known, this will result in

important reduction of both volume and cost of the reactive components used to filter the output and/or

electrical quantities.

Table 1. Main Characteristics Comparison

Part Number BV

DSS

[V]

R

DS(on)

[Ohm]

@ 25°C

Ciss

[pF]

Coss

[pF]

Crss

[pF]

Package

Standard STW15NB50 >500 0.36 2600 330 40 TO-247

MDmesh™ STP12NM50 >500 0.38 1000 160 25 TO-220

4. SWITCHING CHARACTERISTICS.

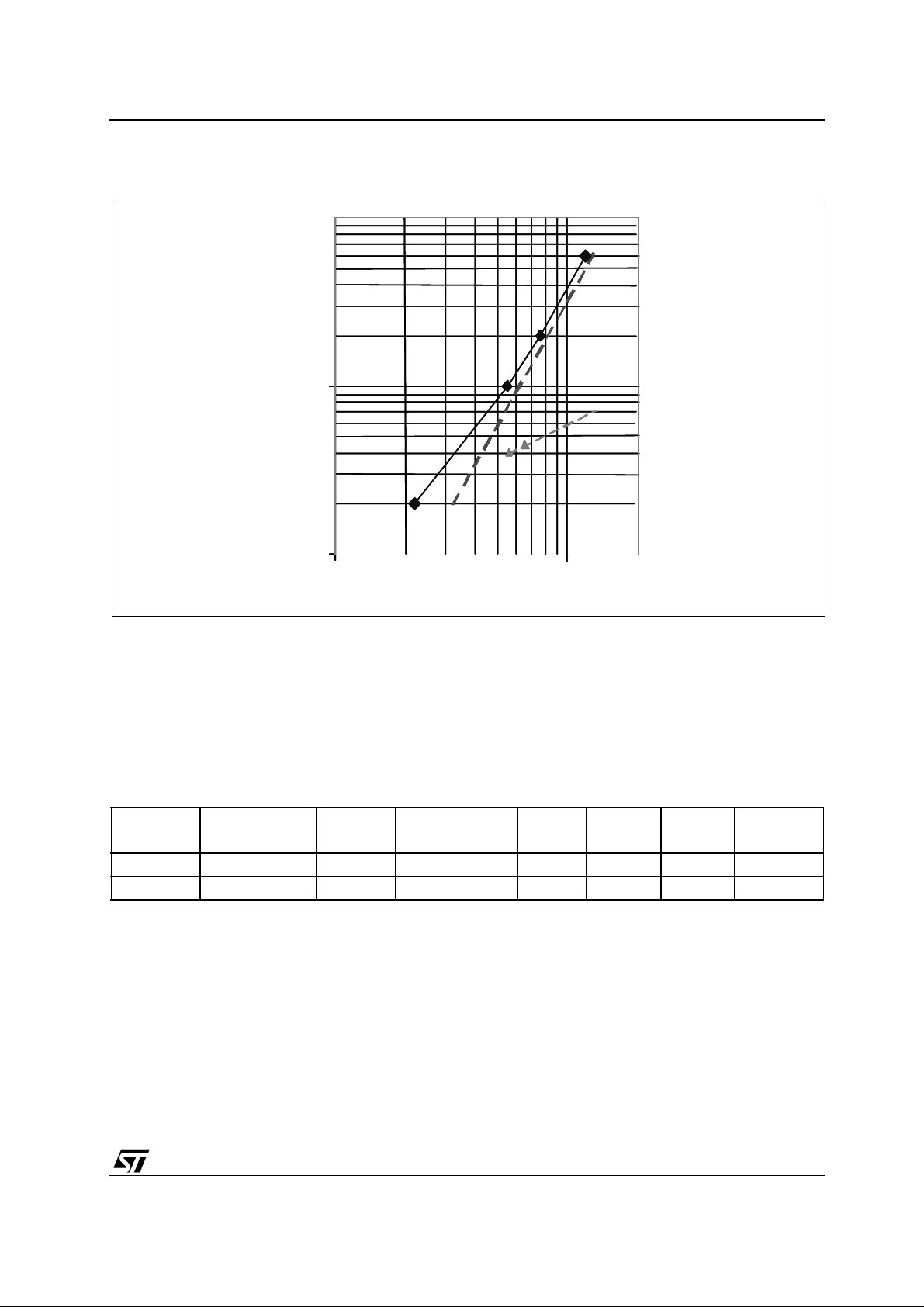

A characterization of the new device has been carried out in order to give evidence to the good switching

