Page 1

AN1387

APPLICATION NOTE

APPL ICATION OF A NEW MON OL IT HI C SM ART IG BT

IN DC MOTOR CONTROL FOR HOME APPLIANCES

A. Alessandria - L. Fragapane - S. Musumeci

1. ABSTRACT

This application notes aims to outline the characteristics of a new power device that joins the peculiarities

of an STMicroelectronics fast-switching PowerMESH™ IGBT with some novel protection features. A

driver circuit is integrated in the power device to implement over-current protection and soft thermal

shutdown. The current limitation also ensures a highly short-circuit rated device. Moreover the low

threshold voltage and inp ut current make it p ossible to drive the device directly from the output pin of a

microprocessor. The static and dynamic behavio r of the device will be illustrated and an applic ation will

be suggested.

2. INTRODUCTION.

In the last few yea rs IGB Ts have been appreciated in many appl ications in t he m id -power range, having

the advantage of bipolar conduction characteristics and insulated gate control. Efficient advances in

process and device technologies have improved conduction losses, working frequencies and

ruggedness under inductive load co nditions in hard switching applications. But nowada ys requirements

are becoming more and more stringent regarding ruggedness and reliability. On the other hand, the

planar technology is reaching its limit in terms of performance [1]. For this reason the monolithic

integration of protection features to prevent the intervention of faulty conditions represents a wi nning

choice in order to improve a device’s limits. Therefore the new trend in power semiconductor

manufacturers is to provide "system-on-chip" solutions [2].

Current literature proposes several sol utions in order to obtain an intelligent s witch in power conv ersion

applications, such as full-protected high voltage MOSFETs or IGBTs for automotive electronic ignition

[3,4]. But these solutions are not suitable for those applications in which conduction losses and switching

speed are both important. Indeed a Power MOSFET is good for high frequency applications, but at lower

current, while at the present time Smart IGB Ts are available only for low frequency applications, and the

research activities in the field of monolithic Smart IGBTs for fast-switching applications are really poor.

Hybrid solutions are actually available, but this approach has some drawbacks like package size,

complex assembly techniques and costs.

The device we are going to present (see figure 1) is very innovative in its product range, bec ause it

shows a high current density with switching performances that match well with the requirements of

applications like motor control drive systems, induction heating and SMPS.

November 2001

1/10

Page 2

AN1387 - APPLICATION NOTE

Figure 1: A Fast-Switching Smart IGBT

The proposed device is a new full-protec ted IG B T, packaged in a convenient three pin TO-220 package,

2

with an active area of about 12mm

, while the cont rol part occupi es an area of about 0.9mm2, including

the input pad and some trimming pads. Concerning the main electrical characteristics, the device has

600V of breakdown voltage and 10A of nomina l current. It is a logic level switch with a gate threshold

voltage of 1.5V and very low input current (1mA). These features allow direct driving from a micro

controller system. In this way STMicroelectronics’ intelligent switch is particularly suitable for motor

control in home appliances, consumer electronics and me dium power industri al servo-drive [5].

This paper will begin by giving some general information about the adopted technology and the static

and dynamic electrical characteristics of the device will then follow. In this context the dynamic

performances will be compared with the requirements of an experimental motor control application.

