Page 1

AN1449

Application note

ST6200C

universal motor drive software

Introduction

This application note describes the software of a low-cost phase-angle motor control drive

system based on an OTP version of the ST6200C microcontroller and a BTB16-600CW

snubberless triac. The application has been developed by STMicroelectronics and is

available as a low-cost evaluation board UMC01EVAL.

This board can be widely used in many applications such as vacuum cleaners, power tools,

food processors and lighting dimmers. The microcontroller implements the following

functions:

■ Speed control: the motor speed is set by a potentiometer on the board. With a look up

table, the MCU can convert speed commands to firing angle delay times. The power

delivered to the motor can be adjusted by changing the firing angle with reference to the

voltage zero crossing signal.

■ Soft start: This reduces the motor inrush current at start-up.

■ Mains period measurement: In order to reduce system cost, a RC oscillator is used on the

UMC01EVAL board as the MCU clock source. However its frequency can vary up to +/20% because it is highly dependent on power supply voltage and temperature. To control

the motor accurately, the mains power line period is measured and used as a time base.

June 2010 Doc ID 8325 Rev 2 1/14

www.st.com

Page 2

Contents AN1449

Contents

1 Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

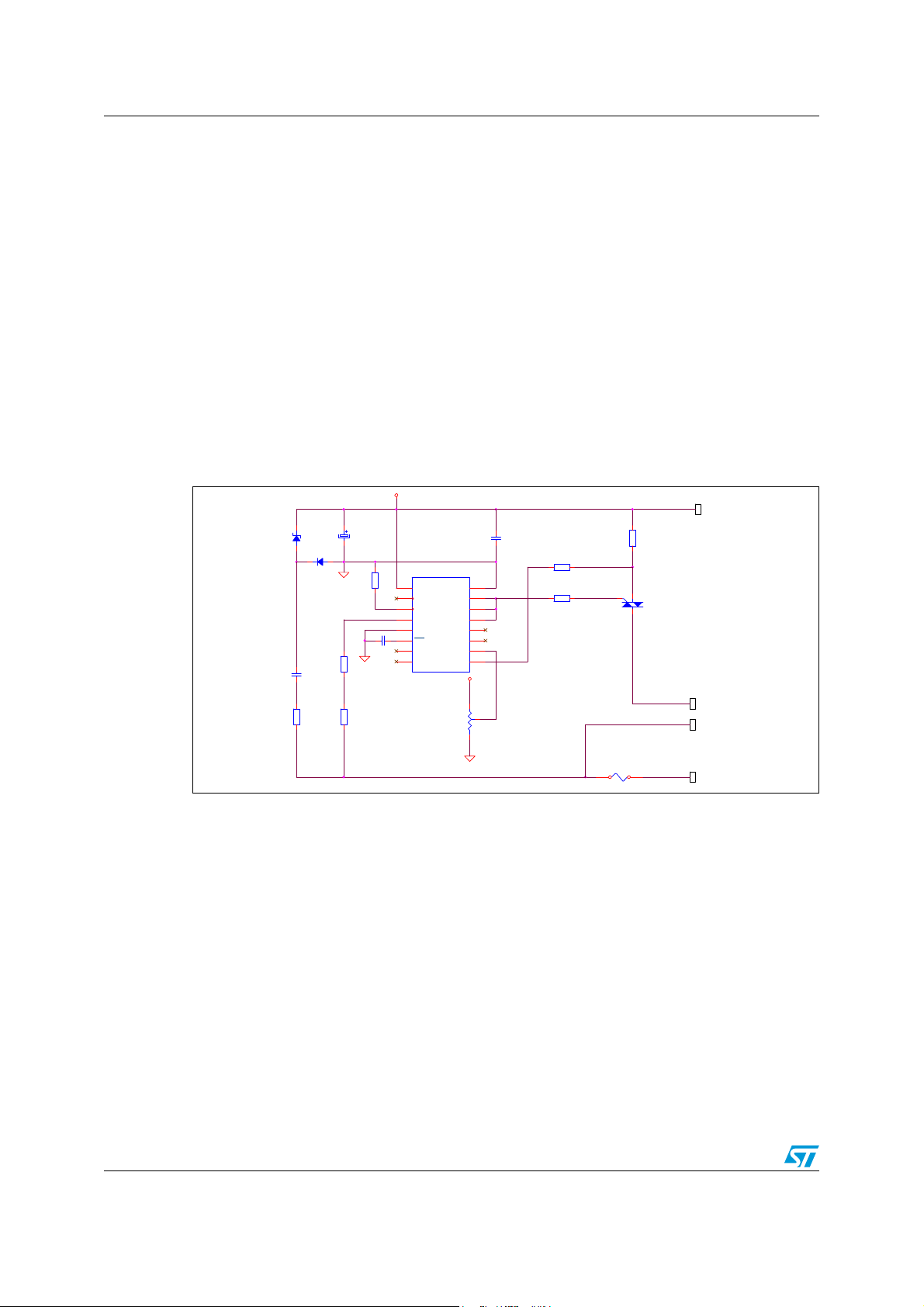

1.2 Board schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Main program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 RC oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Mains period measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Timing definition of main program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Gate pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Phase angle calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Gate pulse generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Interrupt servicing time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Subroutines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Power on reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Soft start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Appendix A Power on reset flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Appendix B Main program flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1