performance of the new de vice. The silic on area shrin king allowed by the M D m esh™ techn ology ad ds a

further benefit to the device’s gate charge due to the parasitic capacitance reduction. Th e gate charge

comparison of figure 4 refers to two devices with equal rated electrical characteristics. At the driving

voltage of 10V the MDmesh™ requires a gate charge reduced by a factor of 3.5 in respect to the

traditional counterpart, at a drain current of 12A and a drain-source voltage of 200V. The charge stored in

the input capacitance is reduced from 50nC (STW15NB50) t o 25nC (STP12NM50). This immediately

suggests to the end-user an effective driving loss reduction. Moreover, as a consequence, this feature

allows an improvement of the performance during the switching transients in comparison with

conventional devi ces [4 ].

3/14

AN1485 - APPLICATION NOTE

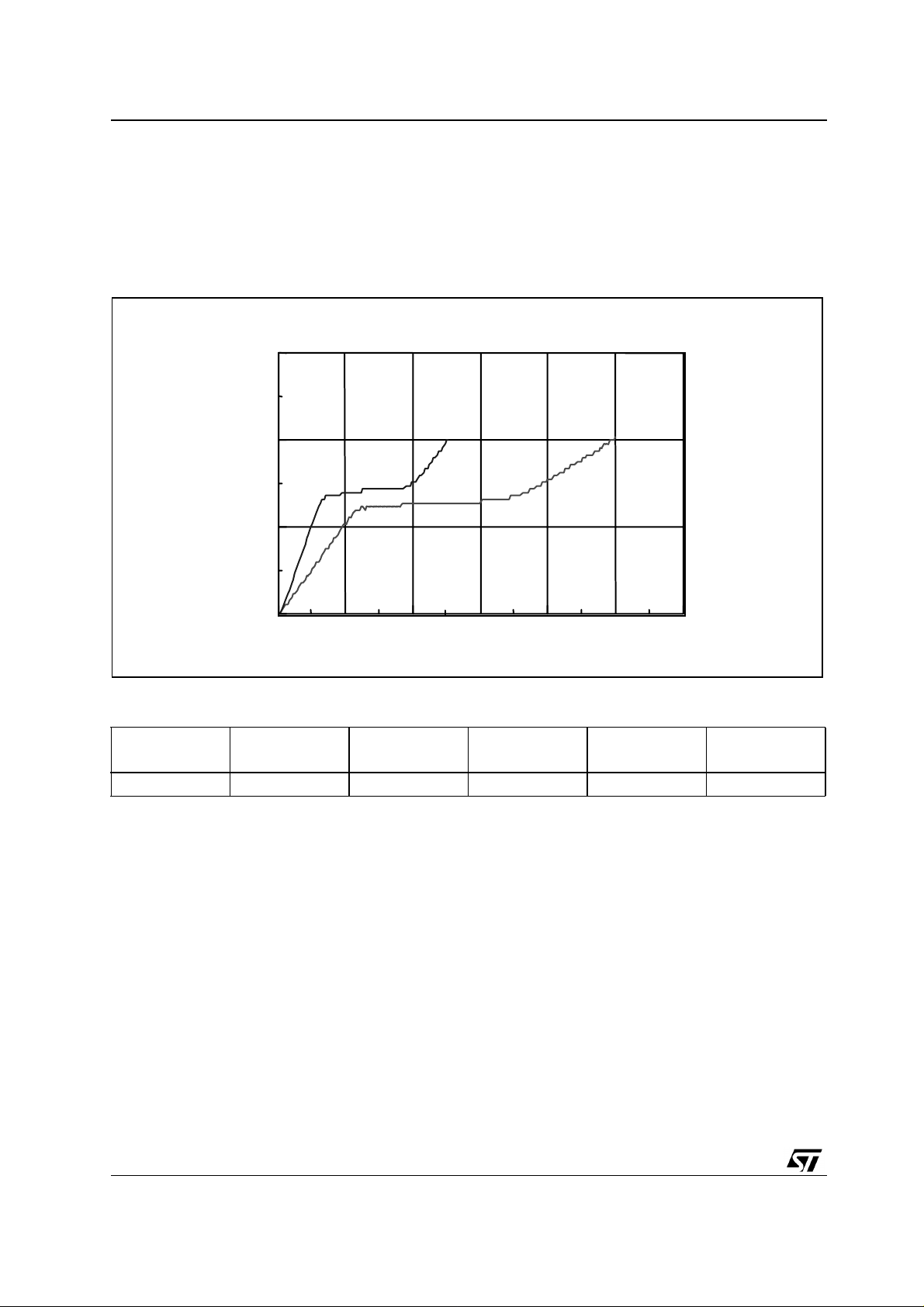

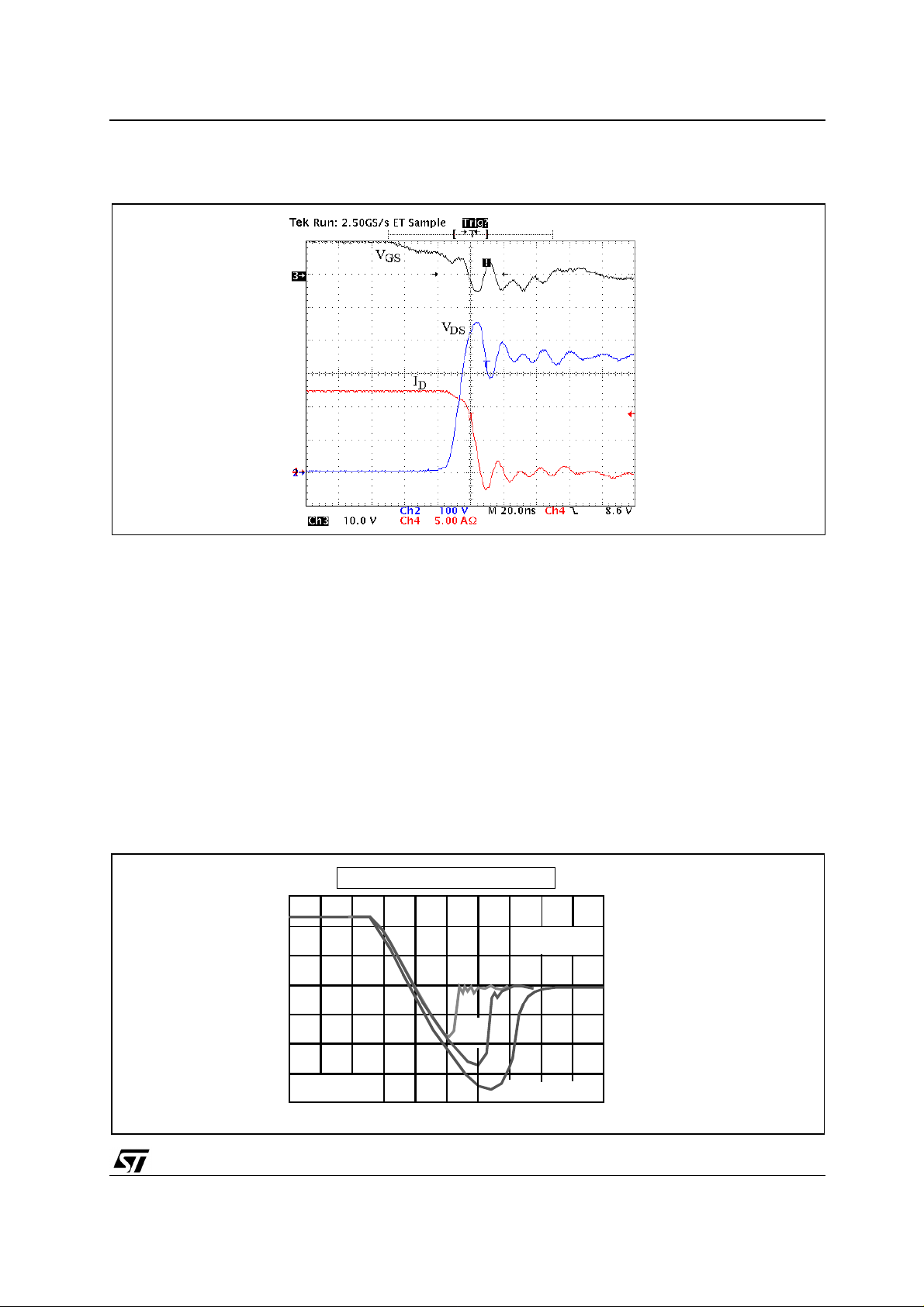

The switching transient evaluation has been performed at room temperature on inductive load at several

gate-driving conditions. The main quantities of a typical c ommutation, in hard switching conditions on

inductive load, are reported in table 2, while in figure 5 the traces of an experimental turn-off switching

transients are shown.