3. TECHNOLOGICAL OVERVIEW.

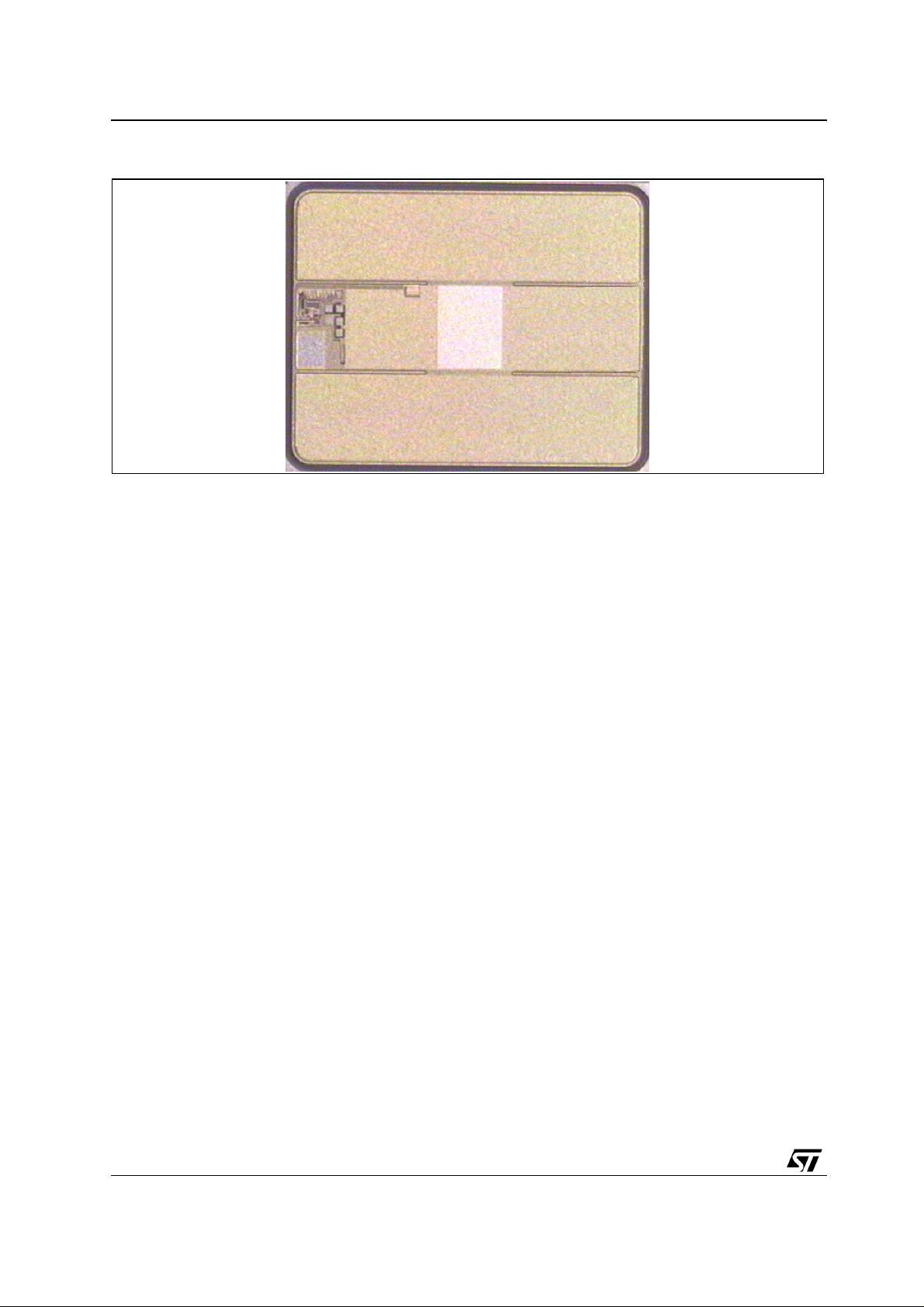

STMicroelectronics’ fast-switching Smart IGBT is manufac tured with a standard process based on its

patented strip horizontal layout. This layout consists of a p-type mesh implanted over an n-type epytaxial

layer. Some steps later n-type strips are then implanted over the p mesh to form the IGBT emitter. In

figure 2 the 3D view of the mesh layout is depicted, while in figure 3 the cross section of the strip layout

is shown.

2/10

Page 3

Figure 2: Mesh Overlay 3D View

N+ SOURC E

N

N

+

B

P

+

S

B

A

C

Figure 3: Strip Layout Cross Section

P EDGE

P

M

E

S

-

D

R

A

U

F

F

E

R

L

U

B

S

T

K

M

E

AN1387 - APPLICATION NOTE

H

I

N

A

Y

E

R

R

A

T

E

T

A

L

This proprietary process improves switching performances and latch-up immunity, moreover the

introduction of gate fingers concur to reduce the gate internal resistance and to speed-up the device turn

off [6]. Furthermore a proprietary lifetime killing m ethod is performed implanting and diffusing platinum

ions.

The technology desi gn al lows to integrate in the same c hi p the Power IGBT and a s imple c ontrol ci rcuit.

This approach ensures a low-cost integration and a high value-added device, indeed only one

photolithography process is added to the standard process flow.

The control circuit is implemented with:

• N-MOS enhancement-mode transistor,

• polysilicon resist or s,

• polysilicon diodes.