Appendix C Soft start flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14 Doc ID 8325 Rev 2

Page 3

AN1449 List of figures

List of figures

Figure 1. UMC01EVAL board schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2. Timing definition of main program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Power on reset flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 4. Main program flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Soft start flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Doc ID 8325 Rev 2 3/14

Page 4

Hardware description AN1449

VCC

VCC

U1

ST62T00

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

VDD

OSCIN

OSCOUT

NMI

VPP/TEST

RST

PB7/AIN4

PB6/AIN3 PB5/AIN2

PB3/AIN1

PB1

PB0

PA3

PA2

PA1

VSS

R7

220K

R6

220K

R4

47K

Q1

BTB16-600CW

R5

470R/1W

C3

470nF/400V

C1

100nF

C2

220uF/16V

D2 1N4148

SPEED

10K

R1

1R/2W

F1

FUSE 10A

D1

BZX85C5.6

R2 3K

C4

100nF

R3 150R

LINE

NEUTRAL

MOTOR

J1

J3

J4

J2

16Pin Socket

1 Hardware description

1.1 General information

The schematics of universal motor control board are shown in Figure 1. On this board, a low

cost capacitive power supply generates +5 V voltage for the ST62T00C MCU and its

application circuit. The motor speed control is managed by the ST62T00C 8-bit MCU. The

MCU clock is generated by on-board RC network. The internal 8-bit timer is used for the

triac triggering control. The voltage zero crossing event is detected by two current limiting

resistors (R6 & R7). The microcontroller triggers the snubberless triac BTB16-600CW

directly with its 20 mA outputs. Three high sink outputs can supply 60 mA gate currents

(I

GT=35 mA). This board is able to drive a universal motor up to 1500 W.

1.2 Board schematics

Figure 1. UMC01EVAL board schematics

The hardware environment of the MCU has the following features:

● The MCU oscillator is implemented by an on-board RC network.

● No external reset circuit is used, this function is handled by the low voltage detector

option of the ST62T00C.

● The voltage zero crossing event is detected through current limiting resistors (R6 &

R7).

● R1 is reserved for future use. It must be replaced by a jumper when the board is

running in open loop mode. In closed loop, it is used as a shunt resistor. It can measure

the motor peak current.

4/14 Doc ID 8325 Rev 2

Page 5

AN1449 Main program

2 Main program

2.1 RC oscillator

In most applications, the MCU internal clock is supplied by a quartz crystal or a ceramic

resonator. On this board, for cost reasons, it has been chosen to generate the system clock

with an external resistor (the capacitor is implemented internally). However as a result of this

choice, clock accuracy is only about +/-20% because the RC oscillator frequency is highly

dependent on supply voltage and temperature variations. For more details, please refer to

the “clock and timing characteristics” section of the ST6200C datasheet.

2.2 Mains period measurement

To obtain a more accurate clock source for driving the motor, the AC power line period is

measured by the microcontroller. It is used as a system clock reference. The voltage zero

crossing detection is performed by the ST62T00C NMI interrupt with two current limiting

resistors (R6 & R7).

Note: For the ROM version, as the injection is forbidden on the NMI pin, it is recommended to use

another pin with interrupt capability.

The interrupt (falling edge only) is generated at each negative voltage zero crossing event. It

triggers the internal 8-bit Timer Counter Register (TCR) to measure the power line period.

The result is stored in the T50HZ register. In 220 V/50 Hz applications, the value of T50HZ

register corresponds to 20 ms when the timer input clock division factor in the Timer Status

Control Register (TSCR) is 64. The same value corresponds to 10 ms when the timer input

clock division factor is 32.

2.3 Timing definition of main program

The basic principle of the phase angle control algorithm is very simple. The ST62T00C can

detect the beginning of a full wave by detecting the negative voltage zero crossing event,

after which it can calculate the phase angle, load the phase delay time PHASE in the 8-bit

Timer Counter Register (TCR) and start the timer counting.