Figure 4: Gate Charge Behavior Of Two Different Power MOSFET Devices

Gate Charge

15

10

(V)

GS

V

STP12NM50

5

STW14NB50

0

0 10 20 30 40 50 60

Charge [nC]

Table 2. MDmesh™ Typical Switching Quantities (RG=4.7Ohm)

E

off

[µJ]

28.6 10.8 7.6 888.9 36.84 33.6

t

fall

[ns]

t

rise

[ns]

di/dt

[A/ns]

dv/dt

[V/ns]

t

delay

[ns]

4/14

AN1485 - APPLICATION NOTE

Figure 5: Current And Voltage Traces During A Typical Turn-Off Transient Of An MDmesh™

(V

=100V/div, VGS=10V/div, ID=5A/div, t=20ns/div)

DS

5. INTRINSIC BODY-DRAIN DIODE.

In some industrial equipment, which requires a conv erter configuration with bi-directional switches, the

intrinsic diode of the MOSFET device may be used as antiparallel diode if its own characteristics are

adequate. In order to optimize the design, the performance of the body-drain diode of the new device has

been investigated. In particular, the switching behavior of t he body-drain diode has bee n widely tested.

The well-established technique of Platinum implanting has been performed in order to reduce the reverse

recovery time (t

) of the body-drain diode b y reducing the carrier lifetime. Platinum implanting a cts as a

rr

lifetime killer by introducing a mi d gap center in the silicon. By increasing the Platinum dose ( Φ) a t

reduction is observed. The obtained experimental waveforms during a reverse recovery transient for

three devices with different Platinum doses are reported in figure 6 that is related to a current slope di/dt

equal to 100A/ms.

Figure 6: Reverse Recovery Of The Body-Drain Diode In Case Of Different Platinum Doses

(ID=5A/div, t=100ns/div)

Vds=100V, di/dt=100A/µs, Id=12A

Φ1 < Φ2

Φ2

Id (A)

Φ1

rr

BV

DSS

=600V

No lifetime killer

100ns/div

5/14

AN1485 - APPLICATION NOTE

6. MDmesh DEVICE IN A PFC CONVERTER APPLICATION.

Power MOSFET devices are very suitable for many power converter applications, operating at high

frequency, which have been proposed aiming to develop SMPS with high power factor value. In these

applications the dev ices experience high voltage, l ow current and high freque ncy. In particular, a PFC

circuit has been cons idered, wh ich is based on a boost conv erter to pology in o rder t o obtain h igh p ower

factor. The control of the converter is performed by an L4981A integrated circuit that behaves as a

continuous mode PFC controller and uses the technique of the average current control [5]. A prototype of

the converter has been prepared and its simplified schematic is shown in figure 7.

Figure 7: A Simplified Block Schematic Of The Control Stage And Power Stage Of The PFC

Application

I

OUT

V

R

0

L

PWM

Modulat or

_

+

_

+

V

ref

Sinusoidal

Referenc e

Controller

Circuit

I

0

C

IN

Current

Sensing

L

V

IN

1

0

snubber

Current

Error

Amplifier

I

D

D

C

_

+

K

x

z=xy

y

Voltage

Mult ipli er

Error

Amplifier

The constraints adopted to design the PFC converter are the following:

• Input AC voltage from universal mains VIN=88V up to 264V, freque ncy 50/60Hz;

• DC regulated output voltage VOUT=400V;

• Full load output ripple voltage DVr<16V;

• Rated output power POUT=200W;

• Maximum output voltage VO(max)=450V;

• Switching frequency in the range of 100-200kHz;

• Maximum inductor current ripple DIL=35%;

• Input power factor PF>0.99;

• Total harmonic distortion of the line current < 5%.