The sign al MOSFET tra nsistors are im planted in the p -type mesh, whi le the polysilic on resistors an d

3/10

Page 4

AN1387 - APPLICATION NOTE

diodes are insulated from the bulk by a thick field oxide.

Moreover a current sensor and a temperature sensor are integrated. Current sensing is made by

insulating an emitter strip with a given sens e ratio, while temperature s ensin g is m ade by monitoring the

variation of the forward voltage drop of some polysilicon diodes.

4. THE DEVICE: STATIC AND DYNAMIC BEHAVIOR.

The Smart IGBT has to be considered as a global switching system. The block diagram of the device is

shown in figure 4 where all the control parts are highlighted.

Figure 4: Block Diagram of the Smart IGBT For Motor Control

C

TEMPERATURE

SENSING

IGBT

SENSE

DRIVER

CIRCUIT

IGBT

MAIN

IN

VOLTAGE

REFERENCE

OVERTEMP.

PROTECTION

OVERCURRENT

PROTECTION

R

SENSE

GND

Although the exterior look of th e device is very similar to a standard IGB T of t he same silicon area (they

are both housed in a three pin package), the ir electrical characteristics are slightly different due to the

intervention of the devoted control circuit. The first difference of the Smart IGBT, with regard to a

standard IGBT, is the input current. The gate pin of an IGBT is an insulated terminal, while the input pin

of the Smart IGBT needs an input current of about 1mA at V

The threshold voltage of t he device is very low (1.5V @ I

consider the device on and correctly working is about 4V.

The output characteristics at high curren t are modified from the presence of the current limiter. In the

knee region of the characteristics we can note an abrupt reduction in the collector saturation current due

to the intervention of the current limiter (see figure 5). Moreover, the transconductance of the device is

smaller with respect to a standard IGBT due to the voltage drop in the control circuit.

=5V in the steady state conditions.

IN

=250µA), but t he minimum input v oltage to

C

The nominal current of the device is about 10A (current dens ity about 100A/cm

2

), at wh ich value the

collector saturation voltage is about 2.5V. In future releases of the device this characteristic will be

improved using further technological approaches.

4/10

Page 5

Figure 5: Smart IGBT Output Characteristics

[

]

20

18

16

14

12

A

10

Ic

8

6

4

2

0

012345678910

AN1387 - APPLICATION NOTE

Vce [V]

The current limitation shows a slight dependence on the value of the supply voltage and, in the

application suggested in th is paper, it starts at about 24A. The presence of the current limitation ensures

a good immunity to several faulty conditions. For example, if a short circuit occurs under switching

conditions, the collector current will be blocked at low values, several amperes below the latching

current, so the device will withstand short-circuit and its immunity is limited only by the capability of the

silicon chip to dissipate energy. In figure 6 a hard switching phase in short-circuit condition is shown. It is

easy to understand that the device does not fail for a very long period during which an external diagnostic

circuit could reveal the faulty condition and disable the input signal.

Figure 6: Ha rd S wi tc hi ng Sh ort C irc ui t Conditions (V

=50V/div, IC=5A/div, VIN=5V/div)

CE

Vce

Ic

Vin

<0

time [10 µs/div]

5/10

Page 6

AN1387 - APPLICATION NOTE

In figure 7 the initial phase of a sof t thermal shutdown due to the intervention of the over-temperat ure

protection circuit is shown. In the worst driving conditions, for example an error occurring in the

frequency or in the duty cycle of the timing train of pulses, the integrated control circuit will sense the high

temperature and will reduce the value of the collector current under limitation conditions.

Figure 7: Overtemperature Protecti on (I

=10A/div, VIN=10V/div, t=1ms/div)

C

IN

V

0>

C

I

0>

Time [1 ms/div]

With regards to switching times the device shows a current fall time of about 120ns, including current tail,

and a voltage rise t ime of about 150ns at room t em perat ure. In figure 9 a typical turn-off of the dev ice is

shown.

Figure 8: Inductive Turn-Off (V

0>

0>

6/10

=100V, IC=5A/div, VIN=5V/div, t=200ns)

CE

IN

V

C

I

Time [200 ns/div]

V

CE

Page 7

AN1387 - APPLICATION NOTE

5. DC MOTOR CONTROL: AN APPLICATION CASE.

Variable speed drives have become widespread in the home appliance field and the electrical

characteristics of the Smart IGBT make it suitable for motor control applications. In this field of

application the Smart IGBT allows a dramatic reduction in the probability of electrical block, improving the

system reliability. Furthermore the integration of the control circuit allows eliminating many external

components, resulting in cost and volume reduction.