When the timer expires, the Timer Counter Register (TCR) is reloaded with a value in

T50NEW register which is equivalent to the duration of one half cycle (e.g. 10 ms at 50 Hz),

after which the first TRIAC triggering pulse is generated. Be aware that the value in the

T50HZ register must be compensated with a look up table (RCTAB) in order to eliminate the

fluctuation of the RC oscillator frequency within one full wave cycle. The compensated value

is stored in the T50NEW register. To obtain the duration of a half cycle, we can use the

same value in the T50NEW register and divide the corresponding timer input clock

frequency by 2. It can be easily implemented by selecting the division factor of prescaler bits

in the Timer Status Control Register (TSCR).

The time base T50HZ of the power line period is averaged every 16 full wave cycles (e.g.

320 ms at 50 Hz) in order to eliminate the influence of the RC oscillator. After that, the

potentiometer measurement is performed with the internal A/D converter. The new speed

command goes through the ramp up or down subroutine and speed look up table

(VREFTB). The new phase angle in the PHASE register for the next cycle is computed. In

addition, as mentioned above, the full wave timer value in register T50HZ must be

Doc ID 8325 Rev 2 5/14

Page 6

Main program AN1449

Triac Pulse

Timer

PHASE T50NEW DELTAT

NMI

Mains Voltage

PA1/PA2/PA3

ZVC Interrupt

Get DELTAT

Reload Timer

Timer Interrupt

Reload Timer

Fire TRIAC

T50HZ Update

Perform ADC

Soft Start

Calculate PHASE

Timer Interrupt

Measure DELTAT

Fire TRIAC

MAINS PERIOD

compensated with the look up table (RCTAB) at different phase angles. This new value is

stored in the T50NEW register.

When the half-cycle timer reaches zero, the second triac triggering pulse is generated. After

that, the timer counter register (TCR) is reloaded with 255 and starts counting. It is used as

a capture to measure the duration from the second triggering pulse to the next voltage zero

crossing event.

When the next voltage zero crossing interrupt occurs, the timer will be stopped by software.

The duration from the second gate pulse to the zero crossing interrupt is stored in the

DELTAT register. The full wave time will be equal to the sum of DELTAT, T50NEW and

PHASE.

In total, one mains full wave period is divided into three parts: phase angle (PHASE

register), half wave period (T50NEW register) and the rest (DELTAT register). The timing

definition of main program is shown in the following figure.

Figure 2. Timing definition of main program

6/14 Doc ID 8325 Rev 2

Page 7

AN1449 Gate pulses

PHASE

T50Hz Vref×

256

------------------------------------- -=

3 Gate pulses

3.1 General description

The gate current pulses are generated during the main program (refer to Figure 2).

Appendix A gives the flowchart of the main program. As soon as a ZVC event is detected,

the ST62T00C reloads the timer with the phase angle delay time and starts the timer. When

the timer reaches zero, the first gate triggering pulse is generated. The timer is reloaded and

enabled with a value of one half-cycle. When the timer reaches zero, the second gate

triggering pulse is generated within one full wave cycle.

3.2 Phase angle calculation

To eliminate the timer clock variations due to voltage and temperature drift, the timer clock

must be synchronized with the line voltage zero crossing. The power line period is

measured by the ST62T00C internal 8-bit timer. The resulting half cycle period is stored in

the T50HZ register and used as the system clock. This number is then divided by 256, which

results in 256 steps per half wave. With this division, 256 discrete phase angles are

possible. This results in a resolution of 0.7 degrees. The actual phase angle PHASE is

calculated as follows:

Dividing by 256 is simply implemented by considering the most significant byte of the

multiplication result of T50Hz and speed reference (Vref). A look-up table relating the delay

time to the power requirement contains 64 different levels. The conduction time of the triac

can be varied from 1.6 ms to 9.2 ms for a 50 Hz application. The user can easily adjust the

minimum and maximum power levels by changing the look up table.

3.3 Gate pulse generation

A universal motor is an inductive load. The motor current and input voltage are not in phase.

The triac will turn off at the current zero crossing. To reduce component cost, the phase shift

between current and voltage is not measured but can be adjusted by defining the maximum

speed constant v_max. This constant should be decreased if the phase shift between

voltage and current is too large.

3.4 Interrupt servicing time

The timer is not started immediately when an interrupt request occurs. This is because

some instructions are executed before starting the timer. For example, before starting to

count the first phase angle time, the program must run the NMI interrupt routine, save the

DELTAT result, reload the timer and restart the timer. This takes 33 CPU cycles. To take the

code execution time into account, we should convert it to the timer counter value (Tcode).