OUT

The values of some passive components of the converter circuit are reported in table 3 in the case of two

different switching frequencies, namely 100kHz and 200kHz. In the structure of the P FC converter a

6/14

AN1485 - APPLICATION NOTE

snubber circuit has been used for the switching device in order to reduce its power losses and to

maintain a low value of the dv/dt looking for the EMI requirements. According to the design criteria of the

RCD snubber, and by imposing for the drain voltage to h ave a ri se time t

=40ns, the capacitor v alue has

r

been fixed at C=350pF (630V) while the resistance value depends on the working frequency.

The value is R=1.8kOhm at 100kHz , and 680Ohm at 200kHz. The efficiency of the power converter is

mainly dependant on the power losses of both the switching device and the snubber circuit.

Table 3. Passive Component Values Selected For Two Switching Frequencies

Switching Frequency

[kHz]

L

0

[mH]

C

IN

[nF]

C

[µF]

0

100 0.9 220 100

200 0.45 114 100

7. THERMAL BEHAVIOR OF THE POWER SWITCH.

The total power losses P

of a switching device can be split into the following components: the

t

commutation power losses (turn-on and turn-off) and the on-state power losses:

PtPON= P

The turn-on losses, which dep end on both the diode choice and the dv/ dt imposed by the R

++ 1()

OFFPcon

G(on)

, can be

designed as a trade off between the power losses and the EMI requirements. The snubber circuit

reduces the turn-off switching power losses, which, in turn, cannot be included. The main contribute to

the device power losses is given by the conduction component that depends on the R

of the device.

DS(on)

With reference to the symbol used in figure 7, the rms current on the inductor is given by:

P

OUT

-------------

I

=2()

0

ηV

IN

where η is the converter efficiency. The current reaches a maximum value at the minimum value of the

main voltage V

at twice the frequency of the main line, the

. From relation (2) and by cons idering t hat the dut y c ycle of t he sw itch is m odul ate d

IN,MIN

rms

current in the MOSFET can be calculated by (as given in

[6]):

P

OUT

-------------

I

=3()

D

ηV

V

IN

-------------

k

V

IN

OUT

,

Lf

R,

s

0

where the function

k

operates as a reduction factor. Finally the on-state power losses P

can be

con

evaluated by:

con

DS on()ID

R

=4()

P

2

At constant output power this value changes according to the variation of the main voltage. The

maximum value of this rms current occurs in the case of the lowest value of the main voltage V

IN,MIN

(88V). In the case study a typical figure for the efficiency η is in the range 0.88-0.90. The maximum peak

value of the device current is given by:

∆I

0

------- -

I

Dmax,

I

+=5()

0max,

2

7/14

AN1485 - APPLICATION NOTE

where ∆I0 is the current ripple on the inductor.

Calculating from (5) for the I

gives a curren t of 4A in the case of 200W output of the converter.

D,max

Moreover, accounting for the peak of the current due to the reverse recovery of the diode, and by adding

a suitable safe margin, a switching device with a rated current carrying capability of 8A has been

selected. The breakdown voltage of the device is determined according to the following relation:

BV

DSSVOUT

where the voltage V

is a suitable value ranging between 10% and 15% of the maximum output voltage.

m

With the above constraints, we need a device having at least BV

∆VrV

++≥ 6()

m

=500V.

DSS

Finally , the freewheeling diode has been specified as a 6A, 600V fast diode, with a reverse recovery time

=25ns.

t

rr

8. JUNCTION TEMPERA TURE CALCULATION.

A dynamic characterization of the Power MOSFET has been carried out. The device is very fast and has

a good switching performance. The current and voltage waveforms of the device during a typical turn-off

transient are reported in figure 8. We can observe that the rise time of the drain voltage in the case

shown is coherent with the design constraints on the voltage slope.

Figure 8: T urn-Off Switching Transient In The PFC Converter At A Main Voltage Of 88V (V

=2A/div, E=1kVA/div, t=50ns/div)

div, I

D

=100V/

DS

The thermal behavior has been performed by a set-up measurement shown in figure 9, where the

thermal model of the device is also indicated. In steady state condition we measured the heatsink

temperature at a different value of the input voltage, and namely at 88V, 110V and 220V. The junction

temperature is higher than the heatsink temperature and can be estimated by the following procedure.