We propose an application of the device as a power switch in a chopper c onvert er for a hom e appliance

DC motor of 400W. The system arrangements with a standard IGBT and with a Smart IGBT are

compared in figure 9. The diagram shows how the device is driven directly from the control circuit without

a driver and any protection circuitry . In order to improve the system reliability in short circuit condition, the

information of V

behavior has bee n supplied to MCU unit by means of a desaturation detection

CEsat

circuit.

Figure 9: A Comparison Of A Motor Control Application Circuit With a Smart IGBT and a Standard

IGBT

V

USER

INTERFACE

main

MCU

PWM

CONTROLLER

SUPPLY

5V

DESATURATION

DETECTOR

SMART

IGBT

OVER

TEMP

M

USER

INTERFACE

V

main

CONTROLLER

OVER VOLTAGE

DETECTOR

MCU

PWM

SUPPLY

15V-5V

DRIVING CIRCUIT

PEAK CURRENT

DETECTOR

OVER TEMPERATURE

DETECTOR

++

M

Several tests have been carried out at different switching frequency (in the range from 10kHz to 20kHz).

In figure 10 the transient phase of the motor starting at a switching frequency fixed at 10kHz is shown;

the supply voltage is 311V and the duty cycle is 50%. In this application the maximum collector current

reaches about 4A while at steady state it reduces to about 2.3A.

A load variation during the steady state conditions is reported in figure 11. The output current both

decrease and rise from light load to full load as simulation of discontinuous load applications.

In figure 12 the intervention of the over tempera ture protection is shown. The current has been strongly

reduced with consequen t temperature decreasing. The over temperature condit ion has been obtained

without heat sink. The temperature measured in the application is about 80°C corresponding at 100°C on

the junction.

7/10

Page 8

AN1387 - APPLICATION NOTE

Figure 10: Motor Control Starting Transient (VCE=100V/div, IC=2A/div, t=5ms)

Figure 11: Load Variation Transient (V

=100V/div, IC=1A/div, t=500ms)

CE

8/10

Page 9

AN1387 - APPLICATION NOTE

Figure 12: Overtemperature Current Reduction (IC=0.5A/div, t=100ms)

6. CONCLUSION.

A new fast smart IGBT with a monolithic control circuit has been presented and described. The device is

cost-effective because, while it has been manufactured with the same process of a standard IGBT, it

offers a great deal of added v alue. All the protection f eatures of the switch hav e been exploited; it was

also shown how they improve the reliability and the ruggedness of the whole system. Moreover a

switching performance of the device in a home appliance motor control application has been show n.

REFERENCES:

[1] Y. Onishi et al., ”Analysis On Device Structures For Next Generation IGBTs”. Procee dings of 1998

ISPSD.

[2] Y. Seki et al., “A New IGBT With A Monolithic Over Current Protection”. Proceedings of 1995 ISPSD.

[3] A. Alosi et al., “A New IGBT With A Monolithic Self-protection Circuit”. EPE 1997.

[4] Z.J. Shen, S.P. Robb, “A New Intelligent IGBT With A Monolithic Over Current and Over Temperature

Self-protection Circuit”. Proceedings of 1996 PCIM.

[5] A. Alessandria et al. “A new monolithic smart IGBT for motor control application”. Proceedings of

2001 EPE.

[6] A. Torres et al., ”A Fully Protected Mo nolithic Smart IGBT Developed With A Standard Technology”.

Proceedings of 1999 PCIM.

9/10

Page 10

AN1387 - APPLICATION NOTE

Information furnished is b elieved to be accurate a nd reliable. Howe ver, ST Microelectronics a ssumes no resp onsibility

for the consequences of use of such information nor for any infringement of patents or other rights of third parties

which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of

STMicroelectronics. Specification ment ioned in this p ublication are subject to change without notice. This pub lica tion

supersedes and repla ces a ll information pre viously su pplied. STM icr oelectro nics pr oducts are not authorized for use

as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2001 STMicroelectronics - Printed in Italy - All rights reserved

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

10/10

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

Loading...

Loading...