As we know, the MCU oscillator frequency (f

Therefore, “N” CPU cycles execution time is 13xN/f

frequency (f

) is divided by 12 to drive the internal timer, and then it is divided by the

CPU

) is divided by 13 to drive the CPU core.

CPU

CPU seconds. The MCU oscillator

Doc ID 8325 Rev 2 7/14

Page 8

Gate pulses AN1449

Tcode

N13×

fcpu

----------------- -

fcpu

12 32×

--------------------

× N

13

384

--------- -

×==

division factor programmed in the TSCR register. In this software, the division factor is 32

during the main program. Therefore, one unit timer counter equals 12x32/f

seconds. We

CPU

can easily work out the relationship between N cycles of code execution time and the timer

counter value (Tcode), as shown below:

For example, the code execution time for 33 cycles approximately equals one unit of the

timer count.

8/14 Doc ID 8325 Rev 2

Page 9

AN1449 Subroutines

4 Subroutines

4.1 Power on reset

After each RESET interrupt, a complete initialization procedure is executed. This subroutine

configures the port A & Port B, timer, A/D converter, interrupt option register and status flag

registers. It waits 100 ms for the supply stabilization, and then it measures the mains period.

The flowchart of this subroutine is shown in Appendix A.

4.2 Soft start

The soft start subroutine is entered when an acceleration or deceleration event occurs. The

soft start feature enhances the life of bulbs, reduces coil stresses in motors, and extends the

life of most loads. It can reduce the inrush current and prevent voltage fluctuations and

flicker in the power supply (refer to Flicker Norm EN61000-3-3).

This subroutine in fact changes the slope of the speed command. The slope is the same for

the accelerating and decelerating edge. It can be modified by changing the step constant.

This flowchart is shown in Appendix C.

4.3 Conclusion

This application note describes the software of a low cost universal motor control system. It

is intend to help you to use this software as a basis for developing your own motor drive and

to adapt it to your own requirements. The software is tested with the Raisonance RIDE ST6

Version 6.0.1 Assembler. For other assemblers the software must be adapted.

Doc ID 8325 Rev 2 9/14

Page 10

Revision history AN1449

5 Revision history

Table 1. Document revision history

Date Revision Changes

Oct-2001 1 Initial release

Format of the document modified.

Modified introduction on first page (reference to OTP version of the ST6200C

07-Jun-2010 2

added)

Replaced ST62T00C with ST6200C.

Added note in Section 2.2: Mains period measurement on page 5.

10/14 Doc ID 8325 Rev 2

Page 11

AN1449 Power on reset flowchart

RESET

PORT A & B Configuration

Inte rrupt O ption R e gister

Initialisation

Wait 100 ms

MAIN_PROG

Tim er & A D C Initialisation

Measure Mains Period

(T50H z)

Registers Initialisation

Status Flag Initialisation

Set Minimum Motor Speed

Phase Angle Calculation

Appendix A Power on reset flowchart

Figure 3. Power on reset flowchart

Doc ID 8325 Rev 2 11/14

Page 12

Main program flowchart AN1449

MAIN_PROG

Wait for ZVC event

Save TCR in DELTAT

Load Timer with Phase Angle

Restart Timer

Wait for Timer

Interrupt

Load Timer with T50NEW

Restart Timer

Generate TRIAC Triggering

Pulse on PA1/PA2/PA3

Make the average of T50HZ

Update T50HZ Register

Configure and Perform

A/D Converter

Get New Speed Command

MVNEW

Process Acceleration or

Deceleration Soft Start

16 times full wave

cycles passed?

Yes

No

Get Next Speed Command

MVOLD

Process Speed

Look Up Table

Calculate the next phase

angle time (PHASE)

Make Half Cycle Time

Symmetrical Compensation

T50NEW

Wait for Timer

Interrupt

Configure Timer to Measure

DELTAT

Generate TRIAC Triggering

Pulse on PA1/PA2/PA3

MAIN_PROG

Appendix B Main program flowchart

Figure 4. Main program flowchart

12/14 Doc ID 8325 Rev 2

Page 13

AN1449 Soft start flowchart

SOFT START

Process Ramp Up

Accelerate or

Decelerate Process?

SPEED PROCESS

Accelerate

Process Ramp Down

Decelerate

Within A/D

Converter Accuracy?

Within A/D

Converter Accuracy?

Within one Step Range? Within one Step Range?

MVOLD = MVOLD + STEP MVOLD = MVOLD - STEP

Yes Yes

No

No

No

No

MVOLD = MVNEW

Get New Speed Command

MVNEW

Appendix C Soft start flowchart

Figure 5. Soft start flowchart

Doc ID 8325 Rev 2 13/14

Page 14

AN1449

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14 Doc ID 8325 Rev 2

Loading...

Loading...