8/14

AN1485 - APPLICATION NOTE

Figure 9: Block Schematic Of The Measurement System To Determine The Heatsink T emperature,

As Well As The Steady State Thermal Model Of The Device

TAR

th, S, ARth, C, SRth, J, CTJ

Temper atur e

Measur em e nt

Firstly, the power loss is calculated:

THTA–

-------------- ------

= 7()

P

D

R

th H A,()

where T

is the measured heatsink temperature, TA is the ambient temperature fixed at 27°C, and R

H

th,H,A

is the thermal resistance of the heatsink established at 7°C/W. Then the junction temperature is

calculated by:

R

+()+=8()

thCH,()

where T

and R

T

jTHPDRthJC,()

is the junction temperature, R

J

is the thermal resistance between the case and the heatsink. The results for the two

th(C,H)

is the thermal resistance between the junction and the case

th(J,C)

switching frequencies considered are reported in table 4. Other results obtained for the same output

power and the results of the experimental tests done at different voltages and frequencies are reported in

table 5. The tests have been carried out at the beginning of the experiments (room temperature, T=27°C)

and in steady state conditions.

Table 4. Heatsink And Junction Temperatures For Different Voltage And Frequency Values

V

[V]

IN

T

H

[°C]

P

[W]

D

T

J

[°C]

100kHz

88 92 9.28 107

110 70 6.14 80

220 46 2.71 50

220kHz

88 98 10.14 1 14.5

1 10 75 6.86 86.2

220 49 3.14 54.1

9/14

AN1485 - APPLICATION NOTE

Table 5. Results Of The Experimental Tes ts At Different Voltages And Frequencies

T

H

[°C]

V

[V]

IN

I

IN

[A]

P

IN

[W]

V

OUT

[V]

I

OUT

[A]

P

[W]

OUT

η%

100kHz

27 88 2.4 211 393.7 0.485 191 90.5

92 2.472 217 395.8 0.488 193.1 89

27 110 1.88 206.6 394.6 0.484 190.9 92.4

70 1.931 21 2.3 397.1 0.49 194.6 91.8

27 220 0. 934 20 4.5 396.8 0.49 194.4 95.1

46 0.948 20 6.3 397 0.489 194.1 94.7

200kHz

27 88 2.487 217.8 395 0.482 190. 4 87.4

98 2.577 22 6.7 395 0.483 190.8 84.2

27 110 1.957 211.9 398 0.489 19 5 92

75 2.016 22 0.7 398 0.499 198.6 90

27 220 0. 959 211 398.5 0. 49 195.3 93

49 0.968 213 398 0.49 195 91.6

9. HARMONIC DISTORTION.

The main results for the converter from the stand point of the harmonic content are reported in table 6,

where the term A-THD% stands for the total-harmonic-distortion (in percentage) of the main current, and

PF is the power factor. The test-rig used to obtain the data given in table 6 is depic ted in figure 10. T he

better performance of the PFC is at a main voltage of 110V and 60Hz. In figure 11 we can s ee the near

zero-value of the phase shift between the input waveforms of the voltage and current. The PF measured

in such a case is 0.999, as reported in table 6. Finally, the voltage and current traces in a whole switching

cycle of the MDmesh™ device are reported in figure 12a, 12c. The test conditions are switching

frequency 200kHz and main voltage V

IN, MIN

=88V.

Figure 10: Experimental Set-Up To Measure The Harmonic Distortion And The Power Factor

V

0

main

AC Source

And Power Meter

t

Oscilloscope

Vprobe

Iprobe

Multimeter

PFC

C

O

LOAD

10/14

Controller

IC

AN1485 - APPLICATION NOTE

Figure 11: Experimental Traces Of The Input And Output Waveforms (VIN=110V, ƒ=60Hz,

=200kHz, VIN=100V/div, V

f

s

=100V/div, I

OUT

=500mA, IIN=1A/div, t=2ms/div)

OUT

Figure 12a: Working Cycles Of The Power MOSFET Device In Loaded Conditions @ 200kHz

(V

=100V/div, ID=2A/div, t=1µ s/ div)

DS

11/14

AN1485 - APPLICATION NOTE

Figure 12b : The MDme sh™ Turn-off In Loa ded Cond itions (VDS=100V/div, ID=2A/div, E=1kVA/div,

t=50ns/div)

Figure 12c: The MDmesh™ Turn-on In Loaded Conditions (V

t=50ns/div)

=100V/div, ID=2A/div, E=1kVA/div,

DS

12/14

Table 6. Performance Of The PFC As A Non-linear Switching Load

AN1485 - APPLICATION NOTE

V

[V]

IN

ƒ

s

[Hz]

I

IN

[A]

PF A - THD% V

OUT

[V]

∆V

OUT

[V]

f = 100kHz

88 60 2.472 0.9984 4 393.7 13

110 60 1.931 0.994 2.4 394.6 13

220 50 0.948 0.9976 4.9 396.8 14

f = 200kHz

88 60 2.577 0.9986 3.7 393 15

110 60 2.016 0.997 1.7 394.6 14

220 50 0.968 0.9981 4.4 397 15

10. DISCUSSION OF THE RESULTS.

The new device features good performance in the experimental tests. In particular, the device works very

well in terms of efficiency and harmonic distortion in a typical power conversion application, like the PFC.

However, it is worth it to note that equivalent results may be obtained by traditional Power MOSFETs

having a larger silicon area. In fact, an equivalent standard device should have two times the area of the

device presented here. The consequence is a smaller package for the MDmesh™ device than a

standard MOSFET, and a lower cost. However, in such a case at equal power losses the smal ler d evice

will assume a greater junction temperature. Obviously we are presuming different total thermal

resistance, which is the c ase. O n the other hand, the new equivalent device has a high current density,

good switching performance and on-state losses comparable to standard MOSFETs.

11. CONCLUSION.

In this paper an extende d charac terization of a new class of P ower MO SFE Ts has been performed. The

advantages and drawbacks relative to the new device has been highlighted. An important improvement

in comparison with equivalent convent ional devices consists i n the area reduction of the silicon. As a

consequence the current density of the proposed device is higher than the current density of a standard

one. The switching performa nce is im proved due to the lower parasitic capacitance and t he lo w on-state

resistance adds major advantages in terms of forward voltage drop.

13/14

AN1485 - APPLICATION NOTE

REFERENCES:

[1] M. Saggio, D. Fagone, S. Musumeci “MDmesh™: Innovative Technology For High Voltage Power

MOSFETs”, Conf. Rec. ISPSD 2000, T oulouse, France, May 22-25 2000.

[2] L. Lorenz , L. Zverev, A. Mittal, J. Hancock “CoolMOS – A New Approach Towards System

Miniaturization And Energy Saving” Conf. Rec. IEEE IAS 2000; Roma, Italia, October 2000.

[3] F. Di Giovanni, A. Magri “STripFET: Innovative Low Voltage Power MOSFETs” Proceedings of the

Power Conversion Intelligent Motion PCIM 1998 Conference, June 1998, Santa Clara, CA.

[4] S. Musumeci, A. Raciti, A. Testa, M. Melito, A. Galluzzo “Switching Behavior Improvement Of

Insulated Gate Controlled Devices” IEEE Transactions On Power Electronics, Vol. 12, No. 4, July 1997,

pp.645-653.

[5] J. Rajasgopalan, F.C. Lee, P. Nora ”A General Technique For Derivation O f Average Current Mode

Control Laws For Single-Phase Power-Factor Correction Circuits Without Voltage Sensing” IEEE

Transactions On Power Electronics, Vol. 14, No. 4.

[6] G. Commandatore, U. Moriconi “Designing A High Power Factor Pre-regulator With The L4981

Continuous Mode” Application Note AN628/0795 by STMi croelectron ics.

Information furnished is b elieved to be accurate a nd reliable. Howe ver, ST Microelectronics a ssumes no resp onsibility

for the consequences of use of such information nor for any infringement of patents or other rights of third parties

which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of

STMicroelectronics. Specification ment ioned in this p ublication are subject to change without notice. This publication

supersedes and repla ces a ll information pre viously su pplied. STM icr oelectro nics pr oducts are not authorized for use

as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2001 STMicroelectronics - Printed in Italy - All rights reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Isreal - Italy - Japan - Malaysia -

14/14

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

Loading...

Loading...